Research on the Influence of Span on Wind Deflection Angle of Insulator Strings in Stochastic Wind Fields

Abstract

1. Introduction

2. Finite Element Modeling and Validation of Transmission Line Simulation

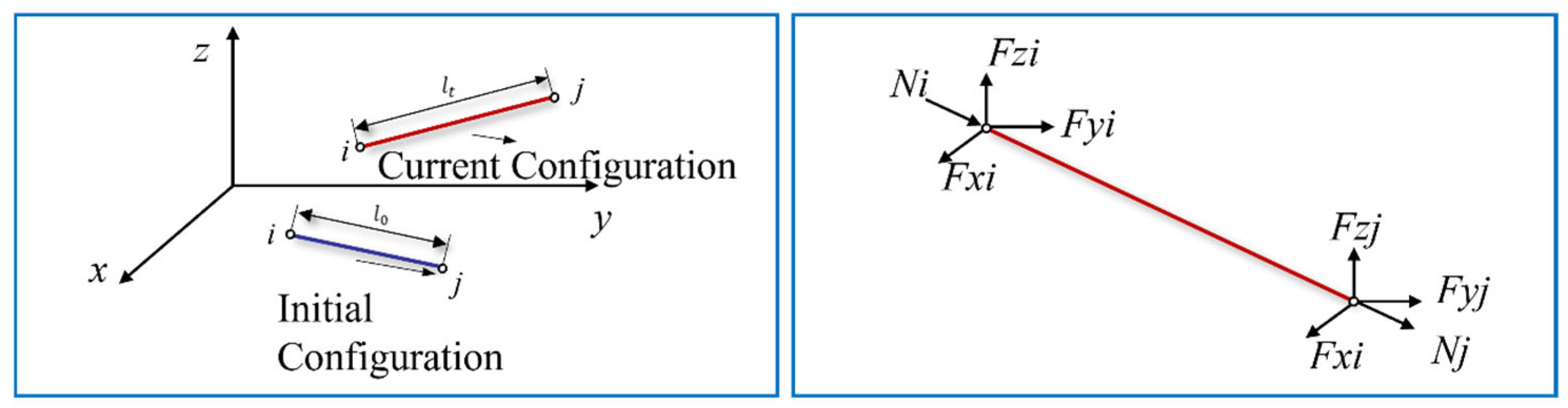

2.1. Geometric Stiffness Matrix of Space Truss Elements Considering Geometric Nonlinearity

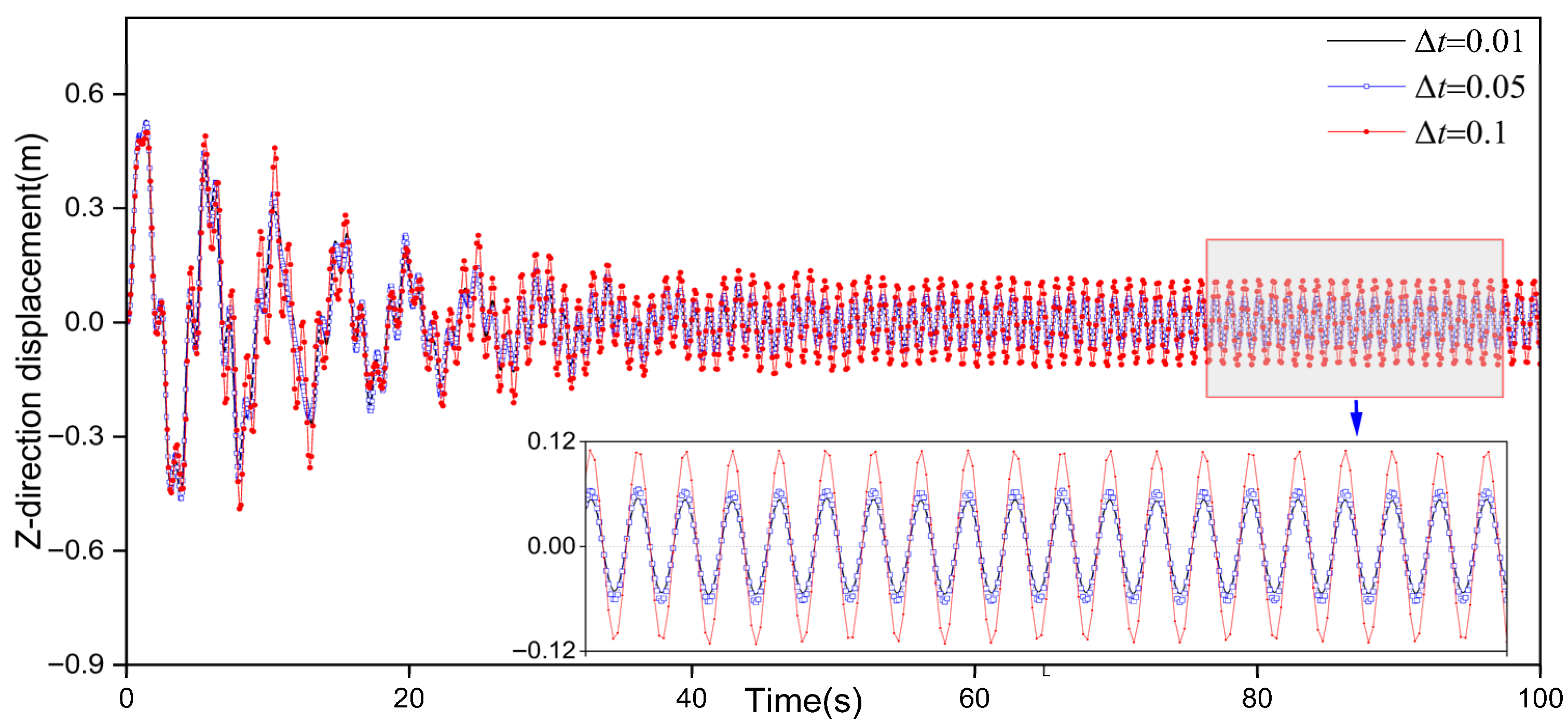

2.2. Dynamic Solution Based on Newmark-β Method

- (1)

- Initialize the displacement, velocity, and acceleration at t + Δt as , and , respectively, where the subscript ‘0’ denotes the initial iteration. The initial displacement at time t + Δt is initialized using the converged displacement at time t, while the velocity and acceleration are estimated as:

- (2)

- Form the stiffness matrix , mass matrix , and damping matrix for the nth iteration.

- (3)

- Assemble the equivalent stiffness matrix:

- (4)

- Compute the equivalent load vector at t + Δt:

- (5)

- Solve for the displacement increment:

- (6)

- Update the displacement:

- (7)

- Update the velocity and acceleration to complete the recursion:

