Influence of Geometric Parameters on Contact Mechanics and Fatigue Life in Logarithmic Spiral Raceway Bearings

Abstract

1. Introduction

2. Logarithmic Spiral Bearing Fatigue Life Model

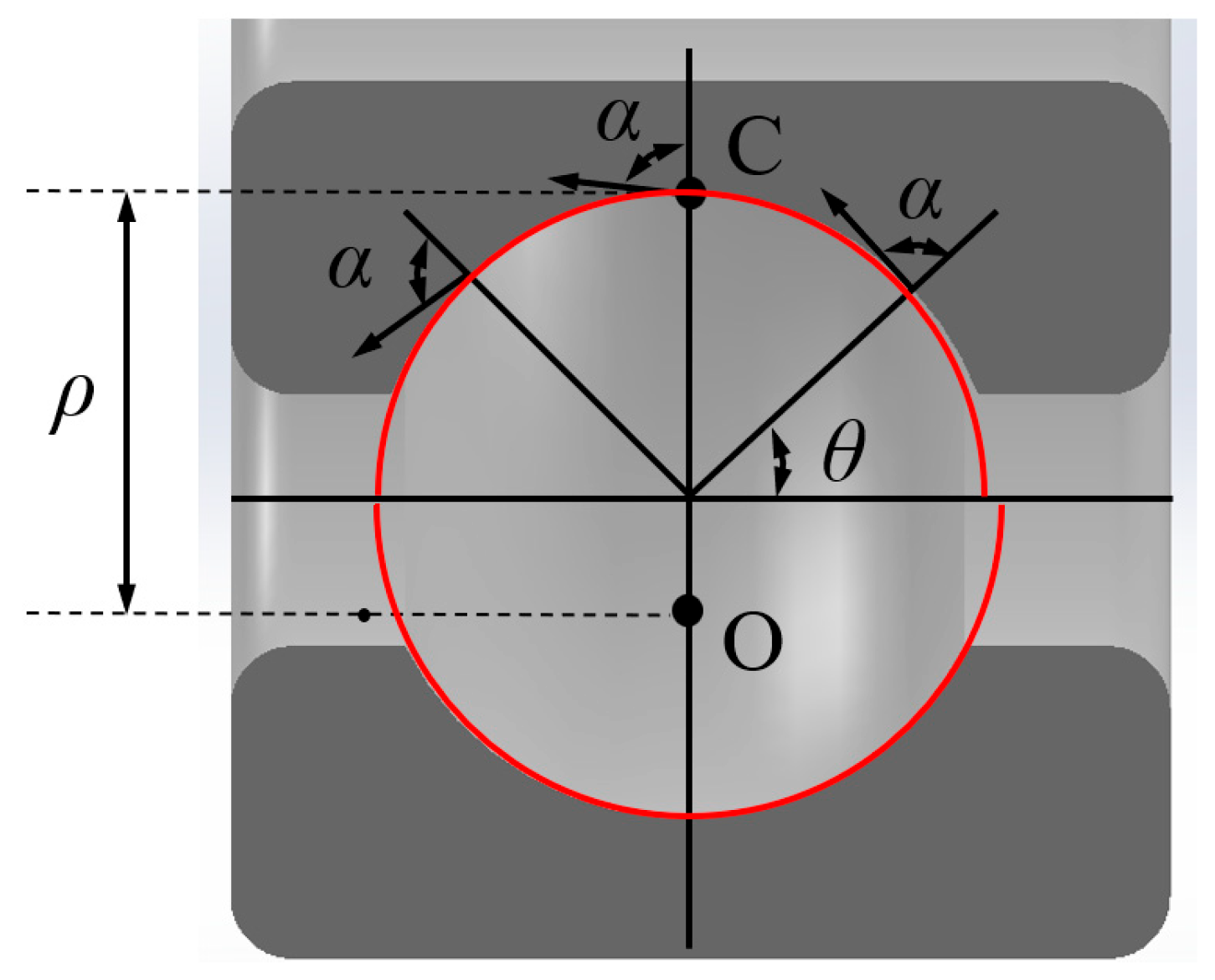

