A GIS-Based Multicriteria Index to Evaluate the Mechanisability Potential of Italian Vineyard Area

Abstract

1. Introduction

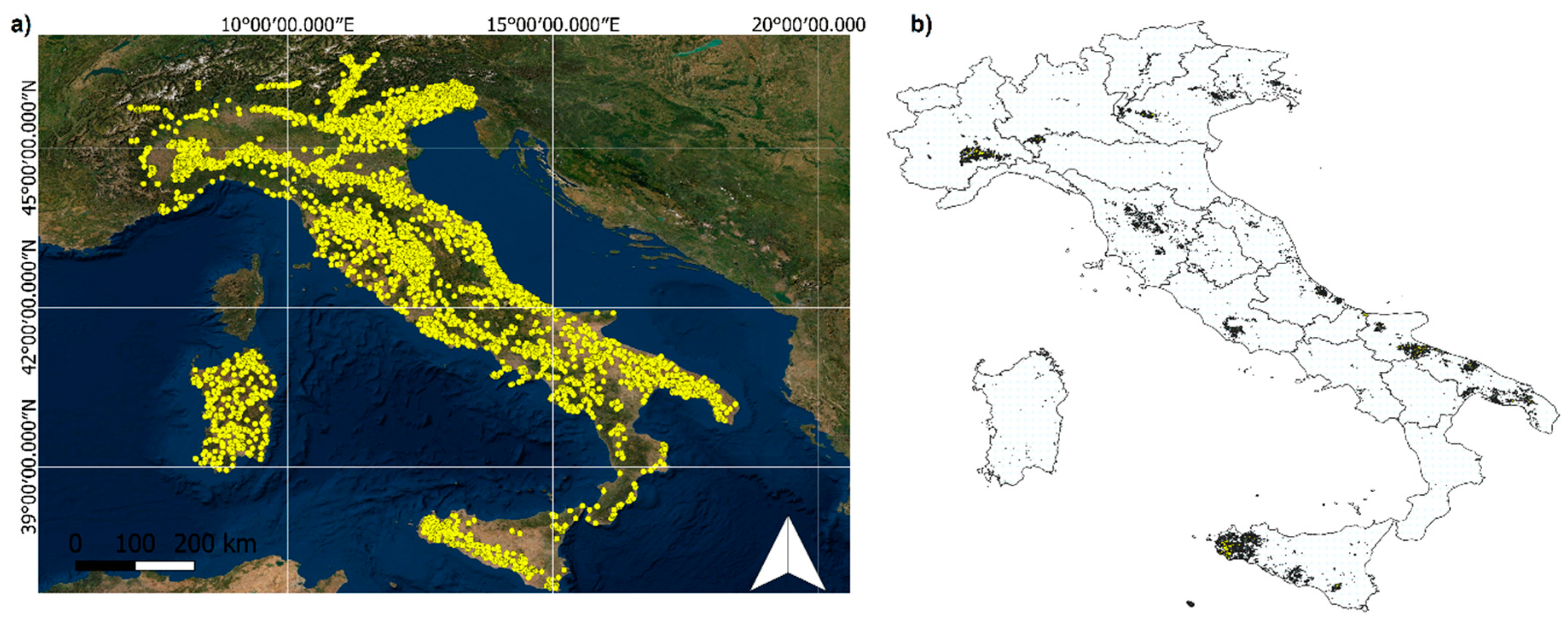

2. Materials and Methods

2.1. Slope

2.2. Vineyard Block Shape and Length-Width Ratio

2.3. Headland Size

2.4. Training System

2.5. Row Spacing

2.6. Level of Mechanisability and Economic Indicators

3. Results

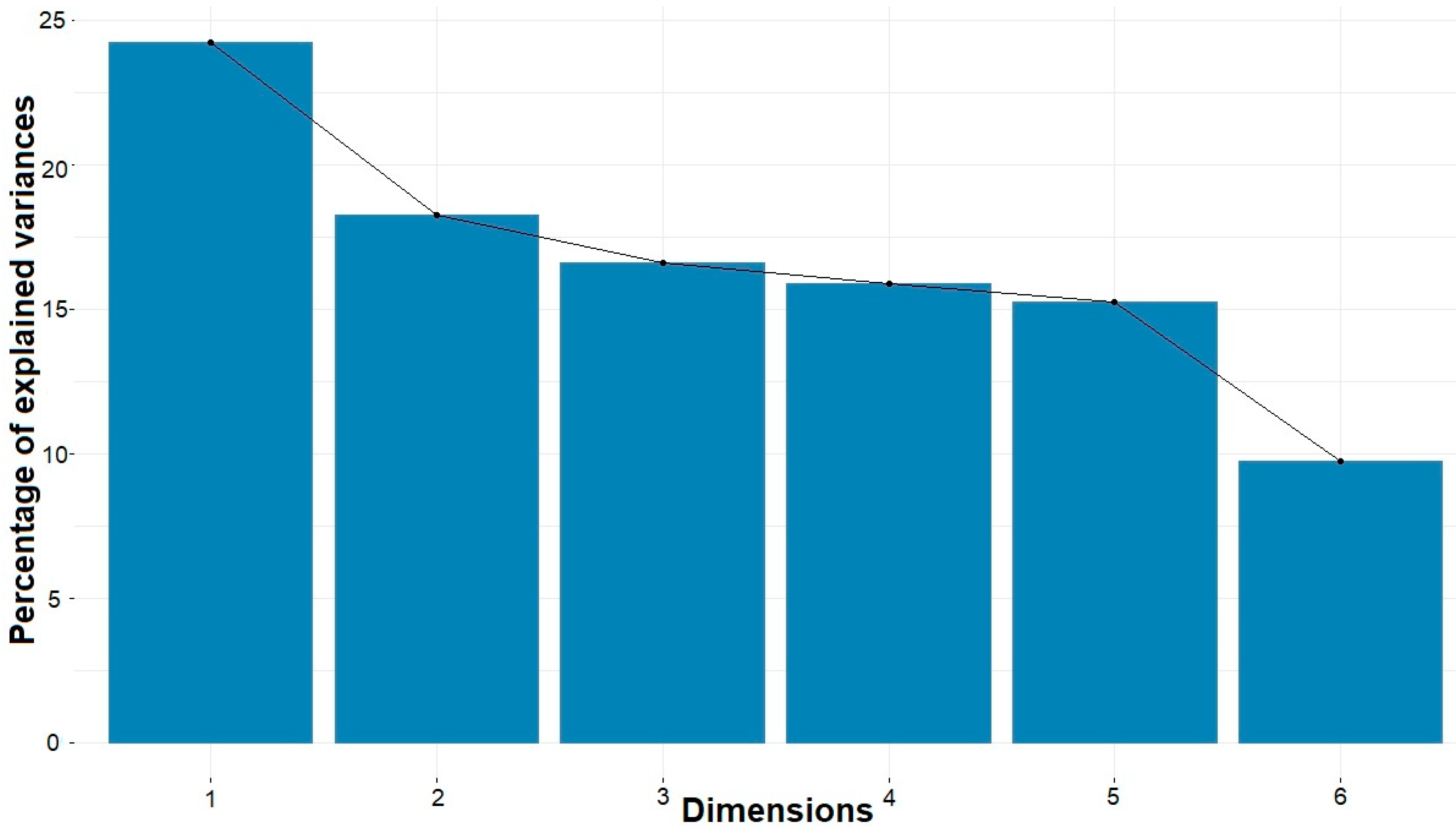

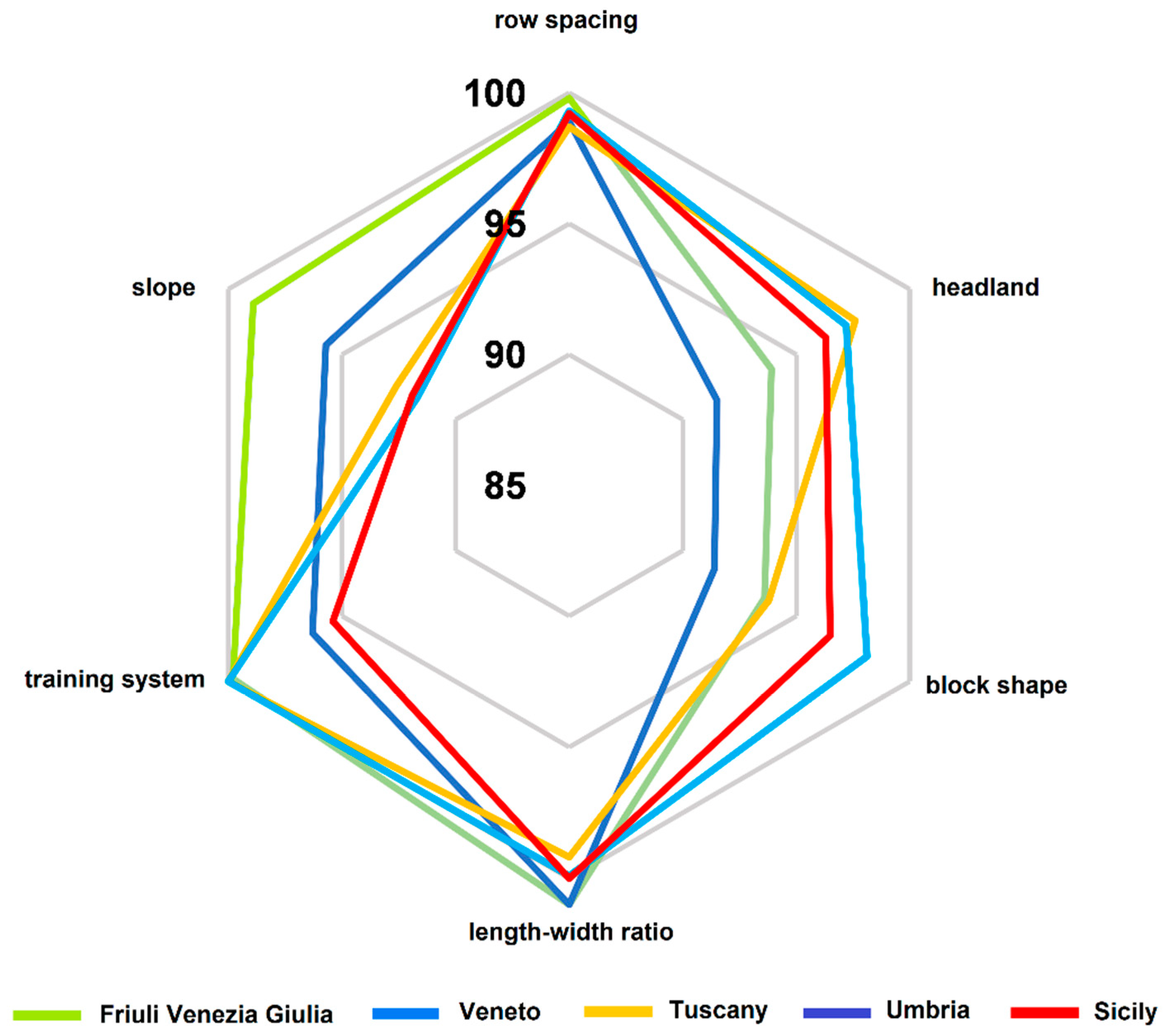

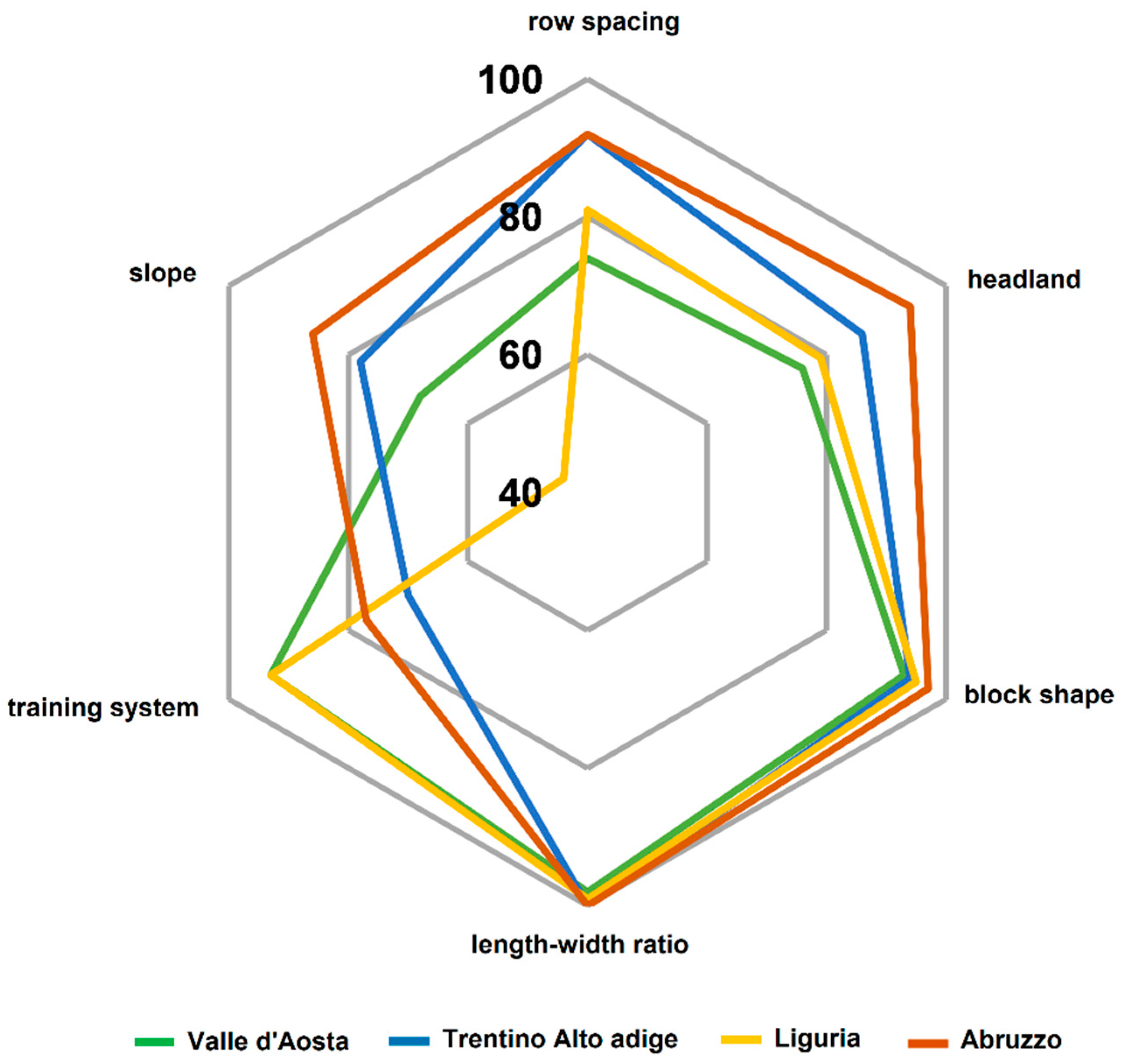