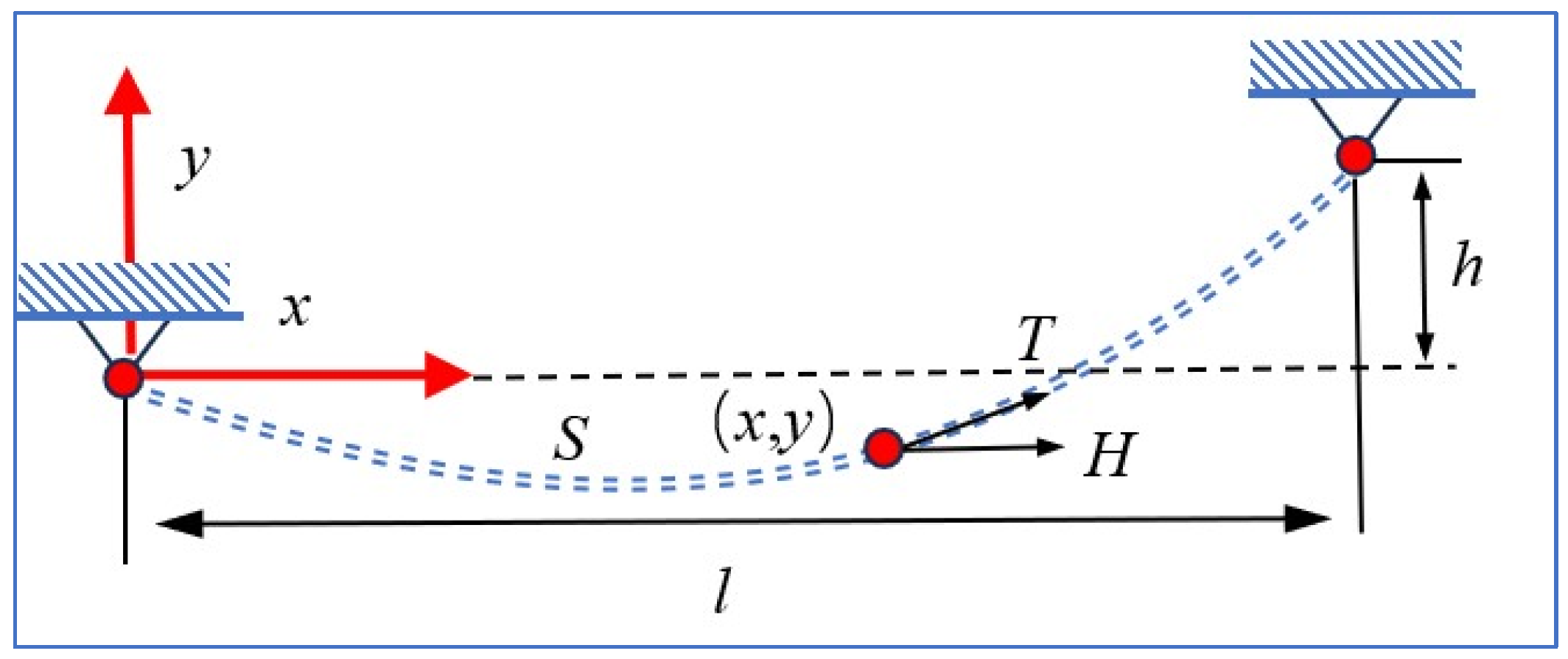

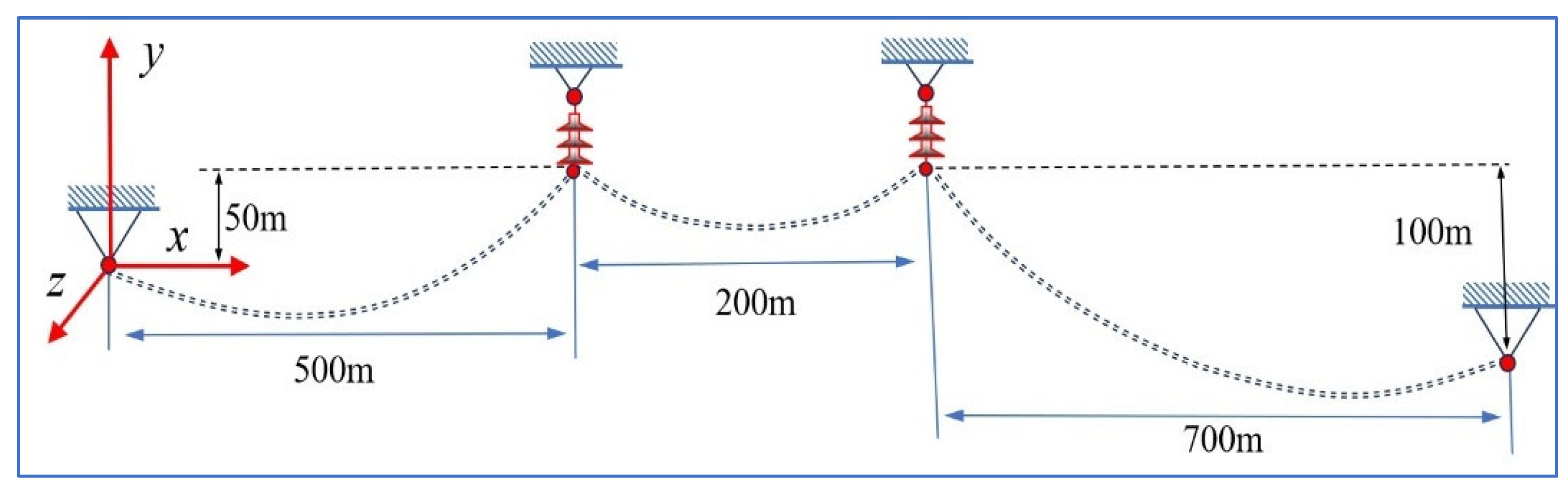

2.3. Wire Shape Verification

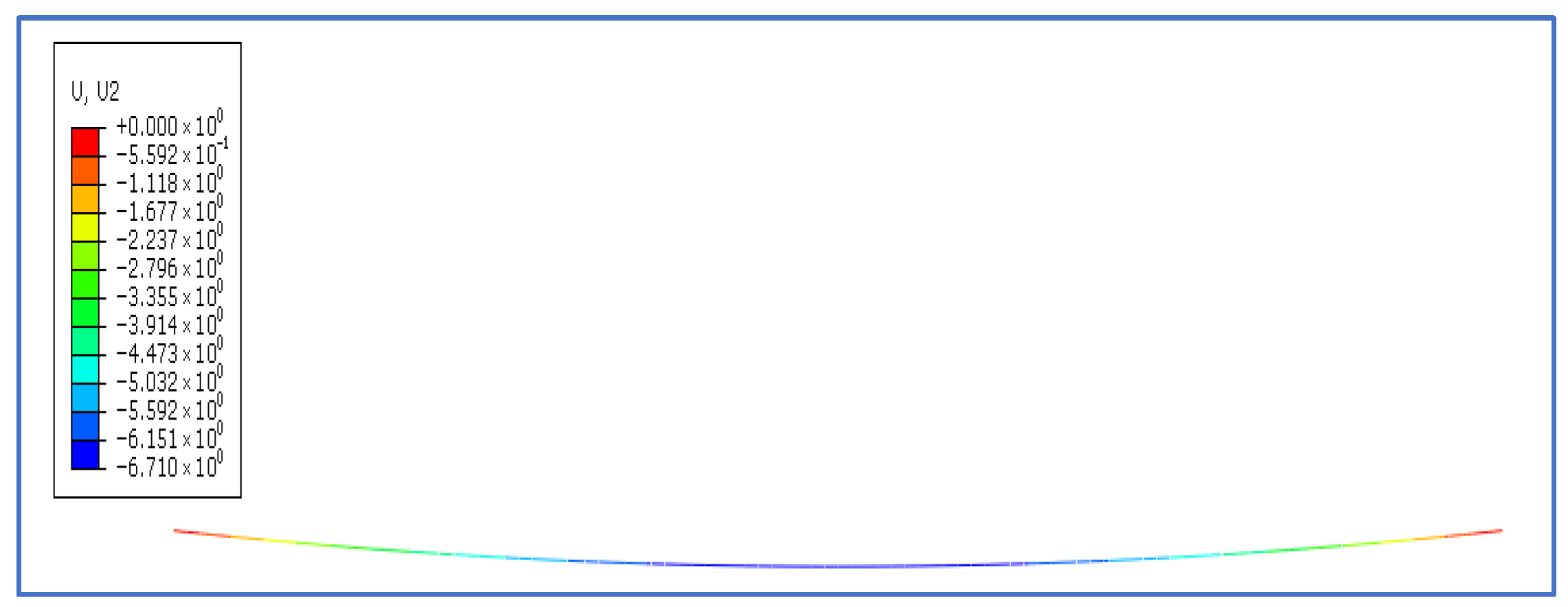

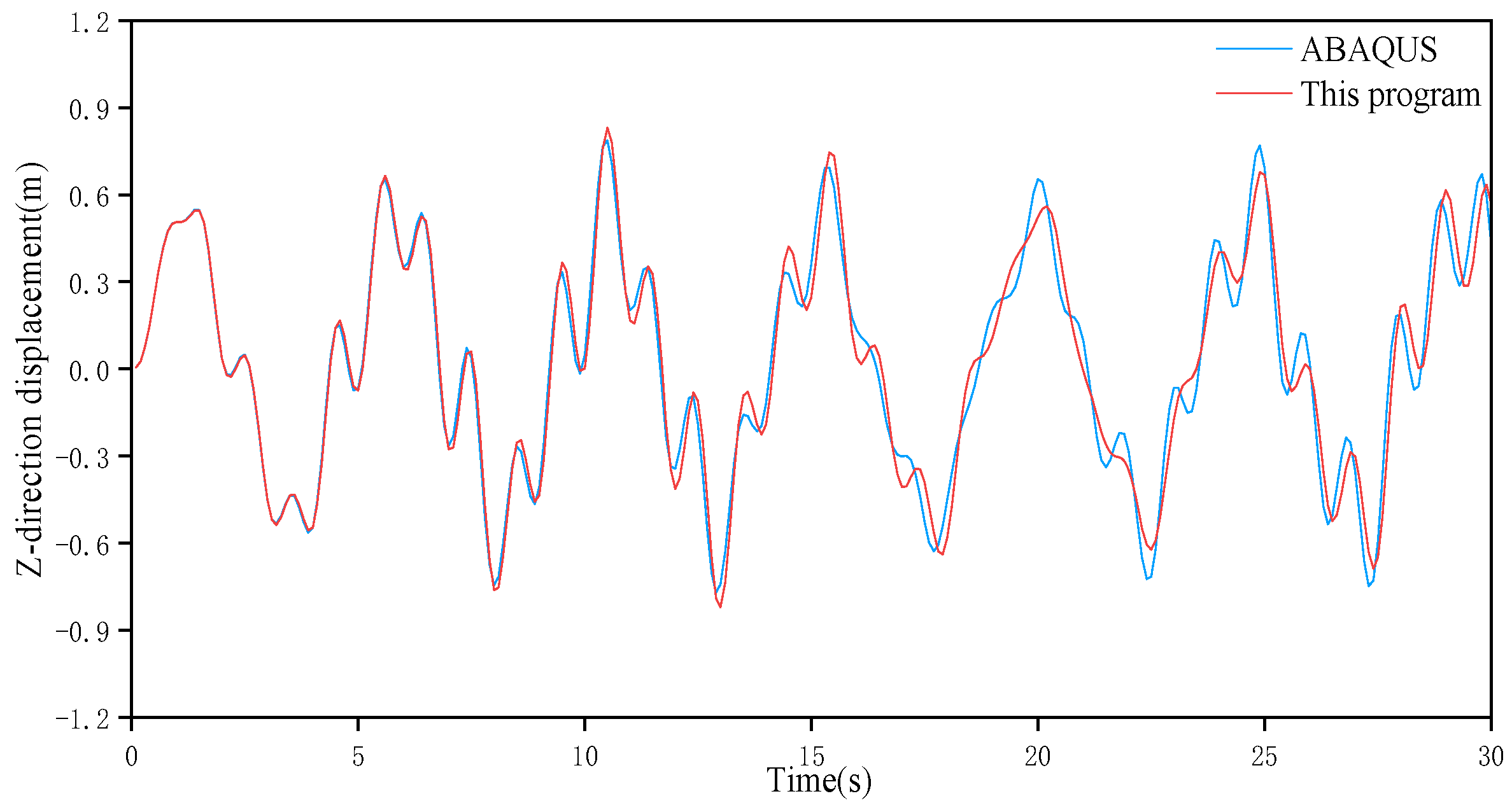

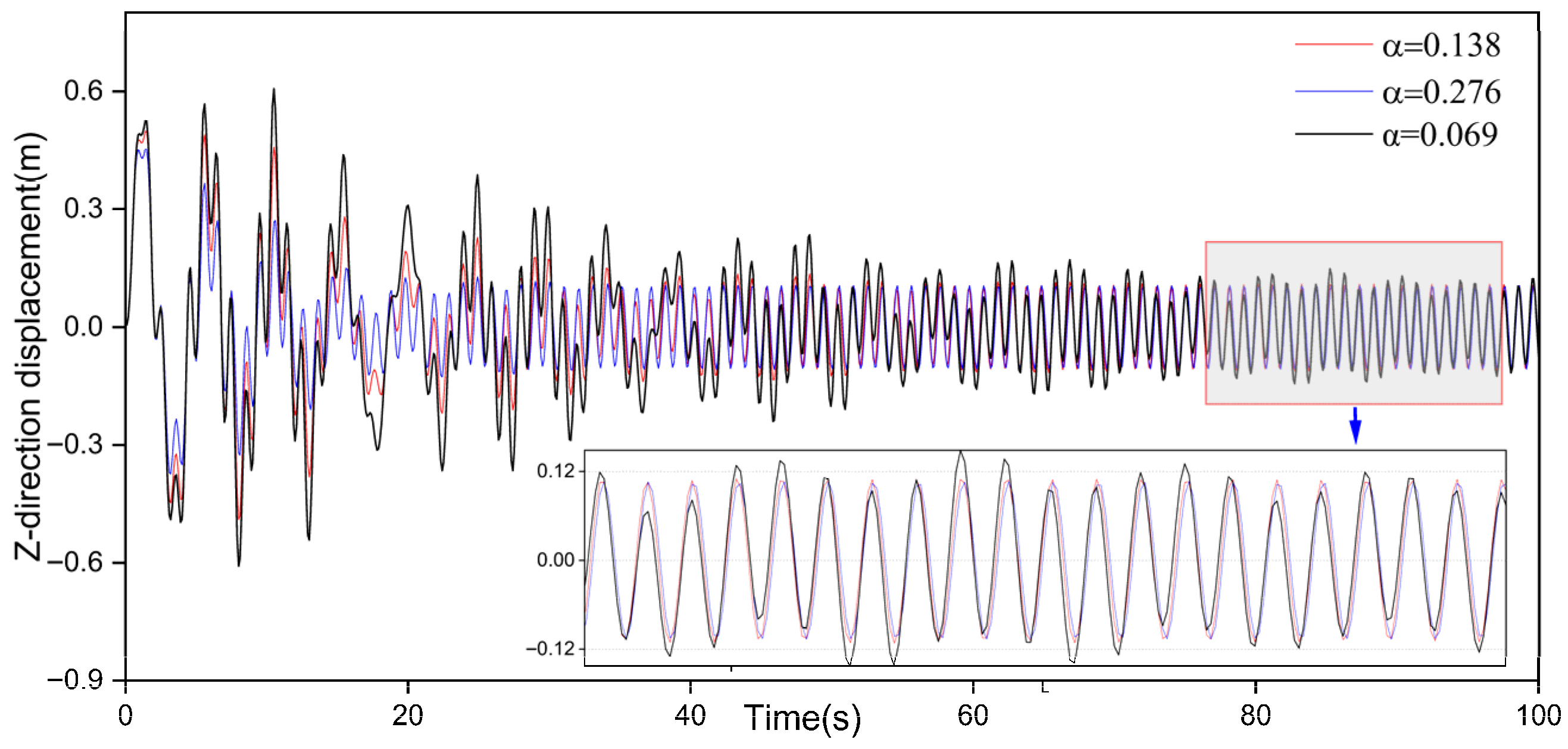

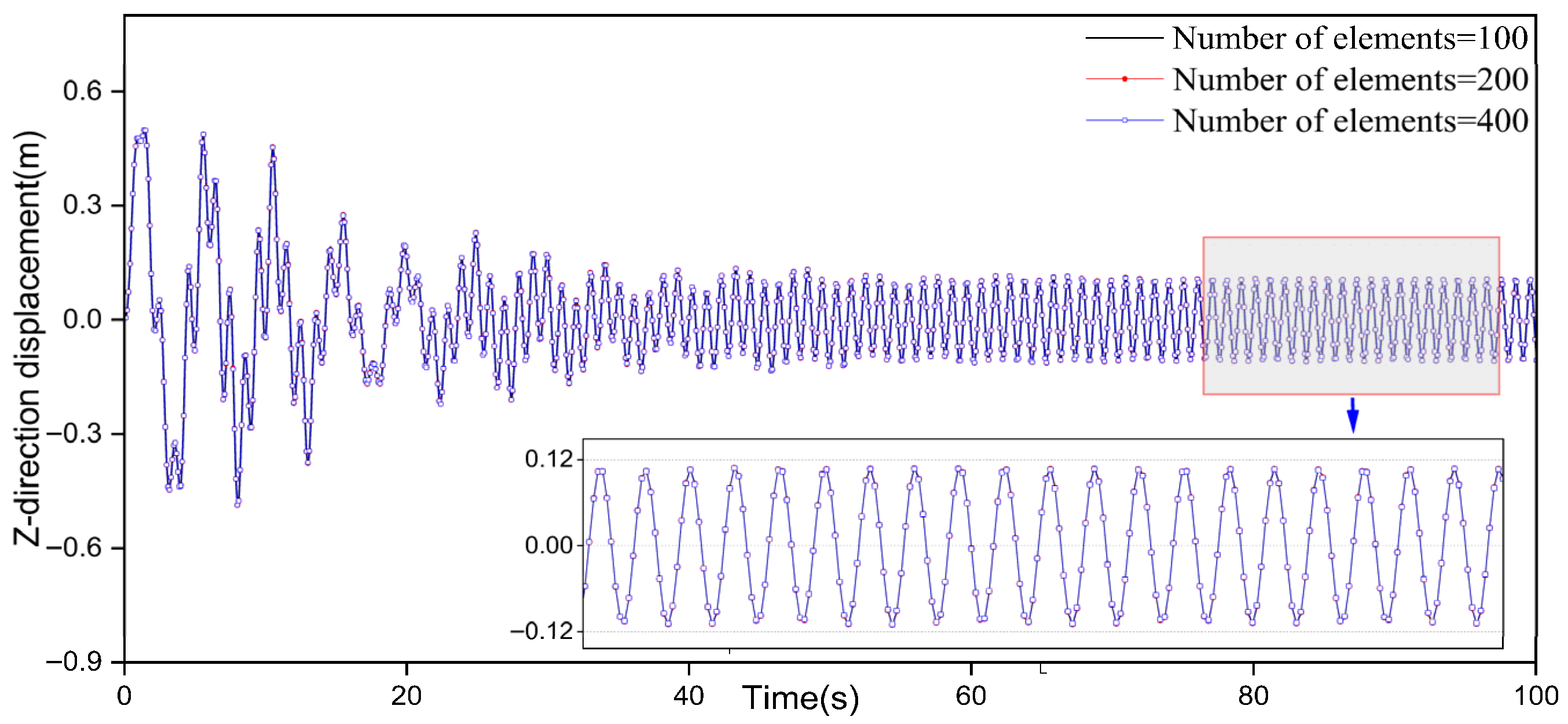

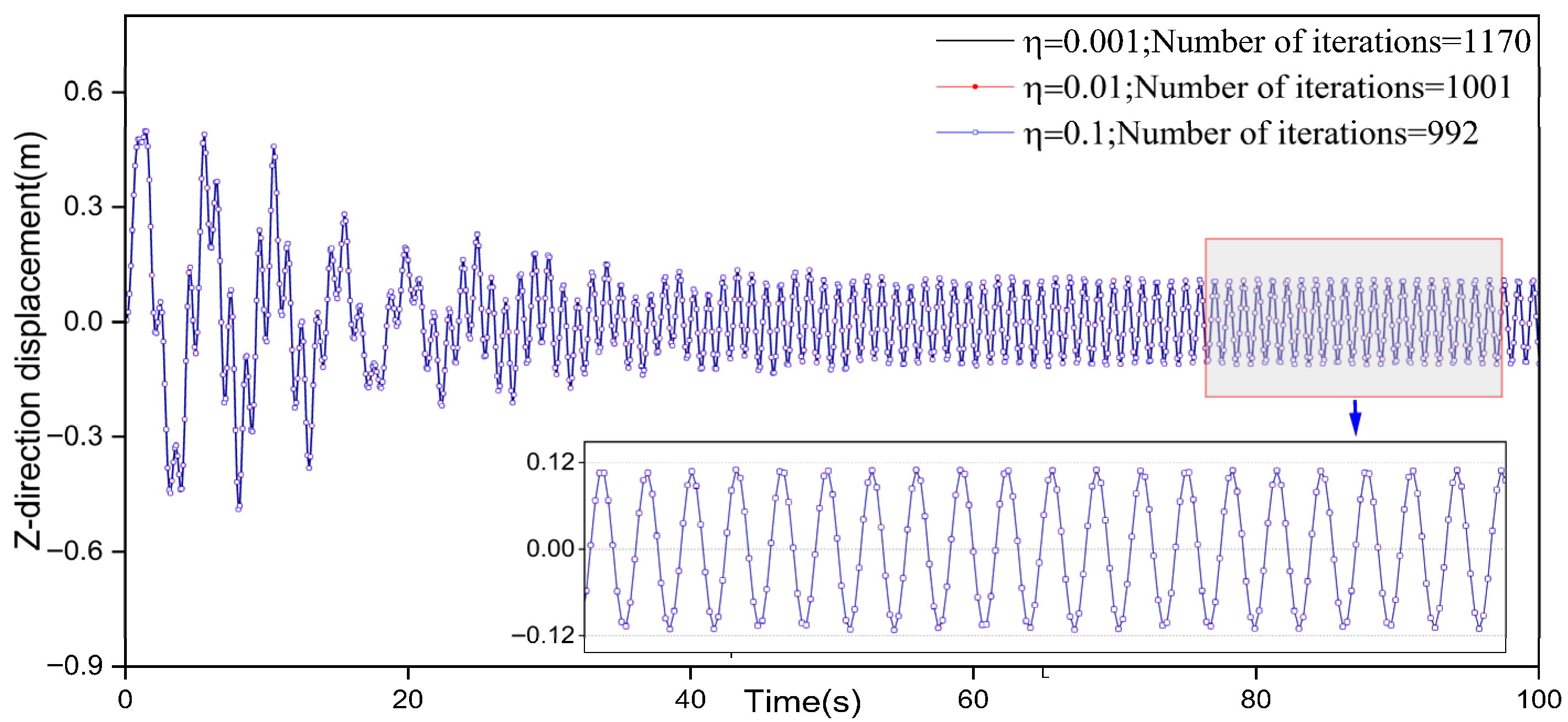

2.4. Forced Dynamic Response Verification

3. The Impact of Span on Wind-Induced Deflection Response

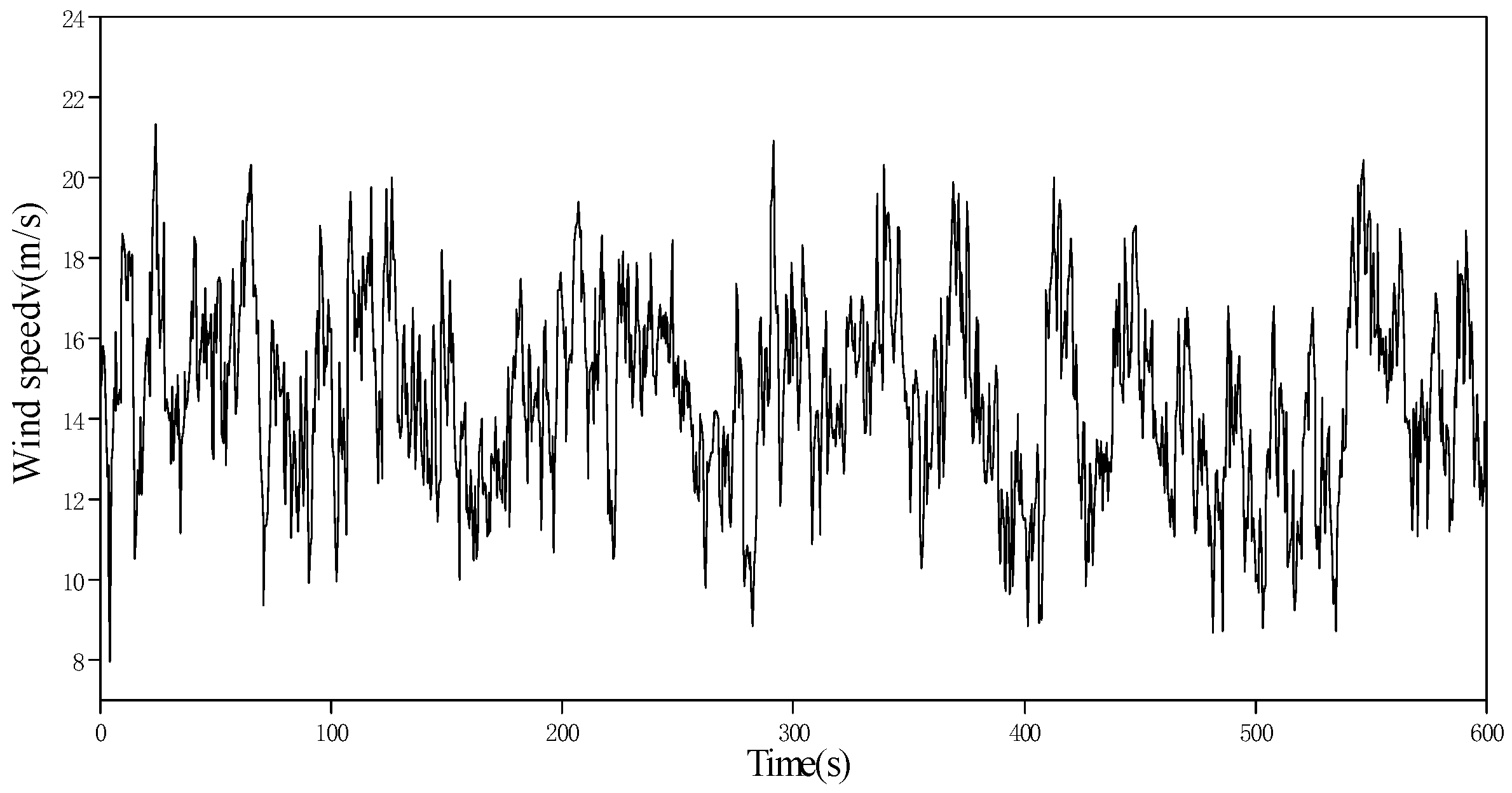

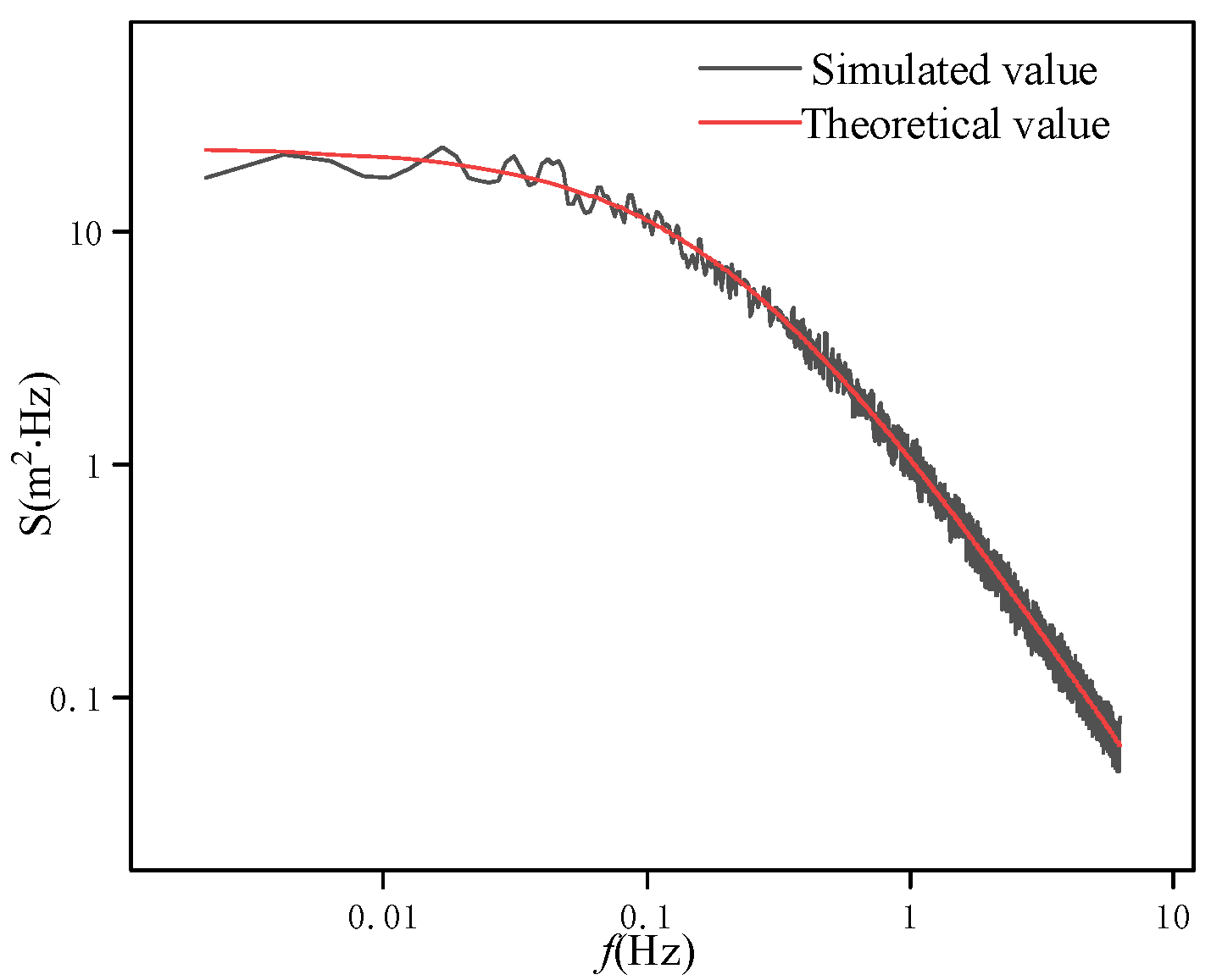

