Research on Eccentric Cavitation Bubble Collapse Dynamics within Droplets

Abstract

1. Introduction

2. Experimental System and Parameters

2.1. Experimental System

2.2. Parameters

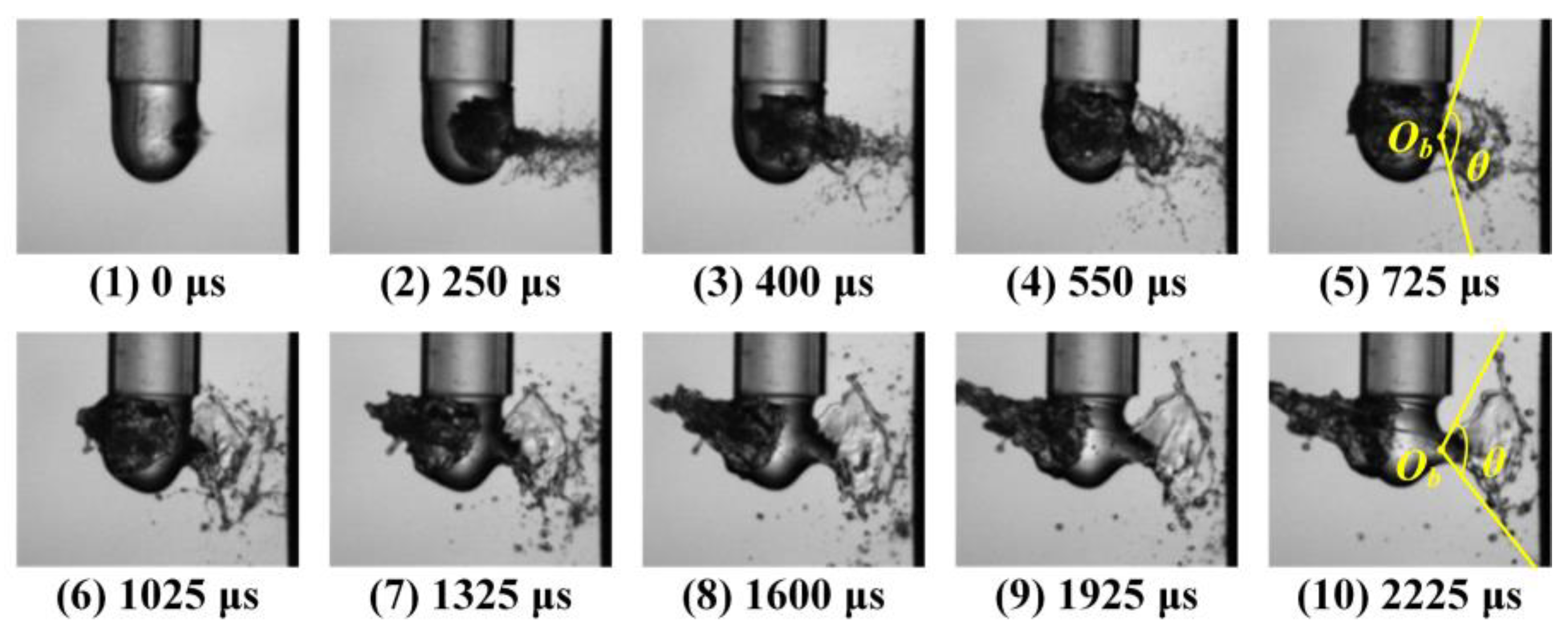