3.1. Preliminary Analysis of the Contributing Parameters

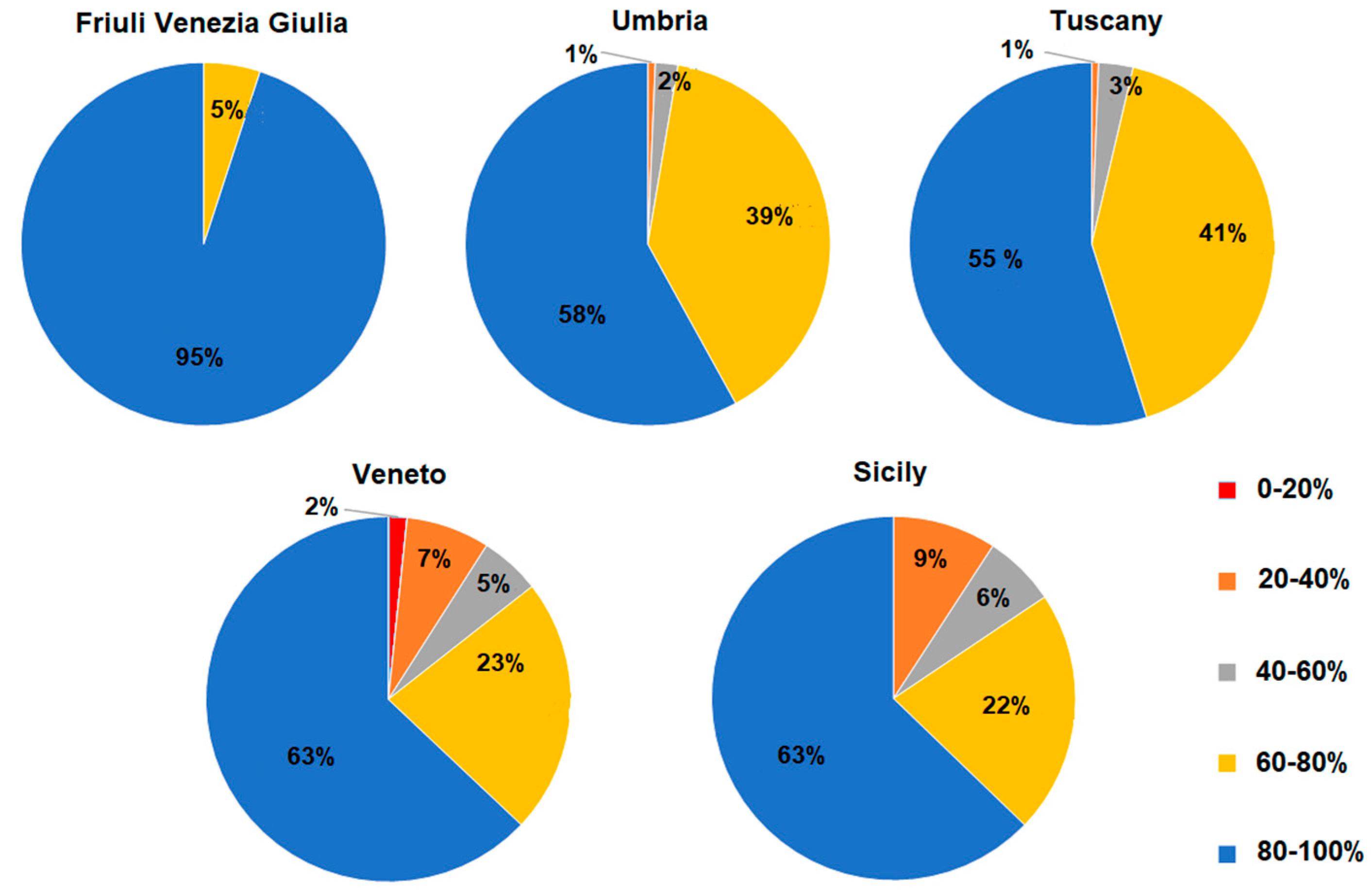

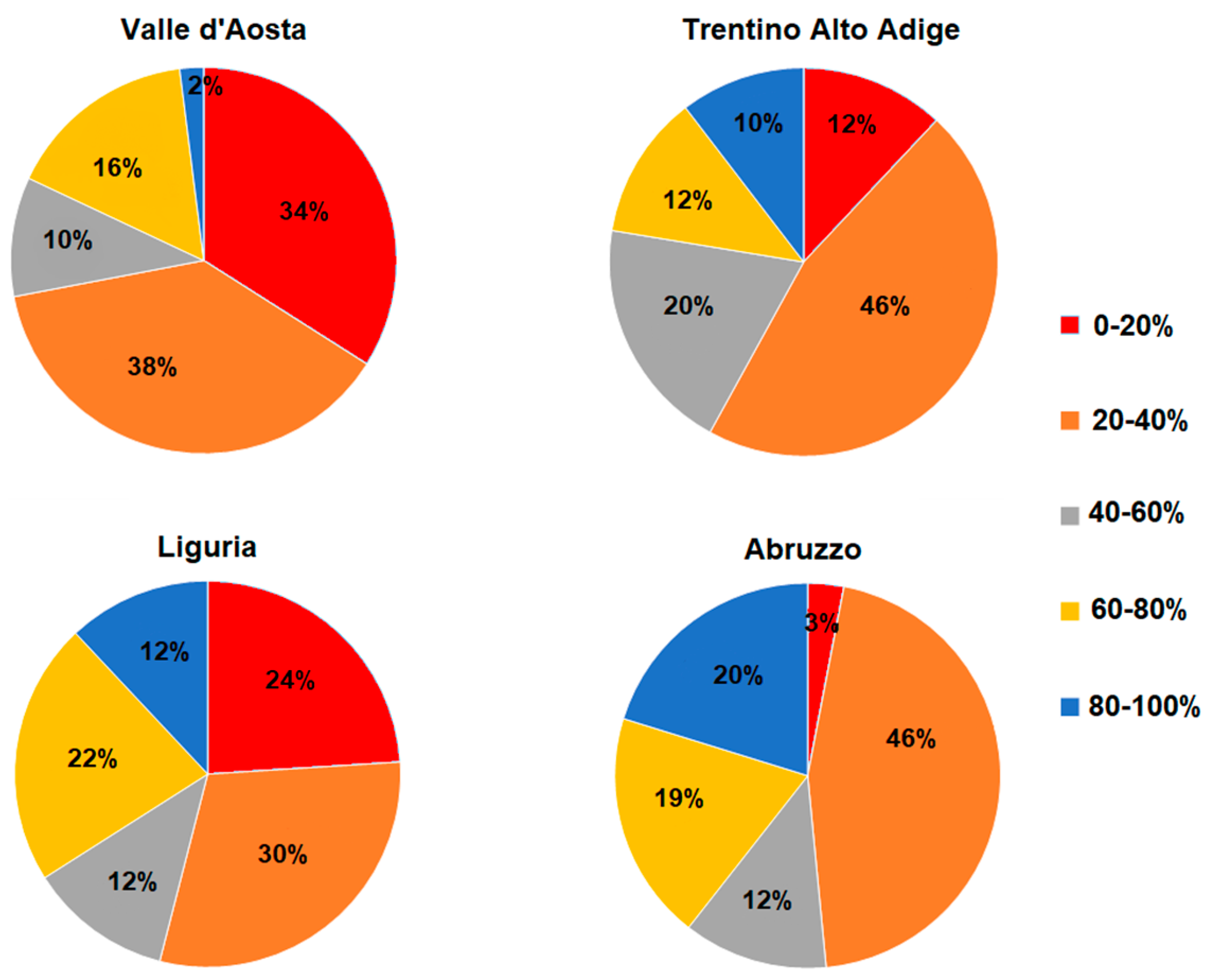

3.2. Level of Mechanisability of Italian Viticultural Areas

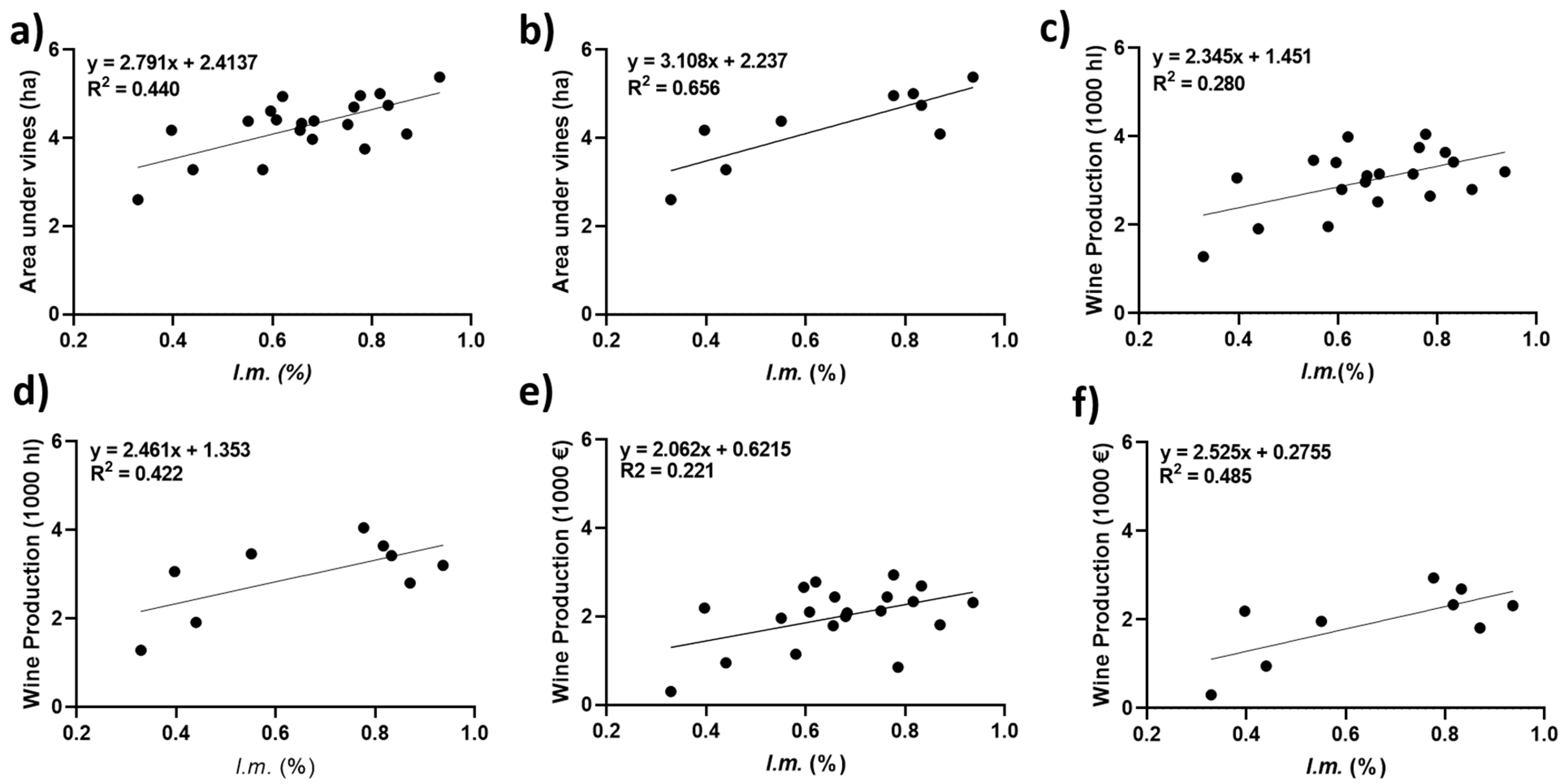

3.3. Correlation between Mechanisability Potential and Economic Indicators

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kristensen, S.B.P.; Busck, A.G.; van der Sluis, T.; Gaube, V. Patterns and drivers of farm-level land use change in selected