3.1. Autogenous Shrinkage Performance

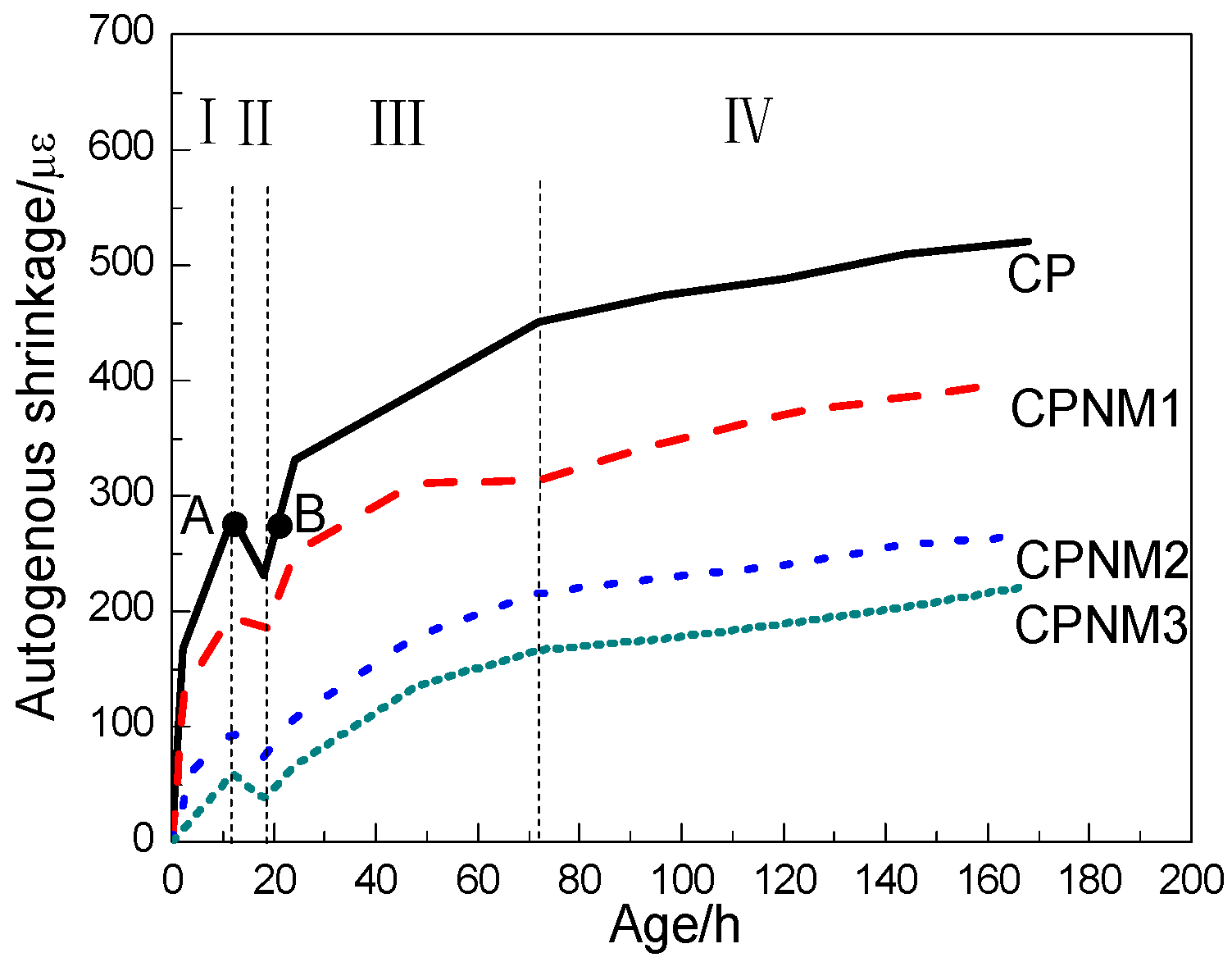

Figure 2 shows the changes of autogenous shrinkage strain of the nano-montmorillonite cement based materials and reference group samples with age. It can be seen from

