1. Introduction

The methods developed in the context of degradation-based modelling have been considered as indispensable and operative procedures to make inference on the lifetimes of different sorts of deteriorating systems (see, e.g., Kharoufeh and Cox [

1], Park and Padgett [

2], Gebraeel and Pan [

3], Si et al. [

4], Jiang et al. [

5], Rafiee et al. [

6], Ye and Xie [

7], Chen et al. [

8], Zhai and Ye [

9], Zhang et al. [

10], Huang et al. [

11], Yousefi et al. [

12], Dong et al. [

13], and Balali et al. [

14]). The lifetime of deteriorating items which exhibit an observable degradation can be generally modeled using a stochastic process and, specifically, by a nonhomogeneous gamma process or nonhomogeneous inverse Gaussian process. For instance, an error of a measurement related to a device which increases over time can be considered. For systems with high reliability, degradation data–based strategies may provide the only possible framework to attain the intention of reliability analysis. Therefore, the methods developed in order for degradation data analysis are becoming typical tools over the last decades. The analysis of degradation data is possible after setting the definition of lifetime (see, e.g, Di Crescenzo and Di Gironimo [

15], Guo and Lee [

16], Lee et al. [

17], and Liu et al. [

18]).

Before navigating to our main idea, the stochastic process describing the degradation model that will be used throughout the paper in different cases is outlined. Stochastic processes with monotone sample paths are considered. The traditional definition of a degradation model assumes that the failure of an item/system occurs when degradation exceeds the predetermined threshold level

. Suppose that the failure is modeled by a stochastic process

entertaining monotonically increasing sample paths as it is ordinarily taken place in many practical situations. Let the time to failure be denoted by the random variable

T. Subsequently, according to the described failure criterion

T is the first passage time to the threshold

, which is given by

. The corresponding distribution function of the failures is denoted by

and the implied survival function is signified by

. The monotonicity of a realization of the stochastic process

assures with probability one that

for

. Therefore,

For instances, gamma process-driven and inverse-Gaussian process-driven deterioration model are given here. Certainly, most practical applications would use degradation models extended beyond the ones listed here.

(I). Gamma process based degradation model

Let

have gamma distribution with a shape parameter

and a scale parameter

, denoted by

, where

, and

is monotonically increasing in

so that

. The density function of

is

Therefore, the corresponding cumulative distribution function is defined, for each

, as

From Equation (

1), it is apparent that

(II). Inverse-Gaussian process based degradation model

It is well-known that under the Brownian motion process, the first passage time is given by the inverse Gaussian distribution (see, e.g., Chhikara and Folks [

19]). Suppose that

follows a inverse gaussian distribution

where

, and

is also nonnegative and monotone increasing in

, with

. Therefore, the density function of

is given by

from which the cumulative distribution function of

is obtained, for each

, as

It is evident from Equation (

1) that

The organization of the residual part of paper will be systematized, as we explain here. In

Section 2, the main failure time model is defined and the resulting lifetime distributions are considered in details. In

Section 3, some methods for identifying a principal component of the model are given. In

Section 4, reliability evaluation of the model using hazard rate and mean residual life functions together with some numerical calculations of theses measures is carried out. In

Section 5, the problem of modelling degradation at failure, as a closely related subject, is considered while using the copula and dependence theory. In

Section 6, we eventually obtain two negative aging properties, namely the decreasing failure rate (DFR) and the increasing mean residual life (IMRL) properties of the model under some conditions. In

Section 7, a characterization property for a partially symmetric degradation model will be established. Finally in

Section 8, we will outline and summarize the results obtained in the paper and also their applicability for future studies.

2. Degradation-Based Model

In this section, a new probabilistic methodology for modelling failure time data based on degradation processes is introduced. It is controversial to consider a predetermined threshold level to define a deterministic criterion for the failure of an item under a degradation path. We provide an update on the failure criterion of the item under consideration to entertain many other situations in practice to consider the possibility of both hard and soft failures of the item.

