Analysis of Instability Mode and Limit Support Pressure of Shallow Tunnel Face in Sands

Abstract

:1. Introduction

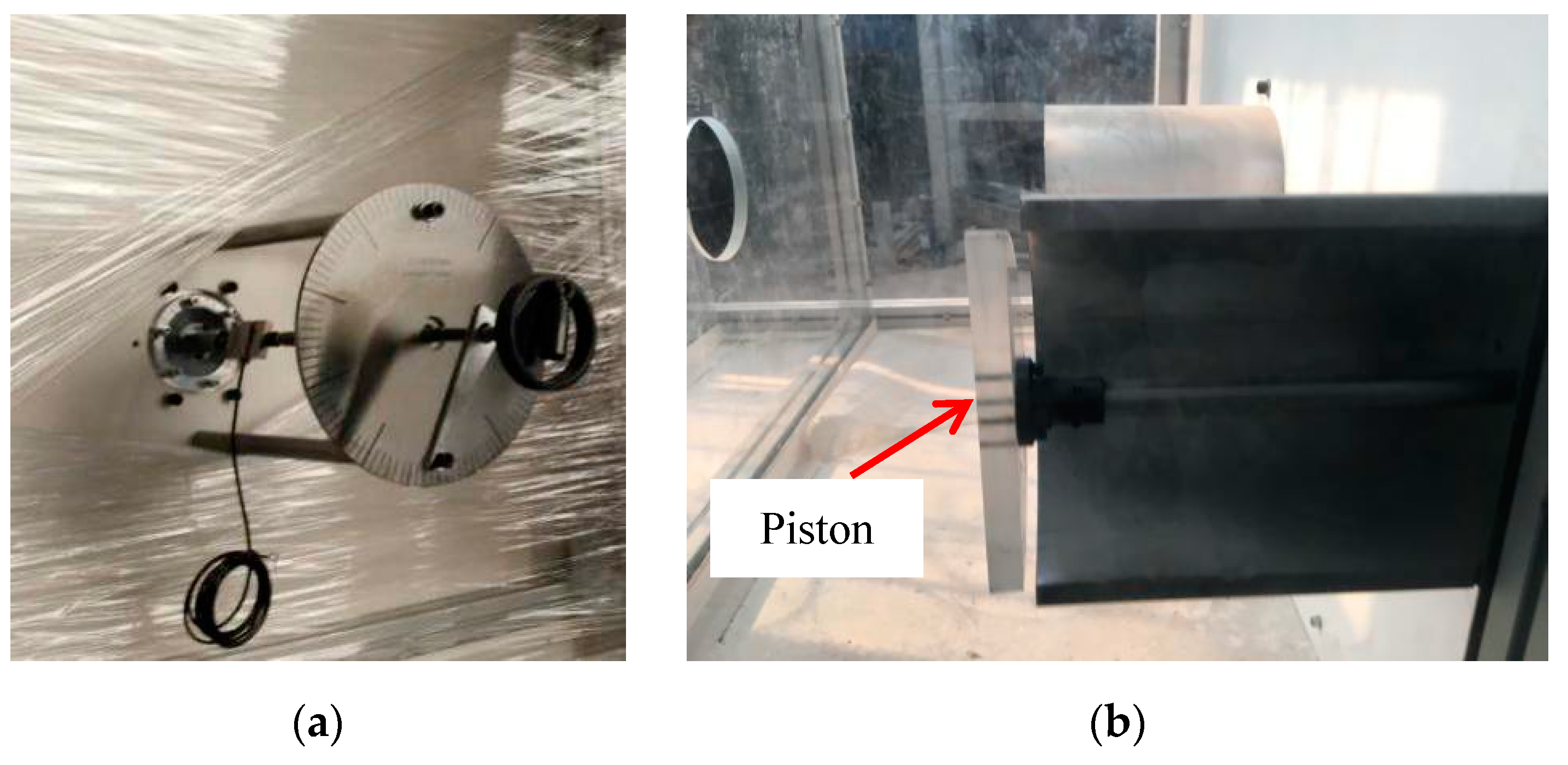

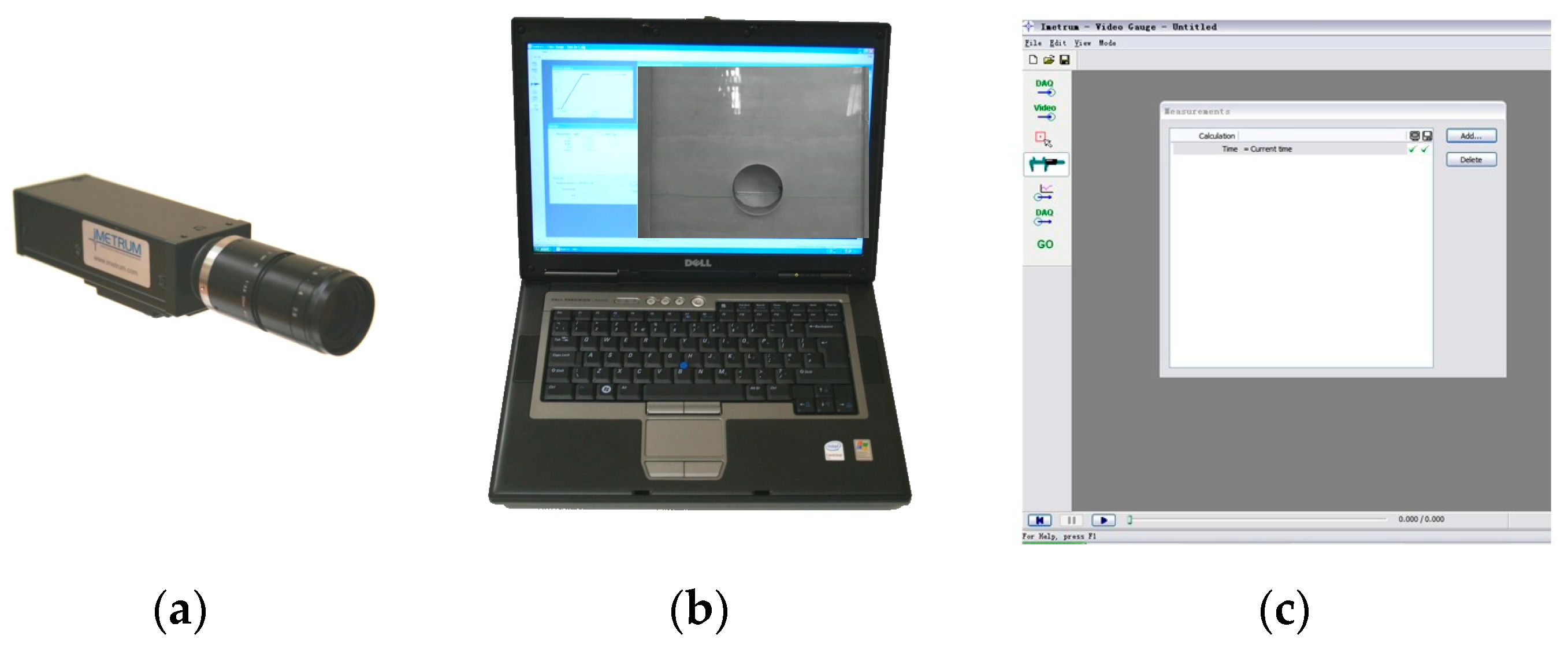

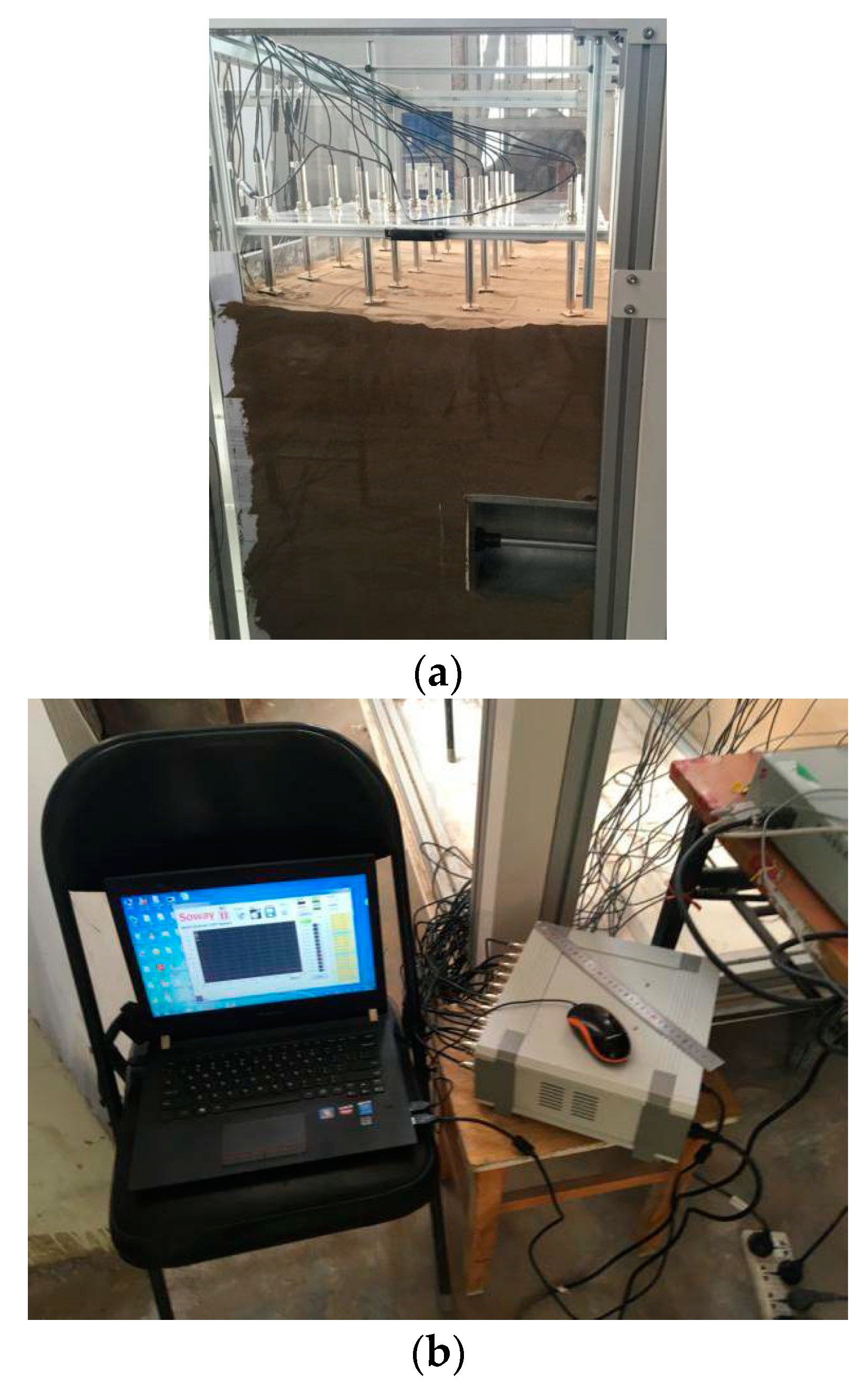

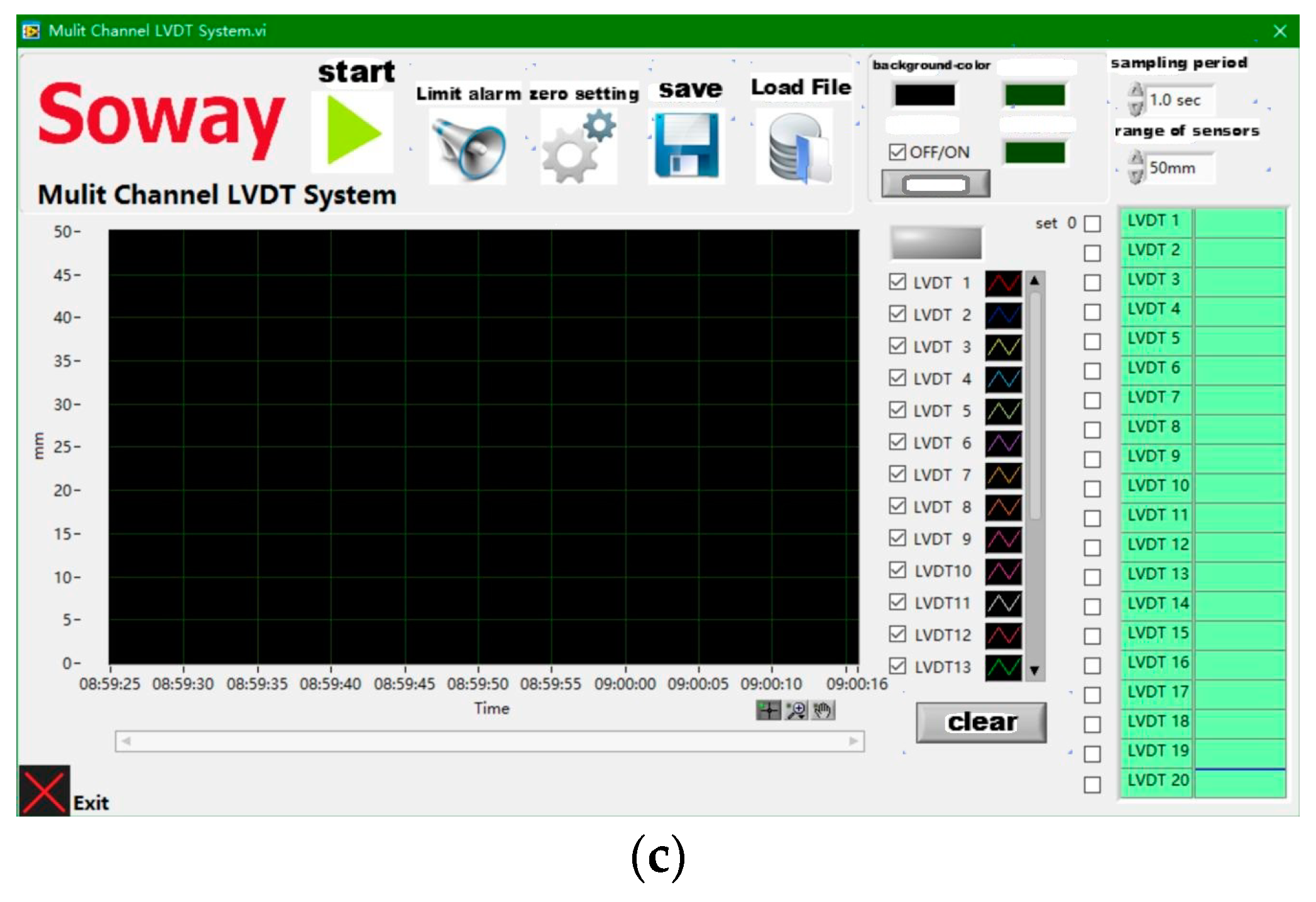