3. Classification of Splash Phenomenon

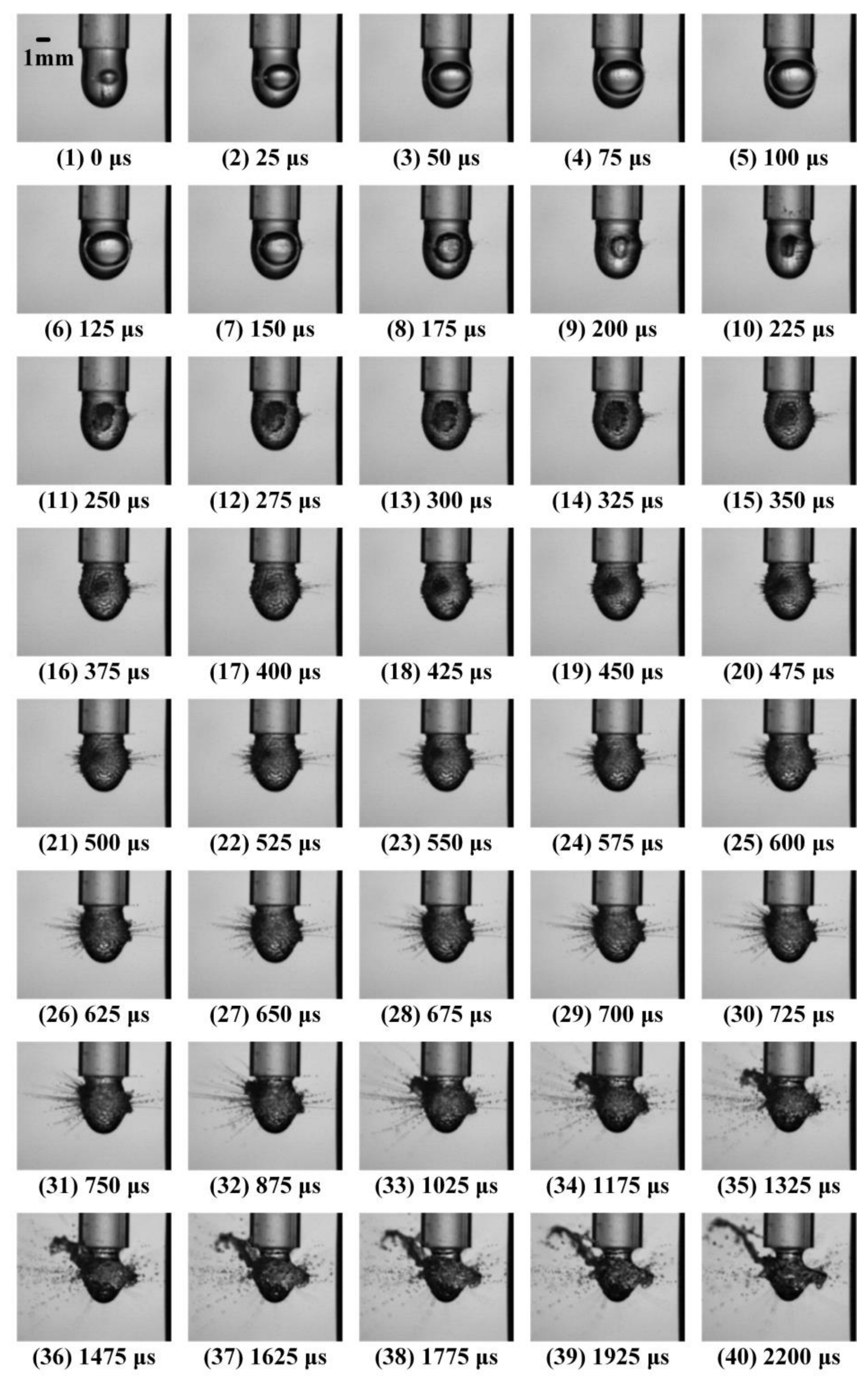

3.1. Case 1

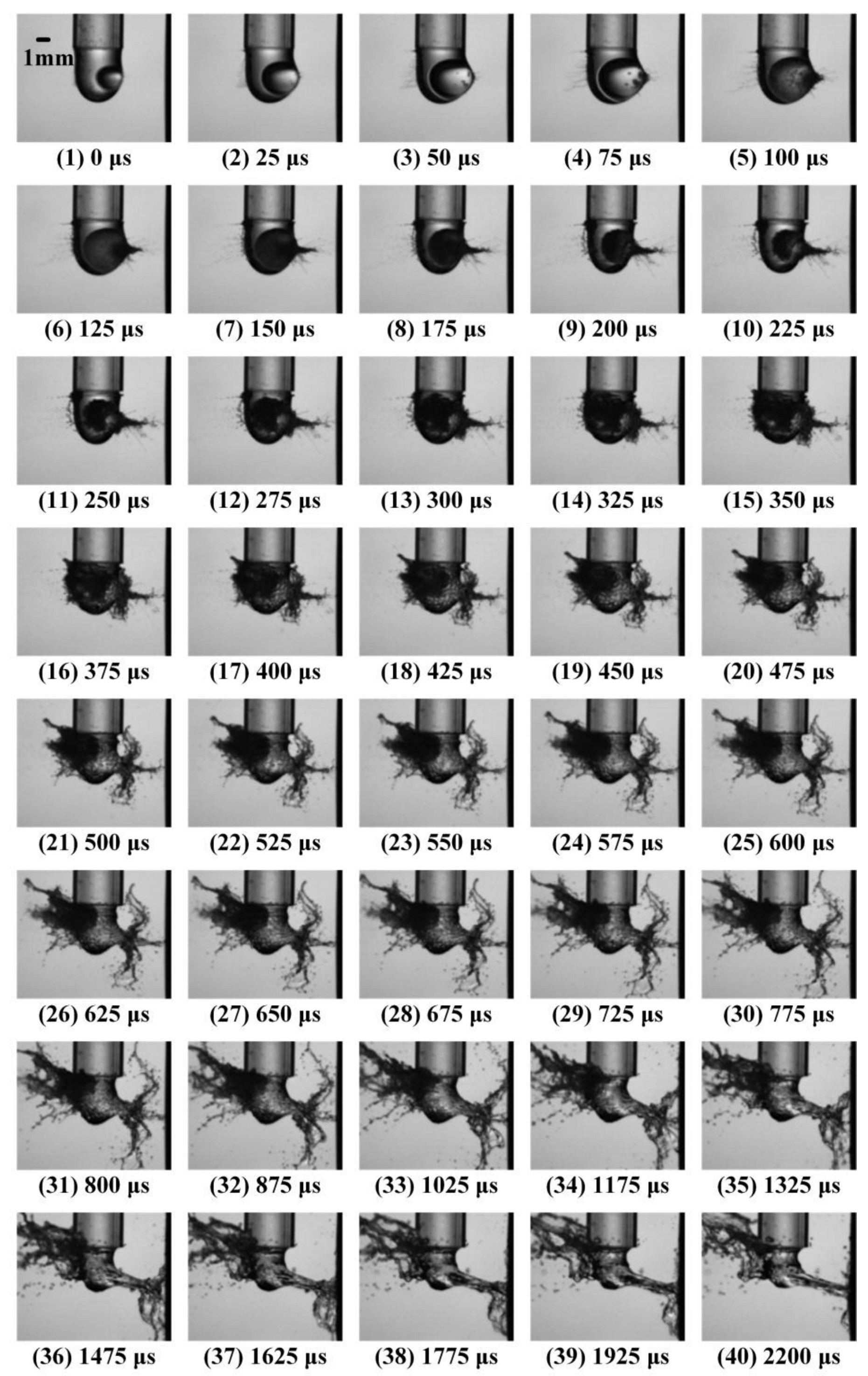

3.2. Case 2

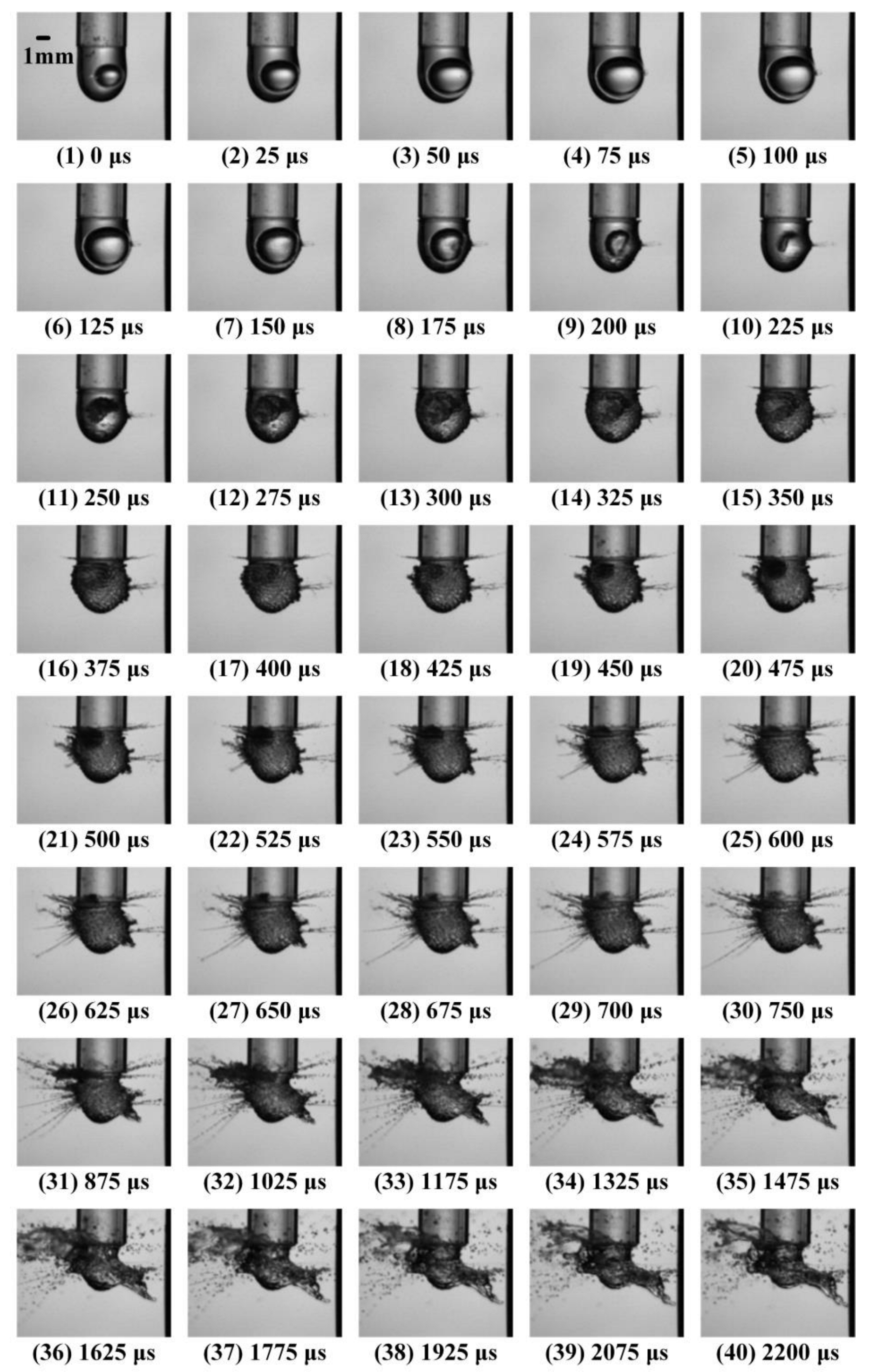

3.3. Case 3

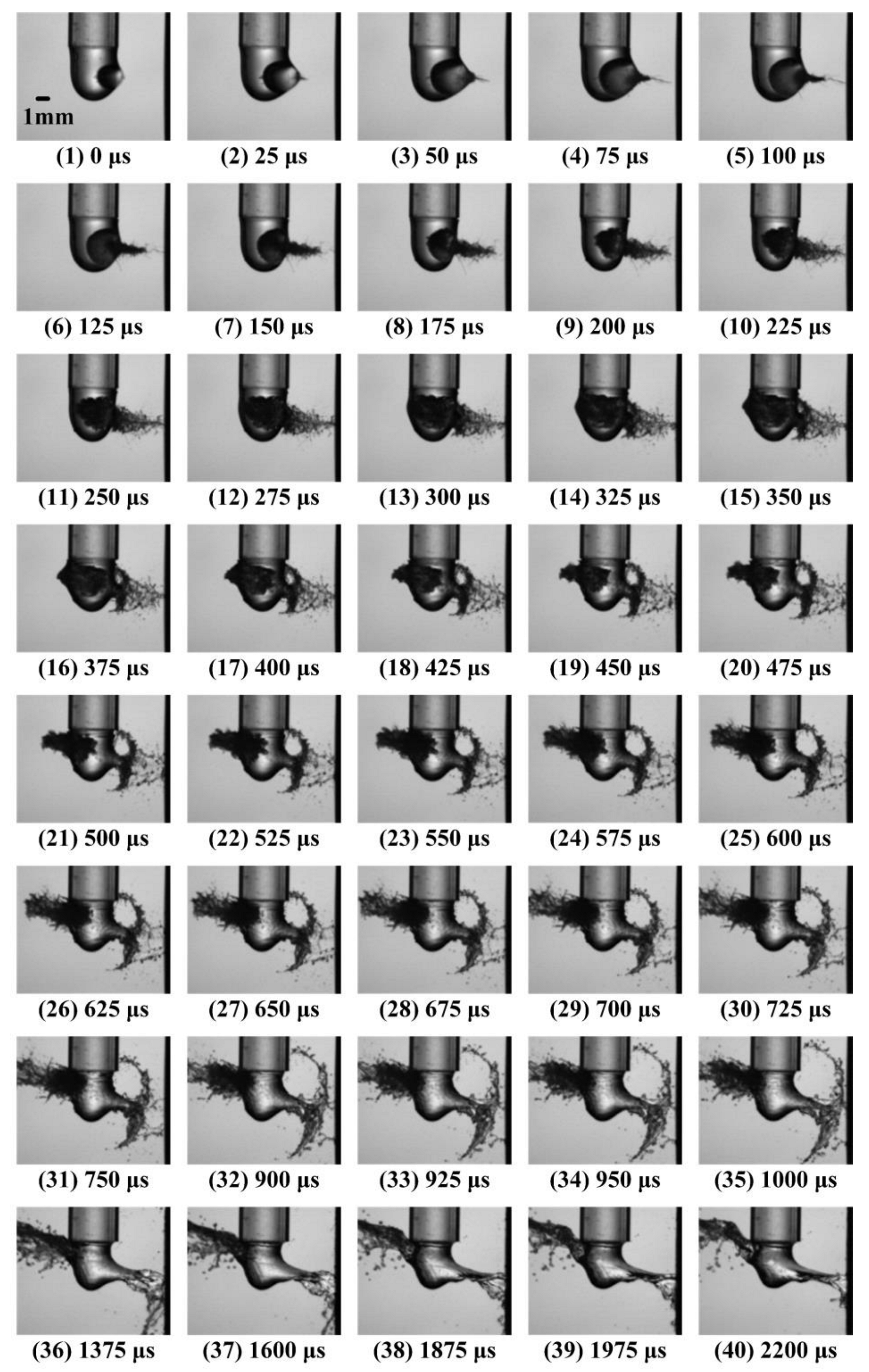

