LCA/LCC Model for Evaluation of Pump Units in Water Distribution Systems

Abstract

:1. Introduction

2. Materials and Methods

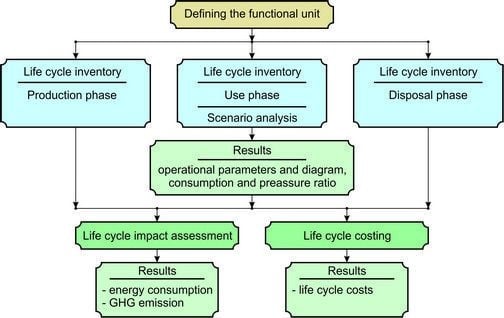

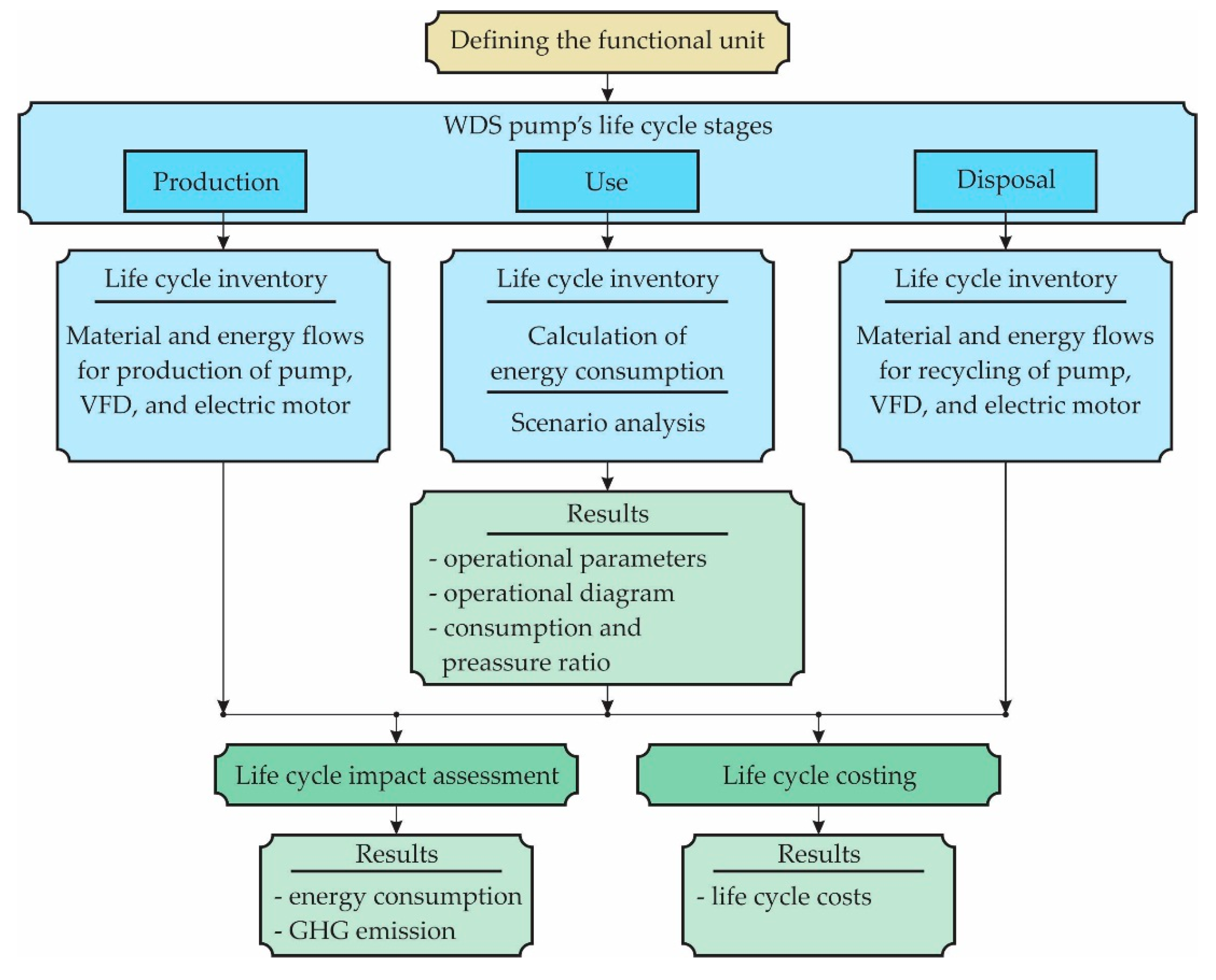

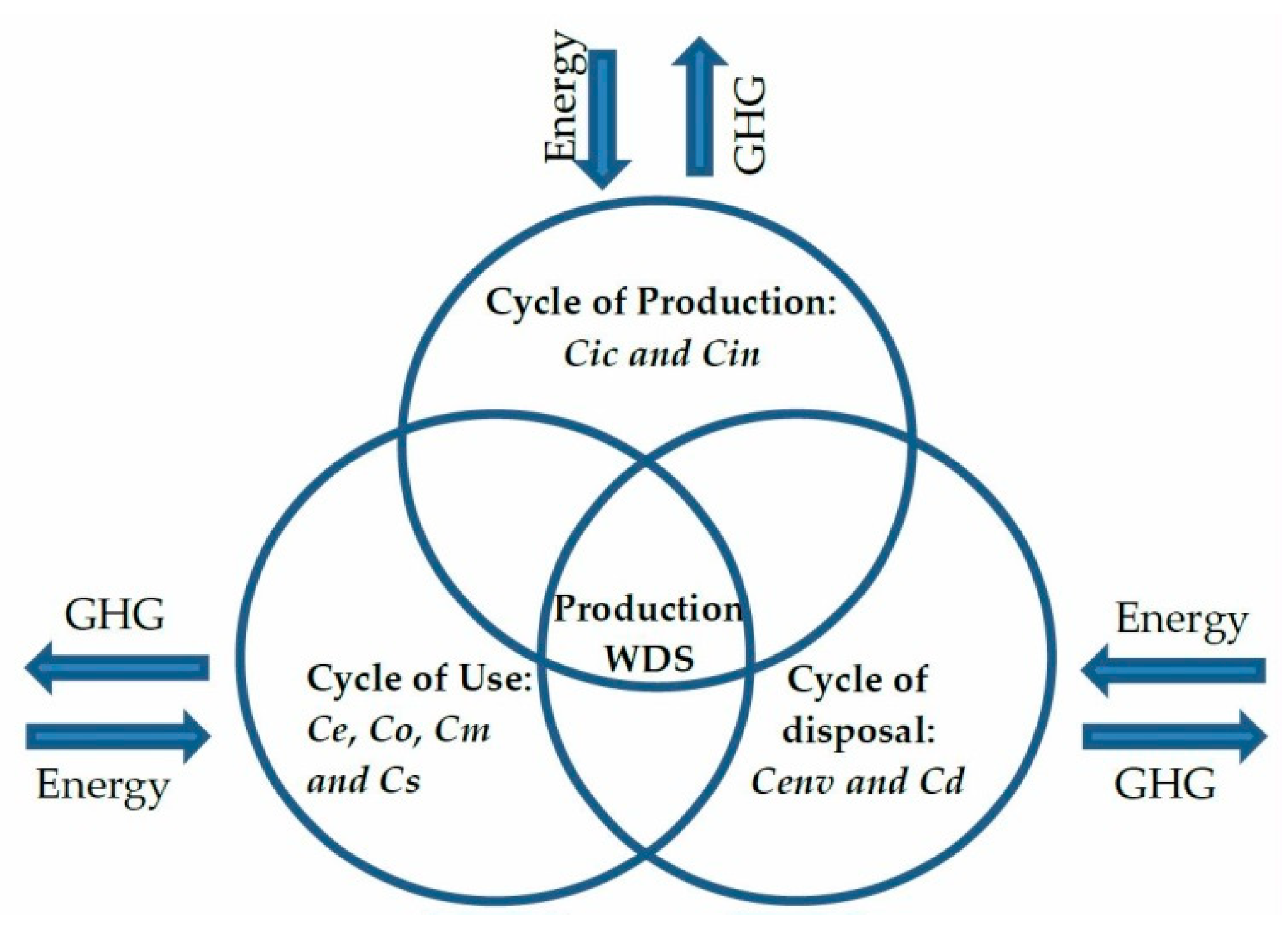

2.1. Methodology of LCA for Pumps/Motors WDS

2.1.1. Production Stage

2.1.2. Use Stage

2.1.3. Disposal Stage

2.2. Functional Unit

2.3. Energy Consumption in the Use Stage—Ee

3. Results

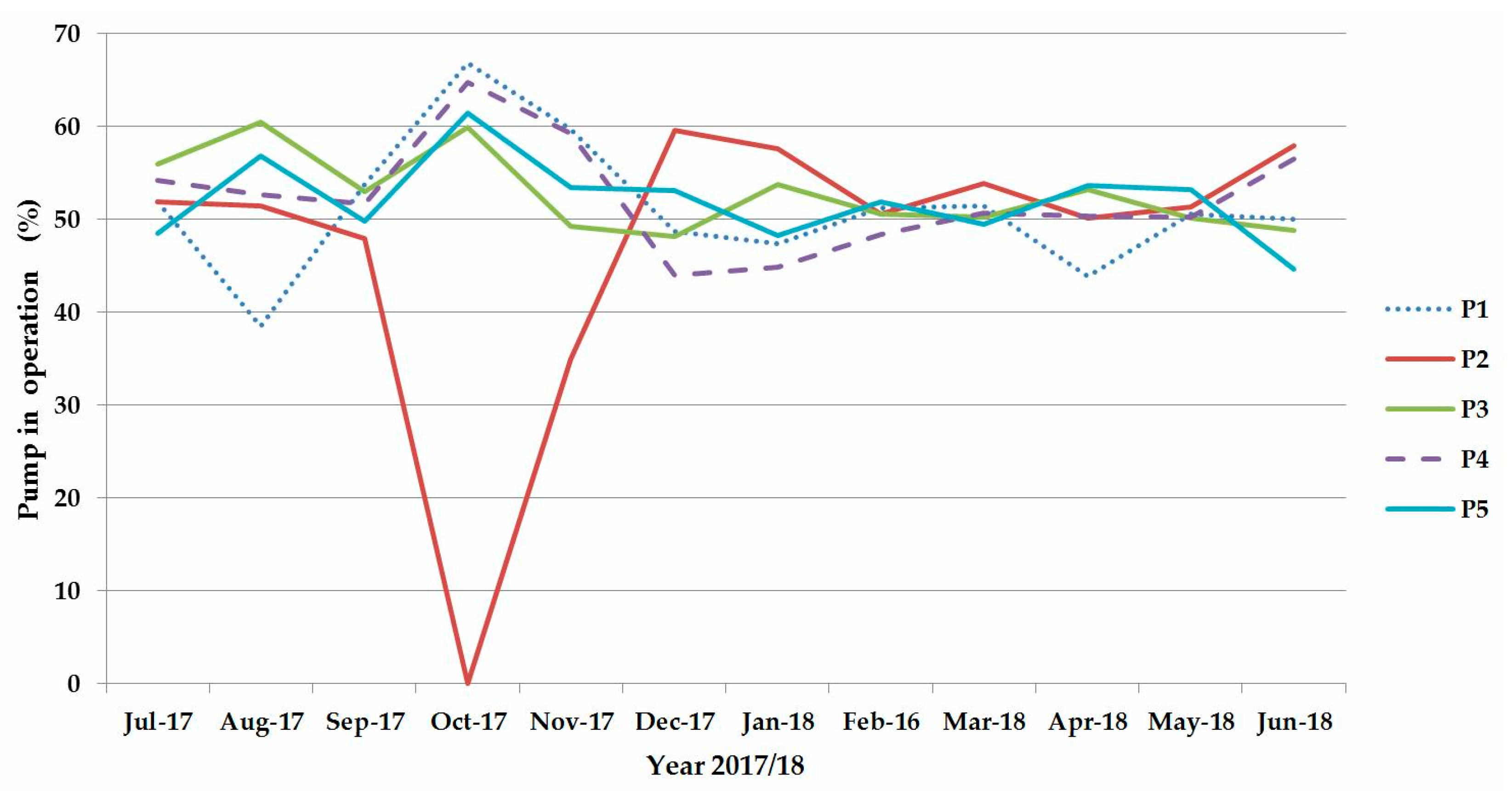

3.1. Characteristics of PU in the Pump Station

- (a)

- P1 pump is in parallel operation with P2, P3, and P5 pumps:

- (b)

- P5 pump is in parallel operation with P1, P2, and P3 pumps:

- (c)

- Finally, when P5 pump is operating independently, the loss is calculated according to the following formula:where are diameters of collecting pipelines; are the total coefficients of local resistance of the collecting pipelines; ds1 = 0.45 m; ds2 = 0.6 m; ds3 = 0.7 m; ds5 = 0.8 m; = 0.5 m; i ξs1 = 0.19; ξs2 = 0.37; ξs3 = 0.033; ξs5 = 0.235; = 0.3; = 1.1.

- (a)

- the pumps in the pump station maintain constant pressure at the outlet from the pump station and allow tank filling at a certain height point;

- (b)

- the pumps in the pump station maintain constant pressure on the outskirts of the urban area with a minimum set pressure of 3.5 bar.

