Abstract

Making consistent and precise octahedral pressure media is crucial for reproducible high-pressure experiments in the multi-anvil press. Here we report a new approach of casting octahedra using 3D-printed molds, and pressure calibrations for octahedra both with and without pre-existing gaskets (“fins”). The 3D-printed molds for casting octahedra from either Ceramacast 584-OF or 646 cement improve the reproducibility of the octahedra and allow for a pre-existing central hole (for the high-pressure cell assembly) in the final cast product. Pressure and temperature calibrations of the octahedra have been performed based on phase transitions in bismuth (Bi) and silica (SiO2), respectively, in order to determine the efficiency and reproducibility of pressure generation and thermal insulation for cast octahedra designed for use with 18/12, 14/8, and 10/5 multi-anvil assemblies. The pressure-generating efficiency of the 14/8 and 10/5 octahedra with pre-existing gaskets, cast from the 584-OF cement, is similar to that of the corresponding COMPRES (Consortium for Materials Properties Research in Earth Sciences) octahedra, and more efficient than pre-cast octahedra made from the same material but lacking pre-existing gaskets. The efficiency of pre-gasketed 18/12 octahedra made of the 646 cement is markedly lower than those of the 584 cement. However, the 18/12 large-volume octahedra, cast (with fins) from the ZrO2-based 646 cement, also provides efficient thermal insulation. Casting octahedral solid pressure media for multi-anvil experiments using 3D-printed “injection” molds is a low-cost and low failure-rate alternative for conducting reproducible experiments at high pressure in the multi-anvil apparatus.

1. Introduction

In an effort to replicate in experimental laboratories the often-extreme conditions known to exist within deep interiors of the Earth, other planets, and moons, earth scientists have pioneered many technical developments in the simultaneous generation of high-pressure and high-temperature conditions using various high-pressure devices. These efforts have been directed in general towards studying the behavior and chemical and physical properties of planetary materials under appropriate conditions. In addition to dynamic compression techniques, static high-pressure equipment such as the diamond anvil cell (DAC) and the multi-anvil press (MAP) have been used to compress samples to study variations in material properties and polymorphous phase transitions as a function of pressure and temperature. The MAP technique is typically employed when a relatively large volume of sample is desired. Since the first 6-8 multi-anvil large-volume apparatus was introduced by Kawai and Endo [1], continuous technical modifications and improvements have been made that facilitate broader investigation of geological processes taking place not only in the deep Earth [2] but also in the upper mantle and lithospheric mantle. One of the most important practical developments was made by Walker [3], who designed and built a removable cylindrical containment ring housing all six of the first-stage anvils as well as the eight carbide cubes of the second stage that enclose the octahedron-shaped pressure medium. The cylindrical containment device was small enough that it could be moved in and out of a hydraulic press between experiments, greatly reducing the cost of setting up a multi-anvil laboratory for high pressure experiments. In order to accommodate a larger sample volume, larger carbide cubes (54 and 75 mm) have been used at Bayerisches Geoinstitut [4] and Ehime University [5]. At the same time, higher tonnage [4], and stiffer materials, such as sintered diamond (SD) and nano-polycrystalline diamond (NPD) [5], were also employed to make second-stage cubes capable of achieving much higher pressures. The use of SD cubes has allowed for progressive increases in the maximum achievable pressure, from 41 GPa [6] in 1989, to 63 GPa [7] in 2005, and to 74 GPa [8] by 2010. The highest pressures documented thus far in the multi-anvil apparatus have reached 88 GPa [9] and 125 GPa [10] with the use of NPD cubes.