2.1. Logarithmic Spiral Raceway and Raceway Parameter Design

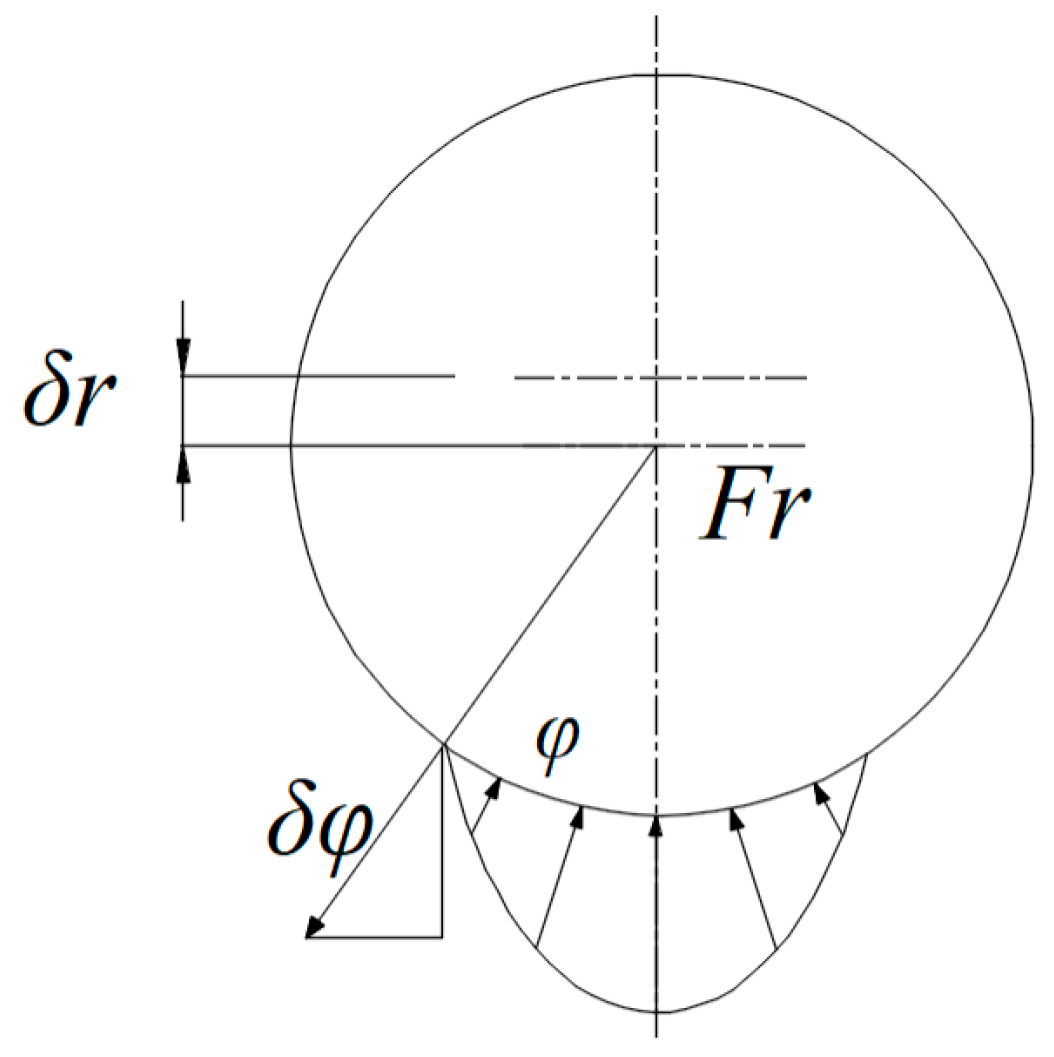

2.2. Contact Stress Analysis

2.3. Fatigue Life Model of Logarithmic Spiral Bearing

