Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation

Abstract

:1. Introduction

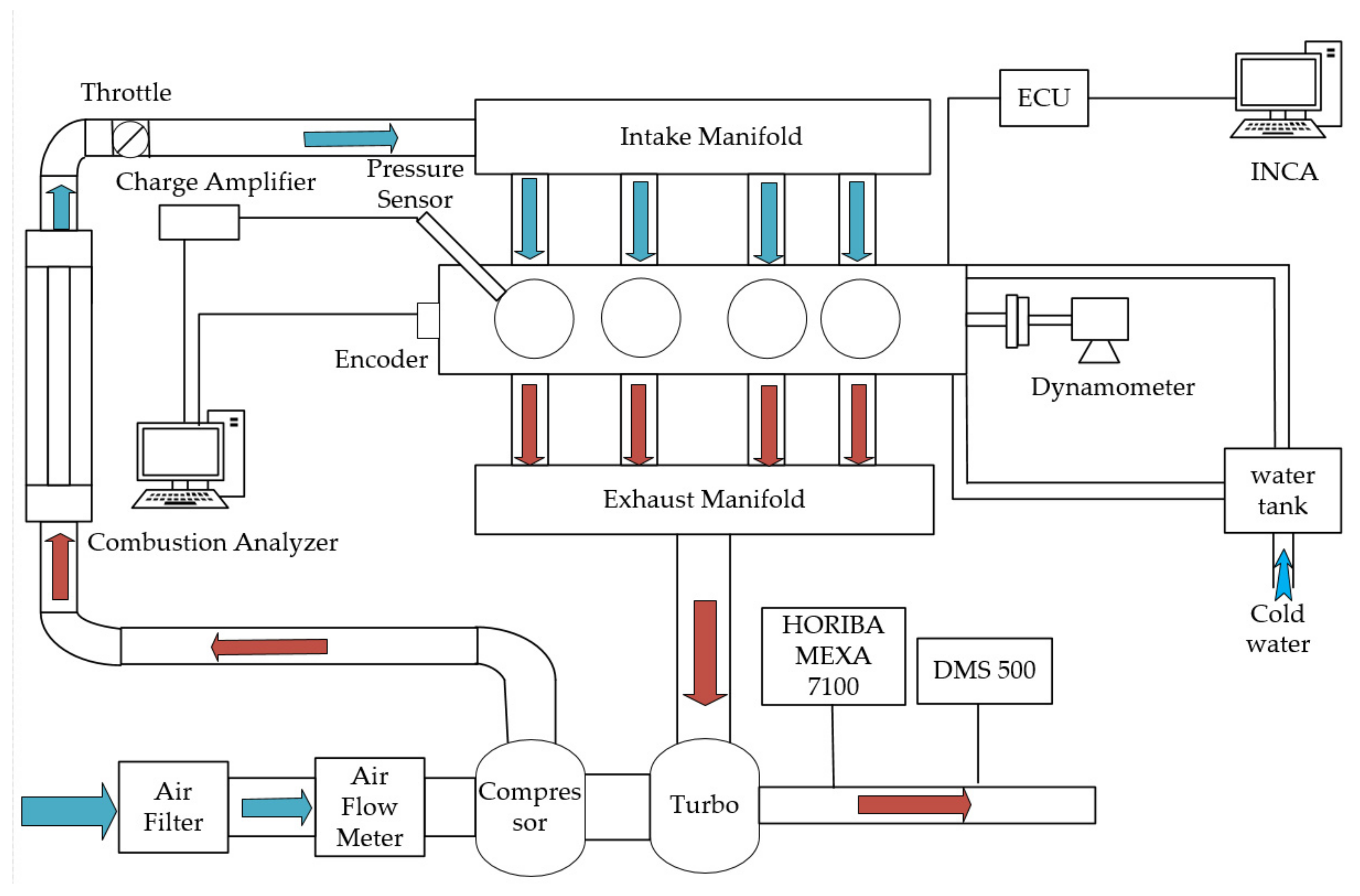

