1. Introduction

The mining industry, characterized by the extraction and processing of minerals, is a powerful factor of environmental transformation and a source of geochemical load on the natural complexes of the adjacent territories. As a result of ore processing at the enrichment plants, after extraction of valuable components, unused waste remains-tailings, which are crushed waste rock. Generally, the volumes of tailings significantly exceed the volumes of extracted useful components [

1]. The main way of wet tailings disposal at enrichment plants is their placement in tailing dumps, where solid and liquid components of tailings are separated. Solid particles settle and accumulate, and clarified water is used in the water recycling system of the technological process.

Tailing dumps are created by building enclosing earth dams. Structural features of the tailing dump and enclosing dams depend on the terrain relief, rocks of the base and the necessary volume of the wastes to be placed [

2,

3]. As the tailing dump fills up, in order to ensure its useful capacity enclosing dams are built up using wastes previously stored in the tailing dump. The main disadvantage of this method is a considerable volume of water discharged through the dam body and discharged at the base [

2]. Many researchers point out that seepage through the dams disrupts their stability and is one of the main causes of emergency situations [

1,

4,

5,

6,

7,

8,

9,

10,

11]. Another negative consequence of seepage discharge through the tailing dumps is the significant loss of water used in the recycling water supply system of the ore beneficiation process [

12]. In addition, seepage discharge through the dams may lead to contamination of soils and natural waters in the adjacent areas [

1,

10,

11].

Tailings dams are typically designed to seep/leak in order to keep the dam itself from becoming saturated, and ideally to lead to the ultimate dewatering of the tailings themselves. Unsaturated tailings pose less risk to the public if a catastrophic dam failure were to occur. Upstream-type dams pose the greatest risk of dam failure, and saturation of the tailings underlying an upstream dam significantly increases this risk. As a result, reliable seepage collection from a tailings impoundment/dam, either by a downgradient seepage collection dam, or by interception wells, is an important part of tailings impoundment design and management. Some seepage will need to occur in perpetuity, since the impoundment is not designed to stop the infiltration of precipitation. Efficiently collecting this seepage should be the primary goal, while reducing the volume of seepage can provide additional environmental and economic value.

The results of a comprehensive assessment of the technogenic impact of iron ore mining and processing enterprises on the natural and technical systems of the adjacent areas indicate a significant role of upstream tailing dumps as pollution focuses [

12,

13,

14,

15,

16,

17]. The liquid phase of the pulp entering the tailings dump contains significant amounts of free oxygen and carbon dioxide, creating favorable conditions for intensive leaching of tailings with the transfer to the liquid phase of a significant number of chemical elements and their compounds. Studies conducted at the “Krasnokamensky mine” OJSC (OAO) tailings dump (Krasnoyarsk Region, Russia) found that the clarified waters of the tailings dump by their chemical composition correspond to the liquid phase of the discharged pulp. In the upper layer (6.0–9.0 m) of the technogenic aquifer in the body of the tailings dump, the content of chemical elements was established at the level of their concentration in clarified waters. In the interval of technogenic aquifer from 9.0 to 30.0 m the content of Fe, Cu, Li, Mo increases three times, Mg—seven times. The concentrations of Ba, Co, Mn, Ni, Pb, Sr, V, Zn are substantially increased [

14].

The tailings contain a number of trace elements that can migrate to the environment. One of the ways of elements migration is their removal as a part of seepage leaks of technogenic water from the tailings dump system. A group of elements, including Ba, Co, Cr, Cu, Li, Mn, Mo, Ni, Pb, Sb, Ti, V, Zn, has migratory abilities. The share of elements dissolution reaches 1% of the gross content on average. The maximum degree of dissolution—up to 7% is typical for iron. Moving to the technogenic aquifer, the elements retain their active migration abilities and can migrate from the tailing dump as part of technogenic waters. The migration of Fe, Ba, Co, Cr, Cu, Li, Mn, Mo, Ni, Pb, Sb, Ti, V, Zn is confirmed by their high concentrations in the seepage discharge waters of the tailings dump. In terms of chemical composition, seepage discharge waters are comparable with technogenic waters from the base of tailings mass within the beach zone [

14].

