Collapsing and Splashing Dynamics of Single Laser-Induced Cavitation Bubbles within Droplets

Abstract

1. Introduction

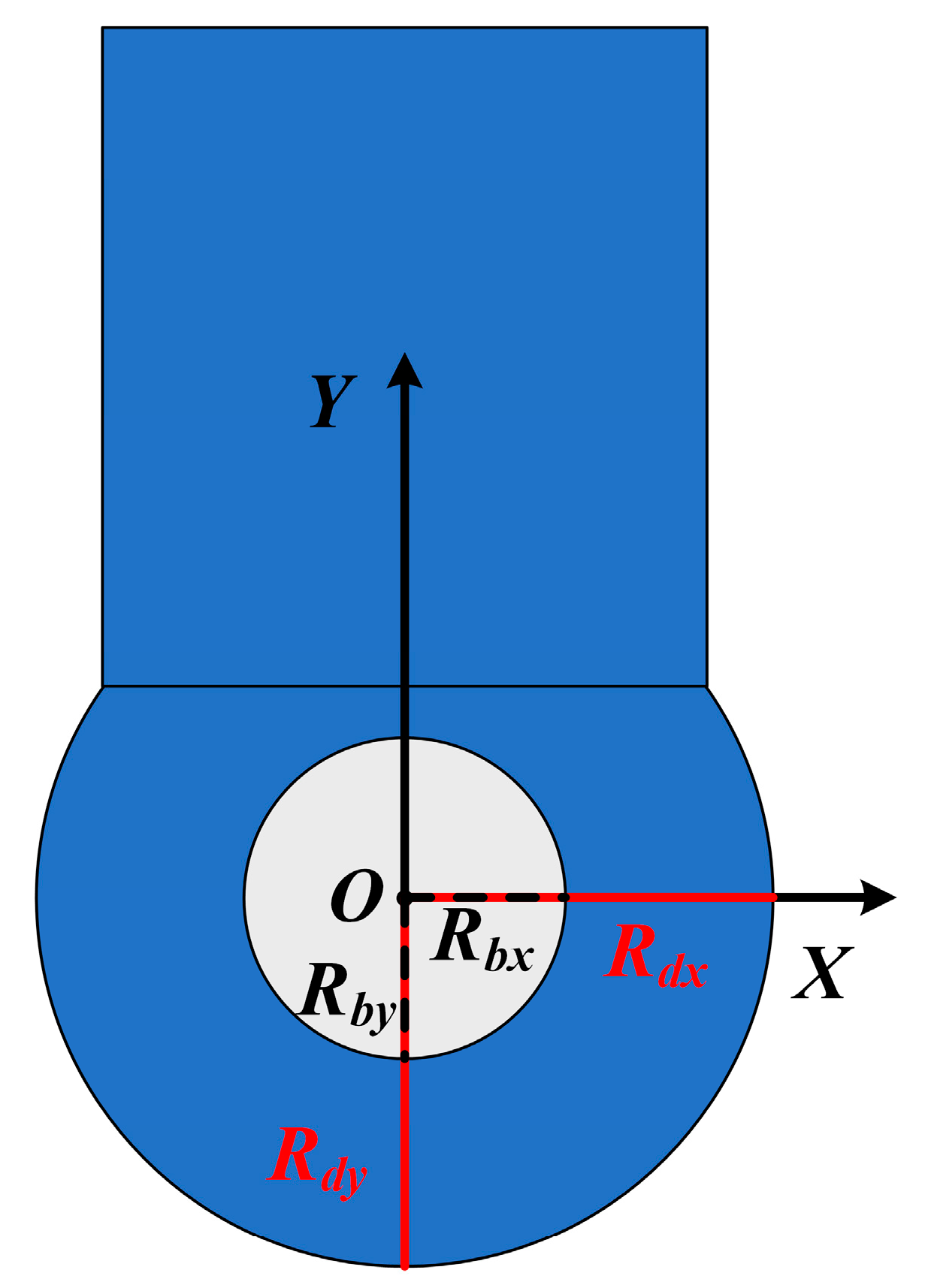

2. Physical Model

2.1. Theory Model

2.2. Numerical Calculation Settings

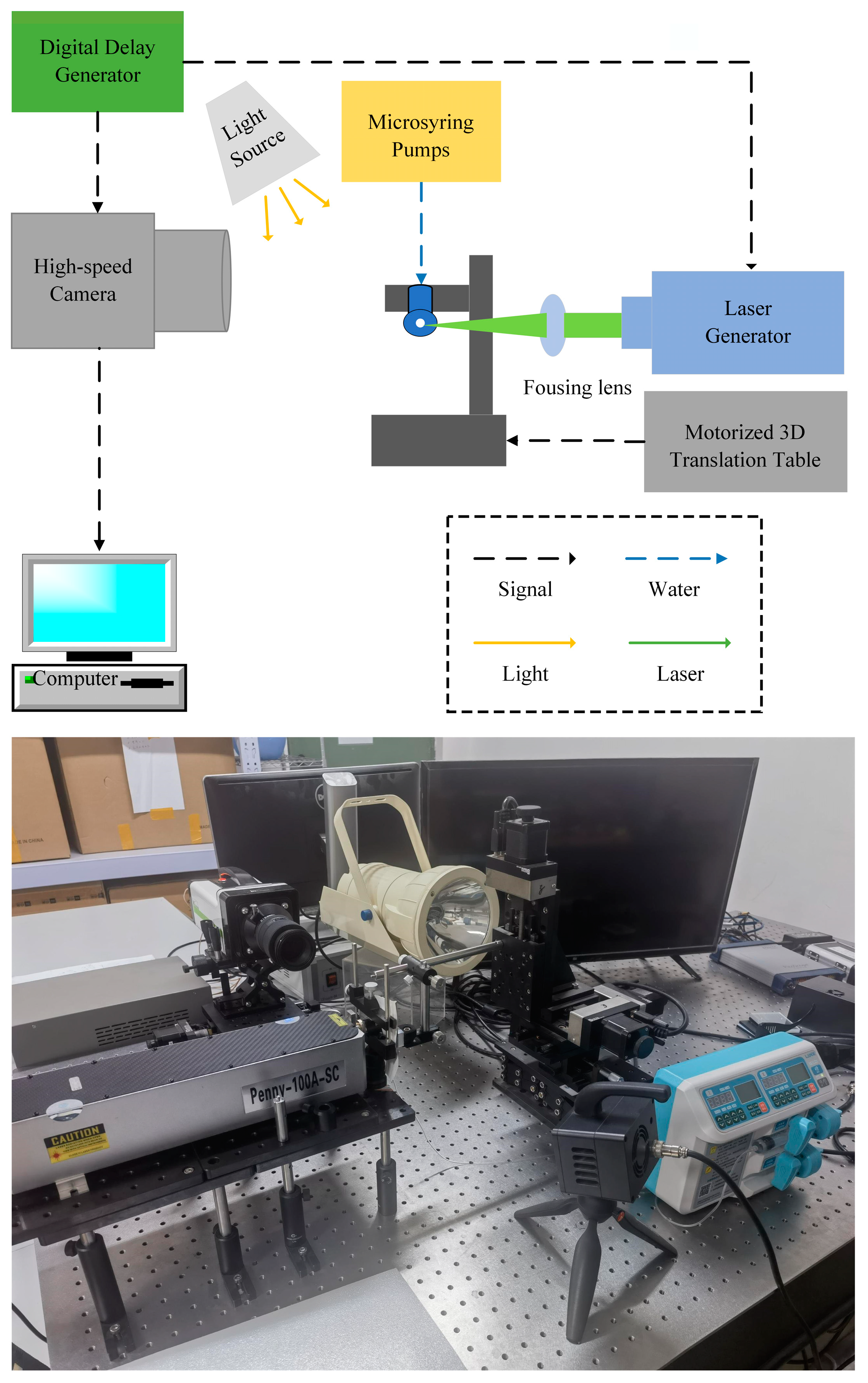

3. Experimental System

3.1. Experimental Equipment

3.2. Experimental Parameters and Process