Figure 2 that the autogenous shrinkage of CP without nano-material can be divided into four different stages according to the development trend. During the rapid growth period (I), the cement paste changed from plastic state to solid state. Before the initial coagulation, the volume shrinkage caused by the cement hydration basically appeared to be decreased by the apparent volume due to the lack of sufficient frame strength to constrain volume deformation. After the initial coagulation, the rate of hydration reaction was accelerated. The self-drying effect led to the increase of capillary pressure, while the overall strength of the paste began to develop which has weak restraint on the apparent volume deformation. Thus the autogenous shrinkage of the cement pastes presented a fast growth trend. In the expansion period (II), the autogenous shrinkage appears to dropped temporarily from point A. As the hydration reaction continued, the moisture in the cement paste was continuously consumed. The self-drying effect was strengthened so that the autogenous shrinkage began to rise to the next stage slowly at point B. The expansion at this stage may be ascribed to cement hydration which leads to an increase in the internal temperature causing the paste to expand [

19]. In the slow growth period (III), the formation of the hardened cement paste skeleton has a certain inhibitory effect on the deformation of the apparent volume due to the gradual slowdown of the hydration reaction of the paste, resulting in a significant decrease of the autogenous shrinkage rate. In the relatively stable period (IV), the stiffness of the matrix was constantly enhanced due to the further weakened hydration reaction, which played a significant role in restraining the volume deformation. As a result, the volume stability was improved and the autogenous shrinkage showed a slight increase with age. Samples doped with nano-montmorillonite have the similar development law of autogenous shrinkage with that of reference group samples.

As can be seen from

Figure 2, the autogenous shrinkage of each specimen mainly occurred in the first 72 h. The autogenous shrinkage of CP, CPNM1, CPNM2 and CPNM3 at the age of 72 h accounts for 86.6%, 78.1%, 81.3% and 74.8% of the total autogenous shrinkage at the age of 168 h, respectively. Compared with the CP group, the autogenous shrinkage of the specimen CPNM1, CPNM2 and CPNM3 is decreased by 23.0%, 48.9% and 57.4% respectively, at the age of 168 h. The results demonstrate that the incorporation of NM into cement based materials has a significant improvement on the autogenous shrinkage of cement paste. The greater the amount of NM, the more obvious the improvement. This phenomenon attributes to the water swelling characteristic of NM itself. The interlayer water of cement paste can play the role of internal curing and relieve the self-drying effect. The self-expansion effect caused by the hydration reaction of conservation water compensated for partial shrinkage. Under the condition of the same chemical shrinkage, which caused by hydration of cement, the self-expansion effect can compensate for partial shrinkage of the volume which caused by chemical shrinkage in the early age of hydration due to the cement hydration of interlayer water, which results in a decrease of autogenous shrinkage [

20,

21].