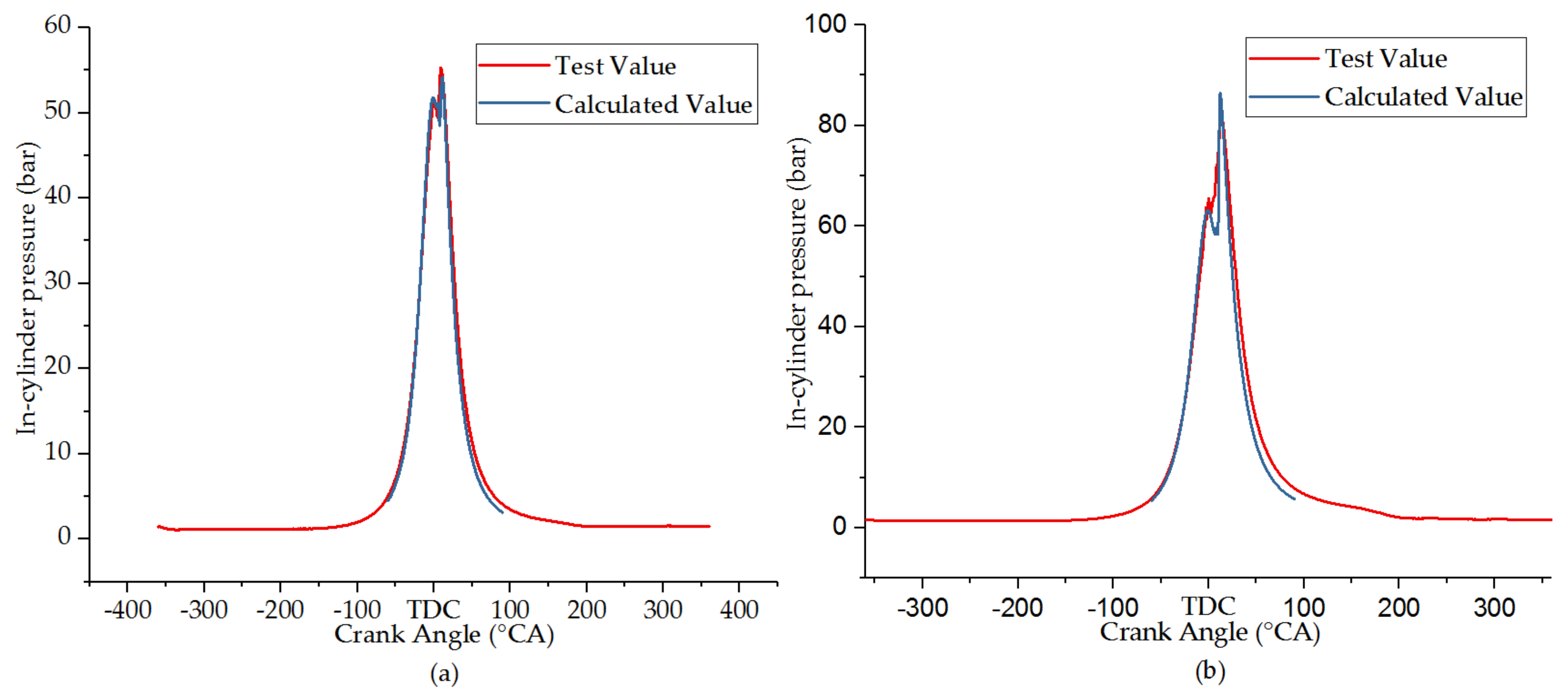

2. Experimental Setup and Methods

2.1. Experimental Apparatus

2.2. Methods

3. Results and Discussions

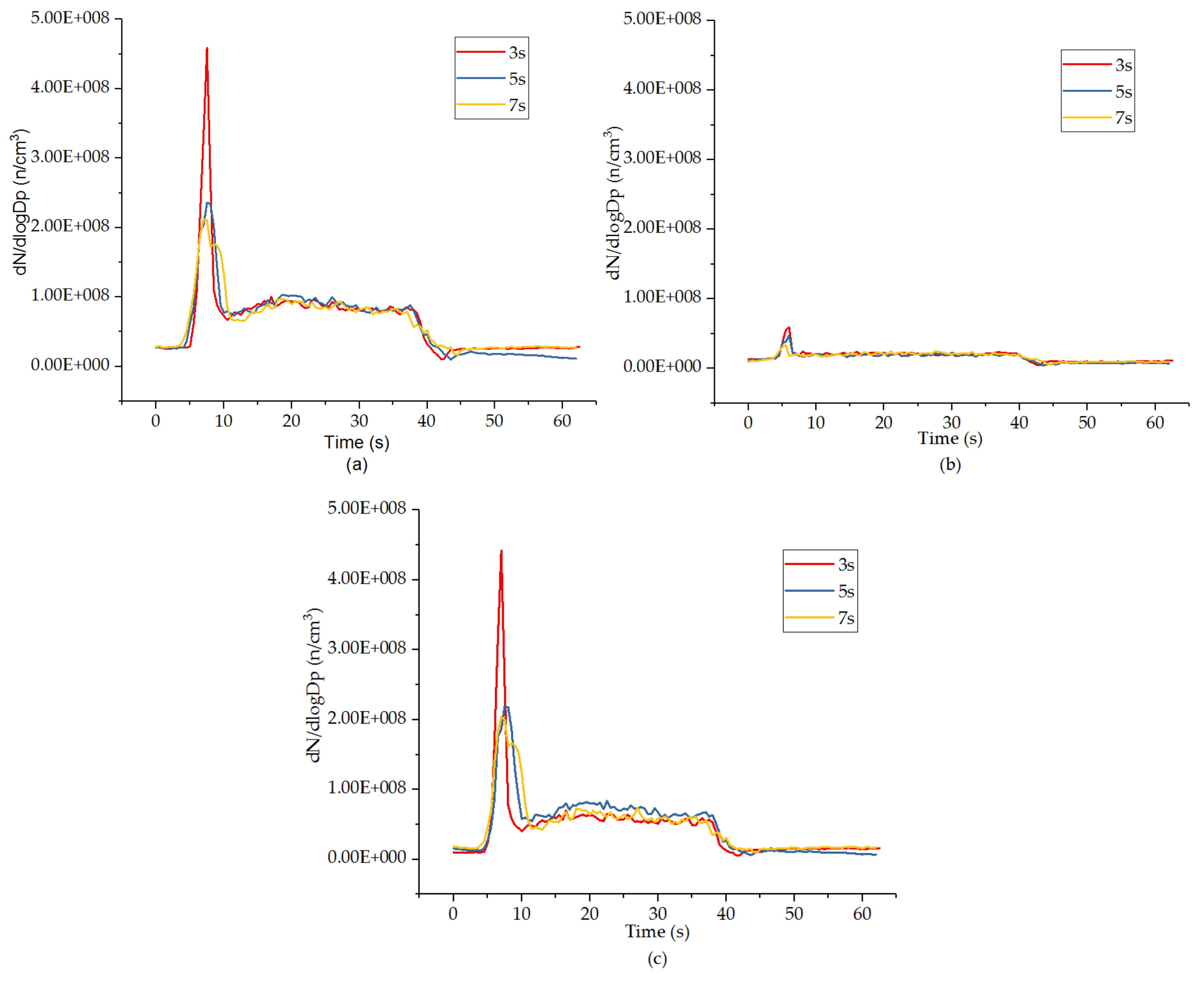