Being discharged at the base of the tailings dumps, seepage water enters the environment, resulting in geochemical transformation of its components. The negative impact of tailing dumps, typified by the increased content of metals-iron ore accompanying minerals, can be traced at considerable distances. Analysis of the variability pattern of landscape pollution in the area of the tailings dump “Lebedinsky GOK” JSC (AO) (Belgorod Region, Russia) indicates an annual increase in the gross iron content at a distance of up to 10 km from the source of pollution [

15].

Studies have shown that, in terms of technogenic loads, the mining and processing plants of the Kursk Magnetic Anomaly affect the environment within a radius of 20 to 30 km, in terms of impact on the quality of agrolandscapes—within a radius of 15 to 20 km [

16].

Increased metal concentrations—Ni (coefficient of technogenic concentration (ratio of chemical element content in the studied soil to background content) Kc = 3.7), Mn (Kc = 5), Cr (Kc = 7)—have been identified in soils of transaccumulative landscapes in the lower gleyed horizons, which are influenced by ground waters associated with the tailings area of “Mikhailovsky GOK” PJSC (ПAO) (Kursk Region, Russia) [

17].

Environmental safety of tailing dumps operation will be largely determined by the adopted water supply and drainage schemes. The priority task of safe operation of mining enterprises is to manage the water balance in order to reduce the amount of polluted wastewater entering the natural environment. Thus, control of seepage discharge is a necessary requirement for the tailings dump operation.

The purpose of the studies is to substantiate the need to control the seepage discharge process by means of enclosing dams to ensure environmentally safe operation of the tailings dump.

The research objectives included field measurements of seepage water volumes at the tailings dump, assessment of seepage water volumes by calculation methods, forecasting of changes in seepage water volumes until 2026, analysis of technogenic geochemical load on natural complexes.

2. Study Area

EVRAZ Kachkanar Mining and Processing Plant (EVRAZ KGOK) is the largest mining enterprise of the Russian Federation and the only enterprise in the world that develops poor vanadium-containing titanium-magnetite iron ores.

Active deposits belong to the Kachkanar intrusive massif located in the western wing of the Tagil megasynclinorium, which is part of the platinum-bearing belt of the Urals. The massif lies among a powerful complex of volcanogenic, volcanogenic-sedimentary, insignificantly sedimentary, in varying degrees metamorphosed rocks of the Upper Ordovician and Silurian. The ore-bearing Kachkanar gabbro-pyroxenite massif covers an area of about 110 km

2. Geochemical spectra of ore elements containing rocks of titanium-magnetite formation have the following form: Fe, Cr, V, Mn, Ni, Co, Cu. The ores are characterized by an iron content of 16–17% in disseminated and 30–45% in schlieren differences with a content of titanium dioxide of 1.2–2.2% and 3–4%, vanadium pentoxide of 0.13% and 0.25%, respectively [

18].

The production capacity of the plant is about 55 million tons of iron ore per year [

19,

20].

High productivity of the plant and low content of useful component in the developed titanium-magnetite ores (15%) determined the main problems of the plant: the need to use large amounts of water in the technological process, which results in the formation of a large number of tailings and significant amounts of wastewater.

In 2014–2016, the enterprise’s water consumption was 32.6–40.8 million m

3/year. Approximately 50% of this volume is discharged into watercourses of adjacent territories with controlled polluted discharge [

21].

In the course of processing of mined ore at the stage of wet magnetic separation, wastes of waste (depleted) rock with a dry matter content of about 10% are generated. Waste is disposed in the tailings dump by means of hydraulic transport system. Annually about 45 million tons of tailings are delivered from the processing plant to the tailings dump [

22].

The tailings dump is used for placing the tailings of wet magnetic separation, clarification of pulp and wastewater with their subsequent inclusion into the recycling water supply system of the enterprise.

The tailings dump is upstream and hillside and is located in the valleys of the Vyia River and its right-bank tributary—the Rogalevka River, at a distance of 1 km from the processing plant. Operation of the tailings dump began in 1963 [

23].

The modern tailings dump consists of three compartments: Rogalevsky, Intermediate and Vyisky (

Figure 1), each with its own pond and drainage facilities. The compartments are located in a cascade: Rogalevsky, Intermediate, Vyisky, with a difference in height on water surface in the settling ponds in the direction from south to north. Capacities of Rogalevsky and Intermediate compartments are formed by enclosing upstream dams and, partially, from the north-east, east and south-east, by hillsides. The capacity of the Vyisky compartment is formed by blocking the embankment dam of the Vyia River valley. Above the Vyia River bed, the compartment is limited by the lower water retaining dam of the Lower-Vyia Reservoir, located in a cascade towards the Vyisky compartment of recycled water. The Rogalevsky and Intermediate compartments are intended for tailings storage for beneficiation and clarification of the liquid phase of pulp. The Vyisky compartment is primarily used to receive clarified water from the Rogalevsky and Intermediate compartments of the settling ponds.

