As a special kind of penetrator, the comprehensive damage characteristics of the truncated cone-shaped PELE projectile will be investigated from two aspects: Penetration ability and the fragmentation effect. In the numerical simulation model, two layers of target plate were constructed, namely the target plate and the after-effect target. The target plate is mainly used to reflect the penetration ability of projectile, while the after-effect target is mainly used to reflect the fragmentation effect after the projectile perforating the target plate.

4.1. Comparison of Penetration Ability between the Truncated Cone-Shaped PELE Projectile and Conventional PELE Projectile

When evaluating the penetration ability of projectiles, the axial residual velocity or the loss of axial residual velocity of the projectile is usually selected as an indicator for characterization. However, the precondition is to ensure that the truncated cone-shaped PELE projectile and the conventional PELE projectile have the same initial kinetic energy. From the geometric structure design of the projectile, it can be seen that the mass of the truncated cone-shaped PELE projectile is 26% less than that of the conventional PELE projectile, which results in the different initial velocity of projectile under the same initial kinetic energy. Therefore, it is obviously unreasonable to choose the axial residual velocity or the loss of axial residual velocity as the indicator for characterization. In this section, the residual kinetic energy of the PELE projectile is directly expressed as an indicator, and the kinetic energy change of the PELE projectile after perforating the target plate is mainly analyzed.

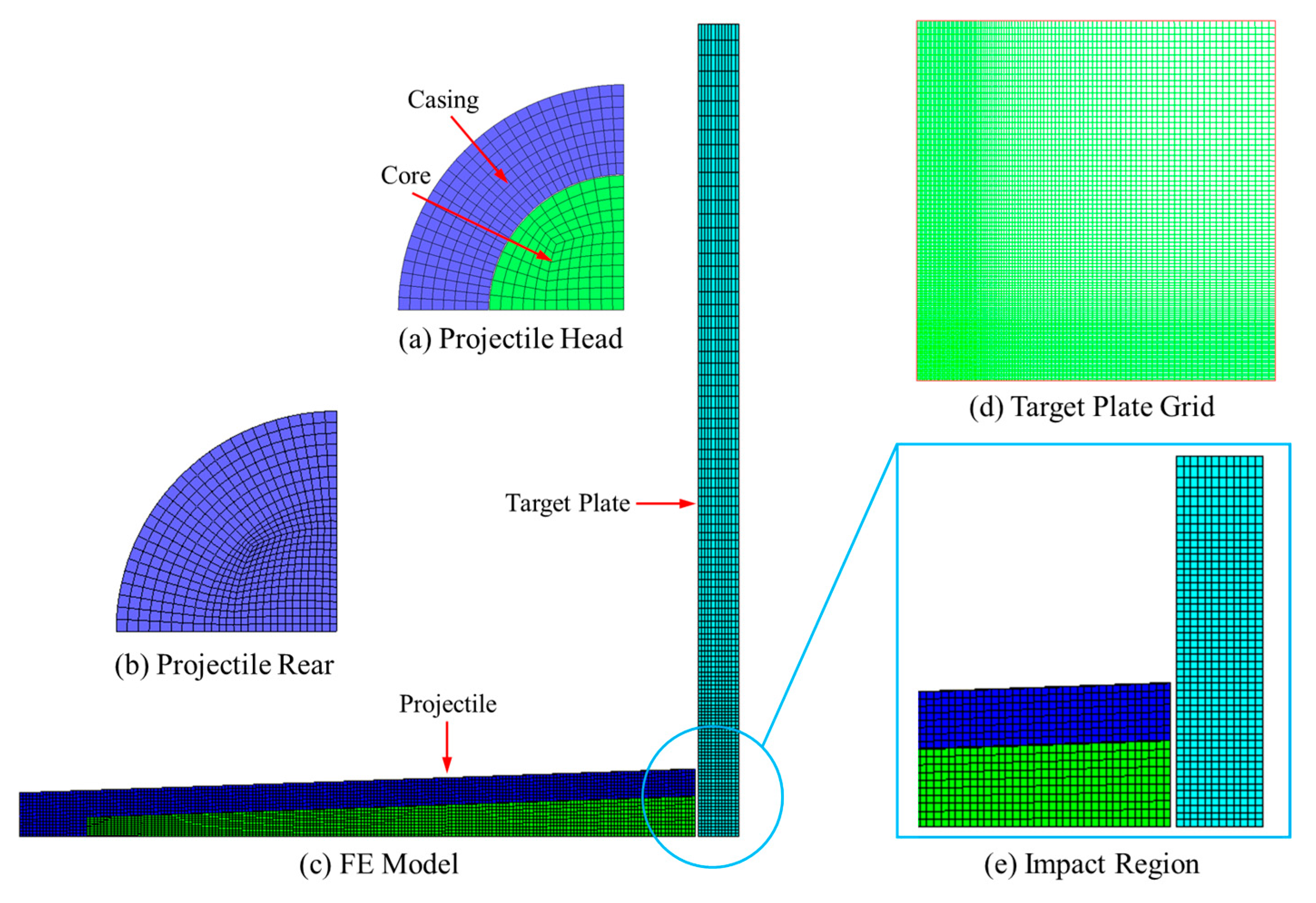

In order to visualize the penetration process of PELE projectiles, this paper takes the #5 working condition as an example and four typical moments were selected, as shown in

Figure 5.

The penetrating ability of the projectile can be reflected by the energy loss of the projectile, while the energy loss of the projectile is mainly used for shear energy dissipation of the target plate. Therefore, the energy loss of the projectile in the range from the projectile body and the target plate just touching to the projectile body just perforating the target plate completely is mainly analyzed to characterize the penetration ability of projectile. The local enlargement diagrams of the two different types of PELE projectile penetrating the target plate are shown in

Figure 6.

According to the simulation conditions in

Table 4, the kinetic energy losses of PELE projectiles after perforating the target plate were counted, as shown in

Table 5. The working condition numbers in

Table 5 are defined as follows. Taking “#1-1” and “#1-2” as examples, it is explained that “-1” represents the conventional PELE projectile, while “-2” represents the truncated cone-shaped PELE projectile. The projectile velocity and target plate parameters corresponding to the “#1” in

Table 5 are consistent with the information corresponding to the “#1” in

Table 2 and

Table 4.