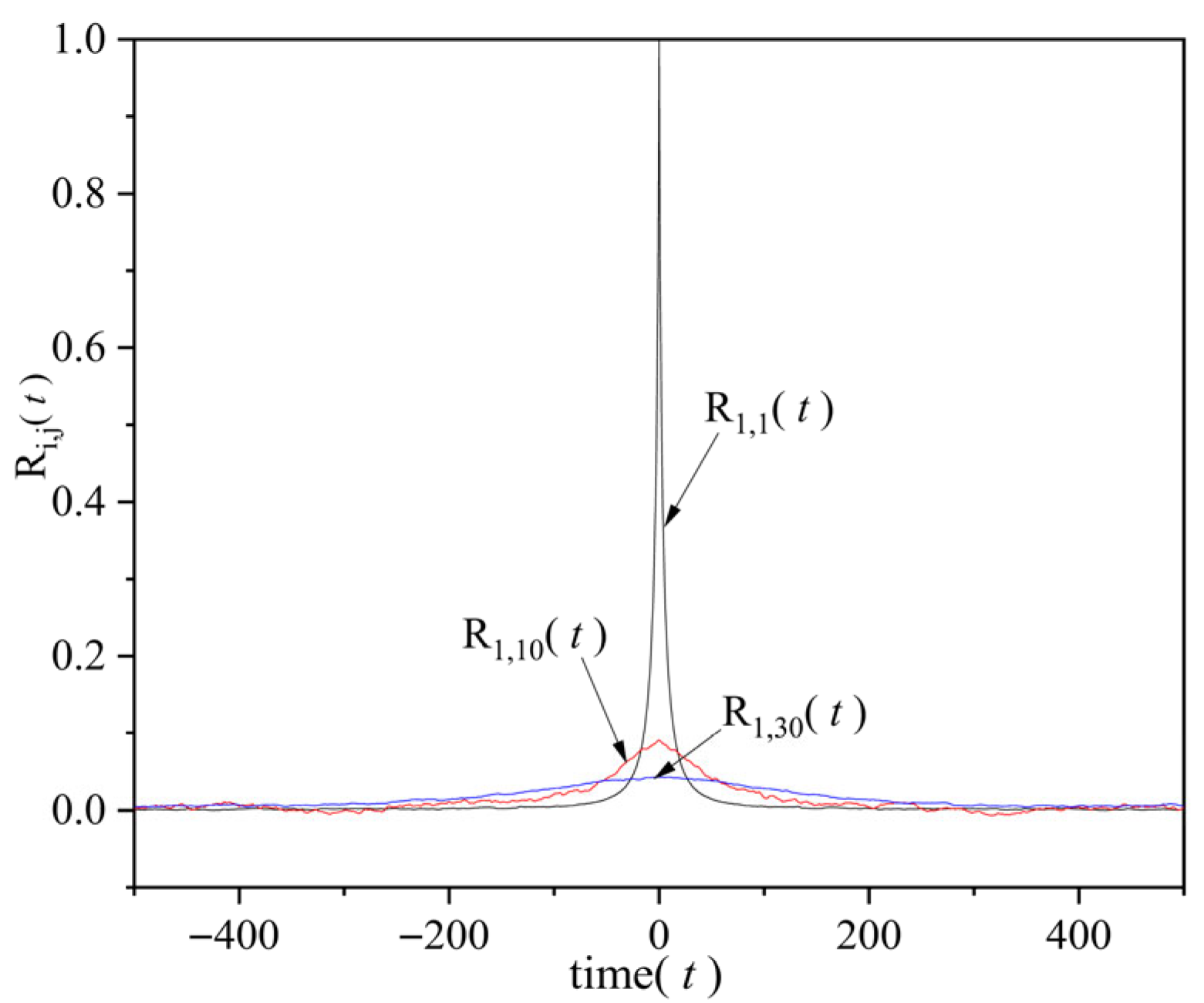

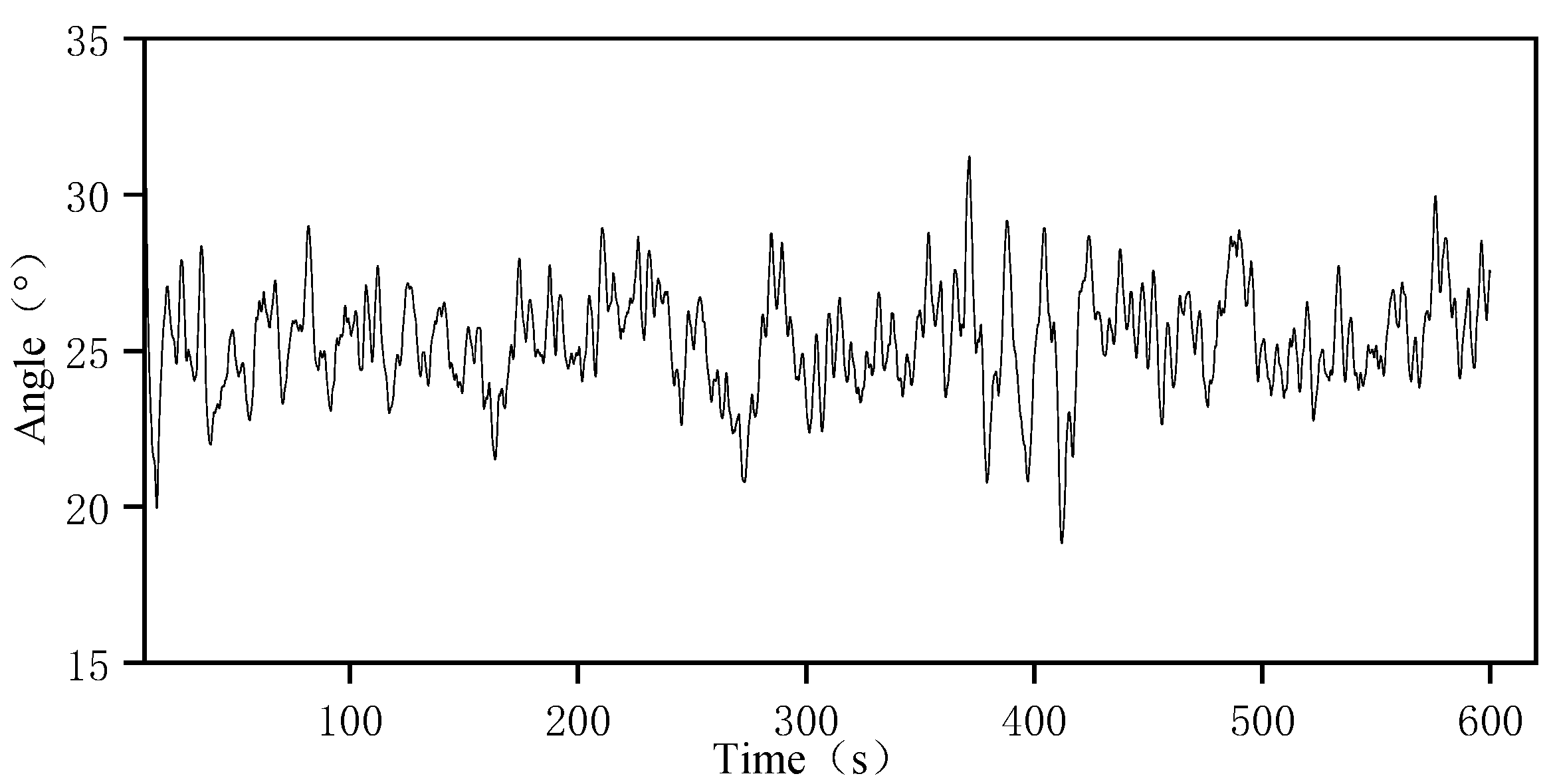

3.1. Simulation of Wind Field

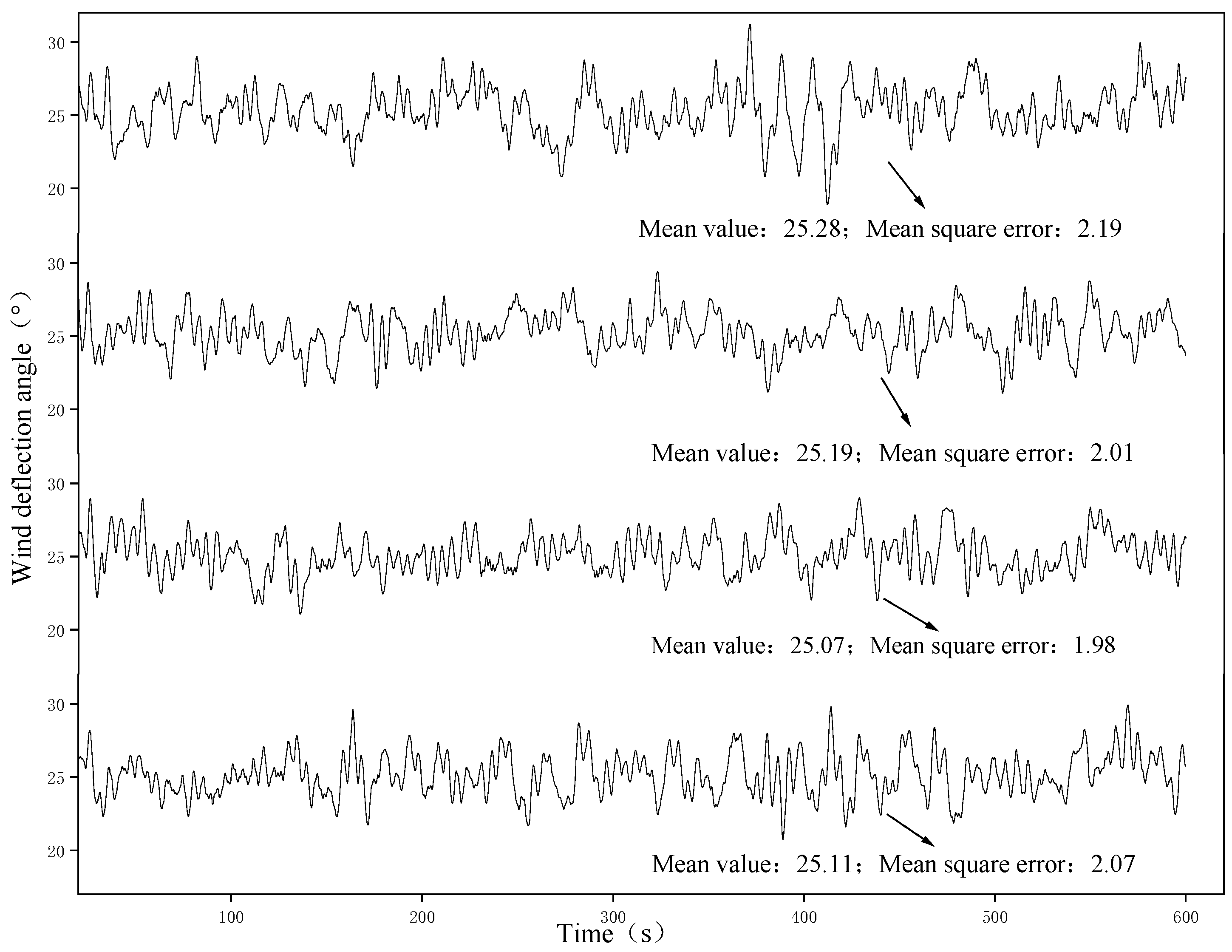

3.2. Wind Deflection Angle Calculation Formula Under Pulsating Wind

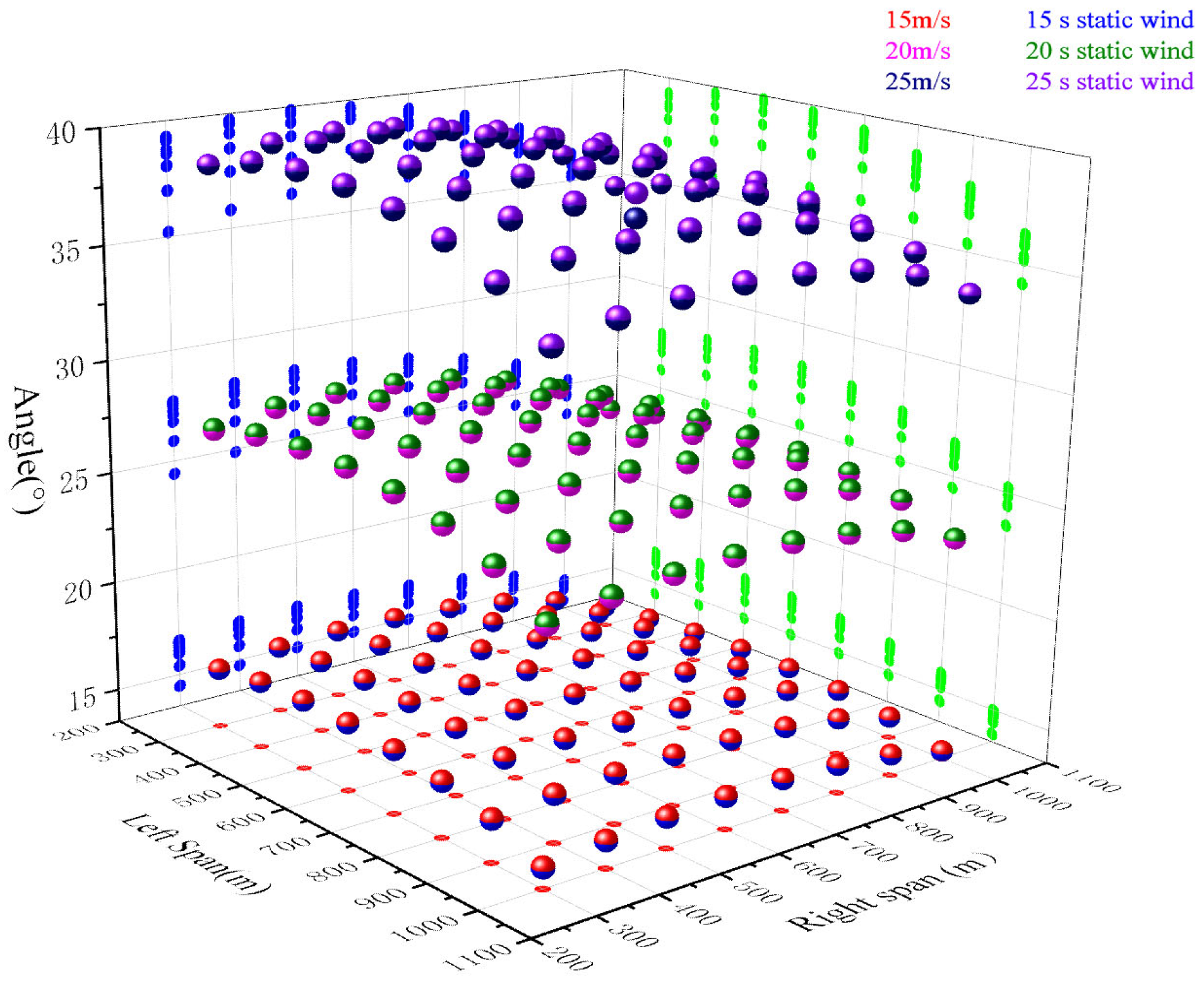

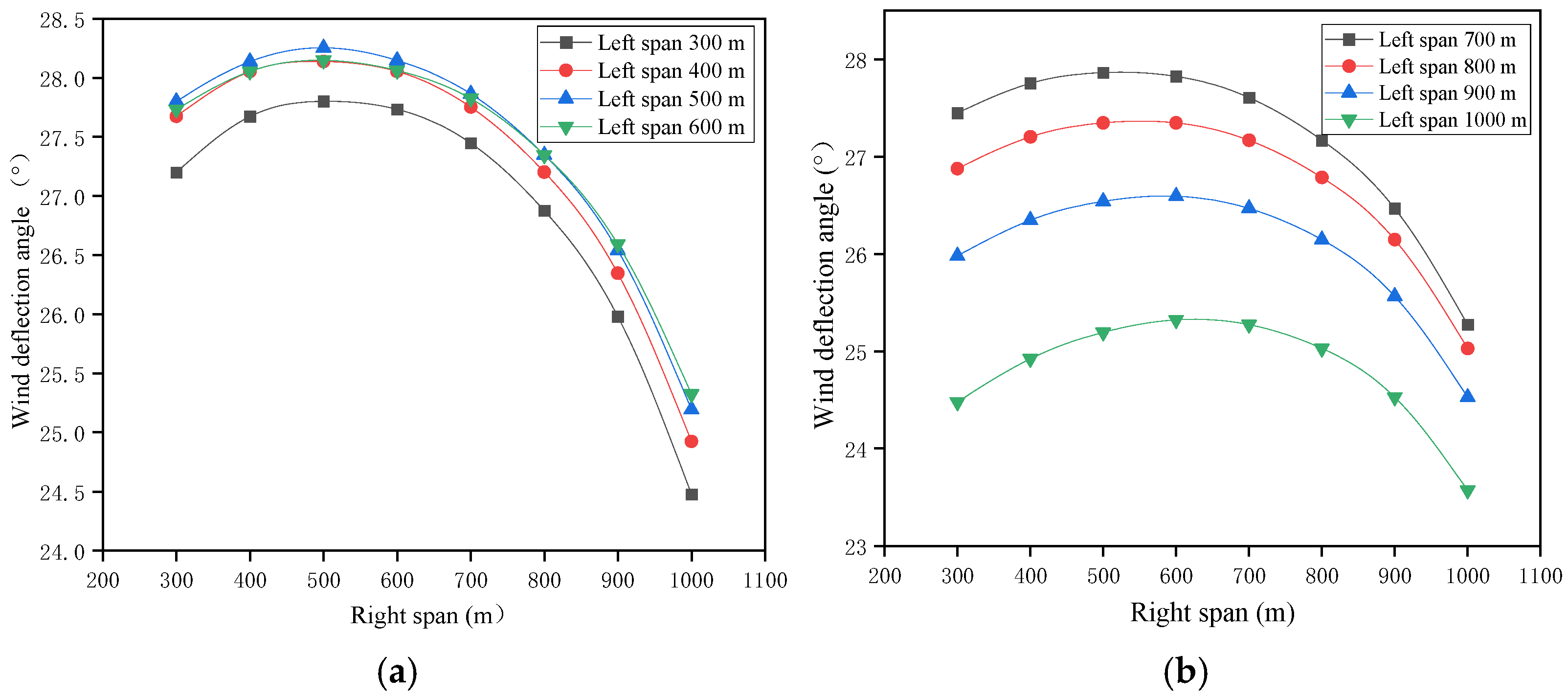

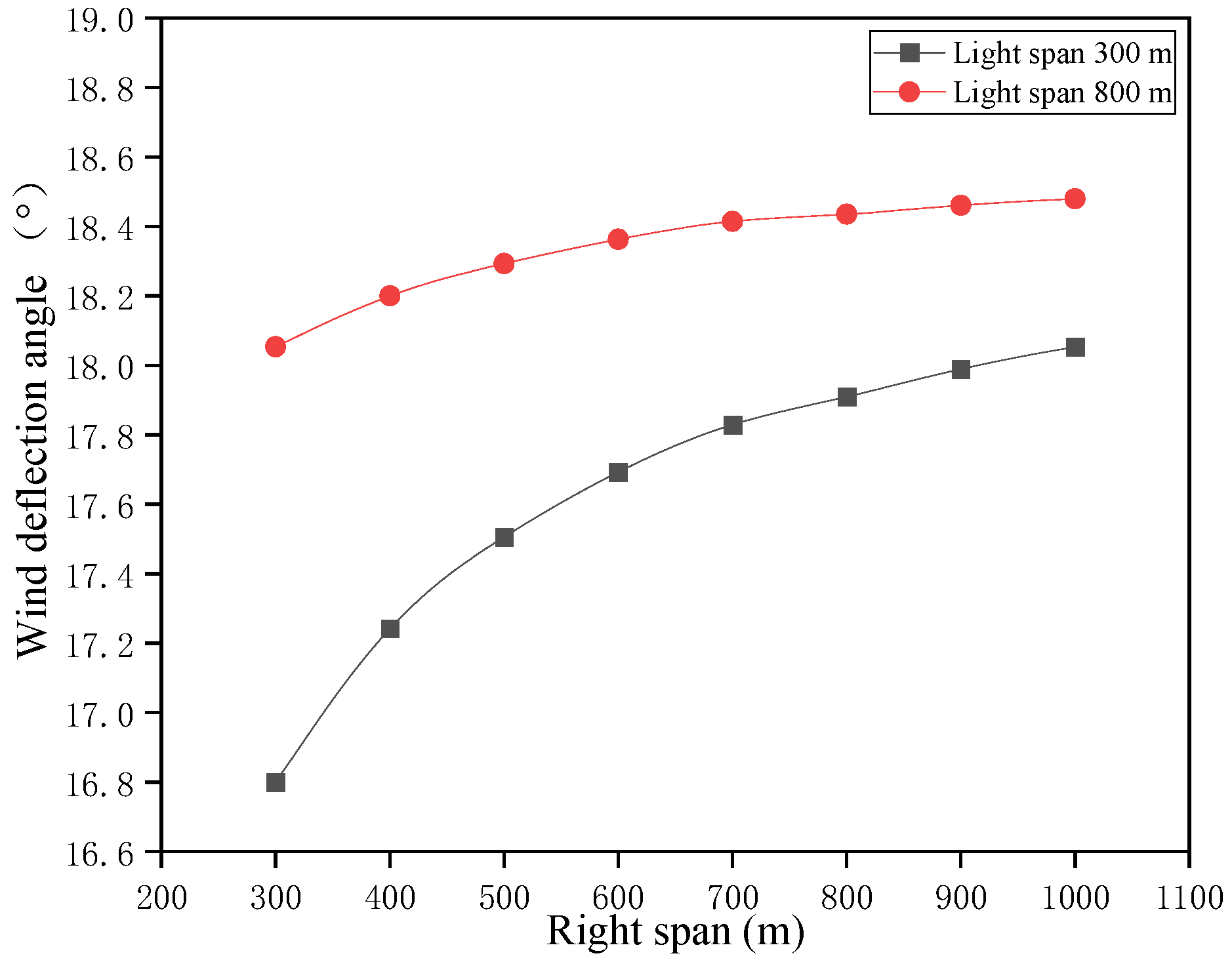

3.3. Effect of Span on Wind Deflection Angle

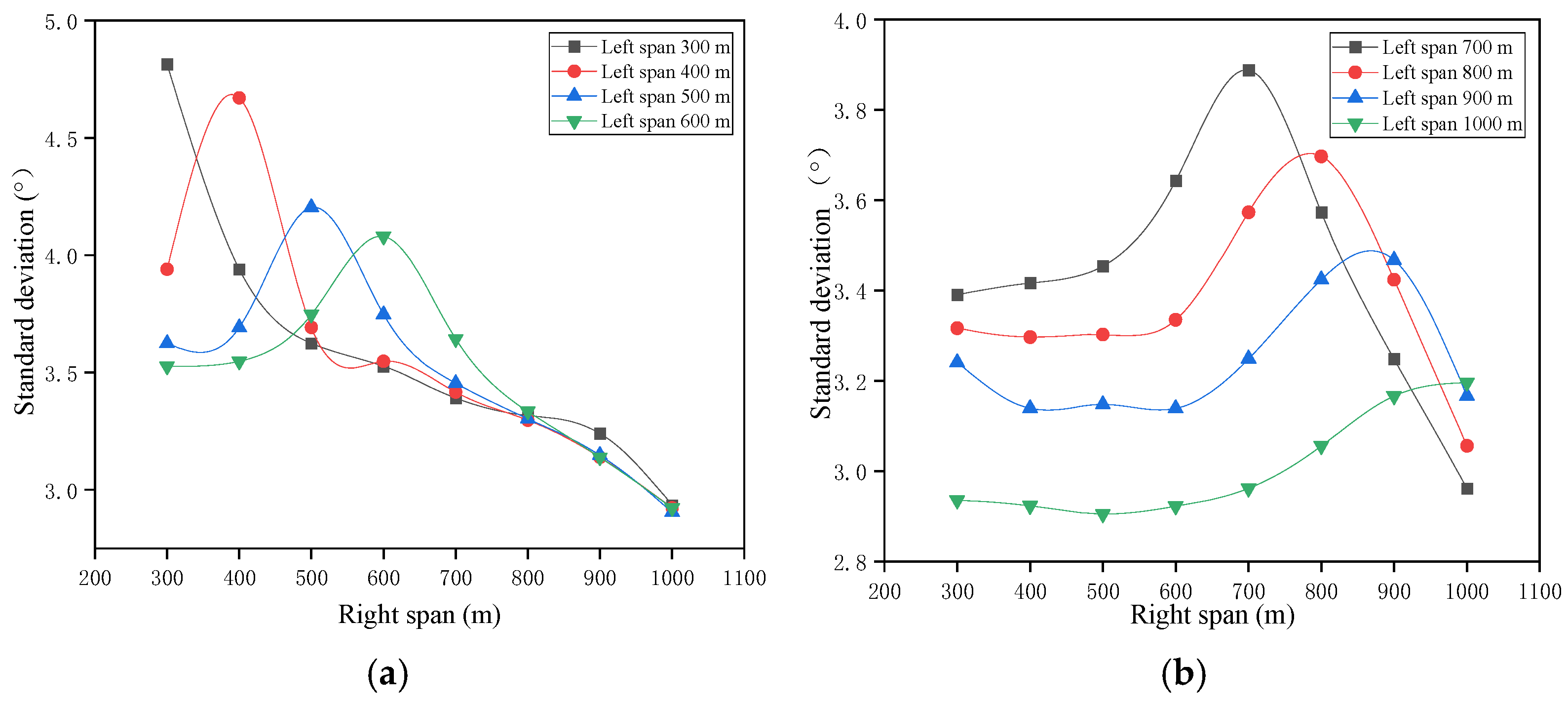

3.4. Influence of Span on Standard Deviation

4. Power Amplification Coefficient

