Damage to the Microstructure and Strength of Altered Granite under Wet–Dry Cycles

Abstract

:1. Introduction

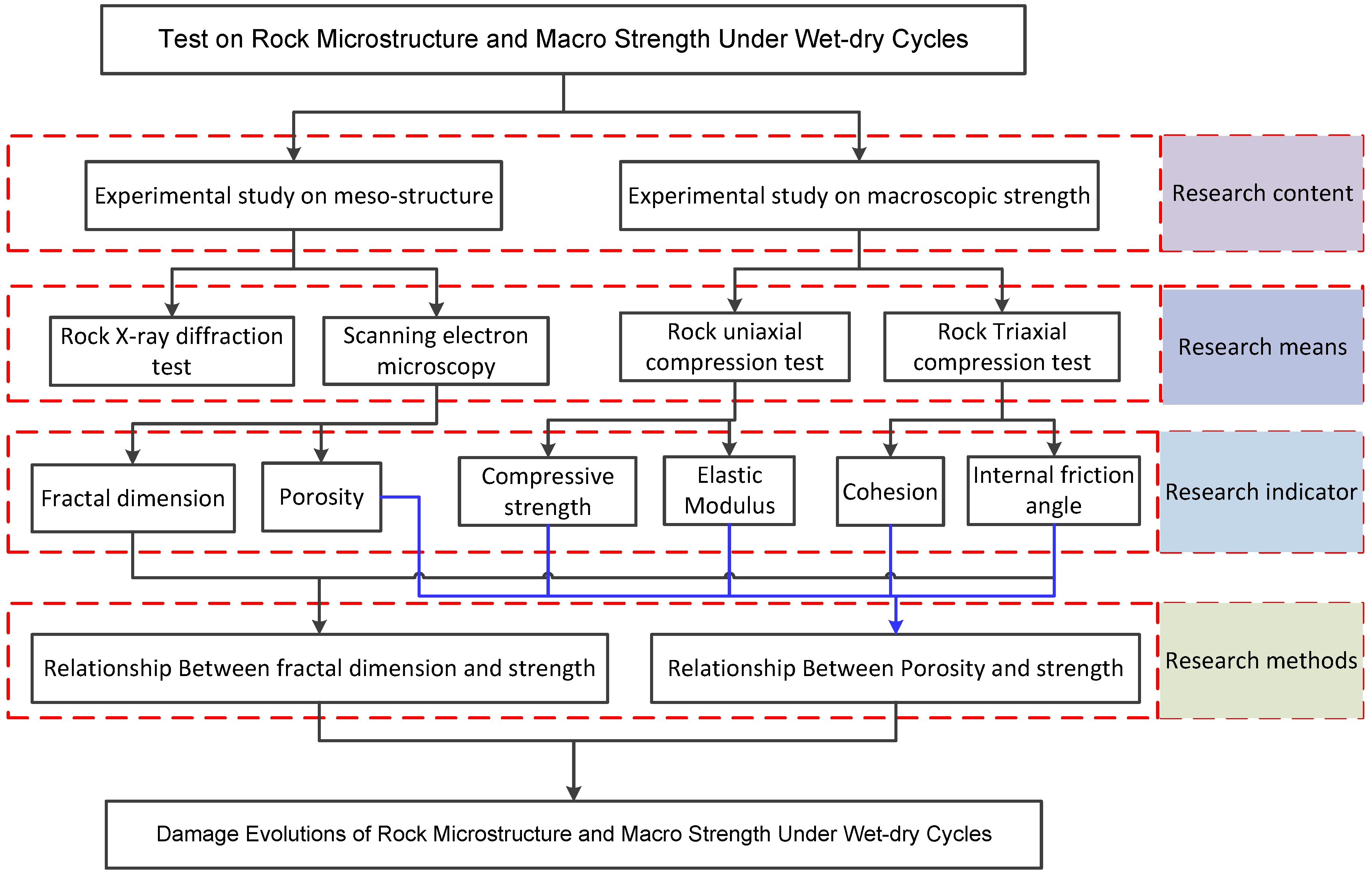

2. Materials and Methods

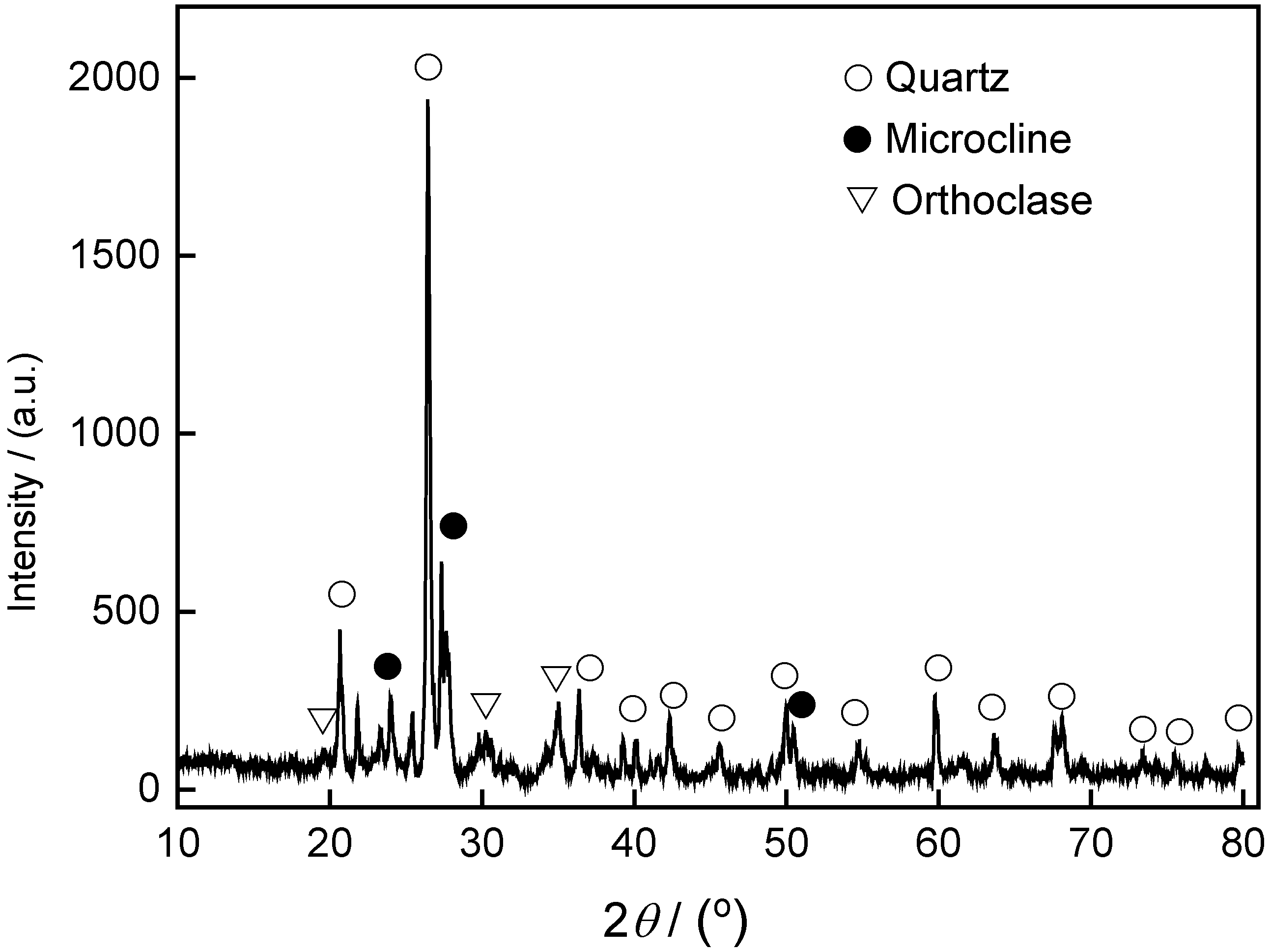

2.1. Engineering Geology

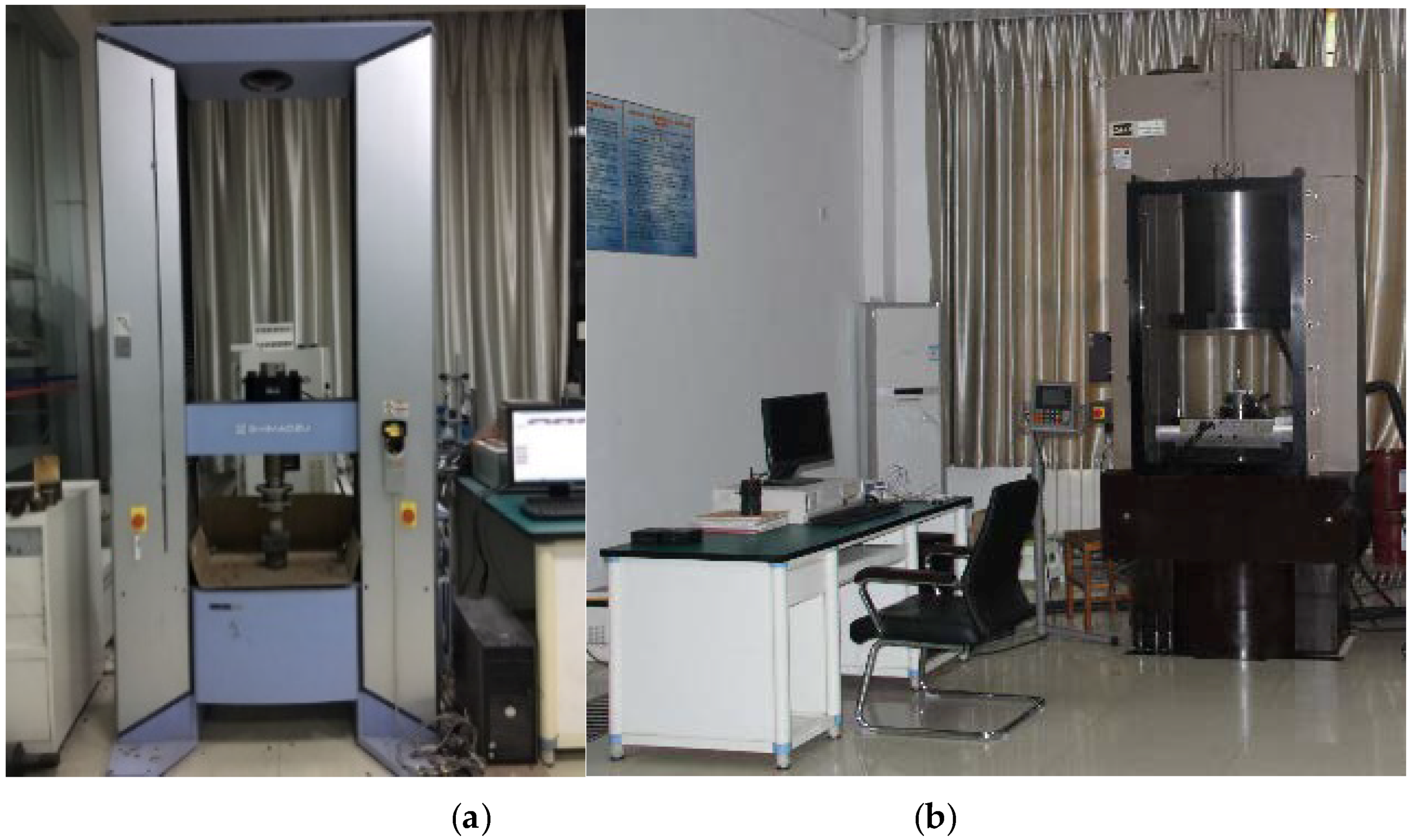

2.2. Rock Compressive Tests

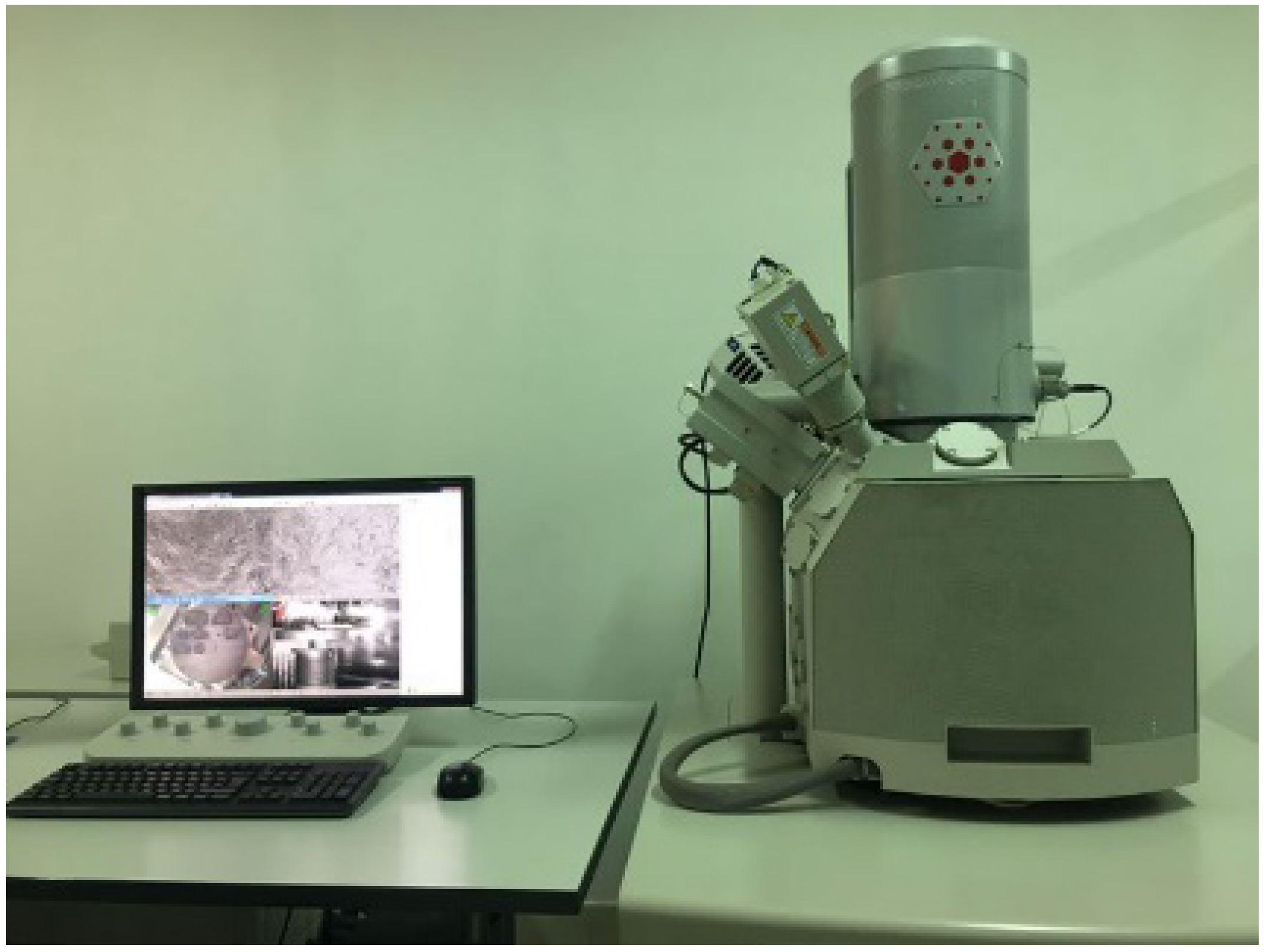

2.3. Analysis of Microstructure Using SEM

3. Results

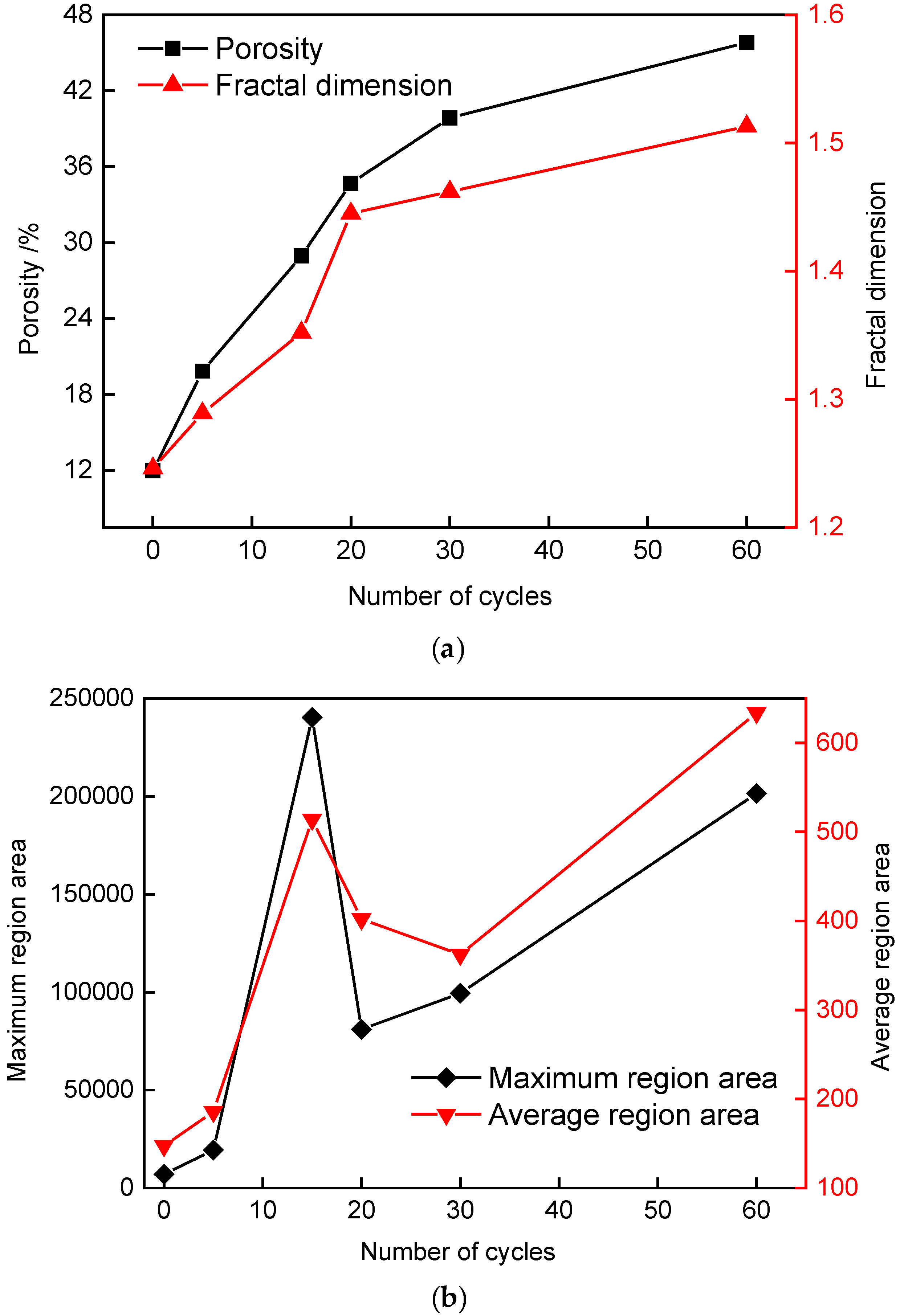