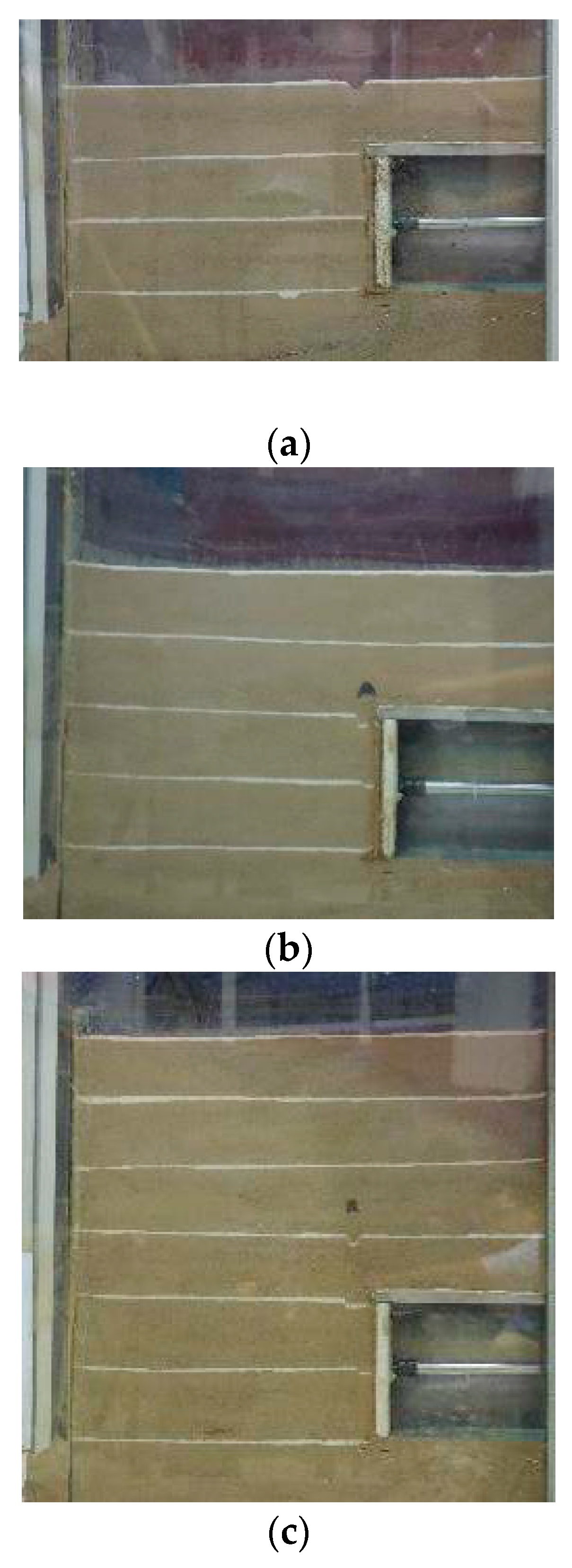

2. Physical Model Test

2.1. Test Setup

2.2. Test Materials

2.3. Test Procedures

3. Experimental Results and Analyses

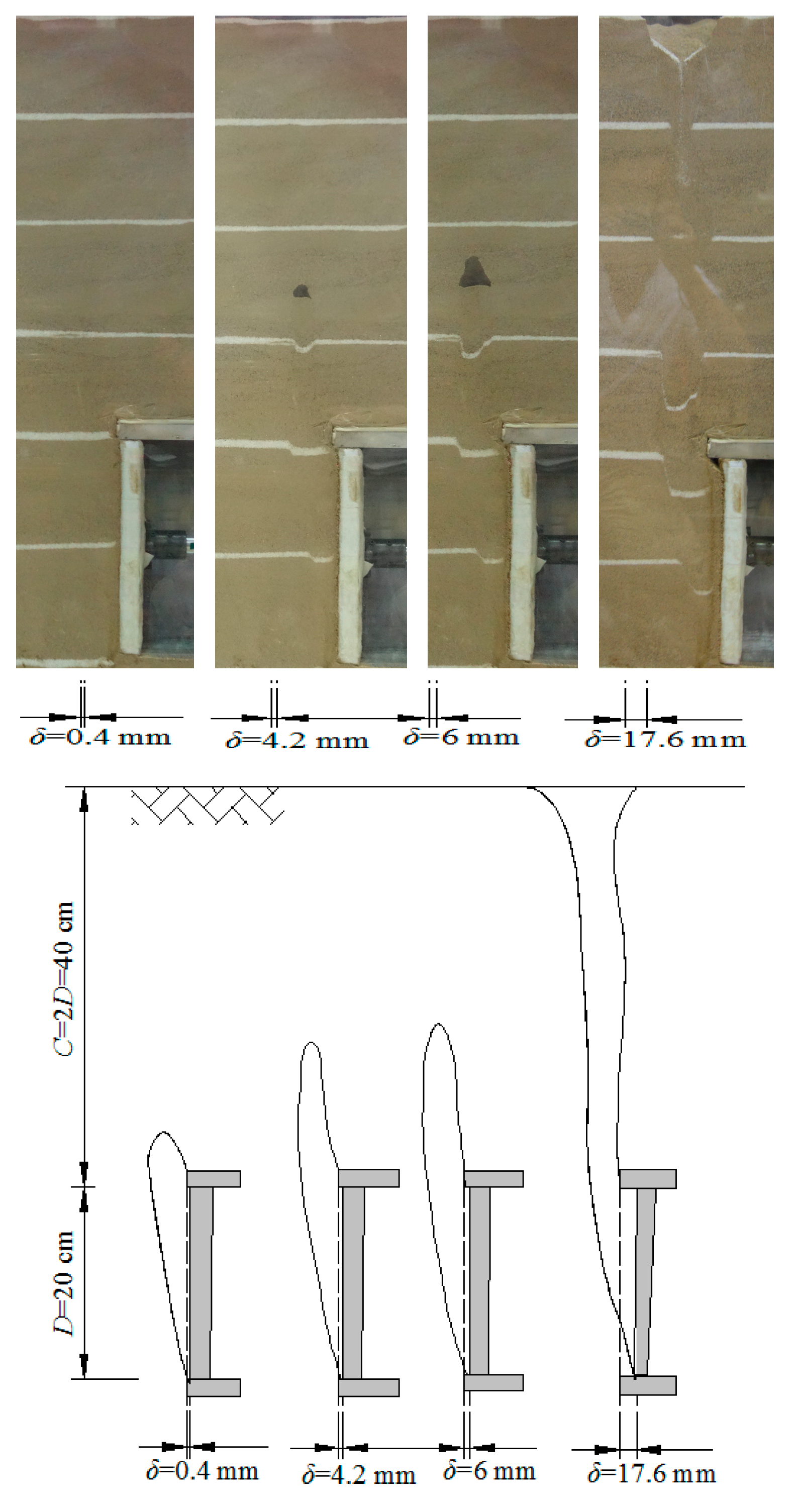

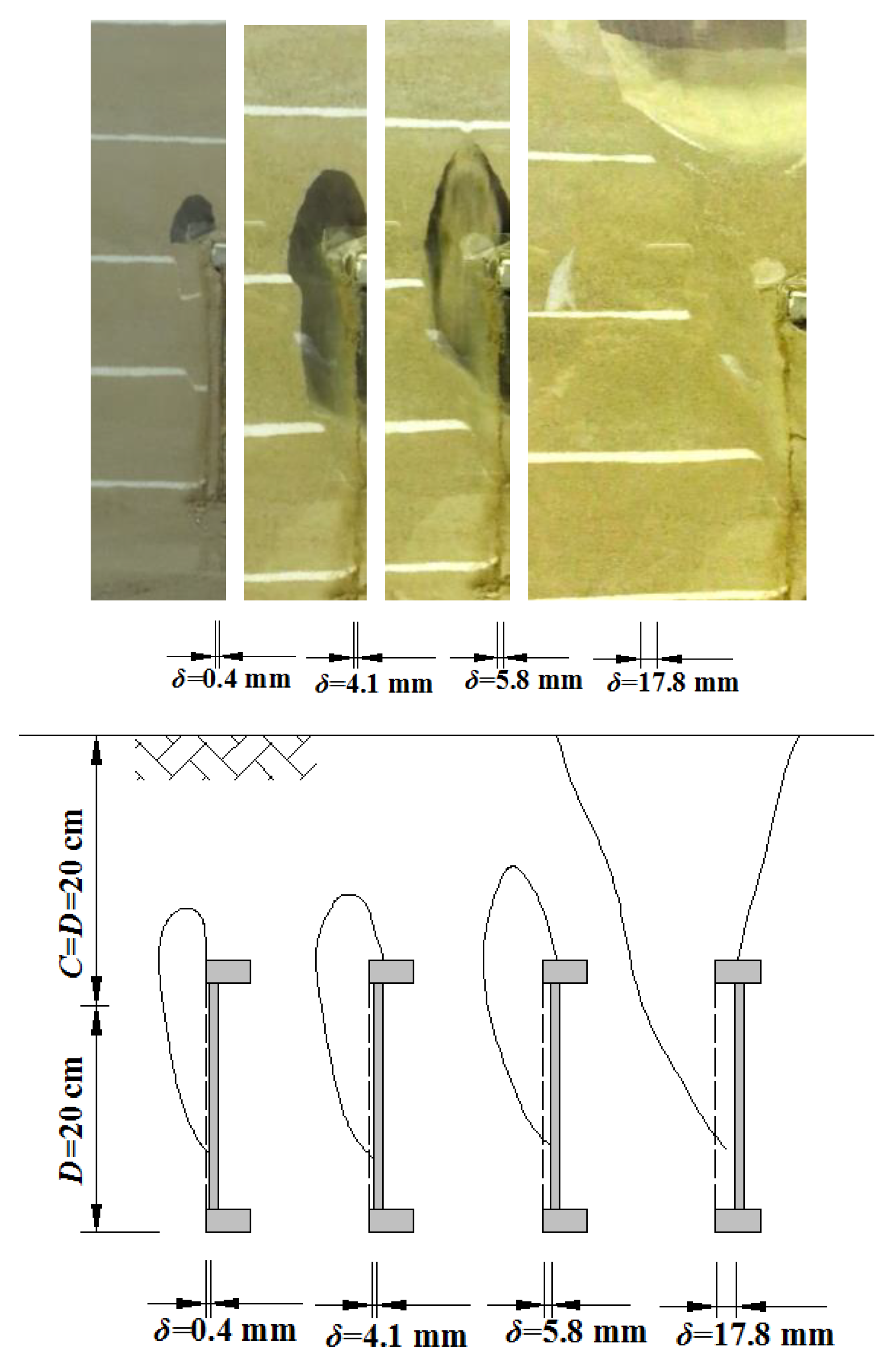

3.1. Progressive Instability Mode

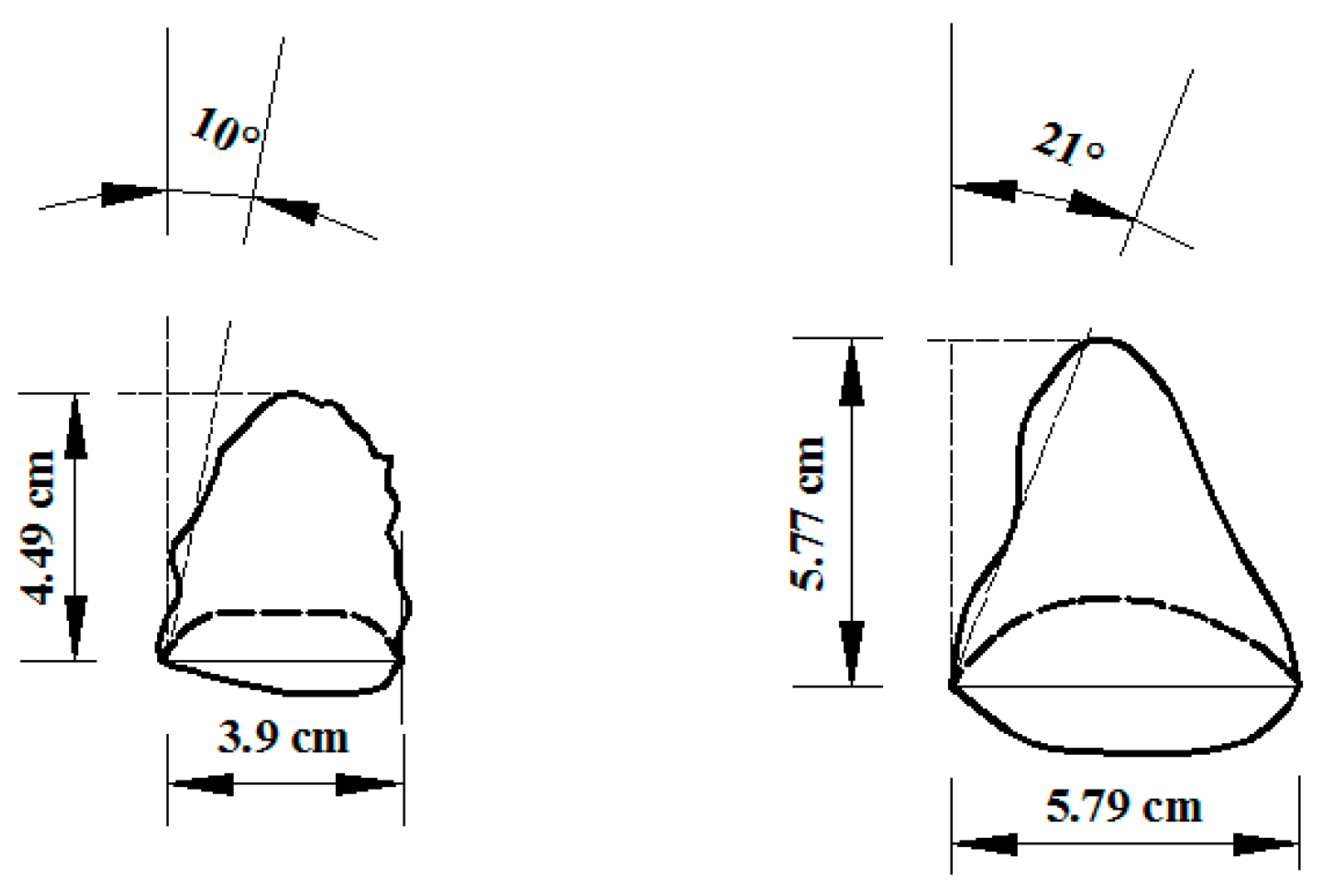

