1. Introduction

In recent years, prefabricated subway station structures have played an increasingly important role in modern urban rail transit construction due to their excellent waterproofing performance, shorter construction periods, and strong sustainability; thus, they have become a major driving force in promoting the development of urban infrastructure toward greater efficiency and environmental protection [

1]. The structural forms for prefabricated subway stations can be categorized into two types: assembly monolithic and assembly splicing structures. The novel assembly splicing subway station is a new type of structure that integrates prefabrication technology with the mechanical characteristics of composite structures. The structure is made up of prefabricated components that are produced by factories, quickly assembled on site, and assembly spliced with precast and cast-in-place concrete. However, soft soil areas are typically characterized by loose strata, low bearing capacity, and a propensity for seismic subsidence or liquefaction during earthquakes, which results in significant soil deformation and uneven stress distribution within structures, thereby markedly elevating the seismic risk that is associated with underground structures [

2]. While the assembly splicing subway station structure excels in construction efficiency and durability, its extensive use of prefabricated components for assembly results in a high number of joints with uneven stiffness distribution. Under seismic action, these joints are susceptible to becoming critical zones for stress concentration and damage progression, potentially compromising the seismic stability and energy dissipation capabilities of the entire structure [

3,

4]. Furthermore, the synergistic performance of the connection interface between prefabricated components and cast-in concrete under complex dynamic actions remains unclear. Hence, conducting systematic research on the seismic response of the assembly splicing subway station structures in soft soil holds immense significance.

The mechanical behaviors and failure mechanisms of prefabricated subway station structures under seismic action have attracted widespread attention from academia and engineering in recent years and have become a hot and cutting-edge field in seismic research of underground structures. Tao et al. [

5,

6] explored the dynamic response difference between a prefabricated station and a cast-in-place integral station. Ding et al. [

7] analyzed an arch prefabricated subway station under horizontal seismic excitation, and their research showed that the prefabricated structure had excellent mechanical properties and structural stability. Gao et al. [

8] demonstrated the considerable influence of the construction process on the seismic performance of prefabricated subway stations by establishing a three-dimensional nonlinear numerical model that considers soil–structure interactions. They found that neglecting the assembly process would lead to initial state deviations, resulting in significant calculation errors in the bending moment and axial force, highlighting the necessity of considering the complete construction sequence in seismic analysis. Yu et al. [

9] used prestressed steel strand joints instead of bolt joints to significantly improve the bending and shear stiffness of prefabricated subway station joints, effectively reducing structural deformation with a maximum vertical displacement reduction rate of 52% and a horizontal deformation reduction rate of 38%, and the greater the prestress and surface overload, the more significant the deformation suppression effect. Feng et al. [

10] proposed U-shaped rod-lap-joint technology for connecting the side walls and bottom plates of prefabricated subway stations. Their experiments showed that its tensile anchoring performance was equivalent to that of 90-degree hook bars, but under cyclic loading, it was prone to fracture in the bending zone, resulting in anchoring failure and a lower bearing capacity and ductility of prefabricated components than cast-in-place structures. Xiong et al. [

11] introduced and experimentally verified a new type of tenon bolt column end joint, which significantly improves the capacity and the bearing performance of prefabricated subway station columns under an axial compression ratio of 0.2–0.5. Integrated with finite element parametric studies, this work offers a robust theoretical and practical foundation for the implementation of dry-precast column connections in subway station construction. Liu et al. [

12,

13] conducted full-scale experiments to compare the mechanical properties of precast concrete internal joints using grouting sleeves, anchoring devices, and cow legs with cast-in-place specimens under low-cycle repeated loads. They proposed and validated a new connection method for optimizing the interface position of concrete slab cross-lap joints. The results showed that precast specimens can achieve the peak strength and deformation capacity of cast-in-place joints, but there are differences in ductility and failure modes. He et al. [

14] proposed and validated a new method for testing the seismic performance of underground prefabricated structures considering the effect of geological constraints, revealing that geological constraints can effectively improve the bearing capacity, energy dissipation capacity, and deformation recoverability of prefabricated side walls, but will reduce ductility and exacerbate shear and bending damage in the core area of the joint, significantly affecting its seismic performance and failure mode.

A large number of numerical simulations and experimental studies have shown that the seismic response of prefabricated structures differs significantly from traditional cast-in-place structures, mainly due to their unique joint distribution, connection methods, and discontinuous structural characteristics. Hong et al. [

15] constructed a mechanical performance monitoring and evaluation system for prefabricated underground stations based on distributed fiber optic sensing, and proposed a five layer armored fiber optic strain transfer model, established a layered performance evaluation framework and a theoretical building intelligent monitoring and evaluation model, and verified the system’s high-precision and high-resolution monitoring capabilities for the mechanical performance of large prefabricated components throughout the construction process, as well as its good adaptability and intelligence level, by combining it with the Shenzhen Metro project case. Jiang et al. [

16] established a calculation method for node bending stiffness and analyzed its influence on the deformation characteristics of prefabricated subway stations, revealing the significant impact of key factors, such as node position, geometric dimensions, soil parameters, and material density, on the uneven distribution of bending stiffness. Yang et al. [

17] explored the influence of auxiliary pre-tensioning devices on bending stiffness on the tension–compression side and established a bending stiffness calculation model while considering the coupling effect of axial force and the bending moment. Mo et al. [

18] demonstrated through ½-scale model experiments and finite element analysis that prefabricated steel-reinforced concrete entrance frames can effectively alleviate the stress concentration in the perforated area of subway station sidewalls, although cracks are more severe at the corners of the openings due to the SRC beam’s end torque. However, the study on the seismic damage of Dakai Subway Station in the Kobe earthquake shows that when large displacement deformation develops in the stratum, the underground structure may be seriously damaged [

19,

20]. Jiang et al. [

21] compared the dynamic response difference between the assembly monolithic structure and the cast-in-place station, and pointed out that the tenon joint of the flexible prefabricated station structure can produce opening deformation and release some internal forces, which has the effect of shock absorption to a certain extent. Chen et al. [

22] established a three-dimensional nonlinear finite element model that was based on the Beijing subway project. They evaluated the seismic behavior of prefabricated and cast-in-place underground structures, revealing that the plastic damage of the central column of the prefabricated structure was smaller, and the prefabricated structure significantly reduced the internal force of the column. Yang et al. [

23] studied the shear performance of grouted mortise and tenon joints through four-point pure shear tests, verified the applicability of the shear key method at zero axial force, proposed an improved shear key method for calculating the shear bearing capacity under various load conditions, and applied it to the Changchun Metro Line 2 project. Yu et al. [

24] studied the impact of different shock absorption and isolation measures for the assembly splicing structure, and found that isolation bearings improved the force transmission mechanism of station structures. Zheng et al. [

25] investigated underground structures with laminated rubber bearings and identified that the isolation bearings had an obvious effect on reducing the high-frequency acceleration response of structural members.

Although significant progress has been made in the mechanical performance, connection configurations, and construction techniques of prefabricated metro stations, considerable disagreement remains regarding the seismic response, and a unified understanding or systematic evaluation framework has yet to be established. Existing studies primarily focus on experimental analyses of individual components or local joints, or they rely on simplified models, seriously lacking systematic investigations into the overall dynamic response of full-scale prefabricated and segmentally assembled subway station structures under seismic excitation. Particularly for the emerging structural form of ASS, the initiation mechanisms, evolution pathways, dominant failure modes, and dynamic interaction mechanisms among the soil, structure, and joints under near-fault strong earthquakes have not been thoroughly revealed through high-fidelity, nonlinear numerical modeling. This gap in research scale hinders the accurate capture of global failure processes under complex interactions and limits a comprehensive assessment of the structure’s true seismic performance. Therefore, there is an urgent need for refined, system-level simulations to bridge the knowledge gap between “component-level behavior” and “overall structural response,” providing a foundation for developing science-based, performance-oriented seismic design methodologies.

To comprehensively evaluate and enhance the stability and seismic safety of assembled segmental metro station structures, this study focuses on the ASS implemented in a station project of Shenzhen Metro Line 15, Guangdong Province. Addressing the limitations of the existing research, the predominant focus on component-level analyses, and lack of in-depth investigations into the holistic dynamic failure mechanisms, this study aims to elucidate the complete process of damage evolution in ASS structures, from the initiation of local joint damage under realistic seismic excitations to global structural failure, clarify the influence of different ground motion characteristics on the response evolution path, and identify the key factors governing seismic performance. To this end, the two-dimensional nonlinear static-dynamic coupled finite element model incorporating soil–structure interactions has been developed. In the model, soil is represented using a constitutive model that captures nonlinear stress–strain behavior, while the structural components, including precast elements, joint connection zones, and cast-in-place segments, are meticulously modeled with material and contact nonlinearities to realistically simulate localized damage behaviors such as joint cracking and slippage and their impact on overall structural performance. To systematically assess structural responses under diverse seismic scenarios, three sets of representative real earthquake ground motion records, covering high, medium, and low-frequency characteristics, were selected as input excitations and were applied at the base of the model for nonlinear IDAs. By progressively increasing the intensity of the input motions, the dynamic response of the structure was systematically tracked throughout its evolution from the elastic stage to severe nonlinearity and approaching collapse. This process yields the response patterns of displacement, internal forces, and damage at critical locations, enabling the identification of vulnerable components and the dominant failure mechanisms. Through this comprehensively validated, high-fidelity numerical model, this study systematically reveals, for the first time, the complete damage evolution sequence and dominant failure mechanisms of ASS structures under near-fault strong earthquakes. Beyond validating general design principles, this research quantifies the threshold effects of key ground motion parameters on the structure’s nonlinear response and identifies potential vulnerability zones, such as cumulative slippage and stress concentration at specific joint regions that are often overlooked by conventional simplified analyses. These refined mechanistic insights and quantitative relationships not only deepen the understanding of the seismic behavior of ASS structures in soft soil regions but also provide essential theoretical foundations and data support for the performance-based seismic design and safety assessment of precast underground structures.