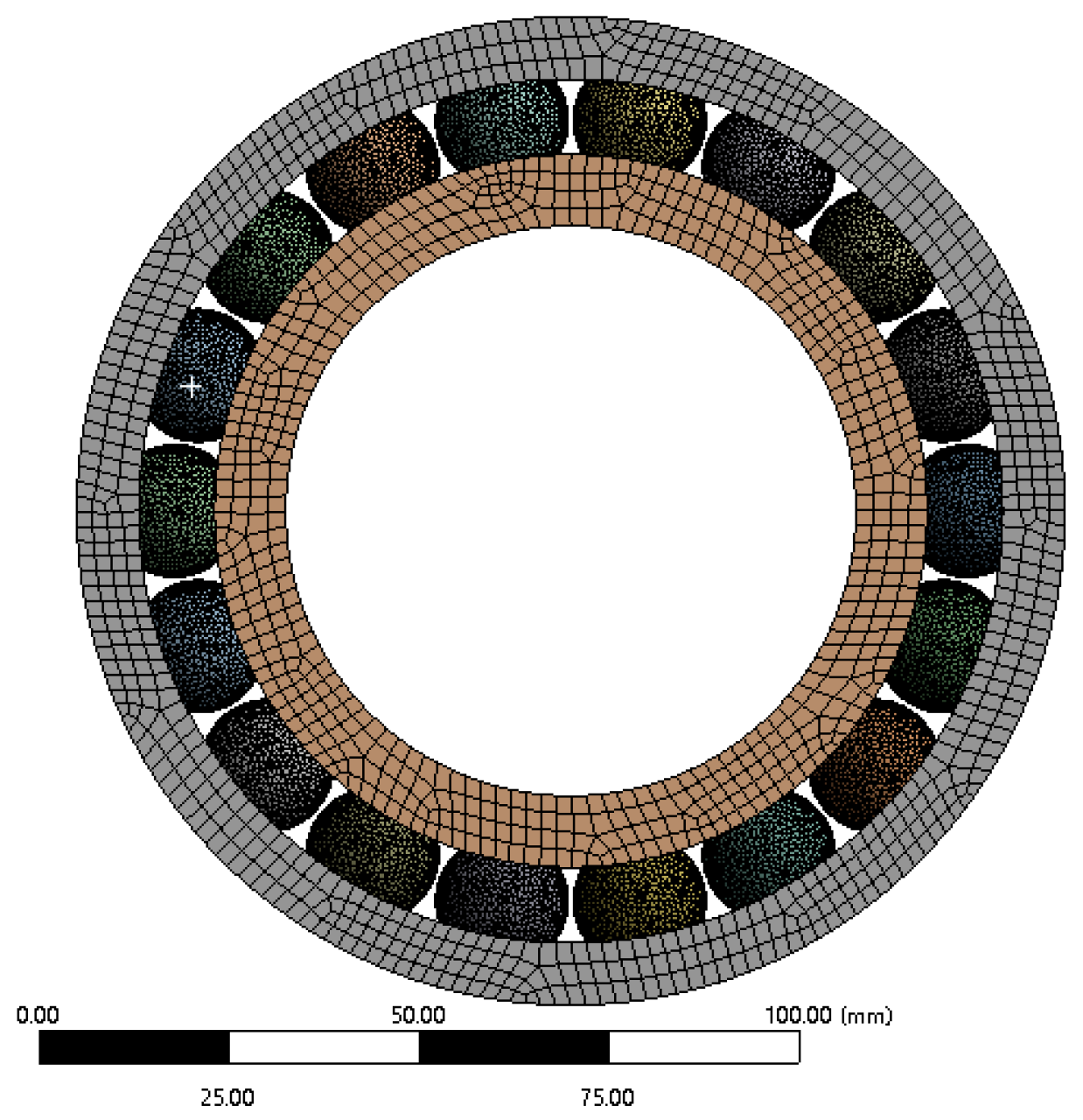

3. Verification of Fatigue Life Model

4. Analysis and Discussion

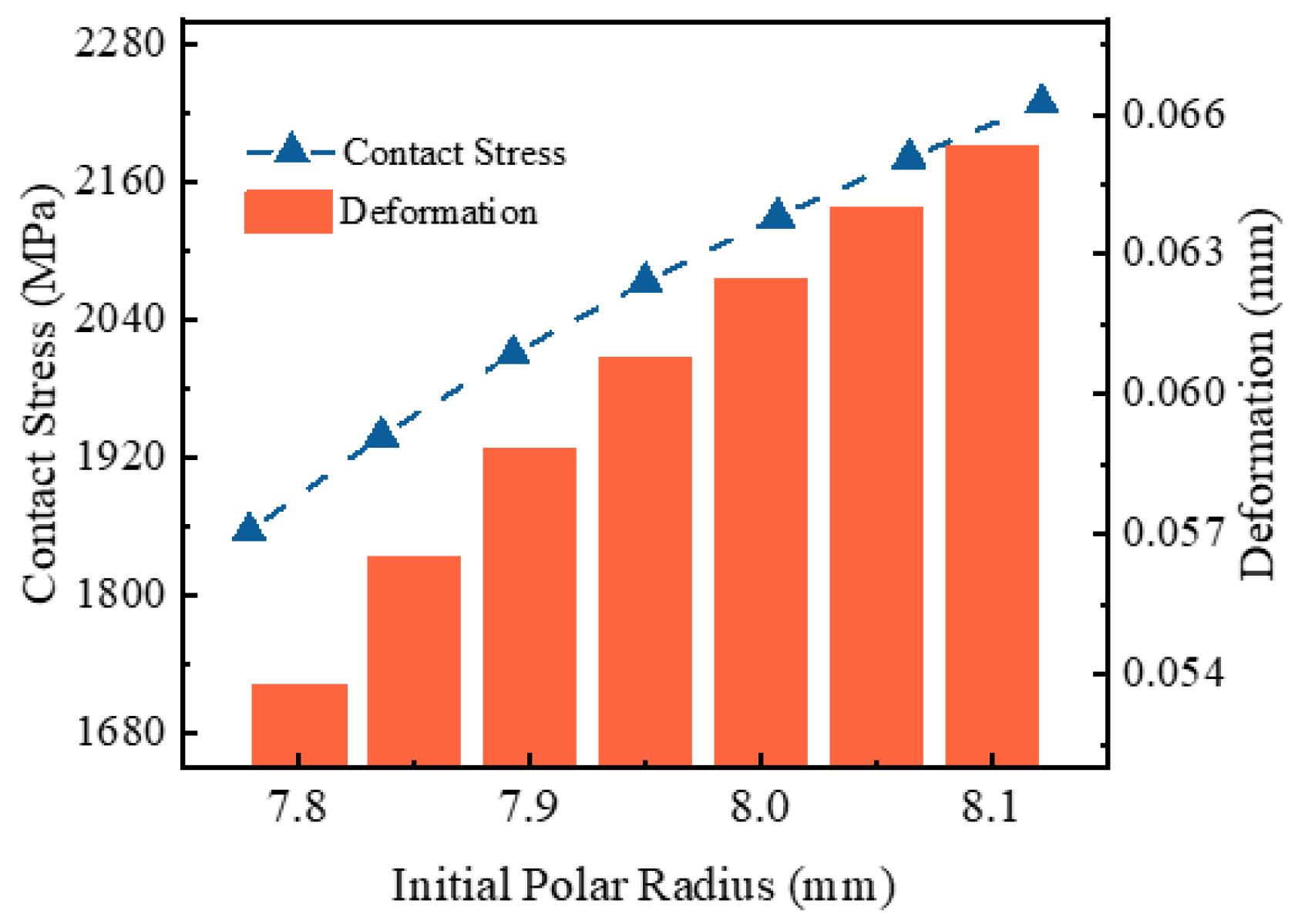

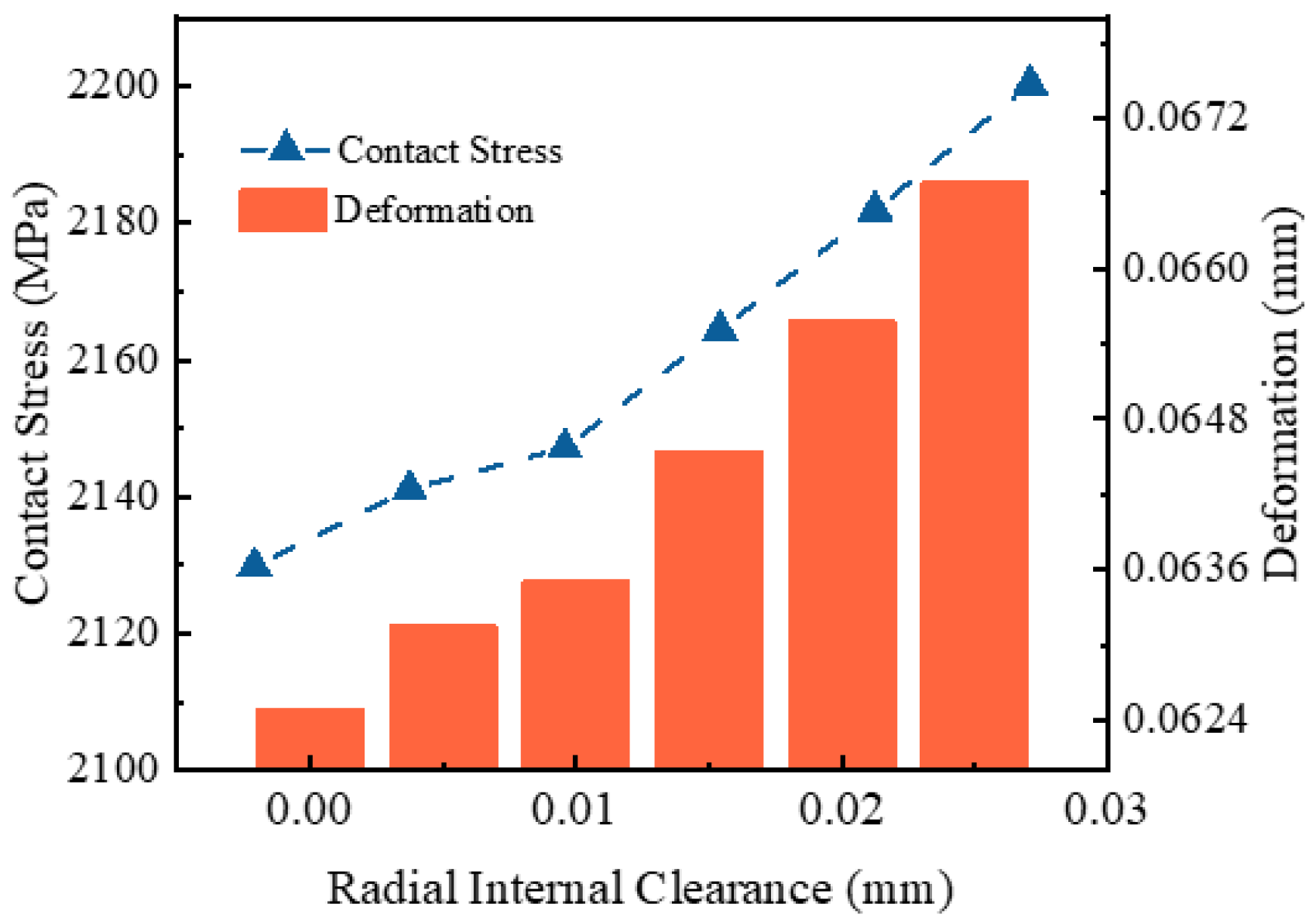

4.1. Contact Stress