3.1.1. Shear Failure Band

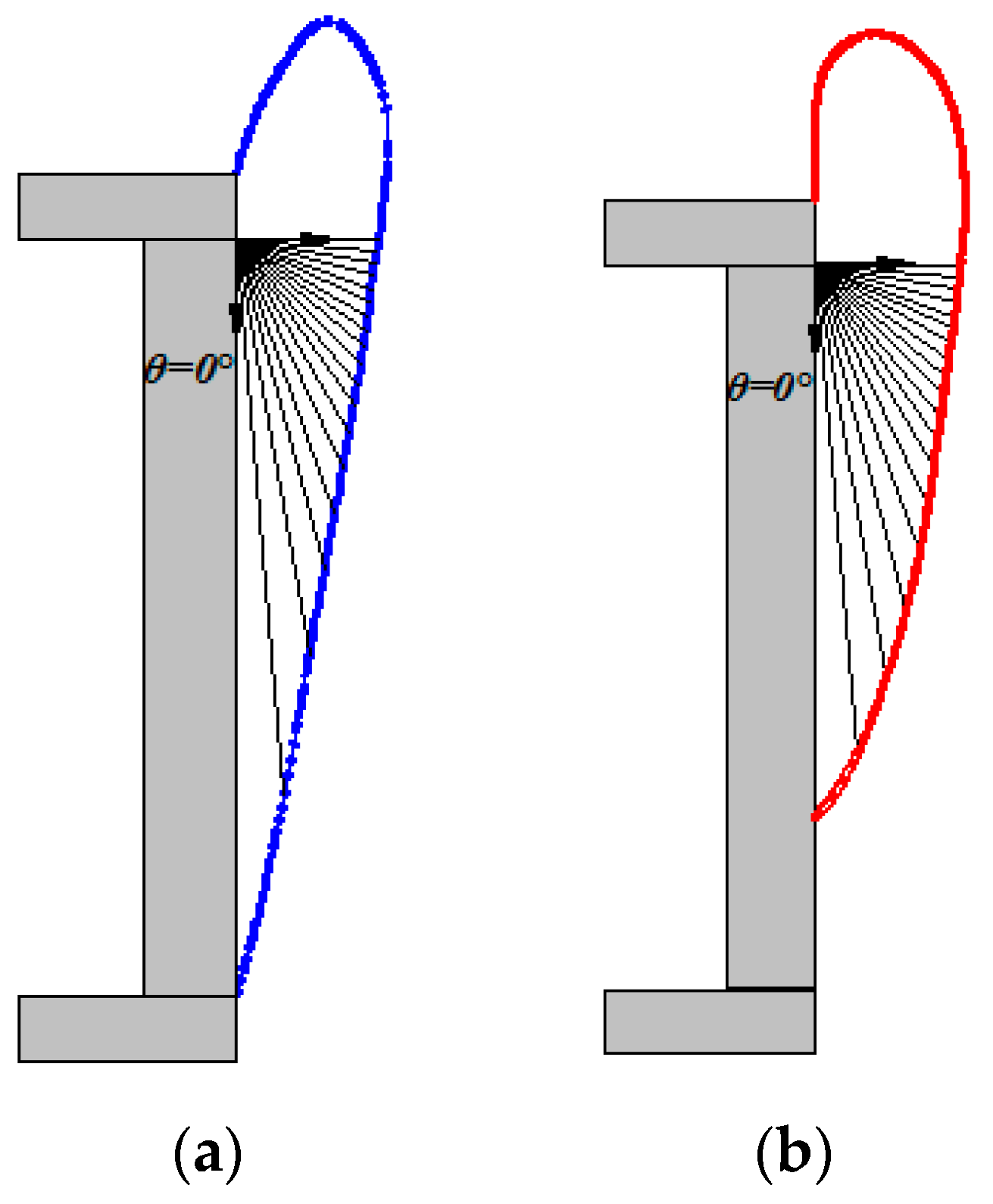

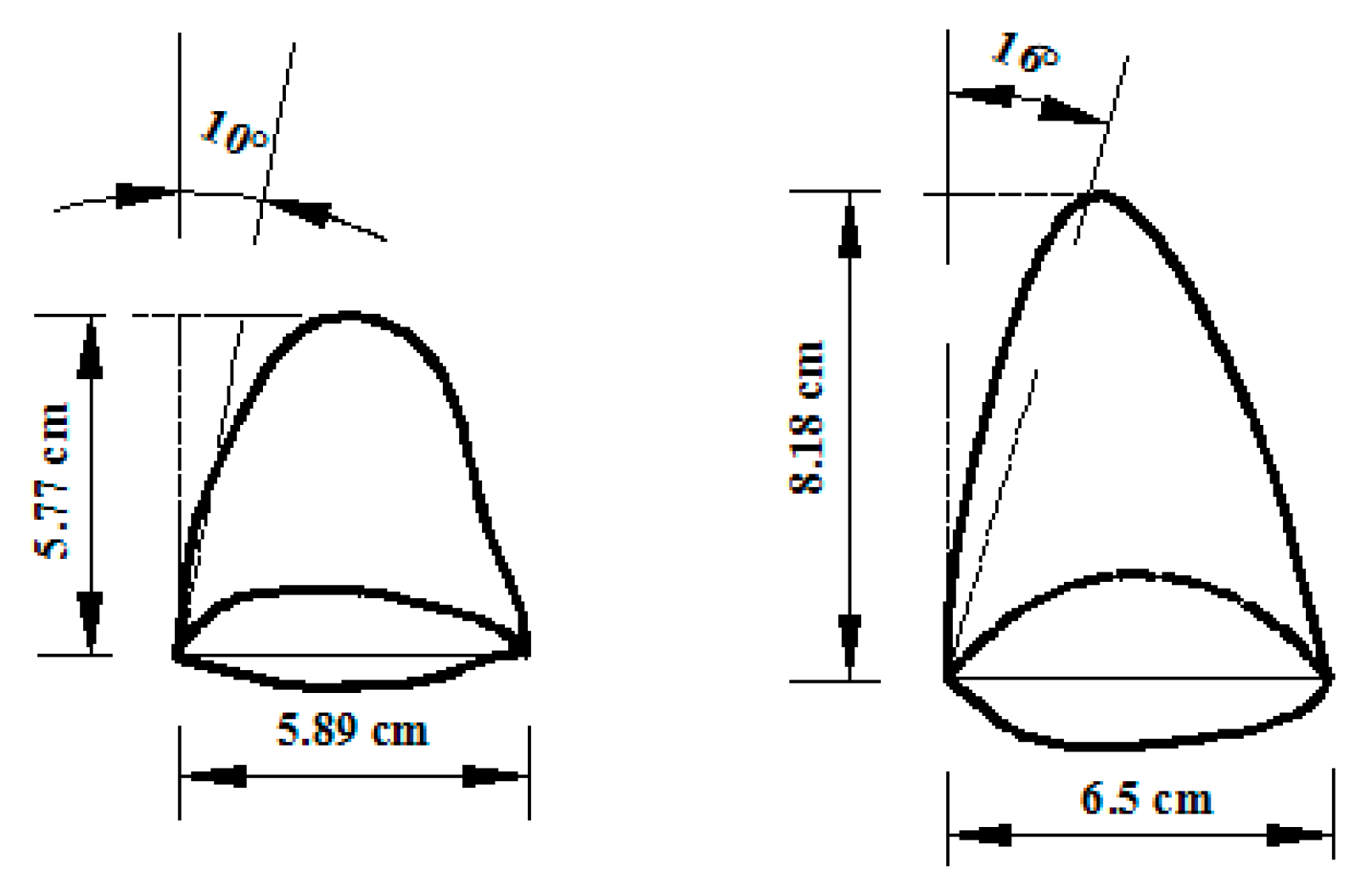

3.1.2. Pressure Arch

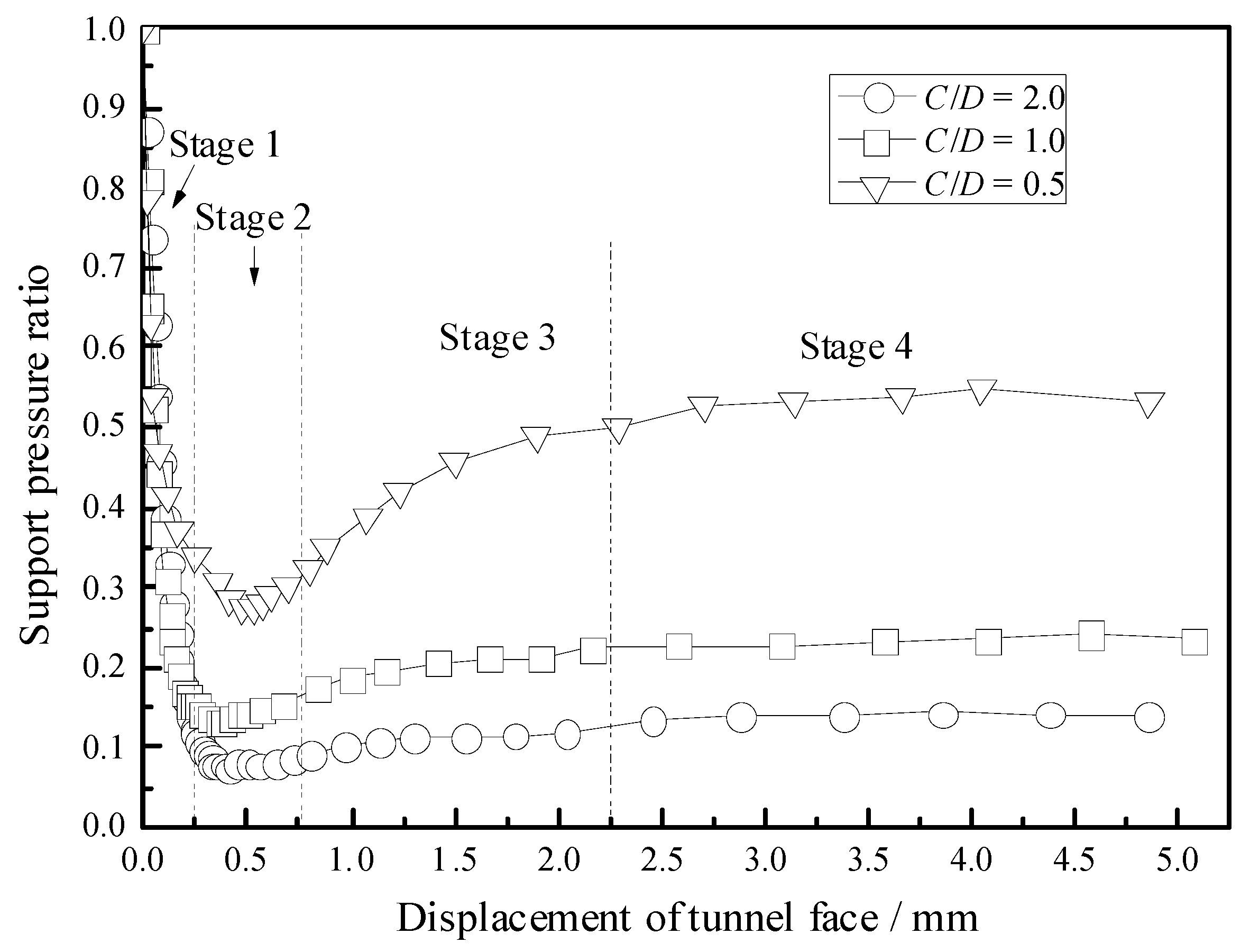

3.2. The Laws of the Development and Evolution of the Support Pressure on the Tunnel Face

- (1)