3.4. Transition between Case 1 and Case 2

3.5. Transition between Case 2 and Case 3

4. Collapse Dynamics of Cavitation Bubble

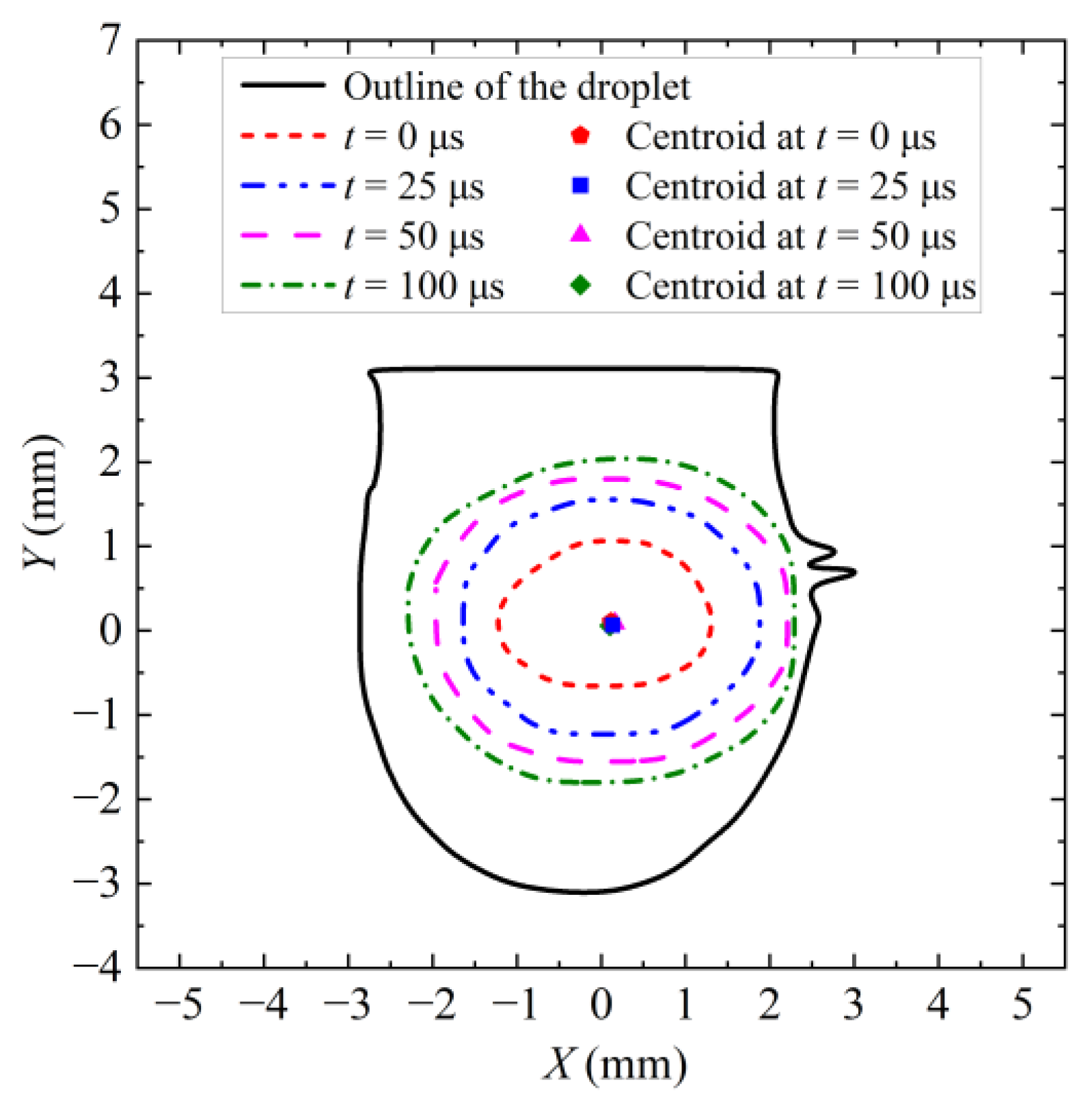

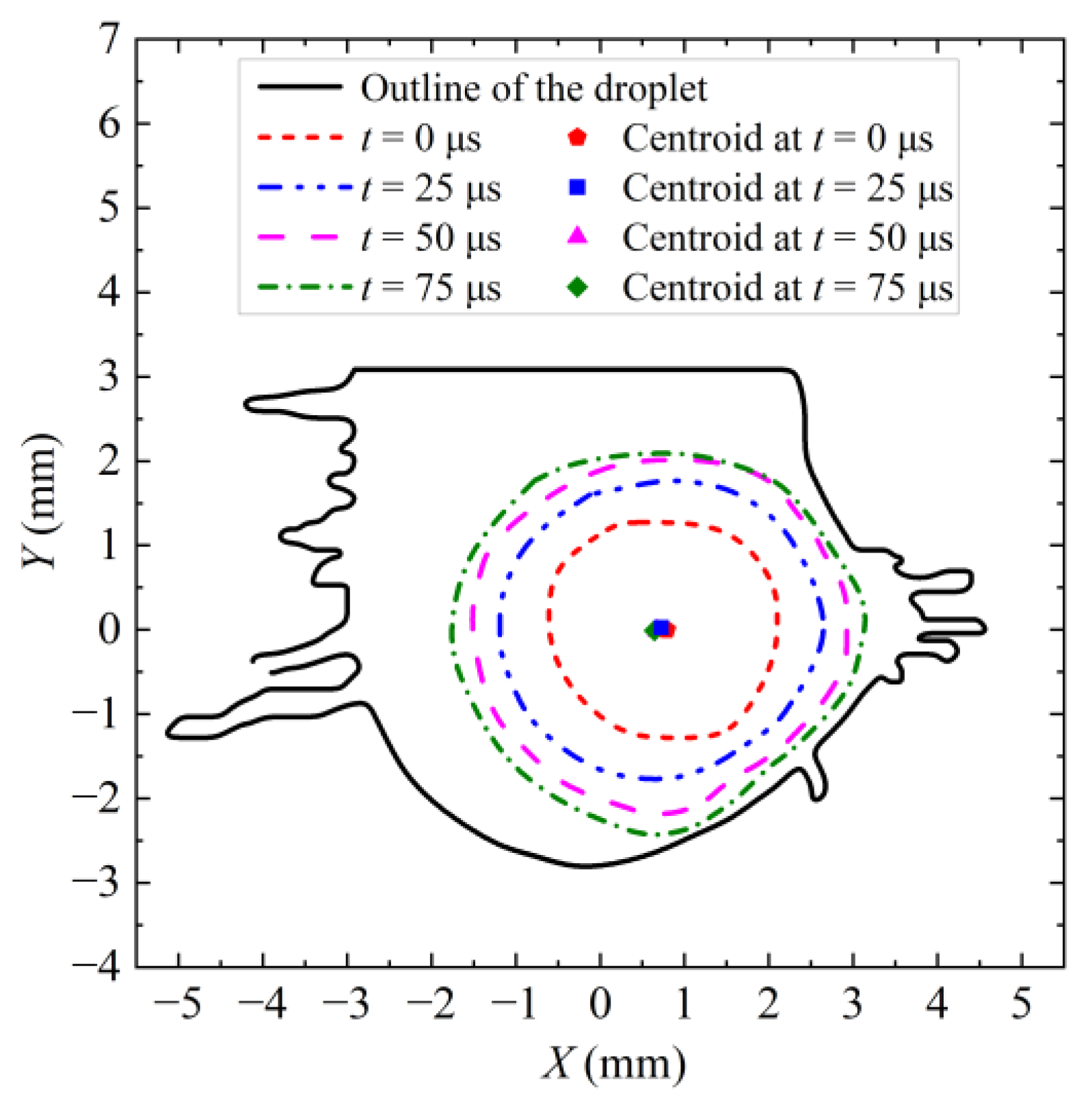