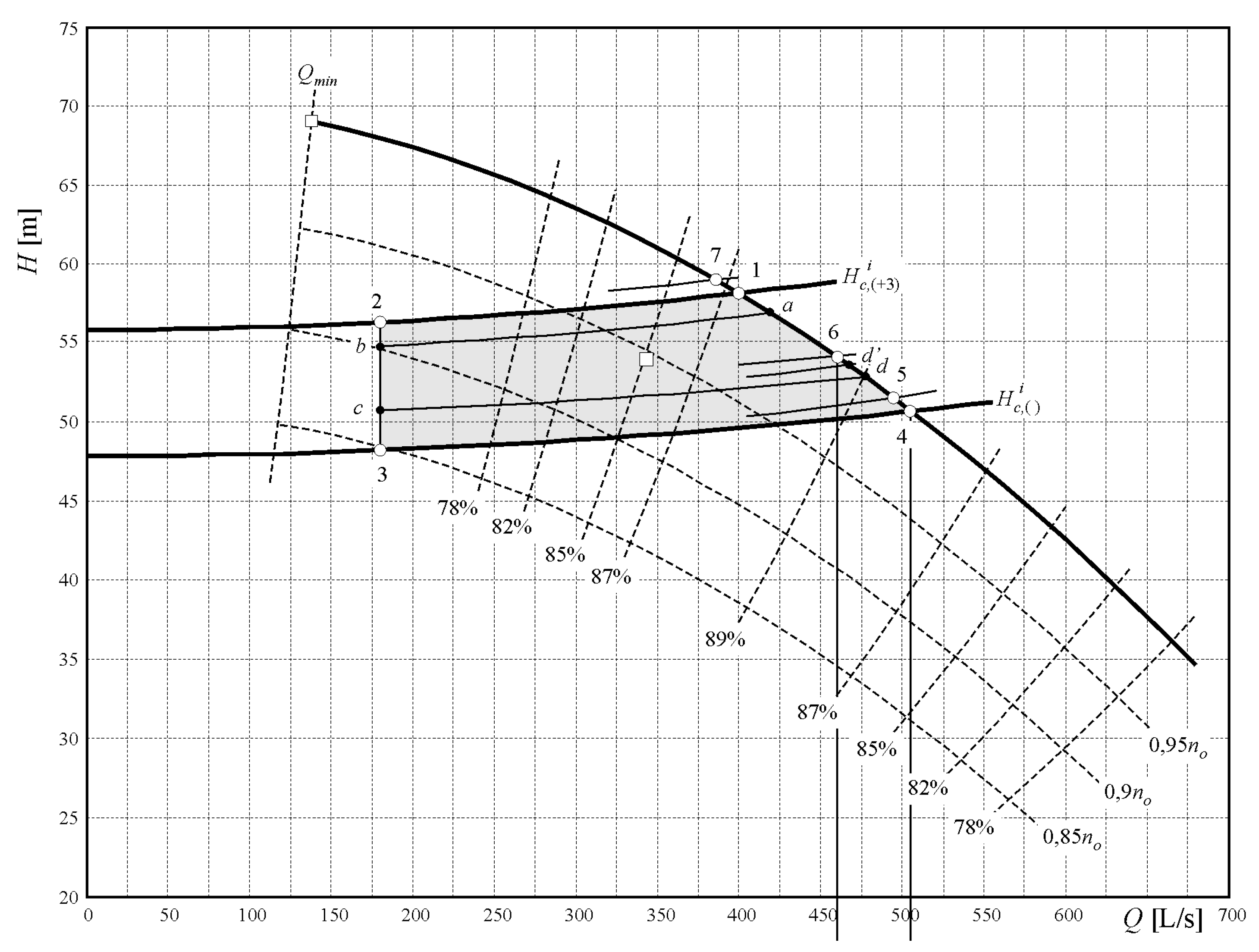

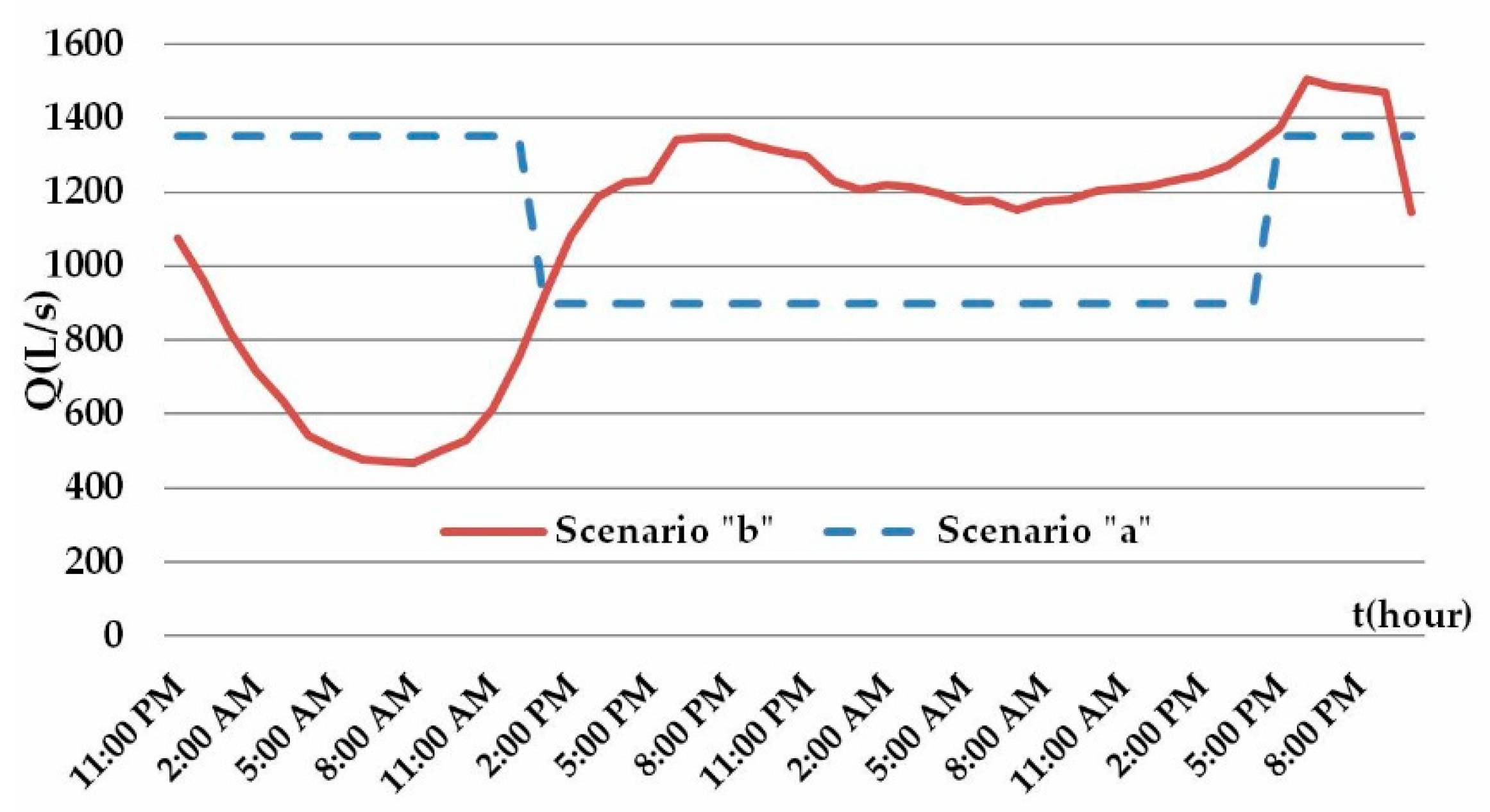

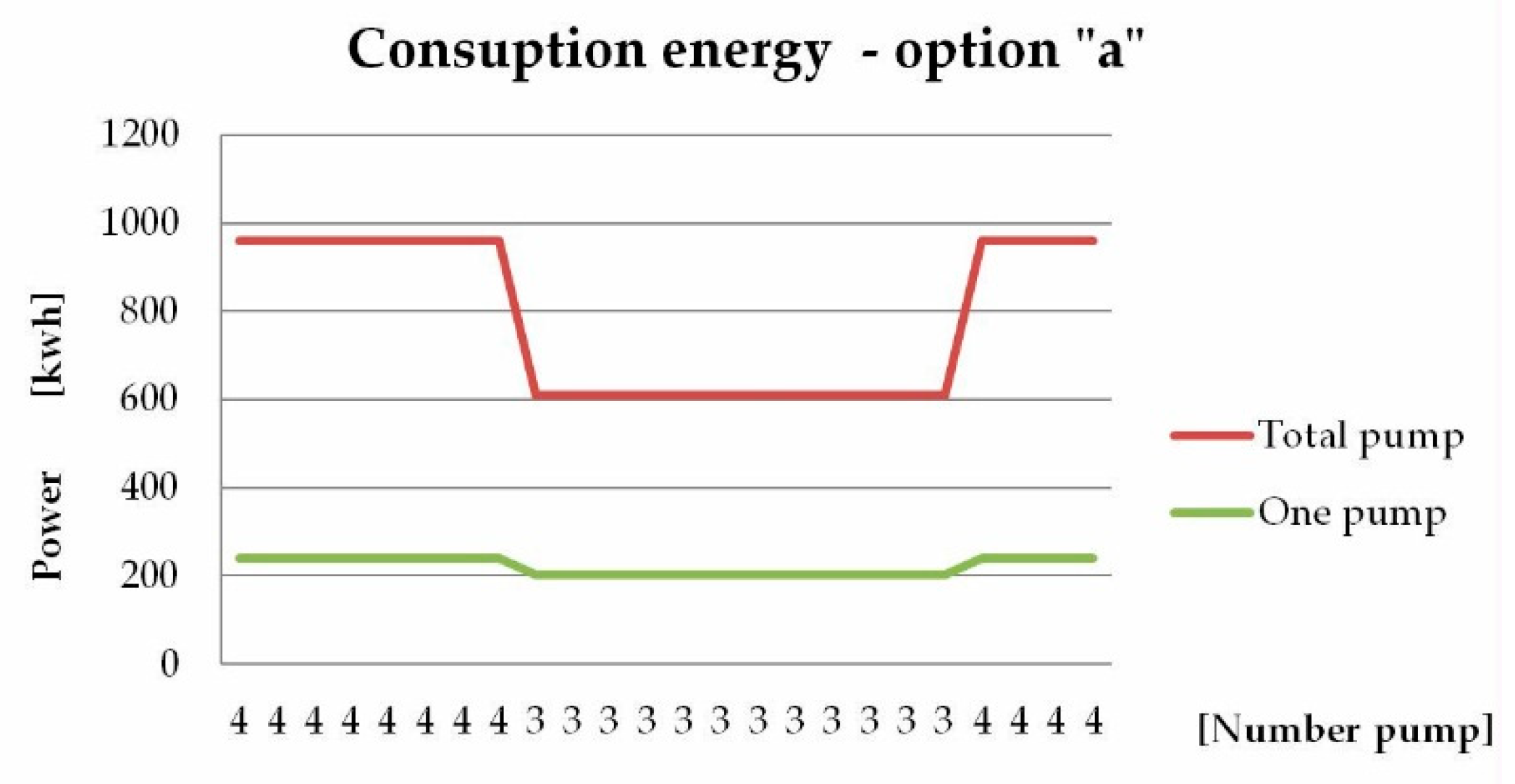

3.1.1. Pump Exploitation—Option “a”

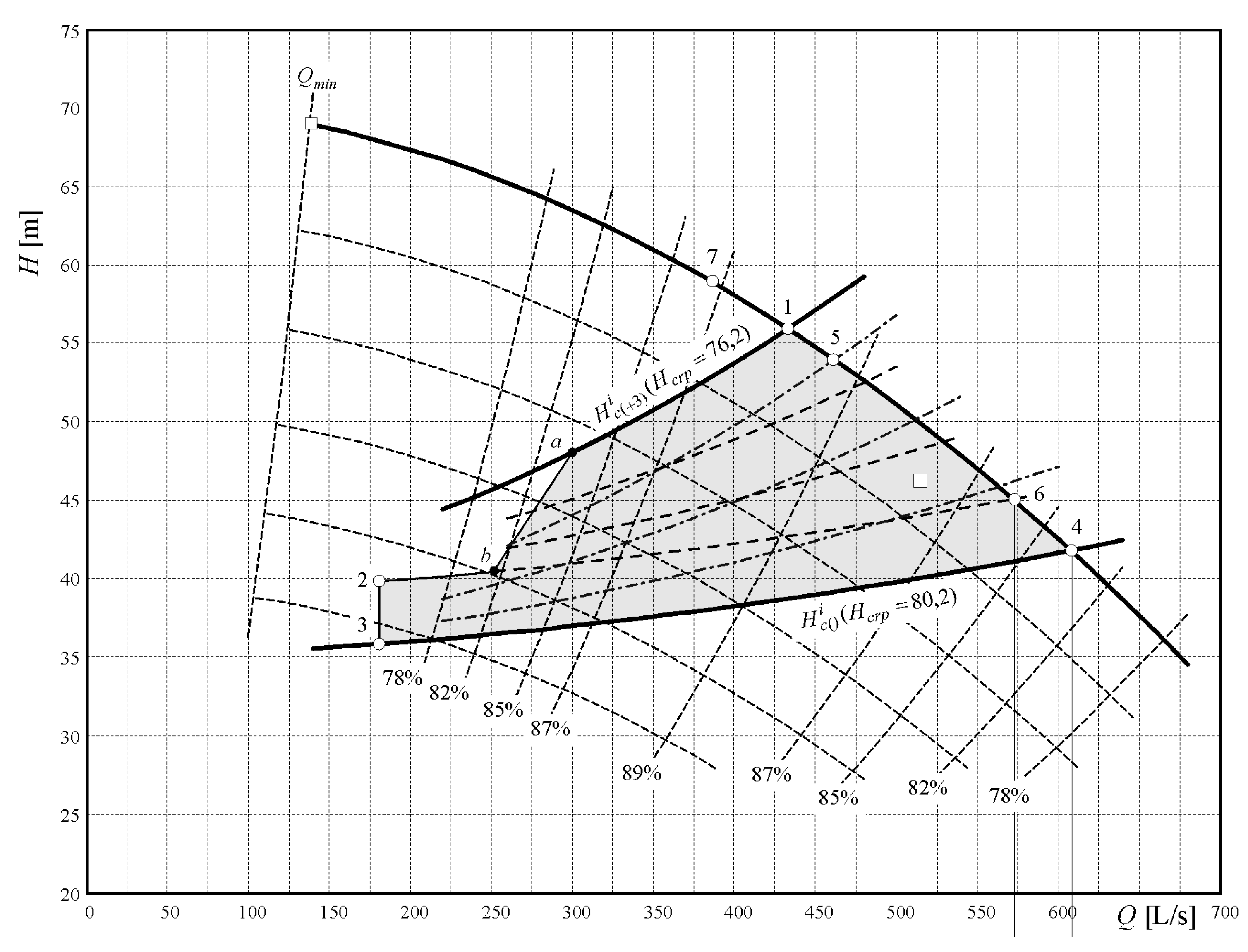