European rural landscapes. Land Use Policy 2016, 57, 786–799. [Google Scholar] [CrossRef]

- Cervelli, E.; di Perta, E.S.; Pindozzi, S. Identification of marginal landscapes as support for sustainable development: GIS-Based Analysis and Landscape Metrics Assessment in Southern Italy Areas. Sustainability 2020, 12, 5400. [Google Scholar] [CrossRef]

- Gazel, M.; Önelge, N. First report of grapevine viroids in the east Mediterranean region of Turkey. Plant Pathol. 2003, 52, 405. [Google Scholar] [CrossRef]

- Santillán, D.; Garrote, L.; Iglesias, A.; Sotes, V. Climate change risks and adaptation: New indicators for Mediterranean viticulture. Mitig. Adapt. Strat. Glob. Chang. 2019, 1–19. [Google Scholar] [CrossRef]

- Tudisca, S.; Di Trapani, A.M.; Sgroi, F.; Testa, R. The cost advantage of sicilian wine farms. Am. J. Appl. Sci. 2013, 10, 1529–1536. [Google Scholar] [CrossRef]

- Bates, T.; Morris, J. Mechanical cane pruning and crop adjustment decreases labor costs and maintains fruit quality in New York “concord” grape production. Horttechnology 2009, 19, 247–253. [Google Scholar] [CrossRef]

- Kurtural, S.K.; Dervishian, G.; Wample, R.L. Mechanical canopy management Reduces labor costs and maintains fruit composition in “Cabernet sauvignon” grape production. Horttechnology 2012, 22, 509–516. [Google Scholar] [CrossRef]

- Kurtural, S.K.; Beebe, A.E.; Martınez-Luscher, J.; Zhuang, S.; Lund, K.T.; McGourty, G.; Bettiga, L.J. Conversion to mechanical pruning in vineyards maintains fruit composition while reducing labor costs in ‘merlot’ grape production. Horttechnology 2019, 29, 129–139. [Google Scholar] [CrossRef]

- Intrieri, C.; Poni, S. Integrated Evolution of Trellis Training Grape Quality and Vintage Quality of Mechanized Italian Vineyards. Am. J. Enol. Vitic. 1995, 46, 116–127. [Google Scholar]

- Keller, M.; Mills, L.J.; Wample, R.L.; Spayd, S.E. Crop load management in concord grapes using different pruning techniques. Am. J. Enol. Vitic. 2004, 55, 35–50. [Google Scholar]

