Thermo-Mechanical Coupled Characteristics for the Non-Axisymmetric Outer Ring of the High-Speed Rail Axle Box Bearing with Embedded Intelligent Sensor Slots

Abstract

1. Introduction

2. Theoretical Model

2.1. Contact Load Model

2.2. Contact Stress Model

2.3. Heat Generation Model

2.4. Heat Transfer Modele

- Natural convection heat transfer

- 2.

- Forced convection heat transfer

3. Bearing Structure and Finite Element Modeling

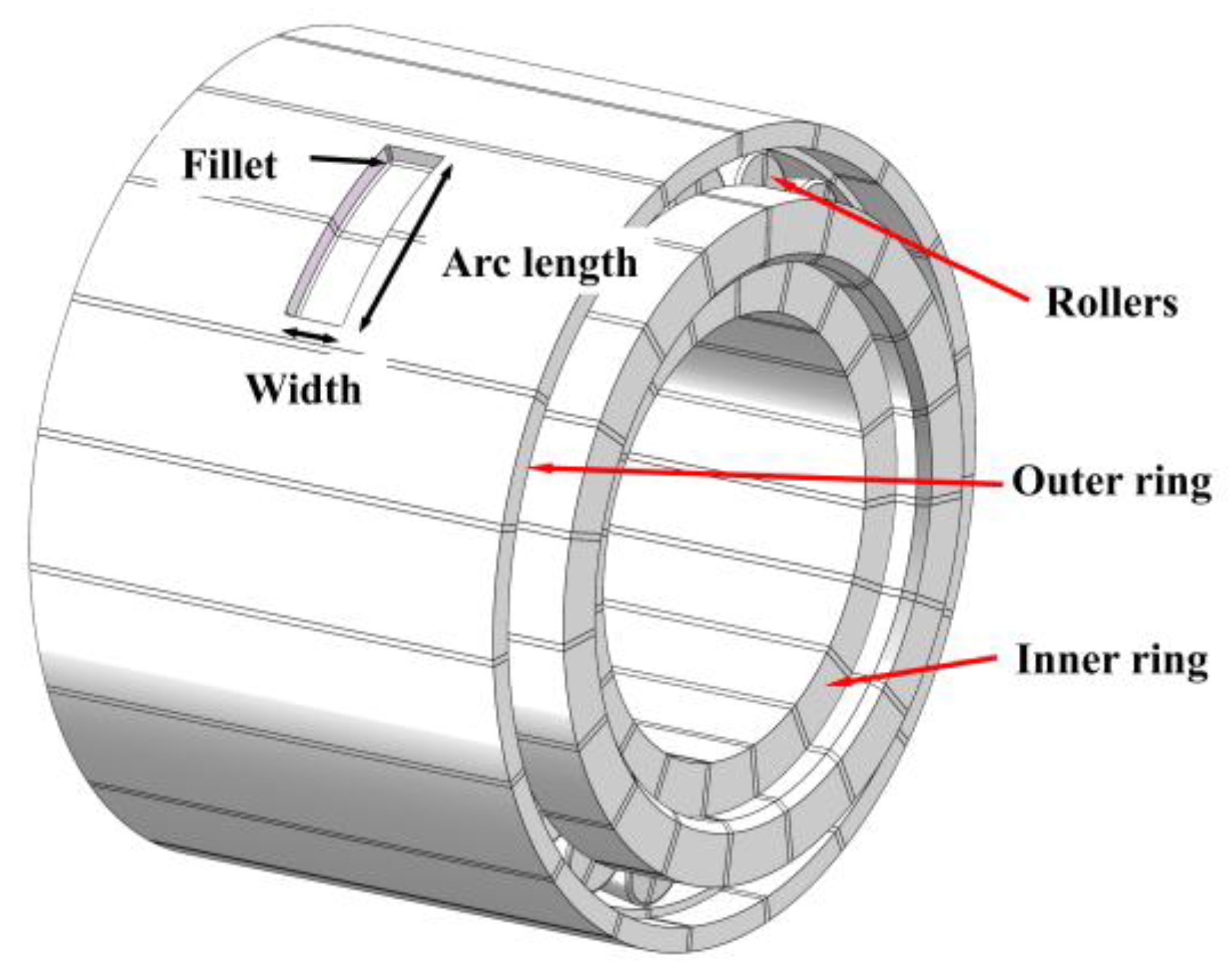

3.1. Bearing Geometry and Structural Parameters

3.2. Design Parameters of the Arc- Shaped Embedded Slot for Flexible Circuit Board

3.3. Finite Element Modeling and Contact Definition

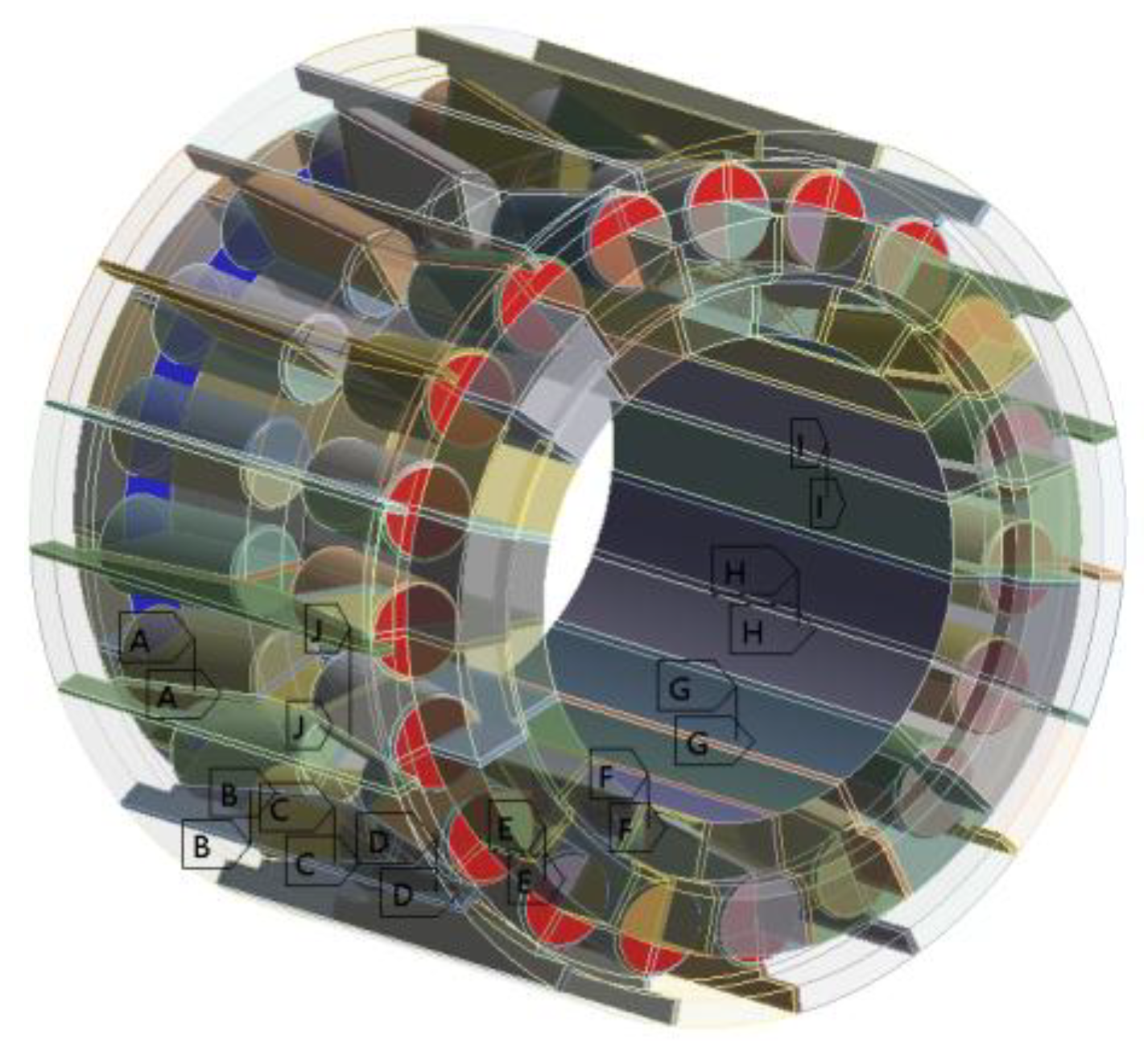

3.3.1. Contact Settings

- 19 contact pairs are defined between the rollers and the inner ring;

- 19 contact pairs are defined between the rollers and the outer ring;

- One bonded contact is defined between the mandrel and the inner ring.

- In the “inner ring–roller” contact pair, the roller is set as the contact surface and the inner ring as the target surface;

- In the “roller–outer ring” contact pair, the roller is the contact surface and the outer ring the target surface.

3.3.2. Finite Element Meshing

- Rollers: the slices use non-uniform swept meshes with local refinement of eight divisions and a sweep bias set to eight, with a mesh size of 2 mm. The rest of the roller uses 10 mm tetrahedral elements;

- Inner ring: the slices use uniform swept meshes with eight divisions and a mesh size of 2 mm. The remaining region is meshed with 10 mm swept elements;

- Outer ring: the slices use uniform swept meshes with eight divisions and a mesh size of 2 mm. The remaining region is also meshed with 10 mm swept elements.

3.4. Material Properties and Boundary Conditions

3.4.1. Material Properties

3.4.2. Applied Loads and Constraints

- The outer surface of the outer ring was fully constrained, fixing all translational and rotational degrees of freedom to simulate the constraints from the bearing housing;

- A virtual mandrel was added to the inner ring. A radial load of 110 kN was applied through the mandrel to represent the actual operational load.

