A Study of Improving Running Safety of a Railway Wagon with an Independently Rotating Wheel’s Flange

Abstract

1. Introduction

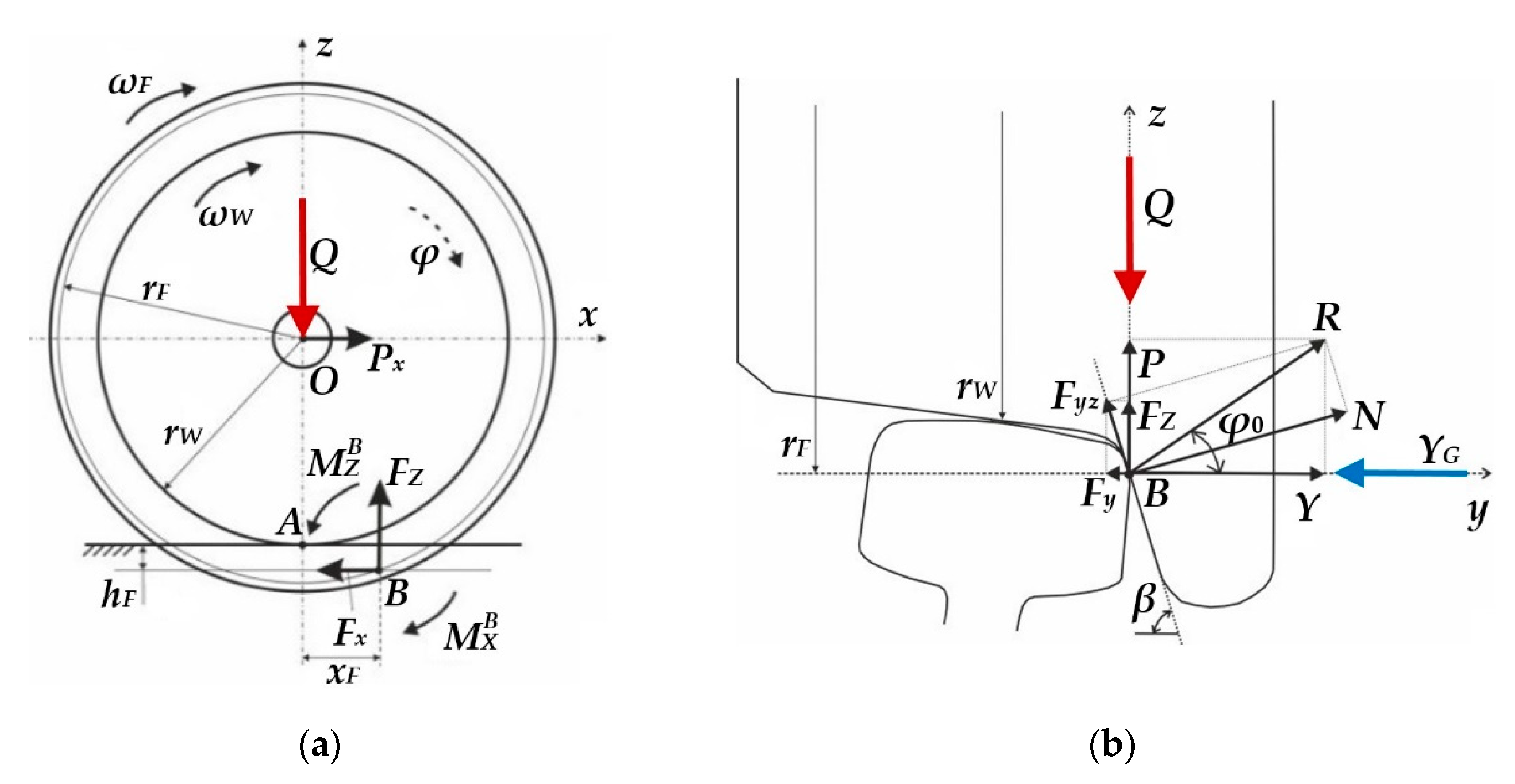

2. A Current State of the Problem

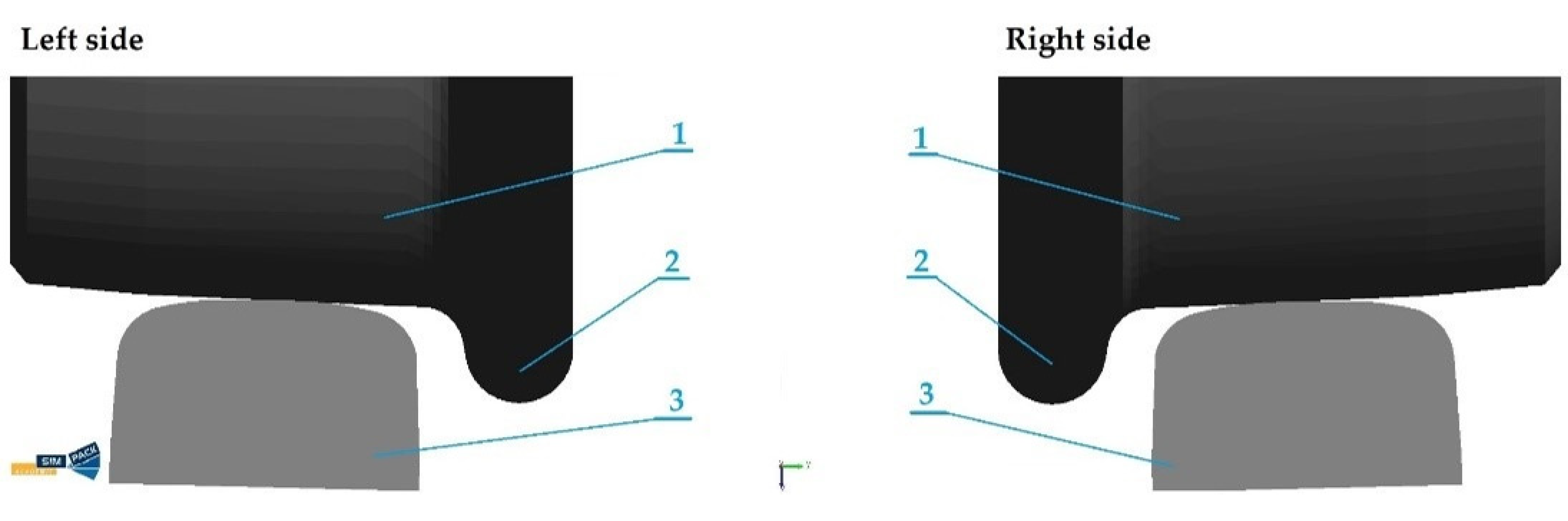

3. Materials and Methods

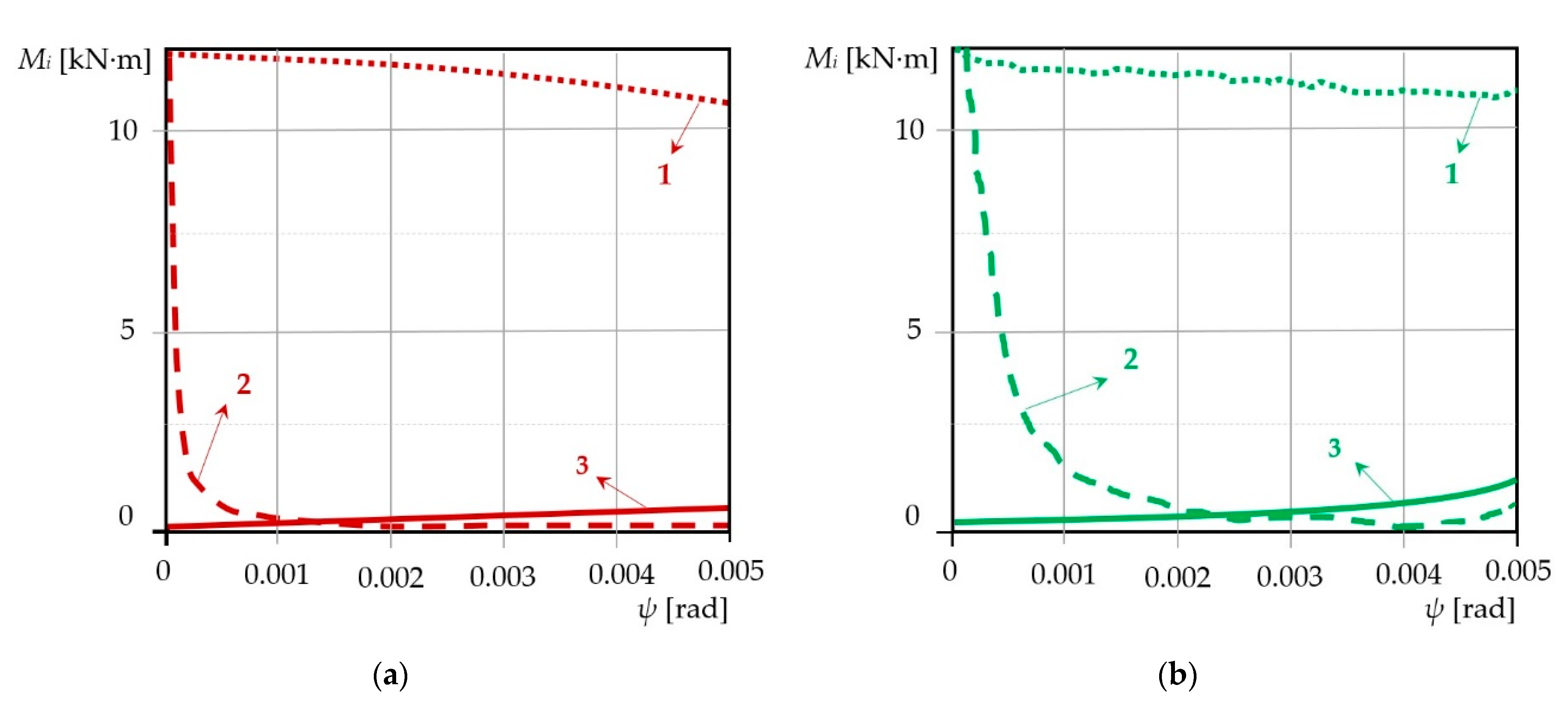

- For a wheel with the TKS:

- For a wheel with the PKS:

4. Results and Discussion

- For a wheel with the TKS:

- For a wheel with the PKS:

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dukkipati, R.V.; Swamy, S.N.; Osman, M.O.M. Independently rotating wheel systems for railway vehicles—A state-of-the-art review. Veh. Syst. Dyn. 1992, 21, 297–330. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.D. An experimental study of independently rotating wheels for railway vehicles. In Proceedings of the International Conference on Mechatronics and Automation 2007, Harbin, China, 5–8 August 2007. [Google Scholar]

- Zaazaa, K.E.; Whitten, B. Effect of independently rotating wheels on the dynamic performance of railroad vehicles. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2007, Seattle, WA, USA, 11–15 November 2007. [Google Scholar]

- Farhat, N.; Ward, C.; Shaebi, O.; Crosbee, D.; Stow, J.; Wang, R.; Goodall, R.; Whitley, M. Controlling a Rail Vehicle with Independently-Rotating Wheels. In Advances in Dynamics of Vehicles on Roads and Tracks; Springer: Cham, Switzerland, 2020; pp. 31–39. [Google Scholar]

- Bracciali, A. Railway Wheelsets: History, Research and Developments. Int. J. Railw. Technol. 2016, 5, 23–52. [Google Scholar] [CrossRef]

- Goodall, R.; Li, H. Solid Axle and Independently-Rotating Railway Wheelsets—A Control Engineering Assessment of Stability. Veh. Syst. Dyn. 2000, 33, 57–67. [Google Scholar] [CrossRef]

- Lu, Z.-G.; Yang, Z.; Huang, Q.; Wang, X.-C. Robust active guidance control using the μ-synthesis method for a tram with independently rotating wheelsets. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 33–48. [Google Scholar] [CrossRef]

- Chudzikiewicz, A.; Korzeb, J. Simulation study of wheels wear in low-floor tram with independently rotating wheels. Arch. Appl. Mech. 2018, 88, 175–192. [Google Scholar] [CrossRef]