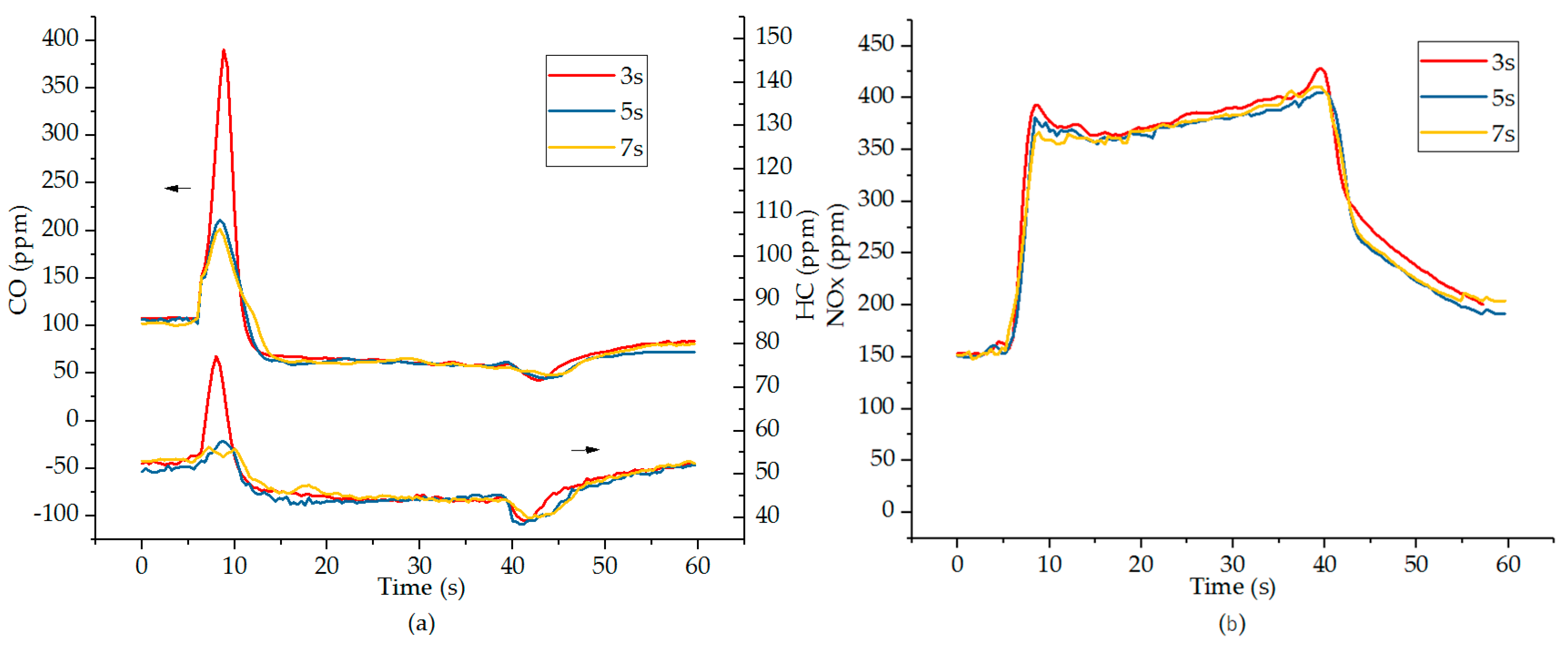

3.1. Effects of Loading and Unloading Duration on Emissions

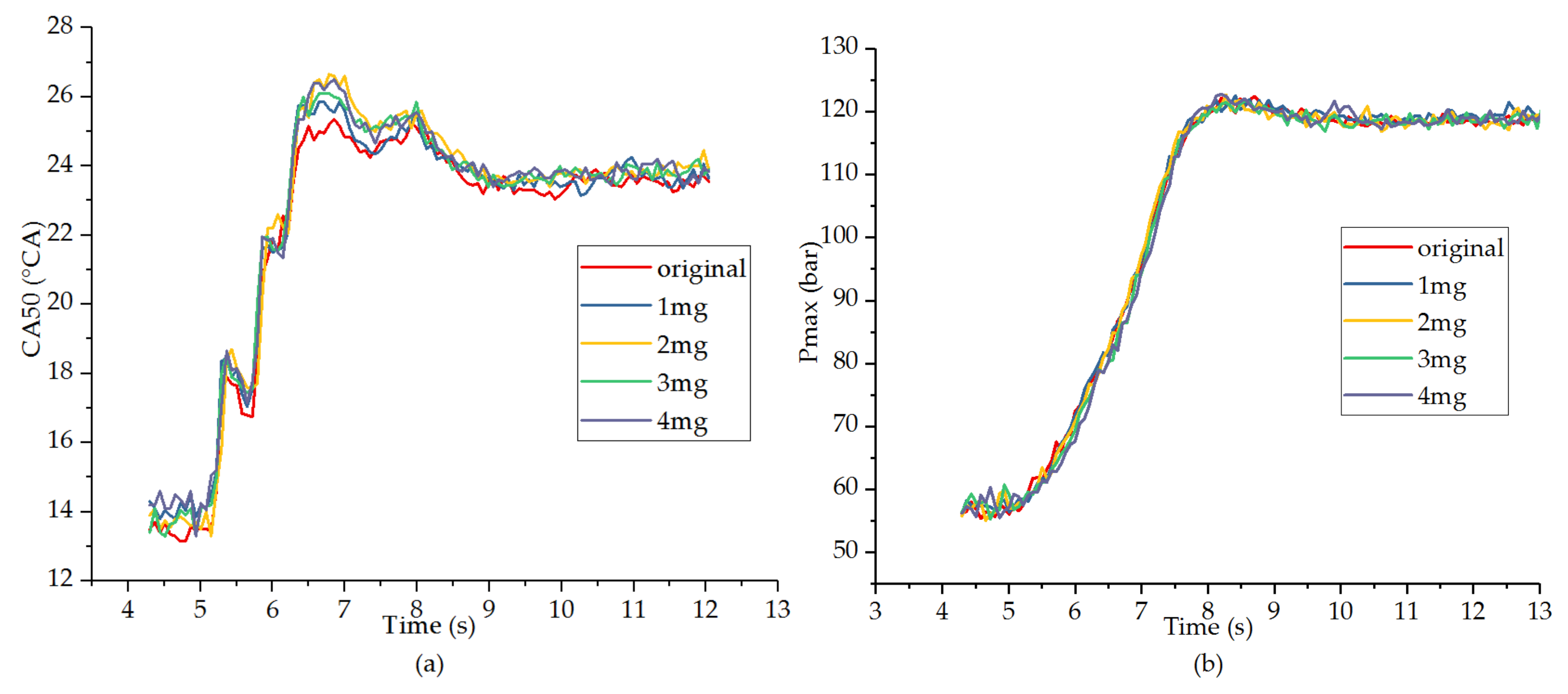