4. Load Analysis and Model Validation

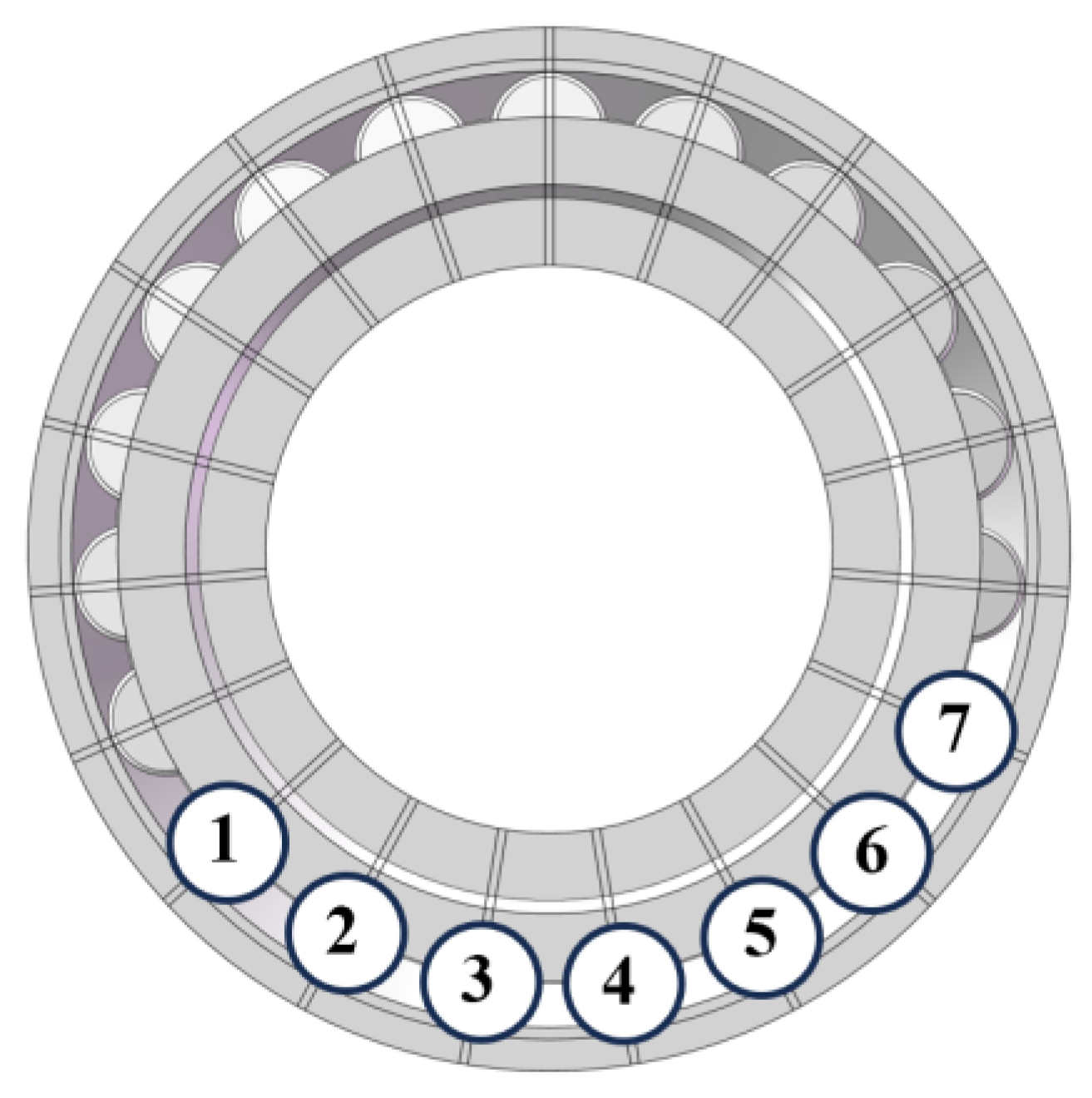

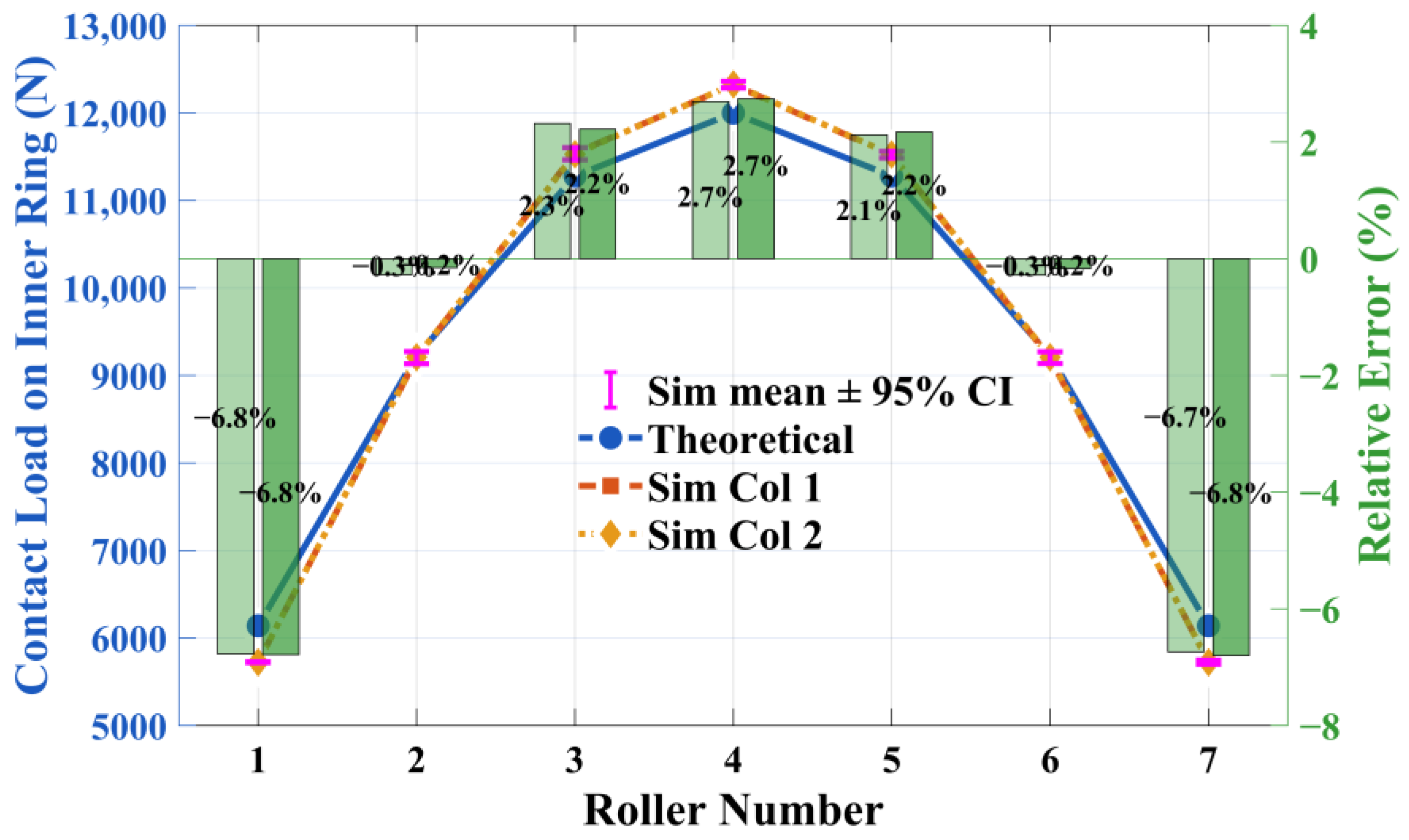

4.1. Validation of Roller Load Distribution

4.2. Validation of Roller Contact Stress Distribution

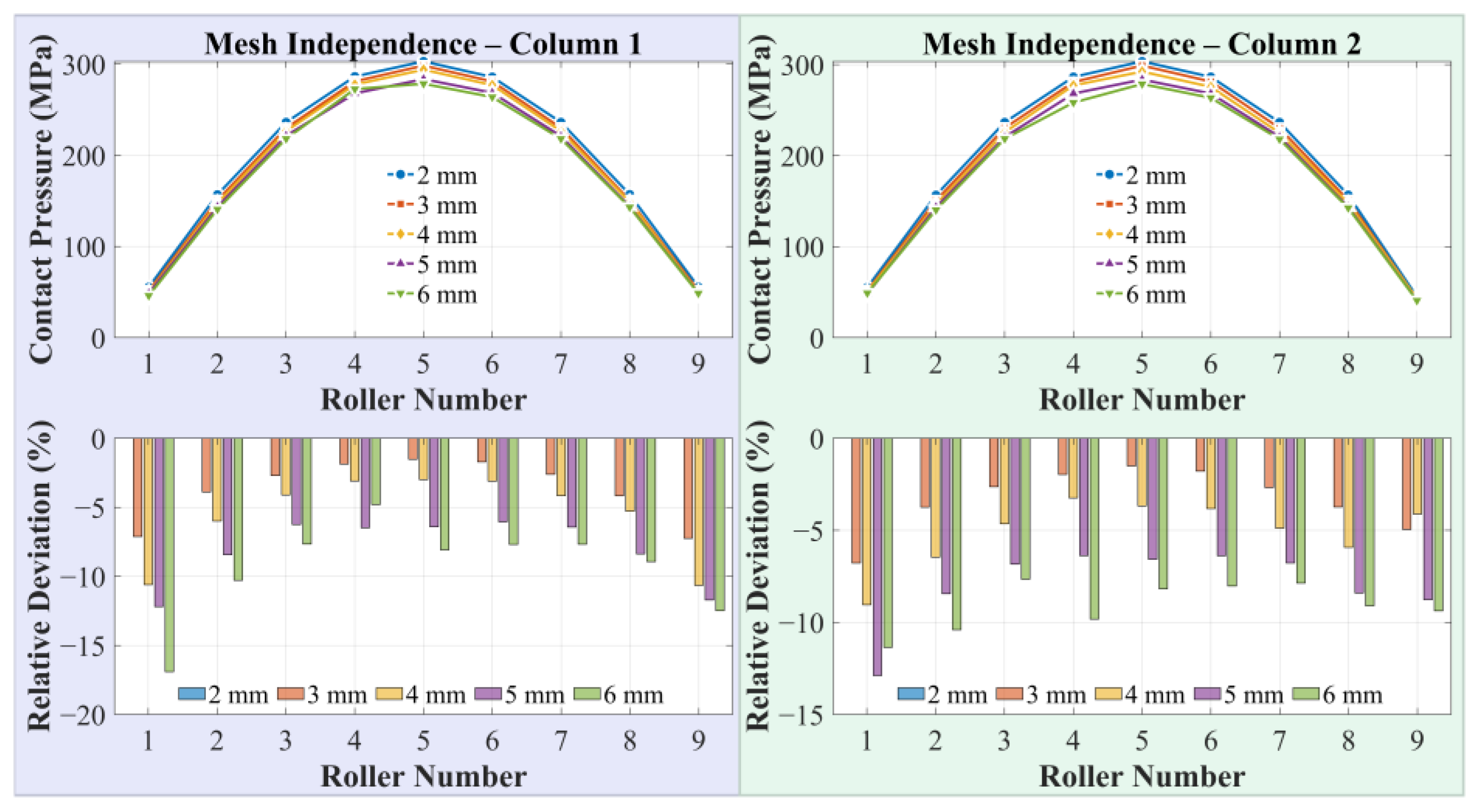

4.3. Validation of Mesh Independence

5. Thermo-Mechanical Coupling Analysis

5.1. Boundary Conditions and Heat Source Definition

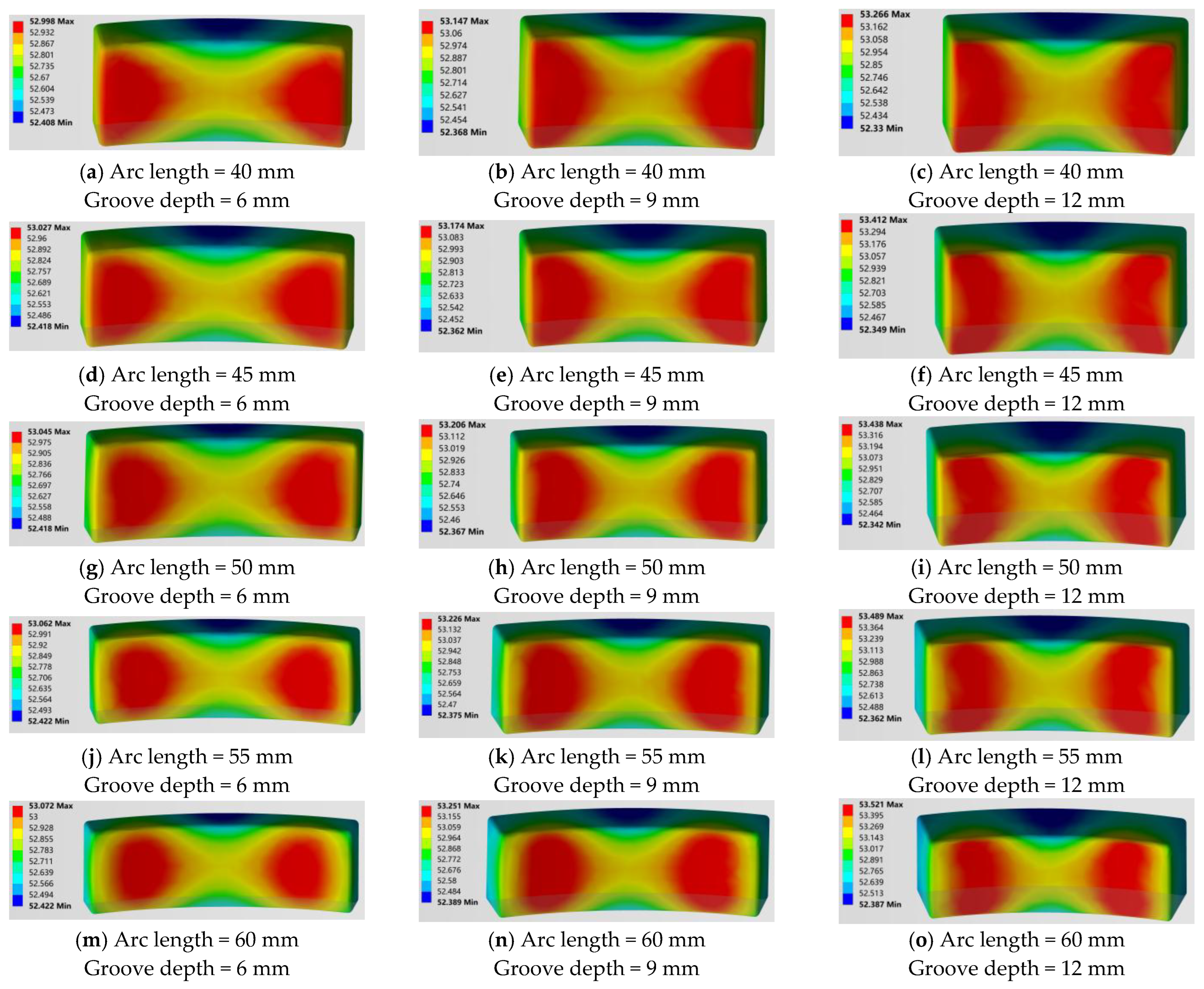

5.2. Thermal Field Response Analysis