4. Experimental Results and Analysis

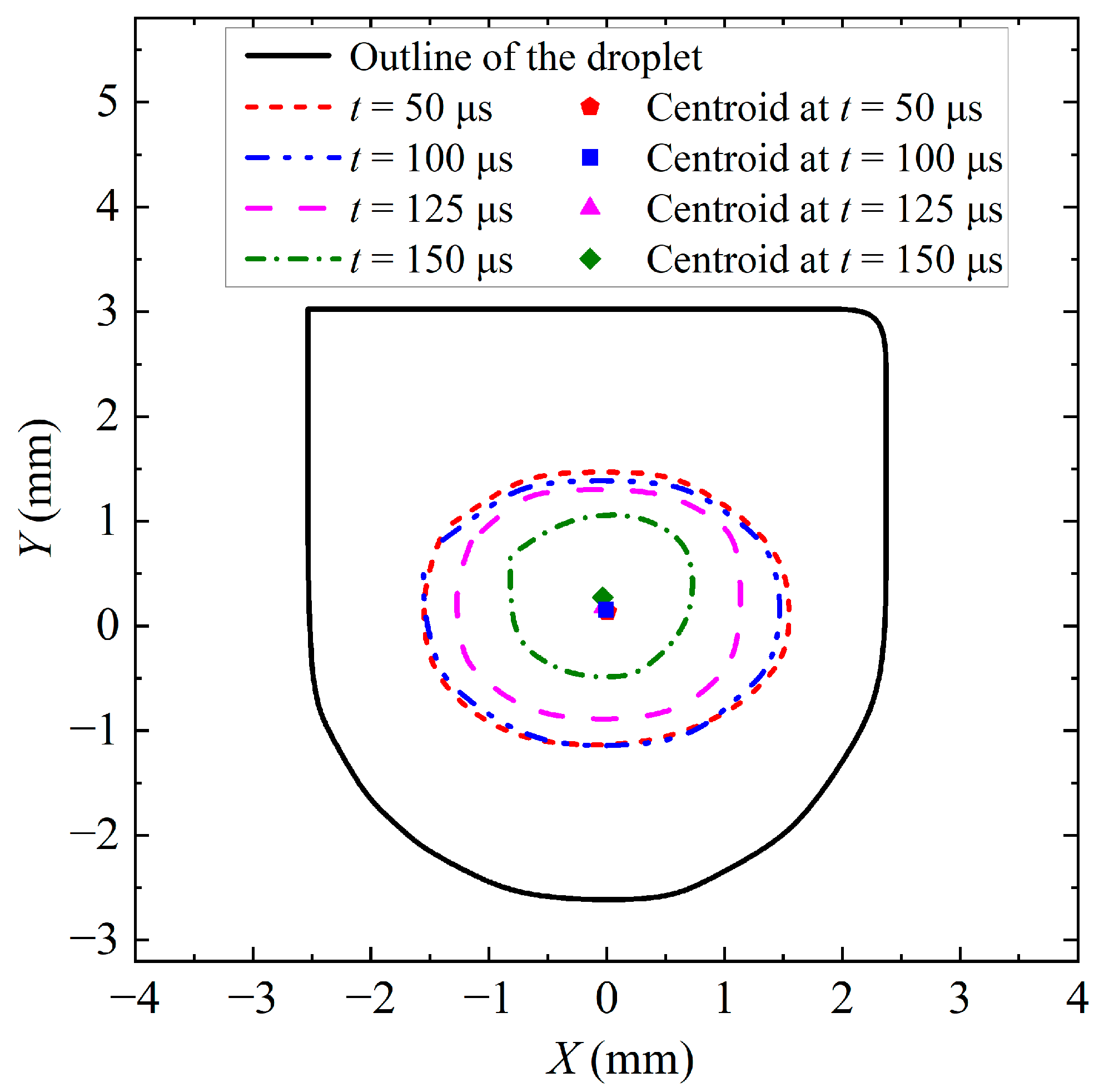

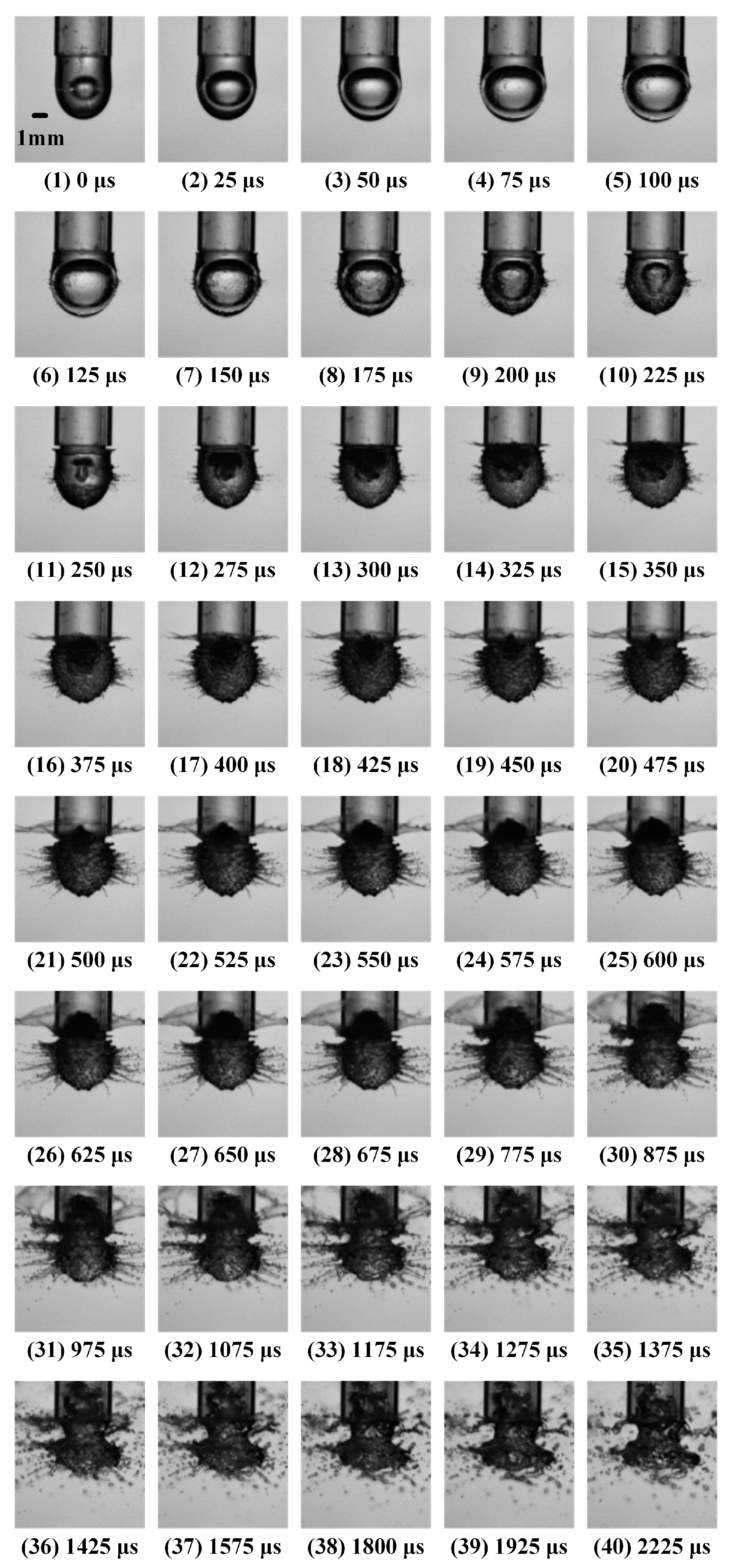

4.1. Case 1: No Splash

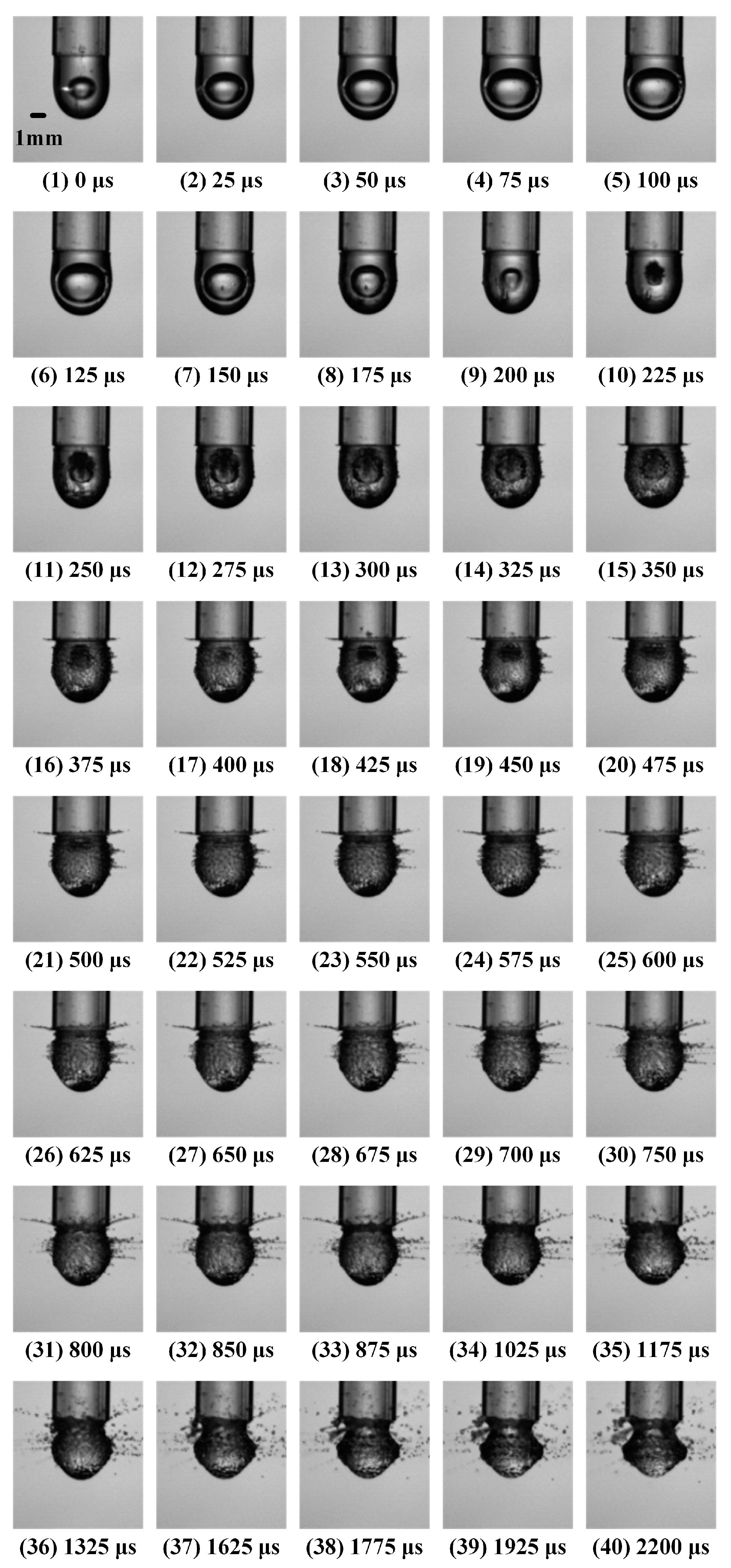

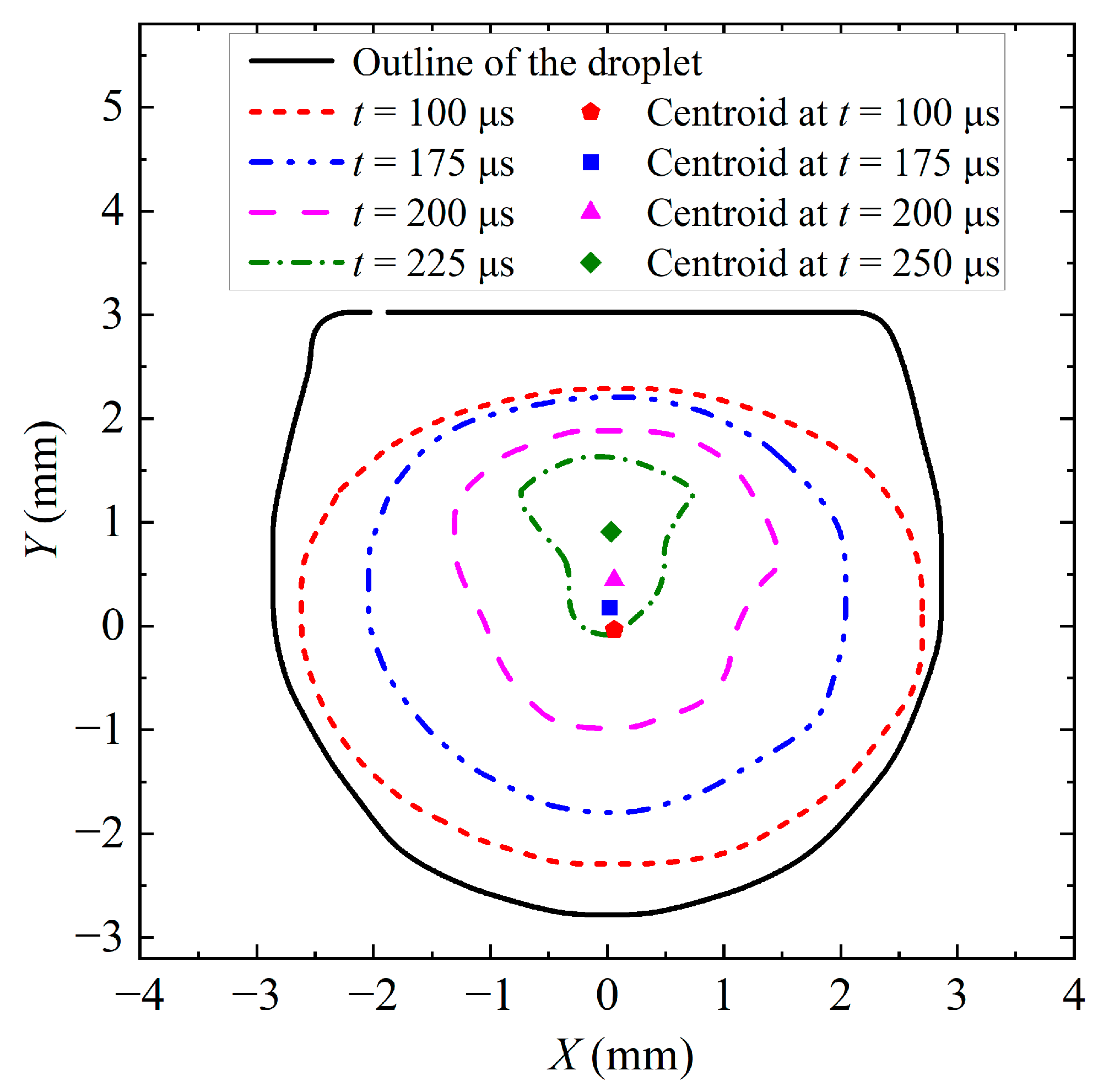

4.2. Case 2: Scattering Splash

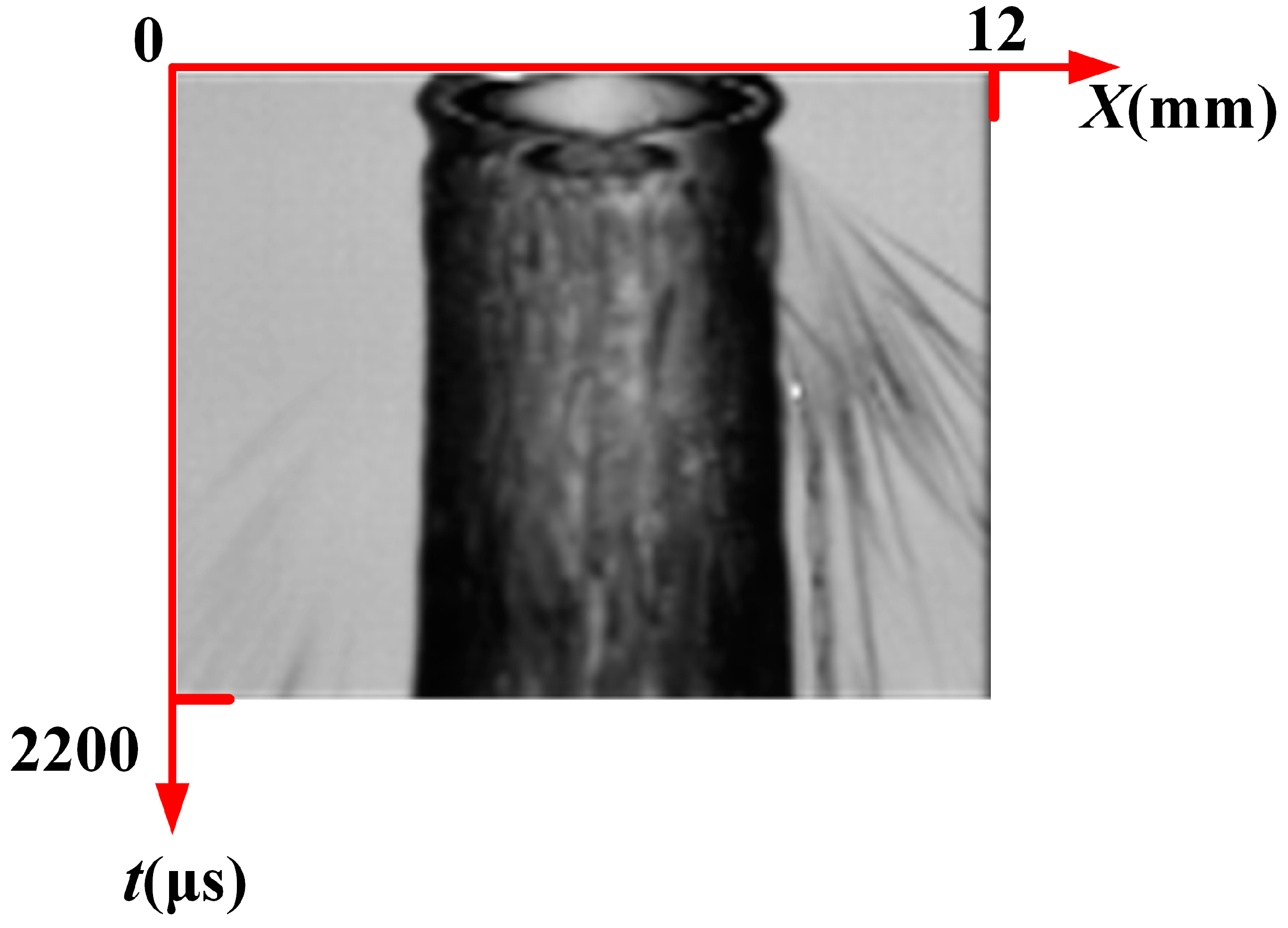

4.3. Case 3: Composite Splash