- The first stage (rapid decline stage). When the Plexiglas support panel is retreated slightly, the support pressure of the excavated surface will decrease rapidly, and the curve of the support pressure and the displacement of the excavated surface are close to linear. At this stage, shear slip zone occurs.

- (2)

- The second stage (minimum stage). As the Plexiglas support panel continues to retreat, the downward trend of the support pressure on the excavated surface gradually slows down, the ellipsoid arch is formed and developed, and the support pressure gradually reaches the minimum value, which is called the limit value P. The ellipsoid arch plays a full role, and load proportion of the overlying soil is the largest.

- (3)

- The third stage (slow rising stage). As the Plexiglas support panel continues to withdraw, an ellipsoid arch forms, and support pressure slowly rises, then forming a temporary stable triangular arch.

- (4)

- The fourth stage (horizontal stability stage). The loose zone continues to develop to the surface and eventually forms the penetrating surface.

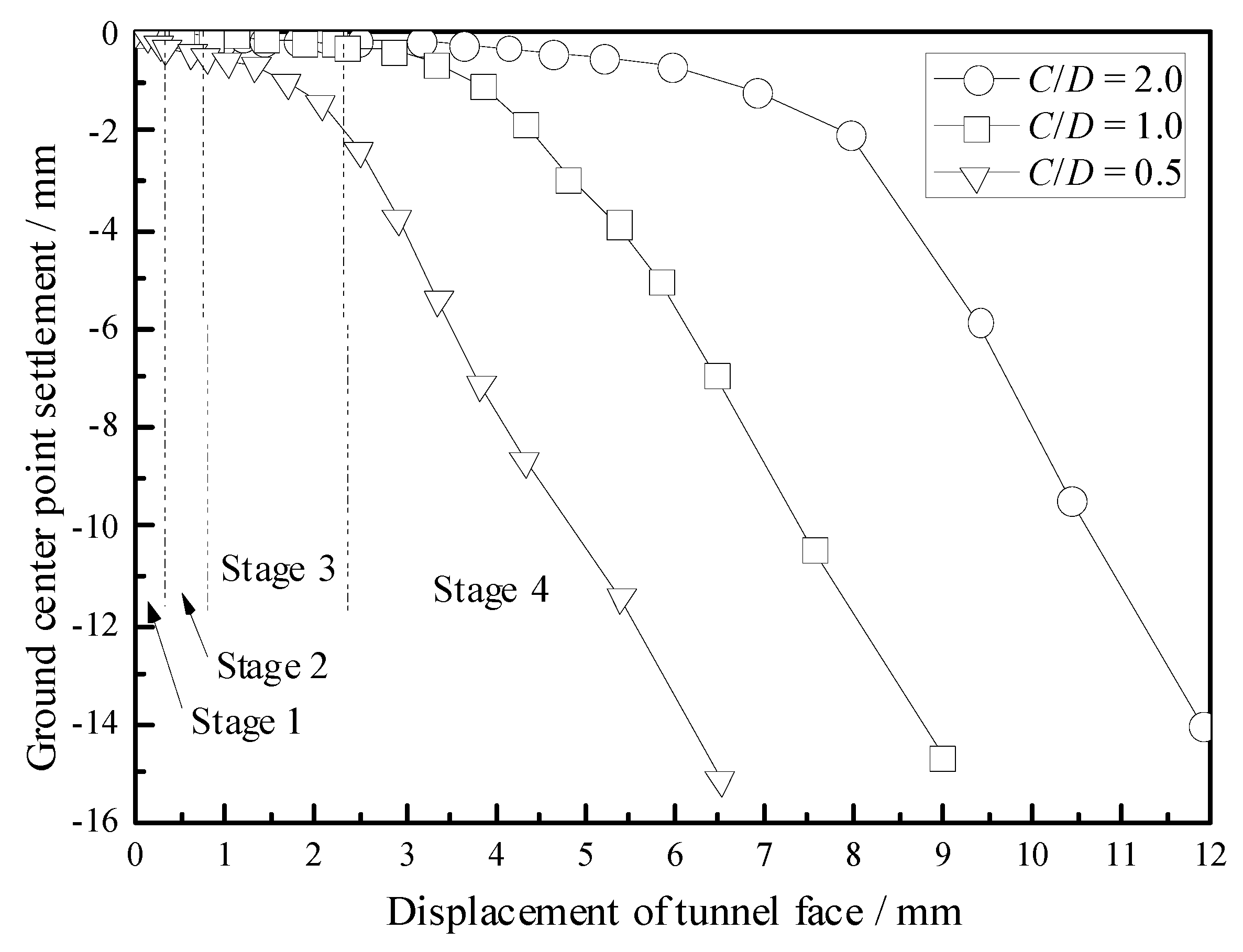

3.3. The Laws of Development and Evolution of the Ground Surface Settlement

4. Conclusions

- (1)