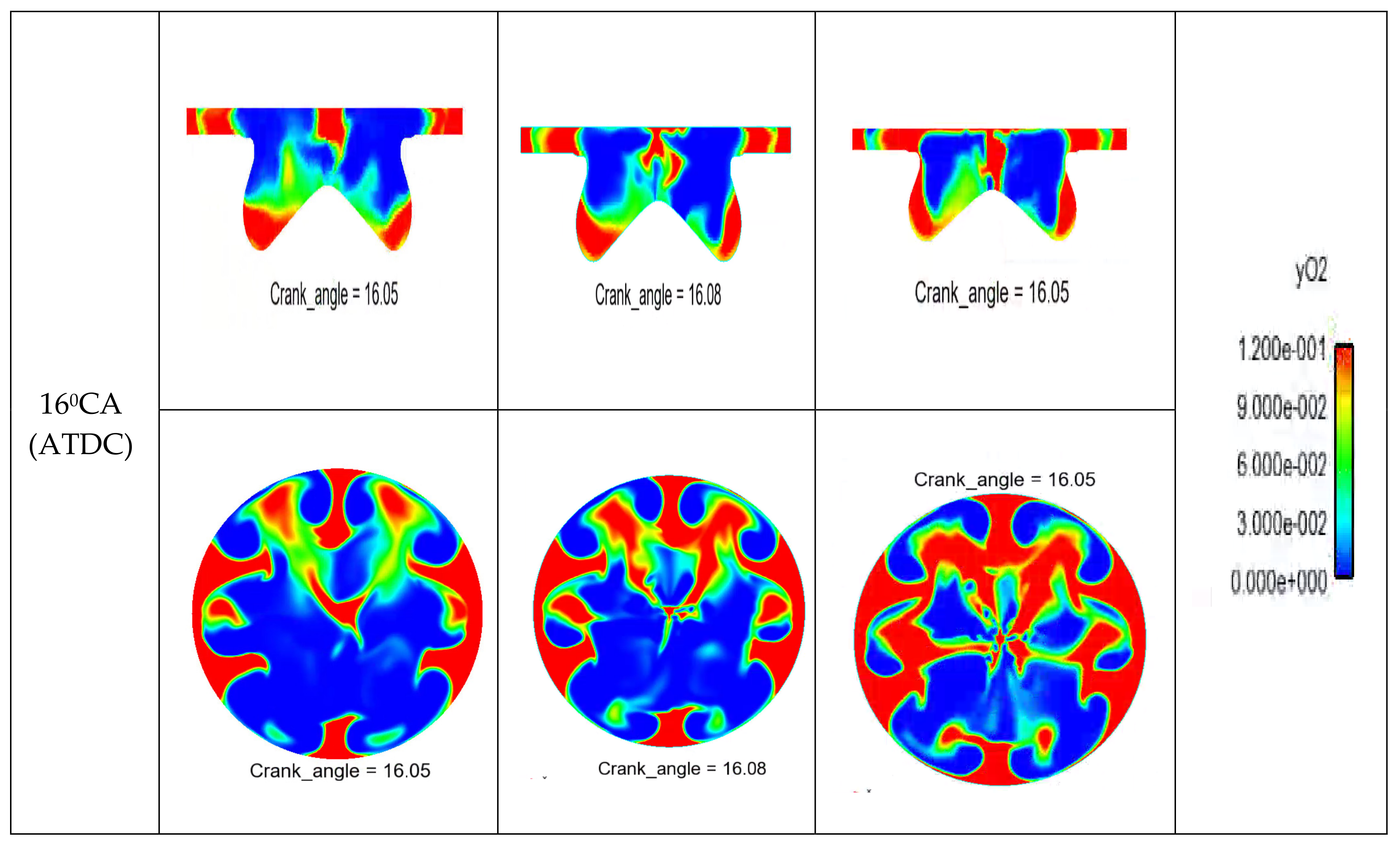

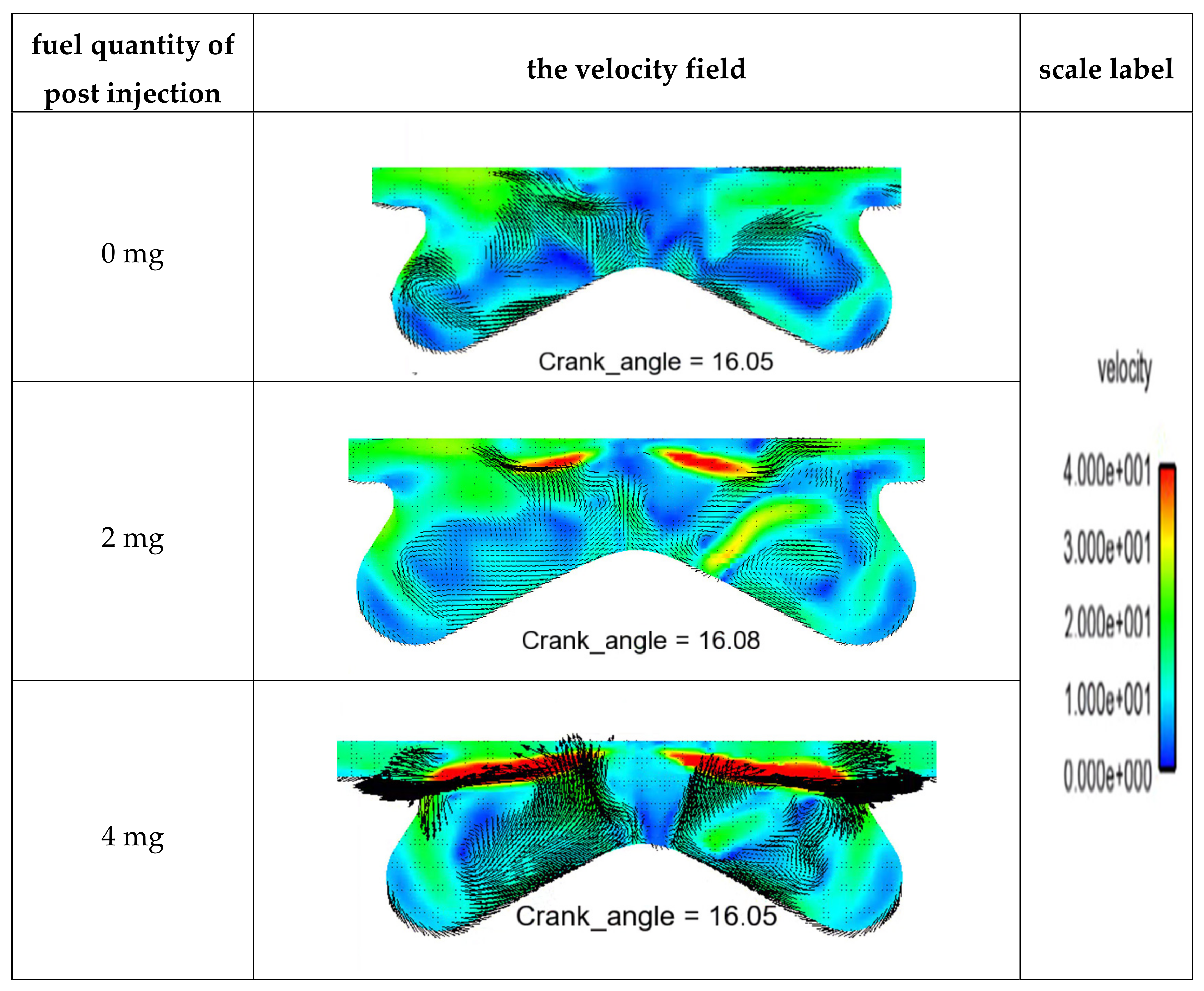

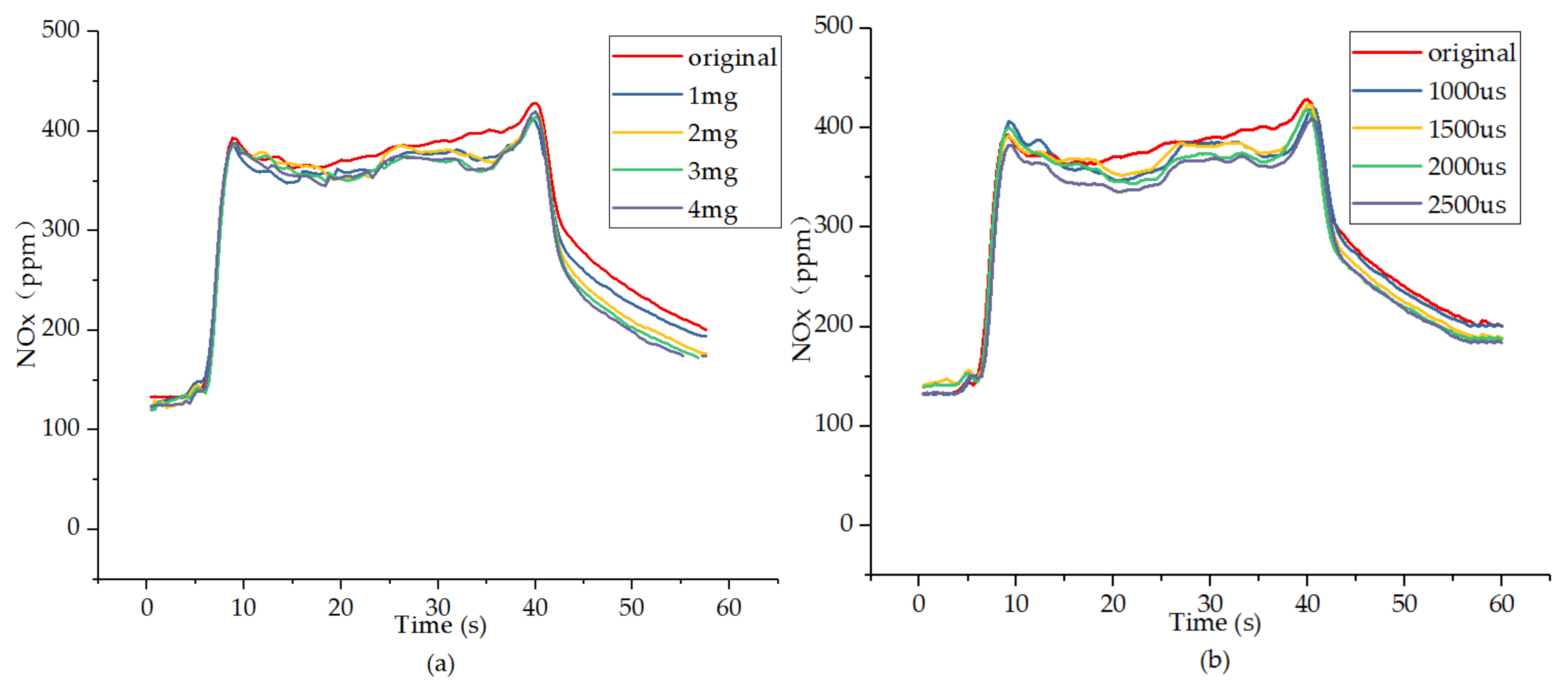

3.2. Effects of Post Injection on Combustion and Emissions

3.3. Effects of Main-Post Injection Time Interval on Combustion and Emissions

4. Conclusions

- (1)