2. Numerical Model

2.1. Geometric Description of the Structure

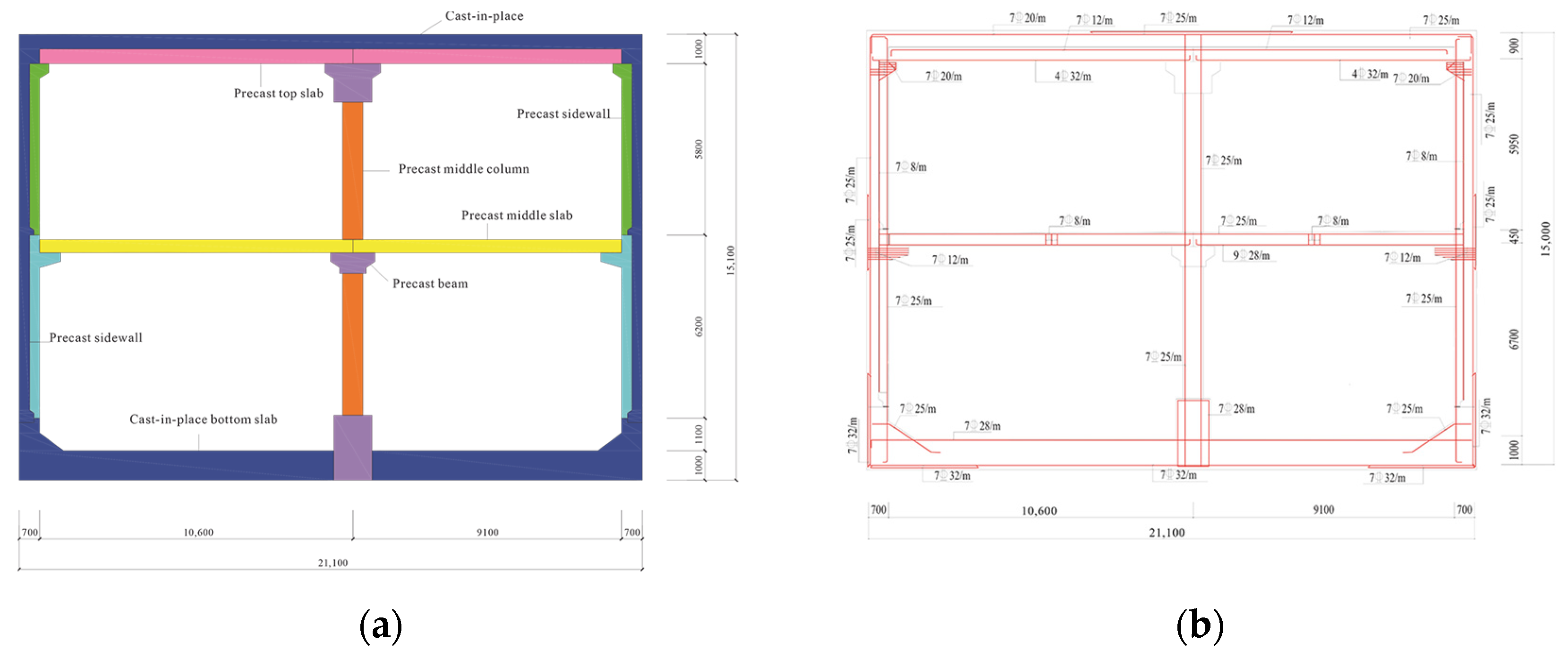

This study is based on the actual engineering design scheme of a subway station on Line 15 of the Shenzhen Metro in Guangdong Province. The station adopts the ASS system, which has typical wet–dry bonding characteristics. The main structure is a reinforced concrete frame system with two floors and two spans, and the plane layout is in an asymmetric form. The total horizontal span is 21.1 m, with a left span width of 11.3 m and a right span width of 9.8 m. The overall structural height is 15.1 m, and the soil thickness above the top slab is 3.5 m.

The ASS structure ingeniously combines the dual advantages of prefabricated assembly technology and cast-in-place concrete technology. The structural system primarily utilizes large prefabricated components manufactured in factories, enabling standardized production, high-precision processing, and rapid on-site installation, which can significantly enhance the construction efficiency and quality controllability. Additionally, the ASS structure significantly improves the self-waterproofing capability, effectively solving the leakage issues caused by improper handling of construction joints in traditional fully assembled stations. The middle column is made of prefabricated reinforced concrete components, with grouting sleeves embedded at the upper and lower ends. The connection between vertical components is achieved through non-shrinkage cement-based grouting material. The middle slab is made of prefabricated concrete, while the sidewalls are made of large prefabricated components with supporting structures, which are used to support the slabs and, together, form the main prefabricated skeleton. The bottom slab is made of cast-in-place concrete. In the horizontal structural system, both the sidewalls and the top slab adopt a composite structure of precast and cast-in-place composite layers; that is, a certain thickness of cast-in-place concrete layer is set on the surface of the prefabricated sidewalls and top slab. In key stress-bearing areas, a cast-in-place concrete post-pouring strip is set up to form a wet connection. All major structural joints in the horizontal direction are connected using two high-strength connection methods, namely, a concrete pouring strip or grouting sleeve connection. In addition, in order to improve the bonding strength of the concrete between prefabricated components, all joint contact surfaces were mechanically chiseled or surface roughened according to the specifications to form a rough interface that meets the standards.

Figure 1 shows the typical cross-sectional construction details of the ASS structure, including the geometric dimensions, division of the prefabricated and cast-in-place areas, and the steel bar arrangement scheme.

2.2. Establishment of Finite Element Model

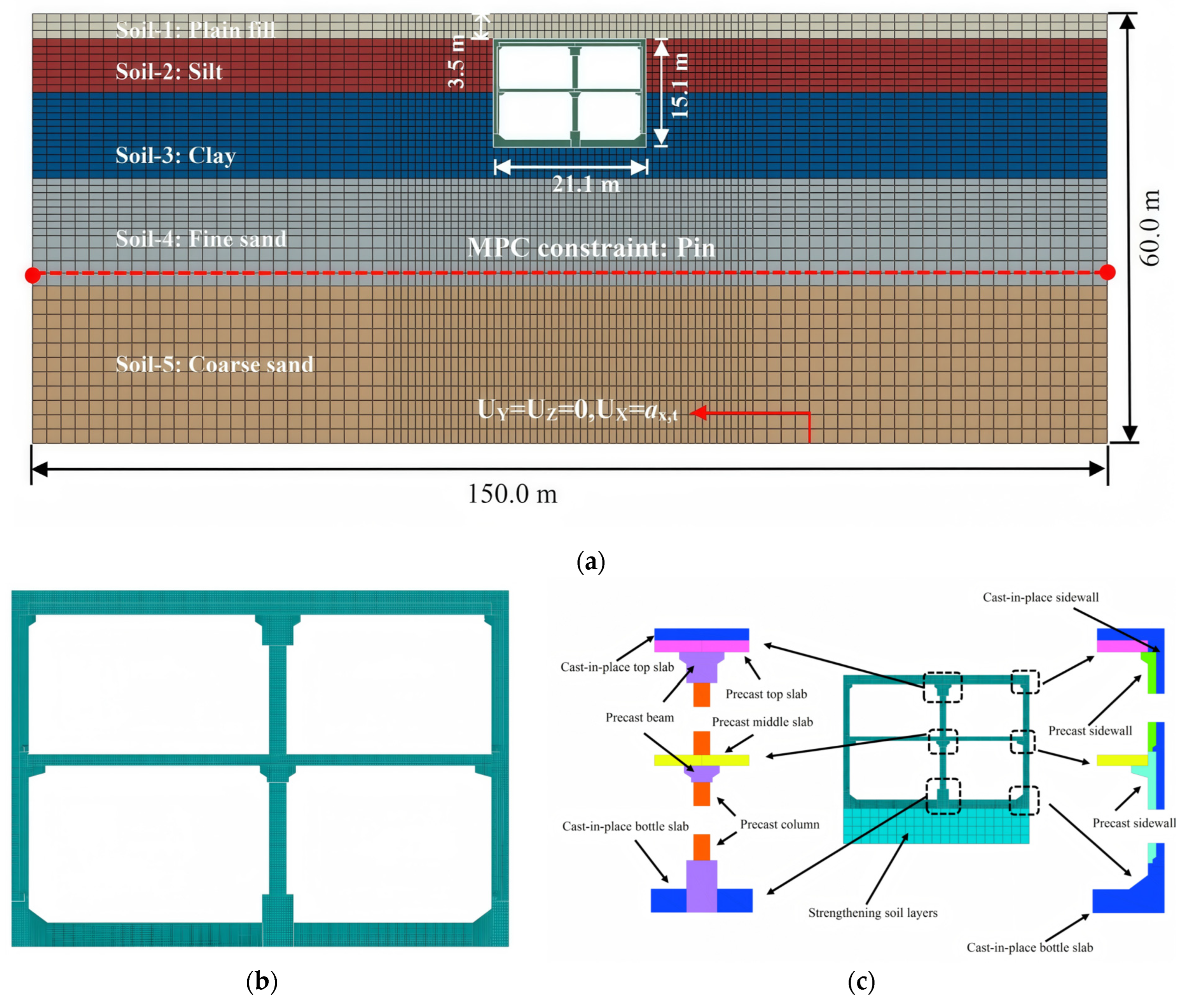

This study used the finite element analysis software ABAQUS 2024 to establish a two-dimensional plane strain finite element model of a rectangular subway station, considering soil–structure interactions, for conducting dynamic time history analysis. To reflect the structural characteristics of prefabricated structures, all prefabricated components in the model were defined as independent geometric parts to simulate the discontinuous mechanical behavior in the joint area in detail. In order to simulate the soil–structure interaction reasonably and minimize the reflection interference of artificial boundaries on seismic wave propagation, the model was fully extended in the horizontal direction. The distance between the left and right boundaries of the structure and the outer edge of the station is not less than three times the total width of the structure [

26,

27,

28]. The overall model has a horizontal span of 150 m, which meets the requirements of far-field boundary conditions. The vertical boundary extends from the surface (upper boundary) to a stable bedrock surface (lower boundary) at a depth of 60 m, fully covering all major soil layers where the subway station is located.