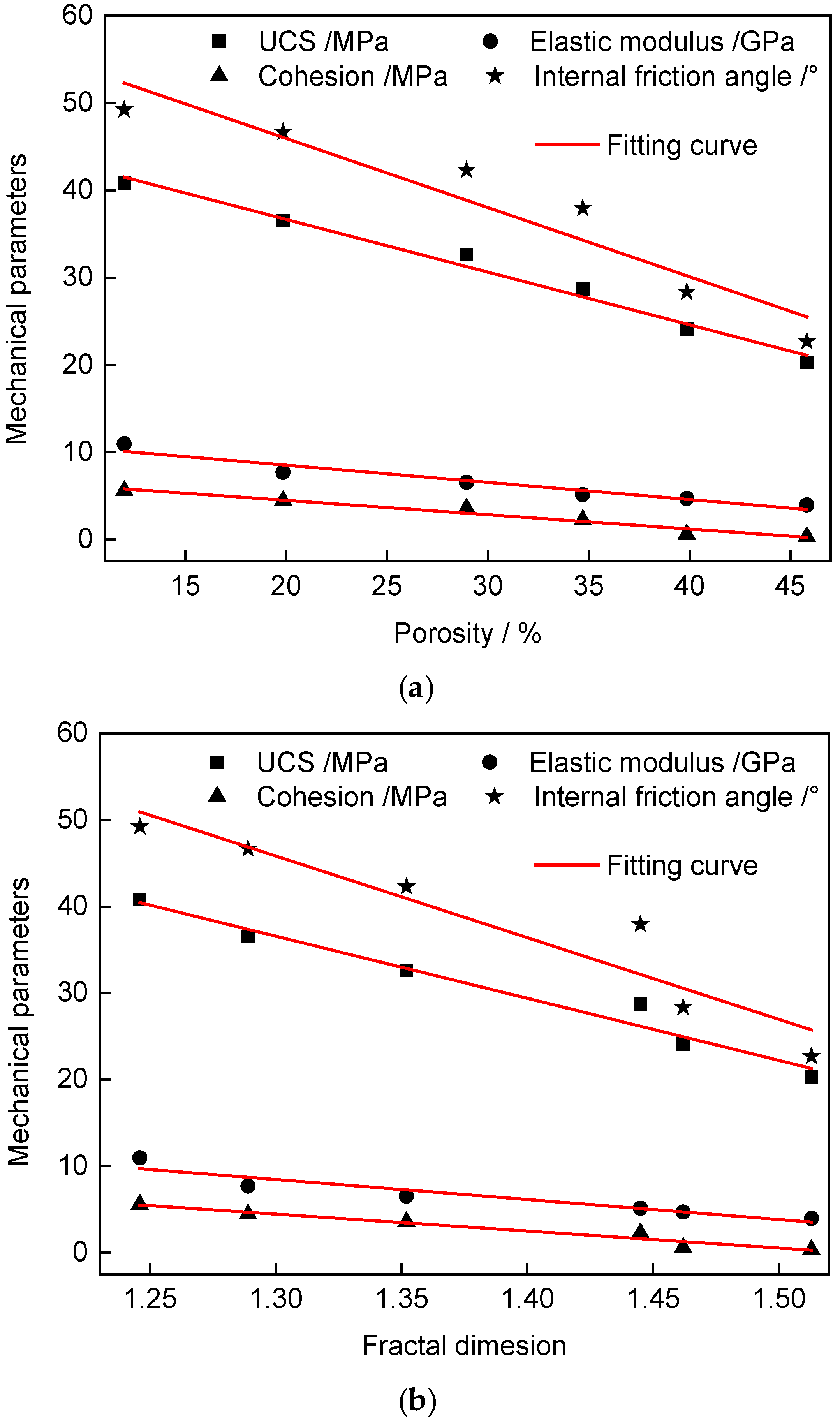

3.1. Rock Mechanics Test Results

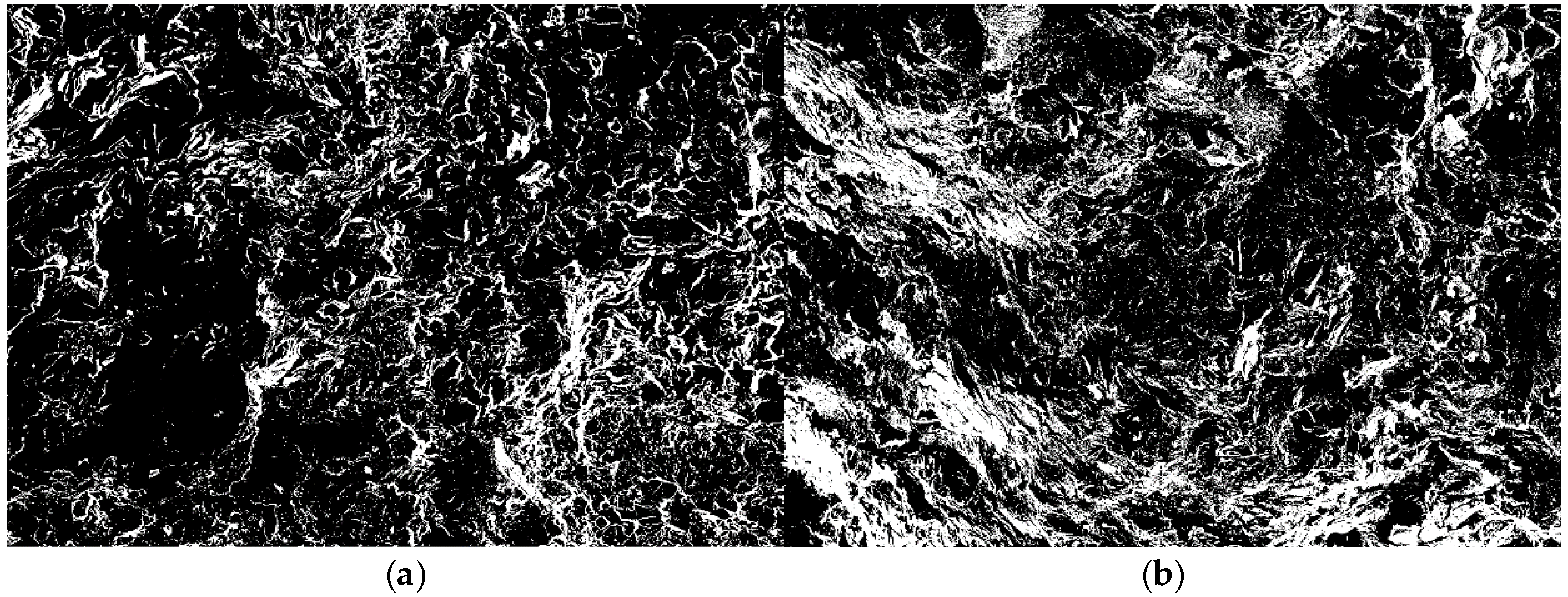

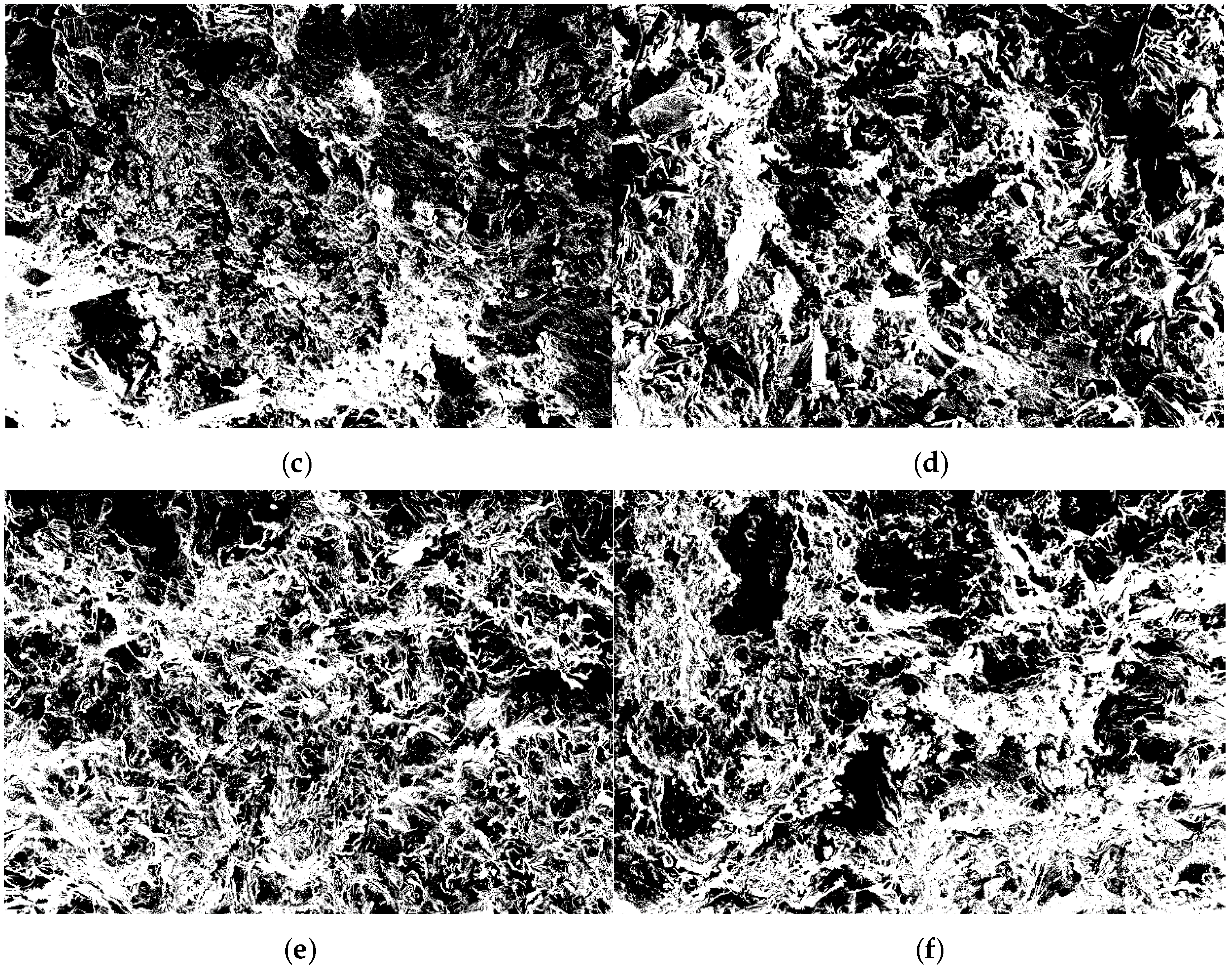

3.2. Rock’s SEM Results

4. Discussion

4.1. Relationship between Strength and Micro-Parameters

4.2. Damage Mechanism under Dry and Wet Cycles

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akcanca, F.; Aytekin, M. Impact of wetting–drying cycles on the hydraulic conductivity of liners made