5. Analysis of Three Droplet Splash Cases

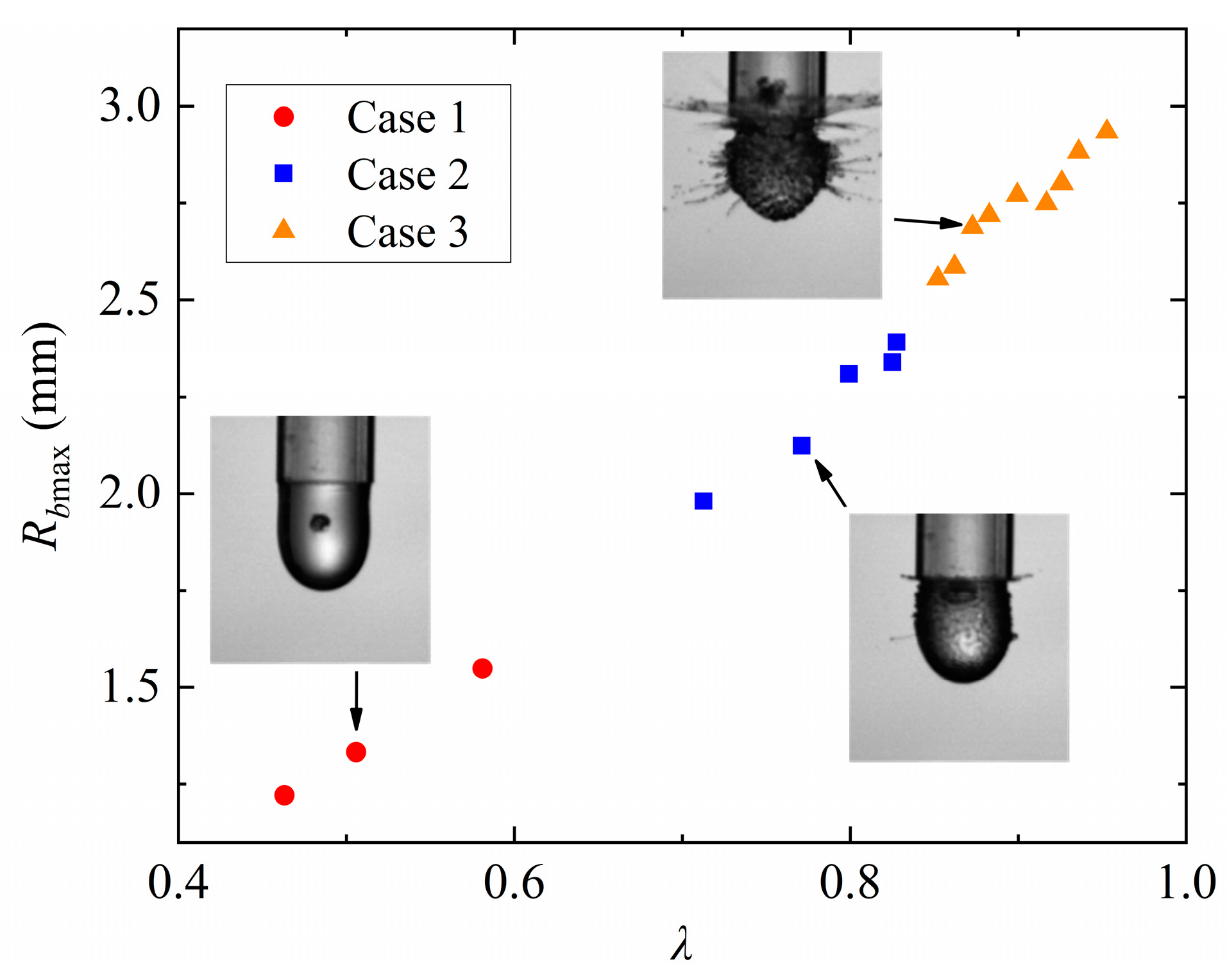

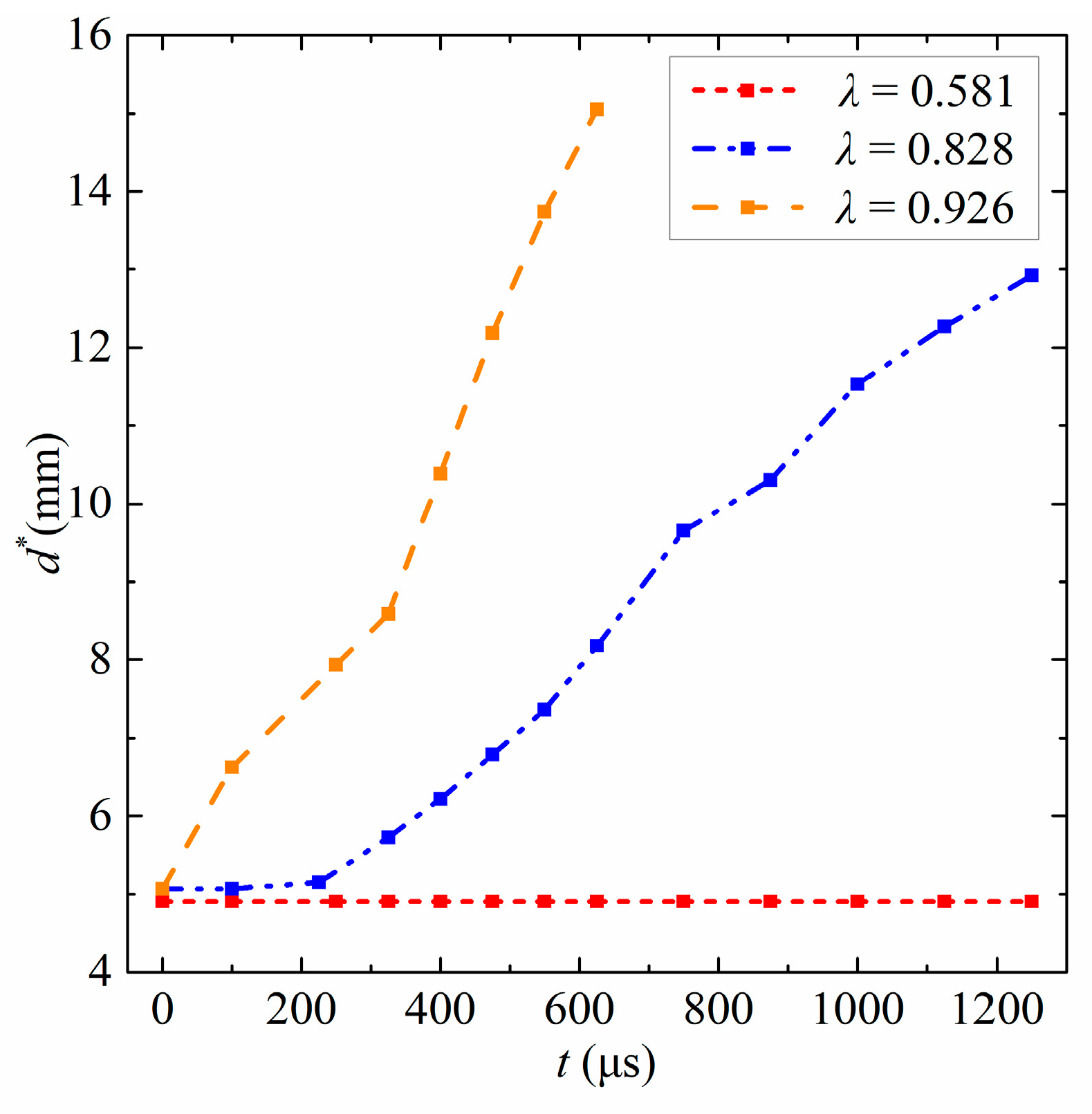

5.1. Comparison of Three Cases under Different Radius Ratios

5.2. Splash Displacement Comparison

6. Theoretical Verification of Bubble Collapse Time

7. Conclusions

- By adding the surface tension and viscosity terms, the bubble dynamics equation is further improved, and the cavitation bubble dynamics within the droplet equation model is proposed.

- With the increase of radius ratio, the influence of the bubble collapse process on the droplet is gradually enhanced. When there is a small radius ratio, the bubble collapse process has little effect on the droplet surface; when there is a medium radius ratio, the bubble collapse process causes a scattering splash on the droplet surface; when there is a large radius ratio, the bubble collapse process causes a “composite splash” on the surface of liquid droplets, including both scattered splash and flaky splash.

- There is an interaction between bubble collapse and droplet splash. Basically, with the increase of radius ratio, the center of the bubble moves more significantly compared with the shape before the first collapse of the bubble. Under the small radius ratio, the bubble contracted into a sphere. Under the middle radius ratio, the bubble contracted into a cone. Additionally, under the large radius ratio, the bubble contracted into a mushroom shape.

