Formation of Symmetric Gradient Microstructure in Carbon Steel Bars

Abstract

1. Introduction

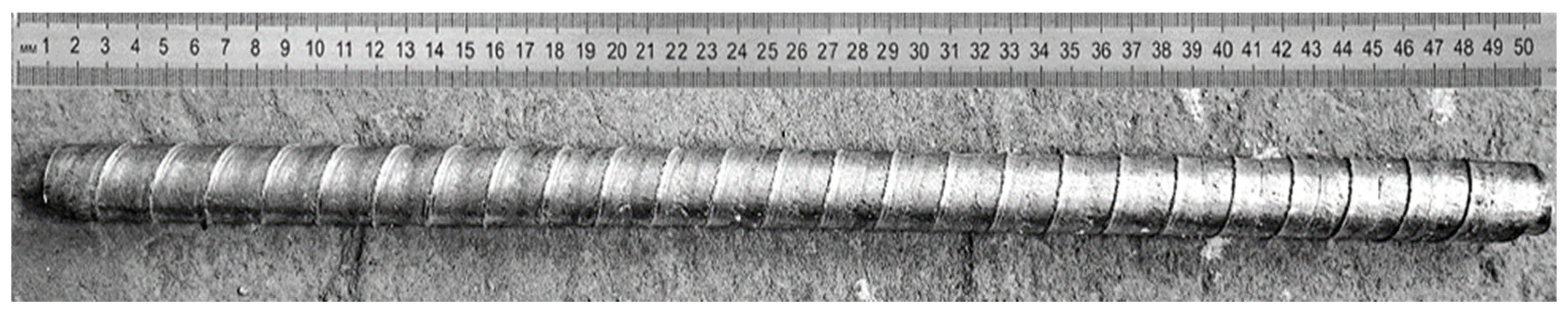

2. Materials and Methods

3. Results and Discussion

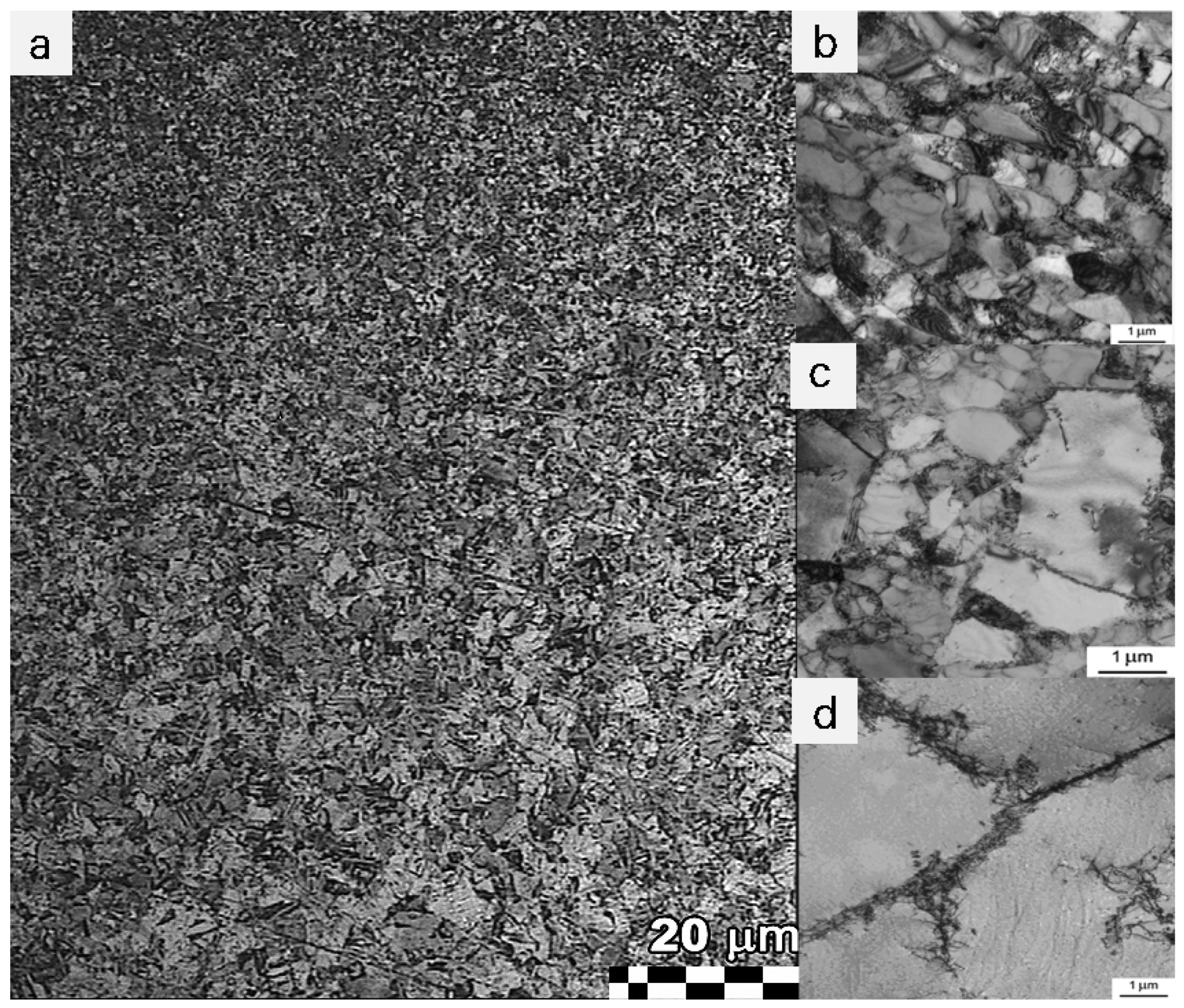

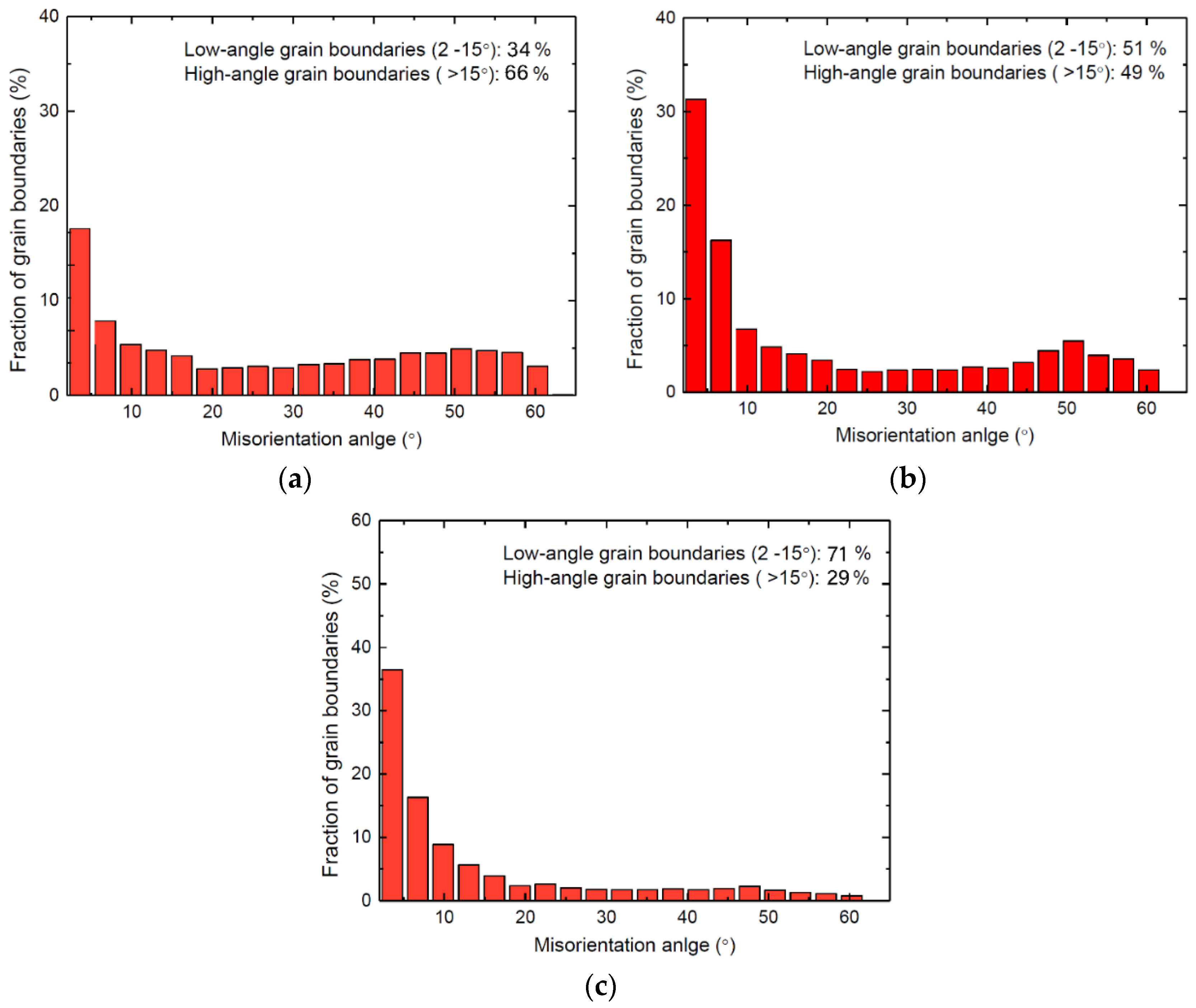

3.1. Metallographic Analysis

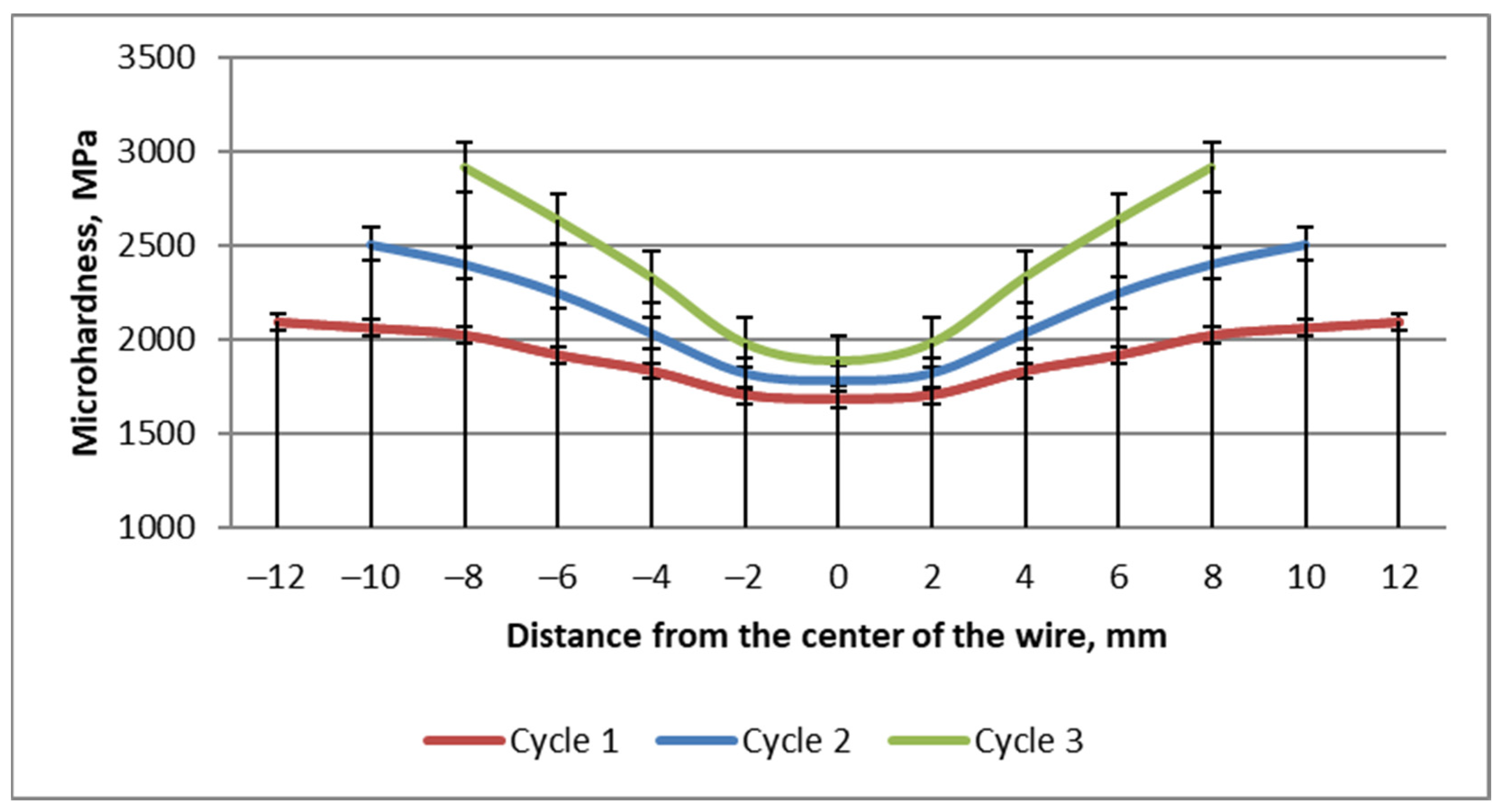

3.2. Analysis of Mechanical Properties

4. Conclusions

- A completely new technology of combined deformation has been developed, which makes it possible to produce steel bars with enhanced strength and plastic characteristics. This technology consists of drawing medium carbon steel bars on a radial-displacement rolling mill and subsequent drawing.

- The deformation resulted in bars with gradient microstructure. The surface area of the bar is significantly ground; the average ferrite size is 0.5 µm. The deformation is not large enough in the neutral zone, so the structure is not so as strongly refined. Ferrite grains are reduced to 2 µm. In the central zone, the microstructure is composed of large grains with an average size of 7 µm.

- The initial microhardness of carbon steel bars was 1515 MPa throughout their entire circumference. Microhardness was 2920 MPa in the surface zone, 2335 MPa in the neutral zone and 1890 MPa in the center of the bar after deformation by RSB-drawing method, and the diameter decreased from 30 mm to 17 mm. This symmetrical spread of the microhardness confirms the gradient microstructure.

