Service-Oriented Real-Time Smart Job Shop Symmetric CPS Based on Edge Computing

Abstract

:1. Introduction

2. Background and Motivation

2.1. CPS in Smart Job Shop

2.2. Real-Time Information in CPS

2.3. Edge Computing in Manufacturing

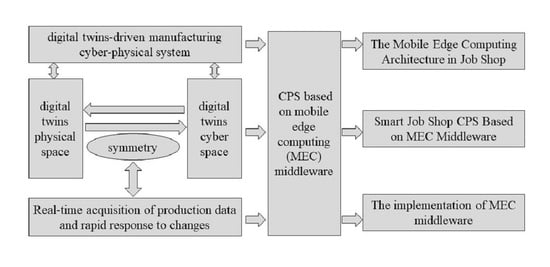

3. The Mobile Edge Computing Architecture in Job Shop

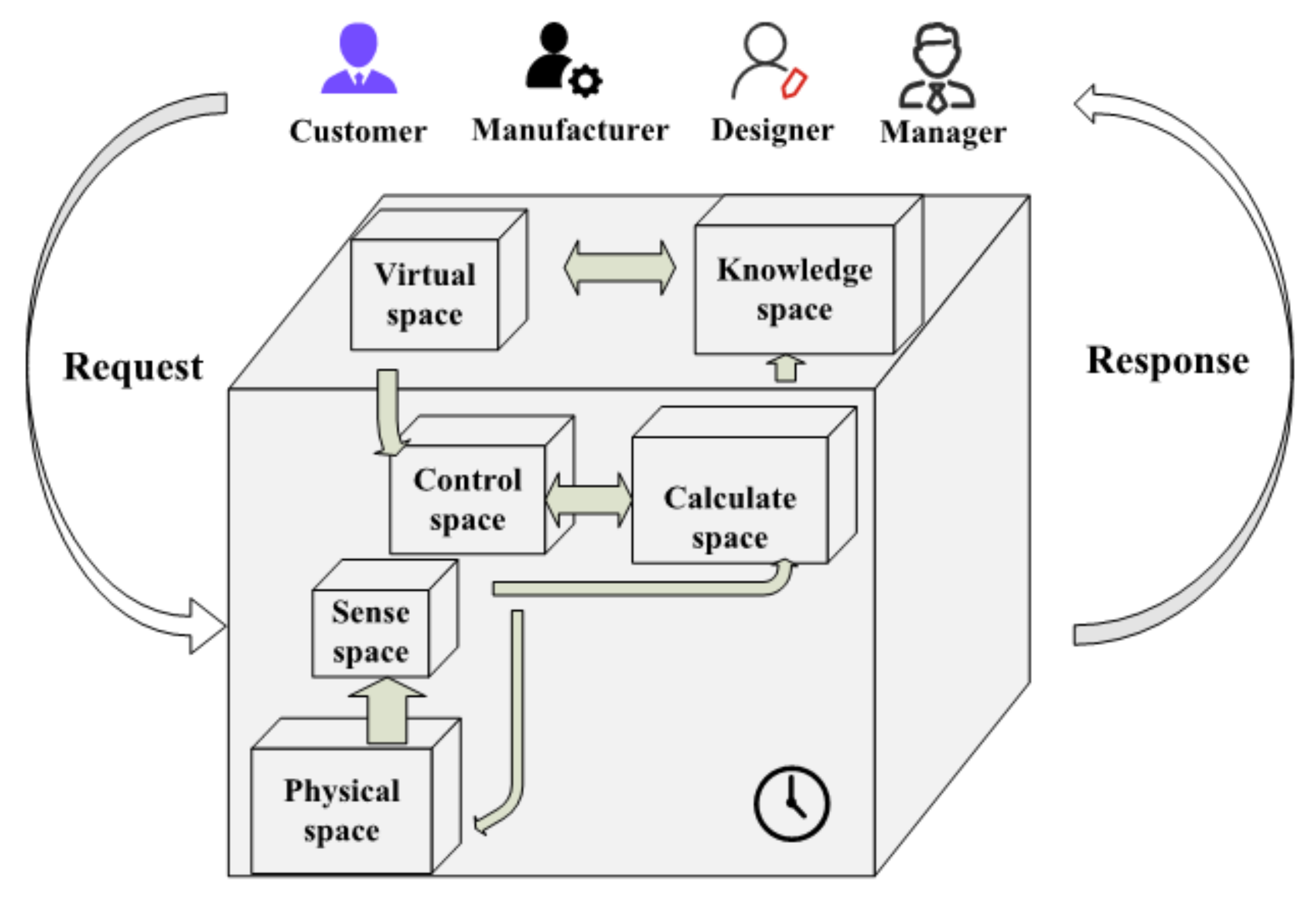

3.1. CPS for Service-Oriented Production Process

