Research on Navigation and Dynamic Symmetrical Path Planning Methods for Automated Rescue Robots in Coal Mines

Abstract

1. Introduction

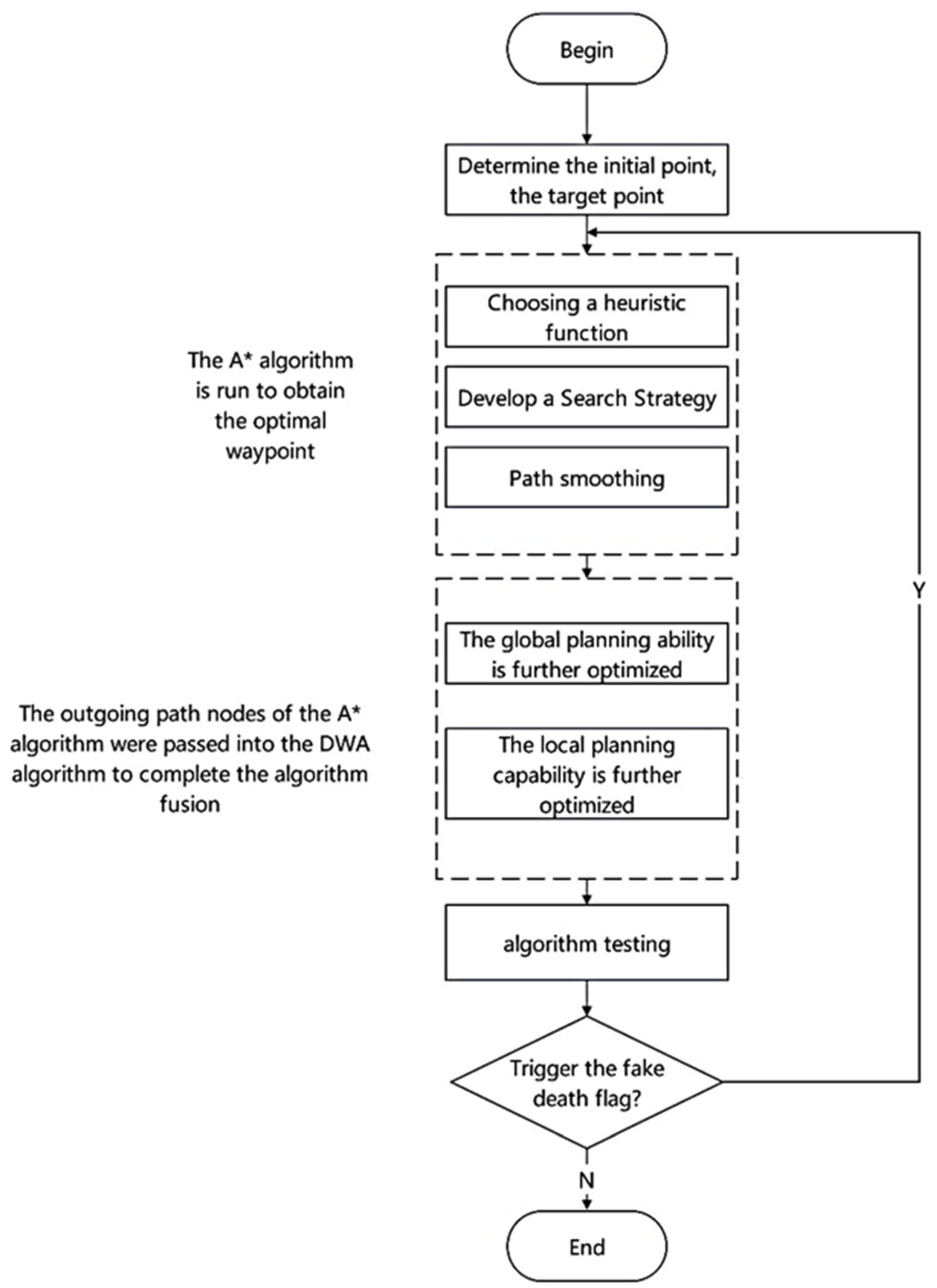

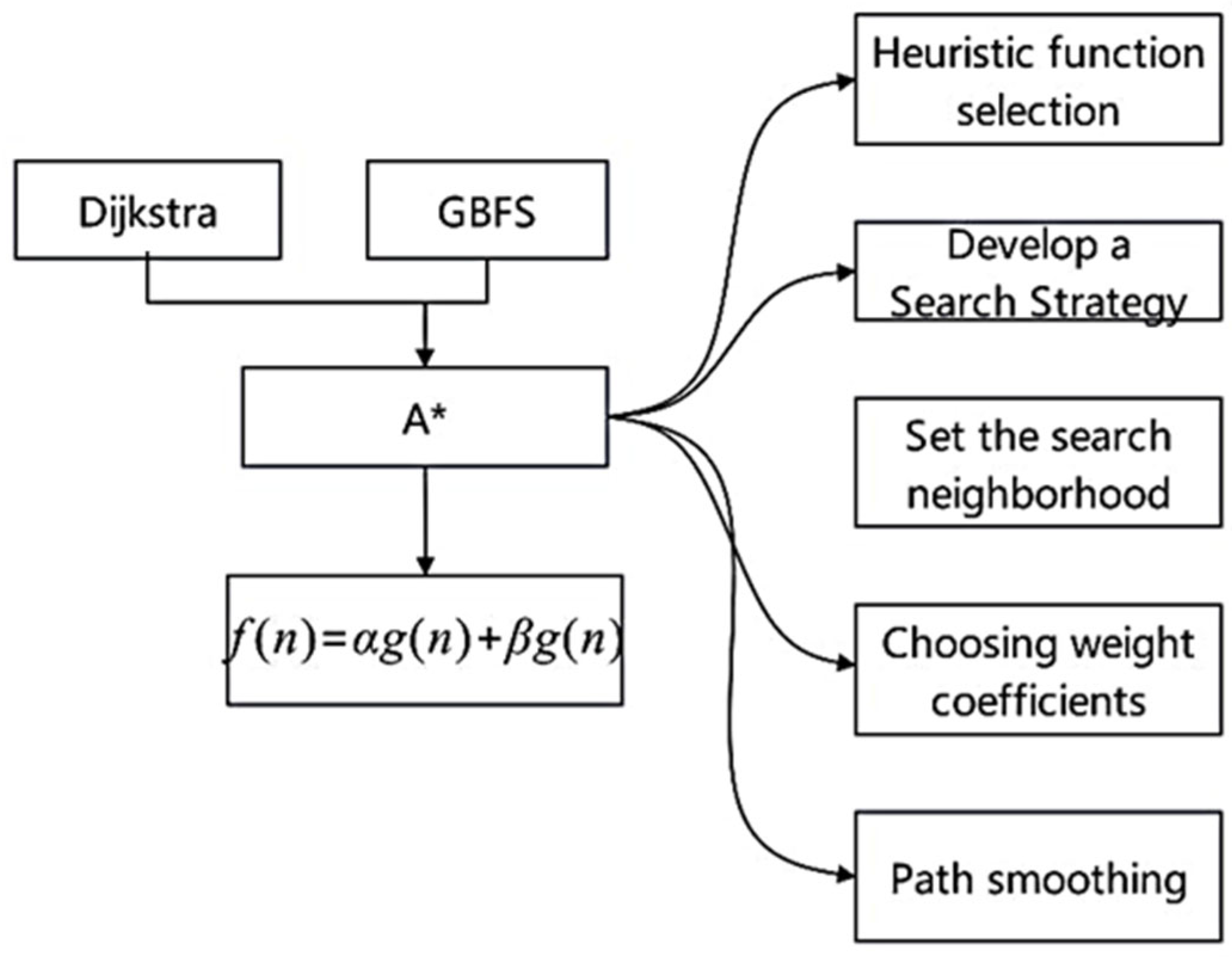

- Path planning based on the A* algorithm. The A* algorithm is a classical heuristic search algorithm, which is widely used in path planning problems. The traditional A* algorithm employs a fixed neighborhood search strategy (such as the 8-neighborhood), generating a large number of redundant turning points in complex tunnels. which results in a 24.1% increase in path length and a 65% increase in computation time. The fundamental reason lies in that the heuristic function does not take into account the dynamic obstacle density and the topology of the tunnel, leading to redundant search space. The global path generated by A* cannot be updated in real time. When dynamic obstacles (such as moving mining vehicles) block the path, it is necessary to re-plan frequently (with an average time consumption of over 10 s), which makes it difficult to meet the real-time requirements of coal mine rescue. According to research [18,19,20], the improved A* algorithm can not only effectively reduce the path length, it also improves the speed of path planning through the strategy of removing redundant nodes and an improved neighborhood search method. Combining a second-order piecewise Bezier curve to smooth the path can further improve the reliability and stability of the motion. Related studies [21,22,23] show that compared with the traditional A* algorithm in a coal mine environment, the improved A* algorithm reduces the computation time by 65% and the path length is reduced by 24.1%, which provides a theoretical basis for the efficient navigation of mobile robots in a coal mine.

- DWA. The dynamic window method is a local motion trajectory planning algorithm for mobile robots, which is particularly suitable for obstacle avoidance tasks in dynamic environments. The DWA algorithm can adjust the motion trajectory in real time, taking into account the robot’s movement ability and the position of dynamic obstacles, thus improving the obstacle avoidance performance. By combining the improved A* algorithm with the DWA, global trajectory planning and local obstacle avoidance can complement each other, improving the navigation efficiency and flexibility of the robot. Experimental results [4,5] show that the proposed method can effectively avoid new dynamic and static obstacles in complex environments and improve the robot’s adaptability in emergency situations. The state window method is prone to getting stuck in local optima in U-shaped or L-shaped narrow tunnels (obstacle avoidance success rate < 60%). The main reason is that the fixed-weight evaluation function cannot dynamically balance the priority of path tracking and obstacle avoidance. Sensitivity to perception noise is also an issue. The DWA relies on real-time sensor data, but in high-dust environments, the laser radar point cloud noise (error ± 0.2 m) significantly reduces the accuracy of distance assessment, resulting in an increase in the failure rate of obstacle avoidance to 35%.