To consistently and reproducibly achieve well-defined high-pressure conditions in the laboratory, various cell assemblies have been designed for the 6-8 multi-anvil apparatus. Standardized cell assemblies have been developed for in situ MAP experiments [11], in which appropriate “windows” were established through the materials comprising the assembly to improve the passage of X-rays. Over the past decade, Leinenweber et al. [12], supported by the Consortium for Materials Properties Research in Earth Sciences (COMPRES), have designed, tested, and calibrated a series of standardized high-pressure cell assemblies that are available to the high-pressure community for general use and interlaboratory comparisons. However, many laboratories are still using the method introduced by Walker in which pre-cast octahedra are used for multi-anvil experiments, which is both cost-effective and relatively easy to assemble and run [13]. The segmented molds proposed by Walker are composed of different size frames, PVC cubes, and Teflon sheets, allowing the experimentalist to cast their octahedron (effectively, the octahedral “pressure-transmitting” medium) with dimensions, usually expressed in terms of their “octahedral edge-length” (OEL) that is appropriate to the corresponding “truncated edge length“ (TEL) on the second-stage cubes (“OEL/TEL”) [13]. The Walker approach has been adopted by many multi-anvil laboratories largely because it allows for MAP experiments that are cheaper and more time efficient. The octahedra made by this approach, however, often suffer from pre-formed gaskets or “fins” that are of uneven thickness or that contain cavities on its outer surface from unfilled air bubbles left over from the casting stage. In addition, after drying and sintering in a 1 atm box furnace at ~1000 °C, the octahedra become not only hardened but also more brittle, which makes drilling the central hole in the octahedron, utilized for accommodating the various components of the cell assembly, difficult, time-consuming, and with a high failure-rate.

In this study, we describe a new, low-cost method for casting octahedral pressure-media for multi-anvil experiments from commercially available ceramic cement that makes use of “semi-injection” molds that have been printed by a 3-D printer. Commercially-available 3-D printers are now relatively inexpensive to purchase and easy to operate and are already used in a number of applications in the Earth Sciences, e.g., in crystallography [14,15], and sedimentology [16]. These 3D-printed molds have been fabricated in different sizes appropriate for casting octahedron of various standard OEL to match the standardized TEL of the corresponding cubes. The important difference is that our ceramic octahedra already have a central hole established in the final cast product prior to sintering at 1000 °C.

The new approach presented here can easily be adopted to any MAP laboratory. Our “injection-molded” octahedra were tested in our mineral physics laboratory at the University of Hawaii at Manoa, using both 1000-ton and 2000-ton presses equipped with Walker-design multi-anvil devices through a series of pressure-calibration experiments based upon the room temperature, pressure-dependent phase transitions in bismuth (Bi) [17], and the high-temperature phase transition in SiO2 from quartz to coesite [18]. We then compare the pressure-generating efficiency and thermal-insulating properties of our cast ceramic octahedra to the calibrations for the corresponding 14/8 and 10/5 COMPRES cell assemblies (where the first number refers to the octahedron’s OEL and the second number refers to the cube’s TEL).