- Melnik, R.; Sowinski, B. Analysis of dynamics of a metro vehicle model with differential wheelsets. Transp. Probl. 2017, 12, 113–124. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Melnik, R. Numerical dynamics study of a rail vehicle with differential gears. Procedia Eng. 2017, 192, 439–444. [Google Scholar] [CrossRef]

- Sapronova, S.; Tkachenko, V.; Fomin, O.; Gatchenko, V.; Malik, S. Research on the safety factor against derailment of railway vehicles. East. Eur. J. Enterp. Technol. 2017, 6, 19–25. [Google Scholar]

- Nozhenko, O.S.; Hauser, V.; Kravchenko, K.O.; Loulova, M. Proposal of wheel with additional tread for vehicle to strongly curved track interaction improvement. In Proceedings of the XXIII Konference s Mezinarodni Ucasti: Soucasne Problemy v Kolejovych Vozidlech 2017/23rd Conference: Current Problems in Rail Vehicles 2017, Ceska Trebova, Czech Republic, 20–22 September 2017. [Google Scholar]

- Bracciali, A.; Megna, G. Contact mechanics issues of a vehicle equipped with partially independently rotating wheelsets. Wear 2016, 366, 233–240. [Google Scholar] [CrossRef]

- Saga, M.; Vasko, M.; Handrik, M.; Kopas, P. Contribution to random vibration numerical simulation and optimisation of nonlinear mechanical systems. Sci. J. Sil. Univ. Technol. Ser. Transp. 2019, 103, 143–154. [Google Scholar] [CrossRef]

- Perez, J.; Busturia, J.M.; Mei, T.X.; Vinolas, J. Combined active steering and traction for mechatronic bogie vehicles with independently rotating wheels. Annu. Rev. Control 2004, 28, 207–217. [Google Scholar] [CrossRef]

- Kapitsa, M.; Mikhailov, E.; Kliuiev, S.; Semenov, S.; Kovtanets, M. Study of rail vehicles movement characteristics improvement in curves using fuzzy logic mechatronic systems. MATEC Web Conf. 2019, 294, 03019. [Google Scholar] [CrossRef]

- Mikhailov, E.; Gerlici, J.; Kliuiev, S.; Semenov, S.; Lack, T.; Kravchenko, K. Mechatronic System of Control Position of Wheel Pairs by Railway Vehicles in the Rail Track. AIP Conf. Proc. 2019, 2198, 020009. [Google Scholar]

- Fu, B.; Giossi, R.L.; Persson, R.; Stichel, S.; Bruni, S.; Goodall, R. Active suspension in railway vehicles: A literature survey. Railw. Eng. Sci. 2020, 28, 3–35. [Google Scholar] [CrossRef]

- Hauser, V.; Kravchenko, K.; Loulová, M.; Nozhenko, O.; Fomin, O. Analysis of a tramcar ride when passing a point frog and when entering small radius arc by specific rail geometry. Manuf. Technol. 2019, 19, 391–396. [Google Scholar] [CrossRef]

- Dvorak, Z.; Leitner, B.; Novak, L. Software support for railway traffic simulation under restricted conditions of the rail section. In Proceedings of the 9th International Scientific Conference TRANSBALTICA 2015, Vilnius, Lithuania, 7–8 May 2015. [Google Scholar]

- Upadhyay, R. Reduced wear wheels and rails. Int. Railw. J. 2000, 7, 33–34. [Google Scholar]

- Mašek, J.; Kendra, M.; Milinković, S.; Vesković, S.; Bárta, D. Proposal and application of methodology of revitalisation of regional railway track in Slovakia and Serbia. Part 1: Theoretical approach and proposal of methodology for revitalisation of regional railways. Transp. Probl. 2015, 10, 85–95. [Google Scholar] [CrossRef]

- Leitner, B.; Môcová, L.; Hromada, M. A new Approach to Identification of Critical Elements in Railway Infrastructure. In Proceedings of the 10th International Scientific Conference on Transportation Science and Technology TRANSBALTICA 2017, Vilnius, Lithuania, 4–5 May 2017. [Google Scholar]