As of the end of 2019, the total area of all the compartments is 19.63 km2, and the volume of waste placed in the tailings dump reaches 949.75 million m3.

Currently, there are nine dams along the perimeter of the tailings dump, composed of wet magnetic separation waste. The average height of the dams as of 2017 is 62 m; the average length is 1510 m [

24]. The dams are built up by moving the tailings of the tailings dump’s beach zone.

The following main components are singled out in the water balance output part of the enterprise’s water balance: seepage water discharge to the surface of the slopes and at the base of the tailings dump, seepage through the tailings dump bed, evaporation from the water surface of the tailings dump, water accumulation in the pore space of the tailings of wet magnetic separation, irretrievable water losses in the technological process, as well as water discharge from the Vyisky compartment through the spillway (if the normal level is exceeded).

Seepage discharge at the base of dams № 1, № 2, № 3, № 4, № 5 and East is the main component of the water balance output part, making 66% of its total volume. The seepage waters of the dams bring contaminants into the natural environment changing the natural geochemical situation in the territories adjacent to the tailings dump.

3. Materials and Methods

Quantitative assessment of seepage discharge volumes through enclosing dams of the tailings dump was made based on the results of the annual cycle of hydrometric studies. Field measurements were performed on a monthly basis from August 2016 to July 2017. Hydrometric work included: measuring the width of the filtration water flow, the average depth, instrumental determination of water flow velocities, calculations of the cross-section wet area, average velocity and flow rate. Flow velocities measurements on velocity verticals were performed by the GR-21M hydrometric flowmeter using the main method. Depth, flow velocity and water flow rate measurements were performed in accordance with the requirements of the Russian Federation Hydrometeorological Service. Location of the hydrometric sections is shown in

Figure 1.

For better accuracy of measurements in several hydrometric control sections automatic water level and temperature loggers, brand Solinst 3001 LT Levelogger Junior Edge (manufacturer Solinst Canada Ltd., Georgetown, ON, Canada), were installed, which registration data were taken into account when determining the cross-sectional area and flow rate. At the water level loggers installation sites, the depth measurements were made and the corresponding flow cross-sections were constructed. Taking into account the calculated areas of the flow cross-section wet area, diagrams of the dependence of the cross-section area on the water level were drawn, and linear approximation equations were obtained.

There are various calculation methods of quantitative evaluation of seepage through earth dams. Mathematical models based on finite difference methods [

25] and finite element methods [

26] are widely used for seepage calculations [

8,

27,

28,

29,

30]. Analytical dependencies based on the Darcy’s law and the Dupuy’s equation are well known and can be used to evaluate seepage discharges through dams composed of sufficiently homogeneous dispersed sediments. Along with field and laboratory methods of research, mathematical methods based on empirical dependencies are used to estimate the hydraulic conductivity of dispersed sediments taking into account their particle size distribution [

31,

32].

Seepage volumes of water discharge through dams, position of depression curve and hydraulic gradients are determined on the basis of seepage calculations. Seepage calculations through the earth dams have been performed according to accepted assumptions: laminar seepage through the homogeneous and isotropic soils of the dam on a horizontal watertight and pervious base—based on the Darcy’s law and Dupuy’s formula [

33,

34].

To estimate seepage through the dams, the hydraulic conductivity of disperse deposits of dam bodies represented by wet magnetic separation tailings was determined taking into account their particle size distribution composition. Samples of the wet magnetic separation tailings were taken from the beach area of the tailings dump along several lines of the dam cross section at distances of 5, 10, 25, 50, 75, 100 and 150 m from the dam crest. The total number of samples taken was 201, including: dam № 1 (42 samples on 6 lines), Eastern dam (47 samples on 4 lines), dam № 2 (42 samples on 6 lines), dam № 3 (35 samples on 5 lines), dam № 4 (35 samples on 5 lines). Methods and results of determination of particle size distribution of wet magnetic separation tailings, calculations of coefficient of grain uniformity of tailings particle size distribution and their porosity as well as calculations of tailings hydraulic conductivity are given in detail [

24].