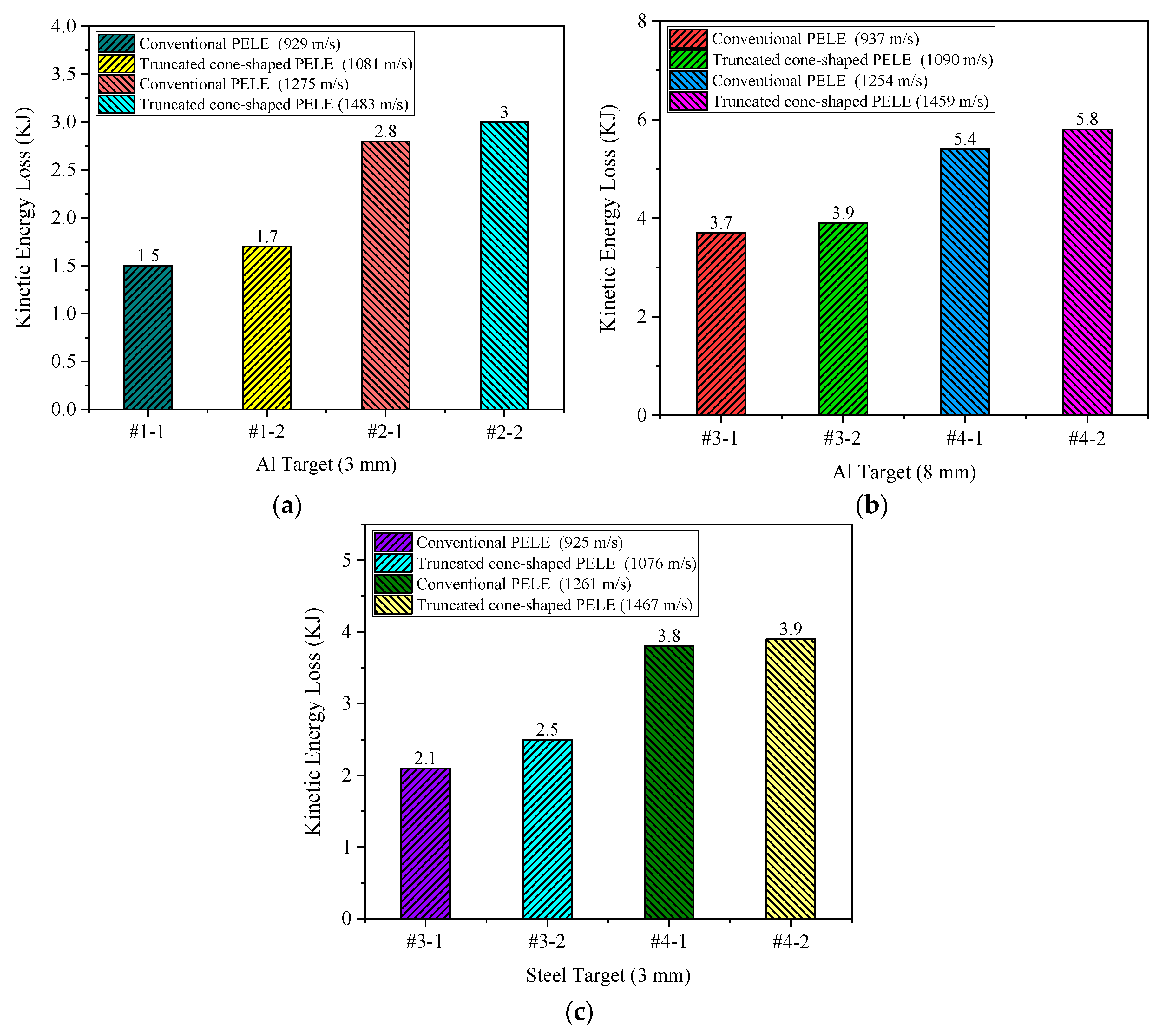

In order to quantify the kinetic energy loss of the conventional PELE projectile and the truncated cone-shaped PELE projectile in the process of penetrating the target plate, the kinetic energy losses corresponding to the different working conditions in

Table 5 are expressed in the form of histogram, as shown in

Figure 7.

According to the design principle of the truncated cone-shaped projectile, the initial kinetic energy of the two different types of projectiles should be identical in theory. While the mass of the projectile cannot be guaranteed to be completely consistent with the theoretical mass during modeling, it leads to some deviation in the initial kinetic energy of the projectiles in the simulation. From the specific values given in

Table 5, the initial kinetic energy difference is small, and it can be basically negligible, so it is approximated that they have the same initial kinetic energy.

Based on the kinetic energy loss after the projectile perforating the target plate shown in

Table 5 and

Figure 7, it can be seen that the difference of kinetic energy loss between the two different types of PELE projectile is quite small, which indicates that the penetration ability of the two projectiles is quite close. In other words, the penetration ability of the truncated cone-shaped PELE projectile is guaranteed and there is no significant reduction. Although the kinetic energy loss of the two kinds of projectiles is quite close, it can be found that the kinetic energy loss of the truncated cone-shaped PELE projectile is slightly larger than that of the conventional PELE projectile through comparative analysis of all working conditions. The reason for this phenomenon may be related to the resistance of the projectile when it penetrates the target plate.

The resistance of the projectile when it penetrates the target plate mainly consists of four parts. The first part is the resistance caused by the strength of the target material, which is the resistance of the target material to the projectile when it resists its own deformation. The magnitude of this part of the force has nothing to do with the velocity of projectile, but only depends on the strength of the target material. The second part is the inertia force or flow resistance, which is mainly caused by the inertia of the target material itself. The magnitude of the force is proportional to the square of the velocity of projectile. In addition to the above two main resistance terms, the penetration resistance usually includes the viscous effect term and the additional mass term of target material. The relationship between the stress of penetration resistance and penetration velocity is as follows:

where

represents the resistance term caused by the strength of target material;

represents the viscous effect term;

represents the inertial force term, and

represents the additional mass term. Thus, the expression of penetration resistance of projectile can be obtained as follows:

where

F is the penetration resistance of projectile;

A is the cross-sectional area of the impact end of projectile; and

c1~

c4 are the resistance coefficients. In general, the second term (viscous effect term) and the fourth term (additional mass term) of the resistance expression can be neglected, and the expression of the penetration resistance of projectile can be rewritten as follows:

Based on the above theoretical analysis, when the cross-sectional area of the impact end of the projectile is constant, the greater the impact velocity of the projectile, the greater the penetration resistance experienced by the projectile, and the greater the kinetic energy loss of projectile during the penetration process. Under the same initial kinetic energy condition, the velocity of the truncated cone-shaped PELE projectile is higher than that of the conventional PELE projectile. Therefore, the penetration resistance of the truncated cone-shaped PELE projectile is greater than the conventional PELE projectile, and it means that the kinetic energy loss of the truncated cone-shaped PELE projectile is greater. In addition, it can be seen from

Table 5 that when the target plate thickness is unchanged, if the target plate material is changed from Al to steel, the impedance exhibited by the target plate will inevitably increase, so that the kinetic energy loss of projectile during penetration will also inevitably increase. When the target plate material is unchanged, if the target plate thickness changes from 3 mm to 8 mm, the impedance exhibited by the target plate will inevitably increase, so that the kinetic energy loss of projectile during penetration will also inevitably increase.

In summary, there is no significant difference in the penetration ability between the truncated cone-shaped PELE projectile and the conventional PELE projectile. However, due to the impact velocity of the truncated cone-shaped PELE projectile is slightly higher, the penetration resistance of the truncated cone-shaped PELE projectile is slightly greater than that of the conventional PELE projectile, and the greater resistance means there will be a little more kinetic energy loss.

4.2. Comparison of Fragmentation Effect between the Truncated Cone-Shaped PELE Projectile and Conventional PELE Projectile

Compared with the conventional armor-piercing projectile, the PELE projectile has a remarkable advantage in its fragmentation effect after penetrating the target, which can improve the damage level of the target after penetrating to a certain extent. From the conclusions obtained in

Section 4.1, it can be seen that there is no obvious difference in penetration ability between the conventional PELE projectile and the truncated cone-shaped PELE projectile. Therefore, this section will focus on the fragmentation effect of the truncated cone-shaped PELE projectile.

In this section, the fragment conversion rate and the damage radius of the after-effect target are mainly investigated to evaluate the fragmentation effect of PELE projectile. The fragment conversion rate of the projectile can be determined by calculating the ratio of the mass of the residual casing to the mass of the initial casing. That is to say, the fragment conversion rate can be converted to the mass change rate of the outer casing. The damage radius of the after-effect target can be measured directly.