of lime-stabilized sand–bentonite mixtures for sanitary landfills. Environ. Earth Sci. 2014, 72, 59–66. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Guo, T.C.; Ning, Z.Y. Numerical Modeling of Stability of Fractured Reservoir Bank Slopes Subjected to Water–Rock Interactions. Rock Mech. Rock Eng. 2017, 51, 2517–2531. [Google Scholar] [CrossRef]

- Kassab, M.A.; Weller, A. Study on P-wave and S-wave velocity in dry and wet sandstones of Tushka region, Egypt. Egypt. J. Pet. 2015, 24, 1–11. [Google Scholar] [CrossRef]

- Waragai, T. The effect of rock strength on weathering rates of sandstone used for Angkor temples in Cambodia. Eng. Geol. 2016, 207, 24–35. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Yang, J.; Zhang, D.F. Effects of Wetting and Cyclic Wetting–Drying on Tensile Strength of Sandstone with a Low Clay Mineral Content. Rock Mech. Rock Eng. 2016, 50, 485–491. [Google Scholar] [CrossRef]

- Liu, X.R.; Zhang, L.; Fu, Y. Experimental study of mechanical properties of argillaceous sandstone under wet and dry cycle in acid environment. Rock Soil Mech. 2014, 35, 45–52. [Google Scholar]

- Özbek, A. Investigation of the effects of wetting–drying and freezing–thawing cycles on some physical and mechanical properties of selected ignimbrites. Bull. Eng. Geol. Environ. 2014, 73, 595–609. [Google Scholar] [CrossRef]

- Khanlari, G.; Abdilor, Y. Influence of wet-dry, freeze-thaw, and heat-cool cycles on the physical and mechanical properties of Upper Red sandstones in central Iran. Bull. Eng. Geol. Environ. 2015, 74, 1287–1300. [Google Scholar] [CrossRef]

- Qin, Z.; Chen, X.X.; Fu, H.L. Damage Features of Altered Rock Subjected to Drying-Wetting Cycles. Adv. Civ. Eng. 2018, 2018, 5170832. [Google Scholar] [CrossRef]

- Chen, X.X.; Gong, Y.P. Features of Shear Strength Parameters Reflecting Damage to Rock Caused by Water Invasion-Loss Cycles. Geotech. Geol. Eng. 2018. [Google Scholar] [CrossRef]

- Ciantia, M.O.; Castellanza, R.; Prisco, C.D. Experimental Study on the Water-Induced Weakening of Calcarenites. Rock Mech. Rock Eng. 2015, 48, 441–461. [Google Scholar] [CrossRef]

- Stoltz, G.; Cuisinier, O.; Masrouri, F. Weathering of a lime-treated clayey soil by drying and wetting cycles. Eng. Geol. 2014, 181, 281–289. [Google Scholar] [CrossRef]