The dependence of the hydraulic conductivity on inhomogeneity of the particle size distribution composition of sediments has been considered in the works of many researchers [

35,

36,

37].

The results of study of wet magnetic separation tailings indicate that the values of effective grain diameter

d10 are in the range of 0.06–0.14 mm, with prevailing values of 0.08–0.10 mm. The values of effective grain diameter

d60 are 0.2–0.6 mm. The values of coefficient of grain uniformity of particle size distribution are in the range from 2 to 8 and mainly do not exceed 5 [

24].

Calculation of hydraulic conductivity

K was performed according to Hazen [

38] and Beyer [

39] equations. These values of hydraulic conductivity were used to estimate seepage through dams.

Assessment of geochemical load on the territory’s natural complexes was carried out by comparing the concentrations of major pollutants in seepage discharge waters with background values of these components in natural waters. The assessment was carried out for the components, average concentrations of which in seepage waters are two or more times higher than the background values. Background water samples were taken mainly from the territory’s main watercourse—the Vyia River (Lower-Vyia Reservoir), upstream of the tailings dump, outside its influence zone. Seepage discharge water samples were taken from dams № 1, East, № 2, № 3, № 4. Sampling points are shown in

Figure 1.

Laboratory research of chemical and mineral composition of tailings was carried out in the Nanomineralogy Sector of the “Center for Collective Use of Perm State National Research University”. Chemical composition of tailings was determined by X-ray fluorescent method on S8 Tiger spectrometer (Bruker), additionally the estimation of microelement composition was carried out using ICP-MS (Aurora M90, Bruker). Mineral composition of tailings was determined by optical mineralogical analysis (Nikon SMZ 745) with control mineral composition determination using diffractometric method (2D PHASER diffractometer, Bruker). Research on determination of microelements concentration in natural and seepage waters were carried out at the Institute of Geology and Geochemistry of Ural Branch of Russian Academy of Sciences by ICP-MS method (ELAN-9000, Perkin Elmer).

4. Results and Discussion

The results of field hydrometric measurements performed to assess the seepage discharge through the earth dams, as well as the results of determining the seepage discharge by calculation methods are presented in detail [

24].

The results of assessment of seepage discharge through the dams of tailings dump by direct hydrometric measurements and based on calculations are presented in

Table 1.

The results of the seepage discharge assessment made on the basis of monthly field observations and determined by the calculation method are comparable. This allows using the calculation method to forecast seepage discharge through the dams of the tailings dump for the period up to 2026. To perform the forecast calculations of seepage through the dams, the average annual water levels in the ponds of Rogalevsky and Intermediate compartments were taken into account for each year according to the plan of dams raise. When estimating the average annual water level in the ponds, specifics of its rise during the year were taken into account: the first half of the year is characterized by slower rise of water levels compared to the second half.

Calculations show that as the height of the dam embankment, the height of the tailings dump and, consequently, the water level in the ponds increase, the total volume of seepage discharge increases from 41.91 million m

3 (in 2017) to 81.44 million m

3 (in 2026) [

24]. Seepage discharge increases in accordance with Darcy’s law: increase of water level in ponds leads to increase of hydraulic gradient and amount of seepage water.

Estimated volumes of seepage discharge through dams were used to forecast the enterprise’s water balance up to 2026. Balance calculations showed that irrecoverable losses as a result of seepage discharge through dams will lead to annually increasing water deficit in the enterprise’s water recycling system [

24].

The increase in water volumes due to other sources of water balance does not fully solve the problem of water shortage. Water withdrawal from the Lower-Vyia Reservoir, which is the main additional source in the recycling water supply system, is limited by the requirements of the Reservoir Use Rules. Thus, construction and commissioning of drainage facilities for collection and return of seepage discharge water through dams of the tailings dump is a necessary condition for the water recycling system operation.

Natural conditions and technogenic factors that change them collectively lead to formation of specific environmental situation (including geochemical) in the territories.

Association of the area with the ore province is the reason of high content of Fe, Ti, V, Cr, Mn, Co, Cu, Zn, Mo in natural waters, and this determines the natural hydrochemical background of the area.

As a technogenic factor in changing the geochemical background, the development of the deposit, accompanied by ore breaking and the formation of tailings of wet magnetic separation, activates transition of some of the elements of the geochemical association into soluble forms upon contact of natural waters and tailings.