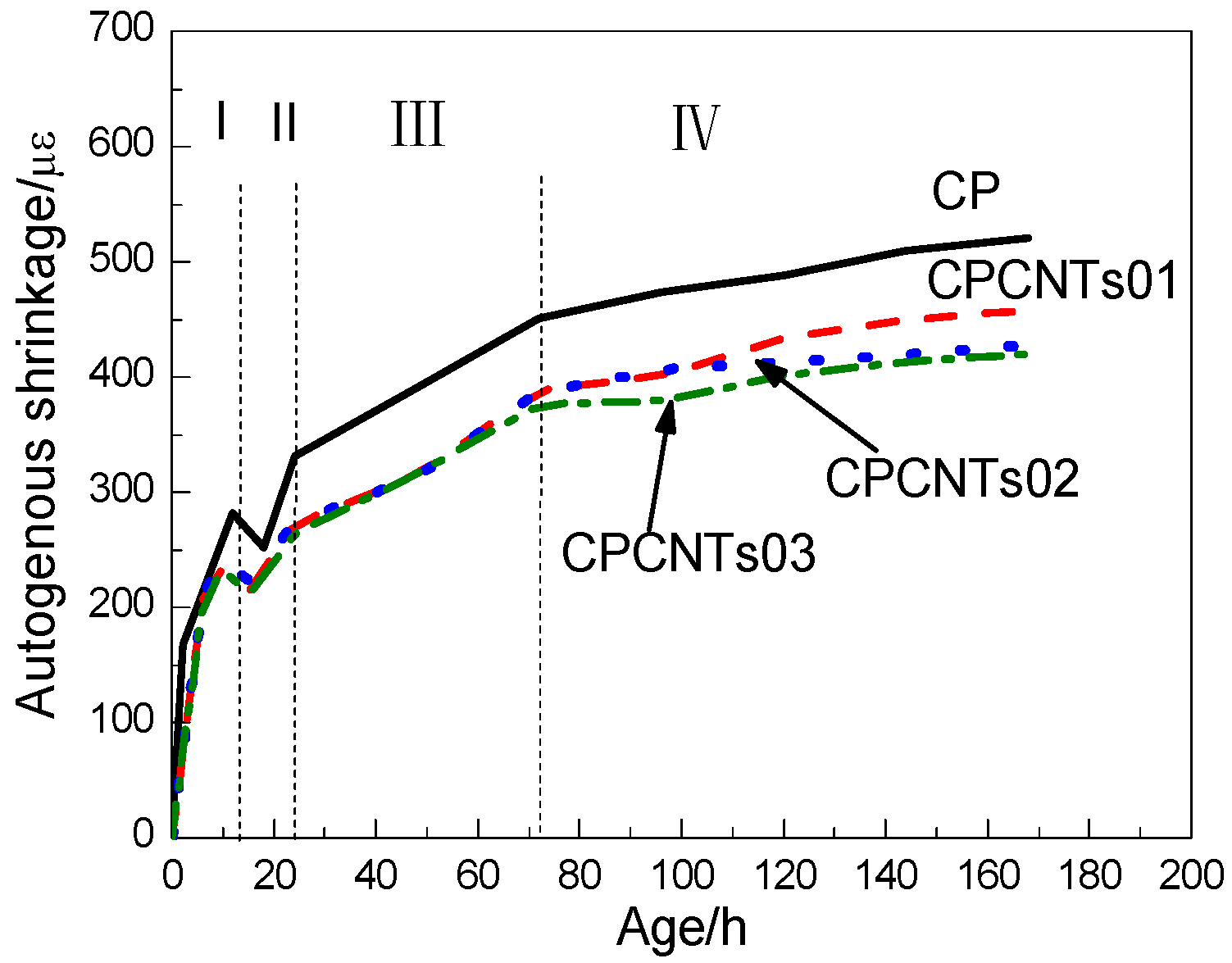

The autogenous shrinkage strain of CNTs-modified cement based materials and the reference group specimens changed with age as shown in

Figure 3. The tendency of autogenous shrinkage of each specimen is similar to that of NM-modified cement based materials. The autogenous shrinkage mainly happened in the first 72 h period. The autogenous shrinkage of CPCNTs01, CPCNTs02 and CPCNTs03 at the age of 72 h accounts for 84.7%, 90.5%, and 89.8% of the total autogenous shrinkage at the age of 168 h, respectively. The decrease of shrinkage of CNTs-modified cement based materials in the expansion stage (II) caused by temperature rise is smaller than that of CP, which may be related to the excellent thermal conductivity of CNTs. When CNTs are uniformly dispersed in the matrix, they can dissipate the heat generated by the cement hydration to the environment, which narrow the temperature difference between cement based materials and the environment. As a result, the expansion due to the temperature rise is reduced. The autogenous shrinkage of CPCNTs01, CPCNTs02 and CPCNTs03 was reduced by 11.9%, 17.9%, and 19.4%, respectively, comparing with the reference group. This indicates that with the increase of the amount of CNTs, the decrease of autogenous shrinkage is increased, but the effect is not obvious. The uniform incorporation of CNTs in cement based materials can significantly reduce the number of pores in the matrix, especially the number of small pores, so as to reduce the capillary pressure [

22,

23]. On the other hand, the structure of the skeleton network formed by uniformly dispersed CNTs in the matrix can inhibit the autogenous shrinkage of the cement based materials [

24,

25].