For instance, to provide a generalized failure criterion, let the item work with probability one while the degradation is less than the predetermined lower threshold , then as the degradation exceeds and is equal at the time t with the item works with the probability and eventually as the amount of the degradation goes up to become greater than the upper threshold the item fails immediately. It is a natural assumption in accordance with the ordinal deterioration of the item that is a decreasing function in for each .

To be more specific, let us set

to display the non-working status of the item at time

t, as follows

which has Bernoulli distribution having success probability

.

T is assumed to have an absolutely continues distribution function. Notice that

means that the item does not work at the time

t and that

induces that the item is working at that time. In a more generalized setting where the failure criterion is associated with deterioration of the system, one has for each

and for

,

Relying on the proposed conventional failure criterion, we have

where

may be independent of

or dependent on it as it is at the end of the data analysts and/or manufacturer. For instance, along with the effect of the degradation, there may be a time effect, separately, on the failure of the item also in the way that it affects the probability of failure of the item. In situations where the deterioration of the item incorporates different reduction in performance rates over time, the dependency on time seems to be a meaningful assumption. We have

For instance, the case of traditional one-threshold degradation model is reached when

, where

is the predetermined threshold level. The fact that only the degradation causes the item deterioration independent of time, as is the case with highly reliable products, assures that

. Therefore, the survival function in (9) is modified as

That the relations (9) and (10) introduce appropriate survival functions must be demonstrated. In both equations, it is evidently apparent that

for all

. We only show that

in (10) is a non-increasing function of

as the similar conclusion may need more assumption(s) in the case of (9).

By utilizing (10), the main degradation based model and also its extracted models are generated. Relying on the extra assumption that

and that

, for all

, by applying integration by parts in (9), one gets

where

for all

It suffices to show that

is non-increasing in

for all

Assume that

is differentiable. The notions of totally positive of order 2 (TP

) and the reverse regular of order 2 (RR

) that will be used in the sequel can be found in Karlin [

20]. Because, for all

and for all

, it holds that

thus by Theorem 3 in Holland and Wang [

21],

is TP

in

implying that

is non-decreasing in

for all

It further implies that

for all

and for all

. Thus, the expression in the right hand side of the identity (11) is non-increasing in

t defining a valid survival function.

The degradation points that are adjacent to each other may instigate an analogous probability of failure, necessitating to use

where

and

The implied survival function is

The function

in (12) defines a valid survival function. The discrete counterpart of (11) can then be written as

where

. In the case when a predetermined interval threshold

is considered as the failure criterion,

In the particular case of

, the identity (10) reduces, as a special case, to (1). To relate the cutoff points of degradation with time, one may assume that

where

is a non-negative function. In the model (12), consider a situation where the item under consideration does not fail until

. Therefore,

is chosen to be step-wise for

as

in which

are some positive real numbers that represent some marginal degrees of degradation in the interval

. The maximum amount of degradation at which the probability of the failure of the item becomes zero has been set to be

. Subsequently, as a special case of (12), the implied survival function will be

3. Some Methods for Assigning

In the setting of the model (9), we need to determine the survival probability based on some statistical methods. It is known that the randomness in the failure time comes from the randomness of the degradation. We illustrate two different approaches for doing it.

3.1. Regression Approach

It may be found in many applications that product’s lifetimes usually fit a lognormal distribution (see, for instances, Ratnaparkhi and Park [

22] and Lu and Meeker [

23]). Let us construct a regression curve with

, as the dependent variable natural logarithm of time to failure of the item under the degradation process, on the amount of the degradation at time

t, i.e.,

for some

, so that

where

is an appropriate function,

is the regression coefficient and

is the error term, which is independent of

, for all

. In the spirit of (15), one can determine

in which

is the cumulative distribution function of the standard normal distribution. It has to be mentioned that the estimation of

and

is possible whenever the amount of degradation

is observable for

n copies of the item at time

t. To be more specific, if

are observed then the information from the variability of degradation at time

t along with the time to failure of the

n copies of the item can be captured to estimate the parameters in (15).