Based on the research results, the content of ore elements in the composition of the tailings of wet magnetic separation is naturally lower than in ores; however, their content is significant. The chemical composition of tailings (

Table 2 and

Table 3) is determined by the presence of predominant minerals. In particular, the presence of silica and calcium and magnesium oxides is explained by the abundance of CaMg[Si

2O

6] diopside among pyroxene grains of the mineral species corresponding in composition. Alumina is mainly present in plagioclases and minerals of the epidote group. Iron is contained in the epidote, amphiboles, goethite and pyrite. The rarest elements are vanadium (in titanomagnetite) and scandium (in pyroxenes). The presence of sulfur is associated with the presence of sulfides, which also contain non-ferrous metals (copper, arsenic, antimony, lead, zinc). Chromium is mainly contained in chromium-spinelids.

Wastewater generated as a result of contact with tailings, including filtration discharge water from dams, enters the environment, leading to contamination of natural waters. Regular observations carried out by EVRAZ KGOK record an increase in V content in the river waters below the tailings dump by 3–6 times compared to the background values. The results of the geoecological studies indicate that the concentrations in the river waters below the tailings dump are higher than the background values: Ti—1.7–9.1; V—4.6–6.0; Co—4.9–6.3; Mo—2.2–2.6 times, which occasionally leads to exceeding the permissible values established for the waters of watercourses of fishery importance. In the waters of the river below the tailings dump, an excess of the permissible level for the content of V was recorded—by 2.3–3.0 times.

Geo-ecological research revealed increased contents of Ti, V, Co, Mo in seepage discharge waters. Content of Ti in seepage discharge waters exceeds background values 1.1–6.4 times; Co—4.0–7.1 times; Mo—5.9–14.8 times; V—7.0–23.1 times.

The total amount of the substance entering the natural environment with seepage discharge waters during the year is given in

Table 4. Values of seepage discharge volumes obtained using direct hydrometric measurements are taken for calculation. Calculation was made for each dam taking into account the volume of seepage discharge and concentration of contaminants in its waters with the subsequent summation.

In the total amount of the substance entering the natural environment, only a part of it is a direct contaminant, since in natural conditions these components are also contained in natural waters.

Table 5 shows the amounts of pollutants that determine the technogenic component in the total amount of the incoming substance. The number of pollutants is calculated with the exception of the natural component due to the background content of components in natural waters.