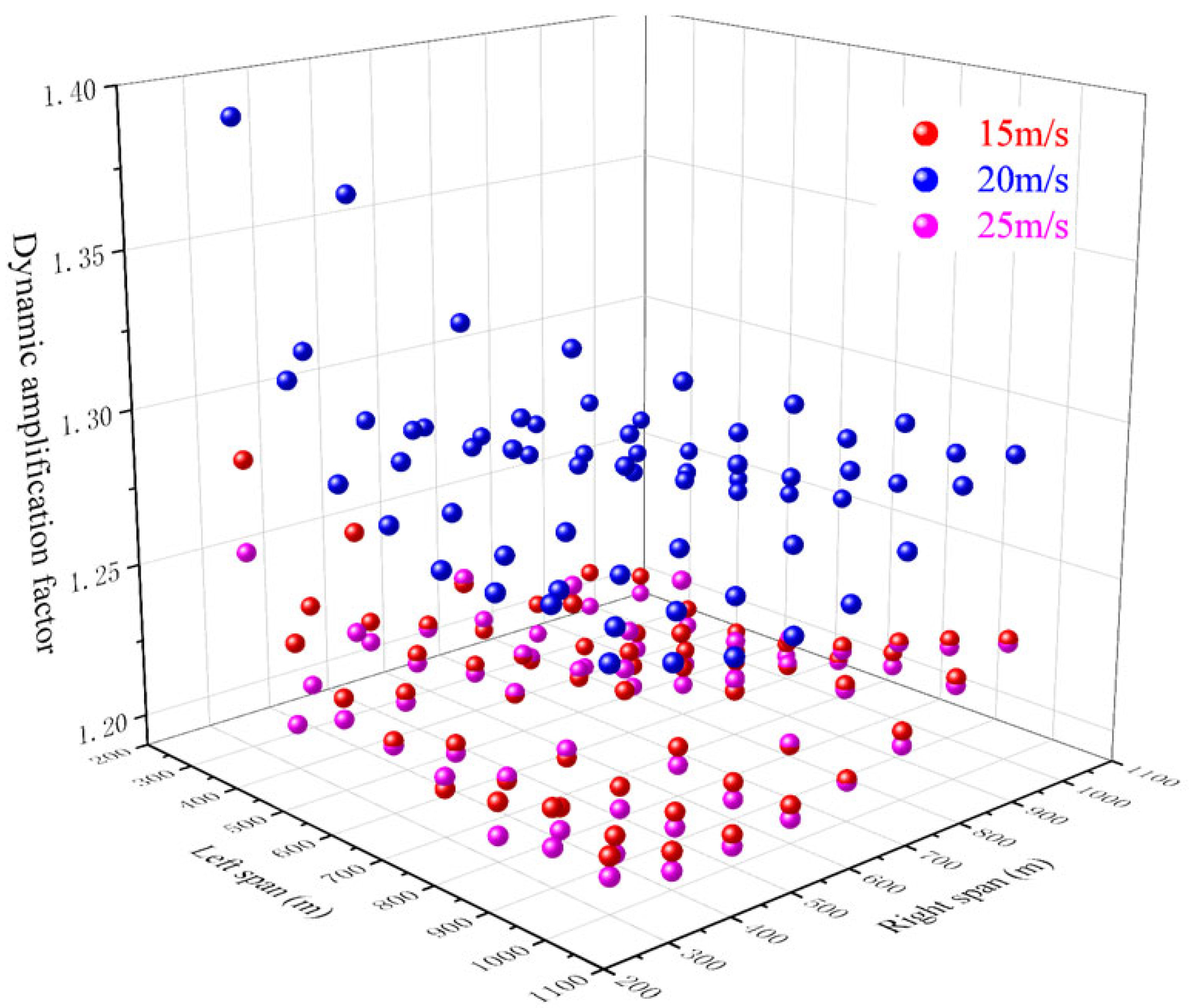

4.1. Dynamic Amplification Under Pulsating Wind

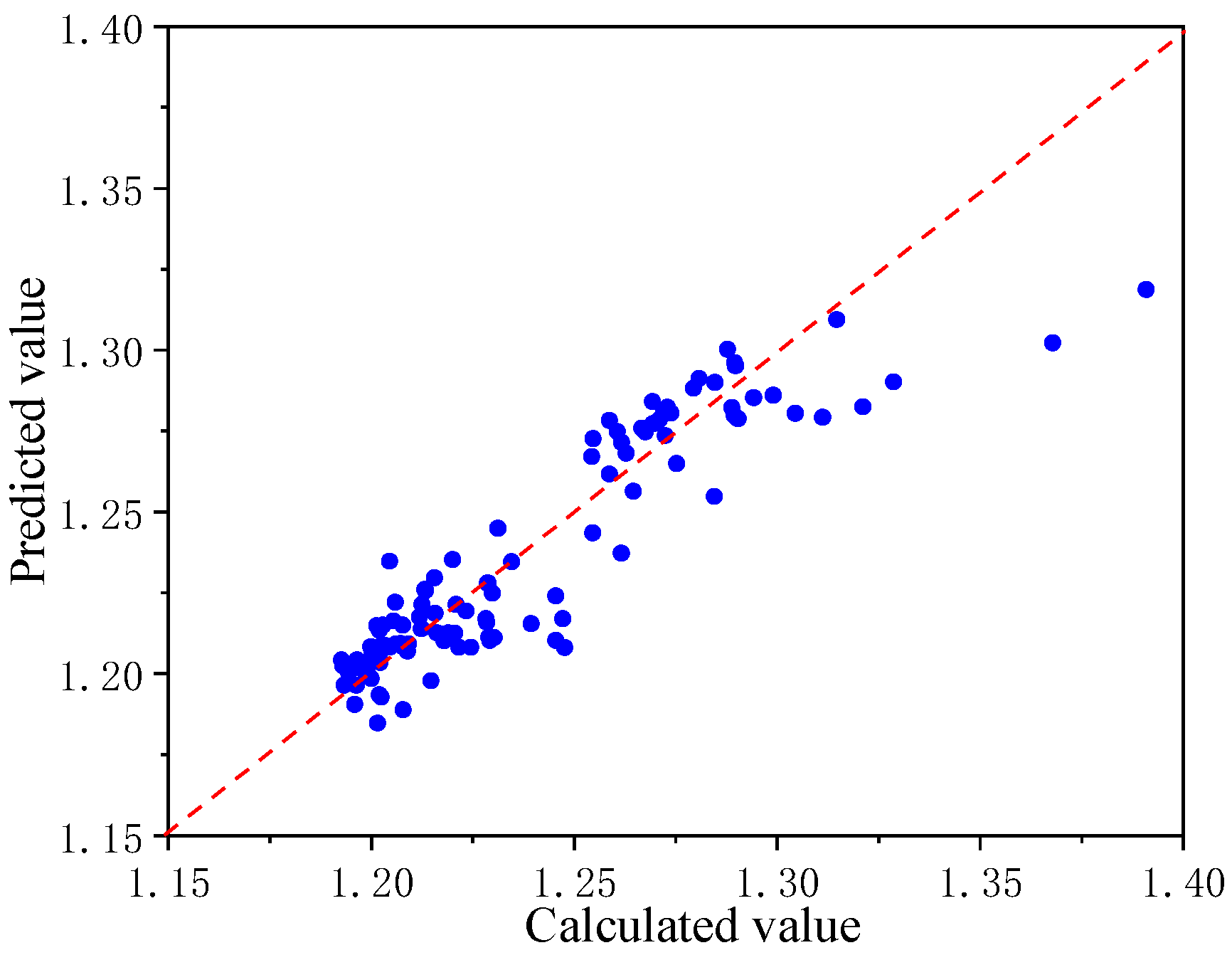

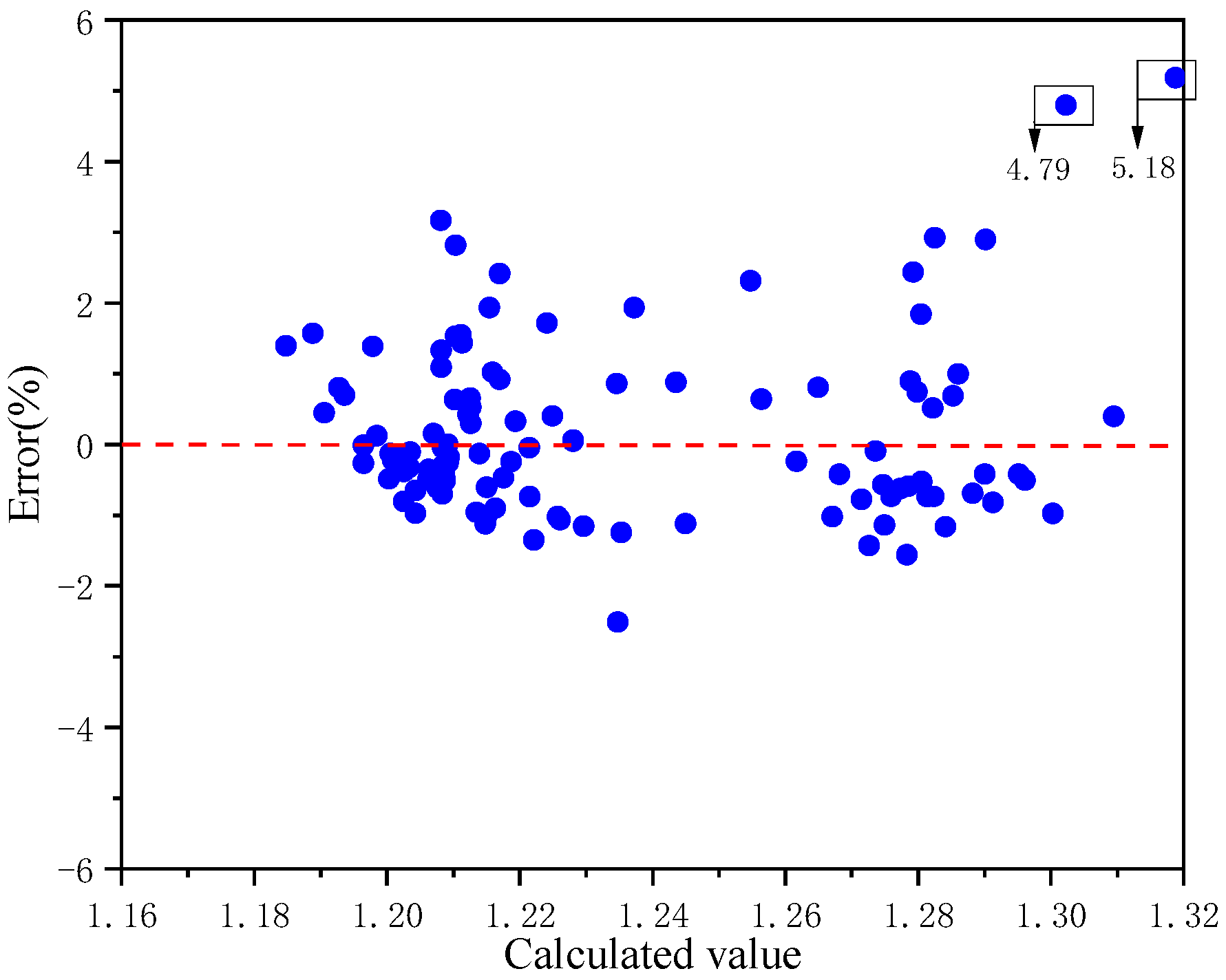

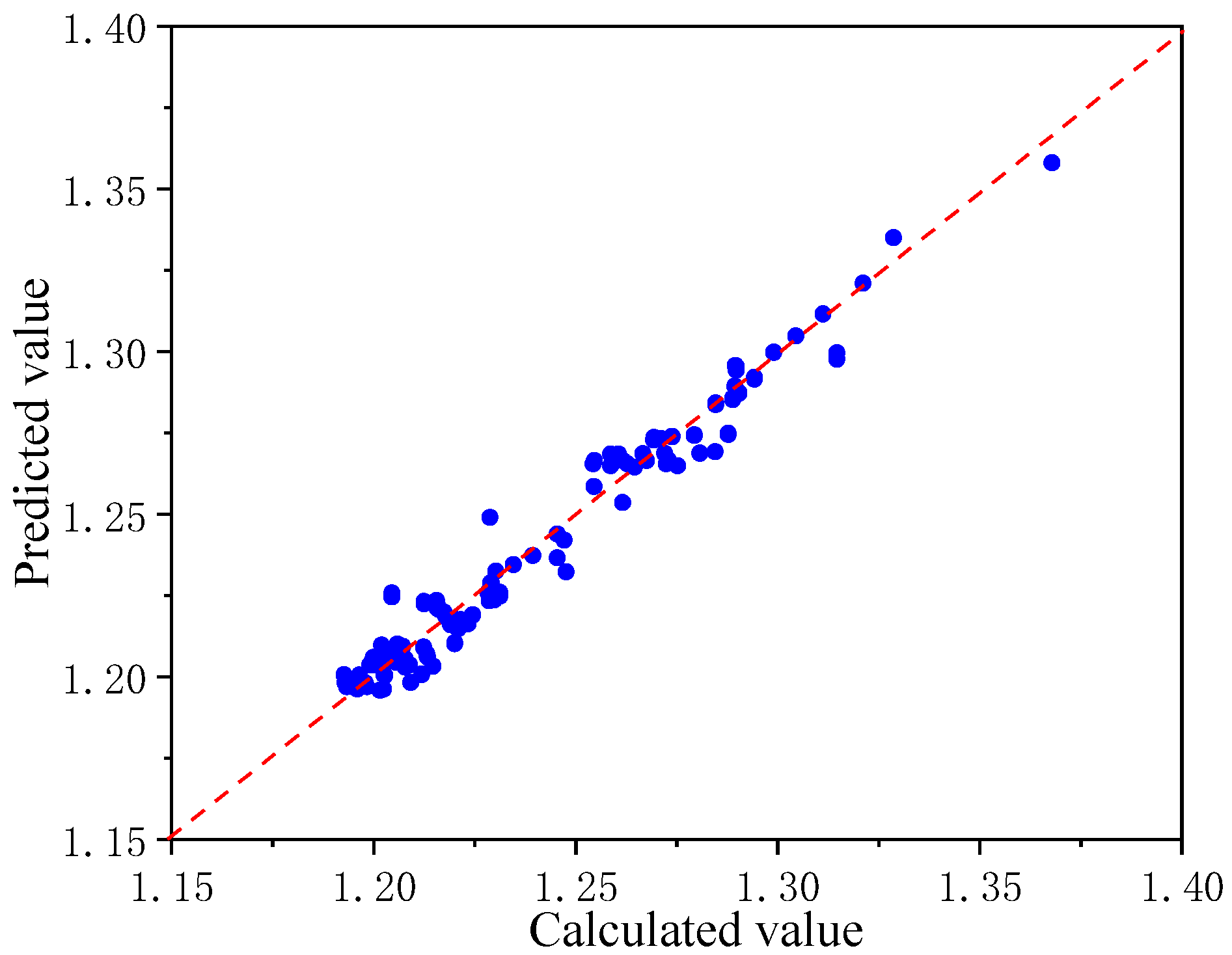

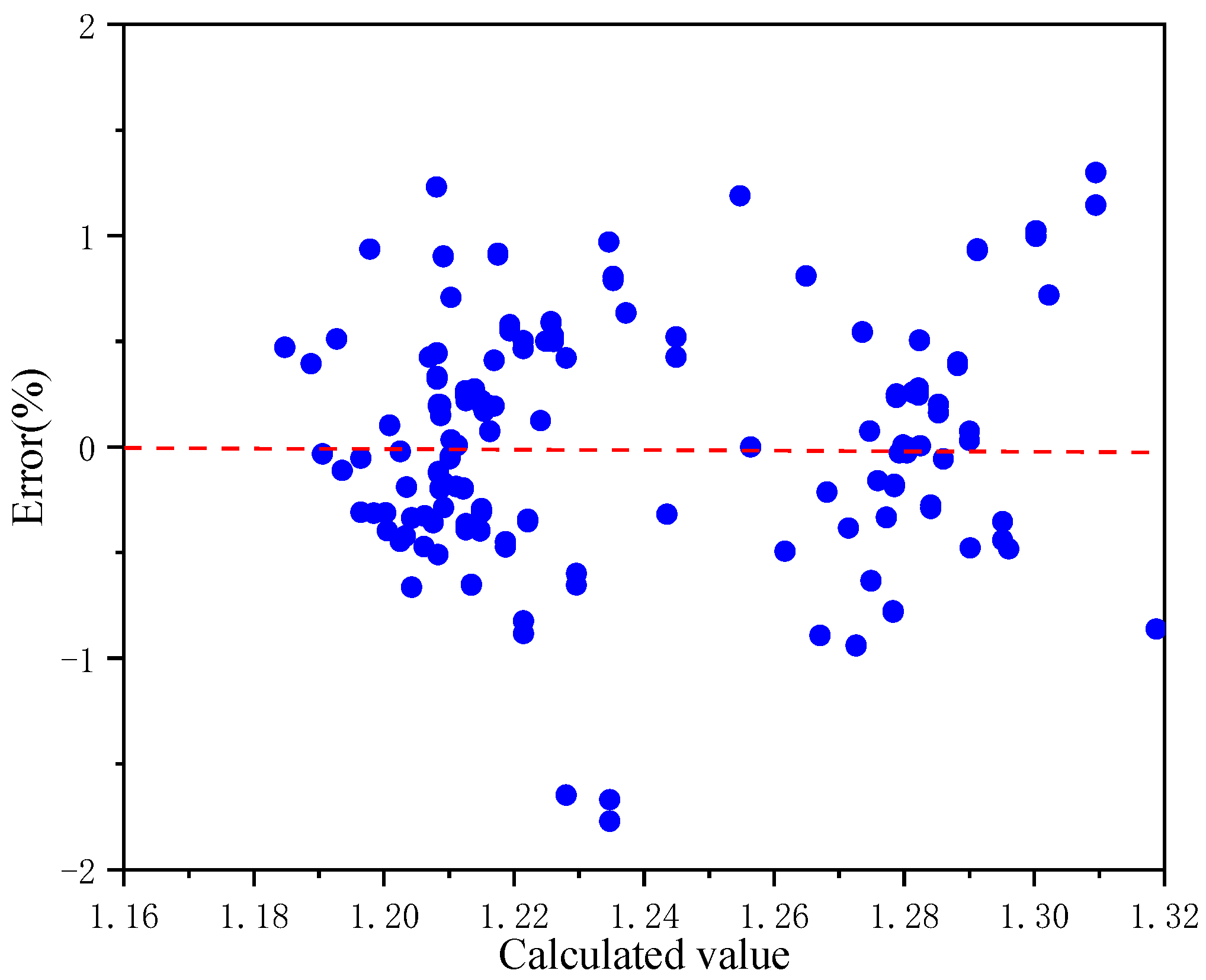

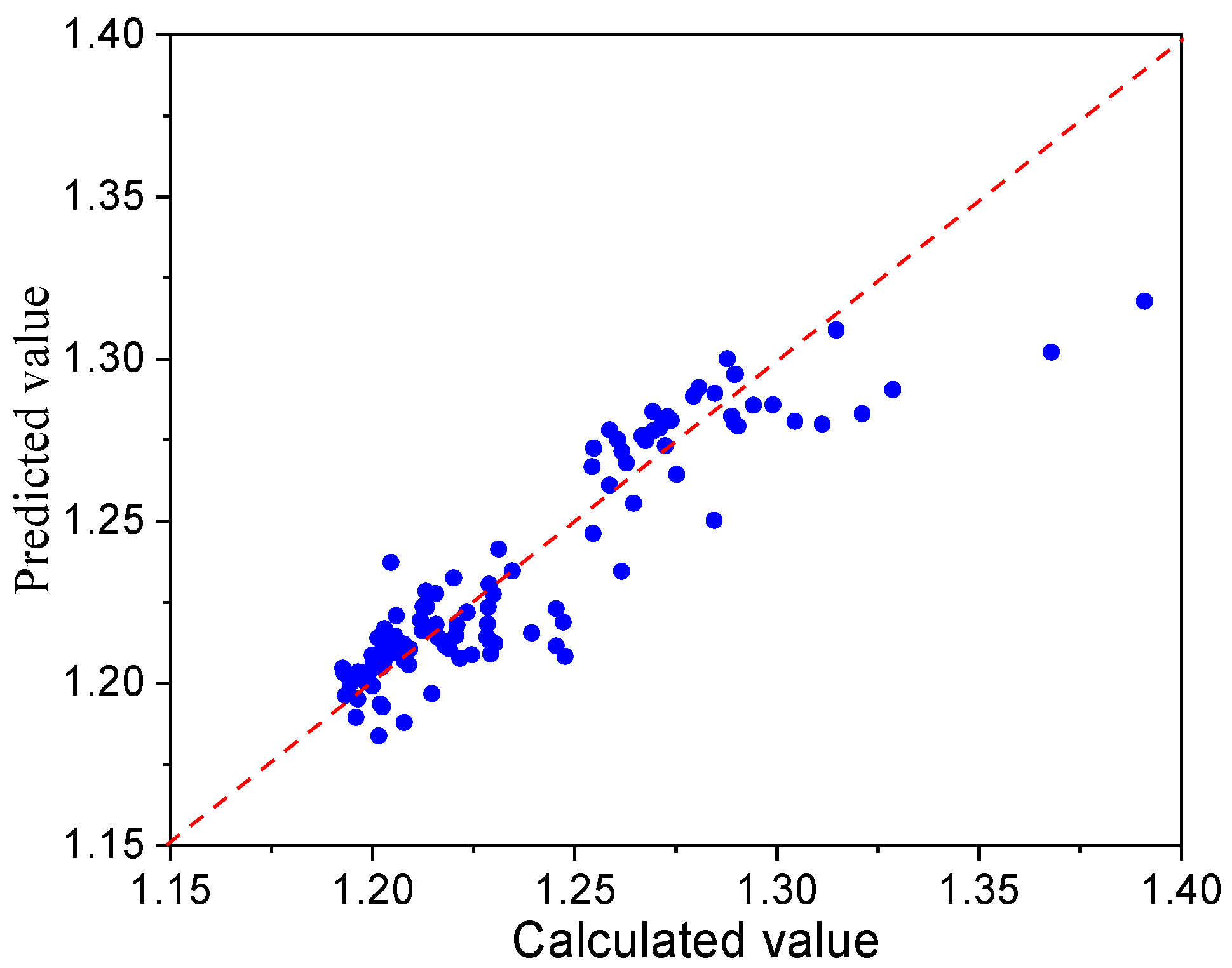

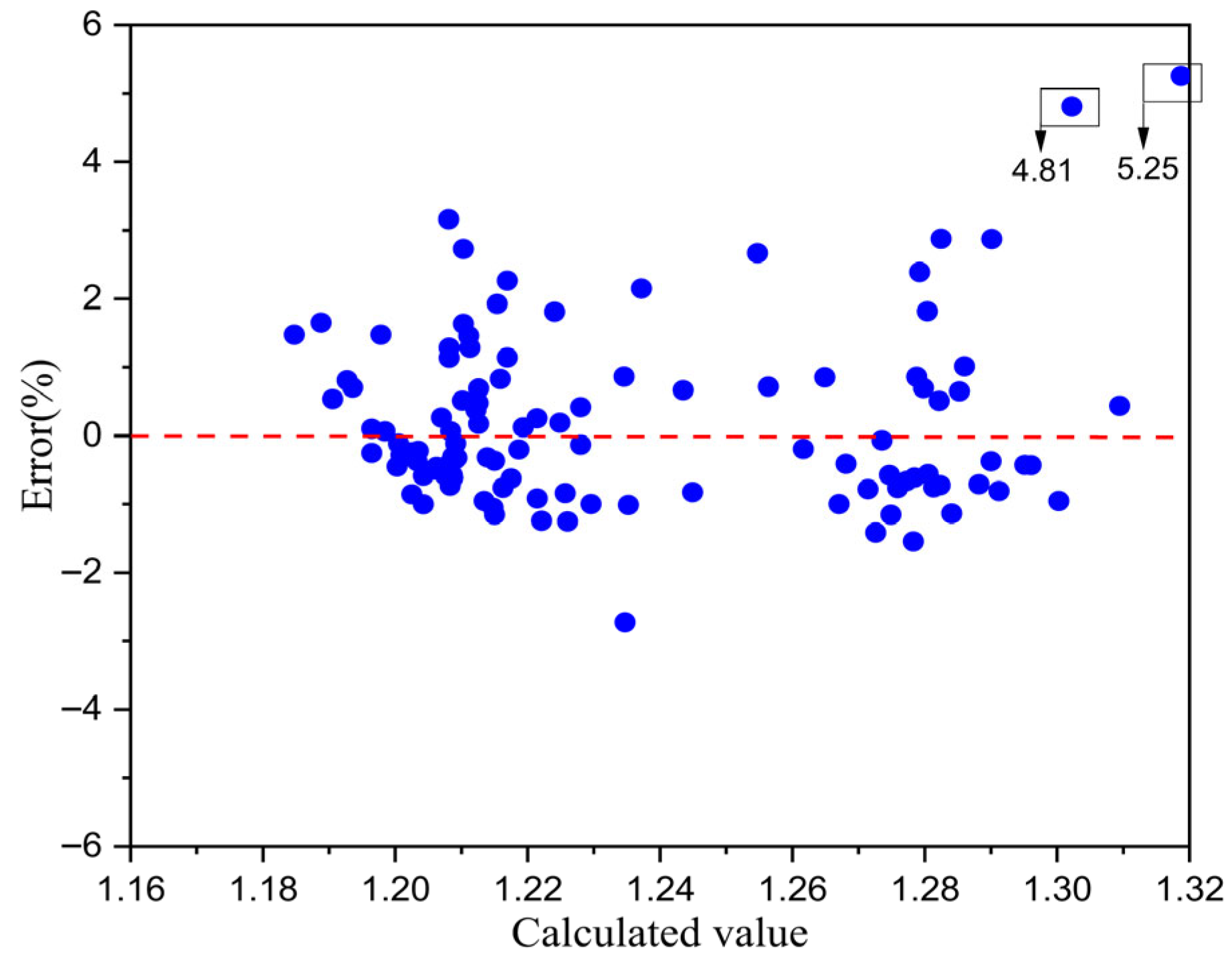

4.2. Polynomial Regression Model for Fitting the Dynamic Amplification Factor

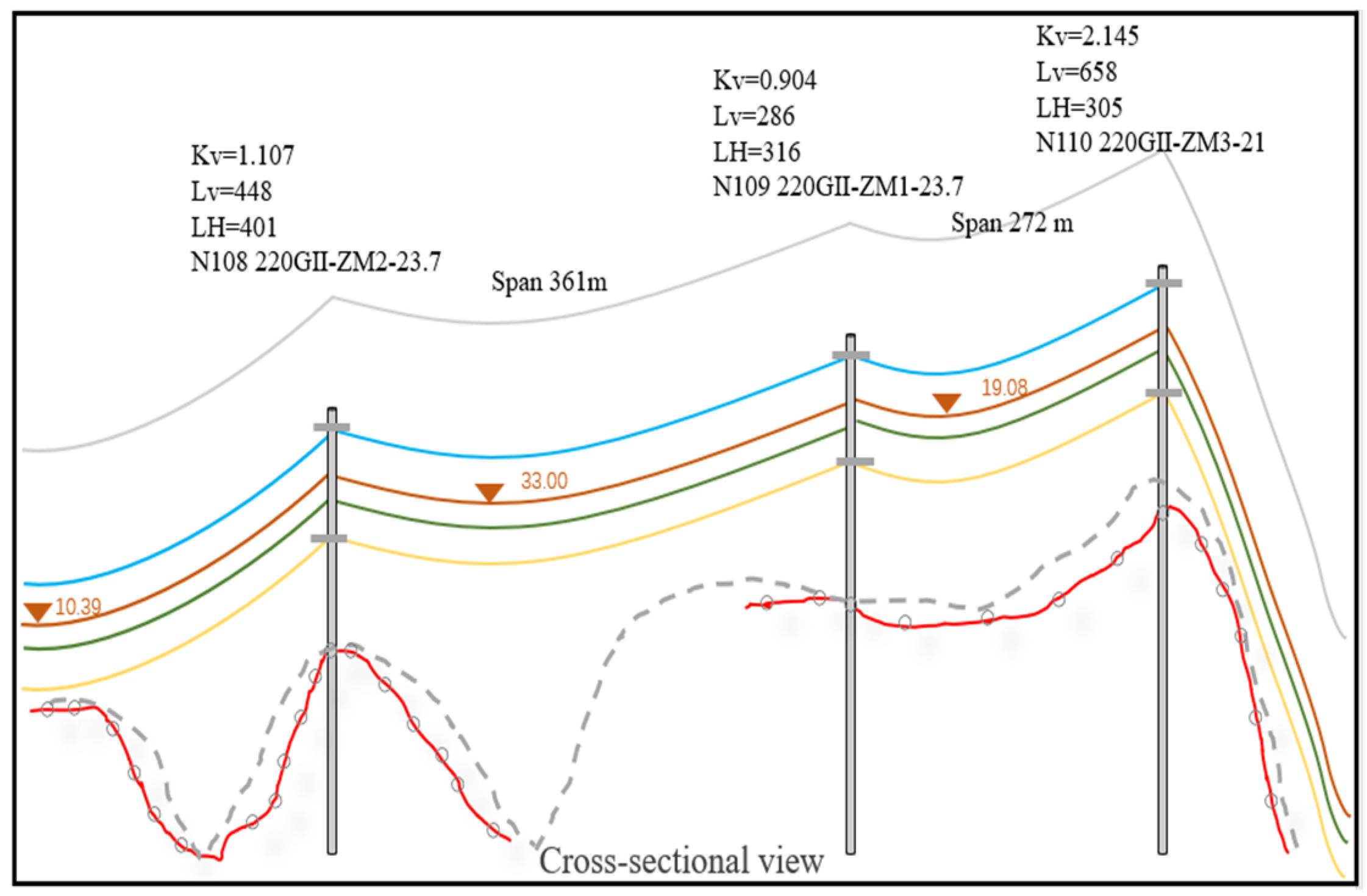

4.3. Engineering Applications

5. Conclusions

- (1)

- The wind deflection angle under static wind action is essentially consistent with the mean deflection angle under pulsating wind conditions. When the span length on one side of the insulator string is fixed, the deflection angle exhibits a nonlinear trend—first increasing and then decreasing—as the span length on the opposite side increases. If the variation in the wind pressure height coefficient is neglected, the deflection angle would continuously increase with span length.

- (2)

- Under pulsating wind excitation, symmetrical span configurations amplify the standard deviation of the deflection angle, demonstrating more pronounced fluctuation characteristics. However, under symmetrical span conditions, the standard deviation of the deflection angle gradually decreases as the span length increases, and the equivalent wind-induced deflection angle exhibits a similar trend. This occurs because increased span length leads to greater conductor sag, reduced ground clearance, and consequently a decreased height coefficient. This reduction in the height coefficient diminishes the wind load, thereby suppressing the fluctuation amplitude of the wind deflection angle.

- (3)

- Pulsating wind exerts a non-negligible dynamic amplification effect on suspension insulator strings. Across various working conditions, the dynamic amplification factor ranges between 1.2 and 1.35, showing a non-monotonic characteristic that first increases and then decreases with rising wind speed.