Figure 2 shows the finite element numerical model of the soil–structure system used in the dynamic time history analysis.

To ensure both computational accuracy and simulation efficiency, this study employs the CPE4R element, a 4-node plane strain quadrilateral with reduced integration and hourglass control for discretizing the soil and concrete segments. The use of reduced integration effectively mitigates shear locking under large deformations and plastic flow, while the hourglass control ensures numerical stability. This combination makes CPE4R particularly well-suited for capturing complex, inelastic mechanical behaviors and ensures robust convergence in modeling contact nonlinearities such as slip and separation at soil–structure interfaces. As a result, the element accurately represents the dynamic response characteristics during a seismic soil–structure interaction. For slender structural components such as rebars and embedded couplers, the B21 element, a 2-node linear beam element, was adopted. The element effectively simulates axial tension compression, bending stiffness, and the yield and post-yield hardening behavior of reinforcement. To achieve realistic composite action between steel and concrete, the “Embedded Region Constraint” technique was used to embed B21 rebar elements within the CPE4R concrete host elements. This approach automatically enforces displacement compatibility between the two materials, ensuring efficient stress transfer while still permitting controlled relative slip. Consequently, it realistically captures the bond–slip effect, particularly in regions that are prone to cracking and interface degradation. The synergistic use of CPE4R for bulk materials and B21 for embedded reinforcement enables a computationally efficient yet physically accurate simulation of the coupled nonlinear behavior in prefabricated underground structures, including material degradation, interface interaction, and the overall system-level seismic response [

29,

30].

The size of the soil elements was determined based on the wave propagation criterion proposed by Kuhlemeyer and Lysmer [

31]. The criterion requires that the size of the finite element mesh is sufficiently small, such that each wavelength in the wave propagation direction contains at least 8 to 10 elements, thereby ensuring the accuracy of the structural response at the highest analysis frequency. The equation of the criterion can be expressed as

where

hmax is the maximum grid size of the element,

fmax is the maximum shear frequency of ground motion, and

νs is the maximum shear wave velocity.

According to Equation (1), the maximum allowable soil element size was calculated to be 2.42 m. To strike a balance between computational accuracy and solution efficiency, in the key influence areas surrounding the subway station structure and within the soil–structure interaction region, the soil elements were further refined to a grid of 1 m × 1 m. In the lateral and bottom far-field areas that are farther away from the structure, due to the smaller seismic response gradient, the stress wave energy has significantly attenuated, and its impact on computational accuracy is relatively limited. Therefore, the soil element size is gradually transitioned and expanded to 2 m × 2 m. In addition, to ensure the precise capture of the mechanical responses in key structural components, particularly the stress concentration in joint areas, as well as damage evolution behaviors, the finite element mesh size of the structure itself was strictly controlled. The maximum mesh size of the structure was set to 0.1 m. The mesh sensitivity analysis was conducted to ensure the independence of the results from mesh discretization. Comparisons of the maximum inter-story drift ratio and peak bending moment under PGA = 0.4 g excitation showed that further refinement beyond the current mesh density resulted in changes of less than 2.5%, confirming that the selected mesh provides a converged solution.

2.3. Material Properties

The combination of the viscoelastic–plastic model and the Mohr–Coulomb yield criterion is widely used in numerical simulations of geotechnical engineering to accurately describe the complex nonlinear mechanical behavior of soil under static and dynamic action [

32,

33]. Then, the viscoelastic–plastic model can comprehensively reflect the elastic deformation, plastic yield, strain hardening, and time-dependent viscous effects of soil, effectively determining the yield and failure conditions of soil under complex stress states. The equation of the Rayleigh damping parameter for the soil layer can be described as

where

ξi is the damping ratio,

ωi is the natural vibration period,

α is the mass damping coefficient, and

β is the stiffness damping coefficient.

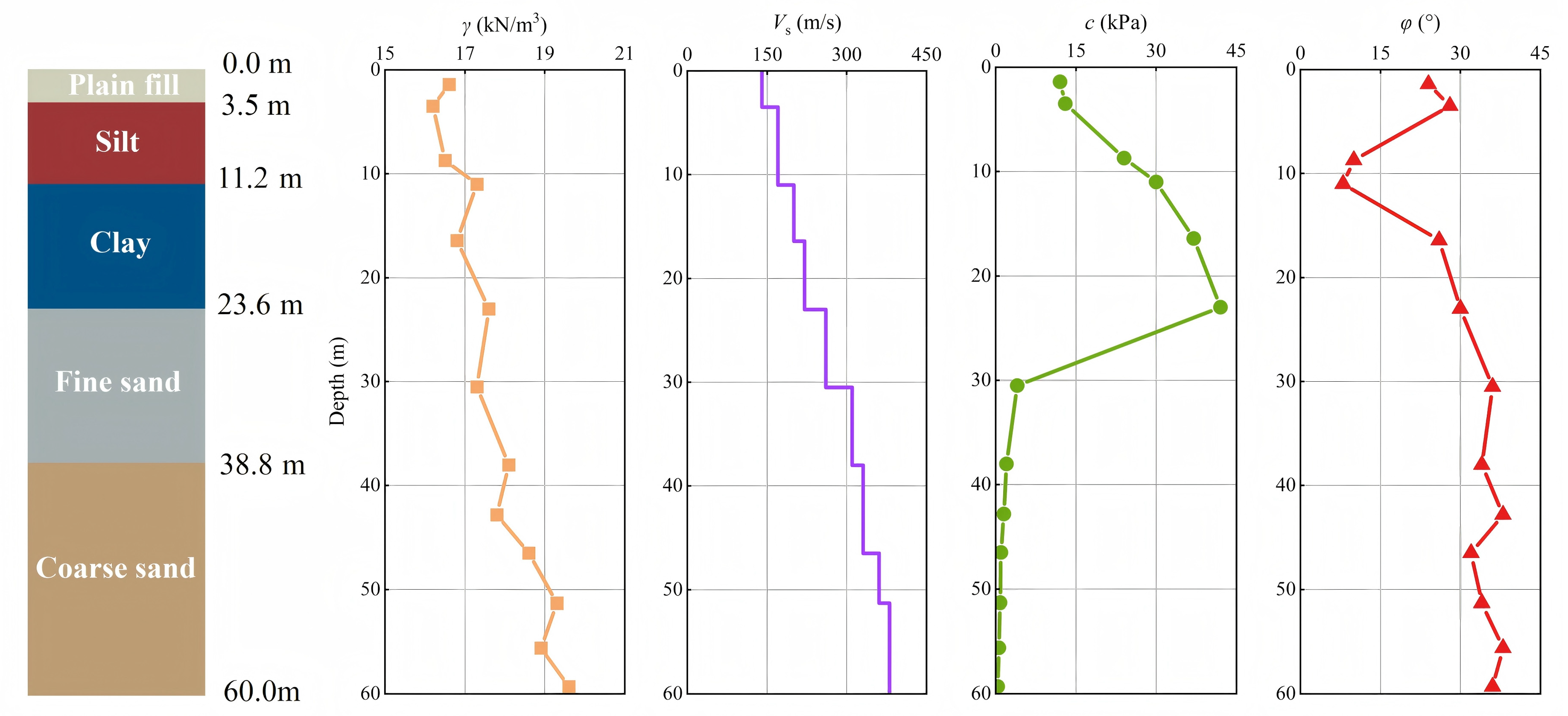

According to geological exploration data, the subway station is located in a typical soft soil site with a complex soil layer distribution, which can be generally divided into five main geological strata. Based on the research results on the mechanical behavior of soft soil in references [

28,

34], combined with the site geological survey report and relevant engineering experience, the basic physical and mechanical parameters of the soft soil used in this study were finally determined.

Figure 3 shows the detailed information on the soil stratum. Where

Vs is the shear wave velocity of the soil,

γ represents the gravity,

c,

φ, respectively, represent cohesion and the friction angle.