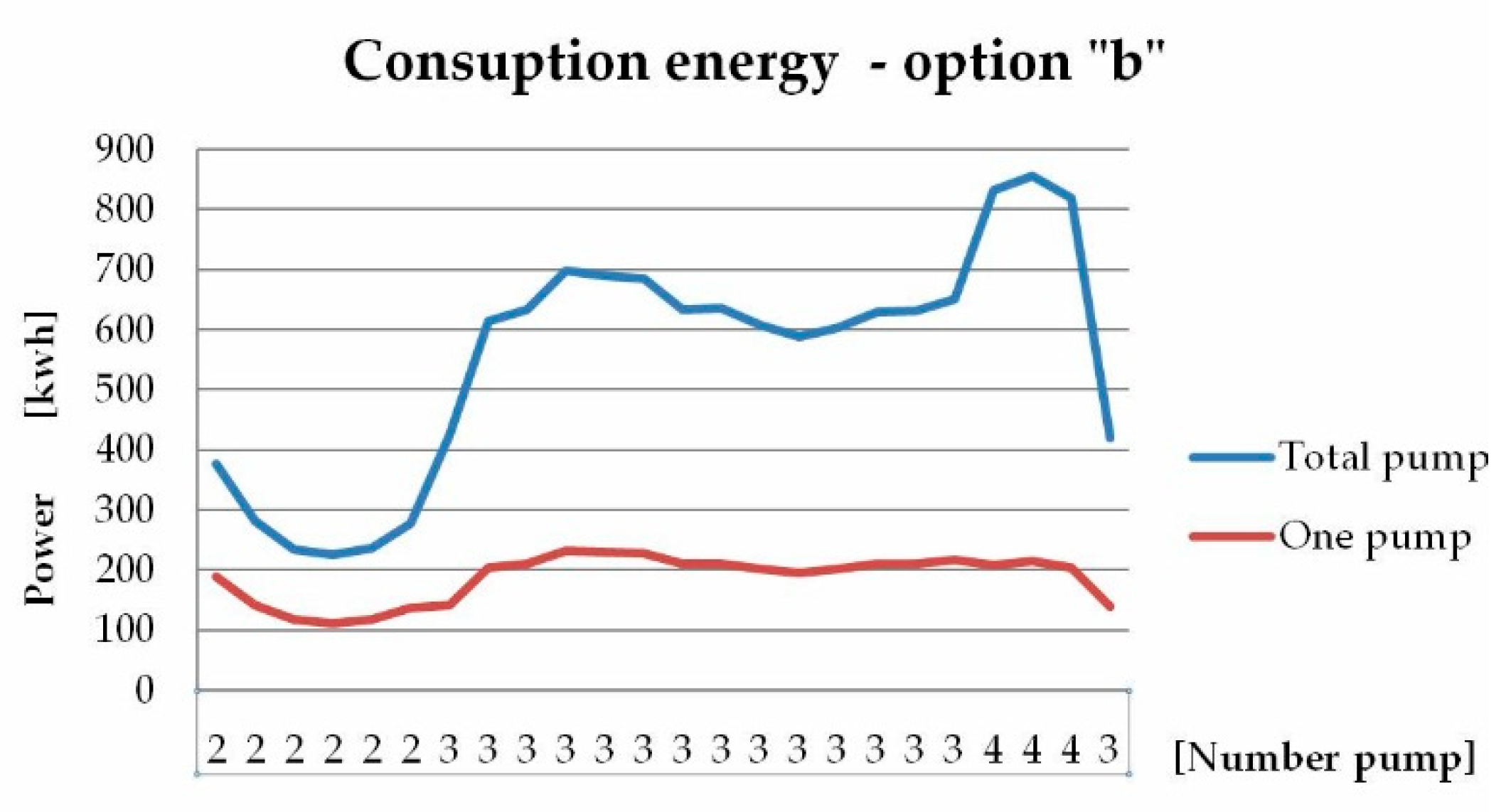

3.1.2. Pump Exploitation—Option “b”

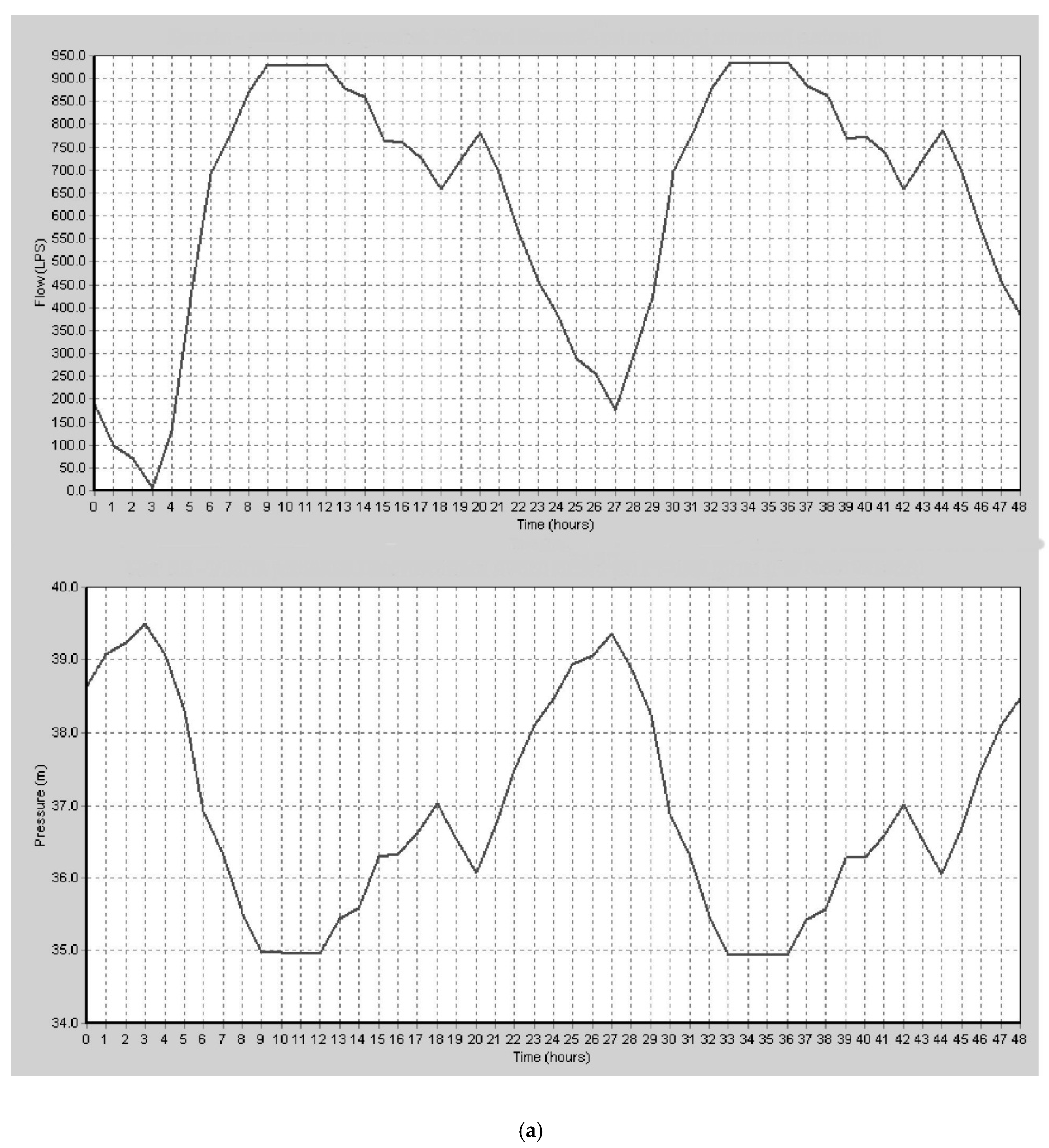

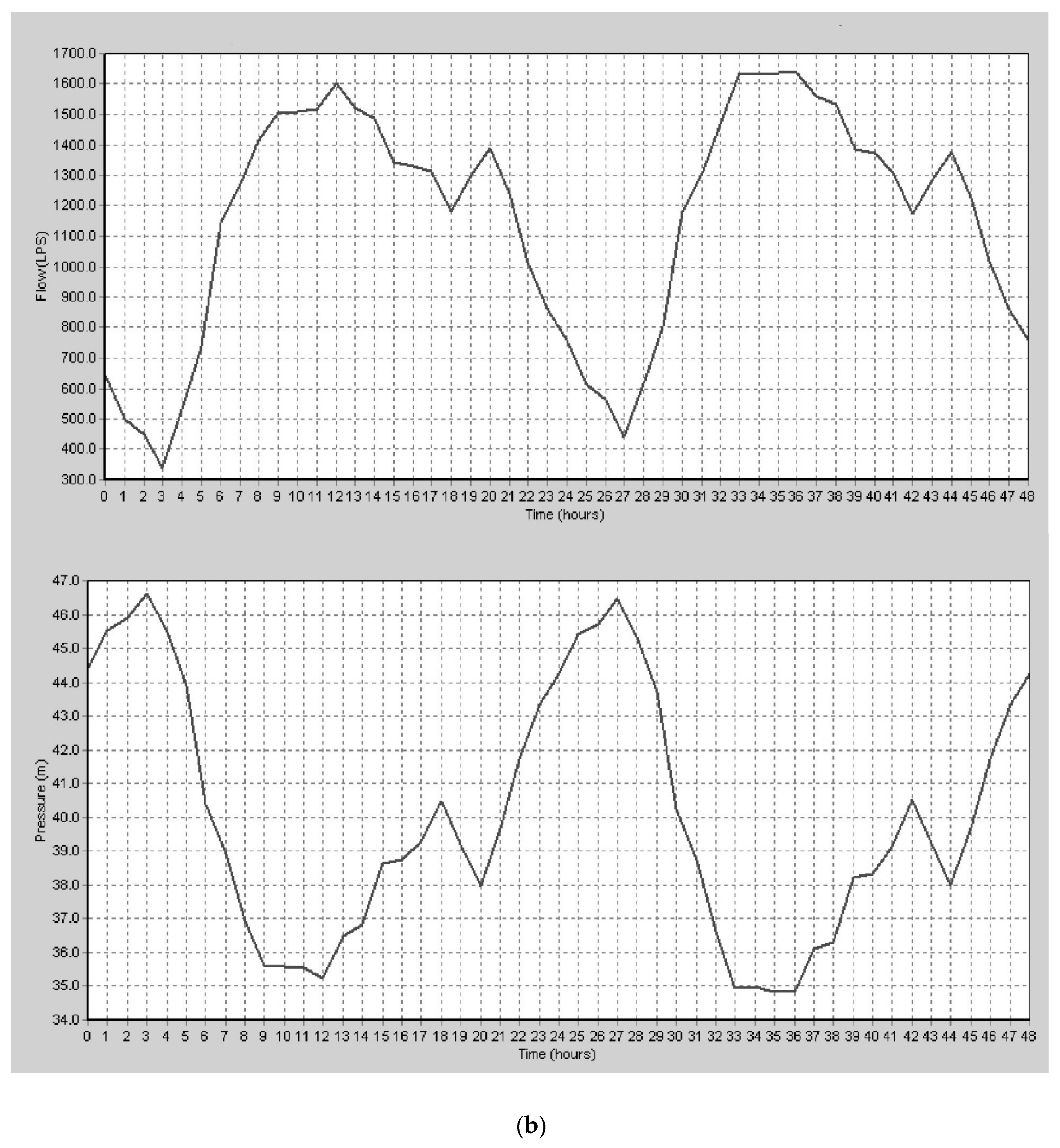

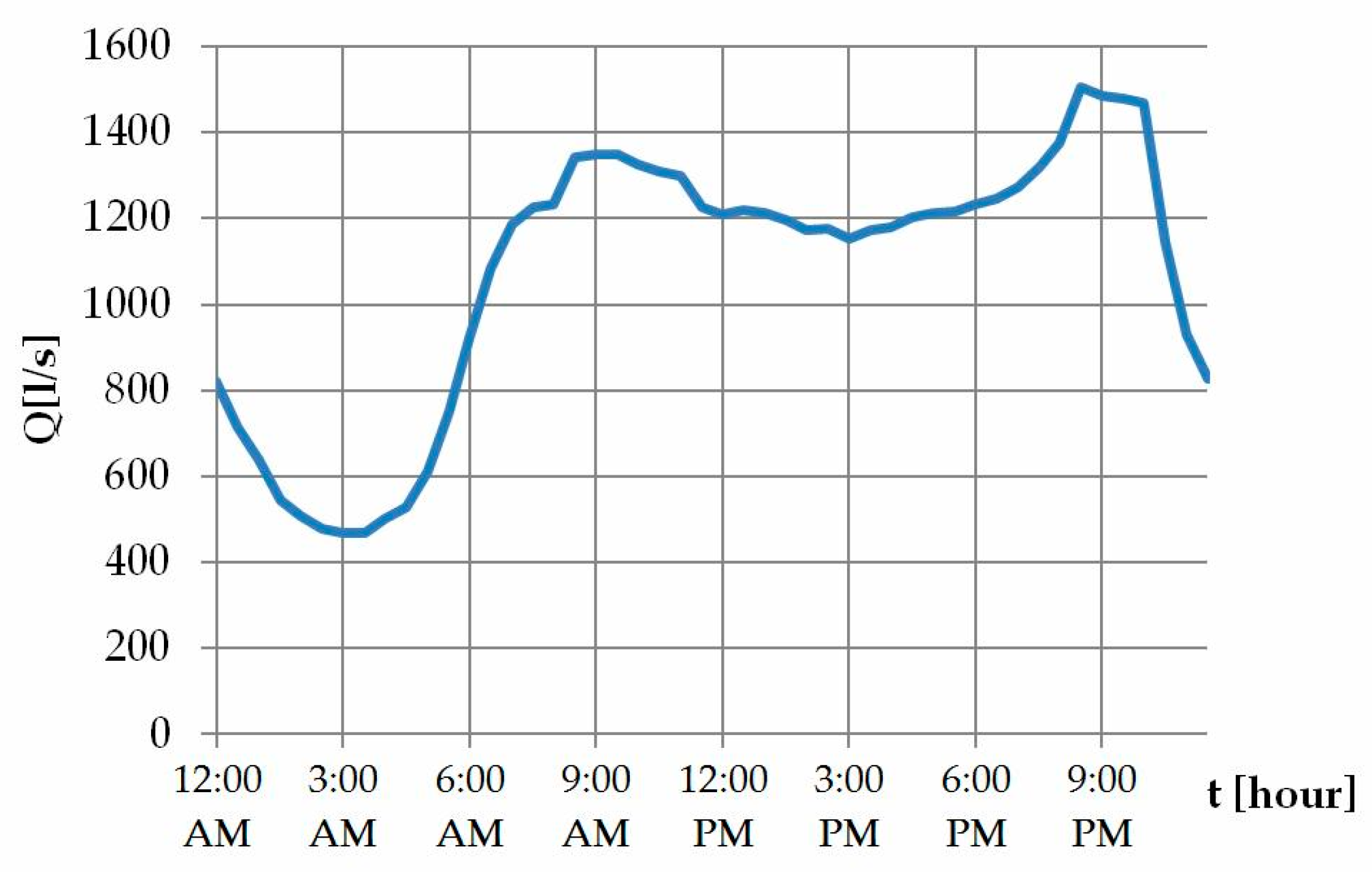

3.2. Planned and Actual Water Consumption in the WDS

3.3. LCA/LCC Coefficients

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ferreira, F.J.; Fong, J.A.; Almeida, A.T. Ecoanalysis of Variable-Speed Drives for Flow Regulation in Pumping Systems. IEEE Trans. Ind. Electron. 2011, 58, 2117–2125. [Google Scholar] [CrossRef]

- Burton, F.L.; Stern, F. Water and Wastewater Industries: Characteristics and DSM Opportunities; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 1993.