- Through numerical calculation, the time of bubble collapse within the droplet can be accurately predicted under the condition of a medium radius ratio.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Roman Letters | |

| amount of substance (mol) | |

| ideal gas pressure inside the bubble (Pa) | |

| ambient pressure in equilibrium (Pa) | |

| external disturbance pressure amplitude (Pa) | |

| liquid side pressure at the surface between the droplet and bubble (Pa) | |

| liquid side pressure at the surface between the droplet and the external gas (Pa) | |

| vapor side pressure at the surface between the droplet and bubble (Pa) | |

| gas side pressure at the surface between the droplet and the external gas (Pa) | |

| instant radius of a single bubble within a droplet (m) | |

| initial moment radius of the bubble within a droplet at equilibrium (m) | |

| instant radius of the droplet containing a bubble (m) | |

| initial moment radius of the droplet containing a bubble at equilibrium (m) | |

| general gas constants (J/mol·k) | |

| the maximum radius of the collapsing bubble (m) | |

| time (μs) | |

| temperature inside the bubble (°C) | |

| volume of the bubble (m3) | |

| Greek Letters | |

| polytropic exponent | |

| radius ratio | |

| gas viscosity coefficient in the external environment (Pa·s) | |

| viscosity coefficient of the droplet (Pa·s) | |

| density of the liquid (kg/m3) | |

| surface tension coefficient (N/m) | |

References

- Suh, H.K.; Lee, C.S. Effect of cavitation in nozzle orifice on the diesel fuel atomization characteristics. Int. J. Heat Fluid Flow 2008, 29, 1001–1009. [Google Scholar] [CrossRef]

- Lü, M.; Ning, Z.; Yan, K.; Fu, J.; Sun, C. Instability and breakup of cavitation bubbles within diesel drops. Chin. J. Chem. Eng. 2015, 23, 262–267. [Google Scholar] [CrossRef]

- Emery, T.S.; Raghupathi, P.A.; Kandlikar, S.G. Bubble growth inside an evaporating liquid droplet introduced in an immiscible superheated liquid. Int. J. Heat Mass Transf. 2018, 127, 313–321. [Google Scholar] [CrossRef]

- Lv, M.; Ning, Z.; Yan, K. The instability of vapor bubble growth within the diesel droplet under the condition of supercavitation. In Advanced Materials Research; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 512, pp. 477–480. [Google Scholar]

- Ming, L.; Zhi, N.; Chunhua, S. Numerical simulation of cavitation bubble collapse within a droplet. Comput. Fluids 2017, 152, 157–163. [Google Scholar] [CrossRef]

- Lü, M.; Ning, Z.; Yan, K.; Fu, J.; Song, Y.; Sun, C. Breakup of cavitation bubbles within the diesel droplet. Chin. J. Mech. Eng. 2014, 27, 198–204. [Google Scholar] [CrossRef]

- Mori, Y.; Hijikata, K.; Nagatani, T. Fundamental study of bubble dissolution in liquid. Int. J. Heat Mass Transf. 1977, 20, 41–50. [Google Scholar] [CrossRef]

- Lauterborn, W. Numerical investigation of nonlinear oscillations of gas bubbles in liquids. J. Acoust. Soc. Am. 1976, 59, 283–293. [Google Scholar] [CrossRef]

- Rafizadeh, S.; Dadvand, A. Droplet generation via oscillation of a transient bubble inside a funnel-like chamber. Eng. Anal. Bound. Elem. 2020, 113, 416–427. [Google Scholar] [CrossRef]

- Obreschkow, D.; Kobel, P.; Dorsaz, N.; De Bosset, A.; Nicollier, C.; Farhat, M. Cavitation bubble dynamics inside liquid drops in microgravity. Phys. Rev. Lett. 2006, 97, 094502. [Google Scholar] [CrossRef]

- Chen, R.H.; Tan, D.S.; Lin, K.C.; Chow, L.C.; Griffin, A.R.; Rini, D.P. Droplet and bubble dynamics in saturated FC-72 spray cooling on a smooth surface. ASME J. Heat Mass Transf. 2008, 130, 101501. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, Y.; Yang, X.; Huang, Y.; Bai, Z.; Xu, X. Interfacial behavior and internal microflow of an oil droplet during the process of the oil droplet covering a gas bubble: Without and with NaCl. Ind. Eng. Chem. Res. 2021, 60, 6006–6015. [Google Scholar] [CrossRef]

- Delrot, P.; Modestino, M.A.; Psaltis, D.; Moser, C. Laser-assisted inkjet printing of highly viscous fluids with sub-nozzle resolution. Laser 3D Manuf. III SPIE 2016, 9738, 14–20. [Google Scholar]

- Jiménez-Fernández, J.; Crespo, A. Bubble oscillation and inertial cavitation in viscoelastic fluids. Ultrasonics 2005, 43, 643–651. [Google Scholar] [CrossRef] [PubMed]

- Giovanneschi, P.; Dufresne, D. Experimental study of laser-induced cavitation bubbles. J. Appl. Phys. 1985, 58, 651–652. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, X.; Zhang, Y.; Du, X. Experimental study of influences of a particle on the collapsing dynamics of a laser-induced cavitation bubble near a solid wall. Exp. Therm. Fluid Sci. 2019, 105, 289–306. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, X.; Zhang, X.; Tang, N. Collapsing dynamics of a laser-induced cavitation bubble near the edge of a rigid wall. Ultrason. Sonochemistry 2020, 67, 105157. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Zheng, X.; Du, X.; Zhang, Y. Theoretical investigation and experimental support for the cavitation bubble dynamics near a spherical particle based on Weiss theorem and Kelvin impulse. Ultrason. Sonochemistry 2022, 89, 106130. [Google Scholar] [CrossRef]

- Wong, Z.Z.; Kripfgans, O.D.; Qamar, A.; Fowlkes, J.B.; Bull, J.L. Bubble evolution in acoustic droplet vaporization at physiological temperature via ultra-high speed imaging. Soft Matter 2011, 7, 4009–4016. [Google Scholar] [CrossRef]

- Hentschel, W.; Lauterborn, W. Acoustic emission of single laser-produced cavitation bubbles and their dynamics. Appl. Sci. Res. 1982, 38, 225–230. [Google Scholar] [CrossRef]

- Miglani, A.; Basu, S.; Kumar, R. Insight into instabilities in burning droplets. Phys. Fluids 2014, 26, 032101. [Google Scholar] [CrossRef]