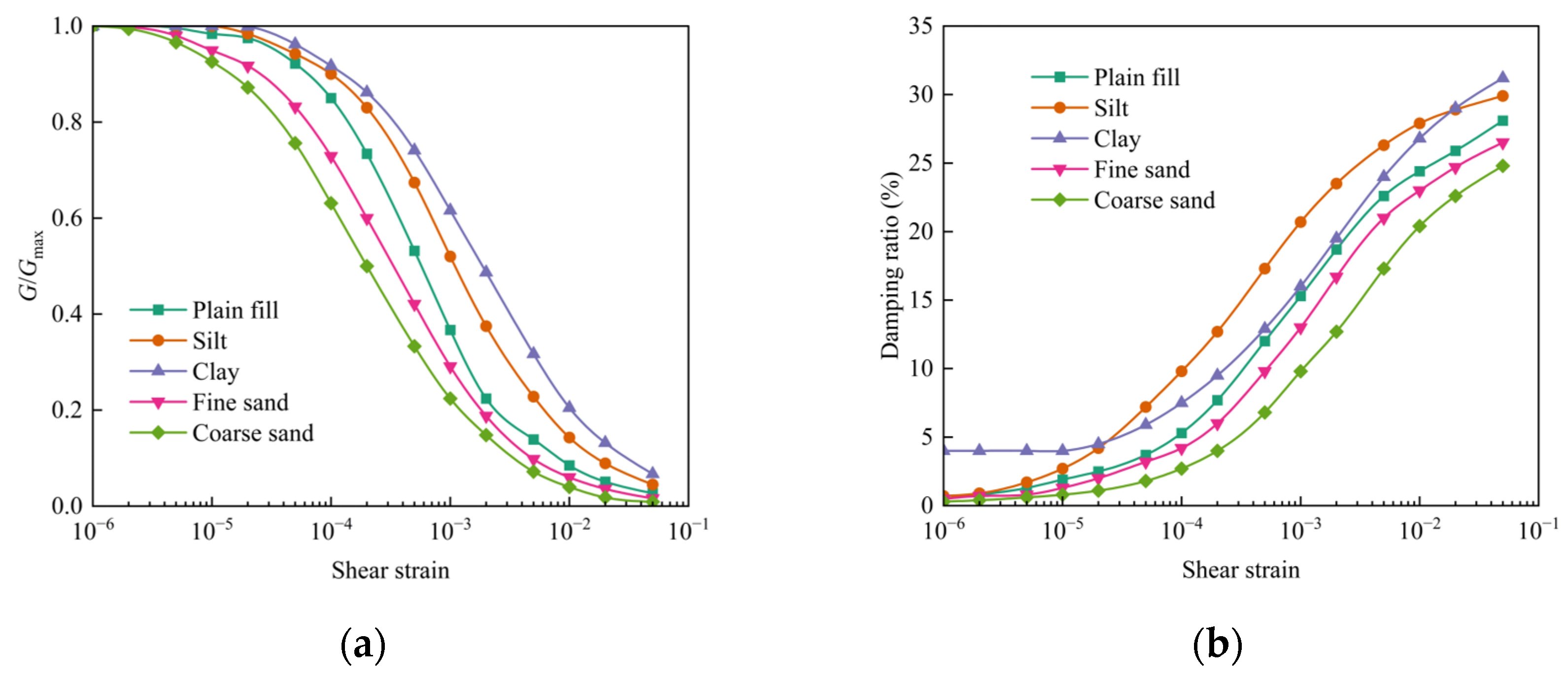

To accurately simulate the nonlinear dynamic response characteristics of soft soil stratums under seismic action, this study used the equivalent linearized seismic response analysis program EERA [

35] to conduct a seismic response analysis of a one-dimensional horizontal layered system of soil stratums at the site. By inputting the dynamic time history that conforms to the regional seismic characteristics and considering the strain dependence of the soil, EERA calculated the strain-compatible equivalent shear modulus ratio G/Gmax and equivalent damping ratio. The process is based on the equivalent linearization assumption, iteratively solving until the shear modulus of each element of the soil stratum matches the calculated shear strain phase, thereby obtaining dynamic parameters that are suitable for the actual strain level, effectively reflecting the stiffness degradation and energy dissipation characteristics of the soil under strong earthquakes. On this basis, referring to the recommended equivalent stiffness calculation method in the Federal Highway Administration (FHWA) Seismic Design Guidelines [

36], the values obtained from the EERA analysis are reasonably mapped to the soil elements in the two-dimensional finite element model to correct the initial shear modulus of each soil stratum, ensuring that the soil exhibits nonlinear stiffness evolution behavior that is consistent with the actual seismic response in the dynamic analysis. When constructing a two-dimensional soil–structure interaction finite element model, the modified shear modulus is combined with the Mohr–Coulomb elastoplastic constitutive model to describe the nonlinear stress–strain relationship of soil. This model can reasonably capture the stiffness degradation, cumulative plastic deformation, and lateral displacement development of soil during earthquakes.

Figure 4 shows typical curves of the shear modulus ratio G/Gmax and damping ratio changes of the soil layers used, which are determined based on field soil sample test data and are referenced to standardized models of typical soils. The soil modeling method, combined with EERA one-dimensional analysis and two-dimensional finite element equivalent parameter input, has been widely validated and successfully applied in multiple seismic studies of underground structures [

37,

38].

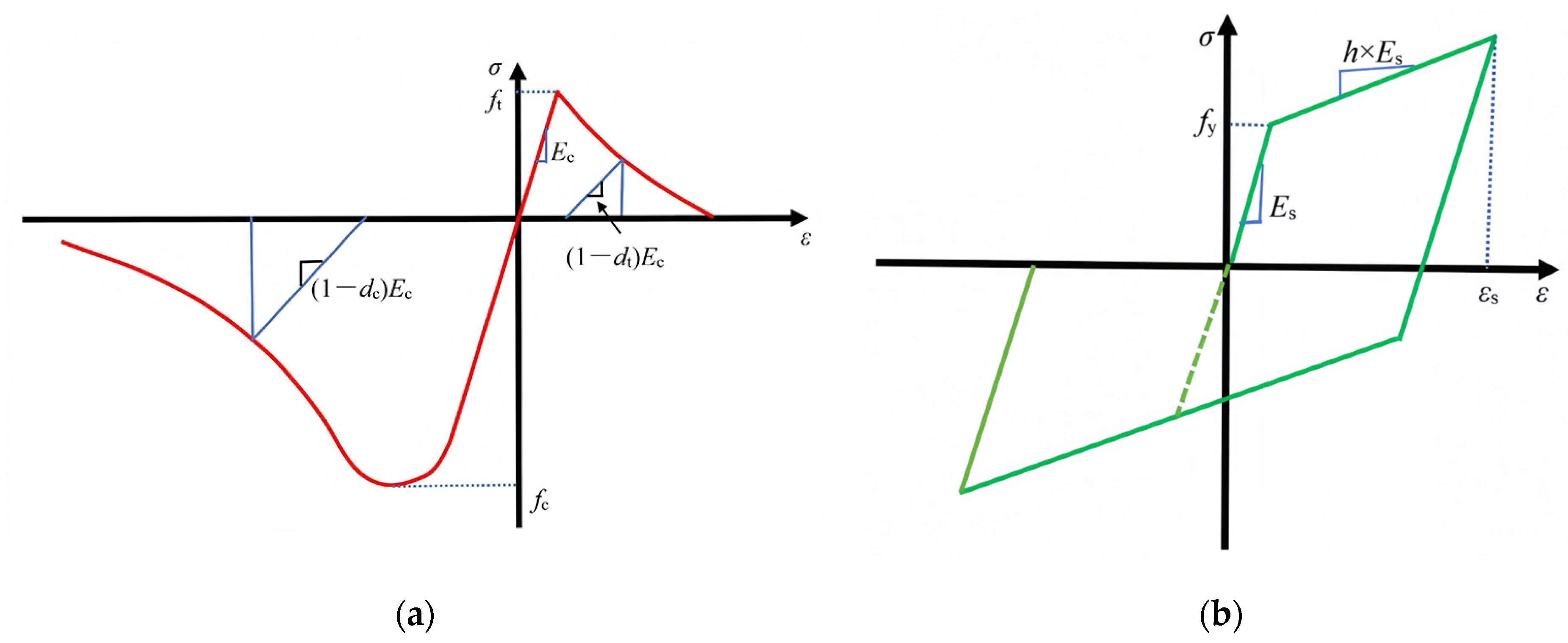

The improved concrete damaged plasticity model (CDP) was employed to describe the nonlinear mechanical behavior of structural components under complex stress states [

39,

40]. The CDP model, which is based on the work of Lubliner et al. [

41], was adopted to simulate the inelastic behavior of concrete under cyclic loading. The model can effectively simulate the stiffness degradation, strength attenuation, and energy dissipation characteristics of concrete during tensile cracking and compressive crushing, making it particularly suitable for structural response analysis under seismic action [

42]. The bilinear stress–strain model was used to simulate the steel bar. All components of this study are made of C50, with HRB400 steel bars embedded in concrete units. The material physical characteristic parameters of C50 are presented in

Table 1 and

Table 2. The elastic modulus

Es of the steel bar is 200 GPa, the yield stress

fy is 400 Mpa, and the ultimate strain

εs is 0.17. To emphasize the initial elastic response characteristics under seismic action, and to streamline the impact of plastic deformation in non-critical areas on the overall analysis, the bolt and sleeve materials adopt the elastic-perfectly plastic model. This model postulates that the material exhibits fully elastic behavior until the stress attains the yield strength, characterized by a linear stress–strain relationship; upon reaching the yield stress, it transitions into the plastic phase, allowing strain to progress further while stress remains constant. The material behavior models adopted for concrete and steel bars are shown in

Figure 5.

2.4. Boundary and Contact Settings

To accurately simulate the dynamic response of a soil–structure system under seismic action, this study adopts a two-stage numerical analysis method to systematically realize the entire process from static initial state establishment to a dynamic response solution. In the first stage, static stress balance analysis was carried out by applying normal displacement constraints on the lateral boundaries on both sides of the model, completely fixing the bottom boundary, and only considering the gradual loading of soil and structural self weight so that the system gradually reaches a stable initial stress state; thus, truly reflecting the in situ stress distribution of the site before the earthquake. When entering the second stage of dynamic time history analysis, a dynamic reconstruction of the boundary conditions was carried out to more reasonably simulate the propagation mechanism of the seismic waves. The original horizontal normal constraint has been replaced with a node-to-node multi-point constraint (MPC), set as a “pin”-type connection, allowing boundary nodes to slide freely in the vertical direction while maintaining displacement coordination in the horizontal direction. This MPC technology couples the horizontal displacement of nodes with the same y-coordinate on the left and right boundaries with the corresponding free-field reference nodes, effectively achieving free-field boundary conditions, significantly reducing non-physical reflections of seismic waves on the lateral boundary, and improving the simulation accuracy of wave-field propagation. At the same time, the x-direction degrees of freedom of the bottom boundary are released to allow for the free input of horizontal shear waves. Horizontal seismic motion is in the form of vertically incident shear waves and is applied upwards from the bottom of the model through a specified acceleration time history curve, simulating the physical process of seismic waves propagating from bedrock to the surface. This two-stage analysis method, combined with a reasonable load application path and advanced boundary treatment techniques, has been validated in multiple seismic response studies [

43,

44,

45].