- Winczek, J.; Gucwa, M.; Mičian, M.; Koňár, R.; Parzych, S. The evaluation of the wear mechanism of high-carbon hard facing layers. Arch. Metall. Mater. 2019, 64, 1111–1115. [Google Scholar]

- Scheffel, H. Passive non-linear elastic suspension devices for improved hunting stability of railway bogies. Veh. Syst. Dyn. 2003, 37, 554–564. [Google Scholar] [CrossRef]

- Giossi, R.L.; Persson, R.; Stichel, S. Improved curving performance of an innovative two-axle vehicle: A reasonable feedforward active steering approach. Veh. Syst. Dyn. 2020, 58, 1–24, in press. [Google Scholar] [CrossRef]

- Keck, A.; Schwarz, C.; Meurer, T.; Heckmann, A.; Grether, G. Estimating the wheel lateral position of a mechatronic railway running gear with nonlinear wheel-rail geometry. Mechatronics 2021, 73, 102457. [Google Scholar] [CrossRef]

- Wilson, N.; Shu, X.; Kramp, K. Effects of Independently Rolling Wheels on Flange Climb Derailment. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2004, Anahaim, CA, USA, 13–19 November 2004. [Google Scholar]

- Opala, M. Study of the derailment safety index Y/Q of the low-floor tram bogies with different types of guidance of independently rotating wheels. Arch. Transp. 2016, 38, 39–47. [Google Scholar] [CrossRef]

- Shen, G.; Zhou, J.; Ren, L. Enhancing the resistance to derailment and side-wear for a tramway vehicle with independently rotating wheels. Veh. Syst. Dyn. 2006, 44, 641–651. [Google Scholar] [CrossRef]

- Wu, H.; Wilson, N. Railway vehicle derailment and prevention. In Handbook of Railway Vehicle Dynamics, 1st ed.; Iwnicki, S., Ed.; Taylor & Francis: Abingdon, UK, 2006; pp. 209–238. [Google Scholar]

- Xu, J.; Wang, J.; Wang, P.; Chen, J.; Gao, Y.; Chen, R.; Xie, K. Study on the derailment behaviour of a railway wheelset with solid axles in a railway turnout. Veh. Syst. Dyn. 2020, 58, 123–143. [Google Scholar] [CrossRef]

- Mikhailov, E.; Semenov, S.; Sapronova, S.; Tkachenko, V. On the Issue of Wheel Flange Sliding along the Rail. In Proceedings of the International Conference TRANSBALTICA 2019, Vilnius, Lithuania, 2–3 May 2019. [Google Scholar]

- Mikhailov, E.; Semenov, S.; Kliuiev, S.; Dižo, J.; Blatnický, M.; Gerlici, J.; Harušinec, J.; Kovtanets, M. Clarification of features of the wheel movement with a perspective constructive scheme on a rail. Appl. Sci. 2020, 10, 6758. [Google Scholar] [CrossRef]

- Jakubovicova, L.; Sapietova, A.; Moravec, J. Static analysis of transmission tower beam structure. MATEC Web Conf. 2018, 244, 01011. [Google Scholar] [CrossRef][Green Version]

- Dukkipati, R. Vehicle Dynamics, 1st ed.; Narosa Publishing House: New Delhi, India, 2000. [Google Scholar]

- Mikhailov, E.; Semenov, S.; Tkachenko, V.; Sapronova, S. Reduction of Kinematic Resistance to Movement of the Railway Vehicles. MATEC Web Conf. 2019, 235, 00033. [Google Scholar] [CrossRef]

- Mikhailov, E.; Semenov, S.; Dižo, J.; Kravchenko, K. Research of possibilities of reducing the driving resistance of a railway vehicle by means of the wheel construction improvement. In Proceedings of the 13th International Scientific Conference on Sustainable, Modern and Safe Transport TRANSCOM 2019, High Tatras, Slovak Republic, 29–31 May 2019. [Google Scholar]

- Suda, Y. Improvement of high speed stability and curving performance by parameter control of trucks for rail vehicles considering independently rotating wheelsets and unsymmetric structure. JSME Int. J. 1990, 33, 176–182. [Google Scholar] [CrossRef][Green Version]