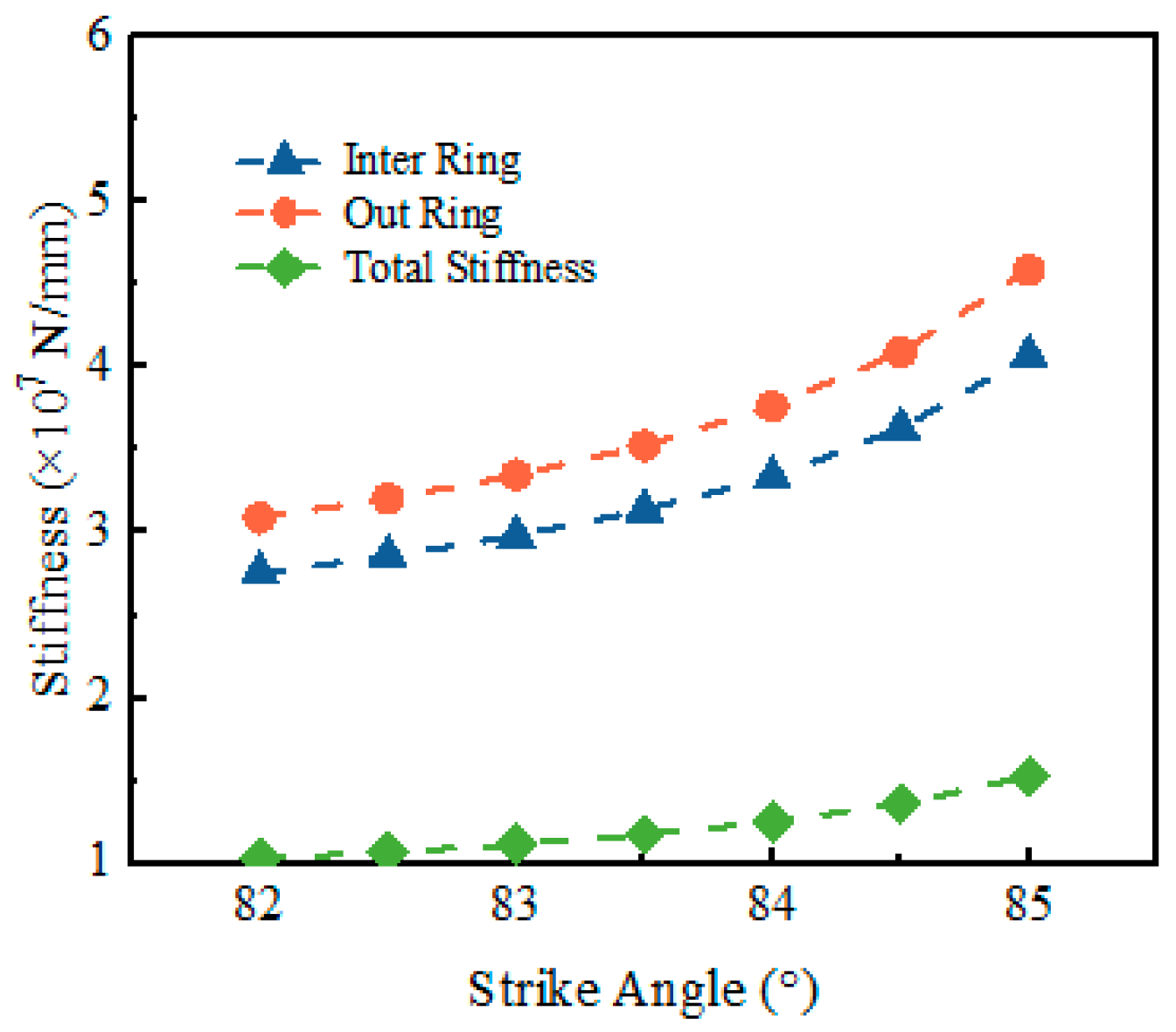

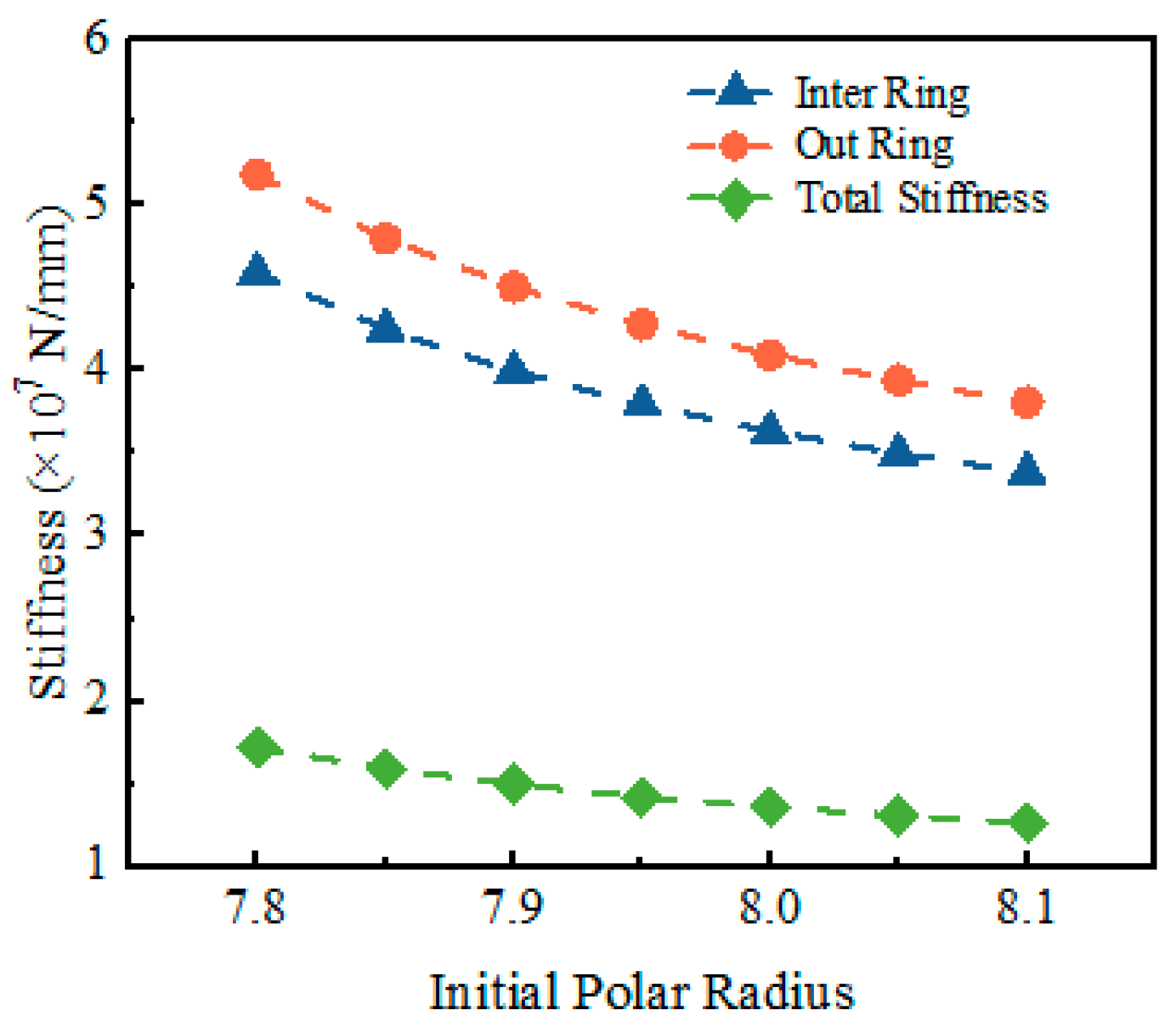

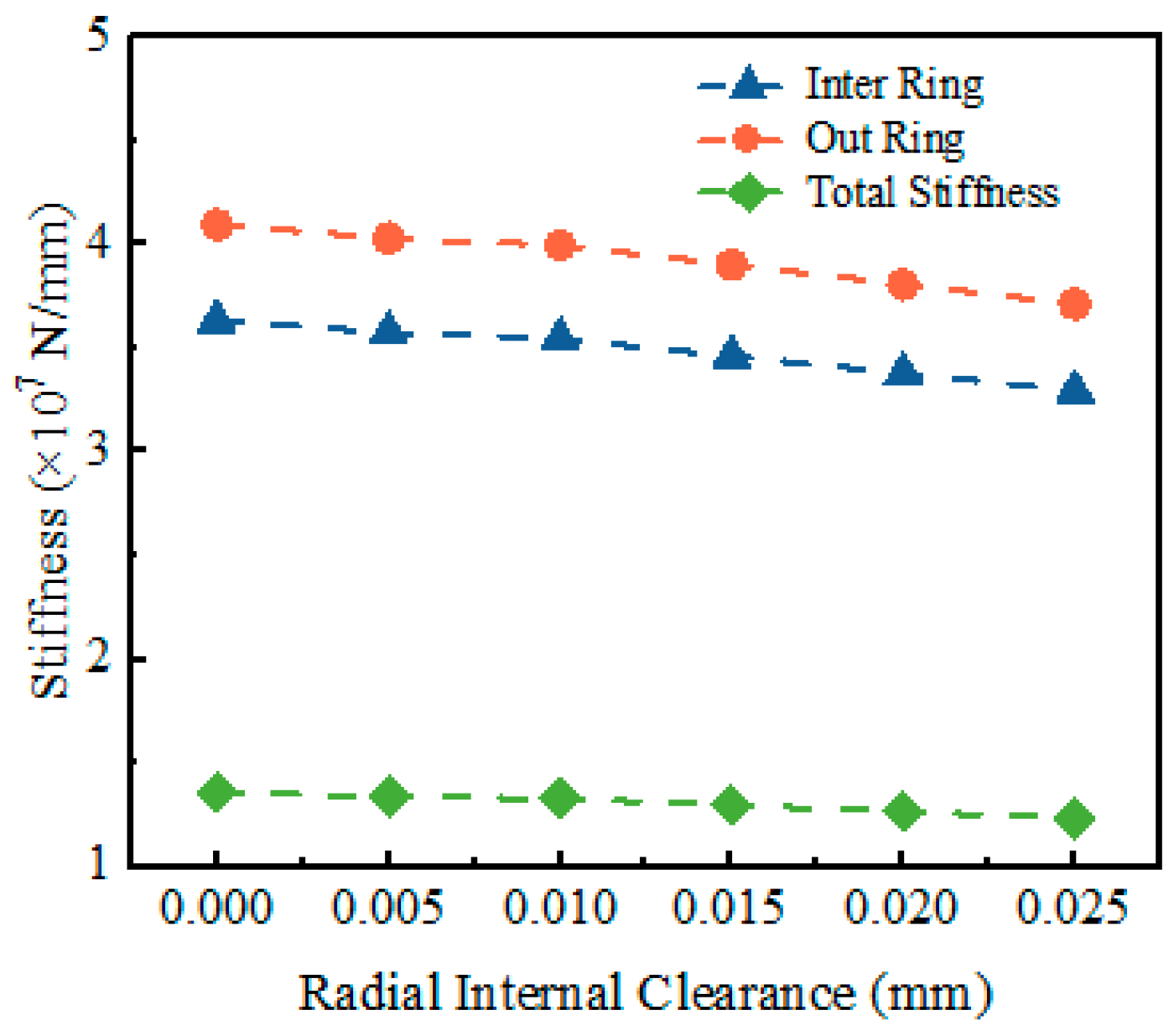

4.2. Radial Stiffness

4.3. Fatigue Life

4.4. Orthogonal Optimization Results

5. Conclusions

- (1)

- The model’s accuracy was validated through finite element simulations, showing that the analytically derived maximum contact stress deviated by less than 8.3% from simulation results.

- (2)