The prefabricated subway station structure is assembled on-site from numerous components prefabricated in the factory, and its overall mechanical performance heavily relies on the force transmission mechanism in the joint area. This transmission mechanism primarily consists of three key components working synergistically. Firstly, it involves the direct transmission of tensile and compressive stress through steel bars that penetrate the joints, exerting the “force transmission rod” effect. Secondly, it utilizes the mechanical interlocking formed by keyways, concave–convex tenons, or shear keys set at the ends of prefabricated components to provide shear bearing capacity—known as the shear key mechanism. Thirdly, the bonding force that is generated between the contact surfaces of the prefabricated components by post-poured high-strength cement-based grouting material or interface mortar effectively transmits shear stress and suppresses interface slip. In numerical simulations, the continuous force transmission of steel bars and the geometric fitting effect of keyway or mortise and tenon structures are accurately reproduced through refined finite element geometric modeling. However, the bonding performance between interfaces is influenced by various factors, and the high uncertainty of interface bonding strength makes the joint area a critical weak link in structural analysis, significantly impacting overall stiffness, deformation coordination, and seismic performance. Therefore, in the analysis, interface properties based on contact algorithms are used for refined characterization.

In finite element analysis, the “pin action” of steel bars and the mechanical shear transfer effect of keyway or mortise and tenon joints are typically achieved by accurately modeling their geometric features in order to capture the local stress transfer mechanism in the joint area. To strike a balance between computational efficiency and engineering practicality, this study employs the “Surface-to-Surface” contact algorithm to simplify the modeling of structural joint interfaces. Furthermore, it sets the most unfavorable bonding state, assuming that relative slip or complete separation may occur between the contact surfaces of prefabricated components. This approach can evaluate the performance degradation trend of the structure under seismic action [

46]. In this framework, the normal behavior of the contact surface is defined as “Hard Contact”, allowing the interface to freely separate under tension but maintain contact and transmit pressure under compression. This accurately reflects the extremely low tensile strength characteristic of concrete materials. The tangential behavior is simulated based on the Penalty Method combined with the Coulomb friction model, using a friction coefficient of 0.8 [

47]. The starting conditions for relative displacement are controlled by slip tolerance parameters, reasonably reflecting the nonlinear degradation process of the interface’s shear transmission capacity. It should be noted that in actual ASS, due to measures such as post-pouring grouting, interface treatment, and steel reinforcement anchoring, the joint bonding strength is usually higher than that of the idealized model assuming complete slip, but it is lower than the continuous state of complete integral casting. Additionally, to simulate the interaction between soil and a structure, a “surface-to-surface” contact pair is defined between the outer surface of all structures and the surrounding soil, with the soil side designated as the “primary surface” and the structure side as the “secondary surface”, using a friction coefficient of 0.4 [

48]. The frictional behavior follows a Coulomb-type yield criterion, consistent with established practices in geotechnical interface modeling [

49].

2.5. Selection of Ground Motions

To comprehensively evaluate the dynamic response and seismic performance of an assembly splicing subway station structure under different seismic characteristics, three sets of representative ground motion records were selected from the PEER NGA West 2 database [

50]. The seismic records are from the Loma Prieta, Imperial Valley-06, and Chi-Chi earthquake events, each possessing unique spectral characteristics and intensity levels, effectively covering different types of seismic inputs. The detailed information of the three records is represented in

Table 3.