2. Experimental Methods

2.1. D-Printed Molds for Casting Octahedra

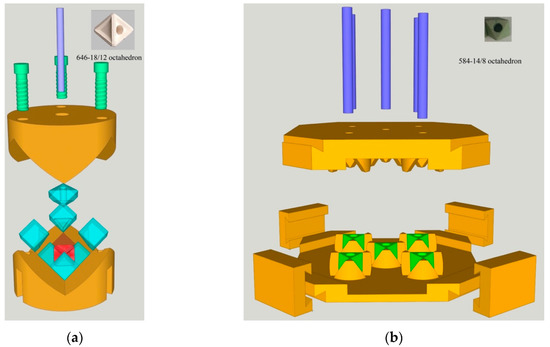

Two types of casting molds were designed and fabricated from PLA filaments using a 3D printer (3D printer model ANYCUBIC i3 MEGA, ShenZhen ANYCUBIC Technology Co., Ltd., Shenzhen, China). The first model is the prototype for ceramic octahedra cast with integrated and continuous gasket fins surrounding all edges of the octahedron and containing a pre-existing, centered, cylindrical hole to accommodate the cell assembly. The mold consists of a two-part casing that encloses the 8 spacing blocks, which impart the overall octahedral shape to the cavity and will be filled with the ceramic slurry; grooves aligned along the edges of the inner faces of these blocks are responsible for creating the pre-formed gaskets. Every two neighboring blocks meet at the ½ height of the gaskets. Thus, the height and width of the pre-formed gaskets are controlled by dimension of the grooves, which were found to be reproducible and consistent when a tight fit of the 8 spacing blocks was achieved by turning the screws to fit together the 2 main casing blocks (Figure 1a). The top and bottom spacing blocks have a central hole of a diameter appropriate to the size of the octahedron being cast, and after the cavity is filled with the ceramic cement (in liquid form), a drill-rod pin is inserted through the top hole, on through the center of the 8 aligned spacing blocks (before the cement can set), and onto the center of the bottom spacing block. When fit together, the 2 main (upper and lower) casing blocks are cylindrical in shape; prior to filling the octahedral cavity with the ceramic slurry, these two blocks can be tightened together with three set screws to prevent leakage of the cement from the mold (additional details are provided in Figure 1a). The insertion of the drill-rod pin also introduces some pressure onto the freshly poured ceramic slurry in the molds, mimicking the “injection”-molding process.

Figure 1.

Schematic 3D pictures of the “injection” molds in different sizes with pre-existing hole. (a) 3D schematic picture of the mold for casting octahedra with gaskets, the inset is a 18/12 octahedron made by 646 cement; (b) 3D schematic diagram of the mold for casting octahedra without gaskets, the inset is a 14/8 octahedron made of 584-OF cement with a 5 wt.% of Cr2O3 in it to reduce the radiative heat loss.

The second type of mold is for casting octahedral pressure media without accompanying gasket fins (“finless” octahedra; Figure 1b). Here, the mold casing consists of only two parts; when fit together, the intersecting upper and lower blocks create multiple octahedral cavities that can cast up to (for this mold) 5 octahedra at a time. Four locking brackets are designed to slide into place around the four corners of the two aligned blocks prior to pouring the cement into the mold. Again, five drill-rod pins of appropriate diameter are inserted into holes on the top plate that are aligned with the centers of the five octahedral cavities below.

2.2. Casting Octahedra from Aremco Ceramacast Cement

Castable ceramics from Aremco Ceramacast were first used by Walker [13] for casting octahedral-shaped pressure media for multi-anvil experiments. Ceramacast 584-OF (Old Formula, hereafter referred to as “584”) and 646 castable ceramic systems have been used in this study: (1) 584-OF is made from 66% MgO + 33% Al2O3 in mass; (2) Ceramacast 646 (hereafter referred to as “646”) is comprised predominantly of ZrO2. The cement powder and activator of different weight and proportions were used in order to completely fill the mold cavity with minimal materials wasted, when casting octahedra (with or without fins) of different sizes (see detailed information for casting 584 octahedra in Table 1. For the 584-OF cement, it was necessary to stir the powder-activator mixture quickly (~10 s) in order to blend evenly and minimize the formation of any air bubbles because the mixture tends to set very quickly. The cement slurry is poured into the mold; the central pin is quickly inserted and forced to the base of the mold; all the cement is allowed to set for 10 min before the drill-rod pin is gently removed. The cast octahedron, still wet, is then allowed to cure in the mold for at least 1 h (preferably overnight) before the two blocks are separated and the octahedron are recovered. The information on the weight and dimension of cast octahedra is listed in Table 1.

Table 1.

Dimensions and weights of octahedra from 584 cement 1.

The 18 mm-OEL octahedra with fins and pre-exiting center hole were also cast as pressure medium using the ZrO2-based Ceramacast 646 cement, using the same 18/12 mold and procedure. The activator for the 646 cement is water, with a typical powder/water ratio of 5.61. According to the instructions from the manufacturer, this cement mixes directly with water; in addition to being simple and easy to mix, the 646 cement has the added advantage that, once mixed with its activator (i.e., water), it remains relatively fluid much longer than the 584 cement mixture. After the cement sets, the mold can be opened and a single octahedron with pre-existing fins and central hole retrieved, ready for drying and heat treatment. It should be noted that it does not require controlled humidity to dry the 646-octahedra, and they are typically free of cracks.