3.2. Distribution Characteristic

For the items deteriorating over time, as the degradation conquests the strength of the aged item, the failure happens. The probability may decrease, for fixed as w goes up in (9), as mentioned earlier. In the context of the proposed double threshold degradation model, and such that for all Therefore, can be considered as a time-dependent survival function of of a non-negative random variable with support and, according to (8), is the associated density function.

In the cases where degradation process is supported in a finite interval consider a random variable

with beta distribution with parameters

and

and let us set

, which has density function

where

is the beta function. Subsequently,

is the conditional survival probability of the item under degradation at time

t provided that degradation at time

t equals

. To fulfill the model that is given in (9), the density function (17) can be utilized.

The binary case that involves the degradation rate in terms of time can be another choice. To fix the idea, since

is increasing in

we take

where

is an appropriate increasing function. The implied lifetime distribution then has survival function

where ∧ takes the minimum. It is obvious from (19) that, when

, then

while for

we have

Note that, in (18), we can substitute

by any appropriate function of time,

say.

In the setting of the model (9), can be the survival function of a non-negative random variable having an arbitrary support in . Suppose that there is no a certain cutoff for the degradation to set a failure criterion, but instead it is assumed that the failure of the item occurs as the degradation gradually goes up.

By considering

with survival function

, where

is a non-negative function. In such a case, if

, then the implied survival function of

T, according to the formula (9), is obtained as

Let us assume that

is not a survival function, as given by

where

and

is a non-negative non-increasing function satisfying

and

. Subsequently. by taking

the implied survival function of

T will be

Next, we apply the former implied lifetime distribution to a real data set.

Example 1. Let us consider sample lifetime data , as reported in Bryson and Siddiqui [24]. Suppose that has survival function . Subsequently, the log-likelihood function of the sample will beThe likelihood equation is derived by whereThe maximum likelihood estimation (MLE) of β is then obtained asIn the particular case when and , the MLE is calculated as 4. Hazard Rate and Mean Residual Lifetime of the Model

It has long been useful to describe the aging behaviour of a lifetime unit through its hazard rate and also the associated mean residual lifetime. The former is applied to measure instantaneous risks for failure at various points of time whereas the latter summarizes the entire residual life of the item at some given points. The study is accomplished in two parts as follows:

4.1. Derivation of the Measures

Suppose that

T is the lifetime of a system or a unit under some circumstances. Denote by

and

the density function and the survival function of

T, respectively, so that

Subsequently, the hazard rate of

T is defined for values of

t with

as

The mean residual lifetime of

T, as another useful characteristic, is defined for all

t with

, as follows:

Based on the model (9), the hazard rate function of

T is obtainable as

For the cases where model (10) is applied, (20) reduces to

The mean residual lifetime of

T with survival function (9) is

The case where

implicates that the only reason to cause the failure of the item is the performance of it according to the degradation process and, therefore, as the time during which no degradation happens goes by, nothing puts the time to failure of the item forward. This is frequently the case in most of the practical situations.

In the next round, the hazard rate and the mean residual lifetime of

T in the cases where it follows the models (10) and (12) under gamma degradations

, i.e., when

are obtained. For

T with survival function (10) applied to the case where deterioration is in agreement with the gamma process, as just described, the hazard rate is

in which

is a non-negative random variable with density

and the mean residual lifetime is

in which

for any

.

For

T with survival function (10) applied to the case where

with associated density function

, as given in (5), the hazard rate is obtained as

where

is a non-negative random variable with density

The mean residual lifetime of

T in this case, is

where

for any

.

Whenever

T has survival function (12) in the case where

, the hazard rate is identified as

where

The associated mean residual lifetime will be obtained by

where

g is as given in (2).

If the random lifetime

T has survival function (12), so that

, the hazard rate is derived as

The related mean residual lifetime is obtained as

where

i is as given in (5).