- Tegeltija, S.; Lazarevic, M.; Stankovski, S.; Cosic, I.; Todorovic, V.; Ostojic, G. Heating circulation pump disassembly process improved with augmented reality. Therm. Sci. 2016, 20, S611–S622. [Google Scholar] [CrossRef]

- Cabrera, E.; Cobacho, R.; Pardo, M.A. Energy Audit of Water Networks. J. Water Resour. Plan. Manag. 2010, 136, 669–677. [Google Scholar] [CrossRef]

- Stjepanovic, A.; Stojcic, M.; Stjepanovic, S. Hybrid Power Energy Source Based on Pem Fuel Cell/Solar System. J. Mechatron. Autom. Identif. Technol. 2019, 4, 5–8. [Google Scholar]

- Loss, A.; Toniolo, S.; Mazzi, A.; Manzardo, A.; Scipioni, A. LCA comparison of traditional open cut and pipe bursting systems for relining water pipelines. Resour. Conserv. Recycl. 2018, 128, 458–469. [Google Scholar] [CrossRef]

- Uche, J.; Martínez-Gracia, A.; Círez, F.; Carmona, U. Environmental impact of water supply and water use in a Mediterranean water stressed region. J. Clean. Prod. 2015, 88, 196–204. [Google Scholar] [CrossRef]

- Fantin, V.; Scalbi, S.; Ottaviano, G.; Masoni, P. A method for improving reliability and relevance of LCA reviews: The case of life-cycle greenhouse gas emissions of tap and bottled water. Sci. Total Environ. 2014, 476–477, 228–241. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Choi, G.; Kim, J.; Byeon, S. Energy Cost Optimization for Water Distribution Networks Using Demand Pattern and Storage Facilities. Sustainability 2018, 10, 1118. [Google Scholar] [CrossRef]

- Herstain, L.; Filion, Y.; Hall, K. Evaluating environmental impact in water distribution system design. J. Infrastruct. Syst. 2009, 15, 241–250. [Google Scholar] [CrossRef]

- Wu, W.; Maier, H.; Simpson, A. Multiobjective optimization of water distribution systems accounting for economic cost, hydraulic reliability, and greenhouse gas emissions. Water Resour. Res. 2013, 49, 1211–1225. [Google Scholar] [CrossRef] [Green Version]

- Makov, T.; Meylan, G.; Powell, J.; Shepon, A. Better than bottled water?—Energy and climate change impacts of on-the-go drinking water stations. Resour. Conserv. Recycl. 2019, 143, 320–328. [Google Scholar] [CrossRef]

- Arden, S.; Ma, X.; Brown, M. Holistic analysis of urban water systems in the Greater Cincinnati region: (2) resource use profiles by emergy accounting approach. Water Res. X 2019, 2, 1000012. [Google Scholar] [CrossRef] [PubMed]

- Schaefer, T.; Udenio, M.; Quinn, S.; Fransoo, J.C. Water risk assessment in supply chains. J. Clean. Prod. 2019, 208, 636–648. [Google Scholar] [CrossRef]

- Nault, J.; Papa, F. Lifecycle Assessment of a Water Distribution System Pump. J. Water Resour. Plan. Manag. 2015, 141, A4015004. [Google Scholar] [CrossRef]

- Filion, Y.R.; MacLean, H.L.; Karney, B.W. Life-Cycle Energy Analysis of a Water Distribution System. J. Infrastruct. Syst. 2014, 10, 120–130. [Google Scholar] [CrossRef]

- Hydraulic Institute, Europump and the US Department of Energy’s Office of Industrial Technologies (OIT). Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems. Available online: https://www1.eere.energy.gov/manufacturing/tech_assistance/pdfs/pumplcc_1001.pdf (accessed on 25 January 2019).

- Trifunovic, N. Introduction to Urban Water Distribution; Taylor & Francis/Balkema: Leiden, The Netherlands, 2005. [Google Scholar]

- Senk, I.; Ostojic, G.; Jovanovic, V.; Tarjan, L.; Stankovski, S. Experiences in developing labs for a supervisory control and data acquisition course for undergraduate mechatronics education. Comput. Appl. Eng. Educ. 2015, 23, 54–62. [Google Scholar] [CrossRef]

- EPANET Application for Modeling Drinking Water Distribution Systems. Available online: https://www.epa.gov/water-research/epanet (accessed on 24 February 2019).

- Vojvodinaprojekt. Preliminary Design of High Pressure Pump Stations STRAND; Vojvodinaprojekt: Novi Sad, Serbia, 2005. [Google Scholar]

- Idelʹchik, I.E.; Fried, E. Handbook of Hydraulic Resistance; Hemisphere Pub. Corp.: Washington, DC, USA, 1986. [Google Scholar]

- Hajdin, G. Mechanics of Fluid—Introduction to Hydraulics; Faculty of Civil Engineering: Belgrade, Serbia, 2002. [Google Scholar]

- Municipal Water Company project. Determining water consumption; Municipal Water Company: Novi Sad, Serbia, 2017. [Google Scholar]

- Statista. Available online: https://www.statista.com/statistics/595803/electricity-industry-price-germany (accessed on 14 January 2019).

- Statista. Available online: https://www.statista.com/statistics/595813/electricity-industry-price-spain/ (accessed on 14 January 2019).

| Parameter | Unit | Value |

|---|---|---|

| Rated flow | (L/s) | 450 |

| Rated head | (m) | 52 |

| Rated power—Motor | (kW) | 315 |

| Rated power—VFD | (kW) | 9 |

| Pump Peak efficiency | (%) | 87.5 |

| Motor Peak efficiency | (%) | 96.3 |

| Pump Capital Cost | (€/per unit) * | 50.000 |

| Motor Capital Cost | (€/per unit) * | 40.000 |

| VFD Capital Cost | (€/per unit) * | 28.000 |

| Q (L/s) | Hout (m a.s.l) | Q (L/s) | Hout (m a.s.l) | Q (L/s) | Hout (m a.s.l) | Q (L/s) | Hout (m a.s.l) |

|---|---|---|---|---|---|---|---|

| 180 | 115.7 | 550 | 117.4 | 950 | 120.5 | 1350 | 124.8 |

| 250 | 116.0 | 650 | 118.1 | 1050 | 121.4 | 1450 | 125.9 |

| 350 | 116.4 | 750 | 118.8 | 1150 | 122.5 | 1550 | 126.9 |

| 450 | 116.9 | 850 | 119.6 | 1250 | 123.5 | 1650 | 128.2 |

| Parameter | Unit | Value |

|---|---|---|

| kprod, pump | (kWh/kg) | 3.15 |

| kprod, motor | (kWh/kg) | 2.2 |

| kprod, VFD | (kWh/kg) | 11.3 |

| Wic, pump | (kg) | 1107 |

| Wic, motor | (kg) | 2831 |

| Wic, VFD | (kg) | 62.37 |

| gprod, pump | (kg-CO2-eq./kg) | 2.59 |

| gprod, motor | (kg-CO2-eq./kg) | 2.19 |

| gprod, VFD | (kg-CO2-eq./kg) | 12.85 |

| LCI | Value | Energy for Production | Emission GHG | kprod,index | gprod,index |

|---|---|---|---|---|---|

| Pump | (kg) | (kWh) | (kg-CO2-eq) | (kWh/kg) | (kg-CO2-eq./kg) |

| market for cast iron production—GLO* | 695 | 1329.95 | 1493.11 | kprod,pump 3.15 | gprod,pump 2.59 |

| market for steel, chromium steel 18/8— GLO* | 177 | 1526.91 | 835.26 | ||

| market for metal working, average for chromium steel production— GLO* | 177 | 483.99 | 339.53 | ||

| market for bronze— GLO* | 25 | 103.69 | 153.1 | ||

| market for silicon carbide— GLO* | 4 | 21.59 | 30.12 | ||

| market for alkyd paint, white, without solvent, in 60% solution state— GLO* | 4 | 26.13 | 22.63 | ||

| market for casting, bronze— GLO* | 25 | 4.68 | 1.59 | ||

| Electrical motor | (kg) | (kWh) | (kg-CO2-eq/kg) | (kWh/kg) | (kg-CO2-eq./kg) |

| market for metal working, average for steel production— GLO* | 1055 | 2700.21 | 2263.294 | kprod,motor 2.2 | gprod,motor 2.19 |