- The temperature peak is concentrated in the contact region between the roller and the inner ring;

- As groove depth and arc length increase, the temperature in the slot region gradually rises;

- The temperature field exhibits significant symmetry, and thermal gradients occur on both sides of the groove, potentially inducing local thermal distortion.

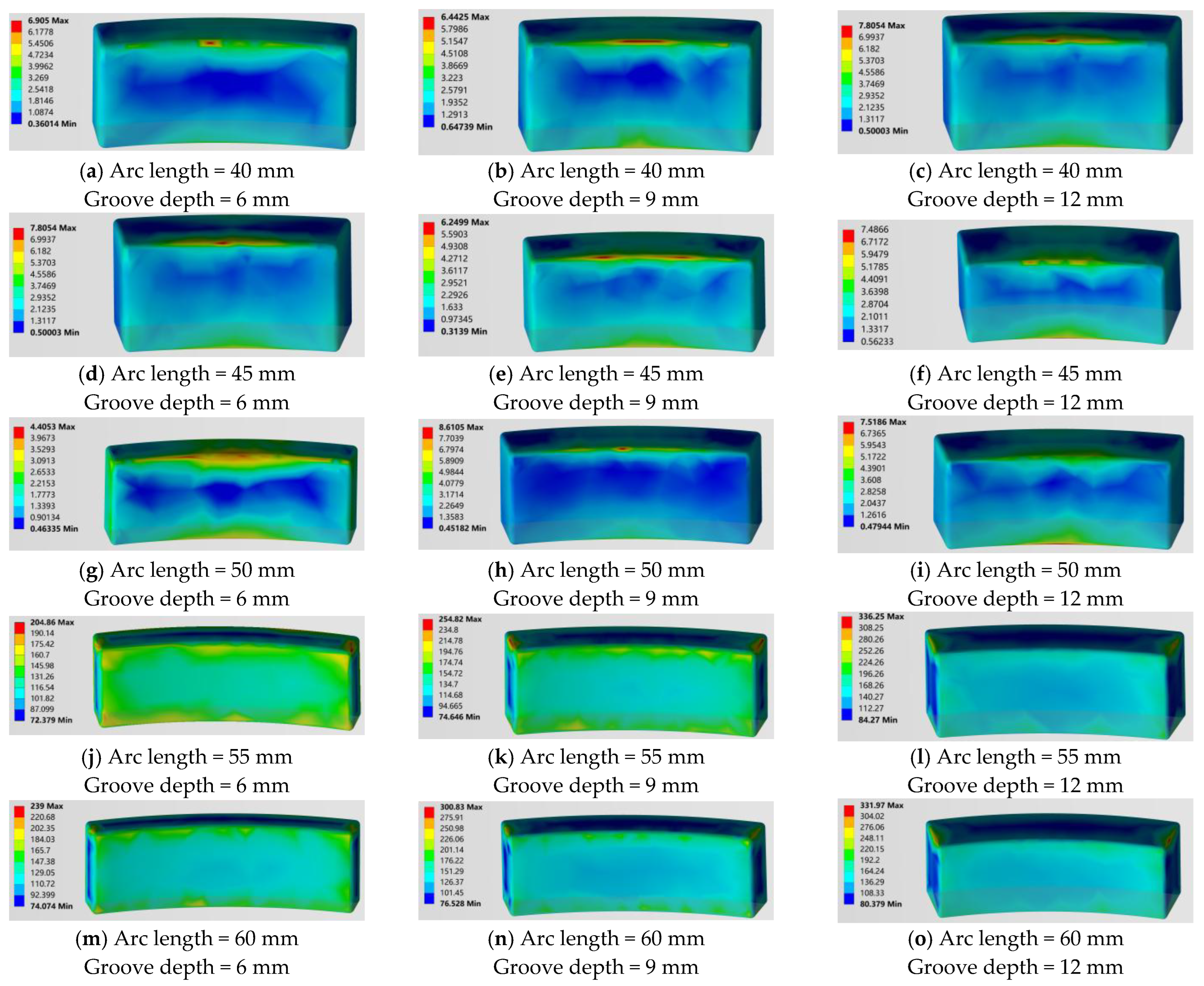

5.3. Coupled Stress Field and Local Structural Response

- High-stress regions are primarily located at the groove shoulder transitions, where the disruption of structural continuity is the main cause of stress intensification;

- When the arc length exceeds 55 mm, pronounced stress concentrations appear at the edges of the groove, with maximum equivalent stress reaching 331.97 MPa, approximately 60% of the yield strength of GCr15-bearing steel;

- Structural strength significantly deteriorates under conditions of large groove depth and long arc length.