2.3. Pressure Calibrations

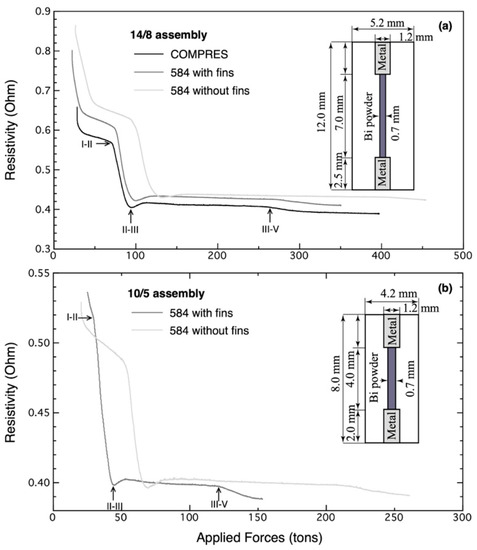

Room-temperature pressure-load calibrations of 18/12, 14/8 and 10/5 multi-anvil assemblies using octahedra cast with our newly-designed “injection” molds were conducted based on electrical resistance measurements of bismuth (Bi) during compression at room temperature [18,19] and were performed in both the 1000-ton and 2000-ton presses at the University of Hawaii at Manoa, both equipped with Walker-design, cylindrical multi-anvil devices. For these calibrations, Bi powder was packed into a MgO cylinder, and aluminum or copper plugs were placed at both ends of the cylinder, serving as electrical contacts with the exposed corners of two tungsten carbide cubes (Toshiba Tungaloy Grade F tungsten carbide) on either side of the centrally-located, cylindrically shaped high-pressure cell assembly (see dimensions in the insets of Figure 2). Resistance was measured by a high-precision multimeter (model HP 4333a) during the compression of the cell assembly at each run (Figure 2). The changes in the electrical resistance of Bi phase result from phase transitions from the trigonal to monoclinic (Bi I–II) at 2.55 GPa, from monoclinic to tetragonal (Bi II–III) at 2.69 GPa, and from tetragonal to body-centered cubic (Bi III–V) at 7.7 GPa (Figure 2). The Bi II–III and III–V phase transitions are sluggish in solid pressure media, and thus, the minimum in the electrical resistance labeled as “II–III” in Figure 2 was typically placed at 3.1 GPa for the pressure calibration of multi-anvil assemblies [19,20]. The Bi III–V phase transition at 7.7 GPa was indicated by the start of electrical resistivity reduction [17].

Figure 2.

Representative electrical resistivity of bismuth (Bi) across the I–II, II–III, and III–V phase transitions as measured as a function of applied forces in (a) 14/8 and (b) 10/5 multi-anvil assemblies at room temperature. The insets at the top-right corner are the cross section of the Bi sample assembly with dimensions.

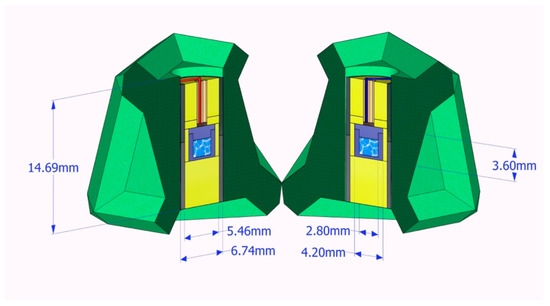

For pressure calibrations at high temperatures using 18 mm octahedra with gaskets cast from 646 ceramic, quench experiments were performed on amorphous or crystalline SiO2 powders [18] near the pressure-temperature conditions appropriate to the quartz-coesite phase transition (see Figure 3 for the cross section of the high-temperature assembly). After reaching the target pressure/load, the sample was heated at a rate of 1°/s until the target temperature (1000 °C) was achieved by applying AC voltage to the graphite heater; type-C thermocouples were used to monitor temperature. For the high-temperature pressure calibration, SiO2 samples were heated at 1000 °C for 2–4 h.

Figure 3.