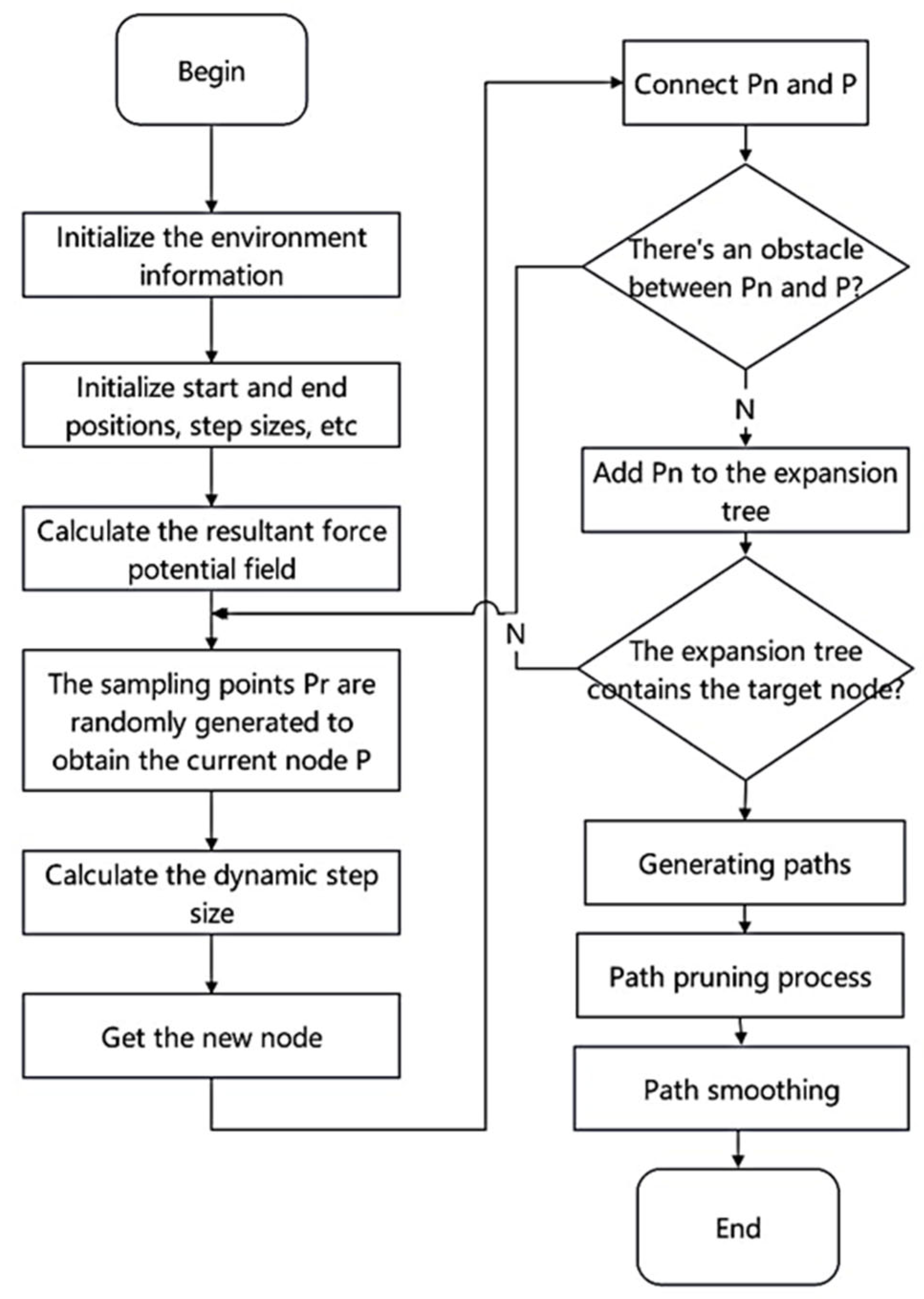

- RRT algorithm. Rapidly-exploring Random Tree (RRT) algorithm is widely used in path planning due to its simplicity and adaptability. Due to its dynamic step size and gravity field, the algorithm significantly improves the convergence rate and search efficiency in path planning. Experimental results [6,7] show that the path planning time of the proposed method is reduced by 33.84% and 34.93% in simple and complex environments, respectively, and the path length is also effectively reduced. This method provides a solution to the problem of generating directions for new nodes in complex obstacles and improves the reliability of path planning. RRT relies on random expansion trees to generate paths. In static obstacle-dense areas (such as equipment storage areas), the convergence speed significantly decreases (planning time > 3 min). Experiments show that the path success rate in narrow tunnels is only 58%. The paths generated by RRT require secondary optimization (such as B-spline interpolation), increasing the computational cost by 20%, and do not consider the kinematic constraints of the robot (such as the minimum turning radius), resulting in an infeasible trajectory.

2. Materials and Methods

- Redundant node removal strategy: In the path planning process, redundant nodes are removed to reduce the path length to improve the computational efficiency;

- Improved neighborhood search method: An adaptive neighborhood search strategy is used to increase the flexibility of search and find the optimal path quickly;

- Target function optimization: The weight of the target function is adjusted to balance the path length and security to improve the overall performance of the algorithm.

- Determine the dynamic window of the velocity space: Calculate the allowed velocity spaces of the robot and select the optimal velocity given the current velocity, acceleration, and obstacle position.

- Design the target function: According to the relative position of the target point and the obstacle, design a complex target function to balance the relationship between the trajectory of approaching the target and avoiding obstacles.

- 3.

- Path Optimization: Local path optimization provides flexible response of the robot to out-of-the-ordinary situations and timely path adjustment during the movement.

- Designing the gravitational field and repulsive force field: The gravitational field comes from the target point and forces the robot to follow the target. The repulsion field comes from the surrounding obstacles and allows the robot to avoid collisions.

- Dynamic step size adjustment: The step size of the RRT algorithm adjusts in real time based on environmental changes and allows it to adapt to environments with different levels of complexity.

- Route generation and optimization: Under the action of the resulting potential field, new optimal nodes are generated to improve the efficiency and feasibility of the path.