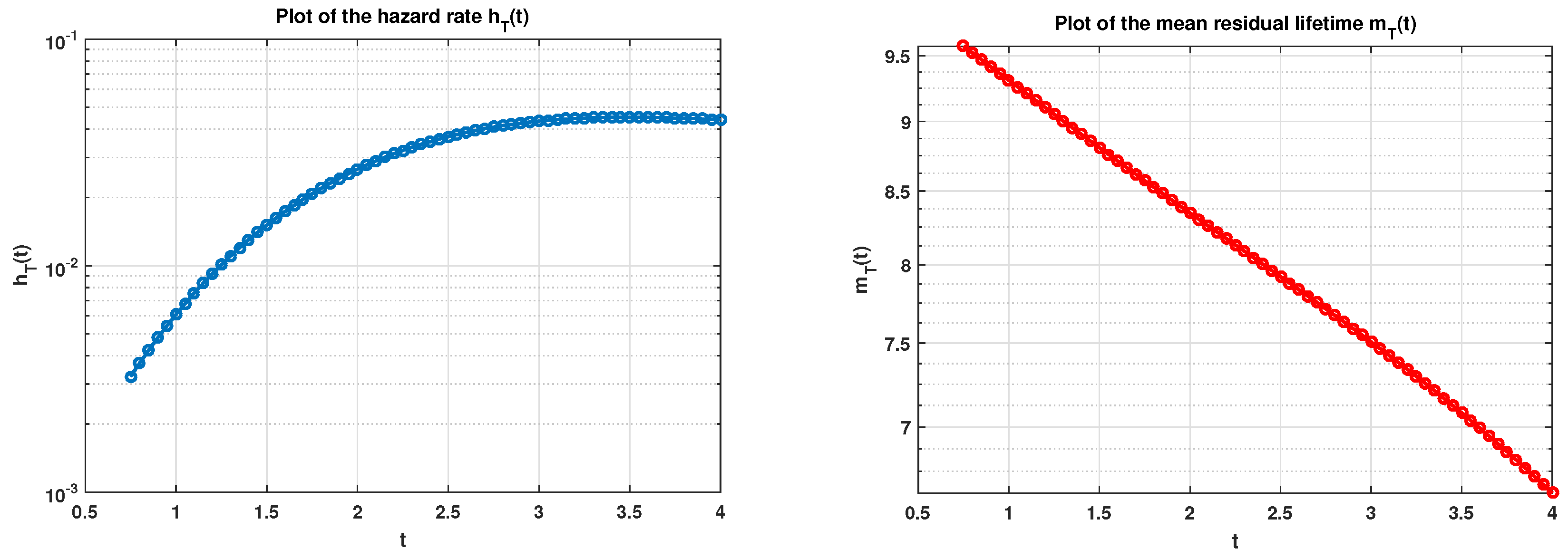

4.2. Numerical Illustration and Graphical Analysis

Here, by taking , , and , the amounts of hazard rate functions (27) and (29) and also the amounts of mean residual lifetime functions (28) and (30) are partially calculated numerically and the associated graphs are plotted in order to visualize the behaviour of these reliability measures over time points .

For the Gamma process-driven degradation model, by taking as the scale parameter, we plot the graphs and also make the calculations of (27) and (28) and give a table of the calculated amounts of and for the time points given earlier.

For the Inverse-Gaussian process-deriven degradation model by taking and , we shall plot the graphs of (29) and (30), and give a table of the calculated amounts of and in the specified points.

The value of integrals utilized in (27)–(30) have been numerically computed. The Composite 2-point Gaussian–Legendre quadrature rule has been applied to provide approximations for the amounts of the integrals (see, e.g., Gerald and Wheatley [

25] and Chapra and Canale [

26]).

The values of the hazard rate

of

in Equation (

27) and also the values of the associated mean residual lifetime

in (28) for the previously inserted points of time are given in

Table 1.

The amounts of the hazard rate

of

in Equation (

29) and further the values of the associated mean residual lifetime

in (30) are evaluated in

Table 2.

The graphics of the hazard rate function (29) and the associated mean residual lifetime function (30), in the special cases with the given quantities and parameters, as was assumed, have been plotted in

Figure 1 and

Figure 2.