Cross section of the 18/12 assembly with graphite heater (gray), molly capsule (blue), MgO plugs (yellow), and pre-gasketed octahedra cast by ZrO2-based 646 cement (green). The thermocouples are placed axially into the center hole in an Al2O3 4-bore sleeve, with the junction situating on top of the sample chamber.

3. Results and Discussion

3.1. Reproducible Octahedral Pressure Media for Multi-Anvil Experiments

After removal from the mold, all octahedra cast from 584 were allowed to cure for more than 7 days in a suitably humid environment (typically in sealed plastic bags) in order to minimize cracking as the ceramic continued to dry, prior to heating in a muffle furnace from room temperature at a rate of ~100 °C/min up to 1000–1100 °C, where they were held for ~2–10 h. Table 1 provides detailed information on the weight and dimensions of the octahedra cast from the 584 cement using the 3D-printed molds.

After casting a number of these “semi-injection-molded” octahedra, they were found to have the following general features: (1) there are few if any cavities or bubbles on the surface of the octahedra and within the preformed gaskets surrounding the octahedra, which we attribute to the effective pressurization of the ceramic slurry when the central pin is inserted, mimicking the effect of an injection mold; (2) the cast gaskets surrounding the octahedron are of equal thickness around all the edges of the octahedron, which we attribute to the tight seal between the upper and lower blocks that the three alignment screws permit; (3) the central hole is pre-indented in the octahedra and well centered before the cement cures, so that there is no need to drill the octahedron after firing.

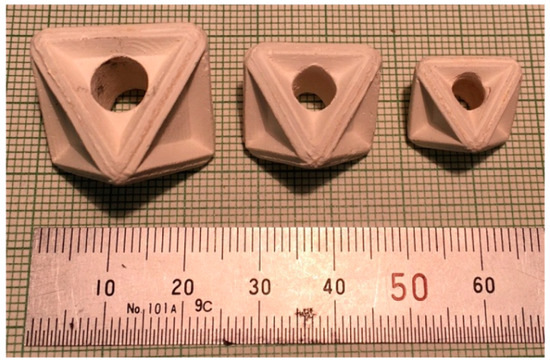

Following the outlined procedure, octahedra can be readily and reproducibly made from castable ceramic using our 3D-printed “injection” mold design (see insets in Figure 1 for photos of 584 and 646 octahedra). Pre-gasketed octahedra from 646 cement were cast by following the same procedure for 584 cement. The advantage of the 646 castable cement includes longer pot life (tens of minutes) and longer shelf life (years). The octahedra cast from 646 cement generally demonstrated better surficial quality (insets in Figure 1a and Figure 4) relative to those made from the 584 cement (inset in Figure 1b). The cost of materials for each cast octahedron is estimated to be $1 to $3 US dollars depending on its OEL. The 3D models for the two types of molds, which are available in the Supplementary Materials, can be downloaded and ready for fabrication by a 3D printer.

Figure 4.

Pictures of octahedra with gaskets and pre-indented center hole cast from Ceramacast 646 cement by 3D-printed molds for the 18/12, 14/8, and 10/5 multi-anvil assemblies.