3. Results and Discussion

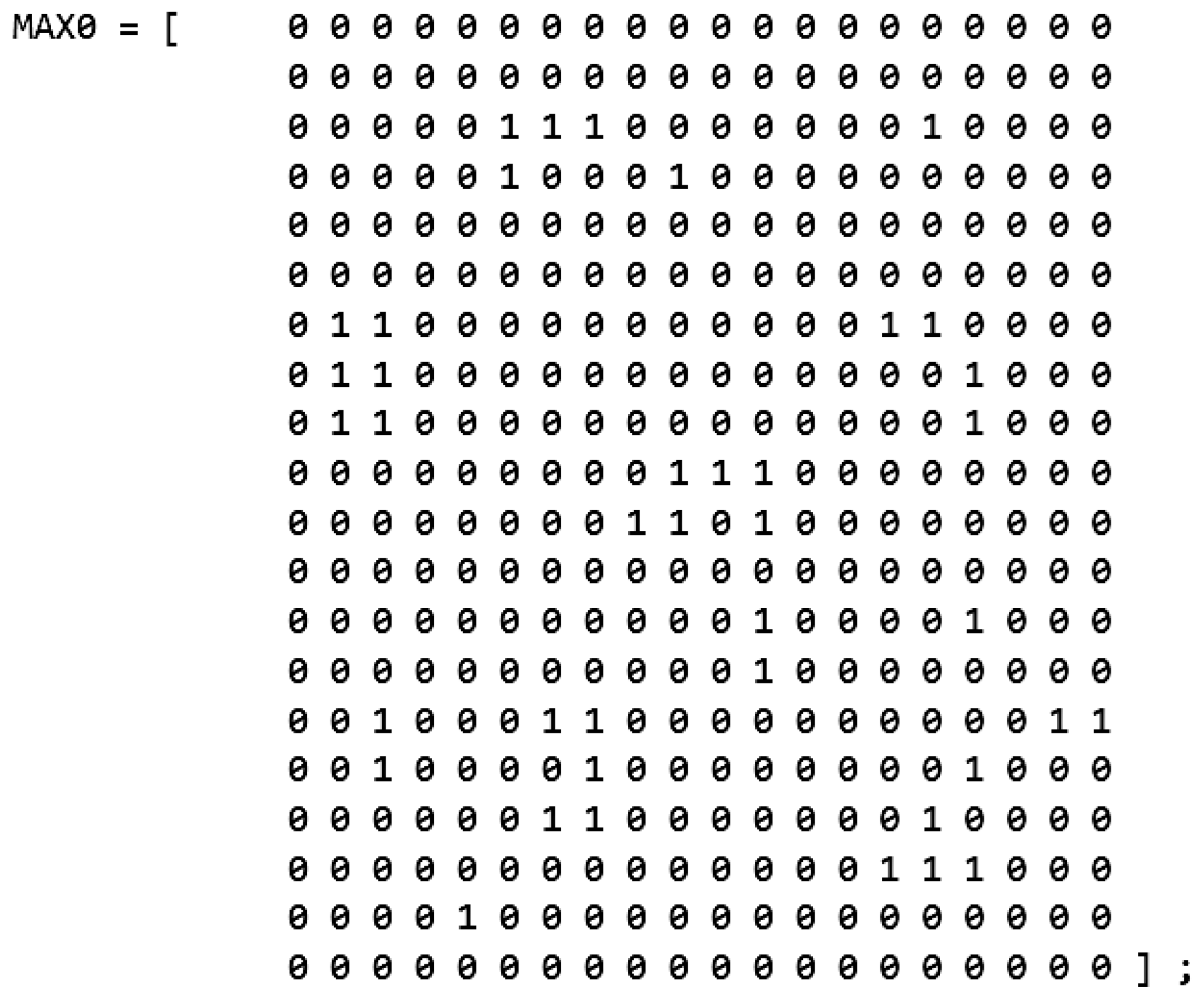

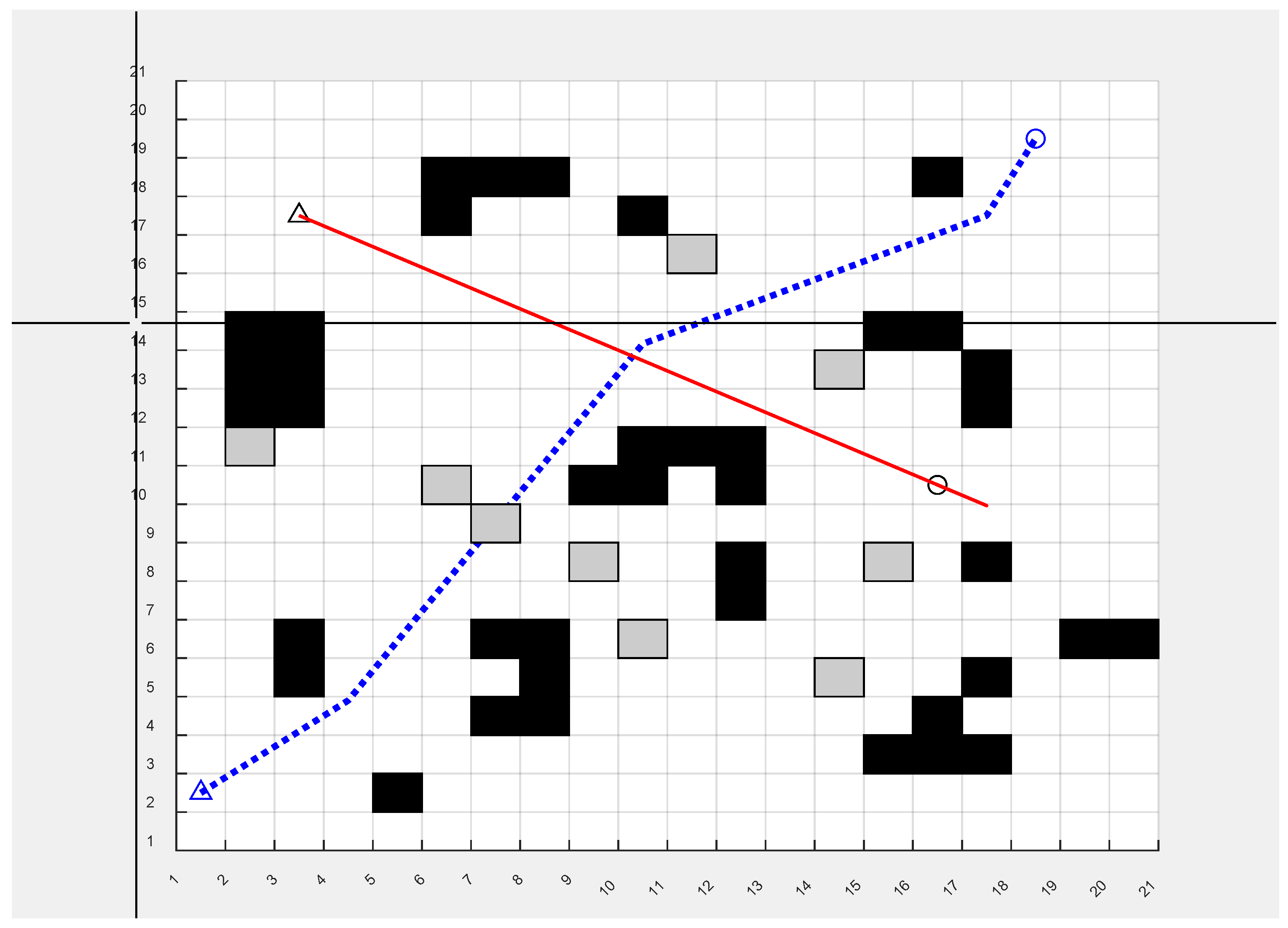

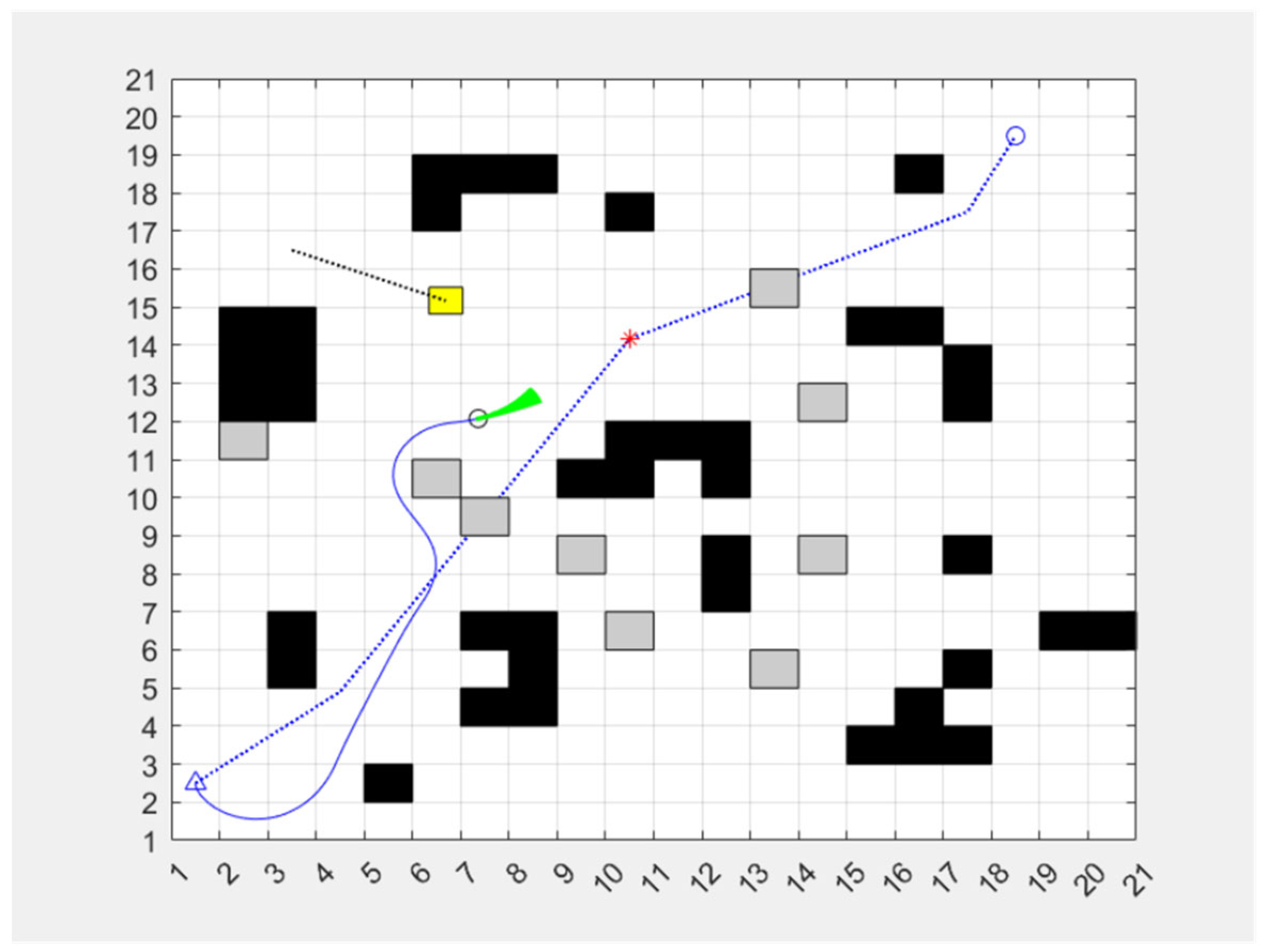

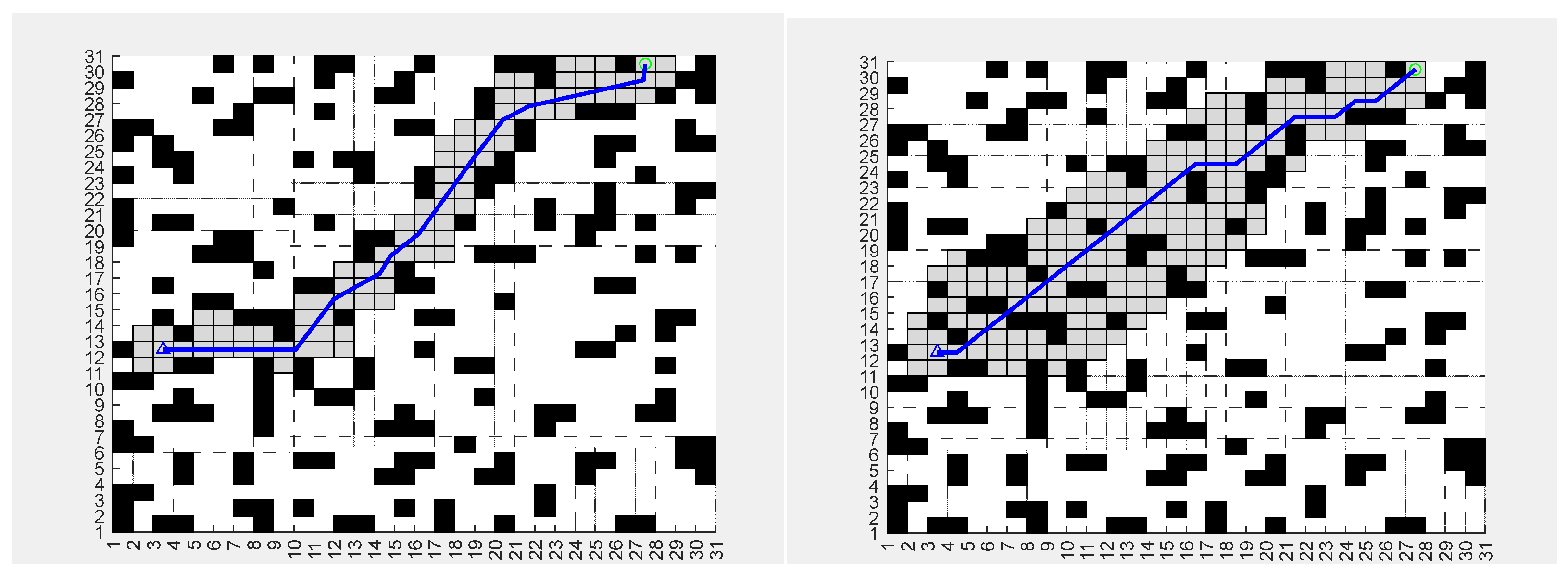

- Static obstacles: These obstacles are fixed when the map is initialized, such as rock walls, equipment, and other fixed obstacles. This type of obstacle is mainly used to model the fixed structure in the mine, which challenges the global path planning. In Figure 5, static obstacles are depicted by black squares.