| market for steel, low-alloyed— GLO* | 1055 | 2255.061 | 2108.202 | ||

| market for cast iron— GLO* | 441 | 843.90 | 947.431 | ||

| market for copper— GLO* | 110 | 227.63 | 558.8027 | ||

| market for epoxy resin, liquid— GLO* | 17 | 0.32 | 116.254 | ||

| market for aluminum, cast alloy— GLO* | 31 | 87.41 | 98.72751 | ||

| market for wire drawing, copper— GLO* | 110 | 80.66 | 73.55919 | ||

| market for alkyd paint, white, without solvent, in 60% solution state— GLO* | 6 | 39.20 | 33.94907 | ||

| market for polyvinylchloride, bulk polymerized— GLO* | 6 | 0.09 | 13.19395 | ||

| Variable frequency drive | (kg) | (kWh) | (kg-CO2-eq/kg) | (kWh/kg) | (kg-CO2-eq./kg) |

| market for electronics, for control units— GLO* | 19.845 | 495.13 | 550.2368 | kprod,VFD 11.3 | gprod,VFD 12.85 |

| market for printed wiring board, for power supply unit, desktop computer, Pb containing— GLO* | 2.835 | 134.97 | 164.7126 | ||

| market for metal working, average for steel product manufacturing— GLO* | 14.175 | 36.28 | 30.40966 | ||

| market for steel, low-alloyed— GLO* | 14.175 | 30.29 | 28.32584 | ||

| market for polyvinylchloride, bulk polymerized— GLO* | 8.505 | 0.13 | 18.70243 | ||

| market for aluminum, cast alloy— GLO* | 2.835 | 7.99 | 9.02879 |

| Parameter | Unit | Value |

|---|---|---|

| ew | (kWh/€) | 7.69 |

| gw | (kg-CO2-eq./kWh) | 1.077/0.665/0.487 * |

| ftest | (test/year) | 0.1 |

| fmain,pump | (h/year) | 75 |

| fmain,motor | (h/year) | 50 |

| ctest | (€/test) | 1000 |

| cmain,pump | (€/h) | 50 |

| cmain,motor | (€/h) | 50 |

| coverhaul | (€) | 15,000 |

| Noverhaul | (-) | 0.1 |

| T | (year(s)) | 40 |

| Parameter | Unit | Value |

|---|---|---|

| erec | (kWh/€) | −2.32 |

| grec | (kg-CO2-eq./kg) | −2.13 |

| Wtmm | (kg) | 2563 |

| Al | (kg) | 33.83 |

| Steel | (kg) | 2382.17 |

| Copper | (kg) | 110 |

| El.scrap | (kg) | 22.68 |

| PVC | (kg) | 14.5 |

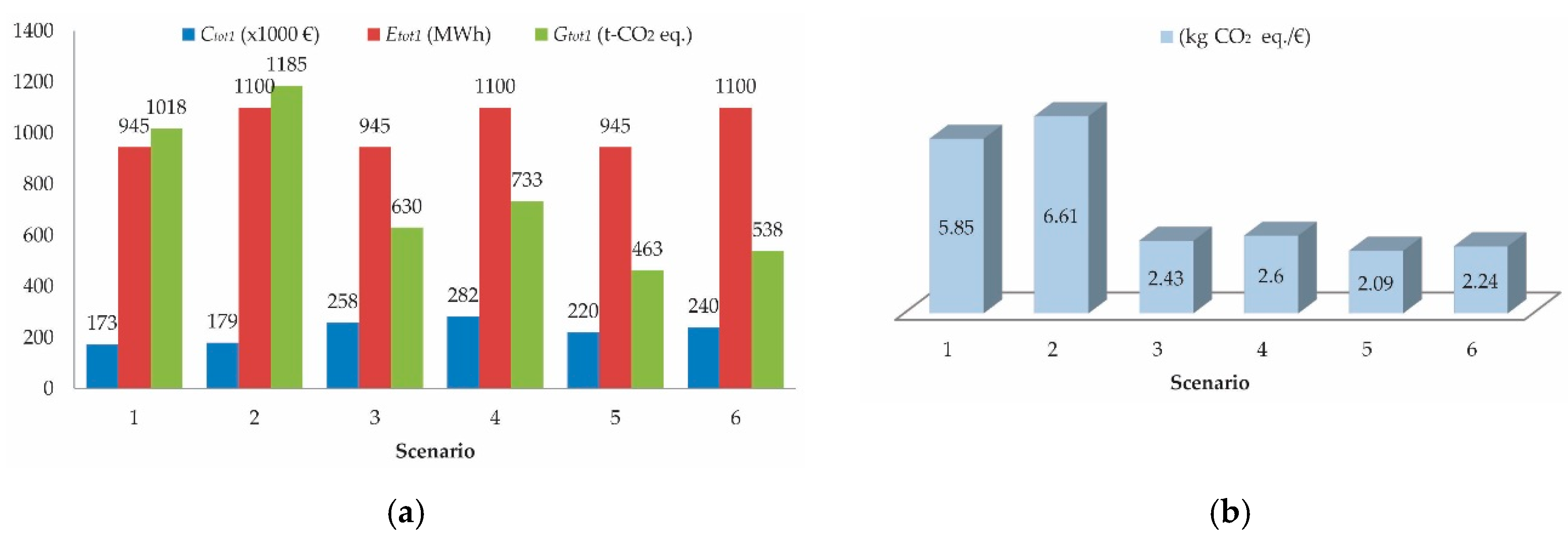

| Scenario | Ctot1 (×103 €) | Ctot40 (×103 €) | Etot1 (MWh) | Etot40 (MWh) | Gtot1 (t-CO2-eq.) | Gtot40 (t-CO2-eq.) | Gtot1/Ctot1 (kg-CO2-eq.)/€ |

|---|---|---|---|---|---|---|---|

| 1 | 173.89 | 2316.50 | 945.05 | 37,627.40 | 1018.18 | 40,555.04 | 5.85 |

| 2 | 179.16 | 2527.02 | 1100.47 | 43,844.13 | 1185.69 | 47,255.53 | 6.61 |

| 3 | 241.23 | 5010.03 | 945.05 | 37,627.40 | 630.24 | 25,037.50 | 2.43 |

| 4 | 261.44 | 5818.20 | 1100.47 | 43,844.13 | 733.65 | 29,173.91 | 2.60 |

| 5 | 220.55 | 4182.73 | 945.05 | 37,627.40 | 463.13 | 18,352.83 | 2.09 |

| 6 | 240.15 | 4966.89 | 1100.47 | 43,844.13 | 538.92 | 21,384.69 | 2.24 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jocanovic, M.; Agarski, B.; Karanovic, V.; Orosnjak, M.; Ilic Micunovic, M.; Ostojic, G.; Stankovski, S. LCA/LCC Model for Evaluation of Pump Units in Water Distribution Systems. Symmetry 2019, 11, 1181. https://doi.org/10.3390/sym11091181

Jocanovic M, Agarski B, Karanovic V, Orosnjak M, Ilic Micunovic M, Ostojic G, Stankovski S. LCA/LCC Model for Evaluation of Pump Units in Water Distribution Systems. Symmetry. 2019; 11(9):1181. https://doi.org/10.3390/sym11091181

Chicago/Turabian StyleJocanovic, Mitar, Boris Agarski, Velibor Karanovic, Marko Orosnjak, Milana Ilic Micunovic, Gordana Ostojic, and Stevan Stankovski. 2019. "LCA/LCC Model for Evaluation of Pump Units in Water Distribution Systems" Symmetry 11, no. 9: 1181. https://doi.org/10.3390/sym11091181

APA StyleJocanovic, M., Agarski, B., Karanovic, V., Orosnjak, M., Ilic Micunovic, M., Ostojic, G., & Stankovski, S. (2019). LCA/LCC Model for Evaluation of Pump Units in Water Distribution Systems. Symmetry, 11(9), 1181. https://doi.org/10.3390/sym11091181