- Rao, D.C.K.; Karmakar, S.; Basu, S. Bubble dynamics and atomization mechanisms in burning multi-component droplets. Phys. Fluids 2018, 30, 067101. [Google Scholar] [CrossRef]

- Avila, S.R.G.; Ohl, C.D. Fragmentation of acoustically levitating droplets by laser-induced cavitation bubbles. J. Fluid Mech. 2016, 805, 551–576. [Google Scholar] [CrossRef]

- Liang, Y.; Jiang, Y.; Wen, C.Y.; Liu, Y. Interaction of a planar shock wave and a water droplet embedded with a vapour cavity. J. Fluid Mech. 2020, 885, R6. [Google Scholar] [CrossRef]

- Kobel, P.; Obreschkow, D.; De Bosset, A.; Dorsaz, N.; Farhat, M. Techniques for generating centimetric drops in microgravity and application to cavitation studies. Exp. Fluids 2009, 47, 39–48. [Google Scholar] [CrossRef]

- Brujan, E.A.; Nahen, K.; Schmidt, P.; Vogel, A. Dynamics of laser-induced cavitation bubbles near an elastic boundary. J. Fluid Mech. 2001, 433, 251–281. [Google Scholar] [CrossRef]

- Philipp, A.; Lauterborn, W. Cavitation erosion by single laser-produced bubbles. J. Fluid Mech. 1998, 361, 75–116. [Google Scholar] [CrossRef]

- Tomita, Y.; Kodama, T.; Shima, A. Secondary cavitation due to interaction of a collapsing bubble with a rising free surface. Appl. Phys. Lett. 1991, 59, 274–276. [Google Scholar] [CrossRef]

- Lindinger, A.; Hagen, J.; Socaciu, L.D.; Bernhardt, T.M.; Wöste, L.; Duft, D.; Leisner, T. Time-resolved explosion dynamics of H2O droplets induced by femtosecond laser pulses. Appl. Opt. 2004, 43, 5263–5269. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Lam, J.K.; Wood, C.F.; Chu, B.T.; Chang, R.K. Explosive vaporization of a large transparent droplet irradiated by a high intensity laser. Appl. Opt. 1987, 26, 4731–4737. [Google Scholar] [CrossRef] [PubMed]

- Villermaux, E. Fragmentation. Annu. Rev. Fluid Mech. 2007, 39, 419–446. [Google Scholar] [CrossRef]

- Villermaux, E.; Bossa, B. Single-drop fragmentation determines size distribution of raindrops. Nat. Phys. 2009, 5, 697–702. [Google Scholar] [CrossRef]

- Thoroddsen, S.T.; Takehara, K.; Etoh, T.G.; Ohl, C.D. Spray and microjets produced by focusing a laser pulse into a hemispherical drop. Phys. Fluids 2009, 21, 112101. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, S.P.; Zhang, A.M. Experimental study on the interaction between bubble and free surface using a high-voltage spark generator. Phys. Fluids 2016, 28, 032109. [Google Scholar] [CrossRef]

- Luo, J.; Niu, Z. Jet and Shock Wave from Collapse of Two Cavitation Bubbles. Sci. Rep. 2019, 9, 1352. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-M.; Zhang, A.-M.; Wang, Q.X.; Zhang, S. The jet characteristics of bubbles near mixed boundaries. Phys. Fluids 2019, 31, 107105. [Google Scholar]

- Liang, X.; Linz, N.; Freidank, S.; Paltauf, G.; Vogel, A. Comprehensive analysis of spherical bubble oscillations and shock wave emission in laser-induced cavitation. J. Fluid Mech. 2022, 940, A5. [Google Scholar] [CrossRef]

- Li, D.; Zhang, D.; Zheng, Z. Numerical analysis of hollow droplet impacts on a dry flat surface. Int. J. Heat Mass Transf. 2019, 129, 753–763. [Google Scholar] [CrossRef]

- Reese, H.; Schädel, R.; Reuter, F.; Ohl, C. Microscopic pumping of viscous liquids with single cavitation bubbles. J. Fluid Mech. 2022, 944, A17. [Google Scholar] [CrossRef]

| Case | Phenomenon | λ | Rbmax (mm) | Collapse Time (μs) |

|---|---|---|---|---|

| 1 | The upward movement of the center of the bubble is not obvious, and the droplets have no splash. | 0.463~0.581 | 1.221~1.549 | 50~100 |

| 2 | The center of the bubble moves upward obviously, and there are scattering splashes on both sides of the droplet. | 0.581~0.834 | 1.549~2.205 | 100~130 |

| 3 | The bubble oscillates violently, the center of the bubble moves significantly, and the “composite splash” is formed on the surface of the droplet. | 0.834~0.953 | 2.205~2.935 | 130~170 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, X.; Zhang, X.; Zhang, S.; Zha, K.; Li, Z.; Zhang, Y. Collapsing and Splashing Dynamics of Single Laser-Induced Cavitation Bubbles within Droplets. Symmetry 2023, 15, 1323. https://doi.org/10.3390/sym15071323

Zhang Y, Zhang X, Zhang X, Zhang S, Zha K, Li Z, Zhang Y. Collapsing and Splashing Dynamics of Single Laser-Induced Cavitation Bubbles within Droplets. Symmetry. 2023; 15(7):1323. https://doi.org/10.3390/sym15071323

Chicago/Turabian StyleZhang, Yuning, Xiaofei Zhang, Xiangqing Zhang, Shurui Zhang, Kehui Zha, Zhaohao Li, and Yuning Zhang. 2023. "Collapsing and Splashing Dynamics of Single Laser-Induced Cavitation Bubbles within Droplets" Symmetry 15, no. 7: 1323. https://doi.org/10.3390/sym15071323

APA StyleZhang, Y., Zhang, X., Zhang, X., Zhang, S., Zha, K., Li, Z., & Zhang, Y. (2023). Collapsing and Splashing Dynamics of Single Laser-Induced Cavitation Bubbles within Droplets. Symmetry, 15(7), 1323. https://doi.org/10.3390/sym15071323