- (4)

- Based on symbolic regression and the least squares method, this study derived three distinct expressions for the dynamic amplification factor in terms of span length and wind speed. Accuracy evaluation reveals that the two polynomial expressions obtained through symbolic regression and the least squares method both demonstrate maximum errors approaching 5%, with coefficients of determination (R2) reaching approximately 0.85. This indicates that representing the relationship among span length, wind speed, and dynamic amplification factor using polynomial forms still entails certain deviations. Furthermore, symbolic regression yielded an additional expression with superior goodness-of-fit (R2 = 0.97), though characterized by relatively complex formulation. In engineering design, appropriate models can be selected from these alternatives according to specific accuracy requirements. Finally, the rationality and applicability of the proposed predictive formulas were validated through actual engineering case studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| node displacement vector of the truss element | |

| member end incremental force | |

| oncremental displacement | |

| elastic modulus area of the truss element | |

| cross-sectional area of the truss element | |

| the axial force in a truss element at node | |

| tangent stiffness matrix | |

| stiffness matrix | |

| mass matrix | |

| damping matrix | |

| denotes the friction velocity | |

| Mohrisch–Coulomb coordinate | |

| the average wind speed at z | |

| reference wind speed at 10 m height | |

| f = ω/2π | the frequency (Hz) |

| z | the height (m) |

| z0 | ground roughness length |

| α | ground roughness coefficient |

| positive definite matrix | |

| φm | equivalent deflection angle |

| average deflection angle, respectively | |

| μ | assurance coefficients |

| σ | standard deviations, respectively |

| l | the left span length of the pulsating wind |

| r | the right span length of the pulsating wind |

| v | the average wind speed of the pulsating wind |

References

- Liu, J.; Ma, H.M.G.; Wang, B.; Cao, L.W.; Chen, C.; Wei, B. Study on the Influence of Wind Profile Coefficient and Turbulence Intensity on Wind Deflection Angle and Tower Head Size Design of Transmission Lines in Tibet. Electr. Eng. 2025, 129–133. [Google Scholar]

- Man, C.Y.; Man, H.W.; Xie, W. Cause Analysis of Wind Deflection Trip of 220kV II Xiangshan-Suyuan Line. Electr. Eng. 2025, 99–100+104. [Google Scholar]

- Gu, Y.; Zhang, Y. A Review of Wind-Induced Swing Response Calculations for Transmission Conductors. Eng. Solut. Mech. Mar. 2024, 1, 10. [Google Scholar]

- Alcayde-García, F.; Salmerón-Manzano, E.; Montero, M.A.; Alcayde, A.; Manzano-Agugliaro, F. Power transmission lines: Worldwide research trends. Energies 2022, 15, 5777. [Google Scholar] [CrossRef]

- Hileman, A.R. Weather and its effect on air insulation specifications. IEEE Trans. Power Appar. Syst. 1984, PAS-103, 3104–3116. [Google Scholar] [CrossRef]

- Tsujimoto, K.; Yoshioka, O.; Okumura, T.; Fujii, K.; Simojima, K.; Kubokawa, H. Investigation of conductor swinging by wind and its application for design of compact transmission line. IEEE Trans. Power Appar. Syst. 1982, PAS-101, 4361–4369. [Google Scholar] [CrossRef]

- Hiratsuka, S.; Matsuzaki, Y.; Fukuda, N.; Yukino, T.; Ishida, H. Field test results of a low wind-pressure conductor. In Proceedings of the IEEE Region 10 International Conference on Electrical and Electronic Technology, Singapore, 19–22 August 2001; IEEE: New York, NY, USA, 2002; Volume 2, pp. 664–668. [Google Scholar]

- Rikh, V.N. Conductor spacings in transmission lines and effect of long spans with steep slopes in hilly terrain. IE (I) J. 2004, 85, 8–16. [Google Scholar]

- McClure, G.; Lapointe, M. Modeling the structural dynamic response of overhead transmission lines. Comput. Struct. 2003, 81, 825–834. [Google Scholar] [CrossRef]

- Yan, B.; Lin, X.; Luo, W.; Chen, Z.; Liu, Z. Numerical study on dynamic swing of suspension insulator string in overhead transmission line under wind load. IEEE Trans. Power Deliv. 2009, 25, 248–259. [Google Scholar] [CrossRef]

- Diana, G.; Bruni, S.; Cheli, F.; Fossati, F.; Manenti, A. Dynamic analysis of the transmission line crossing “Lago de Maracaibo”. J. Wind. Eng. Ind. Aerodyn. 1998, 74–76, 977–986. [Google Scholar] [CrossRef]

- An, L.; Guan, Y.; Zhu, Z.; Zhang, R. Research on windage yaw flashovers of transmission lines under wind and rain conditions. Energies 2019, 12, 3728. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, Y.; Wang, B.; Li, Q.; Gao, Q.; Wan, Y. Research on Influencing Factors and Wind Deflection Warning of Transmission Lines Based on Meteorological Prediction. Energies 2024, 17, 2612. [Google Scholar] [CrossRef]

- Li, J.X.; McClure, G.; Wang, S.H. Ensuring the structural safety of overhead transmission lines by design. J. Aerosp. Eng. 2021, 34, 04021010. [Google Scholar] [CrossRef]

- Song, P.; Lang, X.; Zhang, S.; Yang, B.; Zhang, S.; Rong, K.; Tian, L. Study on windage response suppression of large-span transmission tower-line system using a spring-pendulum dynamic vibration absorber. Energies 2024, 17, 5638. [Google Scholar] [CrossRef]

- Chen, X.; Han, M.; Yang, X.; Wang, B. Stability Analysis of Parametric Vibration in Overhead Conductors Under Time-Varying Tension. Symmetry 2025, 17, 464. [Google Scholar] [CrossRef]

- Zhao, S.; Yue, J.; Savory, E.; Yan, Z.; Chen, J.; Zhang, B.; Peng, L. Dynamic windage yaw angle and dynamic wind load factor of a suspension insulator string. Shock Vib. 2022, 2022, 6822689. [Google Scholar] [CrossRef]

- Tripathi, A.N.; Verma, A.R. Assessment of Voltage and E-Field Distribution in Outdoor Composite Insulator in 500 kV System for Interface Defects. In Proceedings of the 2023 4th International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar Bali, Indonesia, 6–10 August 2023; IEEE: New York, NY, USA, 2023; pp. 304–308. [Google Scholar]

- Bao, H.; Xia, L.; Chai, S.; Cheng, Y.; Cao, S.; Lan, Z. Nonlinear Buckling Analysis and Optimization Design of the Y-Type Composite Insulator String. Adv. Civ. Eng. 2022, 2022, 4398388. [Google Scholar] [CrossRef]

- Fatima, K.; Shareef, H. Dynamic Bayesian Network Model for Overhead Power Lines Affected by Hurricanes. Forecasting 2025, 7, 11. [Google Scholar] [CrossRef]

- Goulioti, E.G.; Nikou, T.Μ.; Kontargyri, V.T.; Christodoulou, C.A. Smart-Grid Technologies and Climate Change: How to Use Smart Sensors and Data Processing to Enhance Grid Resilience in High-Impact High-Frequency Events. Energies 2025, 18, 2793. [Google Scholar] [CrossRef]

- Snaiki, R. Performance-based ice engineering framework: A data-driven multi-scale approach. Cold Reg. Sci. Technol. 2024, 224, 104247. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Zhang, C.; Yan, Z.; Zhang, X.; Zhang, B.; Dai, X. Extreme-Value Combination Rules for Tower–Line Systems Under Non-Gaussian Wind-Induced Vibration Response. Buildings 2025, 15, 1871. [Google Scholar] [CrossRef]

- Hou, H.; Zhang, Z.; Yu, J.; Wei, R.; Huang, Y.; Li, X. Damage prediction of 10 kV power towers in distribution network under typhoon disaster based on data-driven model. Int. J. Electr. Power Energy Syst. 2022, 142, 108307. [Google Scholar] [CrossRef]

- Qian, T.; Xie, Z.; Shi, W.; Shi, Z.; Tan, L. Investigation on the flow field characteristics of composite insulators under extreme wind loads. Eng. Fail. Anal. 2021, 129, 105699. [Google Scholar] [CrossRef]

- Qian, X.; Gao, Z.; Wang, T.; Wang, L.; Ke, S. Nonlinear aeroelastic response analysis of 100-meter-scale flexible wind turbine blades. Acta Aerodyn. Sin. 2022, 40, 220–230. [Google Scholar]

- Tian, C.; Tan, Z.Q.; Lu, X.L. Analysis of Wind Vibration Response of Large—Span Asymmetric Suspension Structures with Series Inerter Dampers. Appl. Math. Mech. 2025, 46, 310–323. [Google Scholar]

- Lou, W.-J.; Zhang, Y.-L.; Xu, H.-W.; Huang, M.-F. Jump height of an iced transmission conductor considering joint action of ice-shedding and wind. Cold Reg. Sci. Technol. 2022, 199, 103576. [Google Scholar] [CrossRef]

- Huang, G.; Yan, B.; Guo, Y.; Zhang, B.; Wu, G. Experimental study on dynamic response characteristics of isolated-span transmission lines after ice-shedding. High Volt. 2023, 8, 196–208. [Google Scholar] [CrossRef]

- Lu, J.; Wang, J.; Lu, Z.; Huang, Z.; Fan, L.; Wu, C.; Liu, X. Research on icing four-split wire-induced de-icing algorithm based on CR method. Chinese Journal of Computational Mechanics. Chin. J. Comput. Mech. 2024, 6, 1116–1123. [Google Scholar]

- Cai, S.; Liu, K.; Long, S.; Shen, P. Co-Rotational procedure for geometric non-linear finite element method of space truss. In Proceedings of the 13th National Conference on Structural Engineering (Volume I), Jinggangshan, China, 16–18 October 2004; Tsinghua University Press: Beijing, China, 2004; pp. 251–255. [Google Scholar]

- Chen, Z.T.; Fan, Q.S.; Wu, H.Y. Nonlinear motion analysis on 500kV compact line conductor. J. Tsinghua Univ. (Sci. Technol.) 1999, 12, 101–104. [Google Scholar]

- Crisfield, M.A.; Tassoulas, J.L. Non-Linear Finite Element Analysis of Solids and Structures: Essentials. J. Eng. Mech. 1993, 119, 1504–1505. [Google Scholar] [CrossRef]

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear Finite Elements for Continua and Structures; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Wei, S.T.; Zhao, C.; Sun, Q. Investigating the non-Gaussian property and its influence on extreme wind pressures on the long-span cylindrical roof. Appl. Sci. 2023, 13, 7691. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, T.; Yan, B.; Liu, M.; Van Phuc, P.; Shu, Z. LES study of topographical effects of simplified 3D hills with different slopes on ABL flows considering terrain exposure conditions. J. Wind. Eng. Ind. Aerodyn. 2021, 210, 104513. [Google Scholar] [CrossRef]

- Wu, K.; Yan, B.; Yang, H.; Lu, J.; Xue, Z.; Liang, M.; Teng, Y. Dynamic Response Characteristics of Isolated-Span Transmission Lines After Ice-Shedding. Power Deliv. IEEE Trans. (T-PWRD) 2023, 38, 12. [Google Scholar] [CrossRef]

| Span | Length (m) | Height Difference (m) | Theoretical Sag (m) | Computed Sag (m) | Error (%) |

|---|---|---|---|---|---|

| 1 | 500 | 50 | 15.8434 | 15.8441 | 0.00444 |

| 2 | 200 | 0 | 2.5276 | 2.5275 | −0.00336 |

| 3 | 700 | −100 | 31.2775 | 31.2776 | 0.00025 |

| Parameter | Value |

|---|---|

| Ground Roughness Index | 0.12 |

| Ground roughness length/(m) | 0.03 |

| Average wind speed at 10 m height/(m/s) | 15 |

| Start circular frequency/(rad/s) | 0 |

| Frequency Range/(rad/s) | 2π |

| Number of Frequency Points | 3000 |

| Time step/s | 0.5 |

| Total Simulation Time/s | 600 |

| Average Wind Speed (m/s) | Steady Wind Deflection Angle (°) | Pulsating Wind Avg. Deflection Angle (°) | Standard Deviation | Dynamic Amplification Factor (Calculated) | Dynamic Amplification Factor (Formula) | Error (%) |

|---|---|---|---|---|---|---|

| 13 | 27.28 | 27.32 | 2.25 | 1.183 | 1.186 | 0.3 |

| 15 | 35.80 | 35.81 | 3.48 | 1.214 | 1.251 | 3.1 |

| 17 | 45.83 | 45.85 | 4.94 | 1.237 | 1.293 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Lv, Z.; Zhang, B.; Wu, C.; Huang, Z.; Liu, X.; He, J. Research on the Influence of Span on Wind Deflection Angle of Insulator Strings in Stochastic Wind Fields. Symmetry 2025, 17, 1968. https://doi.org/10.3390/sym17111968

Liu G, Lv Z, Zhang B, Wu C, Huang Z, Liu X, He J. Research on the Influence of Span on Wind Deflection Angle of Insulator Strings in Stochastic Wind Fields. Symmetry. 2025; 17(11):1968. https://doi.org/10.3390/sym17111968

Chicago/Turabian StyleLiu, Guanghui, Zhongbin Lv, Bo Zhang, Chuan Wu, Zhan Huang, Xiaohui Liu, and Jinze He. 2025. "Research on the Influence of Span on Wind Deflection Angle of Insulator Strings in Stochastic Wind Fields" Symmetry 17, no. 11: 1968. https://doi.org/10.3390/sym17111968

APA StyleLiu, G., Lv, Z., Zhang, B., Wu, C., Huang, Z., Liu, X., & He, J. (2025). Research on the Influence of Span on Wind Deflection Angle of Insulator Strings in Stochastic Wind Fields. Symmetry, 17(11), 1968. https://doi.org/10.3390/sym17111968