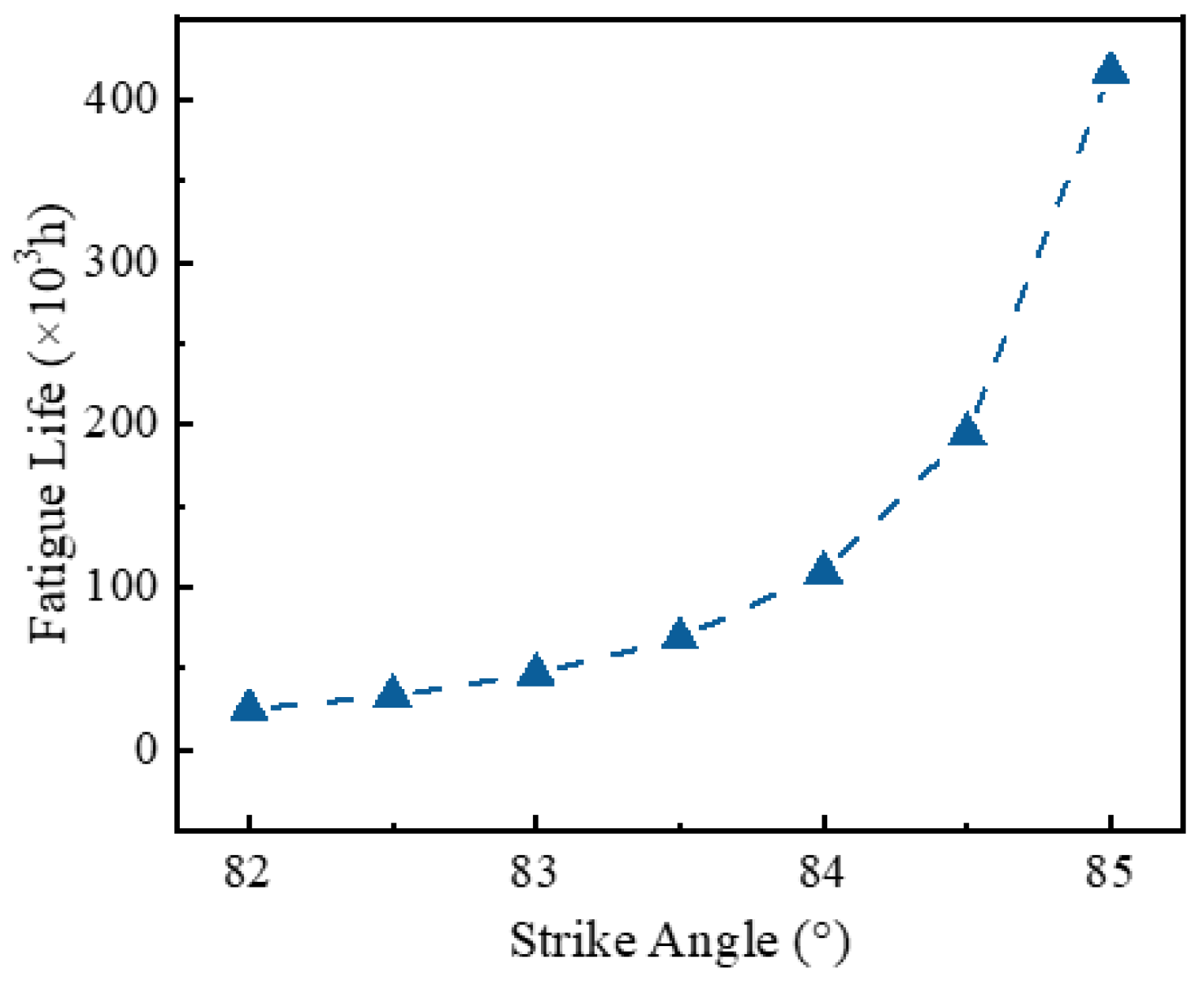

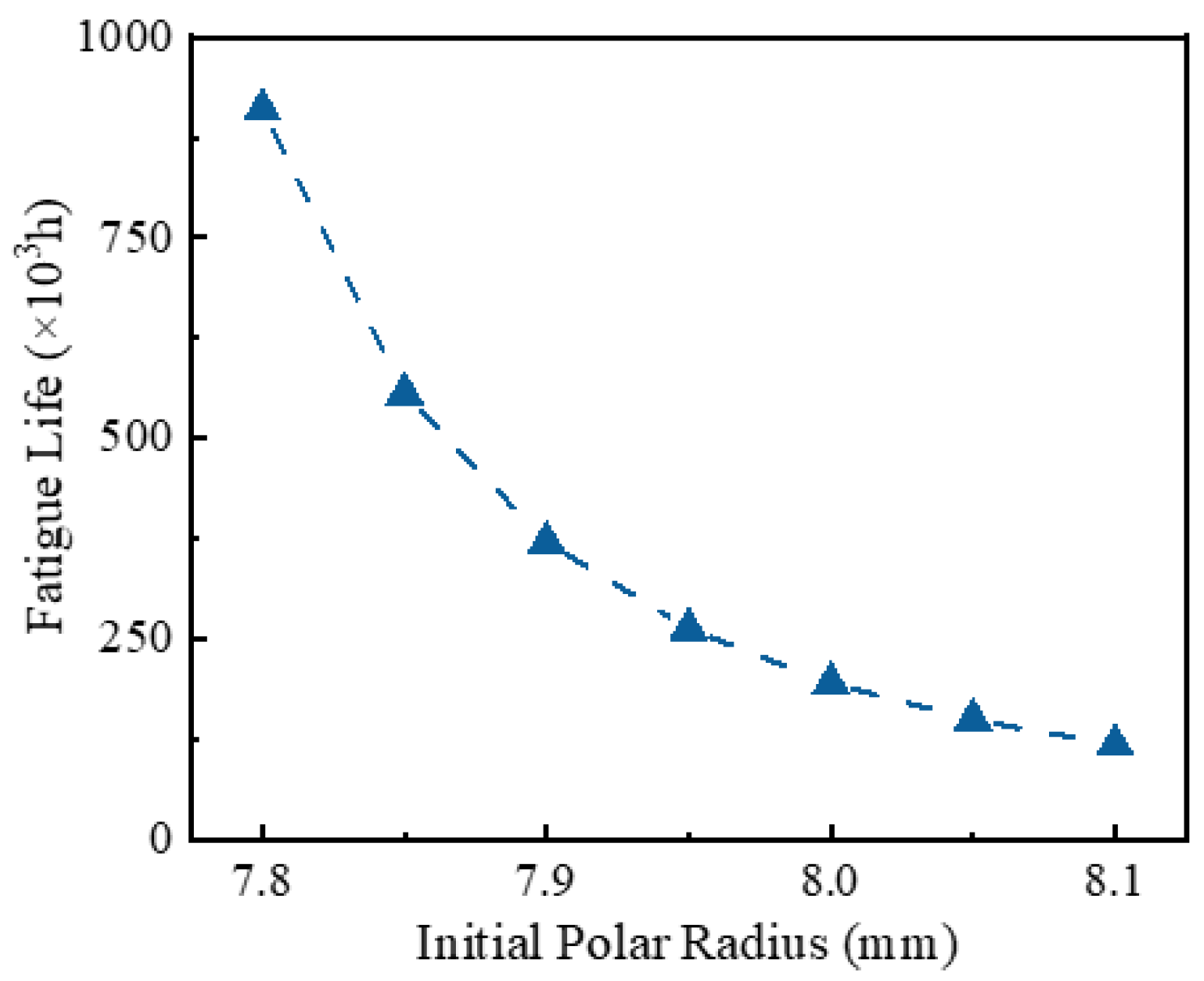

- Building on this validated model, this paper systematically investigated the influence of the strike angle α, the initial polar radius ro, and radial clearance δ on bearing contact behavior and fatigue life. The results revealed pronounced nonlinear effects: an increase in the strike angle α from 82° to 85° led to a 22.8% reduction in contact stress, a 21.2% decrease in elastic deformation, a 48.5% increase in stiffness, and a 15.6-fold extension of fatigue life. Conversely, increasing the initial polar radius ro from 7.8 mm to 8.1 mm resulted in a 20.01% rise in contact stress and a 21.4% increase in deformation, accompanied by a 26.2% reduction in stiffness and an 86.9% decrease in fatigue life. Increasing radial clearance δ from 0 to 0.025 mm caused moderate increases in contact stress by 3.3% and deformation by 6.7% but led to an 8.8% reduction in stiffness and a 26.3% drop in fatigue life.

- (3)