5. Modelling Degradation at Failure Time

Traditionally, a system subjected to degradation is supposed to be considered as a failed system when the degradation level reaches a predetermined amount . The time to failure of the system is then set as . Therefore, it is concluded by the continuity property of the underlying stochastic process that , in which is the amount of degradation at the time of the failure.

However, in a little more dynamic case, the possibility of having at a neighborhood of could be entertained, so that for some , in which is the support of . There may be some concern how certain the investigator is in considering D as a cutoff for the amount of the degradation to switch the status of the system to be considered as a failed system. Hence, the variability and more generally the distribution of may be a useful tool for assessing the considered failure criterion and modifying it in the case of necessity.

For instance, in the case when the variability of

is relatively higher, the interval threshold degradation models discussed in

Section 2, may be the case by the choices

and

. Therefore, the coefficient of variation of

is a qualified measure to be first calculated before proceeding with the degradation model selection.

The approaches that are initiated in this paper establish more dynamic models for time to failure events that consider the degradation magnitude and that how the failure of the system is affected by it. The proposed model (9) presented in

Section 2 provides more dynamics on the way the degradation contrasts the time to failure of the system.

Suppose that

T is the time to failure of system and

is the amount of degradation at the time

T. Denote, by

, the conditional density of

given

T and denote, by

, the conditional density of

T given

for

. The degradation at failure, i.e.,

has the density function

The model in terms of the latter expression has a different role than the former one. The former version of the model is, as a matter of fact, a mixture model with mixing variable

T, while the latter one does not present a mixture model.

The regression curve (15) may be pertained to identify the distribution of

T provided that

for some

at the time point

. Based on (15), we can get for

Now, by letting

we get

where

is the pdf of standard normal distribution. Therefore, it follows that

The survival function of (31) is

Adjoining by copula functions is a method to identify the conditional distribution of given T in (31) and (32) and also the conditional distribution of T given in (32). A bivariate copula function describes the structure of dependence among two continuous random variables. Bivariate copula functions give leave to us to make bivariate distributions with given marginal distributions. The theoretical starting point for the implementation of copula-based modelling has been provided by the Sklar’s theorem, stating that a 2-dimensional copula is a function C from to the interval . The following conditions need to be satisfied:

- (i)

for all

- (ii)

for all and for all

- (iii)

C is

m-increasing (see, e.g., Nelsen [

27]).

Consider a bivariate lifetime distribution function

F, which can be stated in terms of the copula function

C by using Sklar’s theorem as

where

and

are the marginal distribution functions. In lifetime models, we are interested in events involving survival times. Thus, the survival copula

linked to the copula function

C as

If

and

denote the marginal survival functions of

X and

Y, respectively, and

is used to signify the joint survival function of

X and

Y, then one has

As a consequence, to model the dependence structure between

T and

, we may strive to use a copula function so that the model (34) is partially characterized. Notice that, due to the nature of the degradation phenomenon and its effect on the failure of the underlying system, the random variables

and

T may by negatively dependent over

m while the dependency of them for

can be set without any constraint. This may be useful to choose an appropriate copula function in our context.

To fix the idea, let us suppose that

shares a time-dependent survival copula function

. Then,

Thus, the survival function in (34) can be modified as

where

Let us rewrite (35) as

in which

is the right continues inverse function of

. Because, for the time points that are adjacent to each other,

and

T may share a common copula, thus it is natural to break down the survival copula function

, as follows:

where

and

is a survival copula function for each

. The choice of

’s largely depends on the fluctuations of the dependence structure of

T and

over time. By this decomposition, the model (36) can be modified as

where

for each fixed

.

6. Several Reliability Characteristics

The assessment of the reliability of the systems under degradation has been followed out by Bae et al. [

28]. Specifically, several aging properties of the implied lifetime distributions under additive and multiplicative degradation models have been considered in their work. In this section, two aging properties of the failure time models that are introduced in

Section 2 are studied.