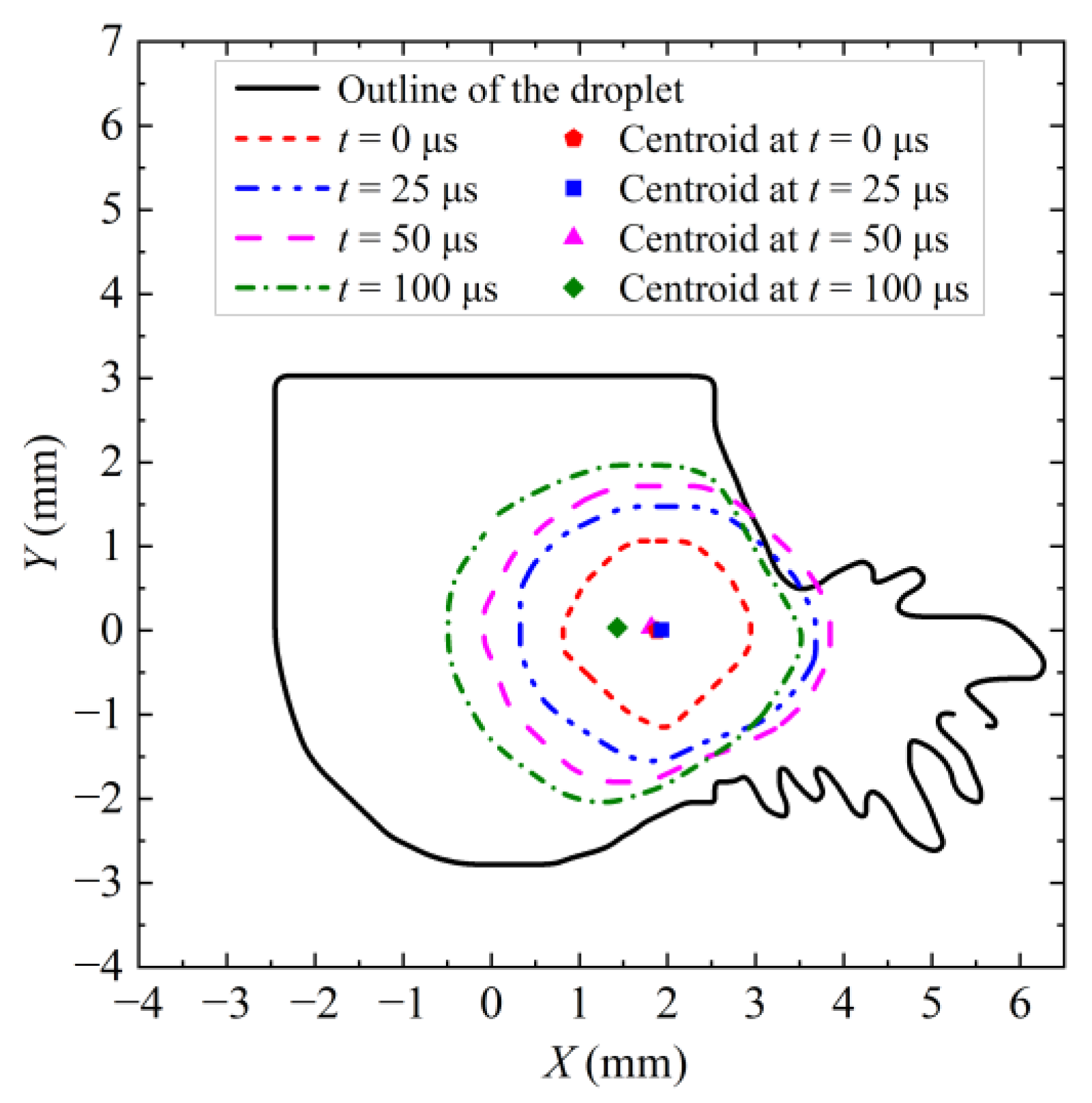

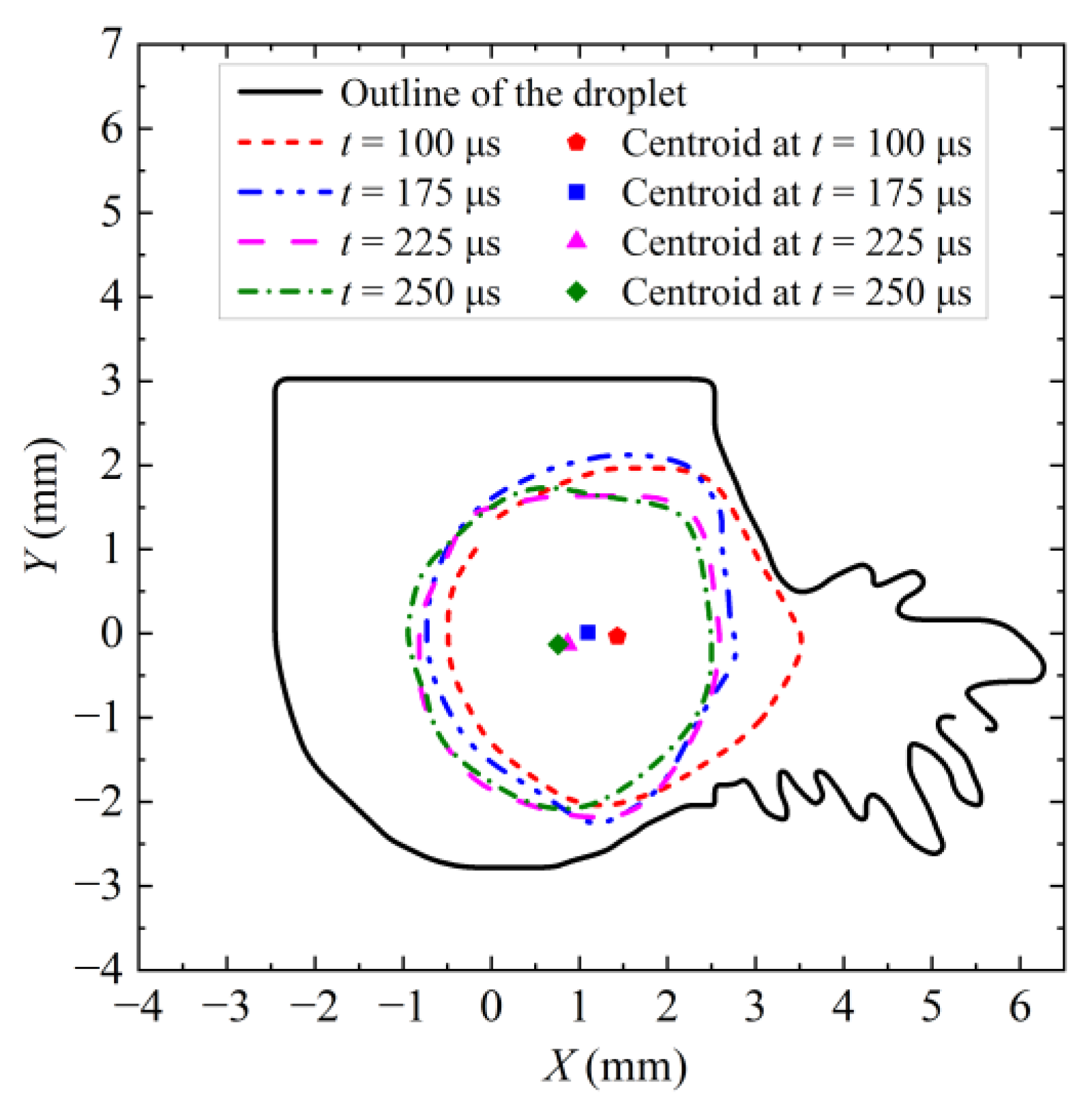

4.1. Outline of Bubble Wall

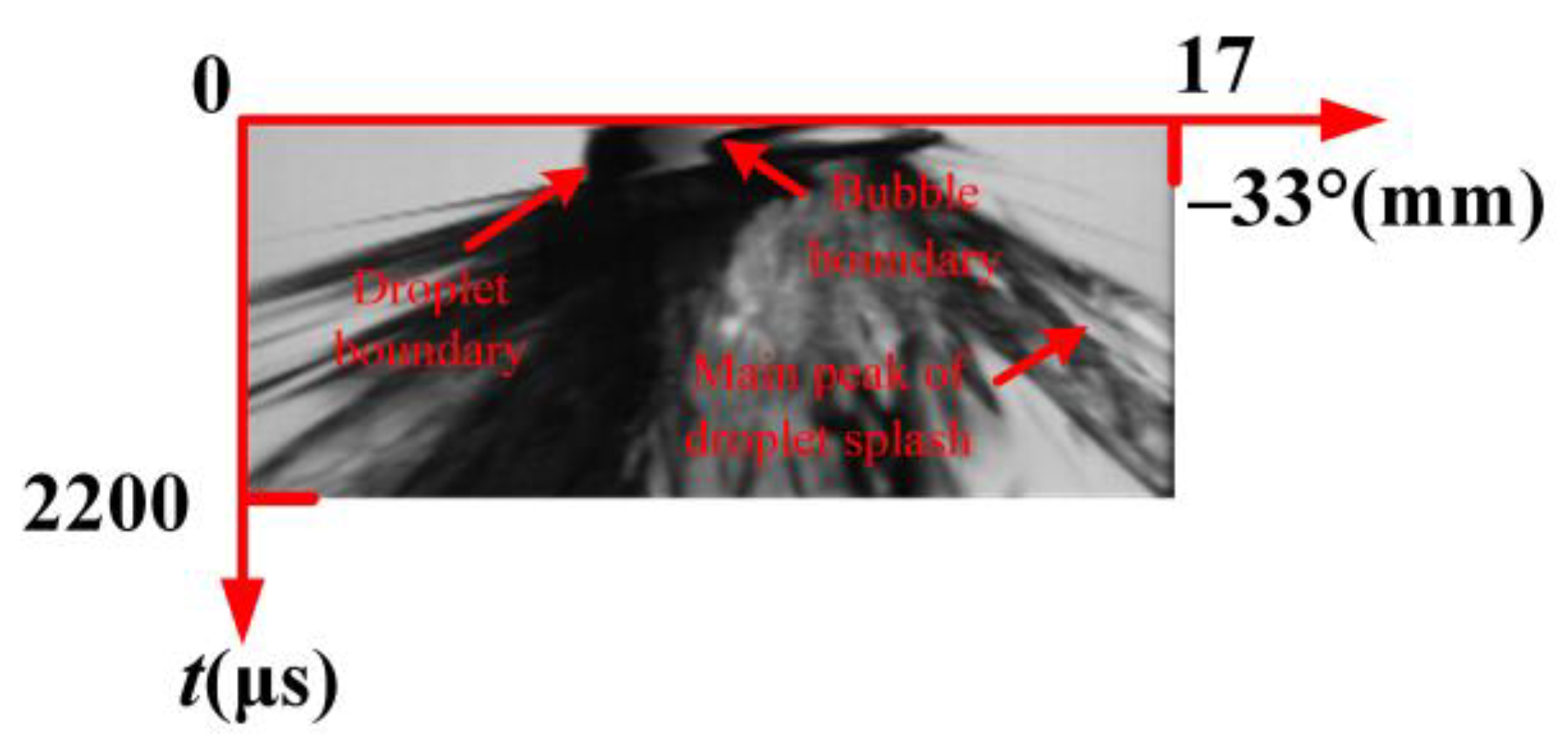

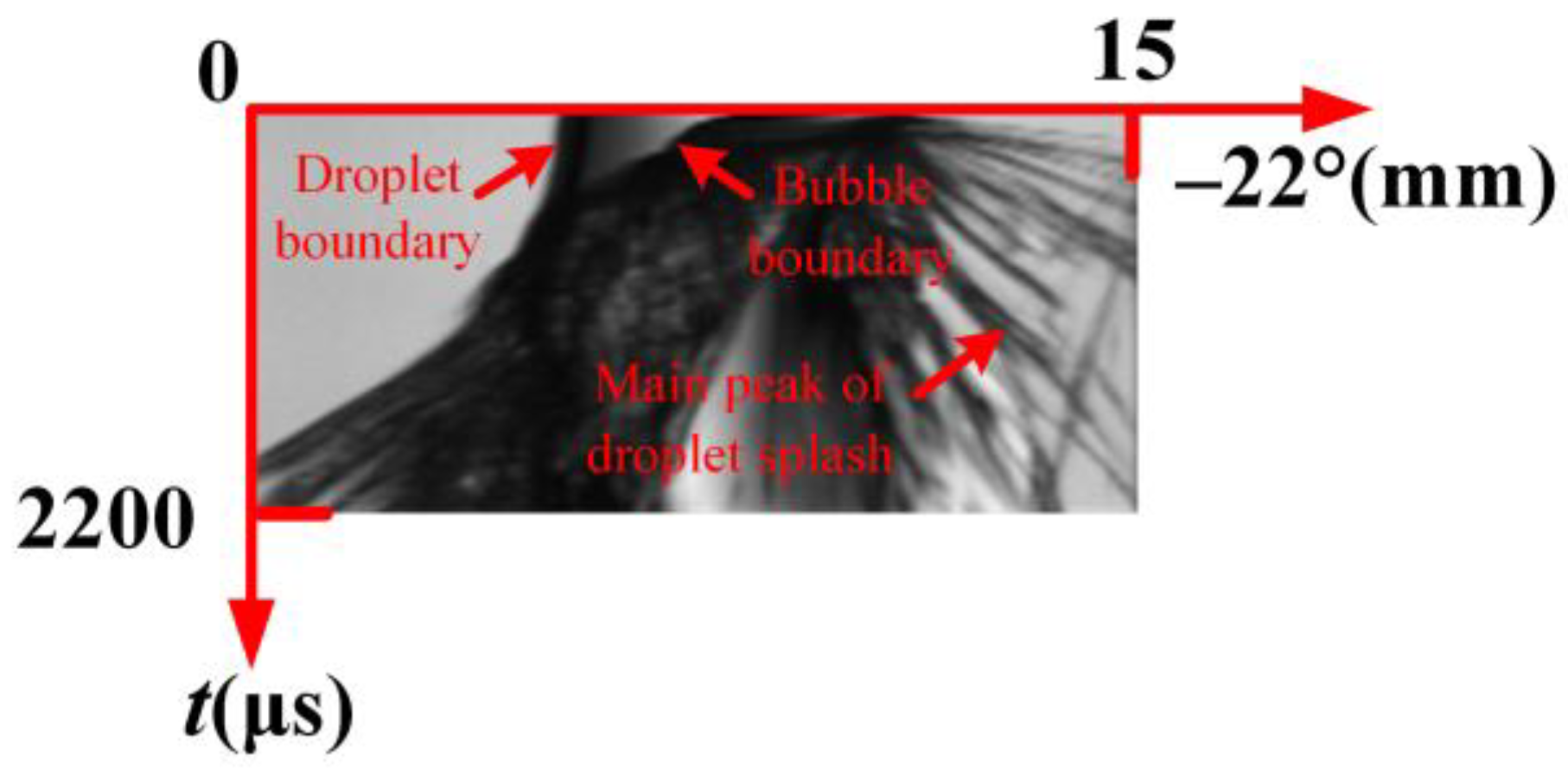

4.2. Image of Bubble and Droplet Boundaries