5.4. Sensitivity Analysis of Ambient Temperature

5.5. Sensitivity Analysis of Train Speed

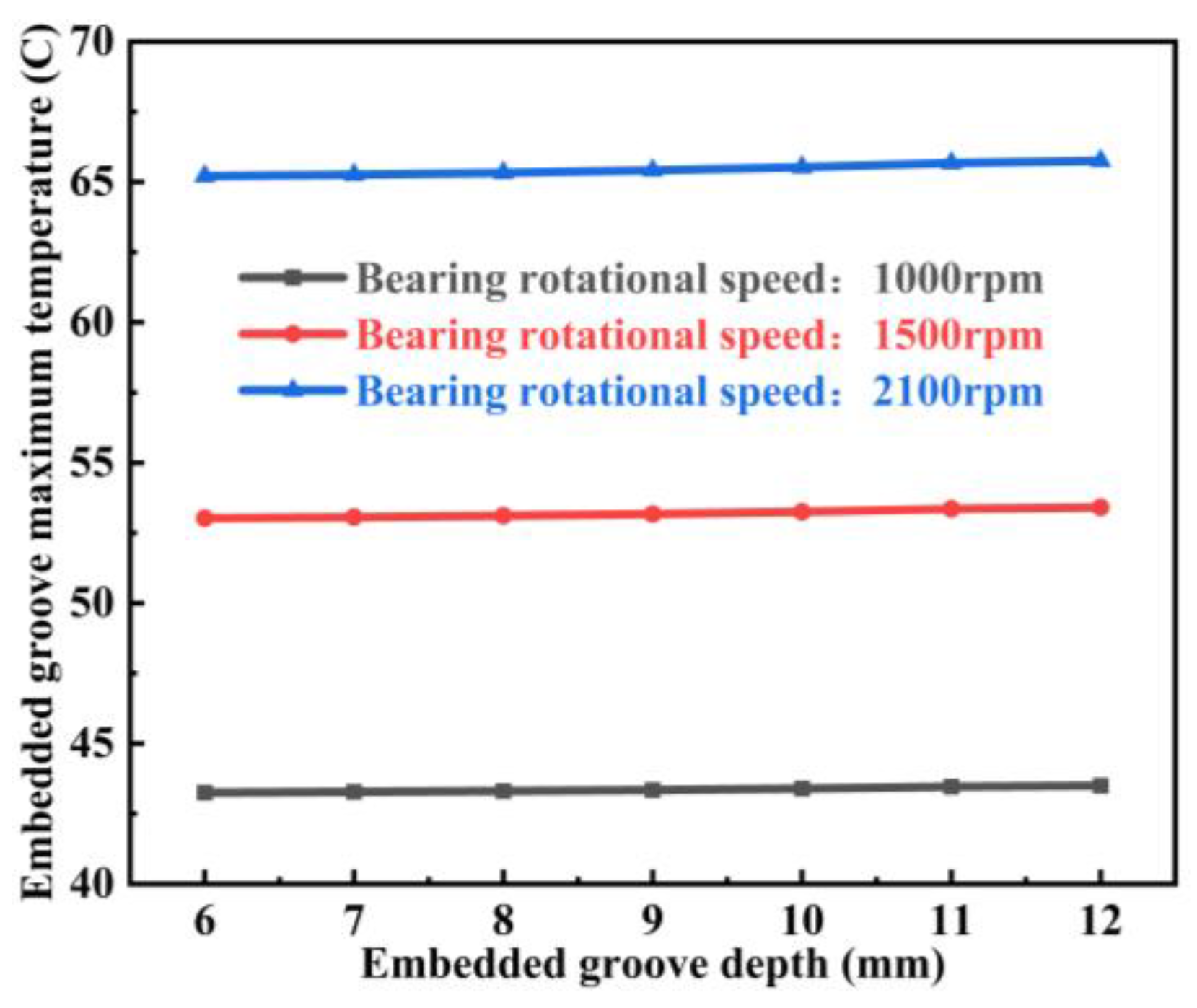

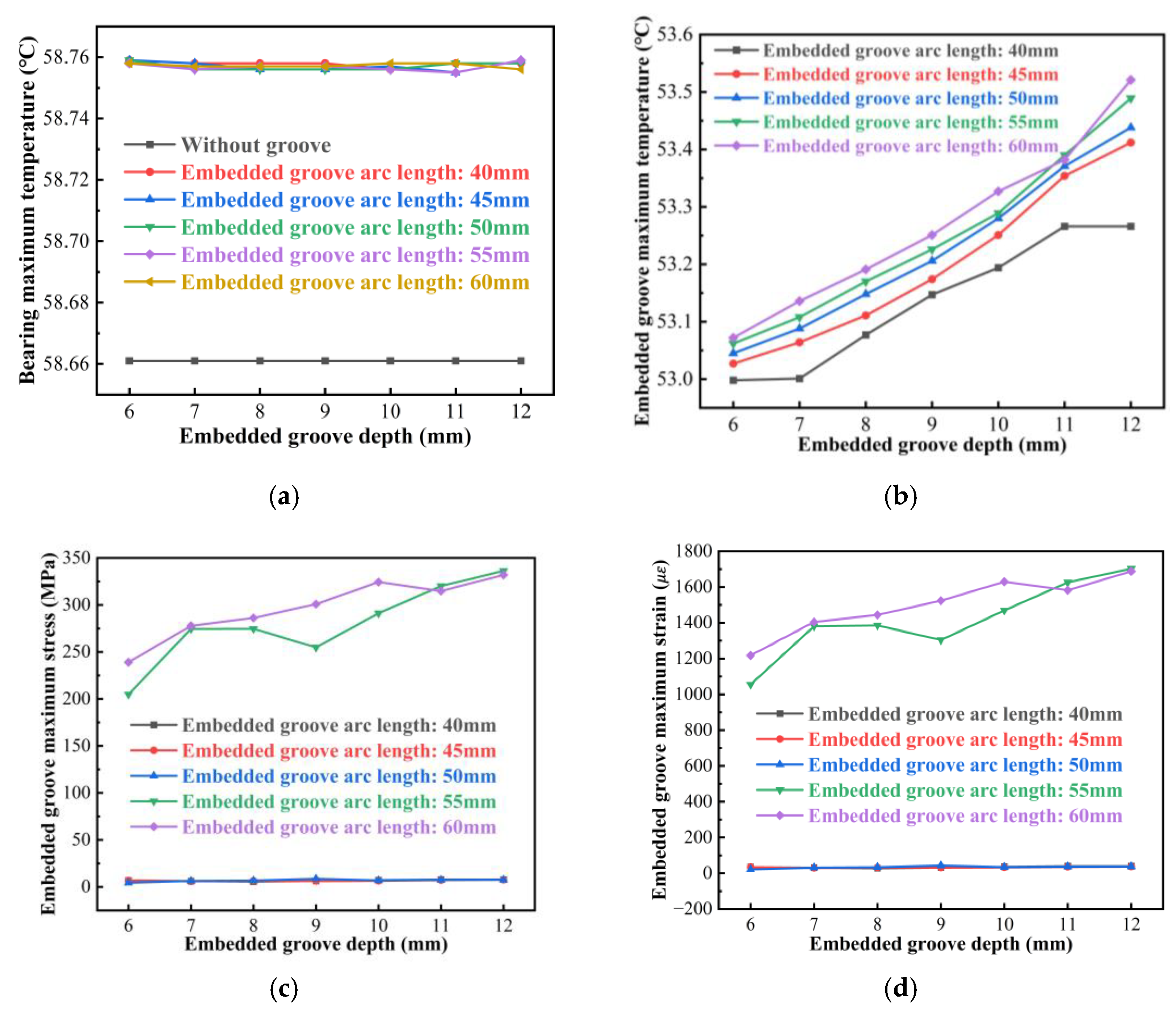

5.6. Parametric Analysis of Temperature and Stress Response Due to Embedded Slot Geometry

5.6.1. Global Bearing Response Trends

5.6.2. Local Disturbance Effects of Embedded Slot

- Thermal response: temperature rises significantly with increasing groove depth and arc length, with evident thermal accumulation;

- Stress response: maximum local stress increases markedly when the arc length reaches 55 mm and 60 mm, with stress concentrations forming at the groove edges;

- Deformation response: as arc length increases to 55 mm and 60 mm, thermal deformation escalates rapidly, and asymmetric structures form on both sides of the groove, adversely affecting sensor encapsulation stability and adhesive reliability.

6. Conclusions

- The errors between the proposed model and the theoretical analytical solutions for roller contact loads and contact stresses are both within 8%, verifying the accuracy and engineering applicability of the developed model;

- Embedded groove structures significantly affect local thermo-mechanical responses. Increasing groove depth and arc length intensifies local thermal accumulation and stress concentration. Improper parameter combinations may lead to heat buildup and a rapid decline in local structural stiffness;

- Considering thermal stability, stress control, and deformation uniformity, it is recommended to keep the groove depth within 6–9 mm and within a suitable arc length. This design range shows good coordination across all metrics and achieves a balanced trade-off between structural strength and sensor integration requirements, offering high overall performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ali, A.; Permana, D.I.; Yudha, H.N. Analysis of variance dimension of reinforcement to stress concentration factor using finite element method. Sinergi 2022, 26, 295–302. [Google Scholar] [CrossRef]

- Xu, K.; Hu, H.; Guo, N.; Ma, X.Q.; Li, X.P. Research on temperature rise characteristics prediction of main shaft dual-Rotor rolling bearings in aircraft engines. Lubricants 2024, 12, 210. [Google Scholar] [CrossRef]

- Li, Z.J.; Zhao, C.Y. Thermal mechanics coupling analysis of angular contact ball bearings installed in pairs in feed system. China Mech. Eng. 2023, 34, 821–829. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.M.; Li, T.J. Thermal coupling simulation analysis of face-to-face tapered roller bearing device. Mach. Des. Manuf. 2025; 1–5, online first. (In Chinese) [Google Scholar] [CrossRef]