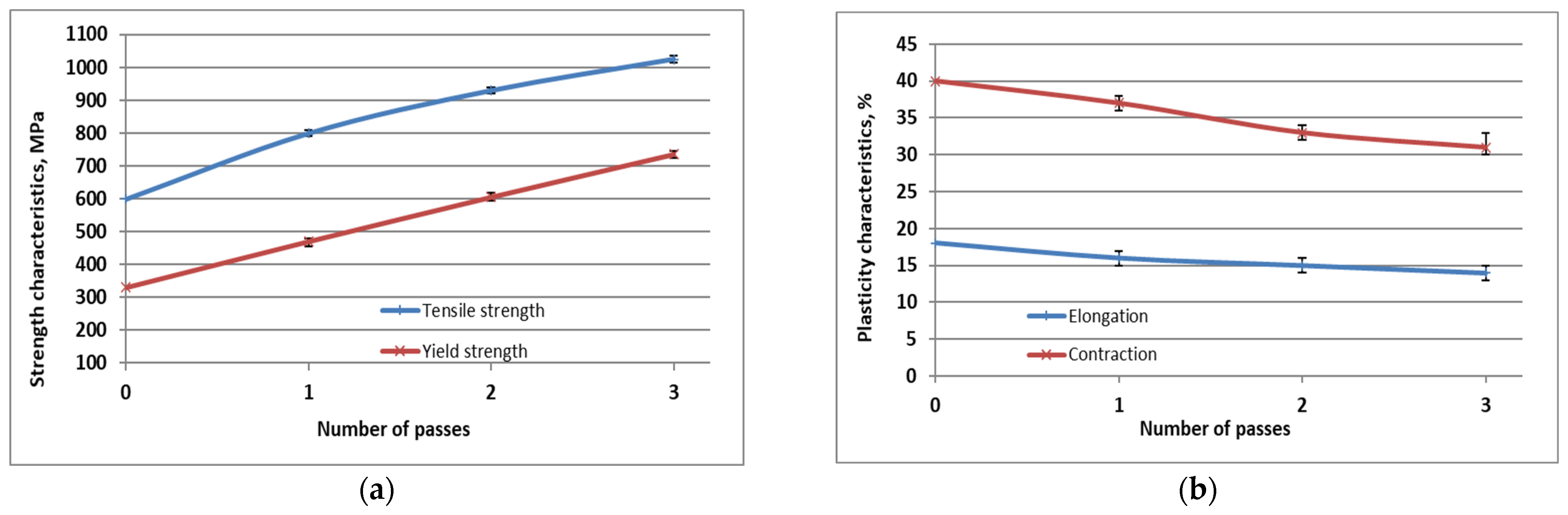

- After three cycles of deformation in the surface zone, the ultimate strength increased by 70%, and the yield strength increased by 123%. Relative reduction and elongation decreased by 22%. Despite a decrease in plasticity, its values remain at a relatively high level.

- The obtained results outcomes attest to the efficiency of the proposed technique of combining radial-shift broaching and drawing to produce long bars with enhanced mechanical properties. It is possible to obtain the required physical and mechanical properties of materials by controlling the process of symmetry of such a structure. This method can be successfully applied to various industries where the production of high-quality and reliable materials is required.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sherov, K.; Serova, R.; Yessirkepova, A.; Mussayev, M.; Zhanakov, K.; Smailova, B.; Turusbekova, A.; Mazhitova, L. Enhancing the efficiency of rebar use in reinforced concrete products’ manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1047, 012025. [Google Scholar] [CrossRef]

- Neamat, S.; Shamsborhan, M. The Investigation of The Different Types of the Ground Rebar Spacers with Proposing New Design Rebar Space Mixed of Concrete Palstic. J. Civ. Eng. Front. 2020, 1, 1–6. [Google Scholar] [CrossRef]

- Lezhnev, S.; Naizabekov, A.; Panin, E. Radial-shear rolling as a new technological solution for recycling bar scrap of ferrous metals. Mater. Sci. Forum 2022, 1052, 498–503. [Google Scholar] [CrossRef]

- Volokitina, I.; Volokitin, A.; Panin, E. Gradient microstructure formation in carbon steel bars. J. Mater. Res. Technol. 2024, 31, 2985–2993. [Google Scholar] [CrossRef]

- Skripalenko, M.M.; Romantsev, B.A.; Galkin, S.P.; Skripalenko, M.N.; Kaputkina, L.M.; Huy, T.B. Prediction of the Fracture of Metal in the Process of Screw Rolling in a Two-Roll Mill. Metallurgist 2018, 61, 925–933. [Google Scholar] [CrossRef]

- Naizabekov, A.; Panin, E. Structure and mechanical properties of steel in the process “pressing-drawing”. J. Mater. Eng. Perform. 2019, 28, 1762–1771. [Google Scholar] [CrossRef]

- Snopiński, P. Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing. Symmetry 2023, 15, 860. [Google Scholar] [CrossRef]