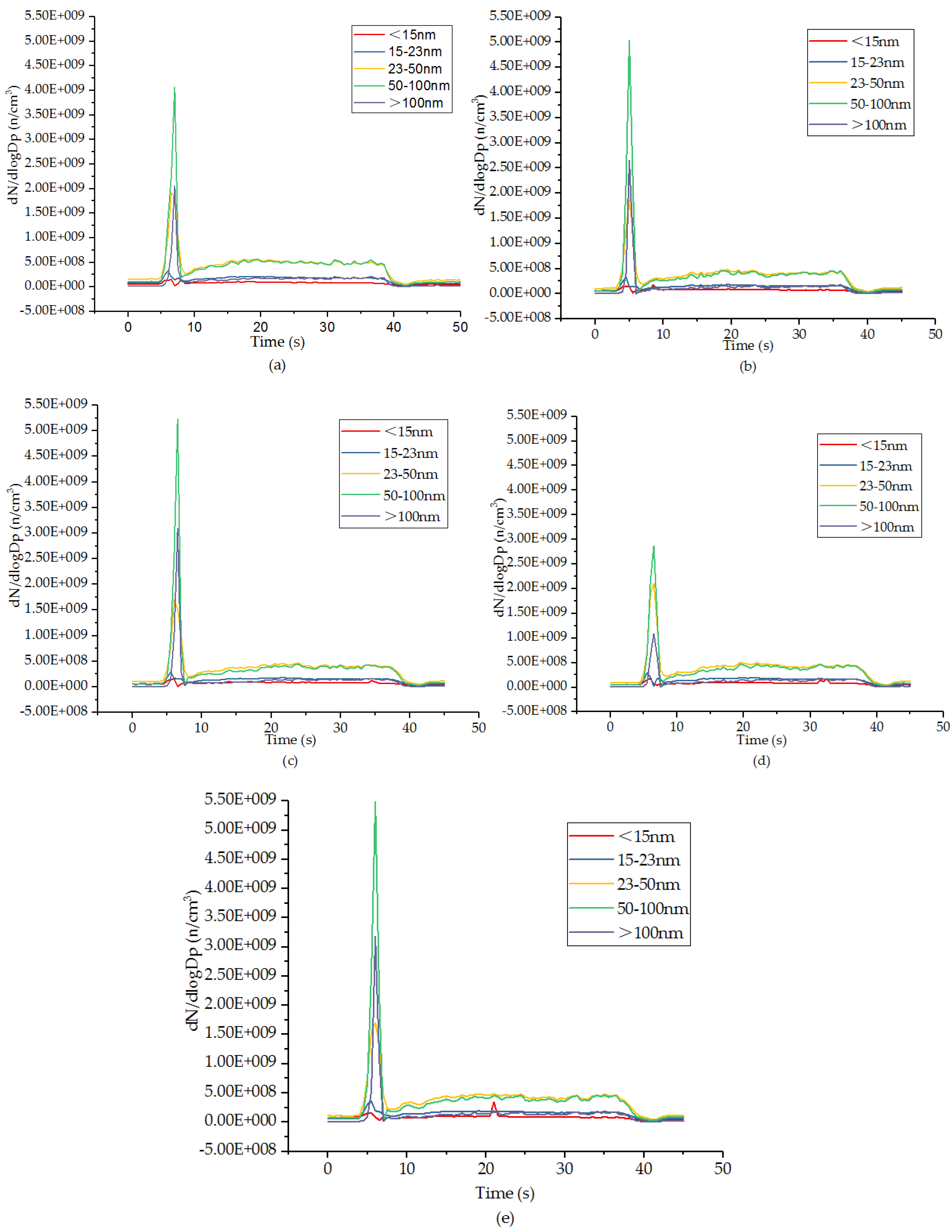

- During instantaneous loading process, the emissions are aggravated. By contrast, when the loading time is 3 s, the deterioration of particulate emissions, HC and CO emissions are the most serious, with the largest peak. The particles with the sizes range of 50–100 nm, 23–50 nm, and >100 nm show more considerably changes with the loading process. In comparison, the change in load has little effect on ultrafine particles with particle size of 15–23 nm and <15 nm.

- (2)

- Under the transient loading conditions, the post injection strengthens the disturbance of the flow field in the cylinder and promotes the mixing of fuel and particles with air, the post injection makes contribution to improve combustion efficiency and promote oxidation of particulate matter.

- (3)

- The addition of post injection will affect the number concentration of particles that size range of 50–100 nm and >100 nm, but the post injection has little effect on NOx emissions. When the amount of post injection fuel is 2 mg and the main-post injection interval is 2000 us, for the transient operating conditions of the test, the effect of suppressing particulate emissions is the best.

- (4)

- During the transient unloading process, due to the turbo charging lag, which causing more oxygen in cylinder, NOx emissions first slightly increased to a peak and then decreased.