- Manually placed obstacles: These obstacles are randomly placed on the map by humans to simulate the temporary placement of tools, materials, etc. The positions of these obstacles are relatively fixed but can change in different experimental scenarios, which are used to test the robustness of the algorithm under different conditions. In Figure 5, the manually placed obstacles are depicted by grey squares.

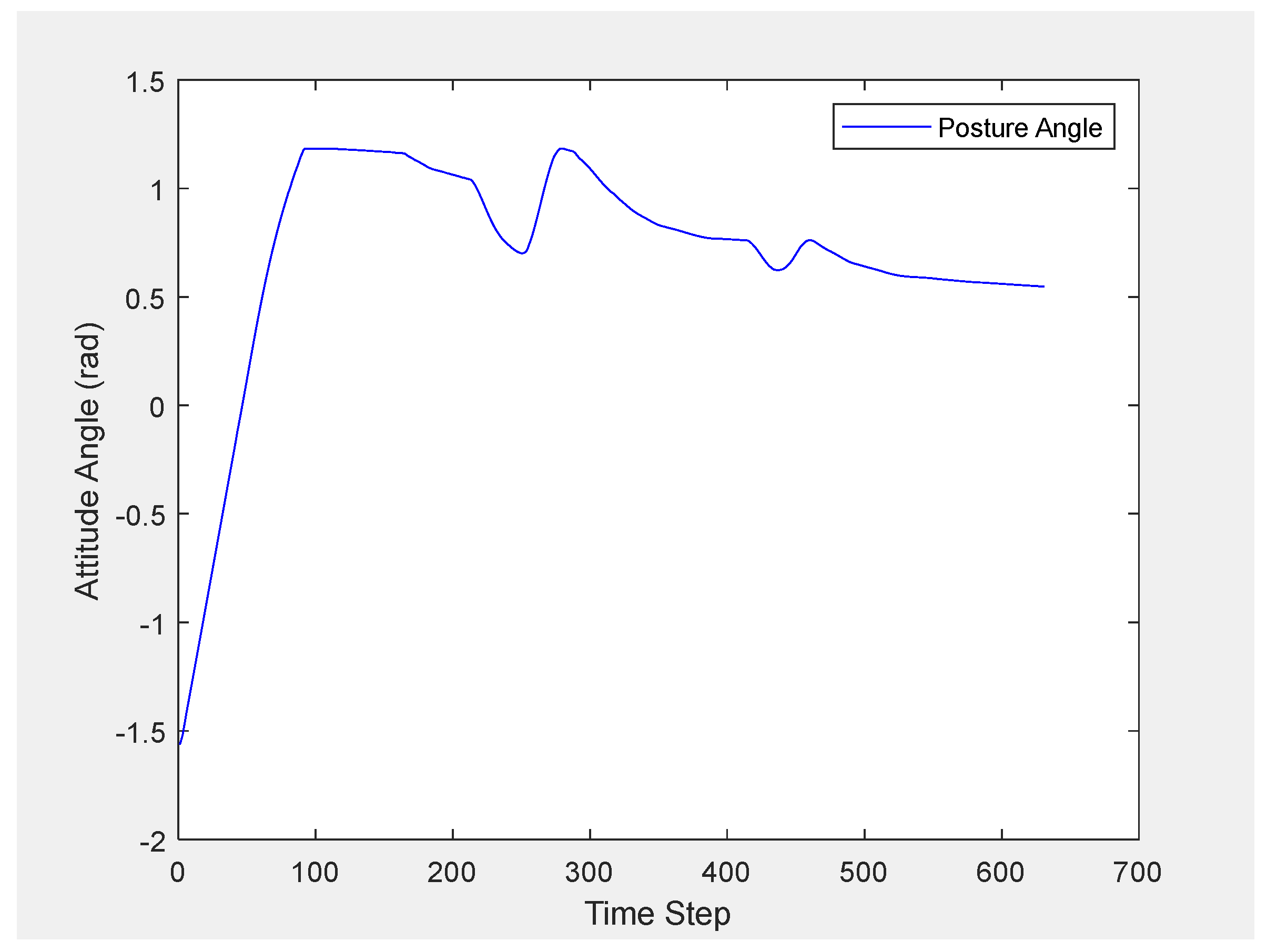

- Dynamic obstacles move randomly across the map, simulating dynamic environments such as harvesters, other mobile robots, or workers. Their trajectories change randomly, which places higher demands on the ability to plan the robot’s trajectory in real time while avoiding obstacles. In Figure 5, the triangle represents the moving object, the red line represents its motion trajectory, and the circle represents its destination.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DWA | Dynamic Window Method |