- The development and evolution of shear failure band, the formation and morphological evolution of pressure arch, the failure range of instability and the progressive instability mode in the sands in front of the tunnel face are observed by using the high-definition digital camera. The results indicate that the shear failure band appears in sands in front of the tunnel face and develops from the tunnel invert to tunnel crown. The upper sands undergo stress redistribution, and the pressure arch appears in the initial form of “ellipsoid”, then of the “pyramid”.

- (2)

- The evolution laws of the support pressure on the tunnel face are summarized based on the measurements of the high-precision pressure sensor in the model test. The test results indicate that the support pressure on the tunnel face experiences four stages with moving the organic glass support panel away from the tunnel face, namely, rapid decline stage, the minimum stage, slowly increasing stage and stable stage.

- (3)

- The evolution laws of the ground surface settlement are also summarized based on the measurements of the LVDT displacement sensor in the model test. Moreover, compared with the evolution laws of the support pressure on the tunnel face, the results render that the ground surface settlement is lagging behind the instability failure of the tunnel face.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Han, K.; Xie, T.; Luo, J. Calculation of limit support pressure for EPB shield tunnel face in water-rich sand. Symmetry 2019, 11, 1102. [Google Scholar] [CrossRef] [Green Version]

- Mi, B.; Xiang, Y. Analysis of the limit support pressure of a shallow shield tunnel in sandy soil considering the influence of seepage. Symmetry 2020, 12, 1023. [Google Scholar] [CrossRef]

- Chambon, P.; Corté, J.F. Shallow tunnels in cohesionless soil: Stability of tunnel face. J. Geotech. Eng. 1994, 120, 1148–1165. [Google Scholar] [CrossRef]

- Hisatake, M.; Eto, T.; Murakami, T. Stability and failure mechanisms of a tunnel face with a shallow depth. In Proceedings of the 8th ISRM Congress, Tokyo, Japan, 25–29 September 1995; pp. 587–591. [Google Scholar]

- Atkinson, J.H.; Potts, D.M. Stability of a shallow circular tunnel in cohesionless soil. Geotechnique 1977, 27, 203–215. [Google Scholar] [CrossRef]

- Mair, R.J. Centrifuge Modelling of Tunnel Construction in Soft Clay. Ph.D. Thesis, Cambridge University, Cambridge, UK, l979. [Google Scholar]

- Bezuijen, A.; Messemaeckers-van de Graaf, C.A. Stabiliteit van het Graaffront bij Vloeistofondersteuning; Technical Report 22; Boren Tunnels en Leidingen: Delft, The Netherlands, 1997. [Google Scholar]

- Takano, D.; Otani, J.; Nagatani, H.; Mukunoki, T. Application of x-ray CT on boundary value problems in geotechnical engineering: Research on tunnel face failure. In Proceedings of the Geocongress 2006, American Society of Civil Engineers (ASCE), Atlanta, GA, USA, 26 February 26–1 March 2006; pp. 1–6. [Google Scholar]

- Idinger, G.; Aklik, P.; Wu, W.; Borja, R.I. Centrifuge model test on the face stability of shallow tunnel. Acta Geotech. 2011, 6, 105–117. [Google Scholar] [CrossRef] [Green Version]

- Sterpi, D.; Cividini, A.; Sakurai, S.; Nishitake, S. Laboratory model tests and numerical analysis of shallow tunnels. In Proceedings of the ISRM International Symposium-EUROCK 1996, Torino, Italy, 2–5 September 1996; pp. 689–696. [Google Scholar]

- Kirsch, A. Experimental investigation of the face stability of shallow tunnels in sand. Acta Geotech. 2010, 5, 43–62. [Google Scholar] [CrossRef] [Green Version]

- Chen, R.P.; Yin, X.S.; Tang, L.J.; Chen, Y.M. Centrifugal model tests on face failure of earth pressure balance shield induced by steady state seepage in saturated sandy silt ground. Tunn. Undergr. Space Technol. 2018, 81, 315–325. [Google Scholar] [CrossRef]

- Lü, X.; Zhou, Y.; Huang, M.; Zeng, S. Experimental study of the face stability of shield tunnel in sands under seepage condition. Tunn. Undergr. Space Technol. 2018, 74, 195–205. [Google Scholar] [CrossRef]

| Buried Depth | Parameters a Fitting Values | Parameters b Fitting Values | R2 |

|---|---|---|---|

| C/D = 2.0 | 11.70 | −0.9312 | 0.8186 |

| C/D = 1.0 | 11.54 | −0.8436 | 0.8752 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, K.; Wang, X.; Hou, B.; Lin, X.; Cao, C. Analysis of Instability Mode and Limit Support Pressure of Shallow Tunnel Face in Sands. Symmetry 2020, 12, 2067. https://doi.org/10.3390/sym12122067

Han K, Wang X, Hou B, Lin X, Cao C. Analysis of Instability Mode and Limit Support Pressure of Shallow Tunnel Face in Sands. Symmetry. 2020; 12(12):2067. https://doi.org/10.3390/sym12122067

Chicago/Turabian StyleHan, Kaihang, Xuetao Wang, Beibei Hou, Xingtao Lin, and Chengyong Cao. 2020. "Analysis of Instability Mode and Limit Support Pressure of Shallow Tunnel Face in Sands" Symmetry 12, no. 12: 2067. https://doi.org/10.3390/sym12122067

APA StyleHan, K., Wang, X., Hou, B., Lin, X., & Cao, C. (2020). Analysis of Instability Mode and Limit Support Pressure of Shallow Tunnel Face in Sands. Symmetry, 12(12), 2067. https://doi.org/10.3390/sym12122067