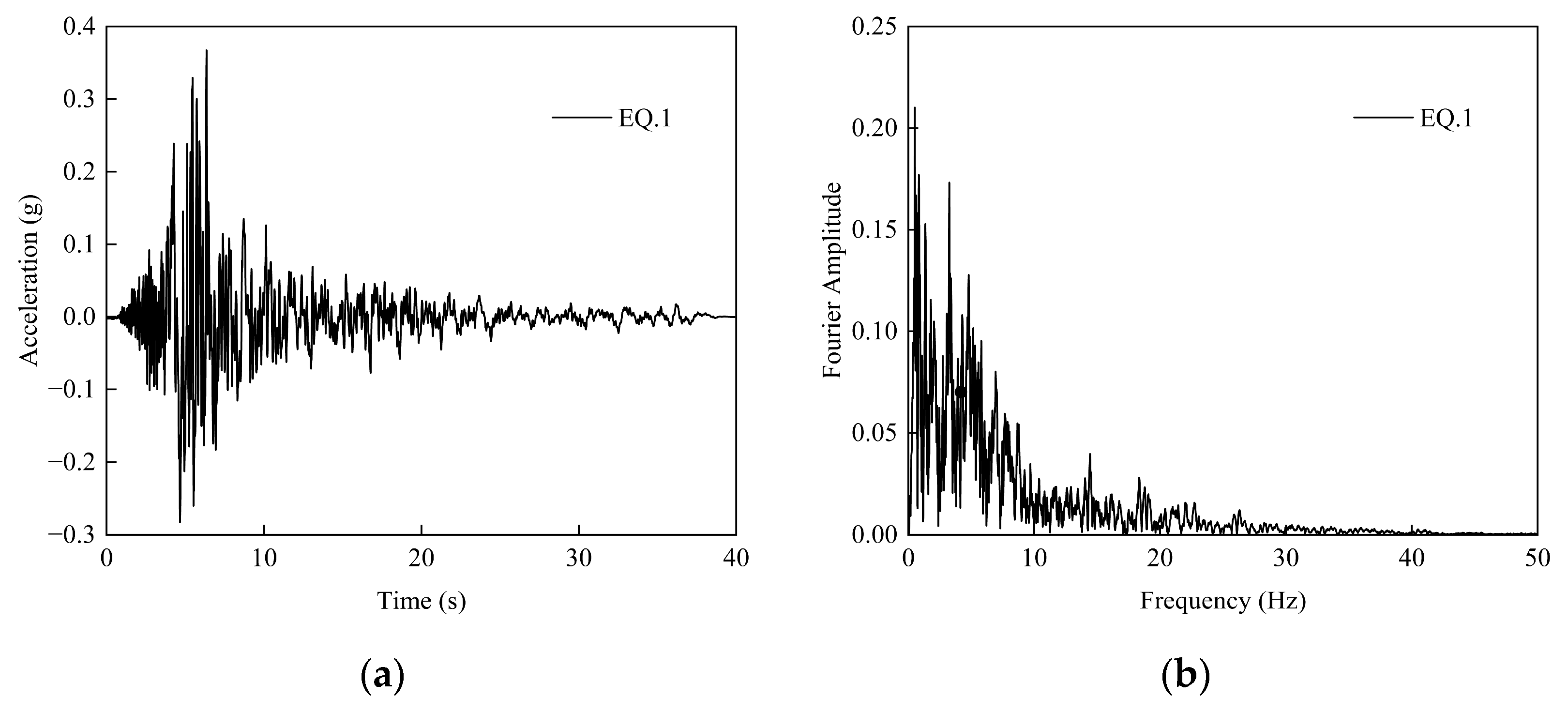

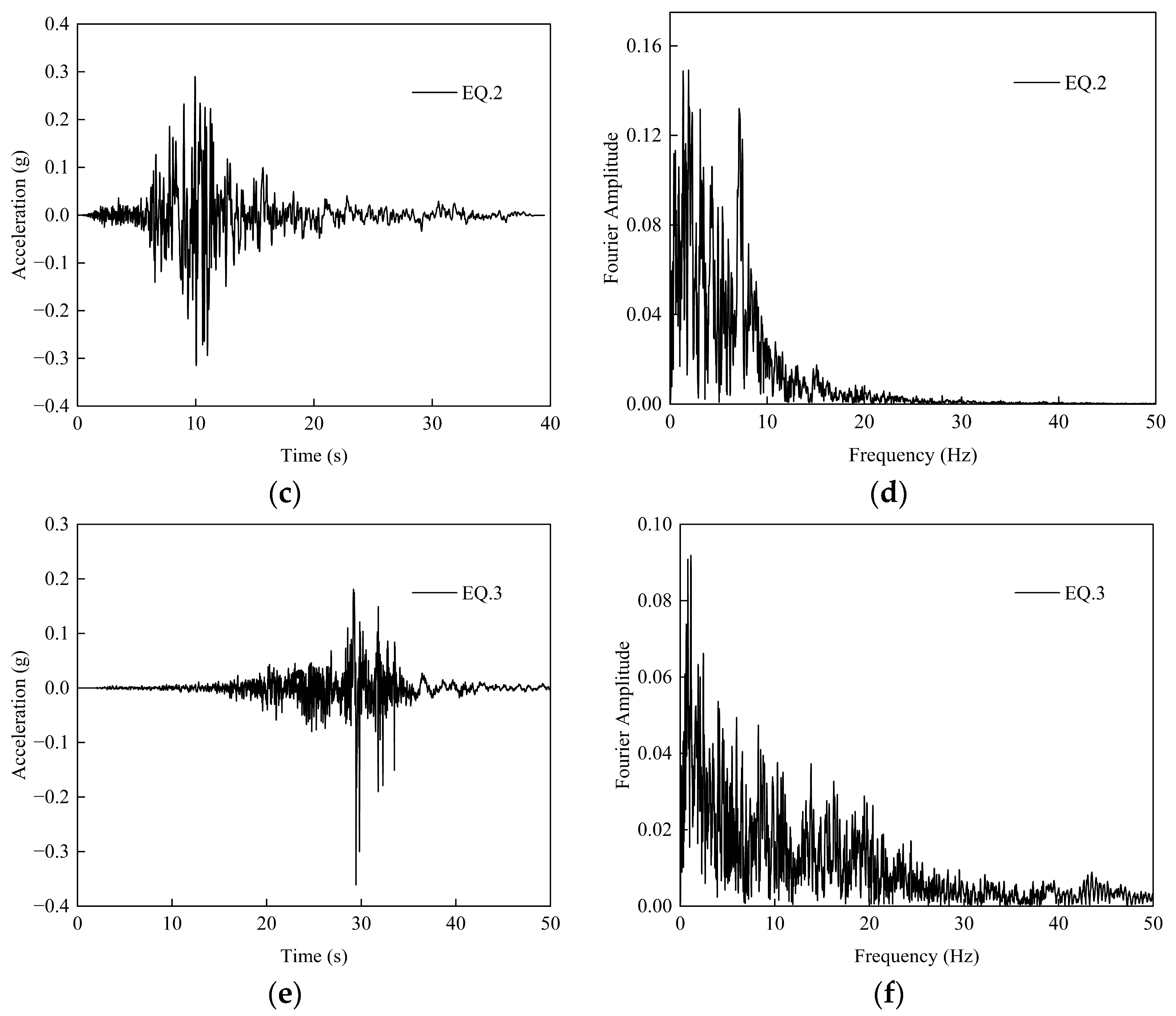

Given the pronounced sensitivity of subway station structures to seismic activity, particularly the significant displacement responses that are triggered by velocity pulse effects and high-frequency energy concentration, the three sets of seismic records chosen in this study are all representative of typical characteristics and high peak ground velocities (PGV), effectively simulating the nonlinear dynamic behavior of underground structures during intense earthquakes. To systematically study the seismic response of structures under varying earthquake intensities, the peak ground acceleration (PGA) of all seismic motions was uniformly adjusted to four levels: 0.1 g, 0.2 g, 0.3 g, and 0.4 g, each corresponding to a distinct level of seismic intensity.

The vibration frequency characteristics can be indirectly reflected by obtaining the ratio of PGA to PGV [

51]. When the ratio of PGA to PGV is greater than 1.2, ground motions are classified as high-frequency earthquake motion; When the ratio of PGA to PGV is between 0.8 and 1.2, ground motions are defined as intermediate-frequency ground motions. When the ratio of PGA to PGV is less than 0.8, ground motions are considered as low-frequency ground motions. By calculation, the PGA/PGV of EQ.1 is equal to 0.75, the PGA/PGV of EQ.2 is equal to 1.01, and the PGA/PGV of EQ.3 is equal to 1.67. The selected input ground motions in this work have low-, medium-, and high-frequency vibration characteristics, respectively.

Figure 6 presents the vibration characteristics under three ground motion records.

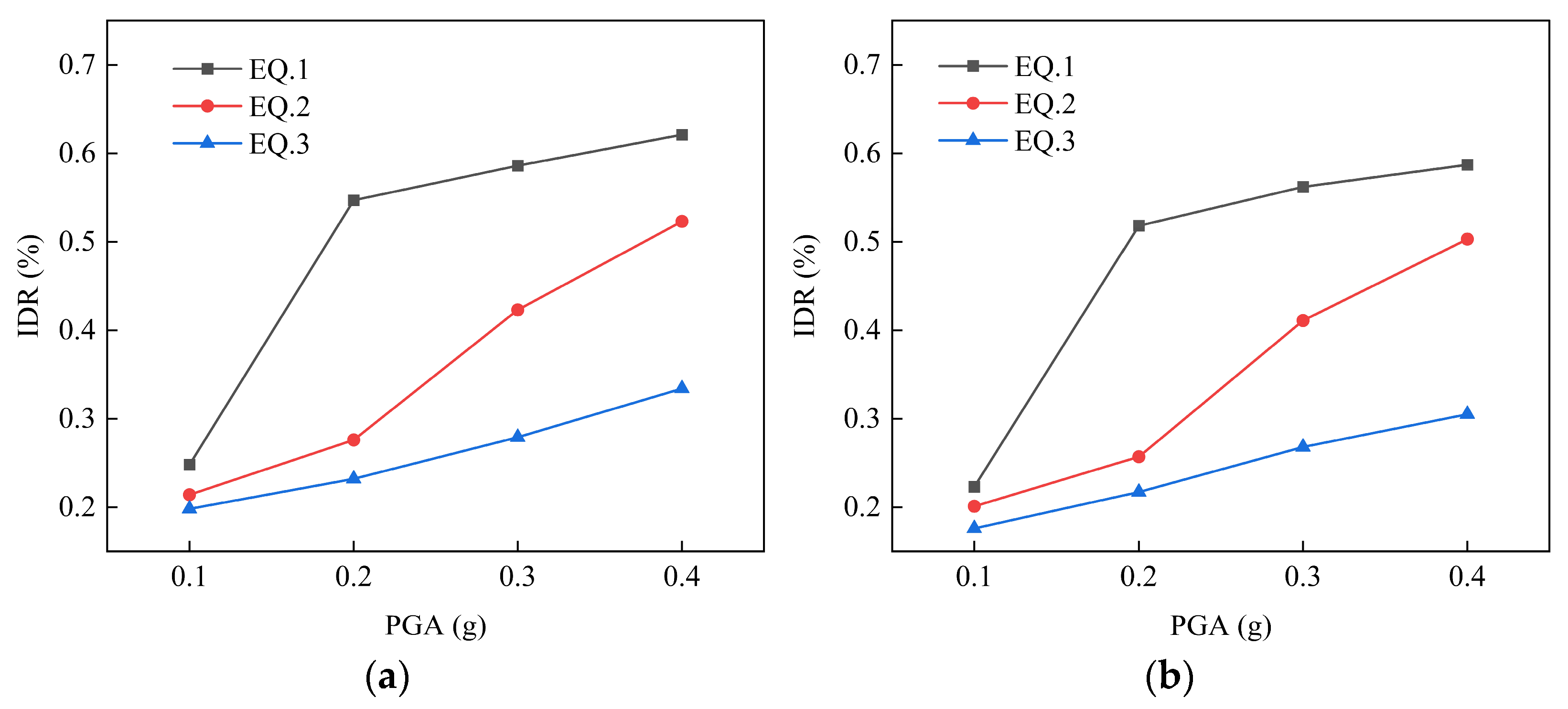

To assess the influence of the frequency characteristics of the selected ground motions on structural response, the PGA/PGV ratio for each record was calculated—a commonly used indicator of the dominant period or frequency content of ground motions. The analysis reveals that, even at the same PGA, structural responses vary significantly across different ground motions, primarily due to the differences in the frequency content. For instance, ground motions with higher PGA/PGV ratios are more likely to excite higher-order modes of the structure, leading to concentrated responses in the upper portions. In contrast, ground motions with lower PGA/PGV ratios may induce more uniform or deeper responses, particularly posing greater risks to long-period structures. This indicates that a structural seismic response depends not only on the magnitude of PGA but is also strongly influenced by the spectral characteristics of the ground motion. Furthermore, by scaling the motions across multiple PGA levels, the complete evolution path of the structure from elastic behavior to nonlinearity and progressive damage accumulation can be clearly identified. The IDA approach, based on multiple real seismic records, effectively reduces the potential bias arising from using a single or a few artificial waves, thereby enhancing the robustness and reliability of the conclusions.