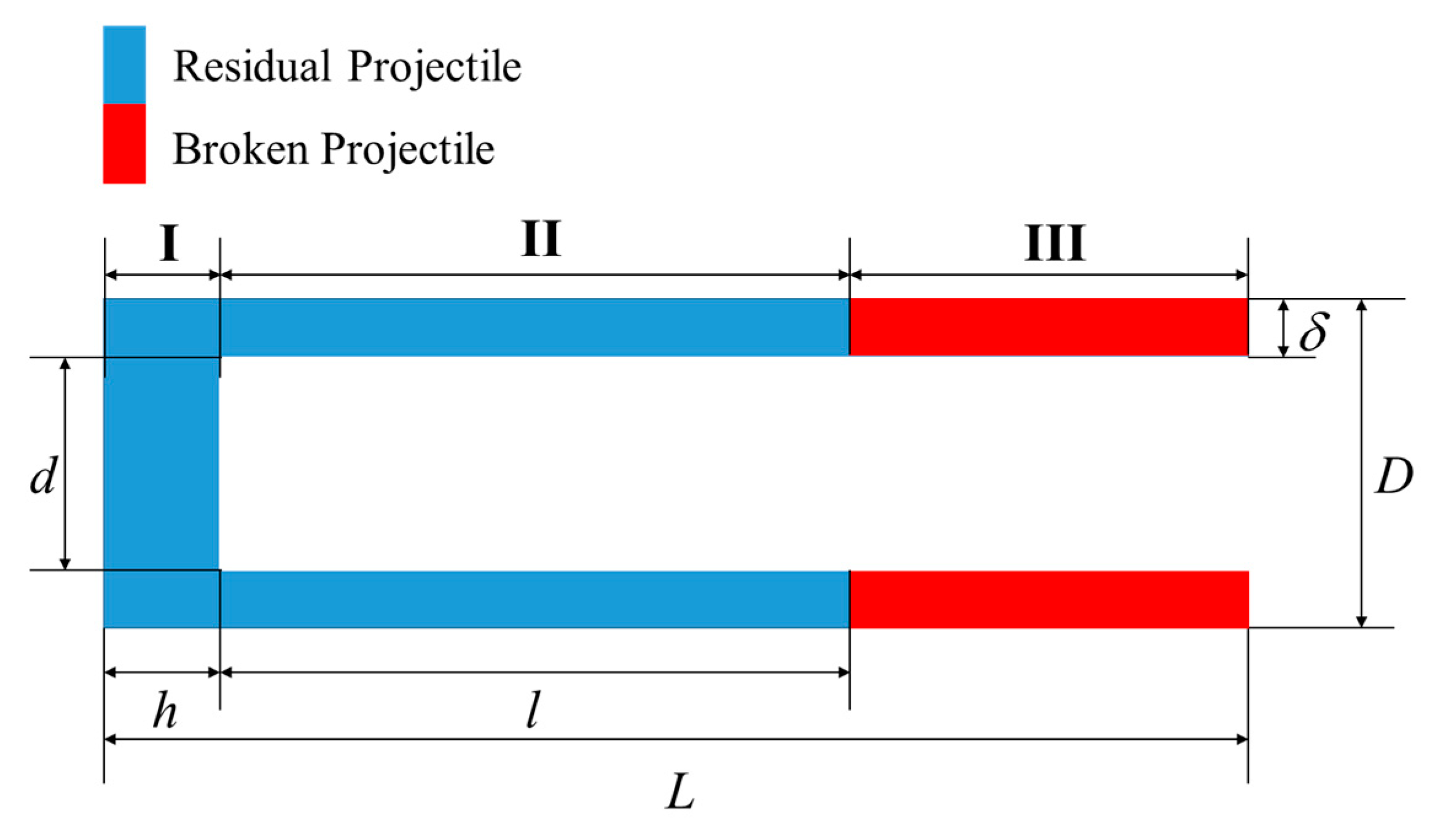

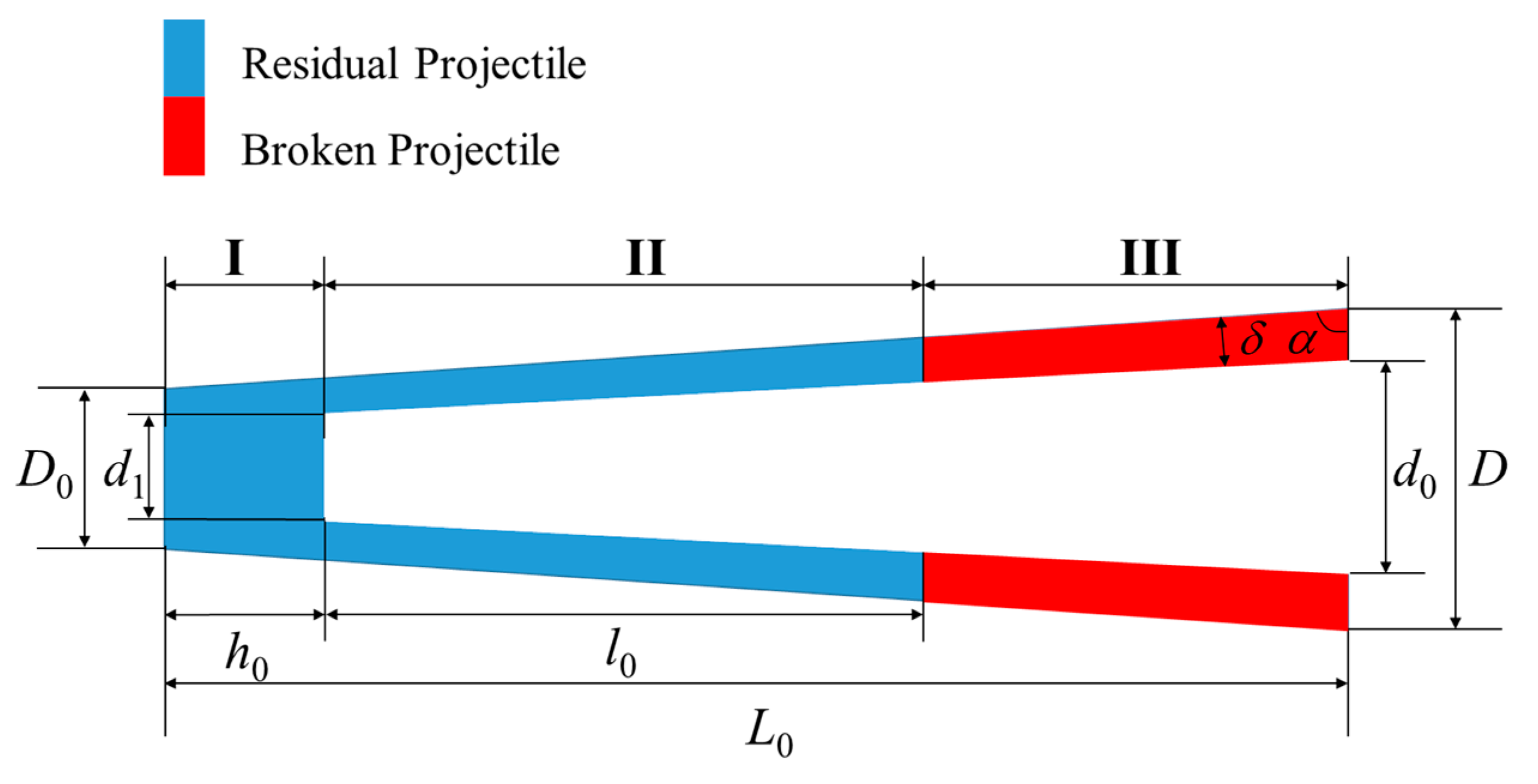

Next, the relationship between the fragment conversion rate and the residual length of the two different types of PELE projectile will be established respectively. In order to analyze the fragment conversion rate intuitively, the entire projectile body is divided into three parts: Projectile rear, unbroken hollow casing, and broken hollow casing which has been converted into fragments. The simplified diagrams of the failed conventional PELE projectile and the truncated cone-shaped PELE projectile are shown in

Figure 8 and

Figure 9, respectively.