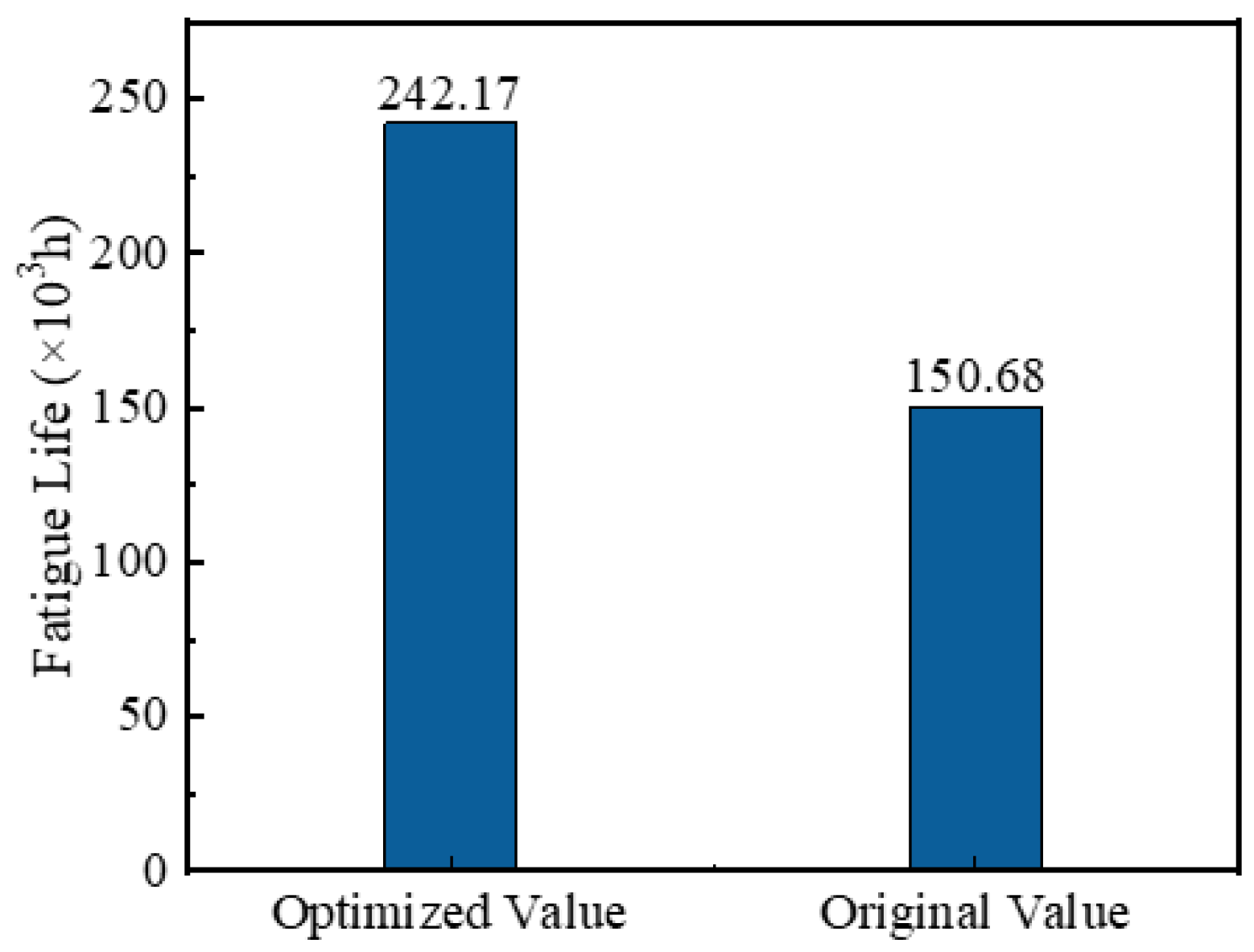

- Orthogonal experimental analysis further identified the dominant factors affecting fatigue life in descending order of significance: the strike angle α of the outer race, the strike angle α of the inner race, the initial polar radius ro of the inner race, the initial polar radius ro of the outer race, and radial clearance. The optimal combination of clearance δ of 0.02 mm, inner race and outer race strike angles α of 85°, inner race initial polar radius ro of 7.8 mm, and outer race initial polar radius ro of 7.9 mm yielded a 60.71% increase in fatigue life.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Y.; Li, H.; Shi, P.; Chai, Z.; Wang, K.; Xie, X.; Chen, Z. A prediction method for the real-time remaining useful life of wind turbine bearings based on the Wiener process. Renew. Energy 2018, 127, 452–460. [Google Scholar] [CrossRef]

- Cavacece, F.; Frache, L.; Tonazzi, D.; Bouscharain, N.; Philippon, D.; Le Jeune, G.; Maheo, Y.; Massi, F. Roller bearing under high loaded oscillations: Life evolution and accommodation mechanisms. Tribol. Int. 2020, 147, 106278. [Google Scholar] [CrossRef]

- Rejith, R.; Kesavan, D.; Chakravarthy, P.; Murty, S.N. Bearings for aerospace applications. Tribol. Int. 2023, 181, 108312. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, Y.; Ye, B. Kinematic characteristics and fault feature frequency of flexible thin-wall ellipse bearing. Mech. Syst. Signal Process. 2021, 149, 107222. [Google Scholar] [CrossRef]

- Rao, B.R.; Tiwari, R. Optimum design of rolling element bearings using genetic algorithms. Mech. Mach. Theory 2007, 42, 233–250. [Google Scholar]

- Waghole, V.; Tiwari, R. Optimization of needle roller bearing design using novel hybrid methods. Mech. Mach. Theory 2014, 72, 71–85. [Google Scholar] [CrossRef]

- Bu, C.G. Radial Clearance is key factor Affecting Roller Bearing Life Prediction in Tri-cone Bit. Adv. Mater. Res. 2008, 44, 233–238. [Google Scholar] [CrossRef]

- Dragoni, E. Optimal design of paired tapered roller bearings under centred radial and axial static loads. Mech. Ind. 2015, 16, 604. [Google Scholar] [CrossRef]

- Kim, S.-W.; Kang, K.; Yoon, K.; Choi, D.-H. Design optimization of an angular contact ball bearing for the main shaft of a grinder. Mech. Mach. Theory 2016, 104, 287–302. [Google Scholar] [CrossRef]

- Xie, Y.H.; Xu, L.X.; Deng, Y.Q. A dynamic approach for evaluating the moment rigidity and rotation precision of a bearing-planetary frame rotor system used in RV reduce. Mech. Mach. Theory 2022, 173, 104851. [Google Scholar] [CrossRef]

- Zander, M.; Otto, M.; Lohner, T.; Stahl, K. Evaluation of friction calculation methods for rolling bearings. Forsch. im Ingenieurwesen 2023, 87, 1307–1316. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, G.; Zhang, W.; Ding, Y. Research on Non-Circular Raceway of Single-Row Four-Point Contact Ball Bearing Based on Life Optimization. Appl. Sci. 2022, 12, 13027. [Google Scholar] [CrossRef]

- Ma, S.; Li, W.; Yan, K.; Li, Y.; Zhu, Y.; Hong, J. A study on the dynamic contact feature of four-contact-point ball bearing. Mech. Syst. Signal Process. 2022, 174, 109111. [Google Scholar] [CrossRef]

- Haug, E.J.; Kwak, B.M. Contcat stress minimization by contour design. Int. J. Numer. Methods Eng. 1978, 12, 917–930. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, Y.; Deng, S. Study on Load Distribution Characteristics of Cylindrical Roller Bearings with Trilobe Raceways. Bearing 2016, 9, 1–6. [Google Scholar]

- Sun, X.; Deng, S.; Zhang, Y.; Chen, G. Study on vibration characteristic of trilobe raceway cylindrical roller bearing with elastic support. J. Mech. Transm. 2017, 41, 11–18. [Google Scholar]

- Deng, S.; Lu, Y.; Zhang, W.; Sun, X.; Lu, Z. Cage slip characteristics of a cylindrical roller bearing with a trilobe-raceway. Chin. J. Aeronaut. 2018, 31, 351–362. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, S.; Ju, H.W. Study on Processing for Non-Circular Raceway of Aerospace Trilobe Cylindrical Roller Bearings. Bearing 2019, 9, 13–17, 20. [Google Scholar]

- Zhang, X.; Luo, Y.; Zhang, Y. Influence of Raceway Shape on Mechanical Properties of Four-Point Contact Ball Bearings. Bearing 2014, 4, 40–42. [Google Scholar]

- Singh, A.P.; Agrawal, A.; Joshi, D. Contact Mechanics Studies for an Elliptical Curvature Deep Groove Ball Bearing Using Continuum Solid Modeling based on FEM Simulation Approach. IOSR J. Mech. Civ. Eng. 2016, 13, 1–11. [Google Scholar]

- Wang, S.; Du, J.; Chen, Y.; Wu, S.; Huang, Z. Influence of elliptical truncation on the raceway in a four-point contact pitching bearing. Eng. Fail. Anal. 2022, 141, 106711. [Google Scholar] [CrossRef]