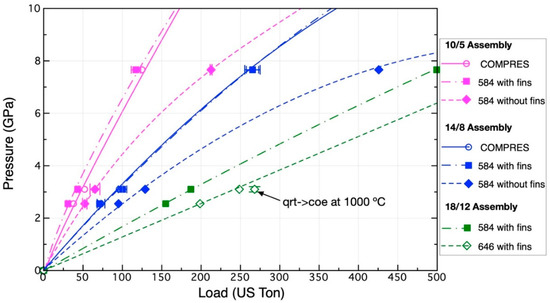

3.2. Room-Temperature Pressure-Load Calibration of the Cell Assemblies

Figure 5 shows the results of the pressure calibration based on Bi phase transitions for the 10/5, 14/8, and 18/12 assemblies using the cast octahedra and a comparison on calibrations with the COMPRES octahedra [12]. The calibrations of the various assemblies include several experimental runs (six runs for 14/8 and five runs for 10/5 assembly) for octahedra cast by our 3-D printed molds, with or without gaskets, and using both the 584 or 646 cement; all these are shown relative to the calibrations for the corresponding COMPRES assemblies using separately machined and individually glued pyrophyllite gaskets (Figure 5). Our calibrations, based on the Bi I–II phase transition at 2.55 GPa, II–III at 3.1 GPa, and III–V at 7.7 GPa [19], suggest that the pressure-generating efficiency of our mold-cast, pre-gasketed 14/8 and 10/5 octahedra using the Cr-doped 584 cement is equal to or only slightly more efficient than the corresponding COMPRES [12] assemblies calibrated with octahedra surrounded by a cage of pyrophyllite gaskets (Figure 2 and Figure 5). The calibrations in experiments using finless octahedra, cast using our mold from Cr-doped 584 cement, and paired with pyrophyllite gaskets, however, suggest that they are much less efficient at generating pressure; that is, they require 25% more load or tonnage for the 10/5 assembly and 34% or more for the 14/8 assembly in order to reach the I–II and II–III phase transitions of Bi at room temperature. And for the 14/8 and 10/5 assemblies using mold-cast, finless octahedra, it appears that 60% to 70% additional load is needed to reach the Bi III–V phase transition at 7.7 GPa (Figure 5). It should be noted that the finless cast octahedra from the 584 cement is 30% less dense or more porous than those COMPRES octahedra (Table 1), which may be the reason why the cast 584-octahedra without fins are less efficient at generating pressure. Furthermore, the oil loads required for the Bi phase transitions (I–II, II–III, III–V) only varies slightly for replicate experimental runs conducted for the same assemblies (see the data points with error bars in Figure 5).

Figure 5.

Load-pressure calibrations of the 18/12, 14/8, and 10/5 assemblies with cast octahedra, in comparison with those of COMPRES assemblies. The room-temperature calibrations are based on phase transitions of Bi (I–II at 2.55 GPa, II–III at 3.1 GPa, and III–V at 7.7 GPa) [19,20]. The vertical lines in the 10/5 and 14/8 assembly symbols are the standard deviation ranges of the calibration experiments. High-temperature calibration based on quartz (qrt) to coesite (coe) transition at 3.1 ± 0.1 GPa at 1000 °C [18] was also conducted for the 18/12 assembly with 646 octahedra with gaskets.

Room-temperature calibrations based on Bi phase transitions were also carried out on the 18/12 assemblies using pre-gasketed 18 mm octahedra and both the 584 and 646 ceramic cement. For calibration experiments using “finned” 18 mm OEL octahedra cast from the 584 cement, the pressure-load relationship is linear, reaching 7.7 GPa at 500 ton (Figure 5). For calibration experiments using “finned” 18 mm OEL octahedra cast from the 646 ceramic cement, 28% to 32% more load is needed to reach the same pressures; note, however, that we did not attempt to increase our load up to and beyond that needed to reach the Bi III–V phase transition at 7.7 GPa (expected to be >600 ton) in these experiments with the 646 ceramic.

3.3. High-Temperature Calibration of the 646-18/12 Assembly

Four high-temperature pressure calibration experiments based on the quartz to coesite phase transition were carried out at 1000 °C for 2–4 h. After recovery of the quenched samples, the molybdenum sample capsules were mounted in resin epoxy, sectioned, and polished to expose the sample, and Raman spectroscopy was used to identify which phase or phases of SiO2 were present (quartz or its high-pressure polymorph coesite) (Table 2). The quartz-coesite phase transition occurs at 3.1 ± 0.1 GPa at 1000 °C [18]. In run PL136, both coesite and minor quartz coexist in the sample capsule; the press load in this experiment was set at 268 ton for the 646-18/12 assembly, corresponding to a sample pressure of 3.1 GPa, which is close to the room-temperature calibration based on Bi phase transitions (Figure 5).

Table 2.

Experimental conditions and results for the 18/12 assembly using 646 octahedra with gaskets.