Author Contributions

Funding

Conflicts of Interest

References

- Kanari, S.; Kii, M.; Suehiro, S. CO2 reduction and cast analysis for installed future technology of automobile. J. JSAE 2010, 64, 84–90. [Google Scholar]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Evaluation of the effect of engine, load and turbocharger parameters on transient emissions of diesel engine. Energy Convers. Manag. 2009, 50, 2381–2393. [Google Scholar] [CrossRef]

- Nilsson, T.; Froberg, A.; Aslund, J. Optimal operation of a turbocharged diesel engine during transients. SAE Int. J. Engines 2012, 5, 571–578. [Google Scholar] [CrossRef]

- Nikzadfar, K.; Shamekhi, A.H. An extended mean value model (EMVM) for control-oriented modeling of diesel engines transient performance and emissions. Fuel 2015, 154, 275–292. [Google Scholar] [CrossRef]

- Finesso, R.; Spessa, E. Real-time predictive modeling of combustion and NOx formation in diesel engines under transient conditions. SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions of diesel engines operating under transient conditions with biodiesel fuel blends. Prog. Energy Combust. 2012, 38, 691–715. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Dimaratos, A.M.; Rakopoulos, C.D. Experimental study of combustion noise radiation during transient turbocharged diesel engine operation. Energy 2011, 36, 4983–4995. [Google Scholar] [CrossRef]

- Resch, T.; Klarin, B. Analysis of engine dynamics under transient run-up conditions 2004-01-1454. SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- Hyungsuk, K.; Patrick, V.F. Experimental investigation of transient emissions (HC and NOx) in a high-speed direct injection (HSDI) diesel engine 2005-01-3883. SAE Tech. Pap. 2005. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Alafouzos, A.I. Study of diesel engine performance and emissions during a Transient Cycle applying an engine mapping-based methodology. Appl. Energy. 2010, 87, 1358–1365. [Google Scholar] [CrossRef]

- Tufail, K.; Winstanley, T.; Karagiorgis, S.; Hardalupas, Y.; Taylor, A.M.K.P. Characterization of diesel engine pumping loss and control methodology for transient specific fuel consumption 2009-01-2748. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Serrano, J.R.; Arnau, F.J.; Dolz, V.; Tiseira, A.; Lejeune, M.; Auffret, N. Analysis of the capabilities of a two-stage turbocharging system to fulfil the US2007 anti-pollution directive for heavy duty diesel engines. Int. J. Automot. Technol. 2008, 9, 277–288. [Google Scholar] [CrossRef]

- Tavcar, G.; Bizjan, F.; Katrasnik, T. Methods for improving transient response of diesel engines—Influences of different electrically assisted turbocharging topologies. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2011, 225, 1167–1185. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Tziolas, V. Modeling a Variable-Geometry Turbocharged Diesel Engine under Steady-State and Transient Conditions. J. Energy Eng. 2018, 144, 04018017. [Google Scholar] [CrossRef]

- Shutty, J. Control Strategy Optimization for Hybrid EGR Engines 2009-01-1451. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Heuwetter, D.; Glewen, W.; Meyer, C.; Foster, D.E.; Andrie, M.; Krieger, R. Effects of Low Pressure EGR on Transient Air System Performance and Emissions for Low Temperature Diesel Combustion 2011-24-0062. SAE Tech. Pap. 2011. [Google Scholar] [CrossRef]

- Nam, K.; Yu, J.; Cho, S. Improvement of Fuel Economy and Transient Control in a Passenger Diesel Engine Using LP (Low Pressure)-EGR 2011-01-0400. SAE Techn. Pap. 2011. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Z.; Tian, J.; Li, L.; Yu, K.; He, K. Effect of EGR and Fuel Injection Strategies on the Heavy-Duty Diesel Engine Emission Performance under Transient Operation. Energies 2020, 13, 566. [Google Scholar] [CrossRef] [Green Version]

- Tan, P.Q.; Ruan, S.S.; Hu, Z.Y.; Lou, D.M.; Li, H. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions. Appl. Energy 2014, 113, 22–31. [Google Scholar] [CrossRef]

- Katoshevski, D.; Ruzal, M.; Shakked, T.; Sher, E. Particle grouping, a new method for reducing emission of submicron particles from diesel engines. Fuel 2012, 89, 2411–2416. [Google Scholar] [CrossRef]

- Ushakov, S.; Valland, H.; Nielsen, J.B.; Hennie, E. Particle size distributions from heavy-duty diesel engine operated on low-sulfur marine fuel. Fuel Process. Technol. 2013, 106, 350–358. [Google Scholar] [CrossRef]

- Wihersaari, H.; Pirjola, L.; Karjalainen, P.; Saukko, E.; Kuuluvainen, H.; Kulmala, K.; Keskinen, J.; Rönkkö, T. Particulate emissions of a modern diesel passenger car under laboratory and real-world transient driving conditions. Environ. Pollut. 2020, 265, 114948. [Google Scholar] [CrossRef] [PubMed]

- Zare, A.; Bodisco, T.A.; Nabi, M.N.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. Engine Performance during Transient and Steady-State Operation with Oxygenated Fuels. Energy Fuels 2017, 31, 7510–7522. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Q.; Guo, L.; Cheng, P.; Li, D.; Yan, Y. Inflence of biodiesel/diesel blends on particle size distribution of CI engine under steady/transient conditions. Fuel 2019, 245, 336–344. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, L.; Yan, Y.; Sun, W.; Li, J.; Wang, Q.; Sun, Y. Experimental investigation on the combustion and emissions characteristics of an N-butanol/CTL dual fuel engine. Fuel 2020, 274, 117696. [Google Scholar] [CrossRef]

- Feng, S.; Hong, W.; Li, X.; Xie, F.; Su, Y. The influence of DISI engine control parameters and M15 fuel on regulated and particulate emissions under light-load. Fuel 2020, 276, 118024. [Google Scholar] [CrossRef]