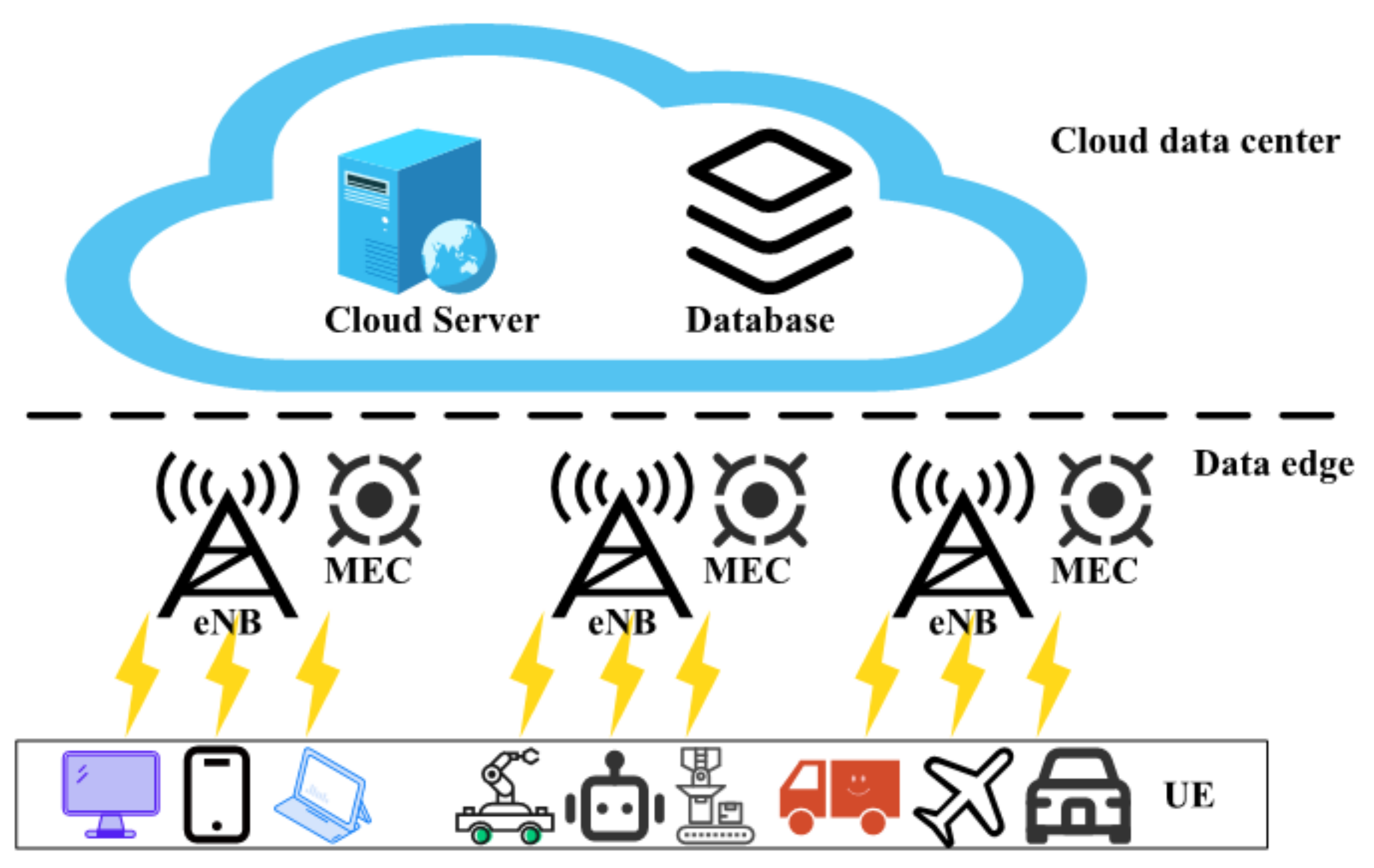

3.2. The Mobile Edge Computing

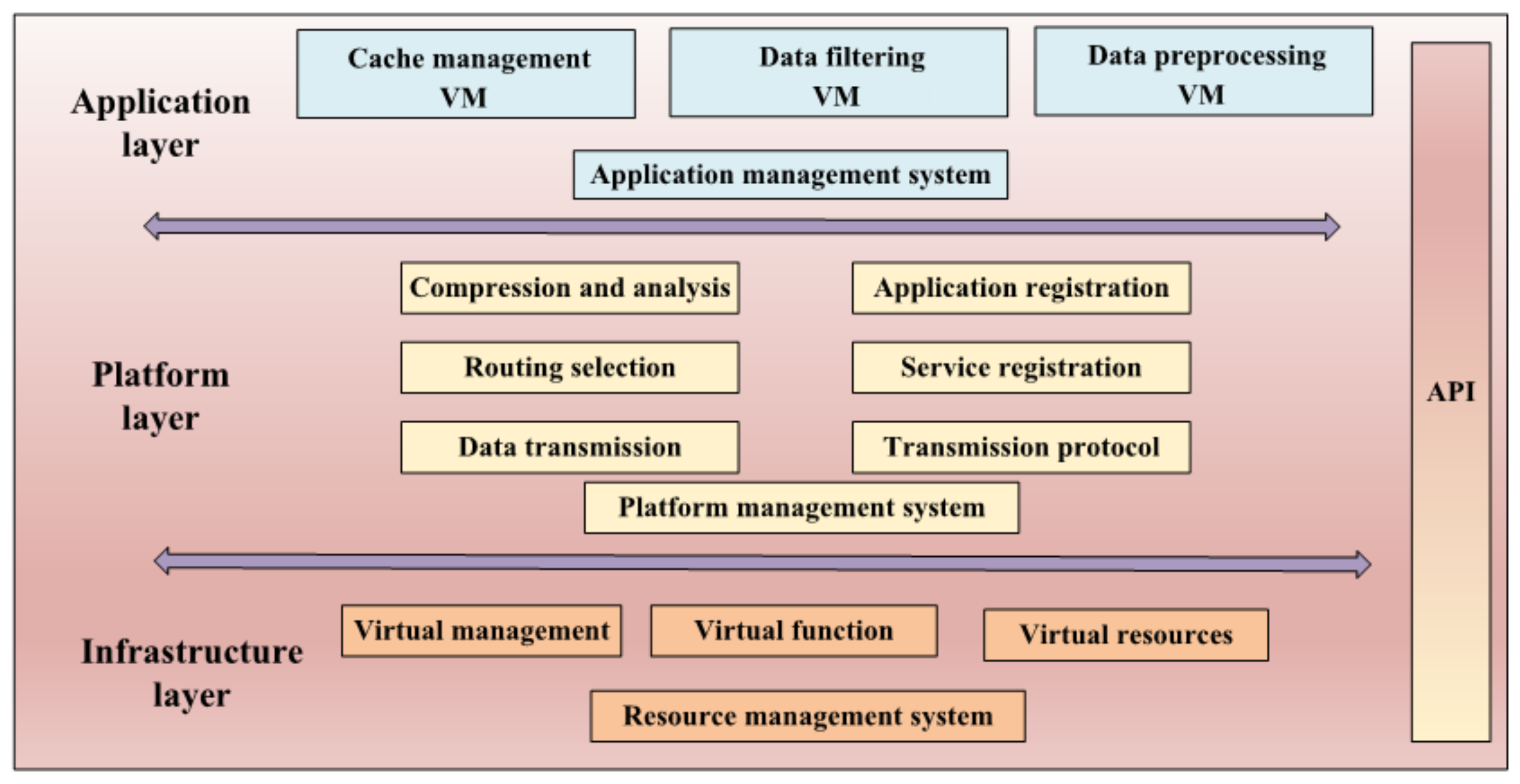

4. Smart Job Shop CPS Based on MEC Middleware

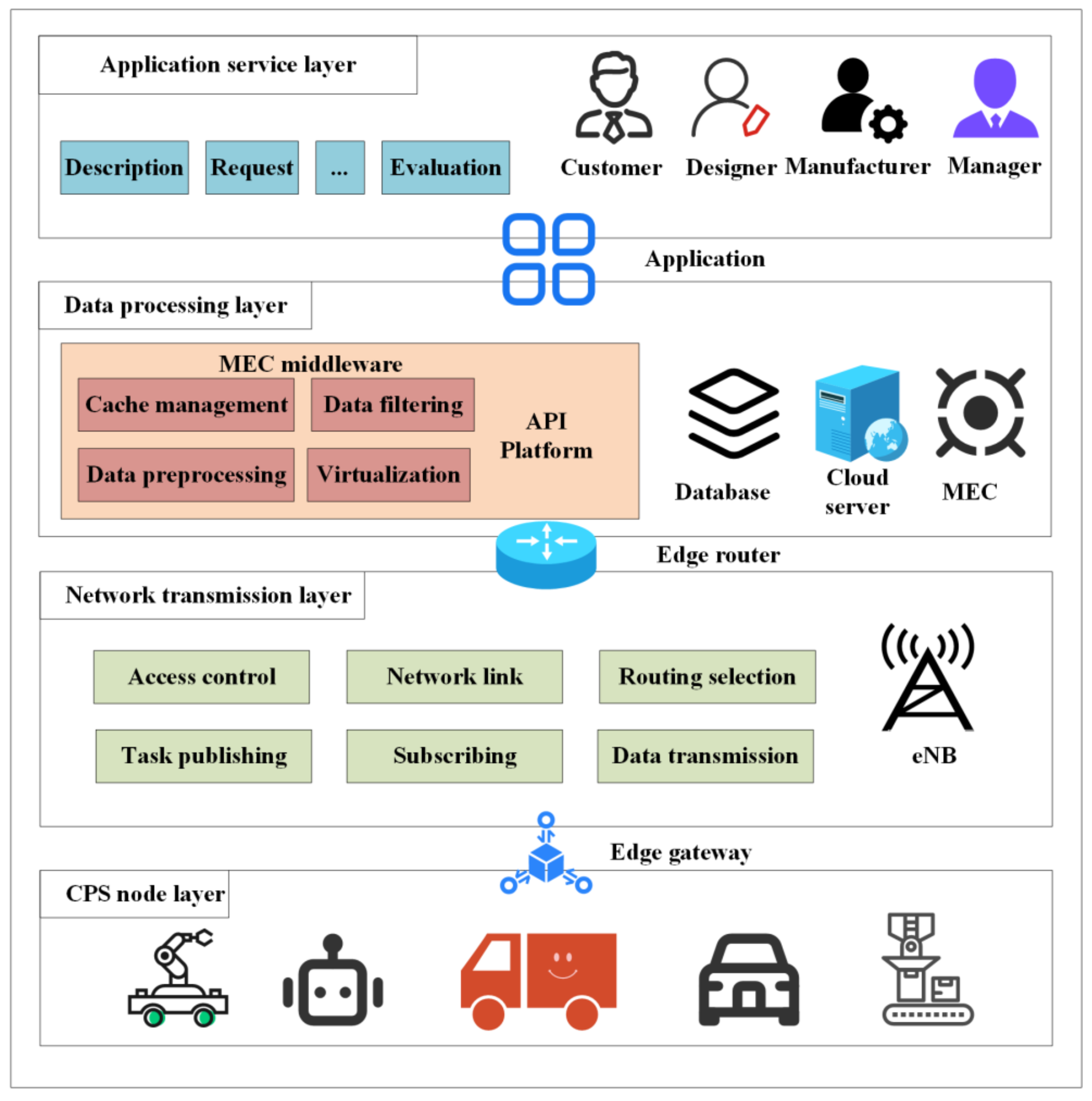

4.1. Smart Job Shop CPS Architecture Model

4.2. The Implementation of MEC Middleware

4.3. The Realization of the Application Layer Function Module

- (1)

- Data cache management

- (2)

- Redundant data filtering

- (3)

