MoHydroLib: An HMU Library for Gas Turbine Control System with Modelica

Abstract

:1. Introduction

- To lower the threshold for hydraulic system modeling, we developed a simple but powerful library with Modelica for gas turbine control systems, which is easy to access, easy to use, and easy to reshape;

- We achieved strong compatibility by designing casual/acausal connections, where multi-platform and multi-domain co-simulation are supported;

- We reduced code lines significantly through devising inheritance relationships and achieved this lightweight library.

2. Design of the Library

2.1. Theory and Element Description

2.1.1. Orifice Element

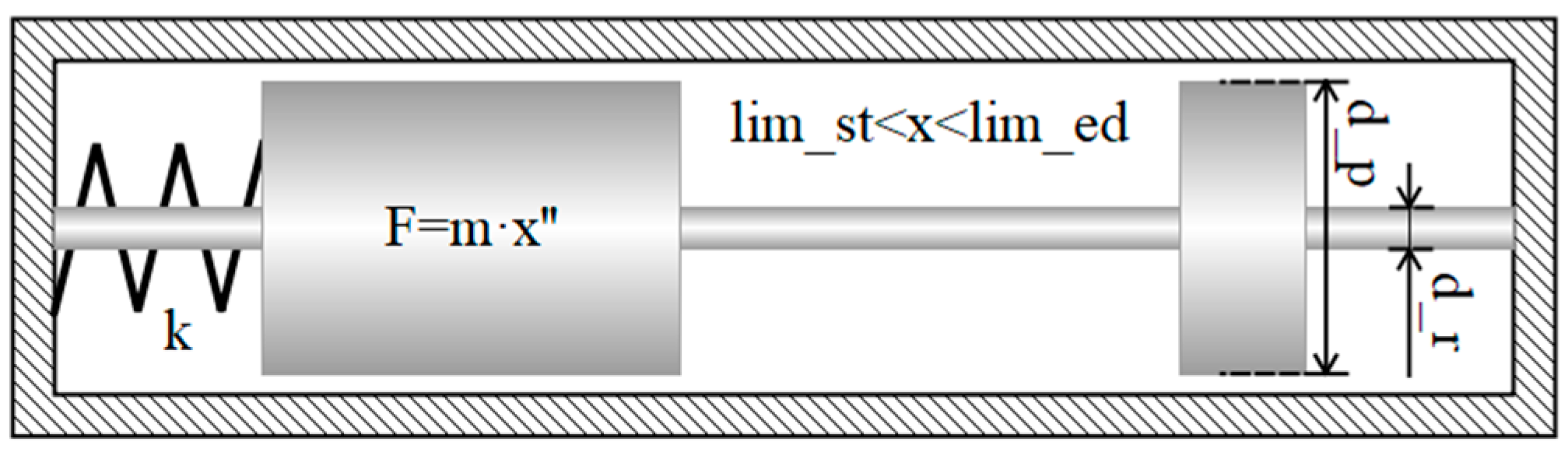

2.1.2. Piston Element

2.1.3. Boundary Element

2.1.4. System Element

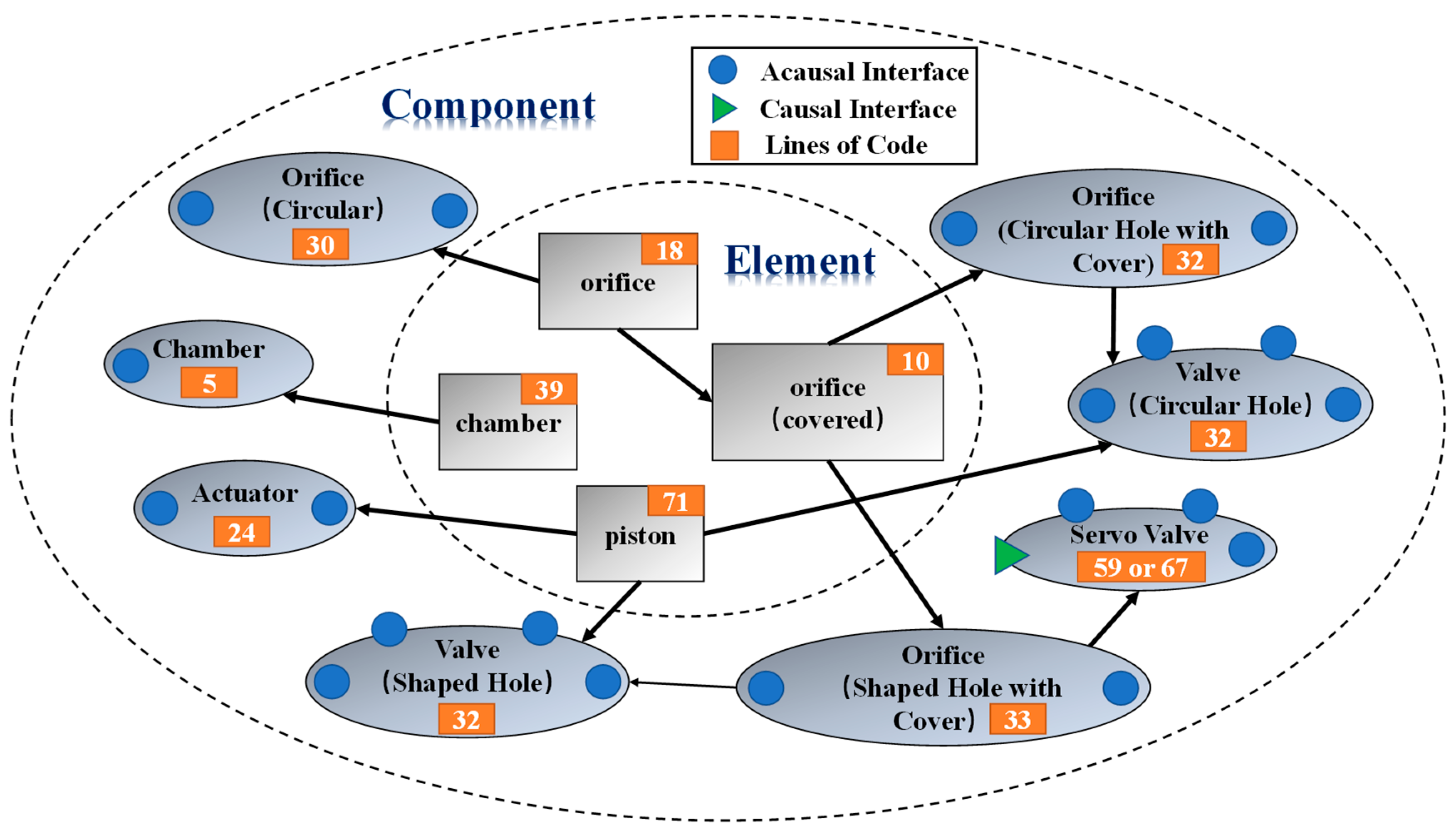

2.2. Component and Inheritance Relationship

2.2.1. Orifice Component

2.2.2. Valve Component

2.2.3. Actuator Component

2.2.4. Servo Component

2.3. Connection Relationship

2.3.1. Acausal Connections

- The pressure on each bond/connection connected to the junction is equal:

- The algebraic sum of volume flow of all bonds/connections is zero:

2.3.2. Causal Connections

3. Application Example

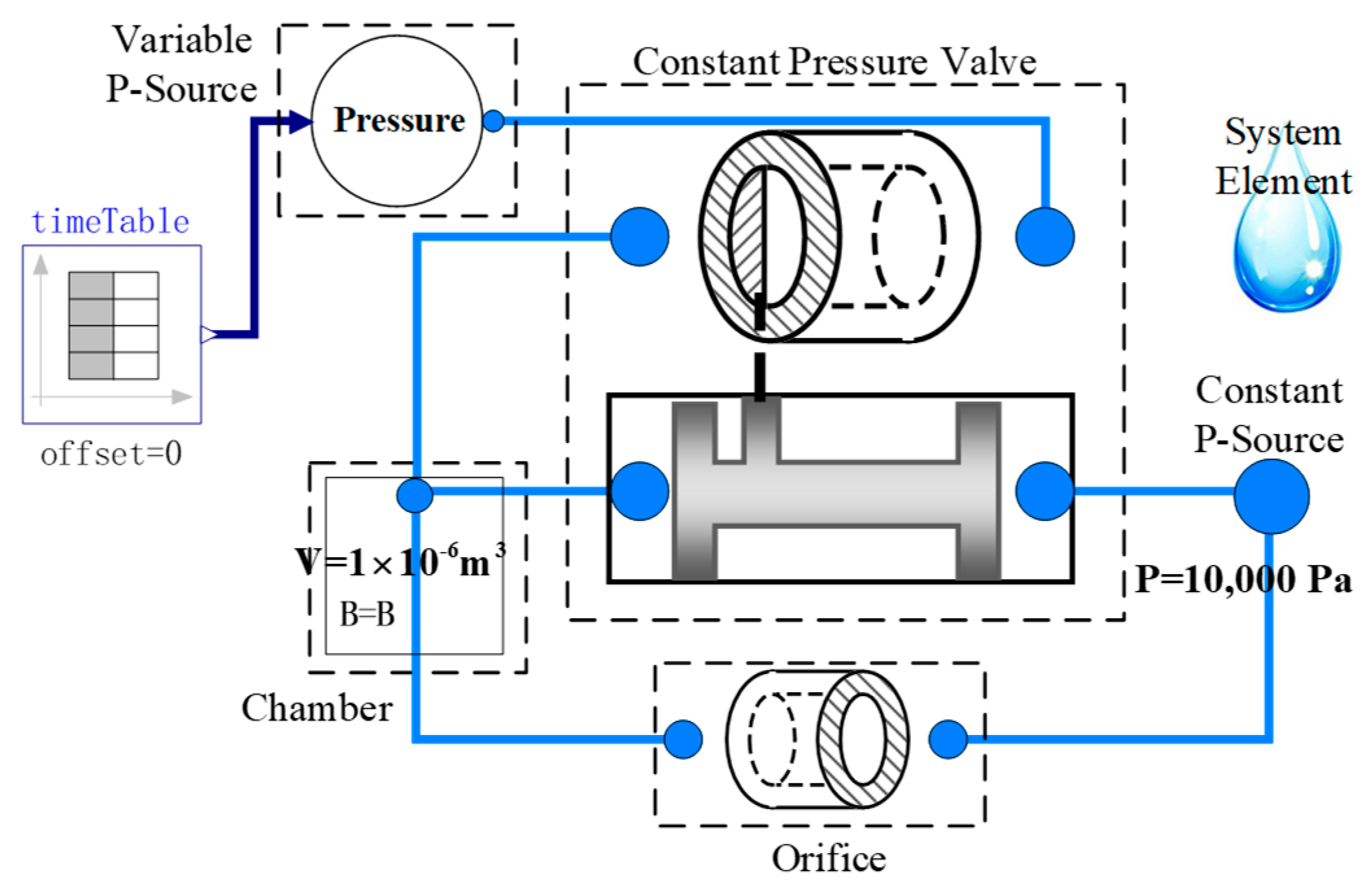

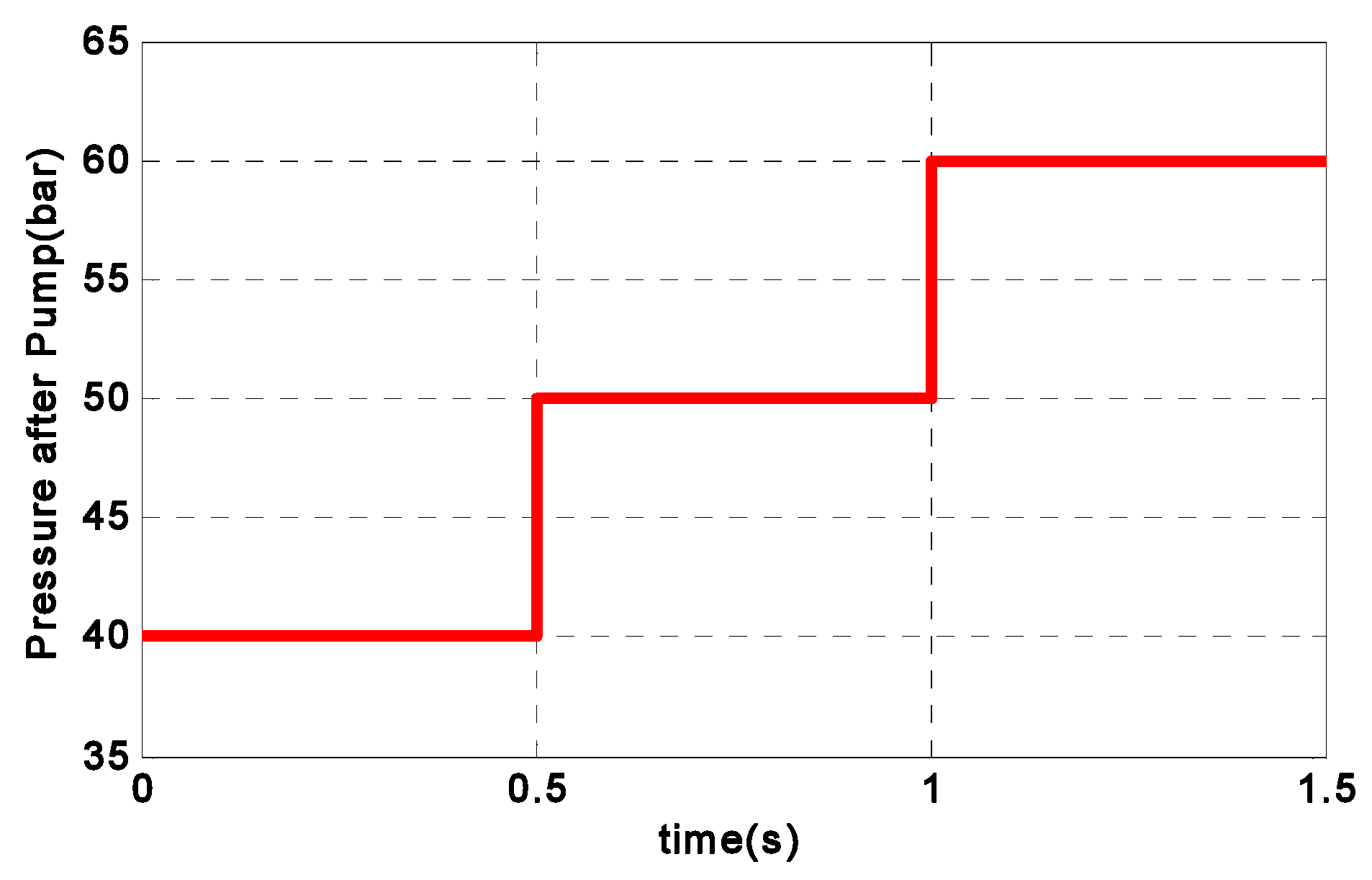

3.1. Constant Pressure Valve Subsystem

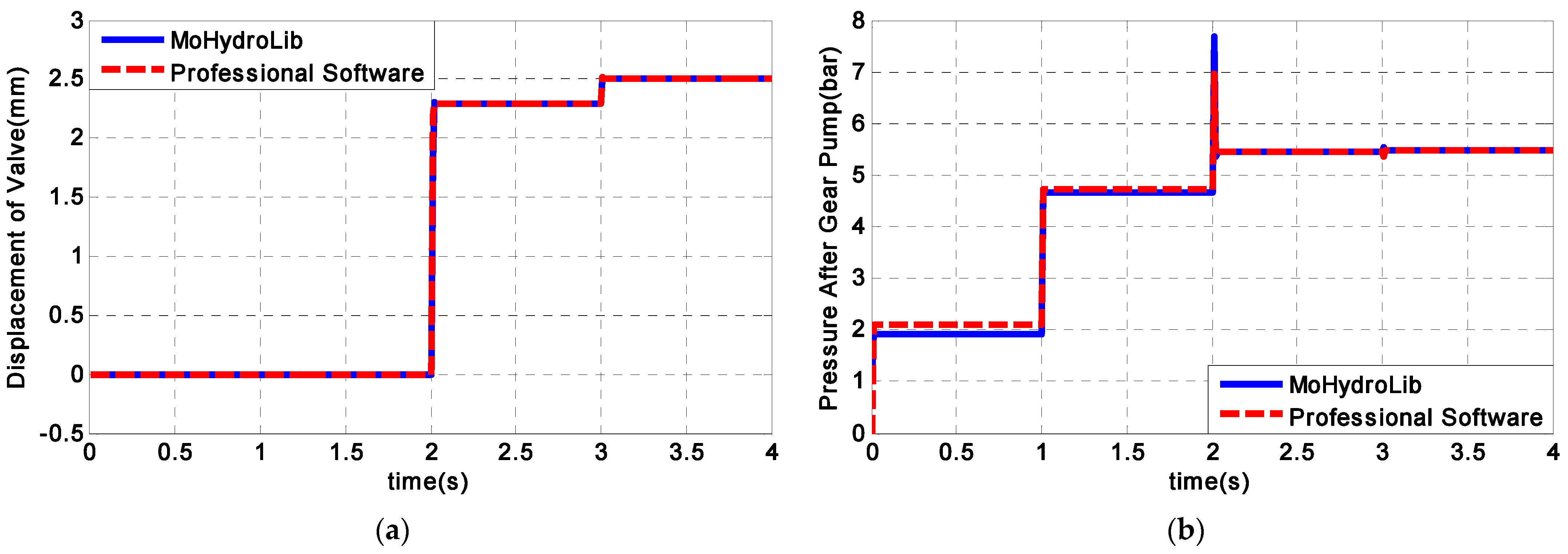

3.2. Safety Valve Subsystem

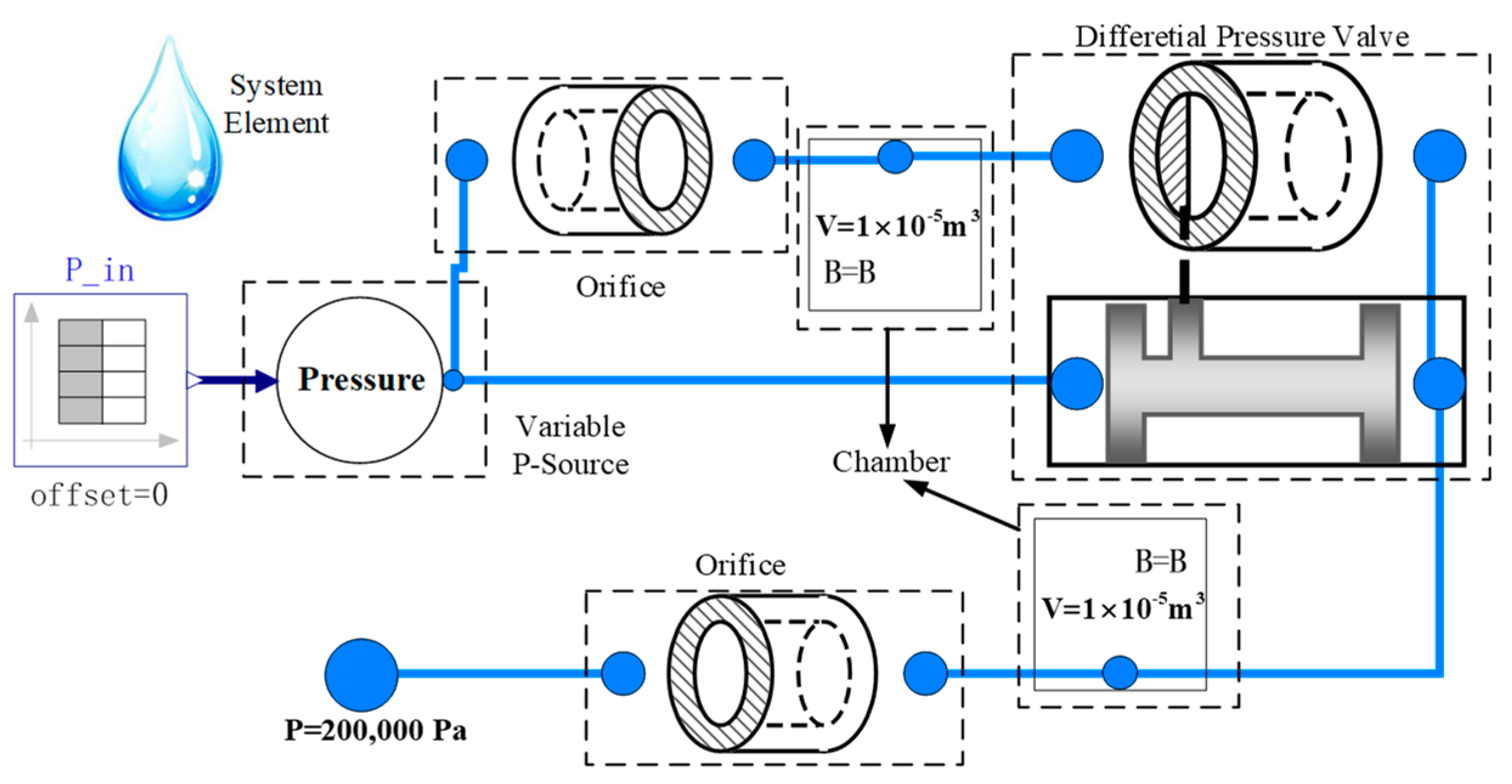

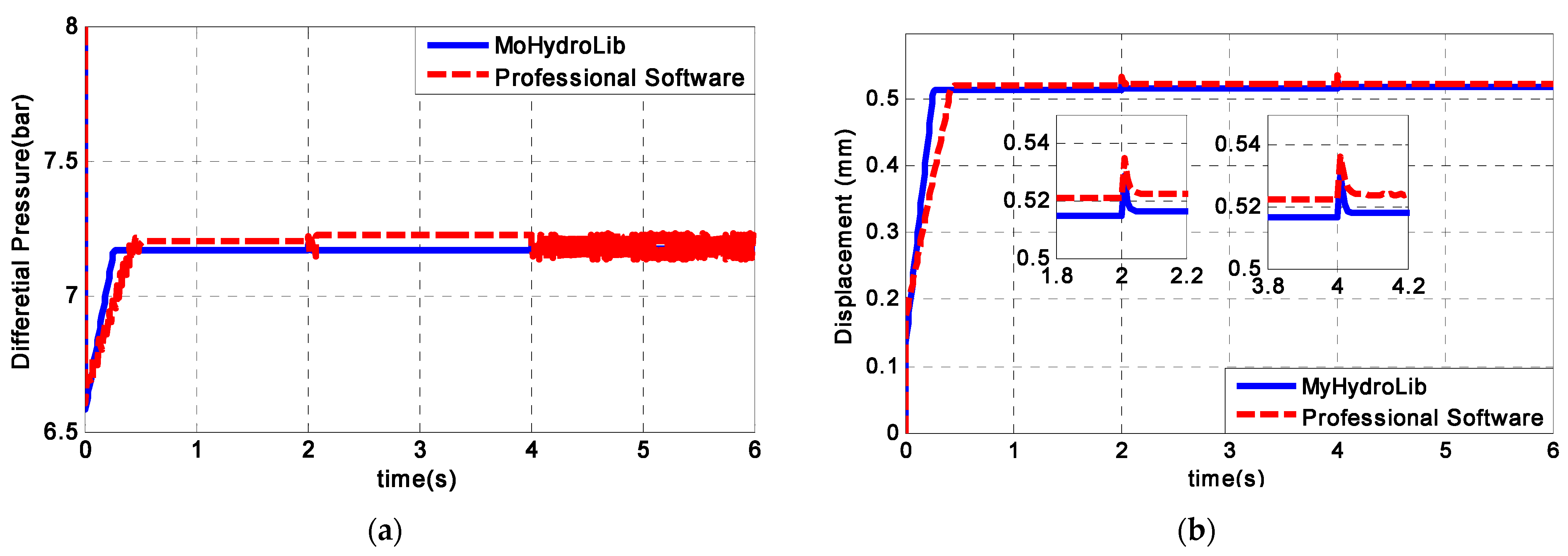

3.3. Differential Pressure Valve Subsystem

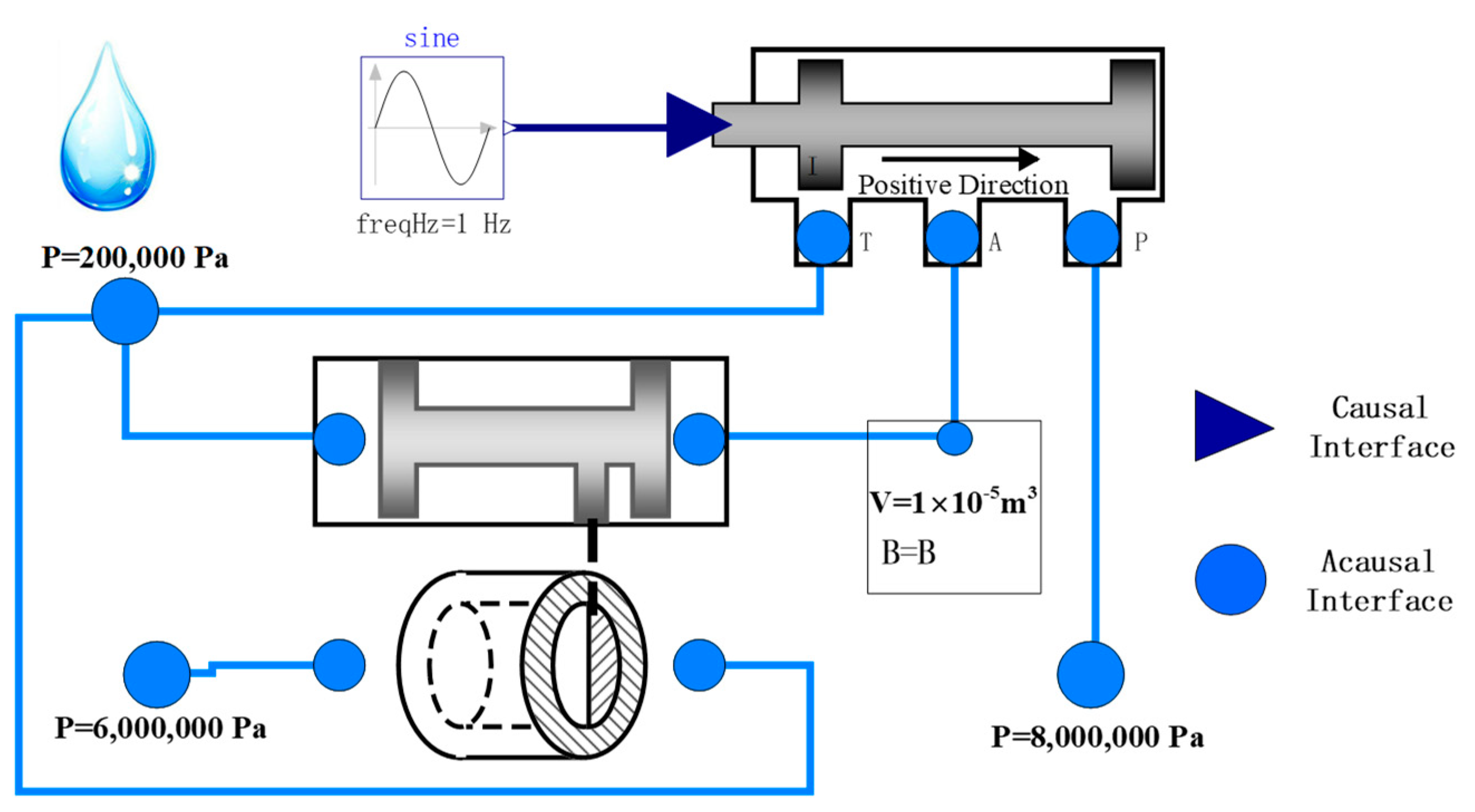