- Intrieri, C. Research and Innovations for Vineyard Mechanization in Italy. In Proceedings of the Justin R. Morris Vineyard Mechanization Symposium-Midwest Grape and Wine Conference, Osage Beach, MI, USA, 2–3 February 2008; pp. 33–52. [Google Scholar]

- Nowacki, T. Methodology Used by ECE Countries in Forecasting Mechanization Developments; AGRI/MECH Report No. 74; United Nations Economic Commission for Europe: Geneva, Switzerland, 1978. [Google Scholar]

- Singh, G. Estimation of a mechanisation index and its impact on production and economic factors—A case study in India. Biosyst. Eng. 2006, 93, 99–106. [Google Scholar] [CrossRef]

- Almassi, M.; Kiani, S.; Loveimi, N. Principles of Agricultural Mechanization; Hazrat Masomeh Publication: Qom, Iran, 2005. [Google Scholar]

- Priyadarshini, P.; Abhilash, P.C. Policy recommendations for enabling transition towards sustainable agriculture in India. Land Use Policy 2020, 96, 104718. [Google Scholar] [CrossRef]

- Ma, L.; Long, H.; Tu, S.; Zhang, Y.; Zheng, Y. Farmland transition in China and its policy implications. Land Use Policy 2020, 92. [Google Scholar] [CrossRef]

- Zangeneh, M.; Omid, M.; Akram, A. Assessment of agricultural mechanization status of potato production by means of Artificial Neural Network model. Aust. J. Crop Sci. 2010, 4, 372–377. [Google Scholar] [CrossRef]

- Sofia, G.; Marinello, F.; Tarolli, P. Metrics for quantifying anthropogenic impacts on geomorphology: Road networks. Earth Surf. Process. Landf. 2016, 41, 240–255. [Google Scholar] [CrossRef]

- Maheshwari, T.K.; Tripathi, A. Quantification of Agricultural Mechanization Status for Etawah District of Uttar Pradesh, India. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 659–666. [Google Scholar] [CrossRef]

- Ostovari, Y.; Honarbakhsh, A.; Sangoony, H.; Zolfaghari, F.; Maleki, K.; Ingram, B. GIS and multi-criteria decision-making analysis assessment of land suitability for rapeseed farming in calcareous soils of semi-arid regions. Ecol. Indic. 2019, 103, 479–487. [Google Scholar] [CrossRef]

- Jasinski, E.; Morton, D.; DeFries, R.; Shimabukuro, Y.; Anderson, L.; Hansen, M. Physical landscape correlates of the expansion of mechanized agriculture in Mato Grosso, Brazil. Earth Interact. 2005, 9. [Google Scholar] [CrossRef]

- Alganci, U.; Kuru, G.N.; Yay Algan, I.; Sertel, E. Vineyard site suitability analysis by use of multicriteria approach applied on geo-spatial data. Geocarto Int. 2019, 34, 1286–1299. [Google Scholar] [CrossRef]

- Jurisic, M.; Stanisavljevic, A.; Plascak, I. Application of Geographic Information System (GIS) in the selection of vineyard sites in Croatia. Bulg. J. Agric. Sci. 2010, 16, 235–242. [Google Scholar]

- Stanchi, S.; Godone, D.; Belmonte, S.; Freppaz, M.; Galliani, C.; Zanini, E. Land suitability map for mountain viticulture: A case study in Aosta Valley (NW Italy). J. Maps 2013, 9, 367–372. [Google Scholar] [CrossRef]

- Yau, I.H.; Davenport, J.R.; Moyer, M.M. Developing a wine grape site evaluation decision support system for the inland Pacific Northwestern United States. Horttechnology 2014, 24, 88–98. [Google Scholar] [CrossRef]

- Bollati, A.; Molin, P.; Cifelli, F.; Petrangeli, A.B.; Parotto, M.; Mattei, M. An integrated methodology of viticultural zoning to evaluate terrains suitable for viticulture: The test area of Cesanese DOC (Latium, central Italy). J. Wine Res. 2015, 26, 1–17. [Google Scholar] [CrossRef]

- Cogato, A.; Pezzuolo, A.; Sozzi, M.; Marinello, F. A sample of Italian vineyards: Landscape and management parameters dataset. Data Brief 2020. [Google Scholar]

- Hameed, I.A.; Bochtis, D.D.; Sørensen, C.G.; Jensen, A.L.; Larsen, R. Optimized driving direction based on a three-dimensional field representation. Comput. Electron. Agric. 2013, 91, 145–153. [Google Scholar] [CrossRef]

- Statuto, D.; Cillis, G.; Picuno, P. Using historical maps within a GIS to analyze two centuries of rural landscape changes in southern Italy. Land 2017, 6, 65. [Google Scholar] [CrossRef]

- Hunter, A.G.M. A review of research into machine stability on slopes. Saf. Sci. 1993, 16, 325–339. [Google Scholar] [CrossRef]