- Suda, Y.; Wada, M. Dynamic stability and steering ability of trucks for rail vehicles with longitudinally unsymmetric structure. Trans. Jpn. Soc. Mech. Ser. C 1991, 57, 2633–2639. [Google Scholar] [CrossRef][Green Version]

- Tanafuji, K.; Matsushika, T.; Saima, T. Dynamic behavior of a heavy haul railway vehicle with forced steering trucks used in a Factory Yard (In case of trucks with a link-type mechanism for axle supporting). Trans. Jpn. Soc. Mech. Ser. C 1995, 61, 2846–2853. [Google Scholar] [CrossRef]

- Goodal, R.; Mei, T.X. Mechatronic strategy for controlling-railway wheelsets with independently rotating wheels. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, (AIM), Como, Italy, 8–12 July 2001. [Google Scholar]

- Mei, T.X.; Goodall, R.M. Wheelset control strategies for a two-axle railway vehicle. In Proceedings of the 16th Symposium of the International Association for Vehicle System Dynamics, Pretoria, South Africa, 30 August–3 September 1999. [Google Scholar]

- Liang, B.; Iwnicki, S. Independently rotating wheels with induction motors for high-speed trains. J. Control Sciebce Eng. 2011, 2011, 1–7. [Google Scholar] [CrossRef]

- Liu, X.Y.; Goodall, R.; Iwnicki, S. Yaw compensation and yaw relaxation controls for active steering of railway wheelsets via electromechanical actuators. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 1–10. [Google Scholar]

- Konowrocki, R.; Kalinowski, D.; Szolc, T.; Marczewski, A. Identification of safety hazards and operating conditions of the low-floor tram with independently rotating wheels with various drive control algorithms. Exsploatacja Niezawodn—Maint. Reliab. 2021, 23, 21–33. [Google Scholar] [CrossRef]

- Kalinowski, D.; Szolc, T.; Konowrocki, R. The new simulation approach to tramway safety againts deraolment evaluation in term of vehicle dynamics. In Proceedings of the 11th Transbaltica International Scientific Conference-Transportation Science and Technology, Vilnius, Lithuania, 2–3 May 2019. [Google Scholar]

- Farhat, N.; Ward, C.P.; Dixon, R.; Goodall, R.M. Benefits of mechatronically guided vehicles on railway track switches. Proc. Inst. Mech. Eng. Part. F J. Rail Rapid Transit 2020, 234, 276–288. [Google Scholar] [CrossRef]

- Farhat, N.; Ward, C.P.; Goodall, R.M.; Dixon, R. The benefits of mechatronically-guided railway vehicles: A multi-body physics simulation study. Mechatronics 2018, 51, 115–126. [Google Scholar] [CrossRef]

- Chudzikiewicz, A.; Sowinska, M. Modelling the dynamics of an unconventional rail vehicle bogie with independently rotating wheels with the use of Boltzmann-Hamel equations. Veh. Syst. Dyn. 2020, 58, 1–9. [Google Scholar] [CrossRef]

- Chudzikiewicz, A.; Sowinski, B. Modelling nad simulation of trams bogies with fully independently rotating wheels. In Proceedings of the 24th Symposium of the International Association for Vehicle System Dynamics, Graz, Austria, 17–21 August 2015. [Google Scholar]

- Uhl, T.; Chudzikiewicz, A. Analytical and experimental investigation of low floor tram dynamics. In Proceedings of the 17th Symposium of the International Association for Vehicle System Dynamics, Lyngby, Denmark, 20–24 August 2001. [Google Scholar]

- Sichani, M.S.; Enblom, R.; Berg, M. An alternative to FASTSIM for tangential solution of the wheel-rail contact. Veh. Syst. Dyn. 2016, 54, 748–764. [Google Scholar] [CrossRef]

- Piotrowski, J.; Bruni, S.; Liu, B.B.; DiGialleonardo, E. A fast method for determination of creep forces in non-Hertzian contact of wheel and rail based on a book of tables. Multibody Syst. Dyn. 2019, 45, 169–184. [Google Scholar] [CrossRef]