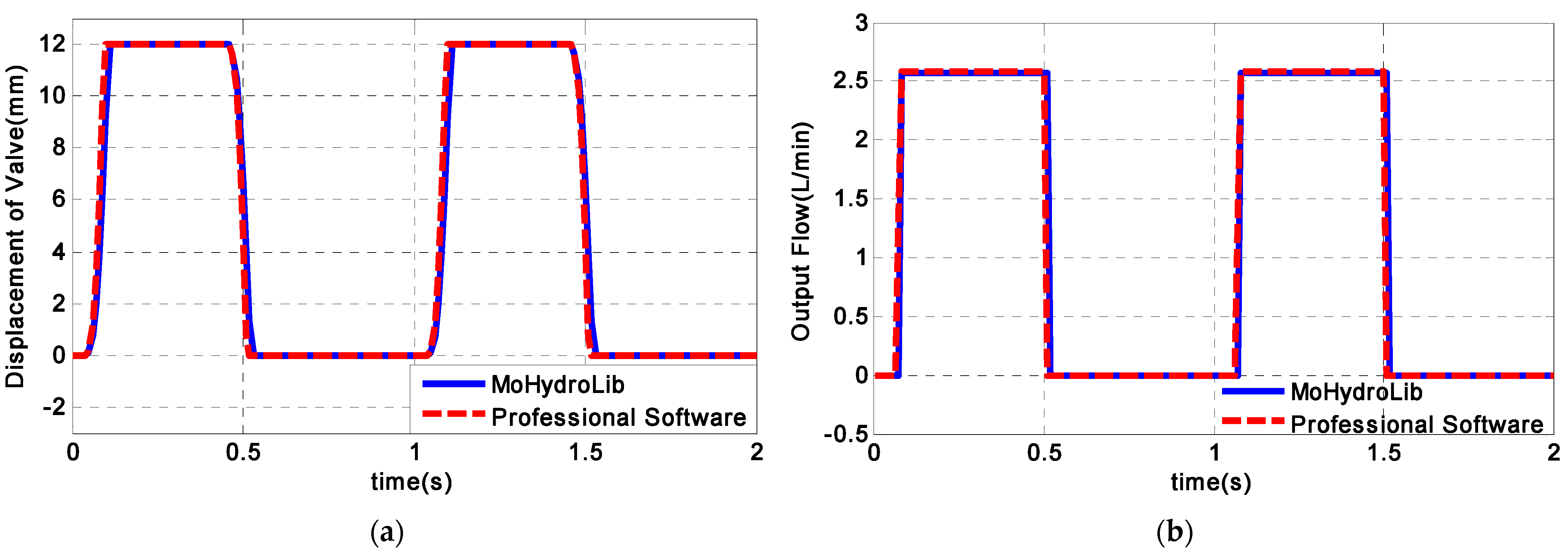

3.4. Servo Metering Subsystem

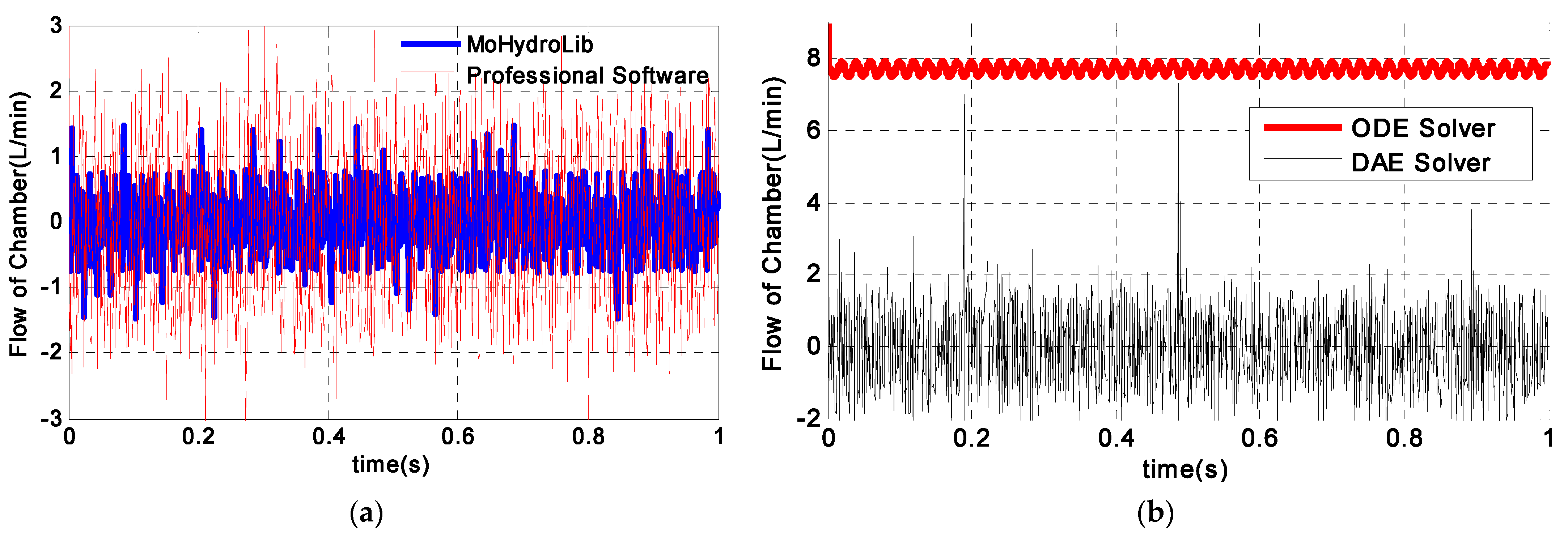

3.5. High Frequency Dynamic Solution Simulation

4. Discussion

- It demonstrates a low threshold; the description of the basic elements in the library is based on the physical equations of the working theory of the HMU, such as Newton’s second law in motion calculation and Bernoulli’s