- Xu, J.; Li, J.; Shan, D.; Guo, B. Microstructural evolution and micro/meso-deformation behavior in pure copper processed by equal-channel angular pressing. Mater. Sci. Eng. A 2016, 664, 114–125. [Google Scholar] [CrossRef]

- Latypova, M.A.; Chigirinsky, V.V.; Kolesnikov, A.S. Effect of Controlled Rolling on the Structural and Phase Transformations. Prog. Phys. Met. 2023, 24, 132–156. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Dao, M.; Lu, L.; Asaro, R.; De Hosson, J.T.M.; Ma, E. Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 2007, 55, 4041–4065. [Google Scholar] [CrossRef]

- Mythili, R.; Kirana, R.; Herojit Singh, L.; Govindaraj, R.; Sinha, A.; Singh, M.; Saroja, S.; Vijayalakshmi, M.; Deb, S. Identification of Retained Austenite in 9Cr-1.4W-0.06Ta-0.12C Reduced Activation Ferritic Martensitic Steel. Symmetry 2022, 14, 196. [Google Scholar] [CrossRef]

- Muszka, K.; Zych, D.; Lisiecka-Graca, P.; Madej, L.; Majta, J. Experimental and Molecular Dynamic Study of Grain Refinement and Dislocation Substructure Evolution in HSLA and IF Steels after Severe Plastic Deformation. Metals 2020, 10, 1122. [Google Scholar] [CrossRef]

- Bychkov, A.; Volokitin, A.; Kolesnikov, A. Natural Aging of Aluminum Alloy 2024 After Severe Plastic Deformation. Metallogr. Microstruct. Anal. 2023, 12, 564–566. [Google Scholar] [CrossRef]

- Vasilyeva, N.; Fedorova, E.; Kolesnikov, A. Big Data as a Tool for Building a Predictive Model of Mill Roll Wear. Symmetry 2021, 13, 859. [Google Scholar] [CrossRef]

- Sapargaliyeva, B.; Agabekova, A.; Syrlybekkyzy, S.; Ulyeva, G.; Yerzhanov, A.; Kozlov, P. Study of changes in microstructure and metal interface Cu/Al during bimetallic construction wire straining. Case Stud. Constr. Mater. 2023, 18, e02162. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Kolesnikova, O.G. Effect of Deformation by High-Pressure Torsion in a Combined Matrix on the Properties of Brass. Metallurgist 2023, 66, 1601–1606. [Google Scholar] [CrossRef]

- Lezhnev, S.; Panin, E. Research of combined process rolling-pressing influence on the microstructure and mechanical properties of aluminium. Adv. Mater. Res. 2013, 814, 68–75. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Sabirov, I.; Kazykhanov, V.U. Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al alloy processed via ECAP-PC. J. Mater. Sci. 2013, 48, 4501–4509. [Google Scholar] [CrossRef]

- Chukin, M.V.; Korchunov, A.G.; Polyakova, M.A.; Emaleeva, D.G. Forming ultrafine-grain structure in steel wire by continuous deformation. Steel Transl. 2010, 40, 595–597. [Google Scholar] [CrossRef]

- Kurapov, G.; Orlova, E.; Turdaliev, A. Plasticity as a physical-chemical process of deformation of crystalline solids. J. Chem. Technol. Metall. 2016, 51, 451–457. [Google Scholar]

- Zhang, X.; Hansen, N.; Gao, Y.; Huang, X. Hall-Petch and dislocation strengthening in graded nanostructured steel. Acta Mater. 2012, 60, 5933–5943. [Google Scholar] [CrossRef]

- Wang, K.; Tao, N.R.; Liu, G.; Lu, J.; Lu, K. Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 2006, 54, 5281–5291. [Google Scholar] [CrossRef]

- Li, W.L.; Tao, N.R.; Lu, K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scripta Mater. 2008, 59, 546–549. [Google Scholar] [CrossRef]