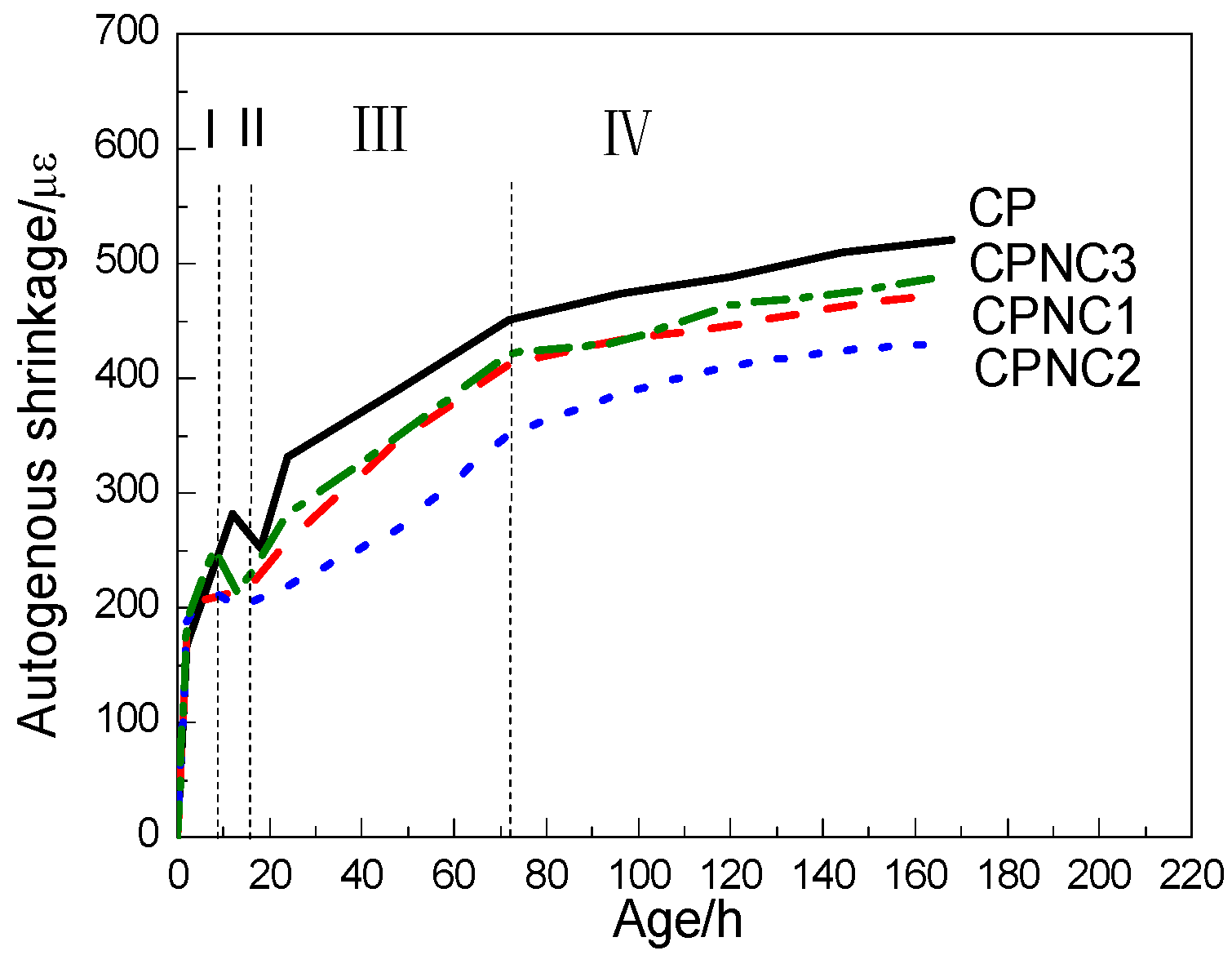

The changes of the autogenous shrinkage strain of the nano-CaCO

3 cement based materials and reference group samples over time were shown in

Figure 4. After the incorporation of NC, with the development stages of autogenous shrinkage of cement based materials can also be divided into four stages. NC has little effect on autogenous shrinkage of cement based materials in the rapid growth stage (I). The autogenous shrinkage of CPNC1, CPNC2 and CPNC3 specimens is decreased by 8.6%, 17.1% and 5.8% respectively, compared with CP group at the age of 168 h. The results show that the incorporation of NC reduced the autogenous shrinkage of the paste. With the increase of the content of NC, the reduction of autogenous shrinkage increased firstly and then decreased, but the effect was not obvious. The effect of NC on cement based materials is due to the fact that NC could increase the content of calcium silicate hydrate (CSH) in cement paste and improve the alignment of calcium hydroxide (CH), so that the interface structure gradually transitioned from plane to space to improve the interface performance. The non-directional arrangement of CH occupied more space, exhibiting a reduction of autogenous shrinkage [

26]. On the other hand, the addition of NC produced a single-carbon type C

3A·CaCO

3·11H

2O, which has some expansibility to compensate for the autogenous shrinkage of cement based materials. When the content of NC increased to 3.0 wt.%, the reduction of autogenous shrinkage decreased. The possible reason is that the specific surface area of NC is large. As the NC content increases, the probability of NC particles’ agglomeration raises. It leads to nonuniform dispersion of NC in the matrix, increasing the air void content in cement paste, which weakens inhibitory effect of NC on the autogenous shrinkage of cement paste [

27].