- Mukutadze, M.A.; Lagunova, E.O. Mathematical Model of Flow of Lubricant and Molten Coating with Micropolar Rheological Properties in Running Clearance of Journal Bearing with Non-circular Bearing Surface Profile, Considering Pressure Dependence of Viscosity. In Proceedings of the 8th International Conference on Industrial Engineering, Sochi, Russia, 16–20 May 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 587–597. [Google Scholar]

- Wang, Q.; Zhao, Y.; Wang, M. Analysis of contact stress distribution between rolling element and variable diameter raceway of cageless bearing. Appl. Sci. 2022, 12, 5764. [Google Scholar] [CrossRef]

- Li, Y.; Mo, J.; Zeng, J.; Xu, T.; Xu, S. Design and Dynamic Characteristics Analysis of a Novel Cageless Ball Bearing with Pure Rolling. J. Mech. Eng. 2023, 59, 256–269. [Google Scholar]

- Xu, T.; Li, Y.; Xu, S.; Mo, J. Experimental Study on Oil Interruption Performance of Novel Cageless Angular Contact Ball Bearings. J. Mech. Transm. 2022, 46, 112–116. [Google Scholar]

- Zhao, X.; Xu, S.; Xu, T.; Xu, Q.; Huang, K. Calculation Method and Experimental Study on Circumferential Total Clearance of Cageless Bearings. Lubricants 2024, 12, 238. [Google Scholar] [CrossRef]

- Lundberg, G.; Palmgren, A. Dynamic Capacity of Rolling Bearings. J. Appl. Mech. 1949, 16, 165–172. [Google Scholar] [CrossRef]

- Tong, R.; Yu, X.; Liu, Y.; Xia, Y.; Su, Y.; Jin, Y. Comparative analysis on properties of 8Cr4Mo4V steel for bearing after vacuum gas quenching and isothermal salt bath quenching. Heat Treat. Met. 2022, 47, 9–14. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Inner diameter d (mm) | 75 | Width B (mm) | 25 |

| Outer diameter D (mm) | 130 | Quantity Z | 18 |

| Ball diameter Dw (mm) | 17.462 |

| Material | Elastic Modulus E/GPa | Poisson’s Ratio ν | Density ρ/(kg/m3) | Ultimate Tensile Strength (Mpa) | Yield Strength (Mpa) |

|---|---|---|---|---|---|

| 8Cr4Mo4V | 210 | 0.30 | 7800 | 2740 | 2540 |

| Number | Fr (kN) | α (°) | ro (mm) |

|---|---|---|---|

| 1 | 10 | 83 | 7.8 |

| 2 | 13 | 84 | 8 |

| 3 | 16 | 85 | 7.9 |

| 4 | 10 | 83 | 8 |

| 5 | 13 | 84 | 7.9 |

| 6 | 16 | 85 | 7.8 |

| 7 | 10 | 83 | 7.9 |

| 8 | 13 | 84 | 7.8 |

| 9 | 16 | 85 | 8 |

| Number | Radial Clearance δ | The Strike Angle α of the Inner Ring | The Initial Polar Radius ro of the Inner Ring | The Strike Angle α of the Outer Ring | The Initial Polar Radius ro of the Outer Ring |

|---|---|---|---|---|---|

| 1 | 0.010 | 82 | 7.8 | 82 | 7.8 |

| 2 | 0.015 | 83 | 7.9 | 83 | 7.9 |

| 3 | 0.020 | 84 | 8 | 84 | 8 |

| 4 | 0.025 | 85 | 8.1 | 85 | 8.1 |

| Number | Radial Clearance δ | The Strike Angle α of the Inner Ring | The Initial Polar Radius ro of the Inner Ring | The Strike Angle α of the Outer Ring | The Initial Polar Radius ro of the Outer Ring | Fatigue Life (h) |

|---|---|---|---|---|---|---|

| 1 | 0.010 | 82 | 7.8 | 85 | 8.1 | 55.70 |

| 2 | 0.010 | 83 | 7.9 | 82 | 7.8 | 34.11 |

| 3 | 0.010 | 84 | 8 | 83 | 7.9 | 51.27 |

| 4 | 0.010 | 85 | 8.1 | 84 | 8 | 83.72 |

| 5 | 0.015 | 82 | 7.9 | 83 | 7.8 | 32.92 |

| 6 | 0.015 | 83 | 7.8 | 84 | 7.9 | 67.66 |

| 7 | 0.015 | 84 | 8.1 | 85 | 8 | 84.41 |

| 8 | 0.015 | 85 | 8 | 82 | 8.1 | 48.07 |

| 9 | 0.020 | 82 | 8 | 84 | 7.9 | 35.57 |

| 10 | 0.020 | 83 | 8.1 | 85 | 7.8 | 123.46 |

| 11 | 0.020 | 84 | 7.8 | 82 | 8.1 | 41.01 |

| 12 | 0.020 | 85 | 7.9 | 83 | 8 | 89.02 |

| 13 | 0.025 | 82 | 8.1 | 82 | 8 | 13.16 |

| 14 | 0.025 | 83 | 8 | 83 | 8.1 | 22.15 |

| 15 | 0.025 | 84 | 7.9 | 84 | 7.8 | 95.73 |

| 16 | 0.025 | 85 | 7.8 | 85 | 7.9 | 150.68 |

| Number | Radial Clearance δ | The Strike Angle α of the Inner Ring | The Initial Polar Radius ro of the Inner Ring | The Strike Angle α of the Outer Ring | The Initial Polar Radius ro of the Outer Ring |

|---|---|---|---|---|---|

| K1 | 56.2 | 34.34 | 78.76 | 34.09 | 71.56 |

| K2 | 58.27 | 61.85 | 62.95 | 48.84 | 76.30 |

| K3 | 72.27 | 68.11 | 39.27 | 70.67 | 67.58 |

| K4 | 70.43 | 92.87 | 76.19 | 103.56 | 41.73 |

| R | 16.07 | 58.53 | 39.49 | 69.47 | 29.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Xu, S.; Zeng, J.; Xu, T. Influence of Geometric Parameters on Contact Mechanics and Fatigue Life in Logarithmic Spiral Raceway Bearings. Symmetry 2025, 17, 889. https://doi.org/10.3390/sym17060889

Zhao X, Xu S, Zeng J, Xu T. Influence of Geometric Parameters on Contact Mechanics and Fatigue Life in Logarithmic Spiral Raceway Bearings. Symmetry. 2025; 17(6):889. https://doi.org/10.3390/sym17060889

Chicago/Turabian StyleZhao, Xiaofeng, Shuidian Xu, Jinghua Zeng, and Tao Xu. 2025. "Influence of Geometric Parameters on Contact Mechanics and Fatigue Life in Logarithmic Spiral Raceway Bearings" Symmetry 17, no. 6: 889. https://doi.org/10.3390/sym17060889

APA StyleZhao, X., Xu, S., Zeng, J., & Xu, T. (2025). Influence of Geometric Parameters on Contact Mechanics and Fatigue Life in Logarithmic Spiral Raceway Bearings. Symmetry, 17(6), 889. https://doi.org/10.3390/sym17060889