- Tang, R.; Cao, S.S.; Gao, L.X.; Li, G.L.; Deng, S.E. Thermal characteristics of angular contact ball bearings with two piece inner rings under thermodynamic coupling. Bearing 2024, 4, 7–17. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M.; Yang, S.P.; Liu, Y.Q.; Chen, Y.H.; Zhang, K. Establishment of the thermo-mechanical coupling model of axle box bearings with track irregularity excitation and analysis of its temperature characteristics. Appl. Math. Mech. Engl. Ed. 2024, 45, 1965–1986. [Google Scholar] [CrossRef]

- Wang, B.S.; Liu, Y.Q.; Liao, Y.Y.; Wang, Y.X. Analysis of temperature characteristics of high-speed train wheelset system under complex operating conditions. Int. J. Mech. Syst. Dyn. 2024, 4, 331–345. [Google Scholar] [CrossRef]

- Yang, C.; Wu, X.W.; Chi, M.R.; Luo, Y.P.; Liang, S.L. Modelling and analysis of thermal characteristics of high-speed train axle box bearings considering vehicle-environment coupling effects. Int. J. Heat Mass Transf. 2024, 235, 126209. [Google Scholar] [CrossRef]

- Ma, Q.Y.; Liu, Y.Q.; Yang, S.P.; Liao, Y.Y.; Wang, B.S. A coupling model of high-speed train-axle box bearing and the vibration characteristics of bearing with defects under wheel rail excitation. Machines 2022, 10, 1024. [Google Scholar] [CrossRef]

- Chen, J.H.; Zhang, W.Y.; Wang, H. Intelligent bearing structure and temperature field analysis based on finite element simulation for sustainable and green manufacturing. J. Intell. Manuf. 2021, 32, 745–756. [Google Scholar] [CrossRef]

- Xue, Y.J.; Meng, F.J.; Yu, Y.J.; Cai, H.C. Thermal–mechanical coupling model of a double-piece inner ring ball bearing based on ADAMS secondary development. Lubricants 2025, 13, 154. [Google Scholar] [CrossRef]

- Liu, J.F.; Zhang, P. Thermo-mechanical behavior analysis of motorized spindle based on a coupled model. Adv. Mech. Eng. 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Chang, Z.Y.; Hou, L.; Lin, R.Z.; Chen, Y.S.; Masarati, P. Monolithic approaches to transient thermo-mechanical interaction in nonlinear rotor systems. Int. J. Mech. Sci. 2025, 290, 110066. [Google Scholar] [CrossRef]

- Zhou, G.W.; Li, G.L.; Chen, P.; Hou, Y.; Wang, X. Research on the load distribution measurement of high-speed train axle box bearing. Part I: Simulation analysis of the notching method of bearing housing. J. Exp. Mech. 2022, 37, 18–26. (In Chinese) [Google Scholar] [CrossRef]