4. Summary and Conclusions

We have conceived, designed, and tested a cost-effective method for quickly and reproducibly casting octahedra for use in high-pressure experiments in the multi-anvil apparatus, using a 3D-printed “injection” mold that produces octahedra with or without preformed gaskets, as well as a pre-existing central hole, eliminating the need for post-sintering drilling or coring of castable ceramic octahedra. Our calibration results indicate that both the 10 mm and the 14 mm OEL “injection”-molded octahedra with gaskets, cast from 584 ceramic cement, have similar pressure-generating efficiency as the corresponding COMPRES octahedra which require individually glued pyrophyllite gaskets. The 10/5 and 14/8 assemblies that use molded, gasketless octahedra cast from the 584 ceramic cement and separate pyrophyllite gaskets require 25% to 30% more load in order to reach the pressures required for the I–II and II–III phase transitions of Bi, respectively, and 60% to 70% more load to reach the Bi III–V phase transition at 7.7 GPa and room temperature. The pressure-load relationship for 18/12 assemblies with pre-gasketed octahedra cast from the 584 ceramic cement is almost linear but requires 28% to 32% less load to reach the same pressure when compared with assemblies run using pre-gasketed octahedra cast from the ZrO2-based 646 cement. High-temperature pressure calibration of the 18/12 assembly, using ZrO2-based castable octahedra and based on the phase transition from quartz to coesite at 3.1 ± 0.1 GPa and 1000 °C, show consistent results relative to the room-temperature calibrations. We close by noting that the designs and 3D printer files for the “semi-injection” molds used in casting our ceramic octahedra are available in the public domain, with the intent that they will be utilized by other laboratories conducting high-pressure research in the multi-anvil apparatus.

Supplementary Materials

The 3D models for the two types of molds for casting 18 mm, 14 mm, and 10 mm OLE octahedra are available online at https://www.mdpi.com/2075-163X/10/1/4/s1, and can be downloaded and ready for fabrication by a 3D printer.

Author Contributions

B.C. conceived and designed the research. H.L. and B.C. designed and fabricated the molds and casted the octahedra; Y.L. and B.C. performed the room-temperature calibration experiments for 14/8 and 10/5 assemblies and analyzed the data. X.L., F.Z., R.P.R., and B.C. conducted pressure calibration experiments for the 18/12 assemblies. Y.L., B.C., and R.P.R. wrote the manuscript; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities (grant number 2652017090) to Y.L., and the National Science Foundation (grant numbers EAR-1555388 and EAR-1829273) to B.C.

Acknowledgments

We acknowledge the comments and suggestions from the three anonymous reviewers, which improved the manuscript. We thank K. Chao, K. Nichols, and J. Switek for their help with the experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kawai, N.; Endo, S. The generation of ultrahigh pressures by a split sphere apparatus. Rev. Sci. Instrum. 1970, 41, 1178–1181. [Google Scholar] [CrossRef]

- Liebermann, R.C. Multi-anvil, high pressure apparatus: A half-century of development and progress. High Pressure Res. 2011, 31, 493–532. [Google Scholar] [CrossRef]

- Walker, D. Some simplifications to multianvil devices for high pressure experiments. Am. Mineral. 1990, 75, 1020–1028. [Google Scholar]

- Frost, D.J.; Poe, B.T.; Trønnes, R.G.; Liebske, C.; Duba, A.; Rubie, D.C. A new large-volume multianvil system. Phys. Earth Planet. Ineriors 2004, 143, 507–514. [Google Scholar] [CrossRef]

- Irifune, T.; Kurio, A.; Sakamoto, S.; Inoue, T.; Sumiya, H. Ultrahard polycrystalline diamond from graphite. Nature 2003, 421, 599–600. [Google Scholar] [CrossRef] [PubMed]

- Ohtani, E.; Kagawa, N.; Shimomura, O.; Togaya, M.; Suito, K.; Onodera, A.; Sawamoto, H.; Yoneda, M.; Tanaka, S.; Utsumi, W.; et al. High-pressure generation by a multiple anvil system with sintered diamond anvils. Rev. Sci. Instrum. 1989, 60, 922. [Google Scholar] [CrossRef]