principle in flow calculation, which is easy to understand in principle;

- It is lightweightl the library adopts the Modelica language and uses the “inheritance” feature of the language. The total code of the modeling library is 452 lines, which is convenient for users to learn, modify and use;

- It demonstrates a strong simulation capability. It is capable of calculating high-frequency dynamic responses of a single port chamber orifice system, and the simulation results are consistent with the results of a professional HMU modeling and simulation software;

- It demonstrates good simulation compatibility. The library is implemented in the open-source Modelica language and supports the FMI protocol. It has good compatibility with other software and languages. Meanwhile, it supports the export of FMU format and the import of dynamic link library files for co-simulation calculations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Padovani, D.; Rundo, M.; Altare, G. The Working Hydraulics of Valve-Controlled Mobile Machines. J. Dyn. Syst. Meas. Control. 2020, 142, 070801. [Google Scholar] [CrossRef]

- Simcenter System Simulation. Available online: https://www.plm.automation.siemens.com/global/en/products/simcenter/simcenter-system-simulation.html (accessed on 1 March 2022).

- Centre for Power Transmission & Motion Control Software. Available online: https://www.bath.ac.uk/case-studies/centre-for-power-transmission-motion-control-software (accessed on 1 March 2022).

- Easy5: Advanced Control & Systems Simulation. Available online: https://www.mscsoftware.com/product/easy5 (accessed on 1 March 2022).