- Lezhnev, S.; Koinov, T. Research of influence equal channel angular pressing on the microstructure of copper. J. Chem. Technol. Metall. 2014, 49, 621–630. [Google Scholar]

- Nayan, N.; Narayana Murty, S.V.S.; Jha, A.K.; Pant, B.; Sharma, S.C.; George, K.M.; Sastry, G.V.S. Mechanical properties of aluminium-copper-lithium alloy AA2195 at cryogenic temperatures. Mater. Des. 2014, 58, 445–450. [Google Scholar] [CrossRef]

- Li, J.; Mei, Q.; Li, Y.; Wang, T. Production of Surface Layer with Gradient Microstructure and Microhardess on Copper by High Pressure Surface Rolling. Metals 2020, 10, 73. [Google Scholar] [CrossRef]

- Galkin, S.P. Moscow State Institute of Steel and Alloys. Method of Helical Rolling. Russian Patent No. 2293619, 20 February 2007. (In Russian). [Google Scholar]

- Galkin, S.P. Radial shear rolling as an optimal technology for lean production. Steel Transl. 2014, 44, 61–64. [Google Scholar] [CrossRef]

- Kharitonov, V.A.; Usanov, M. Study of Radial-Shear Wire Broaching Based on Modelling. Metallurgist 2014, 57, 1015–1021. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Gamin, Y.V.; Galkin, S.P.; Prosviryakov, A.S.; Aleshchenko, A.S.; Noshin, M.A.; Koshmin, A.N.; Fomin, A.V. Radial-Shear Rolling of High-Strength Aluminum Alloys: Finite Element Simulation and Analysis of Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2020, 786, 139424. [Google Scholar] [CrossRef]

- Karpov, B.V.; Patrin, P.V.; Galkin, S.P.; Kharitonov, E.A.; Karpov, I.B. Radial-Shear Rolling of Titanium Alloy VT-8 Bars with Controlled Structure for Small Diameter Ingots (≤200 mm). Metallurgist 2018, 61, 884–890. [Google Scholar] [CrossRef]

- Nurumgaliyev, A.; Zhuniskaliyev, T.; Shevko, V.; Yerekeyeva, G. Modeling and development of technology for smelting a complex alloy (ligature) Fe-Si-Mn-Al from manganese-containing briquettes and high-ash coals. Sci. Rep. 2024, 14, 7456. [Google Scholar] [CrossRef] [PubMed]

- Lezhnev, S.; Naizabekov, A.; Kuis, D.; Kasperovich, A.; Panin, E. Modeling of the rebar products recycling technology by radial-shear rolling and drawing. In Proceedings of the METAL 2021—30th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 26–28 May 2021; pp. 193–198. [Google Scholar] [CrossRef]

- Sapargaliyeva, B.; Agabekova, A.; Liseitsev, Y.; Vavrenyuk, S. Increasing strength and performance properties of bimetallic rods during severe plastic deformation. Case Stud. Constr. Mater. 2023, 19, e02256. [Google Scholar] [CrossRef]

- Volokitina, I.E.; Volokitin, A.V. Changes in Microstructure and Mechanical Properties of Steel-Copper Wire During Deformation. Metallurgist 2023, 67, 232–239. [Google Scholar] [CrossRef]

- Raab, G.I.; Gunderov, D.V.; Shafigullin, L.N.; Podrezov, Y.M.; Danylenko, M.I.; Tsenev, N.K.; Bakhtizin, R.N.; Aleshin, G.N.; Raab, A.G. Structural variations in low-carbon steel under severe plastic deformation by drawing, free torsion, and drawing with shear. Mater. Phys. Mech. 2015, 3, 242–252. [Google Scholar]