4. Impact of Splicing Interface on the Seismic Response

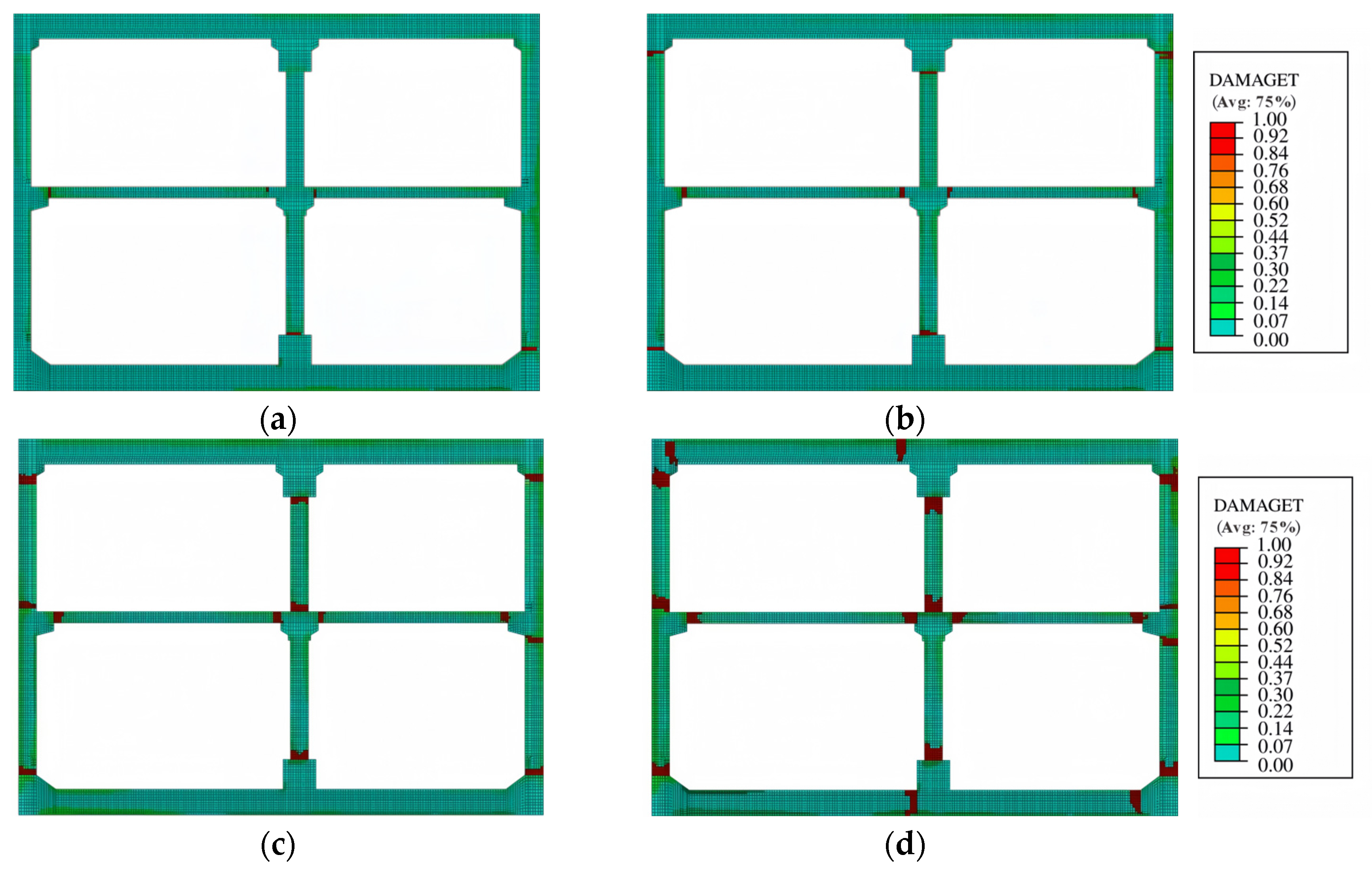

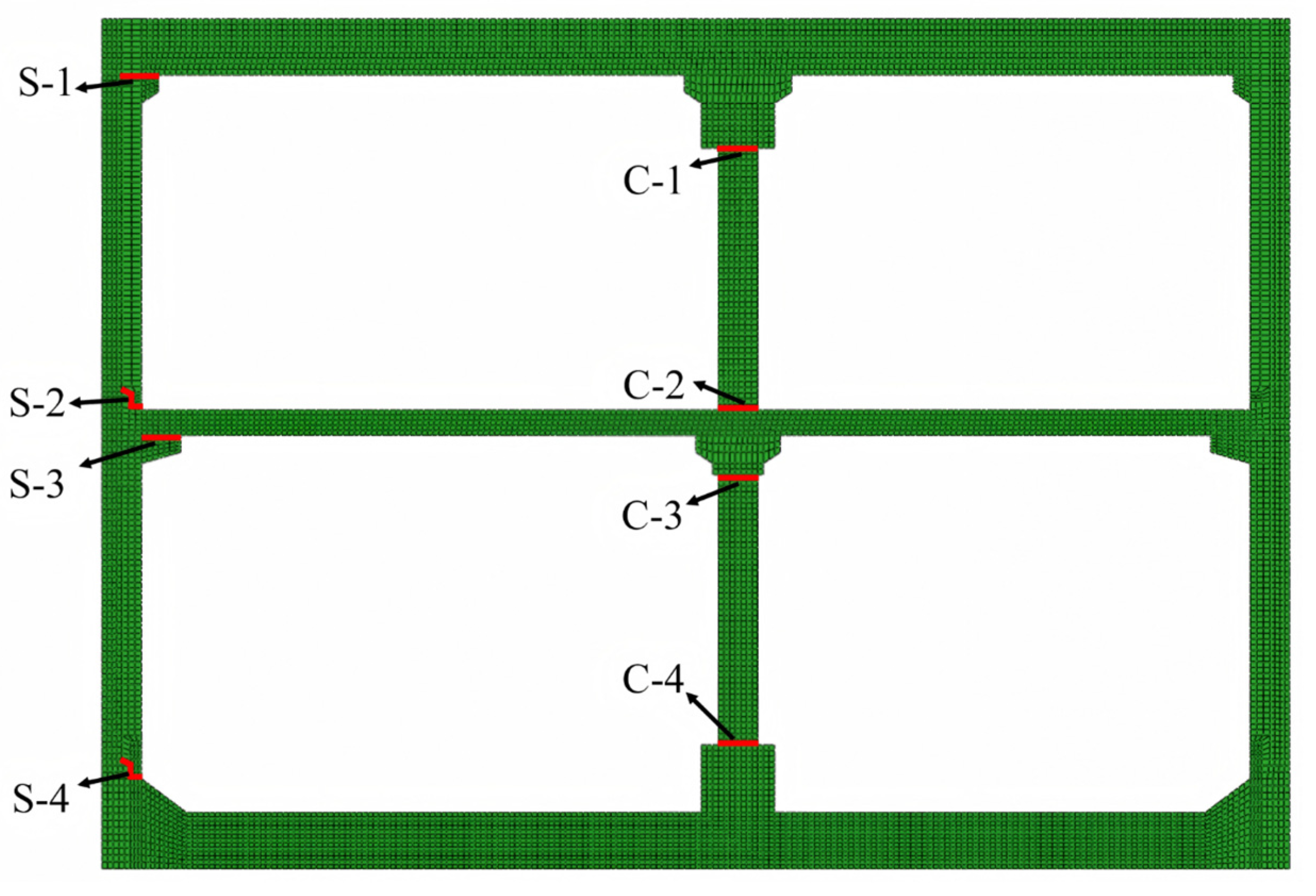

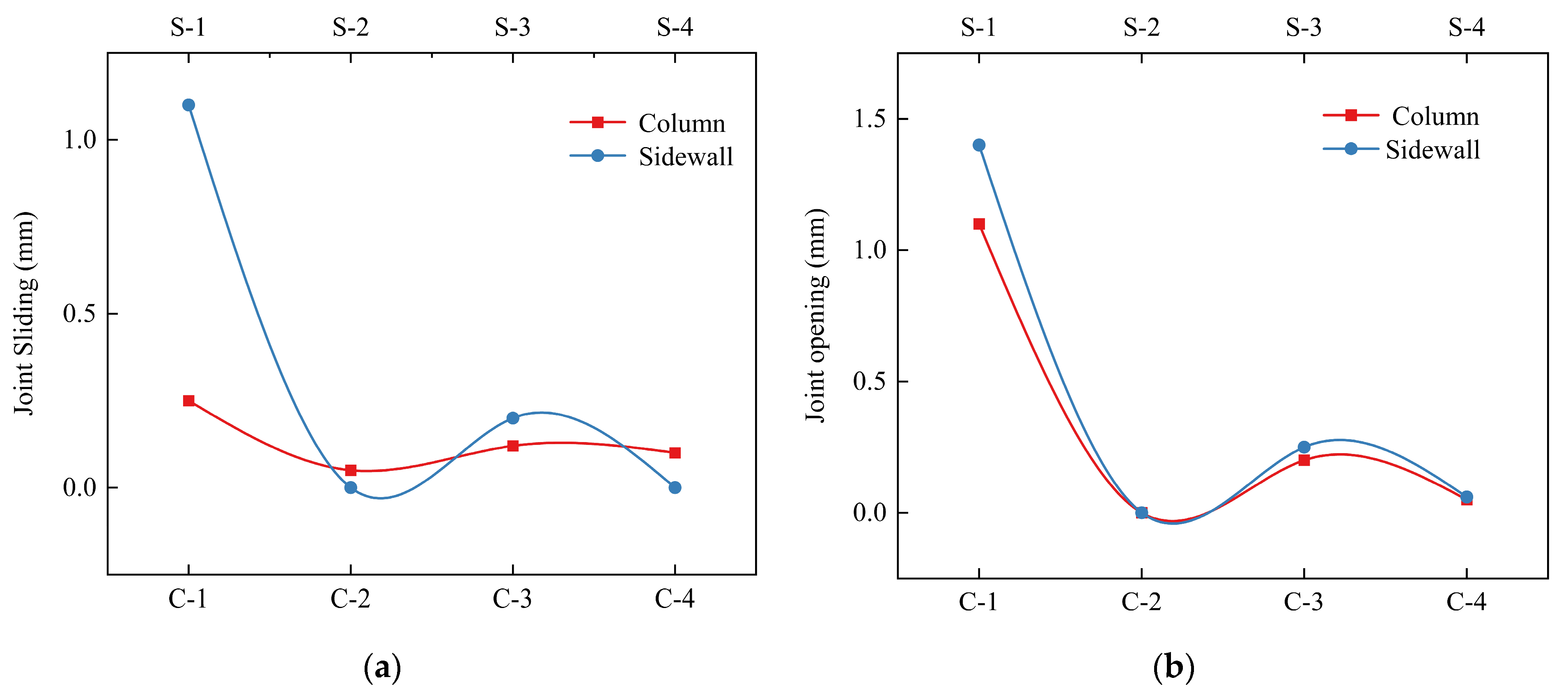

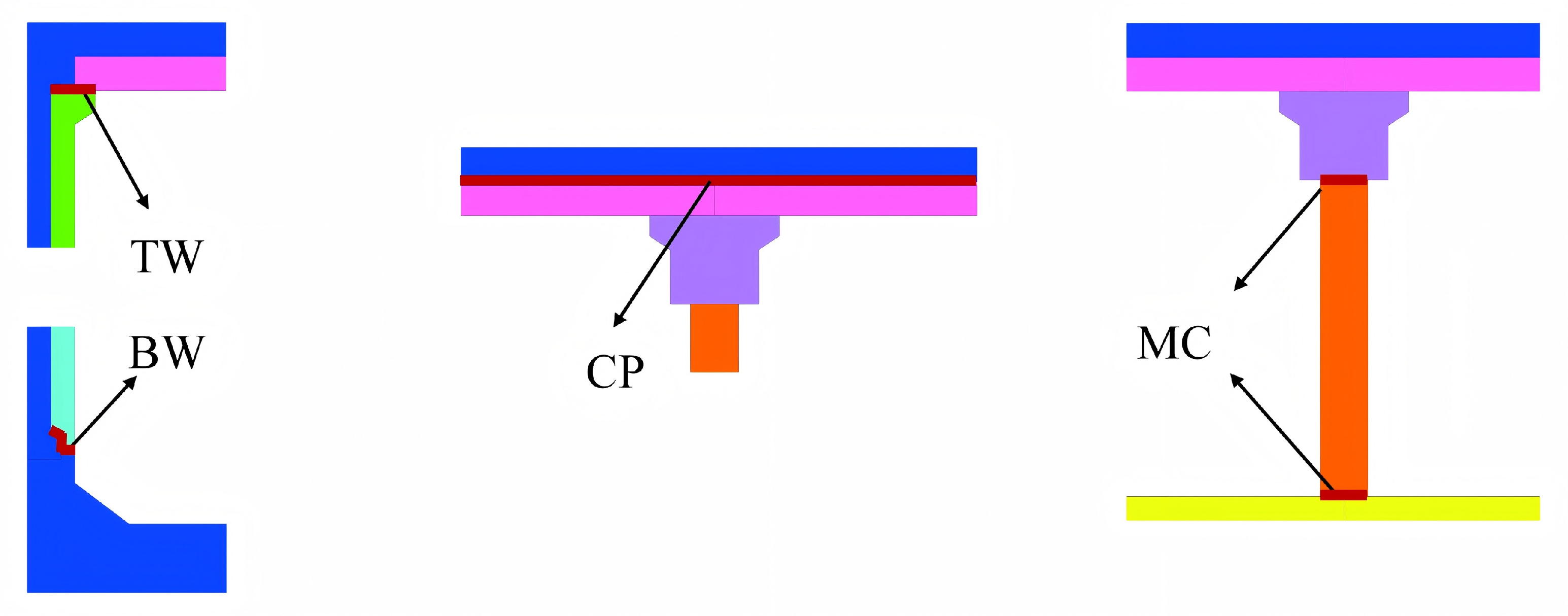

The splicing interface, as a crucial connecting part among assembly splicing structural components, is a core link in the structural force transfer path. To deeply reveal the impact of the splicing interface on the seismic response of the structure, this study adopts two types of contact settings, namely “Surface-to-Surface contact” and “Tie contact”, to simulate the actual mechanical behavior of the splicing interface. This study systematically controls the contact characteristics of component splicing interfaces and deeply explores the mechanism of how splicing interfaces affect the overall interlayer deformation mode and internal force distribution of underground structures under seismic action, as shown in

Figure 11. Where TW represents the splicing interface at the top of the sidewall, BW represents the splicing interface at the bottom of the sidewall. CP represents the splicing interface between cast-in-place and prefabricated components, and MC represents the splicing interface at the end of the column. Six different contact setting methods for splicing interfaces were introduced into the numerical model, comprehensively considering various typical working conditions of nonlinear contact when PGA = 0.4 g. The results are listed in

Table 5. Where T-interface represents the case that the contact form of the component splicing interface at a certain location is set to “Tie contact”; “T” represents “Tie contact”; “S” represents “Surface-to-Surface contact”, and “A” represents all splicing interfaces. Additionally,

u is the interlayer displacement, and

η is the ratio of the IDR of each case to the IDR of the T-A case.

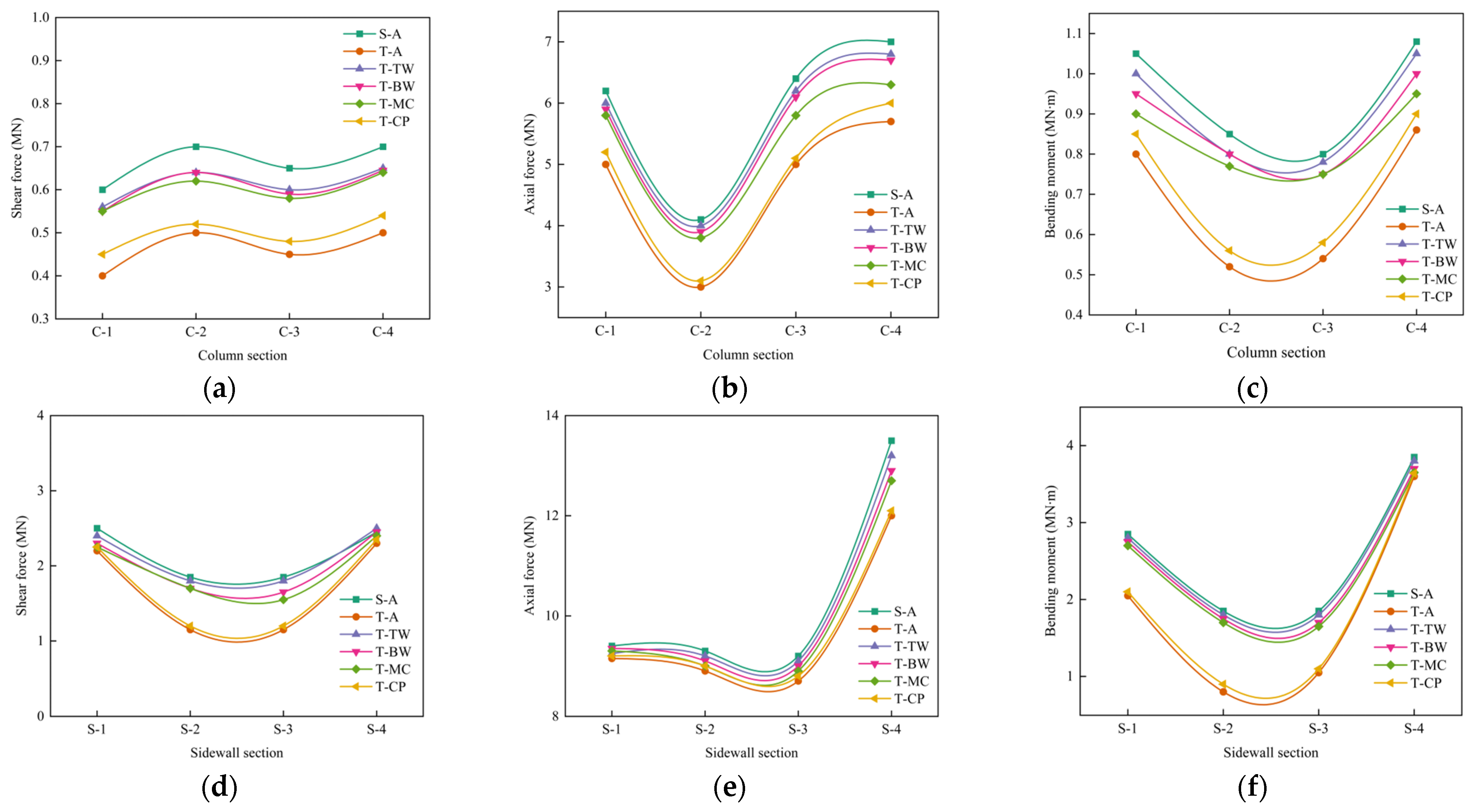

As can be seen from

Table 5, the splicing interface between the cast-in-place component and the prefabricated component exerts the most pronounced influence on the inter-story drift of the underground structure, and is the key factor controlling the overall deformation behavior. The second most influential interface is the splicing interface at the joint area between the top of the sidewall and the top slab, whose connection performance also has a significant impact on the displacement response of the structure. If the bonding strength of the two interfaces is insufficient, sliding and opening at the joints are prone to occur, leading to a decrease in the overall structural rigidity, a significant increase in inter-story drift, and even localized deformation