Table 6 shows the final shrinkage strain values of cement based materials with different nanomaterials. In general, the value of the shrinkage strain for cement pastes containing nano-materials from small to large as follows: NM-modified cement based composites, CNTs-modified cement based composites, NC-modified cement based composites. This means the effect of nano-montmorillonite on autogenous shrinkage of cement paste is the most obvious, followed by carbon nanotubes then nano calcium carbonate. Nano-montmorillonite releases water to reduce the self-drying effect during the process of hydration for its well water swelling. The self-expansion effect caused by hydration reaction of conservation water compensated for partial shrinkage, which results in a decrease of autogenous shrinkage. Carbon nanotubes have the nanometer filling effect and form continuous network to restrain the early autogenous shrinkage of cement paste. Nano calcium carbonate not only decreases the porosity of the cement paste, but also reacts with tricalcium aluminate to generate the expanded product calcium carboaluminate for compensating autogenous shrinkage of cement paste. However, with the increase of the content of Nano calcium carbonate, the reduction of autogenous shrinkage decreased, which is owing to the nonuniform dispersion of Nano calcium carbonate at higher concentration in the matrix. Nano calcium carbonate at higher concentration appears poorly dispersed, forming agglomerates and bundles, which increases the air void content in cement paste and weakens inhibitory effect on the autogenous shrinkage of cement paste.