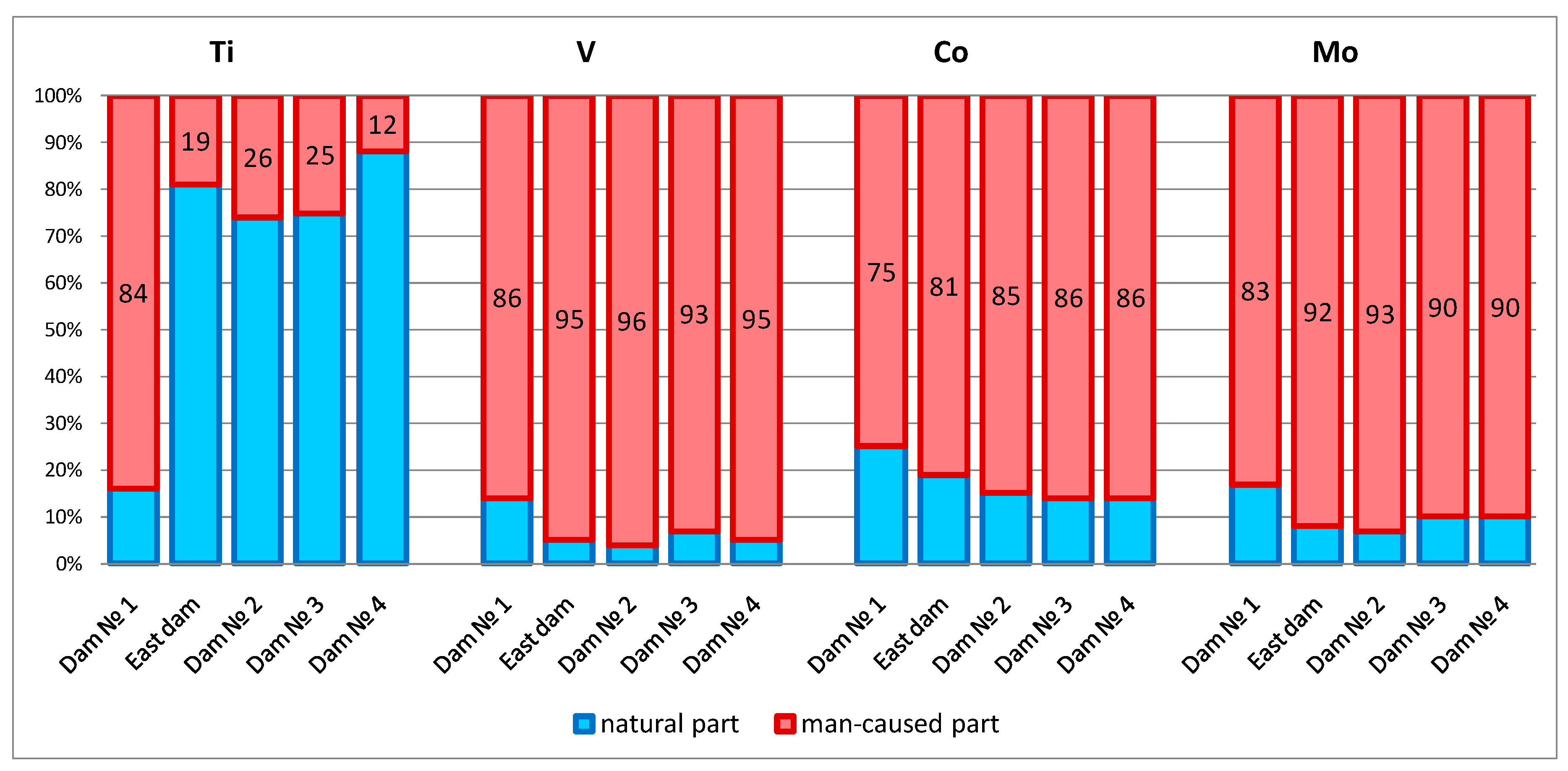

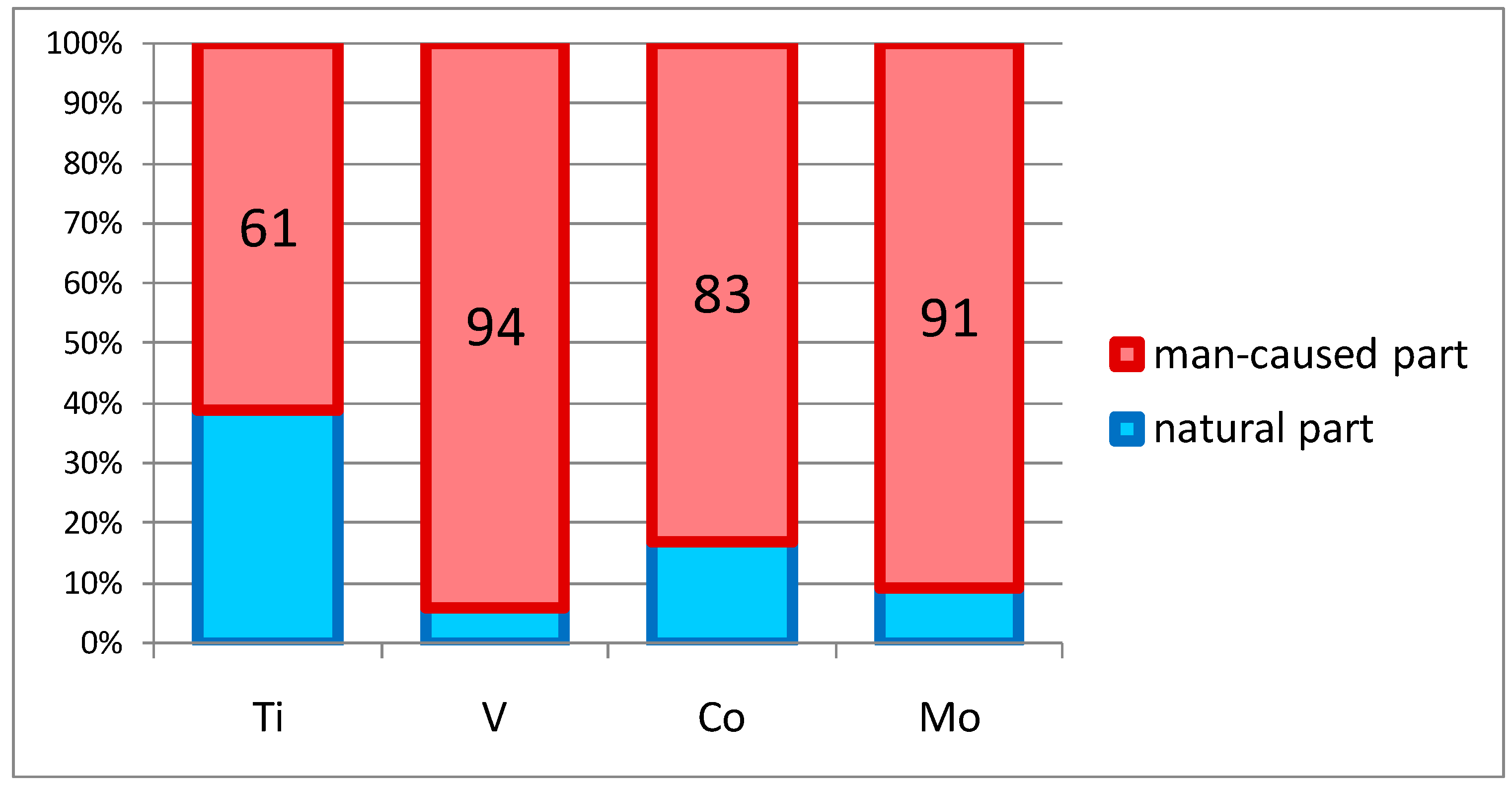

The ratio of natural and technogenic components in the total amount of incoming substance for each dam and in average in the whole seepage discharge volume is shown in

Figure 2 and

Figure 3. The analysis of diagrams indicates the determining role of the technogenic factor in the content of Ti, V, Co, Mo in seepage discharge waters of dams. The share of technogenic component of V, Co and Mo in the total amount of incoming substance reaches 86–96%, 75–86% and 83–93%, respectively. The ratio of natural and technogenic component Ti in the total amount of incoming substance change in a wider range. In seepage discharge of the majority of dams, the share of technogenic component is small and makes 12–26%. Only in seepage discharge waters of dam No. 1, the share of technogenic component reaches 84% which, as a result in the total seepage discharge flow of all dams, leads to the dominating role of technogenic factor in Ti input into natural environment. The share of the technogenic component is 61%.

The amount of substance, the content of which is caused by technogenic factors, exceeds the natural content up to 5.4 times for Ti; 6.0–18.2 times for V; 3.0–6.1 times for Co; 4.9–13.8 times for Mo.

The forecasting of increase of seepage discharge volumes allows confirming the growth of pollutants entering the natural environment. Taking into account that the technological process of beneficiation does not change, the concentration of contaminants in seepage waters can be assumed to be constant when calculating. The volume of seepage discharge is accepted according to the results of the forecast for 2026 made using calculation method [

33]. The results of calculations given in

Table 4 and

Table 5 indicate 1.6–2.9 times growth of technogenic geochemical load for all analyzed components by 2026.