5. Splash Dynamic of Droplet

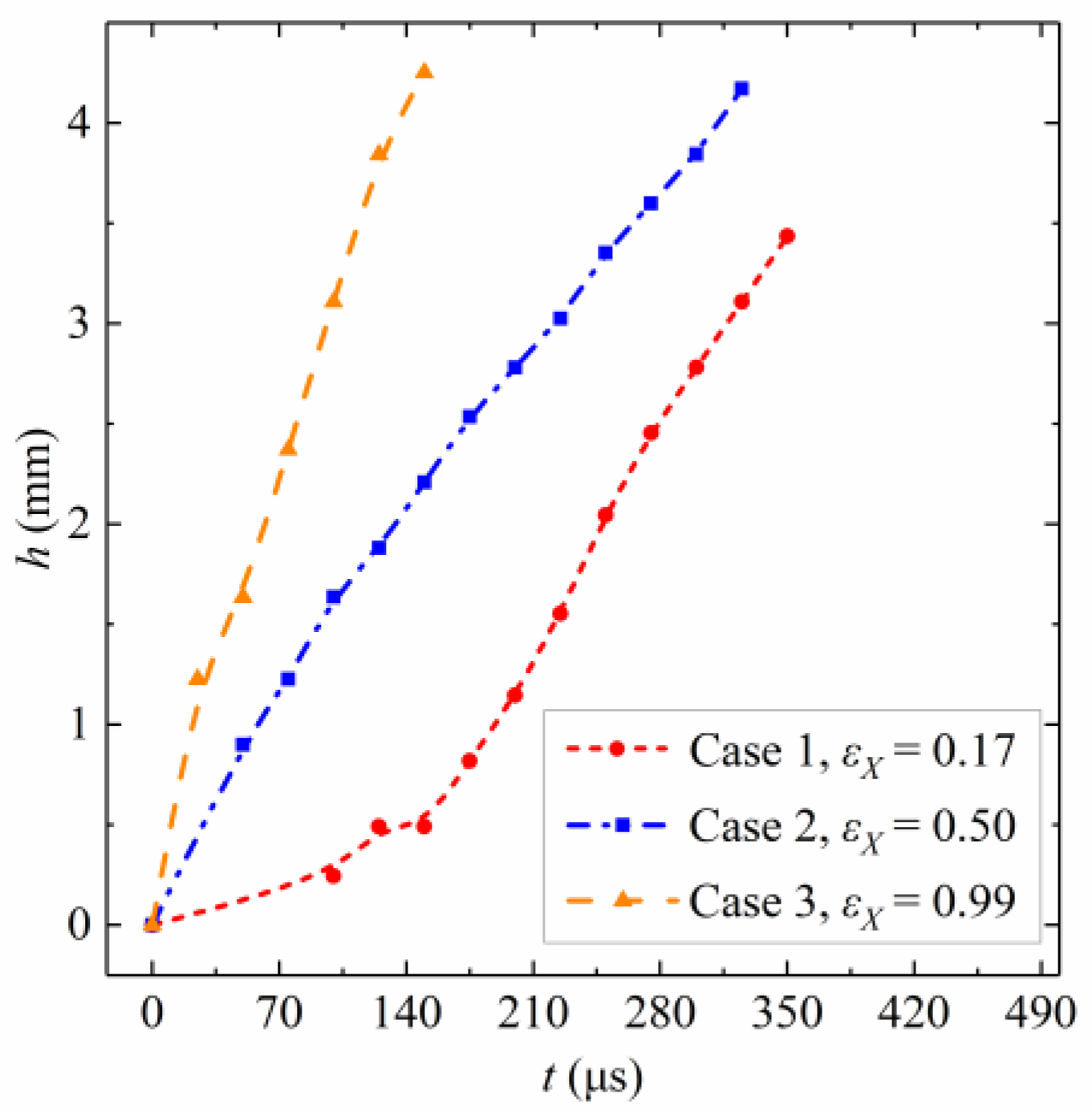

5.1. Height of Main Peak

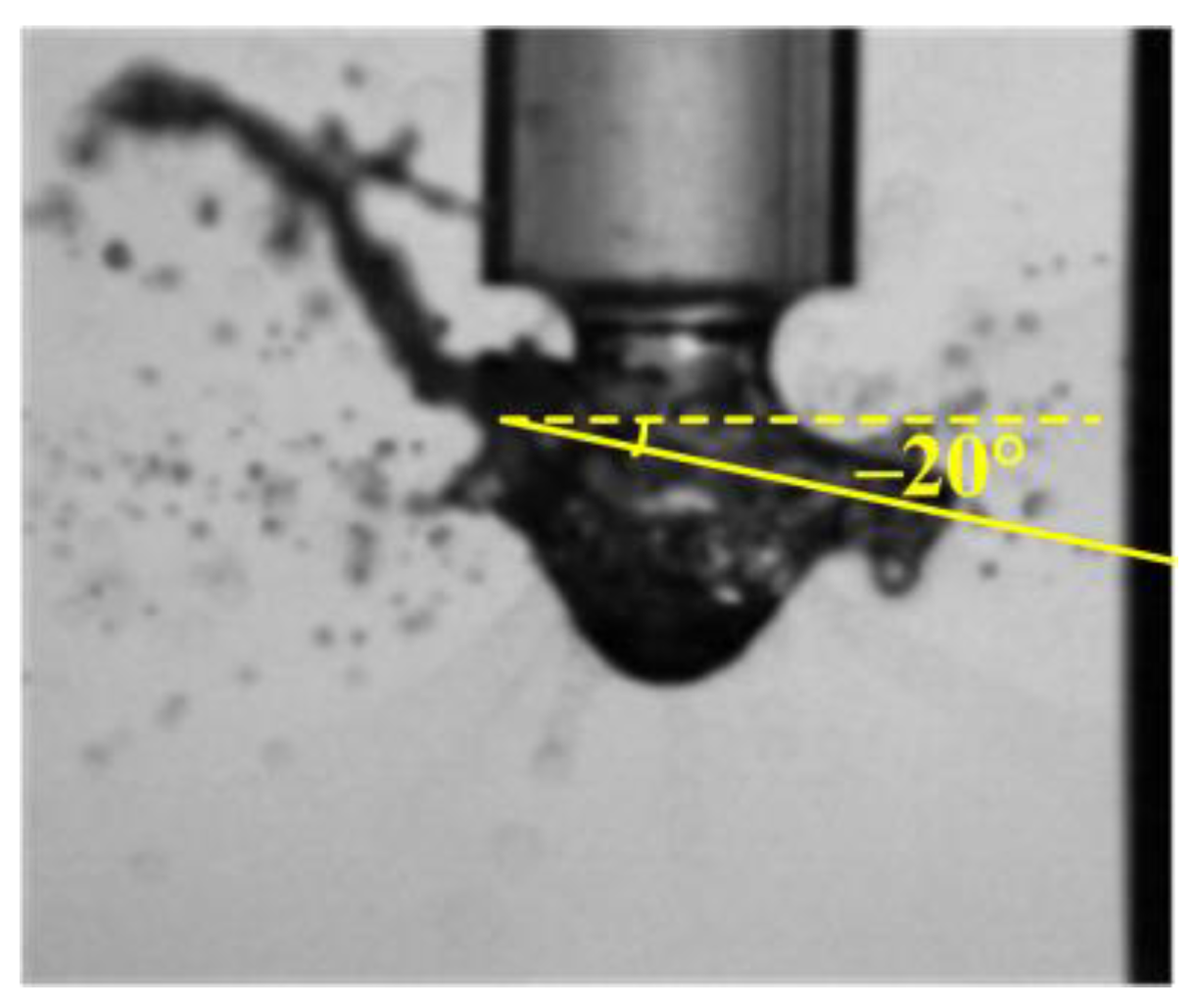

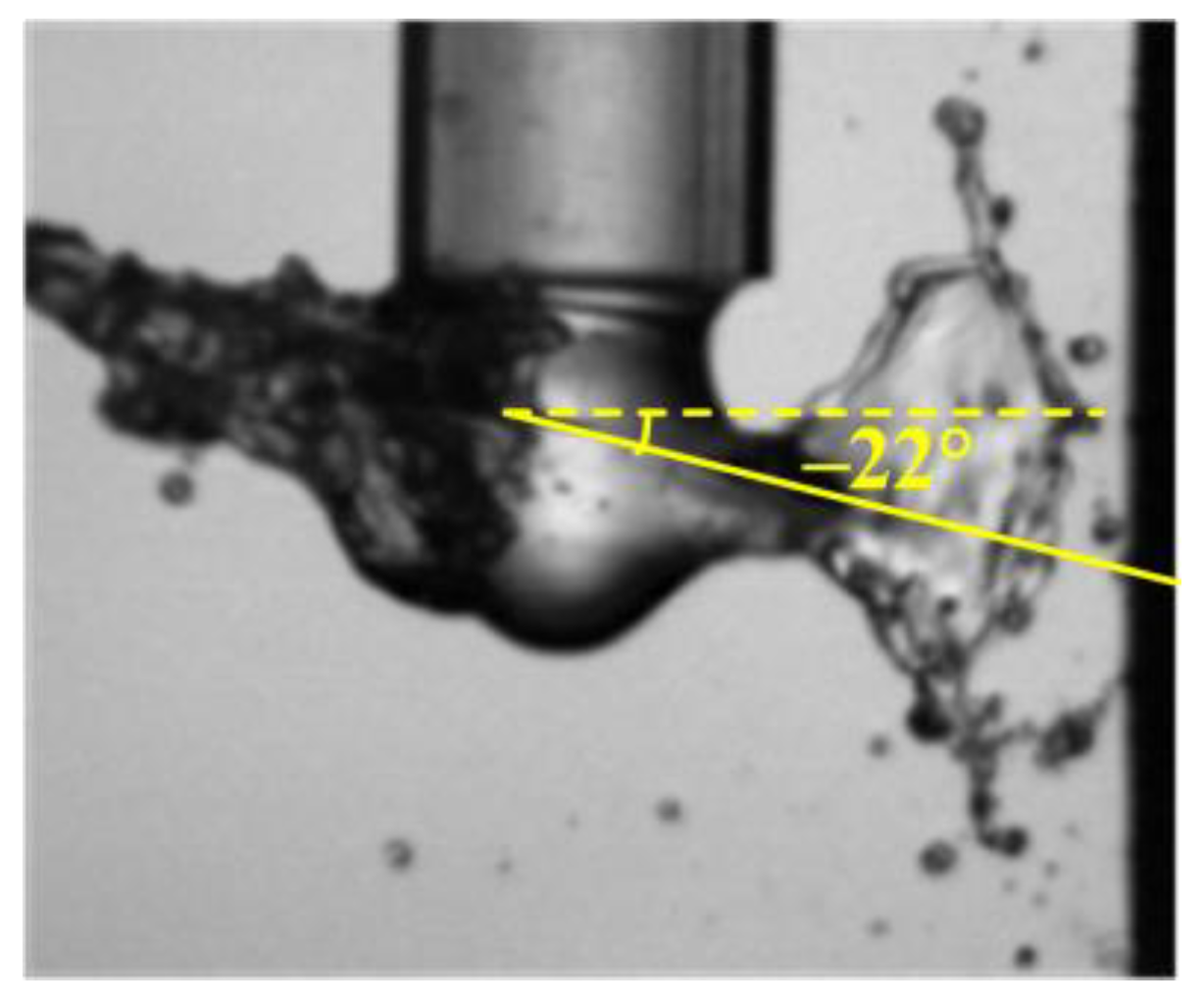

5.2. Angle of Splash