3.2. Electrochemical Impedance Spectroscopy

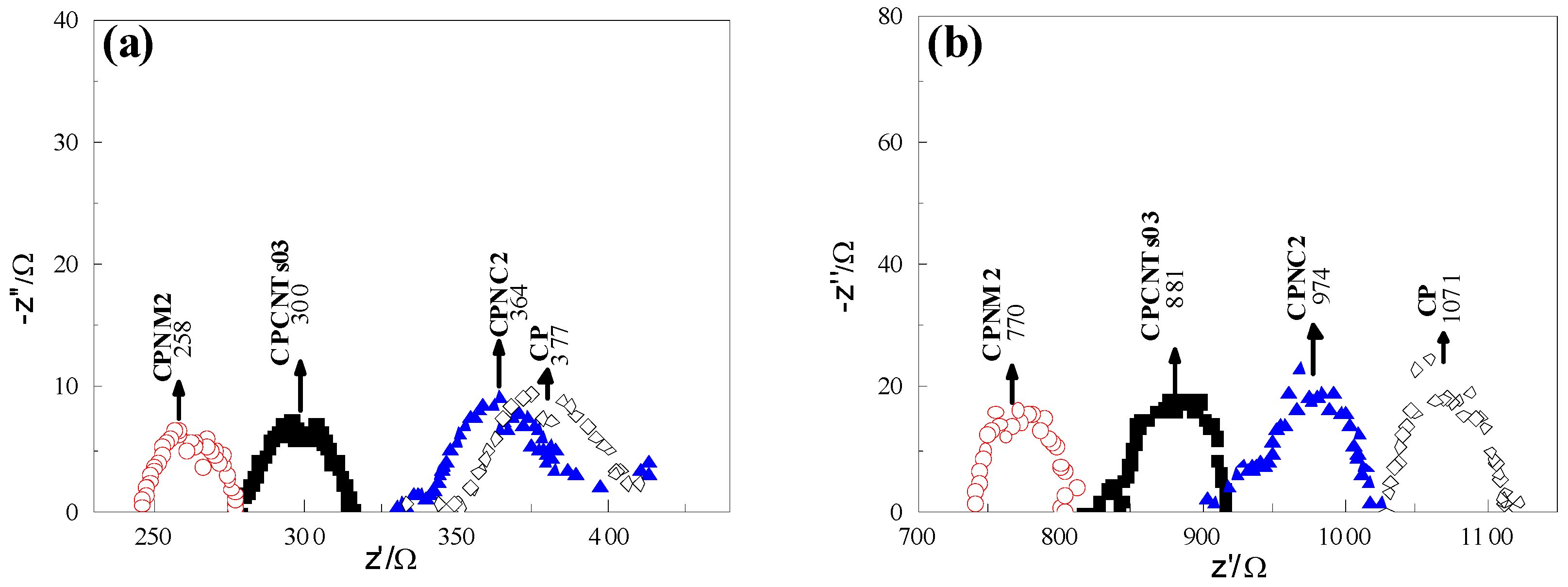

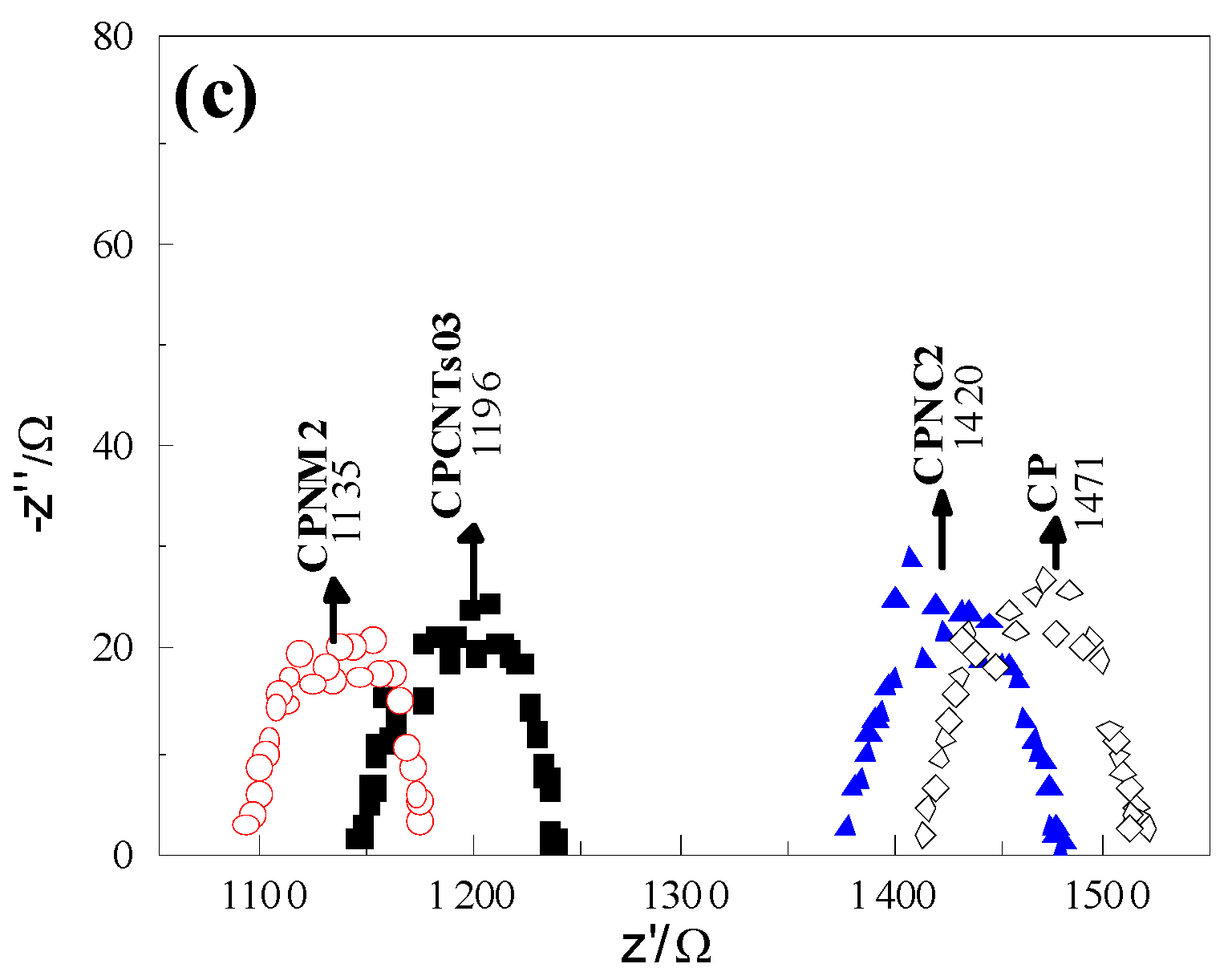

The Nyquist diagrams of samples CP, CPNM2, CPCNTs03 and CPNC2 at different ages were shown in

Figure 5. The value of the intersection point of the arc and the real axis in the Nyquist diagram reflect the value of pore solution resistance R

s. It can be seen from

Figure 5 that the value of the solution resistance R

s changes from small to large as follows: CPNM2, CPCNTs03, CPNC2 and CP. It can also be seen from

Figure 5 that the intersection point of the circular arc and the real axis of Nyquist diagram of each sample moves from left to right as the age increases, which illustrates that R

s is increasing [

28,

29]. And, the changes of the moving distance from 24 h to 72 h are larger than that from 72 h to 168 h, which indicated that the internal structure of the paste changes more in the early age. This is consistent with the autogenous shrinkage changes in

Section 3.1. The resistance of electrolyte in the pore solution represents the conductivity and porosity of the pore solution ions in the matrix. With the development of hydration process, the total amount of Na

+, K

+ and OH

− ions and other ions in the pore solution decreased and the resistance of pore solution electrolyte R

s increased. The autogenous shrinkage of cement based materials due to self-drying results in an increase in the degree of unsaturation of the pore solution as the hydration progresses. The porosity and pore structure of the material changed, and the internal pore size was refined. The compactness of the cement paste was improved by hydration products and also by the filling effect of nanomaterials [

30]. Therefore, the smaller the R

s value of cement based material modified with nano-materials, the smaller the autogenous shrinkage is.