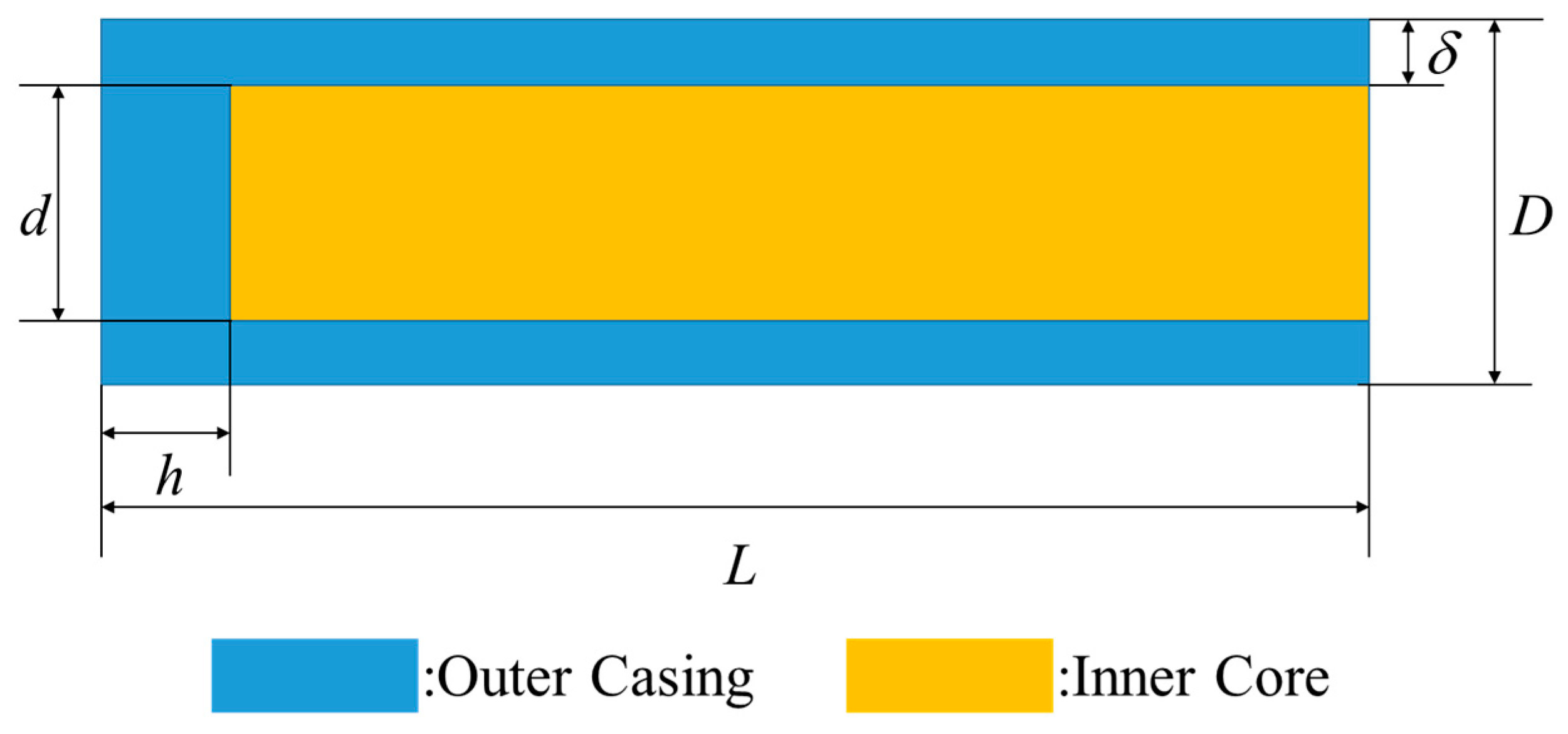

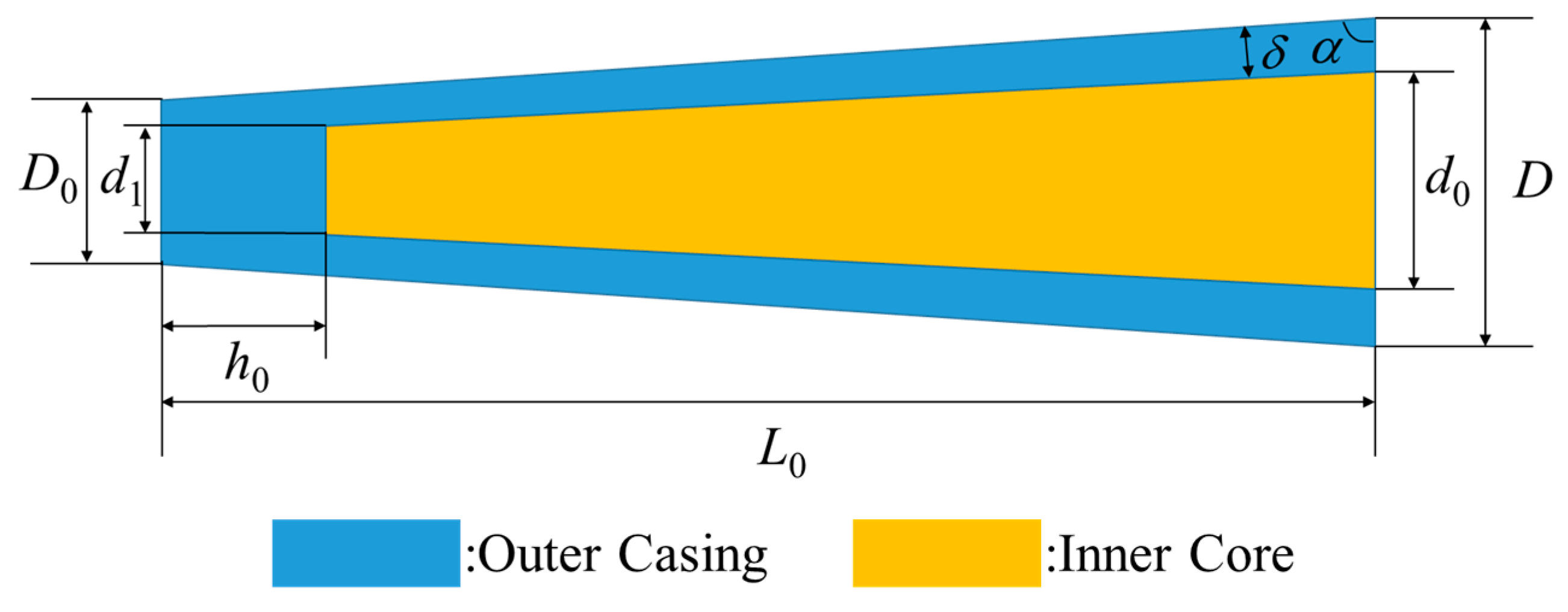

Define the residual length of the projectile after penetrating the target plate as x, the residual length is x = h + l for the conventional PELE projectile, and the residual length is x = h0 + l0 for the truncated cone-shaped PELE projectile. Then, the expressions of the fragment conversion rate η of the two different types of PELE projectile can be obtained as follows.