- Li, Z.; Chen, Q.; Wang, Q.J. Structural comparative analysis of different grooved spherical bearings based on finite element method. Lubr. Eng. 2019, 44, 72–80. (In Chinese) [Google Scholar] [CrossRef]

- Yang, G.L.; Huang, F.T.; Jin, J.; Wang, W.Y.; Wu, G.G. Numerical analysis of gear pump sliding bearing slot based on Matlab simulation. Hydraul. Pneum. Seals. 2020, 9, 21–24. (In Chinese) [Google Scholar] [CrossRef]

- Wang, D.D.; Wang, N.; Chen, Y.H.; Zhang, N.; Zhang, C.M. Mechanism analysis of the influence of slotting on deformation of embedded water-lubricated bearing. J. Shaanxi Univ. Technol. (Nat. Sci. Ed.). 2024, 28, 445–453. (In Chinese) [Google Scholar] [CrossRef]

- Gutarevich, V.O.; Martyushev, N.V.; Klyuev, R.V.; Kukartsev, V.A.; Kukartsev, V.V.; Iushkova, L.V.; Korpacheva, L.N. Reducing Oscillations in Suspension of Mine Monorail Track. Appl. Sci. 2023, 13, 4671. [Google Scholar] [CrossRef]

- Wu, Q.X.; Zhuang, Y.T. Discussion on insertion slot for housings of insert bearings. Bearing 2019, 1, 20–22. (In Chinese) [Google Scholar] [CrossRef]

- Luan, W.L.; Wang, Y.D.; Wang, H.M.; Liu, Y.; Li, X.L.; Xu, F.C. Theoretical analysis on the impact of spiral groove structural parameters on static characteristics of novel hybrid gas foil thrust bearing with spiral grooves. J. Mech. Eng. 2025, 61, 358–371. [Google Scholar]

- Fesanghary, M.; Khonsari, M.M. On the optimum groove shapes for load-carrying capacity enhancement in parallel flat surface bearings: Theory and experiment. Tribol. Int. 2013, 67, 254–262. [Google Scholar] [CrossRef]

- Brito, F.P.; Miranda, A.S.; Fillon, M. Analysis of the effect of grooves in single and twin axial groove journal bearings under varying load direction. Tribol. Int. 2016, 103, 609–619. [Google Scholar] [CrossRef]

- Xu, M.Y.; Chen, W. Study on the performance of liquid metal lubricated V-groove bearing considering turbulence. Appl. Sci. 2021, 11, 940. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Liu, C.P.; Zhao, B. An optimization research on groove textures of a journal bearing using particle swarm optimization algorithm. Mech. Ind. 2021, 22, 1. [Google Scholar] [CrossRef]

- Bättig, P.K.; Wagner, P.H.; Schiffmann, J.A. Experimental investigation of enhanced grooves for herringbone grooved journal bearings. J. Tribol. 2022, 144, 091801. [Google Scholar] [CrossRef]

- Wang, L.K.; Hu, C.; Hu, L.; Liu, F.Y.; Tang, H.B. An investigation on the mechanical characteristics of railway locomotive axle box bearings with sensor-embedded slots. Machines 2025, 13, 358. [Google Scholar] [CrossRef]

- Deng, S.E.; Jia, Q.Y. Design Principles of Rolling Bearings, 1st ed.; China Standard Press: Beijing, China, 2008; pp. 127–130. [Google Scholar]

- Tao, W.Q. Heat Transfer, 5th ed.; Higher Education Press: Beijing, China, 2019. [Google Scholar]

- Wang, J.W.; Su, J.; Meng, Z.Z.; Kouediatouka, A.N.; Jiang, S.; Zheng, J.X.; Dong, G.N. Entrance process and interface distribution of nanoparticles in point contact. Tribol. Int. 2024, 200, 110085. [Google Scholar] [CrossRef]

- Burton, R.A.; Staph, H.E. Thermally activated seizure of angular contact bearings. Tribol. Trans. 2008, 10, 408–417. [Google Scholar] [CrossRef]

- Li, J.N.; Xue, J.F.; Ma, Z.T. Study on the thermal distribution characteristics of high-speed and light-load rolling bearing considering skidding. Appl. Sci. 2018, 8, 1593. [Google Scholar] [CrossRef]

| No. | Parameter | Value |

|---|---|---|

| 1 | Outer ring diameter | mm |

| 2 | Inner ring diameter | mm |

| 3 | Small end diameter of roller | mm |

| 4 | Large end diameter of roller | mm |

| 5 | Outer contact angle | 10.00° |

| 6 | Inner contact angle | 7.57° |

| 7 | Half cone angle | 1.215° |

| 8 | Effective contact length | 52.04 mm |

| 9 | Number of rollers | 38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Hu, C.; Liu, F.; Tang, H. Thermo-Mechanical Coupled Characteristics for the Non-Axisymmetric Outer Ring of the High-Speed Rail Axle Box Bearing with Embedded Intelligent Sensor Slots. Symmetry 2025, 17, 1667. https://doi.org/10.3390/sym17101667

Wang L, Hu C, Liu F, Tang H. Thermo-Mechanical Coupled Characteristics for the Non-Axisymmetric Outer Ring of the High-Speed Rail Axle Box Bearing with Embedded Intelligent Sensor Slots. Symmetry. 2025; 17(10):1667. https://doi.org/10.3390/sym17101667

Chicago/Turabian StyleWang, Longkai, Can Hu, Fengyuan Liu, and Hongbin Tang. 2025. "Thermo-Mechanical Coupled Characteristics for the Non-Axisymmetric Outer Ring of the High-Speed Rail Axle Box Bearing with Embedded Intelligent Sensor Slots" Symmetry 17, no. 10: 1667. https://doi.org/10.3390/sym17101667

APA StyleWang, L., Hu, C., Liu, F., & Tang, H. (2025). Thermo-Mechanical Coupled Characteristics for the Non-Axisymmetric Outer Ring of the High-Speed Rail Axle Box Bearing with Embedded Intelligent Sensor Slots. Symmetry, 17(10), 1667. https://doi.org/10.3390/sym17101667