- Lack, T.; Gerlici, J. A Modified Strip Method to Speed up the Tangential Stress between Wheel and Rail Calculation. In Proceedings of the 22nd International Conference on Current Problems in Rail Vehicles, Prorail, Zilina, Slovakia, 16–18 September 2015. [Google Scholar]

- Lack, T.; Gerlici, J. Speeding up of the rail/wheel contact stress computation by means of modified strip method. In Proceedings of the 22nd International Conference on Current Problems in Rail Vehicles, Prorail, Zilina, Slovakia, 16–18 September 2015. [Google Scholar]

- Nadal, M.J. Locomotives a Vapeur, Collection Encyclopedie Scientifique; Biblioteque de Mecanique Appliquee et Genie: Paris, France, 1908; Volume 186. [Google Scholar]

- Mikhailov, E.; Semenov, S.; Dižo, J.; Kravchenko, K.; Blatnický, M. Possibilities of reducing of a rail vehicle running resistance by means of a new wheel design. In Proceedings of the 24th International Conference “Current Problems in Rail Vehicles—PRORAIL 2019”, Žilina, Slovak Republic, 17–19 September 2019. [Google Scholar]

- Strazovec, P.; Gerlici, J.; Lack, T.; Harusinec, J. Innovative solution for experimental research of phenomena resulting from the wheel and rail rolling. In Proceedings of the 13th International Scientific Conference on Sustainable, Modern and Safe Transport TRANSCOM 2019, Novy Smokovec, Slovakia, 29–31 May 2019. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Weight per a wheelset | 13.8 | t |

| Wheelbase | 2560 | mm |

| Track | 1435 | mm |

| Wheel profile | S1002 | - |

| Wheelset | |||

|---|---|---|---|

| Parameter | Designation | Value | Unit |

| Mass | mW | 1500 | kg |

| Moments of inertia | IWx | 830 | kg∙m2 |

| IWy | 830 | kg∙m2 | |

| IWz | 140 | kg∙m2 | |

| Axle length | lW | 2000 | mm |

| Frame | |||

| Parameter | Designation | Value | Unit |

| Mass | mB | 2660 | kg |

| Moments of inertia | IBx | 1790 | kg∙m2 |

| IBy | 1520 | kg∙m2 | |

| IBz | 3250 | kg∙m2 | |

| Axlebox | |||

| Parameter | Designation | Value | Unit |

| Mass | mA | 175 | kg |

| Moments of inertia | IAx | 3.50 | kg∙m2 |

| IAy | 8.55 | kg∙m2 | |

| IAz | 8.55 | kg∙m2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikhailov, E.; Semenov, S.; Shvornikova, H.; Gerlici, J.; Kovtanets, M.; Dižo, J.; Blatnický, M.; Harušinec, J. A Study of Improving Running Safety of a Railway Wagon with an Independently Rotating Wheel’s Flange. Symmetry 2021, 13, 1955. https://doi.org/10.3390/sym13101955

Mikhailov E, Semenov S, Shvornikova H, Gerlici J, Kovtanets M, Dižo J, Blatnický M, Harušinec J. A Study of Improving Running Safety of a Railway Wagon with an Independently Rotating Wheel’s Flange. Symmetry. 2021; 13(10):1955. https://doi.org/10.3390/sym13101955

Chicago/Turabian StyleMikhailov, Evgeny, Stanislav Semenov, Hanna Shvornikova, Juraj Gerlici, Maxim Kovtanets, Ján Dižo, Miroslav Blatnický, and Jozef Harušinec. 2021. "A Study of Improving Running Safety of a Railway Wagon with an Independently Rotating Wheel’s Flange" Symmetry 13, no. 10: 1955. https://doi.org/10.3390/sym13101955

APA StyleMikhailov, E., Semenov, S., Shvornikova, H., Gerlici, J., Kovtanets, M., Dižo, J., Blatnický, M., & Harušinec, J. (2021). A Study of Improving Running Safety of a Railway Wagon with an Independently Rotating Wheel’s Flange. Symmetry, 13(10), 1955. https://doi.org/10.3390/sym13101955