Conventional PELE projectile:

Truncated cone-shaped PELE projectile:

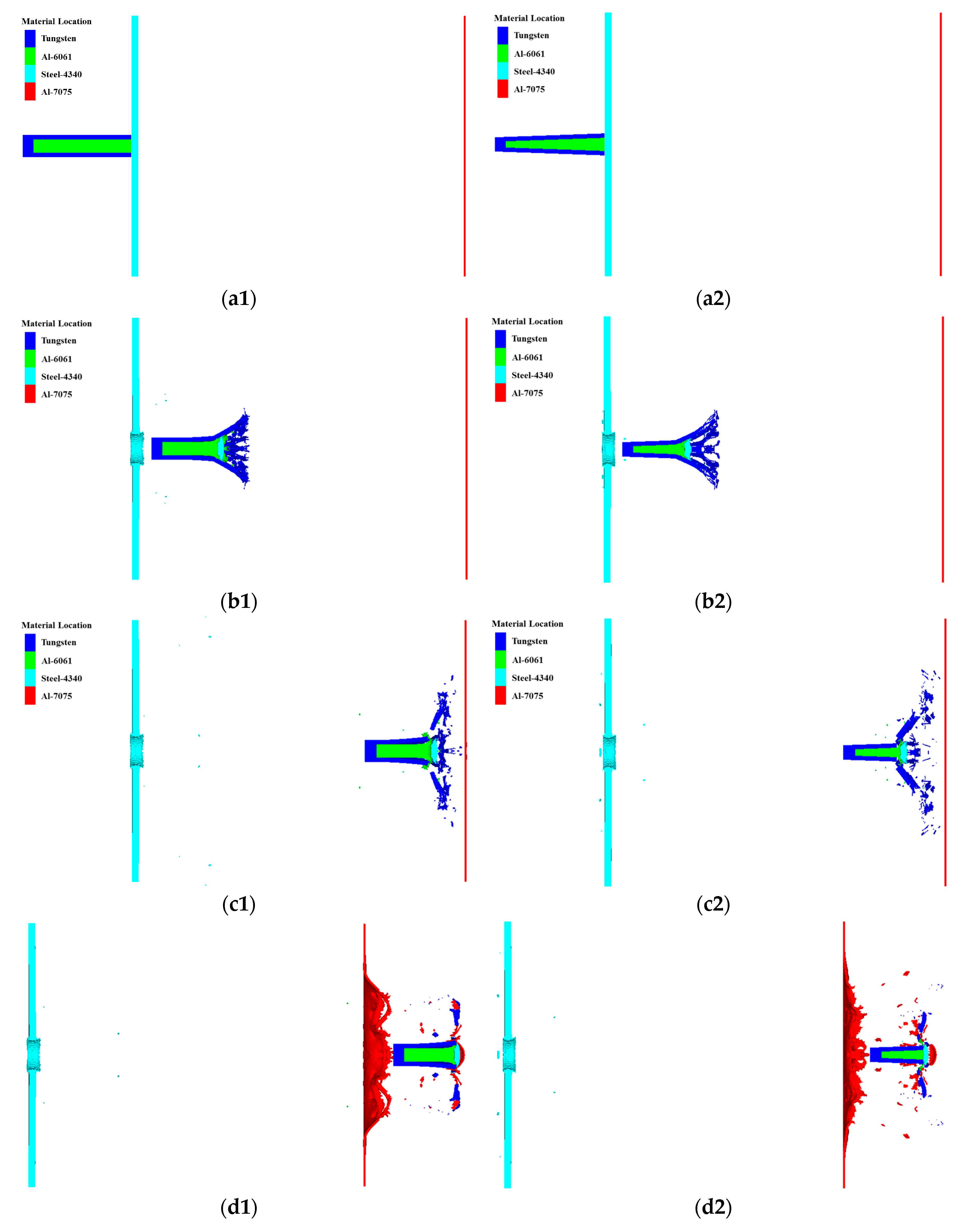

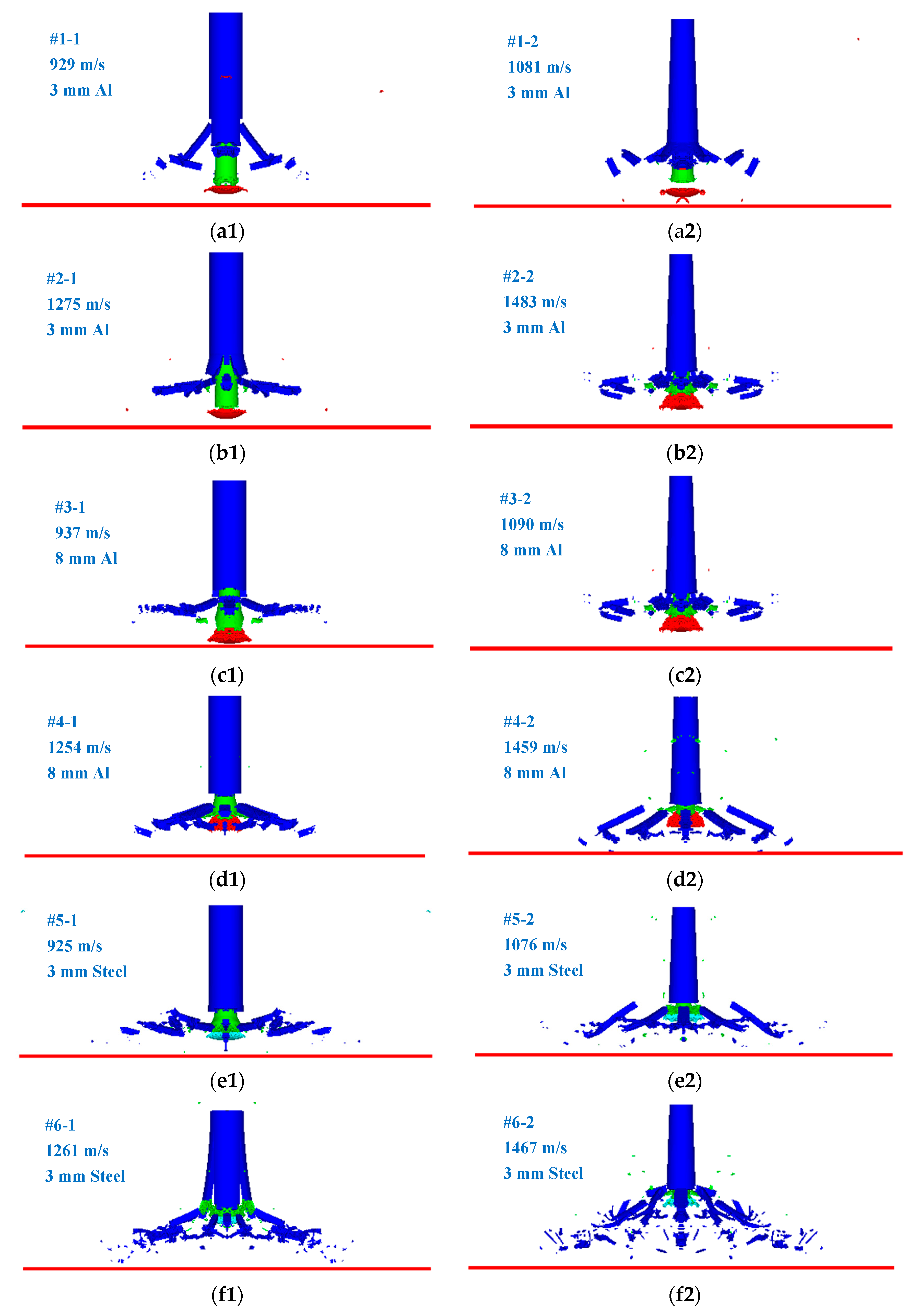

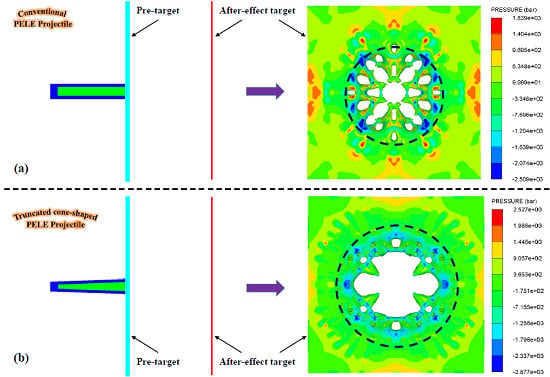

After the PELE projectile perforates the target plate, the outer casing will gradually expand to fracture under the continuous extrusion of the target plug. Under the action of radial force and inertial force, the fragments formed by the outer casing will have radial dispersion velocity, so the damage area formed by the fragments will gradually expand and stabilize with the axial movement of fragments. After analyzing the numerical simulation results, the fragments corresponding to the six sets of working conditions have been fully expanded before reaching the after-effect target. Thus, the status of projectile before impacting the after-effect target is given in this section, as shown in