- Xu, M.; Wang, X.; De-tang, Z. Simulation on hydromechanical controller of modern aero-engine. J. Aerosp. Power 2009, 24. [Google Scholar] [CrossRef]

- Marquis-Favre, W.; Bideaux, E.; Scavarda, S. A planar mechanical library in the AMESim simulation software. Part I: Formulation of dynamics equations. Simul. Model. Pract. Theory 2006, 14, 25–46. [Google Scholar] [CrossRef] [Green Version]

- Marquis-Favre, W.; Bideaux, E.; Scavarda, S. A planar mechanical library in the AMESim simulation software. Part II: Library composition and illustrative example. Simul. Model. Pract. Theory 2006, 14, 95–111. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.; Zhu, J.; Zhang, D. Study on visual modeling and simulation platform of hydraulic system based on bond graph. Proc. SPIE—Int. Soc. Opt. Eng. 2005, 6041, 440–444. [Google Scholar]

- Borutzky, W.; Barnard, B.; Thoma, J.U. Describing bond graph models of hydraulic components in Modelica. Math. Comput. Simul. 2000, 53, 381–387. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, X. An Integral Type µ Synthesis Method for Temperature and Pressure Control of Flight Environment Simulation Volume. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Graeber, M.; Kosowski, K.; Richter, C.; Tegethoff, W. Modelling of heat pumps with an object-oriented model library for thermodynamic systems. Math. Comput. Model. Dyn. Syst. 2010, 16, 195–209. [Google Scholar] [CrossRef]

- Pei, X.; Liu, J.; Wang, X.; Zhu, M.; Zhang, L.; Dan, Z. Quasi-One-Dimensional Flow Modeling for Flight Environment Simulation System of Altitude Ground Test Facilities. Processes 2022, 10, 377. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, X.; Chen, H.; Wang, Y. Design of Speed Closed-Loop Control with Variable Pressure Difference Valve for Aero Engine. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, Online, 21–25 September 2020. [Google Scholar]

- Michael, M.T. Modelica by Example. Available online: https://mbe.modelica.university/front/intro/ (accessed on 2 March 2022).

- Modelica Association. Modelica—A Unified Object-Oriented language for PHYSICAL Systems Modeling. Language Spec. v. 3.4. 2017. Available online: https://modelica.org/documents.html (accessed on 2 March 2022).

- Pazold, M.; Burhenne, S.; Radon, J.; Herkel, S.; Antretter, F. Integration of Modelica models into an existing simulation software using FMI for Co-Simulation. In Proceedings of the 9th International Modelica Conference, Munich, Germany, 3–5 September 2012. [Google Scholar]

- Blochwitz, T. The functional mockup interface for tool independent exchange of simulation models. In Proceedings of the 8th International Modelica Conference, Dresden, Germany, 20–22 March 2011. [Google Scholar]

- Si-qi, F. Aeroengine Control (Volume One), 1st ed.; Northwestern Polytechnic University Press: Xi’an, China, 2008; pp. 141–182. [Google Scholar]

- Thoma, J.U.; Perelson, A.S. Introduction to Bond Graphs and Their Application. IEEE Trans. Syst. Man Cybern. 1976, 6, 797–798. [Google Scholar] [CrossRef]

- Novák, P.; Sindelár, R. Component-Based Design of Simulation Models Utilizing Bond-Graph Theory. IFAC Proc. Vol. 2014, 47, 9229–9234. [Google Scholar] [CrossRef]

- Gawthrop, P.J.; Bevan, G.P. Bond-graph modeling. Control. Syst. IEEE 2007, 27, 24–45. [Google Scholar]

- Zhao, H.C.; Wang, B.; Ye, Z.F. Study on Co-Modeling Method for Digital Control Fuel Metering Unit. J. Propuls. Technol. 2016, 37, 1752–1758. [Google Scholar]

- Zhang, D. Simulating and Experimental Study on Fuel Control System of a Certain Aeroengine. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 1 March 2008. [Google Scholar]

- Wang, B.; Zhao, H.; Yu, L.; Ye, Z. Study of Temperature Effect on Servovalve-Controlled Fuel Metering Unit. ASME J. Eng. Gas Turbines Power 2015, 137, 061503. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, Y.; Yang, S.; Wang, X.; Jiang, Z.; Liu, J.; Zhao, W.; Zhu, M.; Chen, H.; Miao, K.; Zhang, Y. MoHydroLib: An HMU Library for Gas Turbine Control System with Modelica. Symmetry 2022, 14, 851. https://doi.org/10.3390/sym14050851

Long Y, Yang S, Wang X, Jiang Z, Liu J, Zhao W, Zhu M, Chen H, Miao K, Zhang Y. MoHydroLib: An HMU Library for Gas Turbine Control System with Modelica. Symmetry. 2022; 14(5):851. https://doi.org/10.3390/sym14050851

Chicago/Turabian StyleLong, Yifu, Shubo Yang, Xi Wang, Zhen Jiang, Jiashuai Liu, Wenshuai Zhao, Meiyin Zhu, Huairong Chen, Keqiang Miao, and Yi Zhang. 2022. "MoHydroLib: An HMU Library for Gas Turbine Control System with Modelica" Symmetry 14, no. 5: 851. https://doi.org/10.3390/sym14050851

APA StyleLong, Y., Yang, S., Wang, X., Jiang, Z., Liu, J., Zhao, W., Zhu, M., Chen, H., Miao, K., & Zhang, Y. (2022). MoHydroLib: An HMU Library for Gas Turbine Control System with Modelica. Symmetry, 14(5), 851. https://doi.org/10.3390/sym14050851