- Ito, E.; Katsura, T.; Aizawa, Y.; Kawabe, K.; Yokoshi, S.; Nozawa, A.; Funakoshi, K. High-pressure generation in the Kawai-type apparatus equipped with sintered diamond anvils: Application to wurtzite-rocksalt transformation in GaN. In Advances in High-Pressure Technology for Geophysical Applications; Elsevier: Amsterdam, The Netherlands, 2005; pp. 451–460. [Google Scholar]

- Ito, E.; Yamazaki, D.; Yoshino, T.; Fukui, H.; Zhai, S.M.; Shatzkiy, A.; Katsura, T.; Tange, Y.; Funakoshi, K. Pressure generation and investigation of the post-perovskite transformation in MgGeO3 by squeezing the Kawai-cell equipped with sintered diamond anvils. Earth Planet. Sci. Lett. 2010, 293, 84–89. [Google Scholar]

- Irifune, T.; Kunimoto, T.; Shinmei, T.; Tange, Y. High pressure generation in Kawai-type multianvil apparatus using nano-polycrystalline diamond anvils, C.R. Geoscience 2019, 351, 260–268. [Google Scholar] [CrossRef]

- Kunimoto, T.; Irifune, T. Pressure generation to 125 GPa using a 6-8-2 type multianvil apparatus with nano-polycrystalline diamond anvils. J. Phys. Conf. Ser. 2010, 215, 012190. [Google Scholar] [CrossRef]

- Leinenweber, K.; Mosebfelder, J.; Diedrich, T.; Soignanrd, E.; Sharp, T.G.; Tyburczy, J.A.; Wang, Y. High-pressure cells for in situ mutli-anvil experiments. High Pressure Res. 2006, 26, 283–292. [Google Scholar] [CrossRef]

- Leinenweber, K.D.; Tyburczy, J.A.; Sharp, T.G.; Soignard, E.; Diedrich, T.; Petuskey, W.B.; Wang, Y.; Mosenfelder, J.L. Cell assemblies for reproducible multi-anvil experiments (the COMPRES assemblies). Am. Mineral. 2012, 97, 353–368. [Google Scholar] [CrossRef]

- Walker, D. Lubrication, gasketing, and precision in multianvil experiments. Am. Mineral. 1991, 76, 1092–1100. [Google Scholar]

- Casas, L.; Estop, E. Virtual and printed 3D models for teaching crystal symmetry and point groups. J. Chem. Educ. 2015, 92, 1338–1343. [Google Scholar] [CrossRef]

- Casas, L. 3D-printing aids in visualizing the optical properties of crystals. J. Appl. Cryst. 2018, 51, 901–908. [Google Scholar] [CrossRef]

- Luffman, I.; Nandi, A.; Luffman, B. Comparison of geometric and volumetric methods to a 3D solid model for measurement of Gully erosion and sediment yield. Geosciences 2018, 8, 86. [Google Scholar] [CrossRef]

- Knibble, J.S.; Luginbühl, S.M.; Stoevelarr, R.; van der Plas, W.; van Harlingen, D.M.; Rai, N.; Steenstra, E.S.; van de Geer, R.; van Westrenen, W. Calibration of a multi-anvil high-pressure apparatus to simulate planetary interior conditions. EPJ Tech. Instrum. 2018, 5, 5. [Google Scholar] [CrossRef] [PubMed]

- Bose, K.; Ganguly, J. Quartz-coesite transition revisited: Reversed experimental determination at 500–1200 °C and retrieved thermochemical properties. Am. Mineral. 1995, 80, 231–238. [Google Scholar] [CrossRef]

- Decker, D.L.; Bassett, L.; Merrill, H.T.; Hall, H.T.; Barnett, J.D. High-pressure calibration: A critical review. J. Phys. Chem. Ref. Data 1972, 1, 773. [Google Scholar] [CrossRef]

- Walker, D.; Li, J. Castable solid pressure media for multi-anvil devices. Matter Radiat. Extrem. 2019. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).