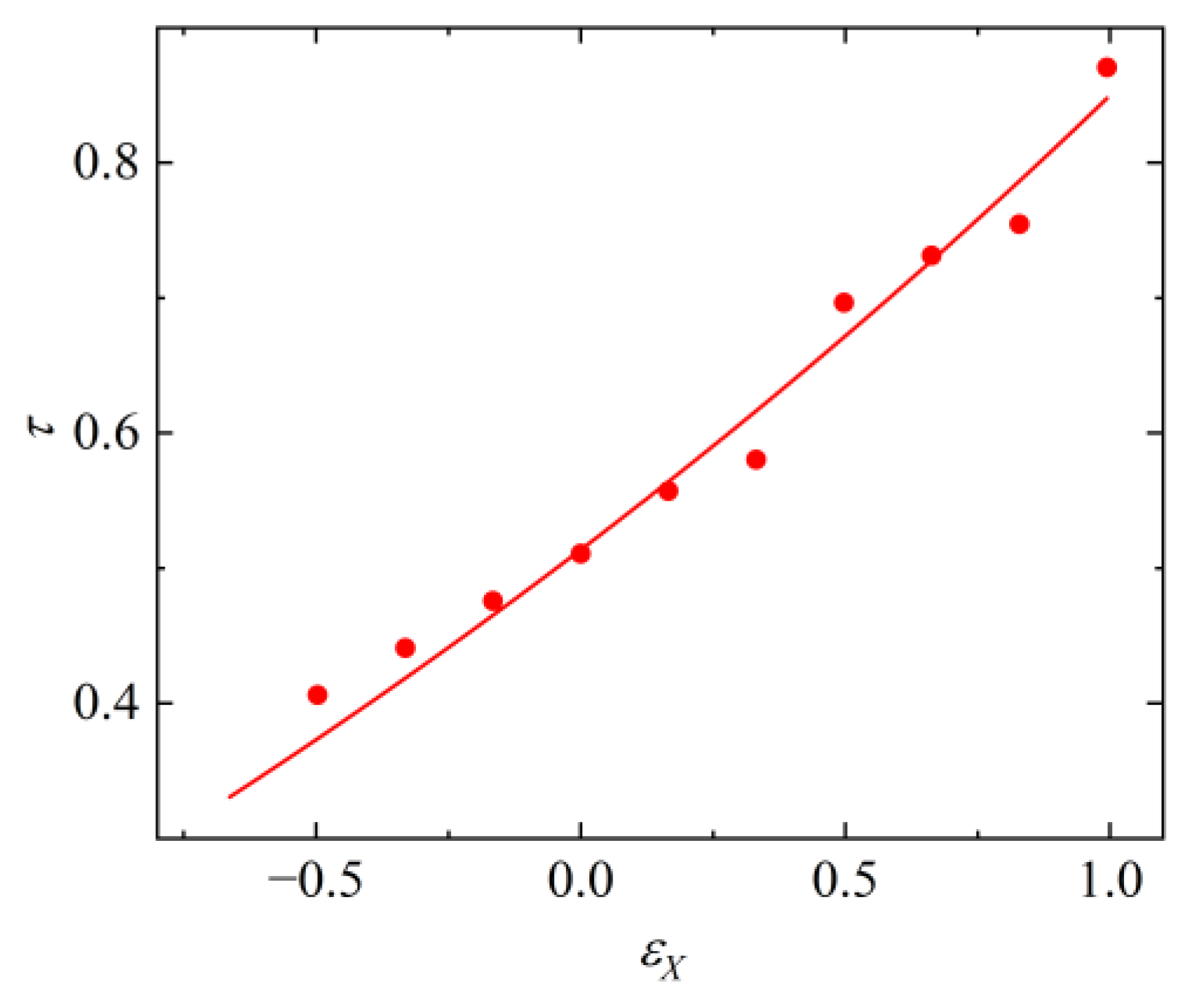

6. Bubble Collapse Time

7. Conclusions

- The forms of droplet splash can be divided into three types: scattered splash, trident splash, and composite splash. And, the movement trend of the cavitation bubble wall can be divided into three categories: spherical, fabiform, and ellipsoidal contraction.

- The main peak height and angle of the droplet splash could be significantly affected by the eccentricity.