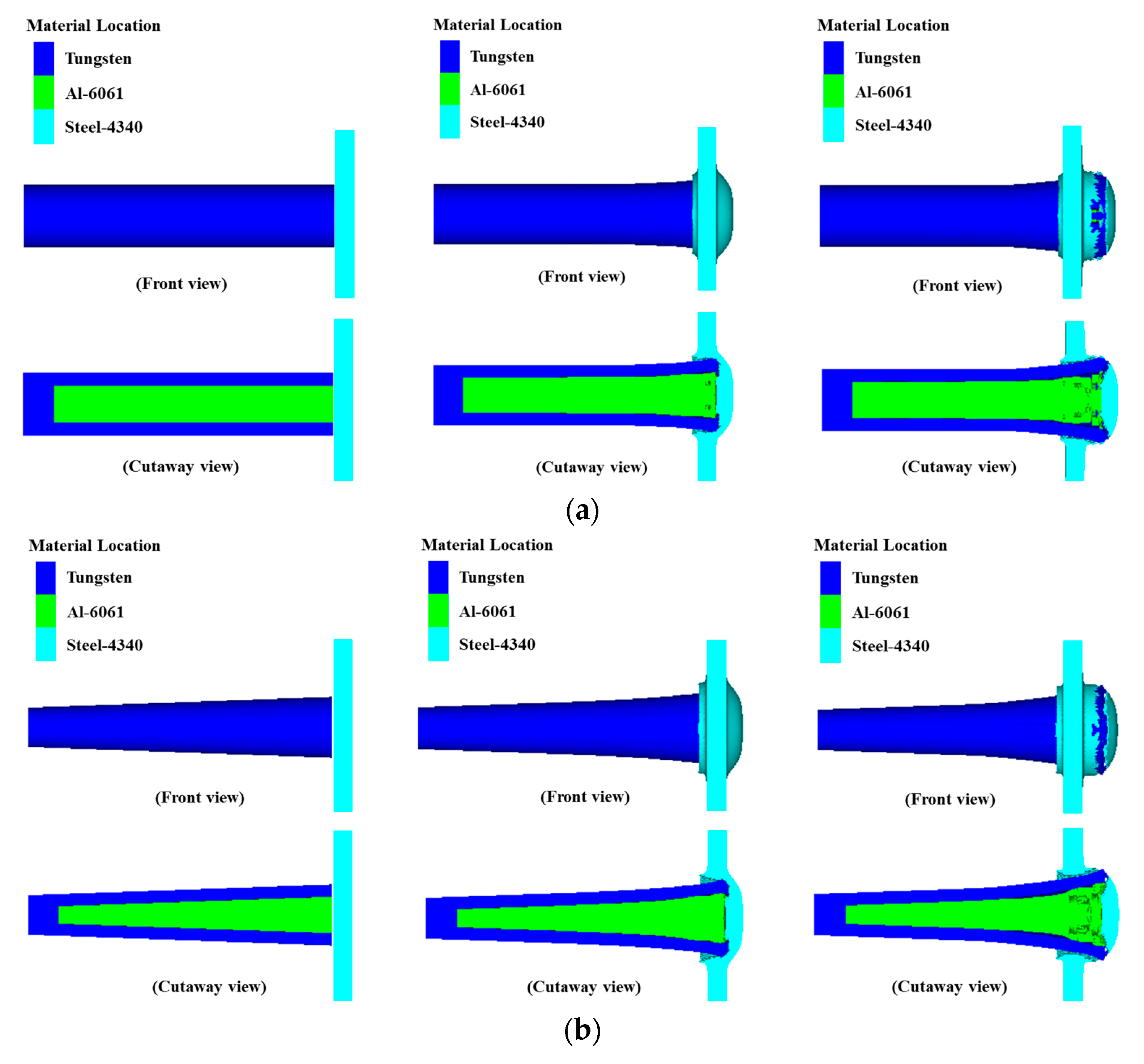

Figure 10. From

Figure 10, the residual length of the truncated cone-shaped PELE projectile and the conventional PELE projectile before impacting the after-effect target can be qualitatively observed, and then the fragment conversion rate of the projectile can be roughly estimated. In addition, it can also be found that the fragment size and the fragment dispersion form of the two types of projectiles are also different. The fragments of the truncated cone-shaped PELE projectile are larger and more scattered, while the fragments of conventional PELE projectile are smaller and more concentrated. Therefore, it can be qualitatively predicted that the damage area radius of the truncated cone-shaped PELE projectile to the after-effect target is larger than that of the conventional PELE projectile. Of course, this conclusion is subject to confirmation from the quantitative analysis below.

At the same time, the axial residual lengths of the projectile body corresponding to several working conditions were counted, and the fragment conversion rates corresponding to different working conditions were also calculated according to the formulas of fragment conversion rate (Formula (19)–Formula (24)), as shown in

Table 6.