- Jian, W.; Storey, J.; Domingo, N.; Huff, S.; Thomas, J.; West, B. Studies of Diesel Engine Particle Emissions During Transient Operations Using an Engine Exhaust Particle Sizer. Aerosol Sci. Technol. 2006, 40, 1002–1015. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Rakopoulos, D.C. Assessment of NOx Emissions during Transient Diesel Engine Operation with Biodiesel Blends. J. Energy Eng. 2014, 140, A4014004. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade., R.A.; Abbas, M.M.; Afzal, A.; et al. Effect of Nano-Graphene Oxide and n-Butanol Fuel Additives Blended with Diesel—Nigella sativa Biodiesel Fuel Emulsion on Diesel Engine Characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Yoon, S.H.; Lee, C.S. Effect of biofuels combustion on the nanoparticle and emission characteristics of a common-rail DI diesel engine. Fuel 2011, 90, 3071–3077. [Google Scholar] [CrossRef]

- Chen, P.; Ibrahim, U.; Wang, J. Experimental investigation of diesel and biodiesel post injections during active diesel particulate filter regenerations. Fuel 2014, 130, 286–295. [Google Scholar] [CrossRef]

- Čedík, J.; Pexa, M.; Holúbek, M.; Aleš, Z.; Pražan, R.; Kuchar, P. Effect of Diesel Fuel-Coconut Oil-Butanol Blends on Operational Parameters of Diesel Engine. Energies 2020, 13, 3796. [Google Scholar] [CrossRef]

- Zheng, Z.; Yue, L.; Liu, H. Effect of two-stage injection on combustion and emissions under high EGR rate on a diesel engine by fueling blends of diesel/gasoline, diesel/n-butanol, diesel/gasoline/n-butanol and pure diesel. Energy Convers. Manag. 2015, 90, 1–11. [Google Scholar] [CrossRef]

- O’Connor, J.; Musculus, M. Post Injections for Soot Reduction in Diesel Engines: A Review of Current Understanding. SAE Int. J. Engines 2013, 6, 400–421. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Wang, P.; Farhan, S.M.; Yi, J.; Lei, L. Effect of post injection on combustion and exhaust emissions in DI diesel engine. Fuel 2019, 258, 116131. [Google Scholar] [CrossRef]

- Guan, W.; Pedrozo, V.B.; Zhao, H.; Ban, Z.; Lin, T. Miller cycle combined with exhaust gas recirculation and post–fuel injection for emissions and exhaust gas temperature control of a heavy-duty diesel engine. Int. J. Engine Res. 2019, 21, 1381–1397. [Google Scholar] [CrossRef] [Green Version]

- Sosnowski, M.; Krzywanski, J.; Grabowska, K.; Gnatowska, R. Polyhedral meshing in numerical analysis of conjugate heat transfer. Eur. Phys. J. Conf. 2018, 180, 02096. [Google Scholar] [CrossRef]

- Makri, K.; Lockett, R.; Jeshani, M. Dynamics of Post-Injection Fuel Flow in Mini-Sac Diesel Injectors Part 1: Admission of External Gases and Implications for Deposit Formation. Int. J. Engine Res. 2019. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, J.; Qiao, X.; Bai, J.; Hu, Z. Effect of injection-strategy on combustion, performance and emission characteristics in a DI-diesel engine fueled with diesel from direct coal liquefaction. Fuel 2014, 121, 141–148. [Google Scholar] [CrossRef]

- Farhan, M.; Pan, W.; Yan, W.; Jing, Y.; Lili, L. Impact of post-injection strategies on combustion and unregulated emissions during different loads in an HSDI diesel engine. Fuel 2020, 267, 117256. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, X.; Tian, J.; Han, Y.; Li, R.; Gao, G. Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR. Energies 2018, 11, 69. [Google Scholar] [CrossRef] [Green Version]

- Tree, D.R.; Svensson, K.I. Soot processes in compression ignition engines. Prog. Energy Combust. 2007, 33, 272–309. [Google Scholar] [CrossRef]

| Engine Parameters | Specifications |

|---|---|

| Engine Type | High-pressure, common-rail, in line, 4-cylinder, 4-stroke |

| Displacement | 3.17 L |

| Bore × Stroke | 98 mm × 105 mm |

| Compression Ratio | 17:1 |

| Maximum injection pressure | 160 MPa |

| Idling speed | 800 ± 30 rpm |

| Maximum Torque | 320 N·m (1600 rpm) |

| Maximum Power | 81 kW (2400 rpm) |

| Equipment | Model | Accuracy | Country |

|---|---|---|---|

| Dynamometer | CW160 | Torque: ±2 N·m Speed: ±1 rpm | China |

| Pressure sensor | KISTLER 6052CU20 | ±0.3% | Switzerland |

| Charge amplifier | KISTLER 5015 | ±0.6% | Switzerland |

| Crank angle encoder | KISTLER 2614CK | ±0.5° | Switzerland |

| Air flow meter | SENSYCON | ±0.5% | China |

| Fuel flow meter | DF-2420 | ±0.2% | China |

| Exhaust gas analyzer | HORIBA MEXA 7100 | THC: ±30 ppm CO: ±0.01% NO: ±20 ppm | Japan |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, S.; Hong, W.; Yao, Y.; You, T. Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation. Symmetry 2020, 12, 2002. https://doi.org/10.3390/sym12122002

Feng S, Hong W, Yao Y, You T. Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation. Symmetry. 2020; 12(12):2002. https://doi.org/10.3390/sym12122002

Chicago/Turabian StyleFeng, Shuang, Wei Hong, Yongming Yao, and Tian You. 2020. "Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation" Symmetry 12, no. 12: 2002. https://doi.org/10.3390/sym12122002

APA StyleFeng, S., Hong, W., Yao, Y., & You, T. (2020). Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation. Symmetry, 12(12), 2002. https://doi.org/10.3390/sym12122002