- The modification coefficient of the collapse time increases with the increase of eccentricity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Theory of Modification Coefficient

References

- Wu, X.; Wang, S. Analysis and Improvement of Throttling Orifice for Recirculating Pipeline in the JND System of NPP. Nucl. Sci. Eng. 2022, 42, 533–538. [Google Scholar]

- Song, Y.; Lu, D.; Qin, H.; Zhong, D.; Cao, Q. Numerical Analysis on Pressure Drop of the Labyrinth Throttle. Nucl. Sci. Eng. 2020, 40, 316–324. [Google Scholar]

- Hu, W. Oscillation Analysis and Design Optimization of Condensate Main Control Valve. Nucl. Sci. Eng. 2022, 42, 427–435. [Google Scholar]

- Wang, X.; Liu, Y.; Zhu, R. Study on shaft-block under small break loss of coolant accident of nuclear main pump. Ann. Nucl. Energy 2019, 131, 344–352. [Google Scholar] [CrossRef]

- Hong, F.; Yuan, J.; Zhang, J.; Lu, J.; Zhang, Y. Numerical analysis of cavitating flow characteristics in residual heat removal pumps during the SBLOCA. J. Harbin Eng. Univ. 2015, 36, 297–301. [Google Scholar]

- Tao, J.; Xian, C.; Chen, J.; Ma, Z. Study on Aerosol Gravitational Sedimentation Characteristics in Containment of HPR. Nucl. Sci. Eng. 2020, 40, 751–756. [Google Scholar]

- Sun, X.; Ji, S.; Chen, L.; Shi, X.; Xiao, Z.; Wei, Y. Development of Aerosol Re-suspension Module in CABSA by Force Balance Model. Numerical Analysis on Pressure. Nucl. Sci. Eng. 2020, 40, 683–687. [Google Scholar]

- Ren, H.; Li, Y.; Yu, J.; Liang, F.; Li, S. Current Situation and Prospect of Radioactive Aerosol Removal Technology. Environ. Sci. Manag. 2020, 45, 92–96. [Google Scholar]

- Wu, H.; Wang, C.; Zheng, G.; Pang, H.; Luo, Z.; Chen, R.; Chen, L.; Wang, Z. Study on the optimization of sample introduction flow rate for aerosol direct injection device and aerosol loss rate. Radiat. Prot. 2021, 41, 27–32. [Google Scholar]

- Su, Y.; Li, Z.; Xu, J.; Zhai, L.; Zhu, F. Direct Introduction of Airborne and Suspension Particles into ICP-MS for on-line Elemental or Isotopic Analysis and Its Applications in Nuclear Field. Northwest Inst. Nucl. Technol. 2019, 40, 447–459. [Google Scholar]

- Brennen, C.E. Cavitation and Bubble Dynamics, 2nd ed.; Cambridge University Press: New York, NY, USA, 2014; pp. 80–195. [Google Scholar]

- Avila, S.R.G.; Ohl, C. Cavitation-induced fragmentation of an acoustically-levitated droplet. J. Phys. Conf. Ser. 2015, 656, 12017. [Google Scholar] [CrossRef]

- Farhat, M. What We Learned from Cavitation Bubbles in Microgravity, 1st ed.; IntechOpen: London, UK, 2020; pp. 1–20. [Google Scholar]

- Lindinger, A.; Hagen, J.; Socaciu, L.D.; Bernhardt, T.M.; Woste, L.; Duft, D.; Leisner, T. Time-resolved explosion dynamics of H2O droplets induced by femtosecond laser pulses. Appl. Opt. 2004, 43, 5263–5269. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Ren, S.; Li, Q.; Li, J. 3D numerical simulation on fluid-structure interaction of structure subjected to underwater explosion with cavitation. Appl. Math. Mech. 2012, 33, 1191–1206. [Google Scholar] [CrossRef]

- Zhang, A.; Yao, X. The interaction between multiple underwater explosion bubbles near free surface. Chin. J. Theor. Appl. Mech. 2008, 40, 26–34. [Google Scholar]

- Chahine, G.L. Spark-generated bubbles as laboratpry-scale models of underwater explosions and their use for validation of simulation tools. In Proceedings of the 66th Shock and Vibrations Symposium, Biloxi, MS, USA, November 1995; pp. 265–276. [Google Scholar]

- Eickmans, J.H.; Hsieh, W.F.; Chang, R.K. Laser-induced explosion of H2O droplets: Spatially resolved spectra. Opt. Lett. 1987, 12, 22–24. [Google Scholar] [CrossRef]

- Ohl, C.; Arora, M.; Dijkink, R.; Janve, V.; Lohse, D. Surface cleaning from laser-induced cavitation bubbles. Appl. Phys. Lett. 2006, 89, 74102. [Google Scholar] [CrossRef]

- Kondo, T.; Ando, K. One-way-coupling simulation of cavitation accompanied by high-speed droplet impact. Phys. Fluids 2016, 28, 33303. [Google Scholar] [CrossRef]

- Gonzalez Avila, S.R.; Ohl, C. Fragmentation of acoustically levitating droplets by laser-induced cavitation bubbles. J. Fluid Mech. 2016, 805, 551–576. [Google Scholar] [CrossRef]

- Marston, J.O.; Thoroddsen, S.T. Laser-induced micro-jetting from armored droplets. Exp. Fluids 2015, 56, 140. [Google Scholar] [CrossRef]

- Zeng, Q.; Gonzalez-Avila, S.R.; Voorde, S.T.; Ohl, C. Jetting of viscous droplets from cavitation-induced Rayleigh–Taylor instability. J. Fluid Mech. 2018, 846, 916–943. [Google Scholar] [CrossRef]

- Guo, W.; Li, H.; Wang, J.; Wang, Y.; Huang, C. Reaserch progress on interaction between a single cavitation and free surface. Chin. J. Theor. Appl. Mech. 2019, 51, 1682–1698. [Google Scholar]

- Obreschkow, D.; Kobel, P.; Dorsaz, N.; de Bosset, A.; Nicollier, C.; Farhat, M. Cavitation bubble dynamics inside liquid drops in microgravity. Phys. Rev. Lett. 2006, 97, 94502. [Google Scholar] [CrossRef] [PubMed]

- Farhat, M.; Obreschkow, D.; Kobel, P.; Dorsaz, N.; de Bosset, A. Interaction of a cavitation bubble with a spherical free surface. In Proceedings of the 6th International Symposium on Cavitation CAV2006, Wageningen, The Netherlands, 11–15 September 2006. [Google Scholar]

- Kobel, P.; Obreschkow, D.; de Bosset, A.; Dorsaz, N.; Farhat, M. Techniques for generating centimetric drops in microgravity and application to cavitation studies. Exp. Fluids 2009, 47, 39–48. [Google Scholar] [CrossRef]

- Robert, E.; Lettry, J.; Farhat, M.; Monkewitz, P.A.; Avellan, F. Cavitation bubble behavior inside a liquid jet. Phys. Fluids 2007, 19, 67106. [Google Scholar] [CrossRef]

- Padilla-Martinez, J.P.; Ramirez-San-Juan, J.C.; Berrospe-Rodriguez, C.; Korneev, N.; Aguilar, G.; Zaca-Moran, P.; Ramos-Garcia, R. Controllable direction of liquid jets generated by thermocavitation within a droplet. Appl. Opt. 2017, 56, 7167–7173. [Google Scholar] [CrossRef]

- Thoroddsen, S.T.; Takehara, K.; Etoh, T.G.; Ohl, C.D. Spray and microjets produced by focusing a laser pulse into a hemispherical drop. Phys. Fluids 2009, 21, 112101. [Google Scholar] [CrossRef]

- Liu, Y. Investigation on the Interaction of a Shock and a Liquid Droplet with and without a Vapor Cavity Inside. Ph.D. Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, X.; Zhang, S.; Yang, Y.; Du, X.; Li, Z.; Zhang, Y. Research on Eccentric Cavitation Bubble Collapse Dynamics within Droplets. Symmetry 2023, 15, 1375. https://doi.org/10.3390/sym15071375

Zhang Y, Zhang X, Zhang S, Yang Y, Du X, Li Z, Zhang Y. Research on Eccentric Cavitation Bubble Collapse Dynamics within Droplets. Symmetry. 2023; 15(7):1375. https://doi.org/10.3390/sym15071375

Chicago/Turabian StyleZhang, Yuning, Xiaofei Zhang, Shurui Zhang, Yihao Yang, Xuan Du, Zhaohao Li, and Yuning Zhang. 2023. "Research on Eccentric Cavitation Bubble Collapse Dynamics within Droplets" Symmetry 15, no. 7: 1375. https://doi.org/10.3390/sym15071375

APA StyleZhang, Y., Zhang, X., Zhang, S., Yang, Y., Du, X., Li, Z., & Zhang, Y. (2023). Research on Eccentric Cavitation Bubble Collapse Dynamics within Droplets. Symmetry, 15(7), 1375. https://doi.org/10.3390/sym15071375