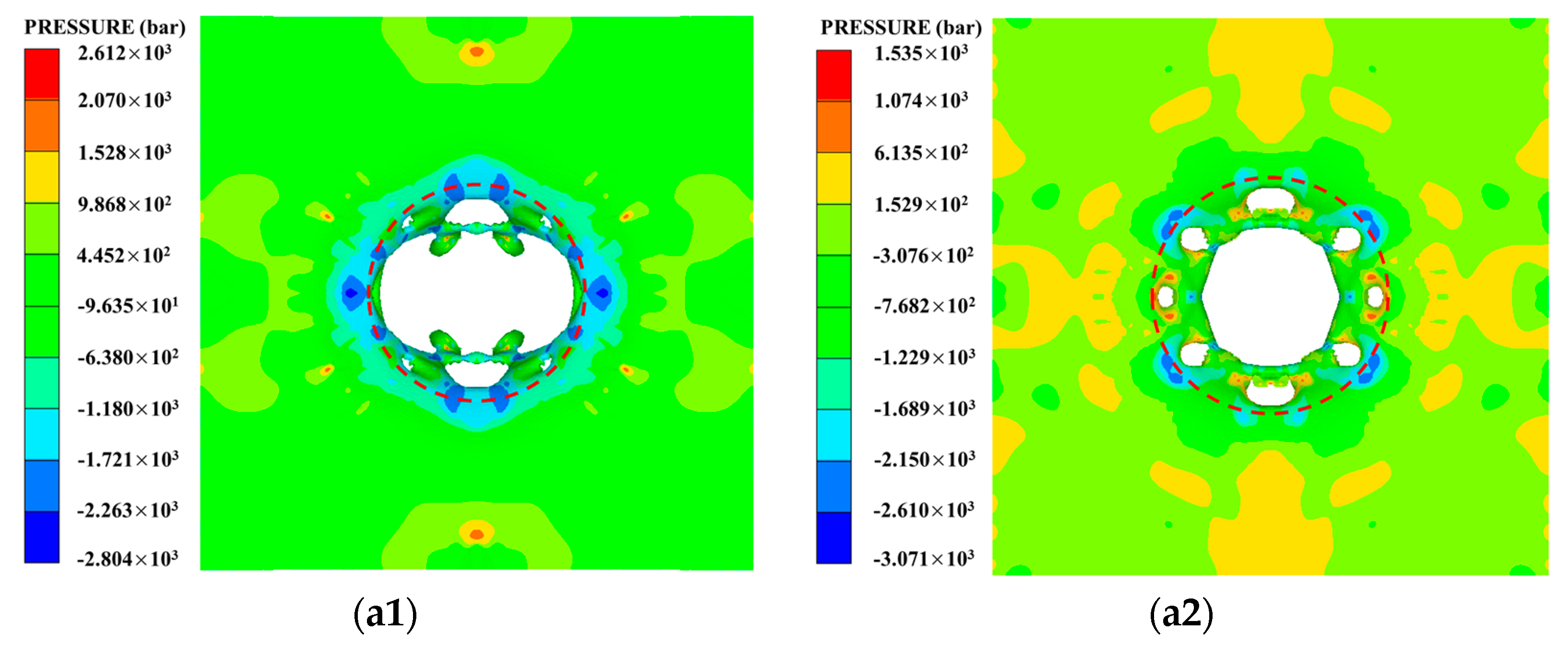

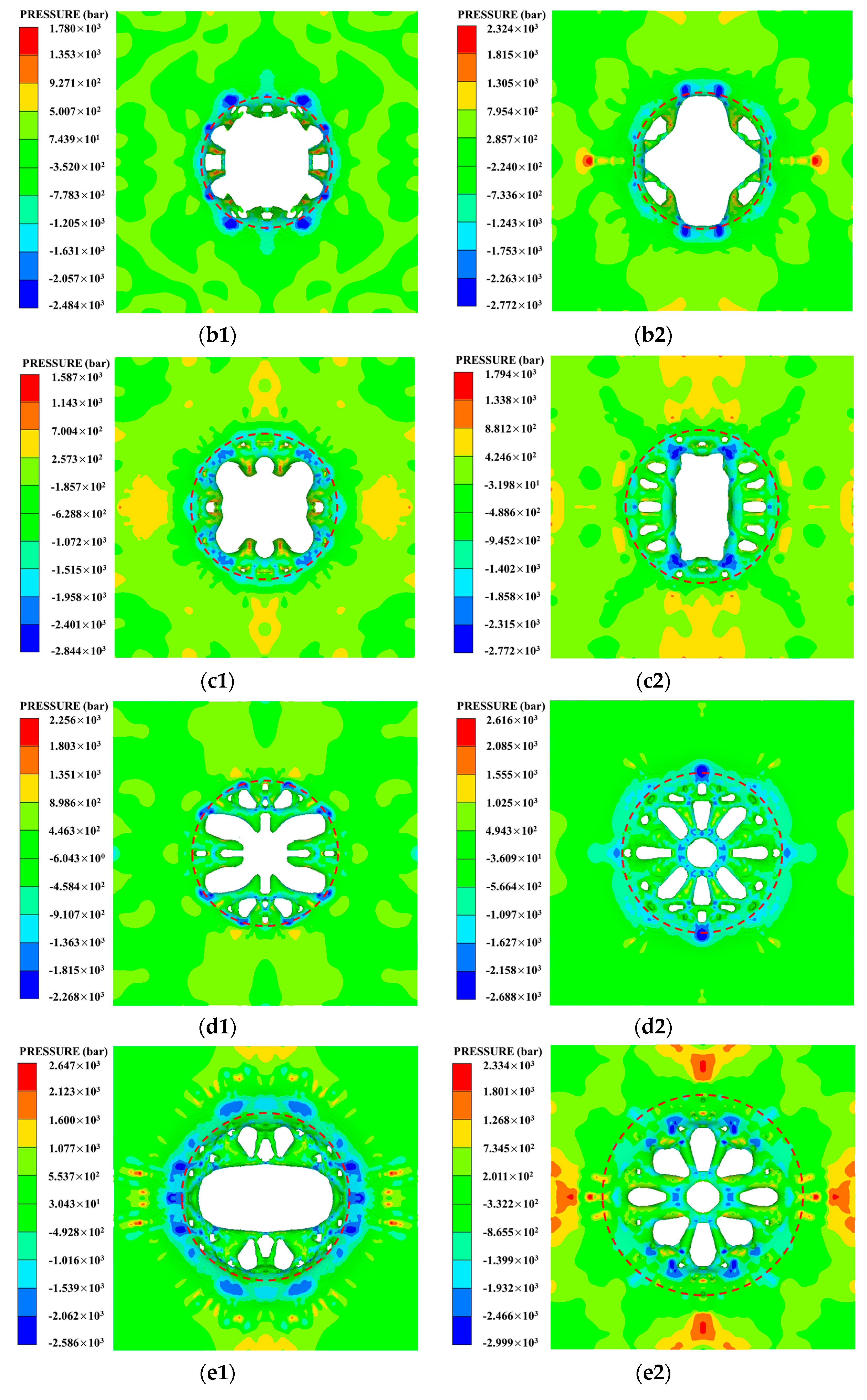

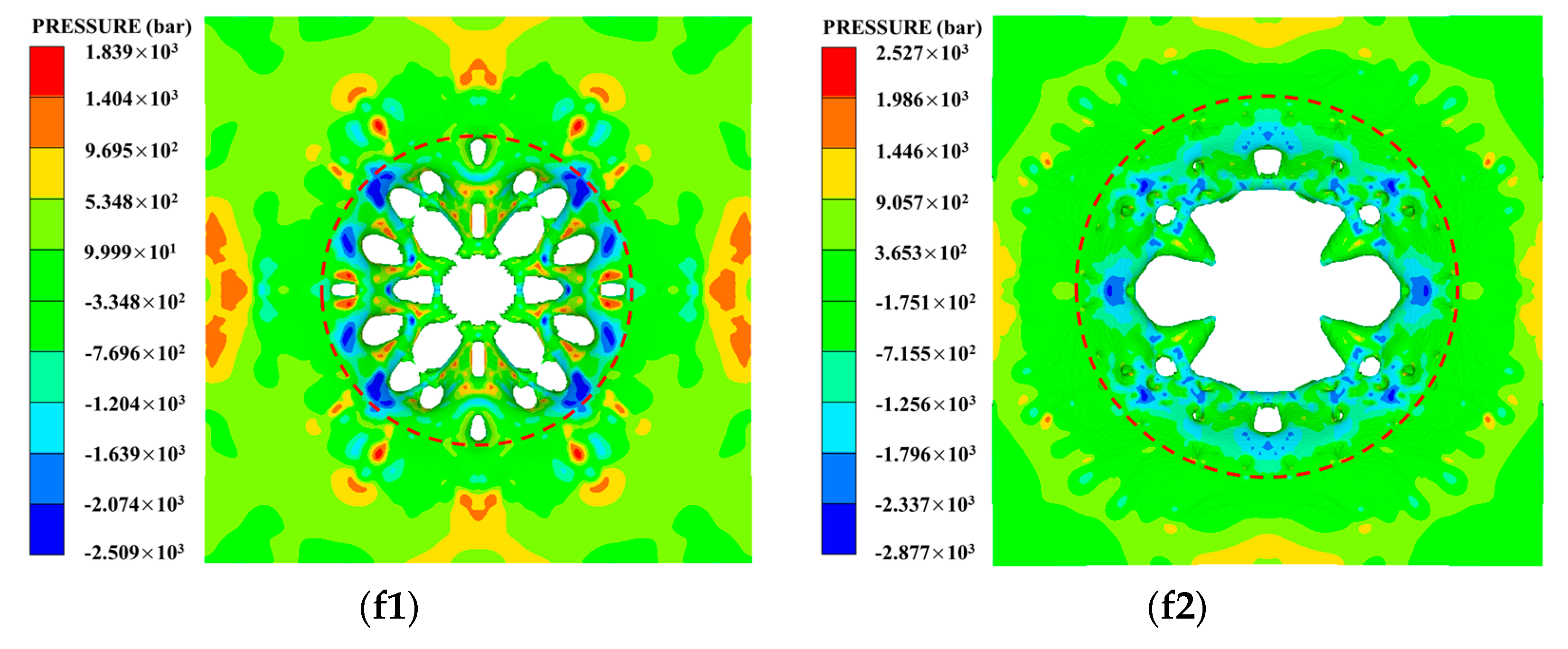

The fragment conversion rate of the PELE projectile is an important index to measure fragment effect; the size (mass) of the fragment and the radial velocity of the fragment should be taken into account in the evaluation of target damage level. If the fragment conversion rate of the projectile is higher but the radial velocity of fragment is lower, the fragment group will be relatively concentrated in the circumferential direction, so that the damage area radius of the target plate is smaller. Similarly, if the fragment conversion rate of the projectile is higher but the fragment size (mass) is smaller, the perforation area of the target plate is smaller, which is also not conducive to improving the damage level. Therefore, the target damage situations of each group of working conditions were analyzed, and the corresponding target damage diagrams of each group of working conditions were obtained as shown in

Figure 11. Since the working conditions studied in this section involve different projectile velocities, different target materials, and different target thickness, the damage area radius of target was regarded as the main criterion in the analysis of target damage rather than the perforation area of target. In addition,

R is defined to represent the damage area radius of the after-effect target, the damage area of the target is marked with red dotted circle, and the pits and perforations of the target plate were both regarded as damage to the target. The damage area radius of each working condition in

Figure 11 was counted, as shown in

Table 7.

Obviously, the two important parameters (fragment conversion rate

η and damage area radius

R) have been obtained, as shown in

Table 6 and