| GBFS | Greedy Best-First Search |

| RRT | Rapidly-exploring Random Tree |

References

- Guo, A.; Wang, B.; Zhao, M. Design and Application of Control System for Underground Inspection Robot. In Proceedings of the 2022 7th Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Tianjin, China, 1–3 July 2022; pp. 18–21. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X. Operation Technology of Unmanned Mining Robot for Coal Mine Based on Intelligent Control Technology. In Proceedings of the International Conference on Computer Simulation and Modeling, Information Security (CSMIS), Buenos Aires, Argentina, 15–17 November 2023; pp. 86–91. [Google Scholar] [CrossRef]

- Xue, G.; Wang, Z.; Wang, Y.; Liu, Y.; Liu, H. Path Planning of coal mine robot based on improved artificial potential field Algorithm. Ind. Mine Autom. 2024, 50, 6–13. [Google Scholar] [CrossRef]

- Fu, S.; Huang, H.; Wang, S. Research on Robot Path Planning Technology by Integrating Particle Swarm Optimization Algorithm and DWA Algorithm. In Proceedings of the 10th International Conference on Control, Automation and Robotics (ICCAR), Orchard District, Singapore, 27–29 April 2024; pp. 147–152. [Google Scholar] [CrossRef]

- Yan, X.; Ding, R.; Luo, Q.; Ju, C.; Wu, D. A Dynamic Path Planning Algorithm Based on the Improved DWA Algorithm. In Proceedings of the International Conference on Global Reliability and Prognostics and Health Management (PHM-Yantai), Yantai, China, 13–16 October 2022; pp. 1–7. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, X.; Zhou, R.; Guo, Z. A Path Planning Method Based on Improved A* and Fuzzy Control DWA of Underground Mine Vehicles. Appl. Sci. 2024, 14, 3103. [Google Scholar] [CrossRef]

- Tao, H.; Yi, Z.; Xiang, Z. Research on Path Planning of Mobile Robot Based on Improved RRT* Algorithm. In Proceedings of the IEEE 6th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 4–6 March 2022; pp. 666–670. [Google Scholar] [CrossRef]

- Jiang, Q.; Man, Y.; Pu, X. Improved Path Planning Algorithm Based on RRT. In Proceedings of the 2nd International Conference on Signal Processing and Intelligent Computing (SPIC), Guangzhou, China, 20–22 September 2024; pp. 463–466. [Google Scholar] [CrossRef]

- Zhu, H.; Hua, R. Path Planning Method for Coal Mine Inspection Robot. Ind. Mine Autom. 2024, 50, 107–114. [Google Scholar] [CrossRef]

- Beloglazov, I.I.; Petrov, P.A.; Bazhin, V.Y. The concept of digital twins for tech operator training simulator design for mining and processing industry. Eurasian Min. 2020, 2, 50–54. [Google Scholar] [CrossRef]

- Zemenkova, M.Y.; Chizhevskaya, E.L.; Zemenkov, Y.D. Intelligent monitoring of the condition of hydrocarbon pipeline transport facilities using neural network technologies. J. Min. Inst. 2022, 258, 933–944. [Google Scholar] [CrossRef]

- Sychev, Y.A.; Aladin, M.E.; Aleksandrovich, S.V. Developing a hybrid filter structure and a control algorithm for hybrid power supply. Int. J. Power Electron. Drive Syst. (IJPEDS) 2023, 3, 1625–1634. [Google Scholar] [CrossRef]

- Lantsev, D.Y.; Frolov, V.Y.; Zverev, S.G.; Uhrlandt, D.; Valenta, J. Thermal protection implementation of the contact overheadline based on bay controllers of electric transport traction substations in the mining industry. J. Min. Inst. 2021, 251, 738–744. [Google Scholar] [CrossRef]

- Klyuev, R.V.; Morgoeva, A.D.; Gavrina, O.A.; Bosikov, I.I.; Morgoev, I.D. Forecasting planned electricity consumption for the united power system using machine learning. J. Min. Inst. 2023, 261, 392–402. [Google Scholar]

- Wang, B.; Liu, Z.; Li, Q.; Prorok, A. Mobile robot path planning in dynamic environments through globally guided reinforcement learning. arXiv 2020, arXiv:2005.05420. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Wang, Y.; Zhou, H.; Zhao, J. Probabilistic membrane computing-based SLAM for patrol UAVs in underground coal mines. J. Adv. Transp. 2021, 2021, 7610126. [Google Scholar] [CrossRef]

- Everett, M.; Chen, Y.F.; How, J.P. Scalable multi-robot motion planning using guidance-informed search heuristics. arXiv 2023, arXiv:2311.10176. [Google Scholar] [CrossRef]

- Dong, J.; Wang, H.; Pan, Q.-K. An Improved Multi-objective Evolutionary Algorithm for A Robot Detect Path Planning Problem. In Proceedings of the 41st Chinese Control Conference (CCC), Hefei, China, 25–27 July 2022; pp. 2071–2076. [Google Scholar] [CrossRef]

- Li, X.; Hu, X.; Wang, Z.; Du, Z. Path Planning Based on Combination of Improved A-STAR Algorithm and DWA Algorithm. In Proceedings of the 2nd International Conference on Artificial Intelligence and Advanced Manufacture (AIAM), Manchester, UK, 15–17 October 2020; pp. 99–103. [Google Scholar] [CrossRef]