- Bian, K.; Liu, J.; Zhang, W.; Zheng, X.Q.; Ni, S.H.; Liu, Z.P. Mechanical behavior and damage constitutive model of rock subjected to water-weakening effect and uniaxial loading. Rock Mech. Rock Eng. 2018. [Google Scholar] [CrossRef]

- Doostmohammadi, R.; Moosavi, M.; Mutschler, T.; Osan, C. Influence of cyclic wetting and drying on swelling behavior of mudstone in south west of Iran. Environ. Geol. 2009, 58, 999–1009. [Google Scholar] [CrossRef]

- Maximiliano, R.V.; Theodoros, T. Swelling behavior of volcanic rocks under cyclic wetting and drying. Int. J. Rock Mech. Min. Sci. 2015, 80, 231–240. [Google Scholar]

- Kalkan, E. Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume. Appl. Clay Sci. 2011, 52, 345–352. [Google Scholar] [CrossRef]

- Xie, K.N.; Jiang, D.Y.; Sun, Z.G. NMR, MRI and AE Statistical Study of Damage due to a Low Number of Wetting–Drying Cycles in Sandstone from the Three Gorges Reservoir Area. Rock Mech. Rock Eng. 2018. [Google Scholar] [CrossRef]

- Al-Mahrooqi, S.H.; Grattoni, C.A.; Moss, A.K. An investigation of the effect of wettability on NMR characteristics of sandstone rock and fluid systems. J. Pet. Sci. Eng. 2003, 39, 389–398. [Google Scholar] [CrossRef]

- Salvoni, M.; Dight, P.M. Rock damage assessment in a large unstable slope from microseismic monitoring-MMG Century mine (Queensland, Australia) case study. Eng. Geol. 2016, 210, 45–56. [Google Scholar] [CrossRef]

- Saksala, T. Modelling of Dynamic Rock Fracture Process with a Rate-Dependent Combined Continuum Damage-Embedded Discontinuity Model Incorporating Microstructure. Rock Mech. Rock Eng. 2016, 49, 3947–3962. [Google Scholar] [CrossRef]

- Liu, C.; Tang, C.S.; Shi, B.; Suo, W.B. Automatic quantification of crack patterns by image processing. Comput. Geosci. 2013, 57, 77–80. [Google Scholar] [CrossRef]

- Liu, C.; Pollard, D.D.; Aydin, A.; Deng, S. Mechanism of Formation of Wiggly Compaction Bands in Porous Sandstone: 1. Observations and Conceptual Model. J. Geophys. Res. 2015, 120, 8138–8152. [Google Scholar] [CrossRef]

| Number of Cycles | Compressive Strength/MPa | Elastic Modulus/GPa | Cohesion/MPa | Internal Friction Angle φ/° |

|---|---|---|---|---|

| 0 | 40.80 | 10.98 | 5.61 | 49.24 |

| 5 | 36.54 | 7.71 | 4.45 | 46.67 |

| 15 | 32.63 | 6.56 | 3.58 | 42.30 |

| 20 | 28.72 | 5.15 | 2.28 | 37.95 |

| 30 | 24.11 | 4.71 | 0.62 | 28.37 |

| 60 | 20.31 | 3.97 | 0.35 | 22.70 |

| Number of Cycles | Porosity/% | Fractal Dimension | Maximum Region Area | Average Region Area |

|---|---|---|---|---|

| 0 | 11.96 | 1.246 | 7002 | 147.39 |

| 5 | 19.84 | 1.289 | 19,365 | 185.79 |

| 15 | 28.94 | 1.352 | 240,247 | 513.94 |

| 20 | 34.70 | 1.445 | 81,021 | 402.04 |

| 30 | 39.86 | 1.462 | 99,429 | 362.23 |

| 60 | 45.82 | 1.513 | 201,454 | 633.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; He, P.; Qin, Z. Damage to the Microstructure and Strength of Altered Granite under Wet–Dry Cycles. Symmetry 2018, 10, 716. https://doi.org/10.3390/sym10120716

Chen X, He P, Qin Z. Damage to the Microstructure and Strength of Altered Granite under Wet–Dry Cycles. Symmetry. 2018; 10(12):716. https://doi.org/10.3390/sym10120716

Chicago/Turabian StyleChen, Xuxin, Ping He, and Zhe Qin. 2018. "Damage to the Microstructure and Strength of Altered Granite under Wet–Dry Cycles" Symmetry 10, no. 12: 716. https://doi.org/10.3390/sym10120716

APA StyleChen, X., He, P., & Qin, Z. (2018). Damage to the Microstructure and Strength of Altered Granite under Wet–Dry Cycles. Symmetry, 10(12), 716. https://doi.org/10.3390/sym10120716