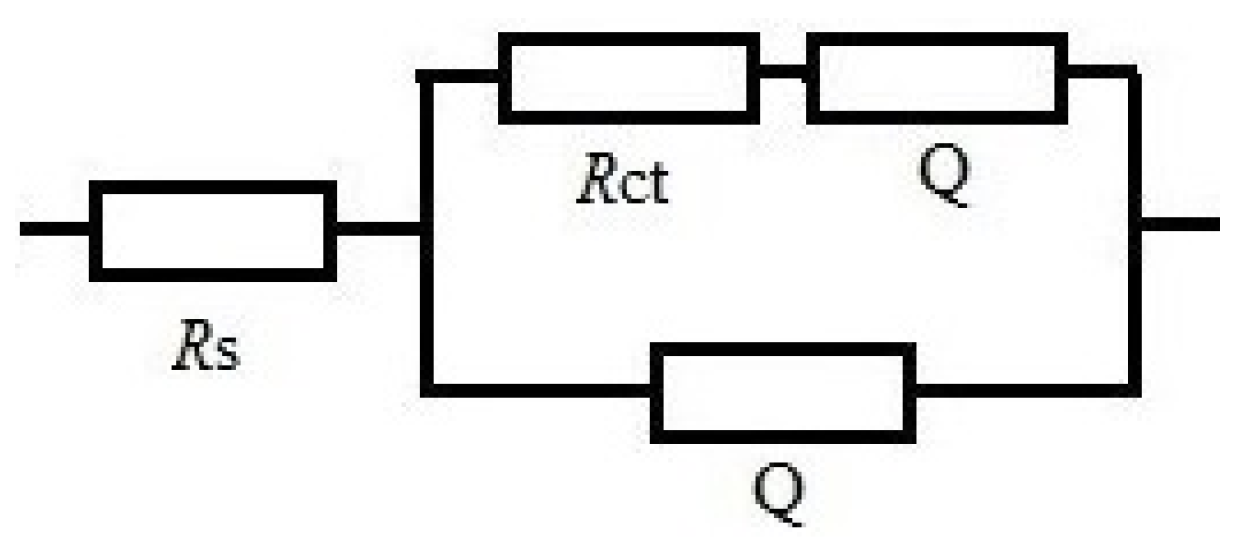

The equivalent circuit diagram shown in

Figure 6 is used to fit the EIS data by using ZSimpWin software. R

s represents electrolyte resistance of cement pastes pore solution, which is conversely proportional to the porosity and ion concentration. R

ct represents charge transfer resistance and Q represents constant phase element. The R

s values simulated by ZSimpWin are shown in

Table 7. It can be seen from the data that R

s values of CP group without adding nanometer materials were greater than other groups adding nanomaterials at all ages. The R

s values of CPNM2 samples are less than that of CP samples due to the internal curing effect caused by water swelling of nano-montmorillonite, which compensated for the shrinkage of cement based materials to a certain extent. The R

s value of CPCNTs03 sample decreases, which means that autogenous shrinkage of CPCNTs03 sample decreases accordingly. This could be owing to that the structure of the skeleton network formed by the uniformly mixed CNTs can restrain the autogenous shrinkage stress and the effect nano-packing of CNTs can reduce the shrinkage of the cement paste. The change of the R

s value of CPNC2 group is related to the shrinkage of cement based material due to its swelling product C

3A·CaCO

3·11H

2O generated in the process of cement hydration. At the same age, R

s values of CPCNTs03 group are greater than that of CPNM2 group, and less than that of CPNC2 group. The influence mechanisms of nanomaterials on the autogenous shrinkage of cement based materials and the R

s value of each group are in accordance with the laws shown in Nyquist diagram, which further validates the accuracy of R

s value variation law using Nyquist diagram of electrochemical impedance spectroscopy [

31].