Despite significant production volumes, the amount of waste and waste water produced by the enterprise has a relatively small negative impact on the environment. This is primarily due to the fact that the mined ores practically do not contain toxic substances that are typical, for example, for nonferrous metal ores, in particular: S, As, Cd, Hg and others. In the process of ore processing and beneficiation, chemical reagents are not used, and imported materials used in the production of agglomerate and pellets—bentonite clay, limestone, coke—are not toxic substances and constitute only 0.7% of the total amount of raw materials used. According to the results of a series of studies conducted by specialists of the Russian Academy of National Economy under the Government of the Russian Federation (Moscow) and employees of the Association “Medicine and Ecology” (Ekaterinburg), the production of EVRAZ KGOK is recognized as non-toxic and safe [

40,

41]. Nevertheless, one of the main priorities of its management is to improve the environmental efficiency of the enterprise, which can be achieved by managing those aspects of the activity that are associated with the most significant impact on the environment [

40]. Ecological efficiency of the water balance management scheme as one of the priority aspects of ecologically directed activity consists of maximum use of recycled water and decrease in the volume of discharged wastewater, including seepage discharge water of dams, and is achieved by thickening the tailing pulp with return of clarified water for technological needs.

Issues related to management of water supply and disposal processes, thickening of stored waste in order to reduce risks of emergency situations at tailing dumps and negative environmental consequences of their operation are discussed in the papers [

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53].