- Data preprocessing

5. Case Study

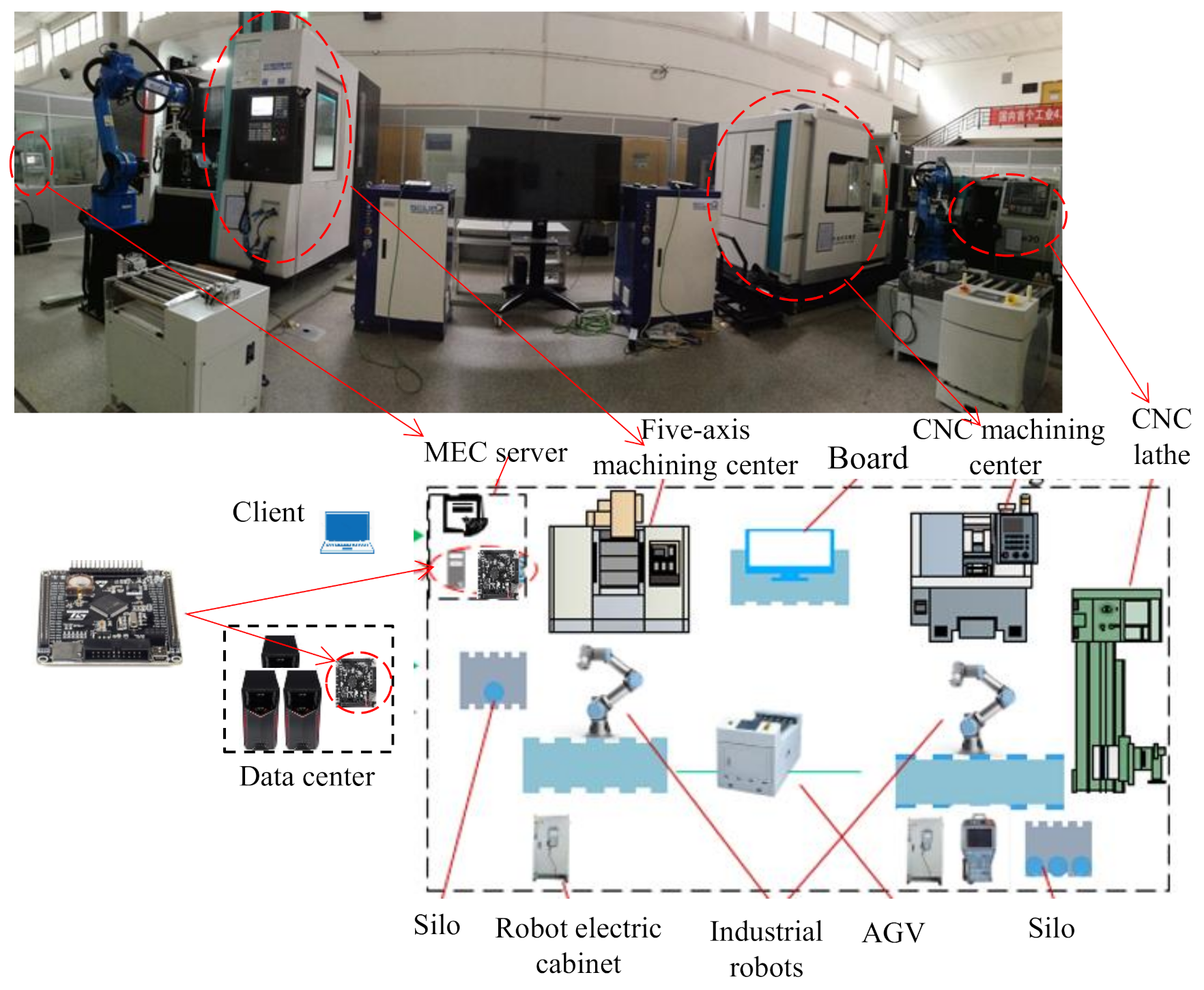

5.1. Experimental Environment

5.2. Experimental Verification and Results

6. Discussion

6.1. Result Analysis

- (1)

- The impact of data packet transmission on network bandwidth

- (2)

- The impact of data packet transmission on packet loss rate

- (3)

- The impact of data packets transmission on delay

- (4)

- The impact of network environment on data transmission time

6.2. Challenges

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Peng, Y.; Wang, B.; Yao, S.; Liu, Z. Review on cyber-physical systems. IEEE/CAA J. Autom. Sin. 2017, 4, 27–40. [Google Scholar] [CrossRef]

- Panetto, H.; Iung, B.; Ivanov, D.; Weichhart, G.; Wang, X. Challenges for the cyber-physical manufacturing enterprises of the future. Annu. Rev. Control 2019, 47, 200–213. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart job shop. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Leng, J.; Jiang, P.; Liu, C.; Wang, C. Contextual self-organizing of manufacturing process for mass individualization: A cyber-physical-social system approach. Enterp. Inf. Syst. 2020, 14, 1124–1149. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Z.; Chen, C.; Luo, W.; Hu, W. Real-Time Prediction of Remaining Useful Life and Preventive Maintenance Strategy Based on Digital Twin. J. Comput. Inf. Sci. Eng. 2021, 21, 1–48. [Google Scholar] [CrossRef]

- Esp-Beltrn, J.V.; Gilart-Iglesias, V.; Ruiz-Fernndez, D. Enabling distributed manufacturing resources through SOA. Robot. Comput.-Integr. Manuf. 2017, 46, 156–165. [Google Scholar] [CrossRef]

- Herwan, J.; Kano, S.; Oleg, R.; Sawada, H.; Kasashima, N. Cyber-physical system architecture for machining production line. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 387–391. [Google Scholar]

- Shi, W.; Cao, J.; Zhang, Q.; Li, Y.; Xu, L. Edge computing: Vision and challenges. IEEE Internet Things J. 2016, 3, 637–646. [Google Scholar] [CrossRef]

- Weisong, S.; Hui, S.; Jie, C.; Quan, Z.; Wei, L. Edge computing-An emerging computing model for the Internet of everything era. J. Comput. Res. Dev. 2017, 54, 907–924. (In Chinese) [Google Scholar]