concentration, weakening the seismic stability of the structure. In contrast, the bond strength of the splicing interface at the end of the central column has a relatively small impact on inter-story drift and can be regarded as a non-sensitive factor. This indicates that although the central column bears the main vertical load, changes in its joint rigidity have limited regulatory effects on overall horizontal deformation. However, it is worth noting that when the splicing interface between the bottom of the side wall and the floor slab adopts a “Tie Contact” setting, the inter-story drift of the structure is significantly reduced. This indicates that a good connection in this area can effectively enhance lateral restraint, improve the integrity and collaborative deformation capacity of the structural bottom, and thus improve the overall seismic performance.

Figure 12 shows the comparative results of the maximum internal force response of the middle column and two sidewalls under six different joint-splicing interface cases when PGA = 0.4 g. From

Figure 12, it can be seen that the T-CP case with CP joint rigid connection exhibits the lowest internal force level, which is very close to the T-A case. Both are at the lower limit of the internal force response range of all cases, indicating that achieving high-quality rigid connection of CP between cast-in-place and prefabricated components can significantly enhance the overall integrity and continuity of the structure, optimize the load transmission path, effectively suppress stress concentration in key components, and thus improve the collaborative working ability and mechanical stability of the structure under seismic action. In contrast, the internal force response curves of the T-TW, T-BW, and T-MC cases almost coincide with the S-A case and are all within the upper limit range of internal force response. This phenomenon indicates that although the rigid connection assumption is adopted at the splicing interfaces, such as TW, BW, and MC, its improvement effect on the redistribution of internal force for the overall structure is very limited, and, thus, it is difficult to significantly reduce the stress level of key parts. Further analysis shows that the CP interface between the cast-in-place and prefabricated components is the key control area that determines the seismic performance of prefabricated subway stations. If the interface connection is weak, it is highly likely to form a weak hinge under strong earthquakes, causing an imbalance in the redistribution of internal force, and even inducing shear slip or bending yield, leading to local failure expanding towards overall instability.