- Liu, M.; Li, J.Y.; Ma, Y.; Yuan, T.Y.; Mei, Q.S. Surface nanocrystallization and property of Ti6Al4V alloy induced by high pressure surface rolling. Sur. Coat. Tech. 2016, 289, 94–100. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, X.; Xu, D.; Lu, L.; Gao, H.; Zhu, T. Gradient plasticity in gradient nano-grained metals. Extrem. Mech. Lett. 2016, 8, 213–219. [Google Scholar] [CrossRef]

- Yang, X.; Ling, X.; Wang, D.; Wang, W. Deformation behavior and formability of gradient nano-grained AISI 304 stainless steel processed by ultrasonic impact treatment. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 1147–1155. [Google Scholar] [CrossRef]

- GOST 9450-76; Measurement of Microhardness by Indentation of Diamond Tips. GOST: Moscow, Russia, 1976.

- GOST 1497-2023; Metals. Tensile Test Methods. RussianGost: Moscow, Russia, 2023.

- Naizabekov, A.; Lezhnev, S.; Panin, E.; Koinov, T.; Mazur, I. Effect of Combined Rolling–ECAP on Ultrafine-Grained Structure and Properties in 6063 Al Alloy. J. Mater. Eng. Perform. 2019, 28, 200–210. [Google Scholar] [CrossRef]

- Volokitina, I.E.; Volokitin, A.V.; Panin, E.; Fedorova, T.; Lawrinuk, D.; Kolesnikov, A.; Yerzhanov, A.; Gelmanova, Z.; Liseitsev, Y. Improvement of strength and performance properties of copper wire during severe plastic deformation and drawing process. Case Stud. Constr. Mater. 2023, 19, e02609. [Google Scholar] [CrossRef]

- Deng, S.Q.; Godfrey, A.; Liu, W.; Zhang, C.L. Microstructural evolution of pure copper subjected to friction sliding deformation at room temperature. Mater. Sci. Eng. A 2015, 639, 448–455. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | Cr | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Mass fraction, % | 0.45 | 0.17 | 0.8 | 0.2 | 0.15 | 0.15 | rest |

| Radial-Shift Broaching | Drawing | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pass | D1, mm | D2, mm | V2, m/s | V1, m/s | ε, % | εln | D2, mm | D3, mm | V3, m/s | V2, m/s | ε, % | εln | ||

| 1 pass | 30.0 | 25.0 | 0.014 | 0.01 | 30.56 | 0.36 | 25.0 | 23.0 | 0.017 | 0.014 | 15.36 | 0.17 | ||

| 2 pass | 23.0 | 20.0 | 0.013 | 0.01 | 24.39 | 0.28 | 20.0 | 19.0 | 0.015 | 0.013 | 9.75 | 0.10 | ||

| 3 pass | 19.0 | 17.0 | 0.012 | 0.01 | 19.94 | 0.22 | 17.0 | 16.0 | 0.014 | 0.012 | 11.42 | 0.12 | ||

| εΣ, % | 67.89 | εlnΣ | 0.87 | εΣ, % | 59.04 | εlnΣ | 0.39 | |||||||

| εln(total) = 1.52 | ||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volokitina, I.; Volokitin, A.; Makhmutov, B. Formation of Symmetric Gradient Microstructure in Carbon Steel Bars. Symmetry 2024, 16, 997. https://doi.org/10.3390/sym16080997

Volokitina I, Volokitin A, Makhmutov B. Formation of Symmetric Gradient Microstructure in Carbon Steel Bars. Symmetry. 2024; 16(8):997. https://doi.org/10.3390/sym16080997

Chicago/Turabian StyleVolokitina, Irina, Andrey Volokitin, and Bolat Makhmutov. 2024. "Formation of Symmetric Gradient Microstructure in Carbon Steel Bars" Symmetry 16, no. 8: 997. https://doi.org/10.3390/sym16080997

APA StyleVolokitina, I., Volokitin, A., & Makhmutov, B. (2024). Formation of Symmetric Gradient Microstructure in Carbon Steel Bars. Symmetry, 16(8), 997. https://doi.org/10.3390/sym16080997