- Mach, P.; Becvar, Z. Mobile edge computing: A survey on architecture and computation offloading. IEEE Commun. Surv. Tutor. 2017, 19, 1628–1656. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Hu, J. Industrial application based on edge computing: AGV control system. Comput. Integr. Manuf. Syst. 2019, 25, 3191–3198. [Google Scholar] [CrossRef]

- Zhang, S. Application of edge calculation in energy-saving control of beam pumping unit. Autom. Expo. 2019, 36, 54–57. [Google Scholar]

- Zhang, Q.; Hu, Y.; Ji, C.; Zhan, P.; Li, X. Edge Computing Applications: Real-time Sensor Data Anomaly Detection Algorithms. Comput. Res. Dev. 2018, 55, 524–536. [Google Scholar]

- Sun, H.; Liang, X.; Shi, W. VU: Video usefulness and its application in large-scale video surveillance systems: An early experience. In Proceedings of the Workshop on Smart Internet of Things, New York, NY, USA, 14 October 2017; pp. 1–6. [Google Scholar]

- Li, H.; Ota, K.; Dong, M. Learning IoT in edge: Deep learning for the Internet of Things with edge computing. IEEE Netw. 2018, 32, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Mao, Y.; You, C.; Zhang, J.; Huang, K.; Letaief, K.B. A survey on mobile edge computing: The communication perspective. IEEE Commun. Surv. Tutor. 2017, 19, 2322–2358. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Zhou, G.; Zhu, Z. Service perspective based production control system for smart job shop under industry 4.0. Robot. Comput.-Integr. Manuf. 2020, 65, 101954. [Google Scholar] [CrossRef]

- Uhlemann, H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Gronau, N.; Grum, M.; Bender, B. Determining the optimal level of autonomy in cyber-physical production systems. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; pp. 1293–1299. [Google Scholar]

- Mordinyi, R.; Biffl, S. Versioning in Cyber-physical Production System Engineering—Best-Practice and Research Agenda. In Proceedings of the 2015 IEEE/ACM 1st International Workshop on Software Engineering for Smart Cyber-Physical Systems, Florence, Italy, 17 May 2015; pp. 44–47. [Google Scholar]

- Graessler, I.; Poehler, A. Integration of a digital twin as human representation in a scheduling procedure of a cyber-physical production system. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 289–293. [Google Scholar]

- Pooranian, Z.; Shojafar, M.; Garg, S.; Taheri, R.; Tafazolli, R. LEVER: Secure Deduplicated Cloud Storage With Encrypted Two-Party Interactions in Cyber-Physical Systems. IEEE Trans. Ind. Inform. 2021, 17, 5759–5768. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, L.; Liu, R.P.; Yu, K.; Srivastava, G. Nonlinear MIMO for Industrial Internet of Things in Cyber–Physical Systems. IEEE Trans. Ind. Inform. 2021, 17, 5533–5541. [Google Scholar] [CrossRef]

- Rathore, S.; Park, J.H. A Blockchain-Based Deep Learning Approach for Cyber Security in Next Generation Industrial Cyber-Physical Systems. IEEE Trans. Ind. Inform. 2021, 17, 5522–5532. [Google Scholar] [CrossRef]

- Xu, J.Q.; Guo, X.J.; Wang, J.; Li, H.; Zhao, H. Research on CPS Resource Service Model and Resource Scheduling. J. Comput. Sci. 2018, 41, 2330–2343. [Google Scholar] [CrossRef]

- Fangfang, L.; Chong, L.; Ge, Y. Scheduling algorithm of events with imprecise timestamps for CPS. J. Front. Comput. Sci. Technol. 2017, 11, 887896. (In Chinese) [Google Scholar]

- Hao, Y.; Chen, M.; Gharavi, H.; Zhang, Y.; Hwang, K. Deep Reinforcement Learning for Edge Service Placement in Softwarized Industrial Cyber-Physical System. IEEE Trans. Ind. Inform. 2021, 17, 5552–5561. [Google Scholar] [CrossRef]