To begin with, we obtain the hazard rate function of

T with survival function (1). The random variable

T is said to have an increasing failure rate (IFR) when

is a non-decreasing function and it is said that

T is DFR whenever

is non-increasing. The IFR and the DFR classes may be useful to describe the aging behaviour of the item under the degradation process over time. The hazard rate function of

T for any

is given by

Hence,

T with survival function (1) possesses an IFR (resp. DFR) aging behaviour whenever

is log-concave (resp. log-convex) in

However, for

T with survival function (9) the hazard rate function is obtained as in (20) when

is differentiable in

t for all

.

Theorem 1. Let be TP (resp. RR) in . Let be log-convex in t for all Subsequently, T is DFR.

Proof. We prove the non-parenthetical part of the theorem as the proof for the parenthetical part will be similar. We have

where

is assumed to be the density function of a random variable

say. From assumption

is TP

in

, which further implies that

for all

and for all

. Because

is log-convex in

t, for any

w, thus

is non-increasing in

t for all

w. Furthermore, since

is TP

in

, thus for all

and for all

thus

for all

. By Lemma 2.2(ii) of Misra and van der Meulen [

29], we obtain the desired result. □

The study can be developed using another aging property based on the mean residual lifetime of T. The random variable T is said to have an increasing mean residual lifetime (IMRL) when given in (22) is non-decreasing in .

Note that, since the DFR class is a subclass of the IMRL class, the conditions in Theorem 1, besides those in the next result, are sufficient conditions to get the IMRL property for T. Nevertheless, the conditions in the next theorem seem to be more relaxed.

Theorem 2. Suppose that is TP (resp. RR) in . Let be log-concave in t for all Then, T has the IMRL property.

Proof. The non-parenthetical part of the theorem is only proved. We can get

where

is as given in the proof of Theorem 1 and

Because

is log-convex in

t, for all

, thus, for all non-negative values of

,

Therefore,

is non-decreasing in

t for all

. The assumption that

is TP

in

persuades to have, for all

, which

It follows from the above inequality that

is non-decreasing in

for all

t. By a similar discussion as in the proof of Theorem 1 together with using Lemma 2.2(ii) of Misra and van der Meulen [

29], it is concluded that

is non-decreasing in

t and hence

T is IMRL. □

7. Symmetric Degradation Models

In some practical works, it is naturally verified, through the empirical process of recording observations, that the amount of degradation follows a symmetric distribution and, therefore, some researchers have concentrated on such models (see, e.g., Gebraeel et al. [

30]).

In what follows, a characterization property of partially symmetric degradation models is derived. It is said that the degradation model, identified by

, is symmetric when there exists a non-stochastic function

such that

is symmetric about

, so that

and

are equal in distribution. In other words, the cumulative distribution of

satisfies, for all

in the support of

,

To be more specific, in an additive degradation model (cf. Bae et al. [

28]), which is recognised by

if

X has a symmetric distribution around

then

will be symmetric about

. For example, if

X is distributed as

then

has a normal distribution with mean

and the variance

. There may be situations in which distribution of a transformation of

is symmetric. For a typical case, we can consider the multiplicative degradation model represented by

. Suppose that

X is distributed as

then

is distributed as

, which is symmetric about

Usually, there are

n subjects that are employed in independent experiments for the sake of observation of their degradation over time. Suppose that

are the amounts of the degradation of the subjects at time

t. Let us suppose there exist functions

, such that for all

and

where

and

are the smallest and the largest order statistics according to the random sample

. Notice that the right hands of the foregoing identities are assumed to be independent of

n.

In the following result, the degradation value at the median of the failure distribution i.e., is characterized as a symmetric distribution after imposing a condition.

Theorem 3. Suppose that, for , it holds thatSubsequently, for follows a symmetric distribution. Proof. By routine calculation, we can obtain

and also

From assumption, it is seen that

, which holds if, and only if,

is equivalent to

for all

Since

is a complex sequence of functions, it is deduced from Lemma 2.1 in Kayid and Izadkhah [

31] that

which further implies that

has a symmetric distribution. The proof is complete. □