3.3. Microstructure Analysis

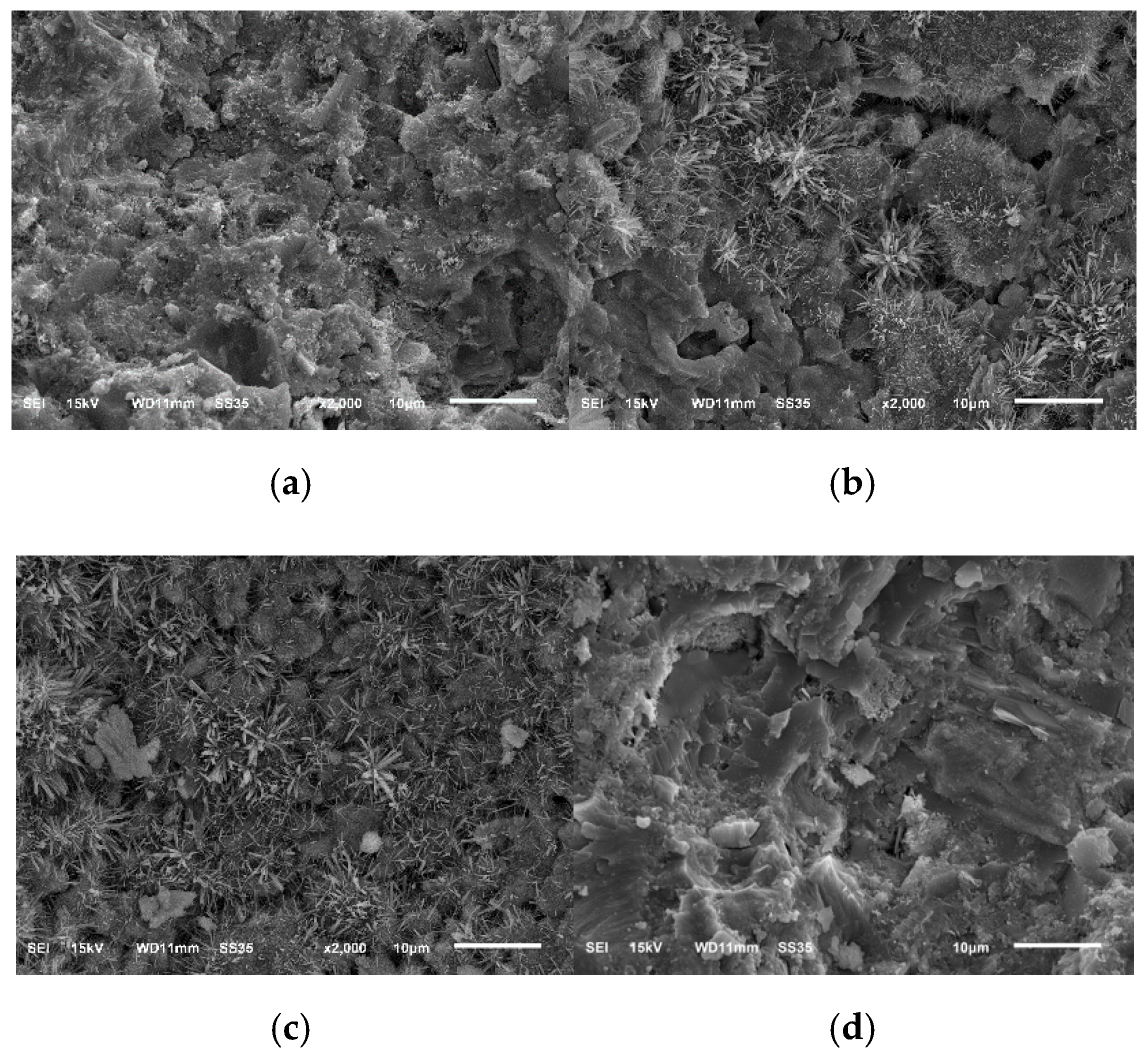

Figure 7a displays the microstructure of the cement paste, and

Figure 7b–d show the morphology of cement based materials with NM, CNTs, and NC, respectively. As shown in

Figure 7a, the hydration products are mainly CSH gel, which are cross-linked into the paste. As can be seen from

Figure 7b, the major hydration products with the addition of NM are CSH gel and Aft. They are relatively dispersed and the CSH is mostly in the form of flocculent gel. As presented in

Figure 7c, with the addition of CNTs into the cement matrix, the carbon nanotubes wound and twisted together into a continuous network structure and tightly packed the hydration products [

32].

Figure 7d shows that CSH gel, calcium hydroxide crystals, and other hydration products form a relatively compact structure. Compared with the CP group, the addition of nanomaterials in cement based materials improved the microstructure and compaction of the matrix.