Table 7. In order to better compare and analyze the fragmentation effect of the truncated cone-shaped PELE projectile and the conventional PELE projectile, the fragment conversion rate and damage area radius corresponding to each working condition were integrated and compared, as shown in

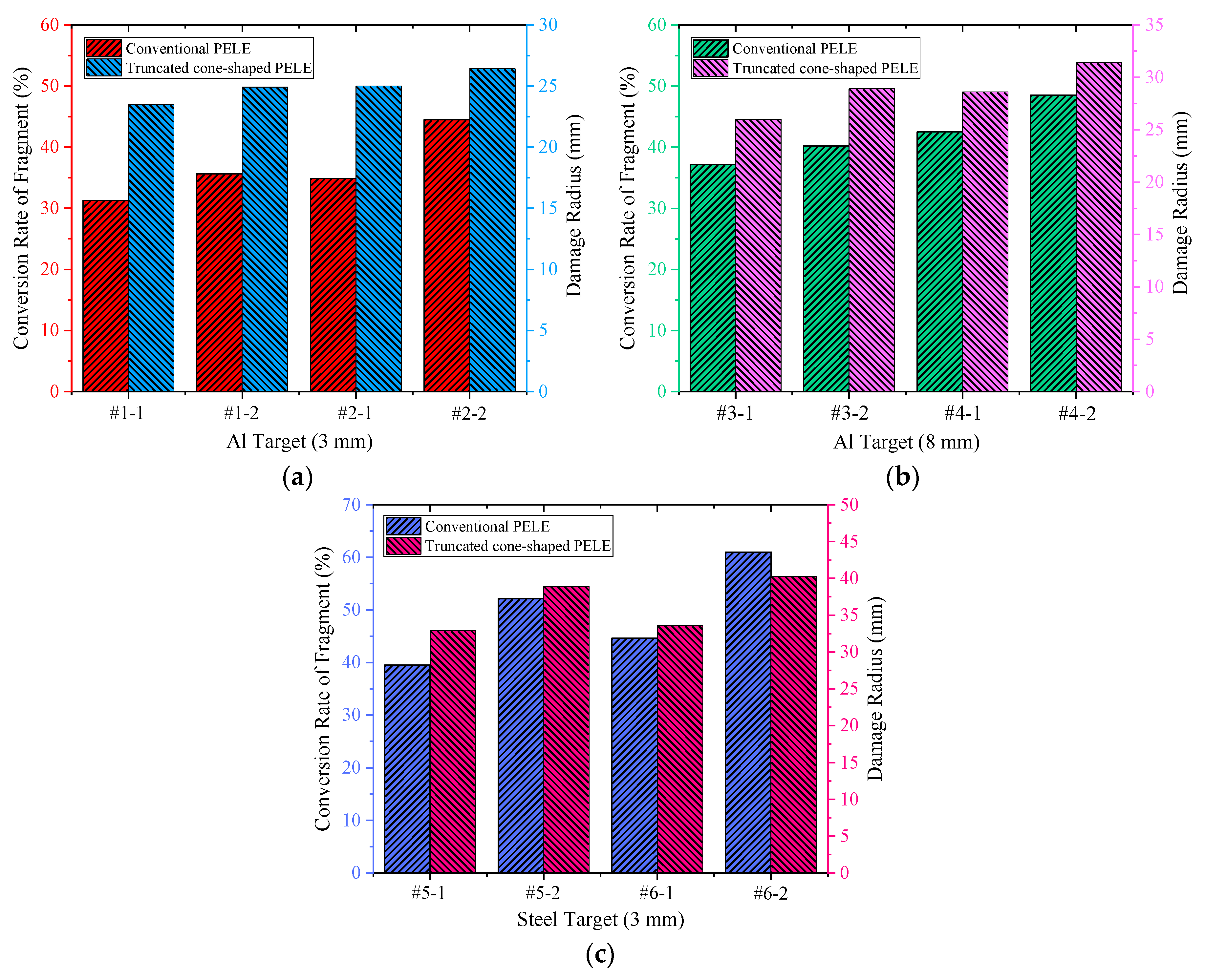

Figure 12.

From the histogram shown in

Figure 12, it can be seen that under the condition of the same initial kinetic energy of projectile and the same thickness and material of the target plate, the fragment conversion rate

η and the damage area radius

R of the truncated cone-shaped PELE projectile are obviously larger than that of the conventional PELE projectile. The above phenomenon can be explained from the following two aspects.

(1) Under the same initial kinetic energy, the mass of truncated cone-shaped PELE projectile is slightly less than that of conventional PELE projectile, so the initial velocity of truncated cone-shaped PELE projectile is slightly higher than that of conventional PELE projectile. The radial dispersion velocity of fragments is positively correlated with the axial velocity of the projectile body.

(2) According to the design idea of truncated cone-shaped PELE projectile, the angle between the busbar and axis of the truncated cone-shaped PELE projectile is greater than 0°, which means that the fragments have an initial deflection angle greater than 0° before formation. As a result, the deflection angle of the fragments during the actual scattering process are greatly improved to some extent.

According to the action mechanism of the PELE projectile, the fragments generated during the penetration process will obtain radial velocity, and the larger the radial velocity and deflection angle, the larger the damage radius of fragments. In short, the above results indicate that the fragmentation effect of the truncated cone-shaped PELE projectile is better than that of the conventional PELE projectile.