- You, M.; Liu, Q.; Sun, H. New communication strategy for spectrum sharing enabled smart grid cyber-physical system. IET Cyber-Phys. Syst. Theory Appl. 2017, 2, 136–142. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Yang, G.; Papanastasiou, G.; Zhang, H.; Rodrigues, J.J.P.C.; de Albuquerque, V.H.C. Industrial Cyber-Physical Systems-Based Cloud IoT Edge for Federated Heterogeneous Distillation. IEEE Trans. Ind. Inform. 2021, 17, 5511–5521. [Google Scholar] [CrossRef]

- Xu, X.; Mo, R.; Yin, X.; Khosravi, M.R.; Aghaei, F.; Chang, V.; Li, G. PDM: Privacy-Aware Deployment of Machine-Learning Applications for Industrial Cyber–Physical Cloud Systems. IEEE Trans. Ind. Inform. 2020, 17, 5819–5828. [Google Scholar] [CrossRef]

- Zhou, X.; Liang, W.; Shimizu, S.; Ma, J.; Jin, Q. Siamese Neural Network Based Few-Shot Learning for Anomaly Detection in Industrial Cyber-Physical Systems. IEEE Trans. Ind. Inform. 2021, 17, 5790–5798. [Google Scholar] [CrossRef]

- Tang, S.; Lee, B.S.; He, B. Fair resource allocation for data-intensive computing in the cloud. IEEE Trans. Serv. Comput. 2016, 11, 20–33. [Google Scholar] [CrossRef]

- Ning, Z.; Dong, P.; Wang, X.; Guo, L.; Rodrigues, J.J.; Kong, X.; Huang, J.; Kwok, R.Y.K. Deep reinforcement learning for intelligent Internet of Vehicles: An energy-efficient computa-tional offloading scheme. IEEE Trans. Cogn. Commun. Netw. 2019, 5, 1060–1072. [Google Scholar] [CrossRef]

- Sun, C.; Hui, L.; Li, X.; We, J.; Xiongl, Q.; Wang, X.; Leun, V.C. Task offloading for end-edge-cloud orchestrated computing in mobile networks. In Proceedings of the 2020 IEEE Wireless Communications and Networking Conference (WCNC), Seoul, Korea, 25–28 May 2020; pp. 1–6. [Google Scholar]

- Li, X.; Wan, J.; Dai, H.N.; Imran, M.; Xia, M.; Celesti, A. A hybrid computing solution and resource scheduling strategy for edge computing in smart manufacturing. IEEE Trans. Ind. Inform. 2019, 15, 4225–4234. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Gao, H.; Xue, Y.; Qi, L.; Dou, W. BeCome: Blockchain-enabled computation offloading for IoT in mobile edge computing. IEEE Trans. Ind. Inform. 2019, 16, 4187–4195. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Lv, Y.; Wang, Q.; Yang, D.; Zhou, G. Service-Oriented Real-Time Smart Job Shop Symmetric CPS Based on Edge Computing. Symmetry 2021, 13, 1839. https://doi.org/10.3390/sym13101839

Wang C, Lv Y, Wang Q, Yang D, Zhou G. Service-Oriented Real-Time Smart Job Shop Symmetric CPS Based on Edge Computing. Symmetry. 2021; 13(10):1839. https://doi.org/10.3390/sym13101839

Chicago/Turabian StyleWang, Chuang, Yi Lv, Qiang Wang, Dongyu Yang, and Guanghui Zhou. 2021. "Service-Oriented Real-Time Smart Job Shop Symmetric CPS Based on Edge Computing" Symmetry 13, no. 10: 1839. https://doi.org/10.3390/sym13101839

APA StyleWang, C., Lv, Y., Wang, Q., Yang, D., & Zhou, G. (2021). Service-Oriented Real-Time Smart Job Shop Symmetric CPS Based on Edge Computing. Symmetry, 13(10), 1839. https://doi.org/10.3390/sym13101839