New technological approaches aimed at solving technical, economic and environmental problems that arise during transportation and storage of waste and recycling water supply of beneficiation plants, appeared in the world practice of tailings storage in the middle of the 20th century [

51,

52]. Storage of tailings in the form of thickened pulp is based on dewatering of tailings material to a condition that does not divide into phases and fractions. Such storage allows using smaller plot of land in comparison with tailings dumps. Currently, almost all projects of tailings facilities in the world consider thickening to a state of paste. The technology of tailings thickening to the state of paste allows successfully storing them in a dump together with overburden rocks. Technological schemes for stacking paste-like tailings together with overburden rocks completely exclude construction of tailing dumps (sludge storage facilities) or allow reducing their vast territories and minimize operating costs [

51].

For the first time in the Russian Federation hydrocyclones for thickening and improving the efficiency of tailing dumps were used at Achisai Polymetallic Plant. Subsequently, hydrocyclones were operated at the tailing dumps of Almalyk, Afrikanda, Mirgalimsay, Kantagi, Khaidarkan and other beneficiation plants. Overseas, application of hydrocyclones for tailing dumps reclamation began in the USA in 1950s. Currently, this technology is widely used in Canada, Africa, Chile, Brazil and South Africa.

In order to increase ecological efficiency, EVRAZ KGOK “Mekhanobr Engineering” JSC (AO) (St. Petersburg, Russia) has developed technical solutions for transition to the modern technology of storage of wet magnetic separation tailings and reconstruction of tailing facilities, providing engineering measures for tailings thickening, interception and maximum exclusion of seepage water entering the adjacent territory. When considering and justifying the tailings storage options, special attention was paid to improving the safety level of the tailings dump and minimizing the negative impact on the environment by using the method of preliminary thickening of pulp [

23]. The fundamental possibility of obtaining paste for each type of tailings largely depends on the content of particles up to 20 μm in the pulp, which should be at least 20–30% of the total amount [

51,

54]. In the composition of the tailings of wet magnetic separation, the particle content of less than 0.074 mm reaches 75%, which proves the possibility of their thickening to paste-like state [

51].

The technology ensures thickening of the initial tailing pulp of the beneficiation plant from 7–11 to 75% of solids content. The volume of water entering the tailing dump as part of wet magnetic separation decreases 40 times—to 12.19 million m

3/year [

55], which is lower than the seepage discharge volumes of the tailing dumps currently observed. The water content of the tailings at 75% thickening is 0.33 m

3 per 1 ton of solid matter, i.e., approximately equal to the volume of pores in the stored tailings. Insignificant volumes of water discharged from the tailings go to the drainage system and further to the water recycling system. Implementation of measures on collection and accumulation of seepage water from the tailings dump with its subsequent use for production needs ensures reduction of geochemical load on natural waters of adjacent territories.

Positive experience of tailings thickening has been obtained, for example, at the Uchalinsky mining and processing plant, which extracts and processes chalcopyrite to produce copper and zinc concentrates. Outotec’s paste thickening technology enabled the enterprise to reduce the volume of water in the tailings and increase the solid content from 20% to 70–72%. The solution makes it possible to efficiently extract process water for reuse. It reduces the area occupied by the tailing dump and the risk of environmental pollution. It also allows effective return of process water and reduces power consumption for pulp and water pumping. Thickened tailings mixed with cement can be used for backfill in a used pit. The possibility of placing thickened tailings in the worked-out area reduces the volume of waste stored in the tailings dump, which makes it possible to increase the operating life of the tailings dump from 20 (with the traditional method of tailings storage) to 50 years [

56].

Application of the technology of dewatering and thickening of the tailings of wet magnetic separation, creation of closed water supply systems and reduction of wastewater discharge, including water from seepage discharge of dams, provides ecological efficiency of the enterprise’s water balance management. As a result, the technogenic load on the environment is considerably reduced, natural water pollution is reduced, and the problem of water shortage for technological needs is resolved. The forecasted ecological efficiency of the implementation of technical solutions is confirmed by the results of the EVRAZ KGOK health risk assessment. The assessment showed that the values of hazard indices calculated for priority pollutants do not exceed 1, which corresponds to the level of acceptable risk. The values of individual carcinogenic risk do not exceed one additional case per 1 million exposed persons, which corresponds to a negligible low level of risk that does not differ from ordinary daily risks [

40].