- Xia, Y.; Zheng, Y.; Wang, X.; Zhang, L.; Wang, L. Research on Path Planning Algorithm of Service Robot in Dynamic Environment. In Proceedings of the 3rd International Conference on Artificial Intelligence and Advanced Manufacture (AIAM), Manchester, UK, 23–25 October 2021; pp. 478–485. [Google Scholar] [CrossRef]

- Kozhubaev, Y.; Yang, R. Simulation of Dynamic Path Planning of Symmetrical Trajectory of Mobile Robots Based on Improved A* and Artificial Potential Field Fusion for Natural Resource Exploration. Symmetry 2024, 16, 801. [Google Scholar] [CrossRef]

- Kim, J.-J.; Cheng, G.; Guo, F.; Wei, H. Optimal Path planning algorithm for coal mine search and rescue robot. Ind. Mine Autom. 2018, 44, 24–28. [Google Scholar] [CrossRef]

- Xue, G.; Liu, S.; Wang, Z.; Li, Y. Path planning method of coal mine robot based on improved probabilistic roadmap algorithm. Ind. Mine Autom. 2023, 49, 175–181. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, J.; Kong, X.; Zhang, F.; Wu, Y.; Li, L. Research on Path Planning of Mobile Robot by Fusing A* and DWA Algorithms. In Proceedings of the 8th International Conference on Intelligent Computing and Signal Processing (ICSP), Xi’an, China, 21–23 April 2023; pp. 1467–1471. [Google Scholar] [CrossRef]

- Wu, D.; Li, Y. Mobile Robot Path Planning Based on Improved Smooth A* Algorithm and Optimized Dynamic Window Approach. In Proceedings of the 2nd International Conference on Signal Processing and Intelligent Computing (SPIC), Guangzhou, China, 20–22 September 2024; pp. 345–348. [Google Scholar] [CrossRef]

- Kabanov, E.I. Analysis of accidents risk in coal mines taking into account human factor. Gorn. Zhurnal 2023, 9, 48–54. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Q.; Dang, Z. Optimization of Two-dimensional Path Optimization Algorithm Based on Dijkstra Ant Colony Optimization Algorithm. In Proceedings of the 2nd International Conference on Signal Processing and Intelligent Computing (SPIC), Guangzhou, China, 20–22 September 2024; pp. 399–402. [Google Scholar] [CrossRef]

- Nair, D.S.; Supriya, P. Comparison of Temporal Difference Learning Algorithm and Dijkstra’s Algorithm for Robotic Path Planning. In Proceedings of the 2nd International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018; pp. 1619–1624. [Google Scholar] [CrossRef]

- Kazanin, O.I. Promising technology trends in underground coal mining in Russia. Gorn. Zhurnal 2023, 1184, 4–11. [Google Scholar] [CrossRef]

- Sowrirajan, A.; Harish, M. Optimizing Pathfinding: A Confluence of Ant Colony Optimization and GBFS. In Proceedings of the International Conference on Data Science, Agents & Artificial Intelligence (ICDSAAI), Chennai, India, 21–23 December 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.L.; Korolev, N.A.; Malkova, Y.M. Monitoring of grinding condition in drum mills based on resulting shaft torque. J. Min. Inst. 2022, 256, 686–700. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, C.; Tao, G.; Ye, C. Dynamic path planning based on the fusion of improved RRT and DWA algorithms. In Proceedings of the 4th International Conference on Mechatronics Technology and Intelligent Manufacturing (ICMTIM), Nanjing, China, 26–28 May 2023; pp. 534–538. [Google Scholar] [CrossRef]

- Guan, C.; Wang, S. Robot Dynamic Path Planning Based on Improved A* and DWA Algorithms. In Proceedings of the 4th International Conference on Control and Robotics (ICCR), Guangzhou, China, 2–4 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Beloglazov, I.; Plaschinsky, V. Development MPC for the Grinding Process in SAG Mills Using DEM Investigations on Liner Wear. Materials 2024, 17, 795. [Google Scholar] [CrossRef] [PubMed]

- Sharikov, Y.V.; Snegirev, N.V.; Tkachev, I.V. Development of a control system based on predictive mathematical model of the c5-c6 isomerization process. J. Chem. Technol. Metall. 2020, 55, 335–344. Available online: https://journal.uctm.edu/node/j2020-2/12_19-28_p_335-344.pdf (accessed on 12 July 2021).

| Name | Manage Time | Degree of Transition | Number of Transitions | Path Length | Number of Traversal Nodes |

|---|---|---|---|---|---|

| A* | 0.032552 | 315.0 | 7 | 31.4558 | 164 |

| Improved A* | 0.076704 | 261.1629 | 9 | 33.1388 | 90 |

| A*(2) | 0.006003 | 337.8254 | 7 | 29.5563 | 188 |

| Improved A*(2) | 0.008537 | 315.0000 | 9 | 30.9430 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozhubaev, Y.; Novak, D.; Ershov, R.; Xu, W.; Cheng, H. Research on Navigation and Dynamic Symmetrical Path Planning Methods for Automated Rescue Robots in Coal Mines. Symmetry 2025, 17, 875. https://doi.org/10.3390/sym17060875

Kozhubaev Y, Novak D, Ershov R, Xu W, Cheng H. Research on Navigation and Dynamic Symmetrical Path Planning Methods for Automated Rescue Robots in Coal Mines. Symmetry. 2025; 17(6):875. https://doi.org/10.3390/sym17060875

Chicago/Turabian StyleKozhubaev, Yuriy, Diana Novak, Roman Ershov, Weiheng Xu, and Haodong Cheng. 2025. "Research on Navigation and Dynamic Symmetrical Path Planning Methods for Automated Rescue Robots in Coal Mines" Symmetry 17, no. 6: 875. https://doi.org/10.3390/sym17060875

APA StyleKozhubaev, Y., Novak, D., Ershov, R., Xu, W., & Cheng, H. (2025). Research on Navigation and Dynamic Symmetrical Path Planning Methods for Automated Rescue Robots in Coal Mines. Symmetry, 17(6), 875. https://doi.org/10.3390/sym17060875