- Morris, J.R. Development and commercialization of a complete vineyard mechanization system. Horttechnology 2007, 17, 411–420. [Google Scholar] [CrossRef]

- Chisango, F.F.T.; Dzama, T. An assessment of agricultural mechanisation index and evaluation of agricultural productivity of some fast track resettlement farms in Bindura District of Mashonaland Central Province: Zimbabwe. Int. J. Soc. Sci. Interdiscip. Res. 2013, 2, 62–82. [Google Scholar]

- Yisa, M.G.; Terao, H.; Noguchi, N.; Kubota, M. Stability criteria for tractor-implement operation on slopes. J. Terramech. 1998, 35, 1–19. [Google Scholar] [CrossRef]

- Madruga, J.; Azevedo, E.B.; Sampaio, J.F.; Fernandes, F.; Reis, F.; Pinheiro, J. Analysis and definition of potential new areas for viticulture in the azores (Portugal). Soil 2015, 1, 515–526. [Google Scholar] [CrossRef]

- Jones, G.V.; Snead, N.; Nelson, P. Modeling Viticultural Landscapes: A GIS Analysis of the Terroir Potential in the Umpqua Valley of Oregon. Geosci. Can. 2004, 31, 167–178. [Google Scholar]

- Spekken, M.; de Bruin, S. Optimized routing on agricultural fields by minimizing maneuvering and servicing time. Precis. Agric. 2013, 14, 224–244. [Google Scholar] [CrossRef]

- Pitla, S.K.; Lin, N.; Shearer, S.A.; Luck, J.D. Use of Controller Area Network (CAN) data to determine field efficiencies of agricultural machinery. Appl. Eng. Agric. 2014, 30, 829–839. [Google Scholar] [CrossRef][Green Version]

- Søgaard, H.T.; Sørensen, C.G. A model for optimal selection of machinery sizes within the farm machinery system. Biosyst. Eng. 2004, 89, 13–28. [Google Scholar] [CrossRef]

- Oksanen, T. Shape-describing indices for agricultural field plots and their relationship to operational efficiency. Comput. Electron. Agric. 2013, 98, 252–259. [Google Scholar] [CrossRef]

- Lacour, S.; Burgun, C.; Perilhon, C.; Descombes, G.; Doyen, V. A model to assess tractor operational efficiency from bench test data. J. Terramech. 2004, 54, 1–18. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G. The vehicle routing problem in field logistics part I. Biosyst. Eng. 2009, 104, 447–457. [Google Scholar] [CrossRef]

- Gambella, F.; Sartori, L. Comparison of mechanical and manual cane pruning operations on three varieties of grape (Cabernet Sauvignon, Merlot and Prosecco) in Italy. Trans. Asabe Am. Soc. Agric. Biol. Eng. 2014, 57, 701–707. [Google Scholar] [CrossRef]

- Trendafilov, K.; Delchev, N. Headland turns using the tractor’s “fifth wheel” steering device instead of front steering wheels. Bulg. J. Agric. Sci. 2018, 24, 1137–1147. [Google Scholar]

- Grose, D.T. Hill Slope Viability for Industrial Viticultural Development in the South Island of New Zealand. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2013. [Google Scholar]

- Mazzetto, F.; Gallo, R.; Vidoni, R.; Bisaglia, C.; Calcante, A. Designing and testing a new small tractor prototype for the mechanisation of terraced-vineyard farming systems in South-Tyrol. In Proceedings of the International Conference RAGUSA SHWA 2012—“Safety Health and Welfare in Agriculture and in Agro-food Systems”, Ragusa, Italy, 3–6 September 2012; pp. 243–250. [Google Scholar]

- Bonsignore, R.; Romano, E.; Manetto, G.; Caruso, L.; Schillaci, G. Development of a towed multi-function row straddling machine for the cultivation of goblet vineyards. In Proceedings of the SHWA2010—Work Safety and Risk prevention in Agro-Food and Forest Systems, Ragusa, Italy, 16–18 September 2010; pp. 368–373. [Google Scholar]

- Intrieri, C.; Poni, S. Physiological response of winegrape to management practices for successful mechanization of quality vineyards. Acta Hortic. 2000, 526, 33–47. [Google Scholar] [CrossRef]

- Intrieri, C. Research and innovation for full mechanization of Italian vineyards at Bologna University. Acta Hortic. 2013, 978, 151–168. [Google Scholar] [CrossRef]

- Delenne, C.; Rabatel, G.; Agurto, V.; Deshayes, M. Vine Plot Detection in Aerial Images Using Fourier Analysis. In Proceedings of the 1st International Conference on Object-based Image Analysis (OBIA), Salzburg, Austria, 4–5 July 2006; pp. 1–6. [Google Scholar]

- Yezekyan, T.; Marinello, F.; Armentano, G.; Trestini, S.; Sartori, L. Definition of reference models for power, weight, working width, and price for seeding machines. Agriculture 2018, 8, 186. [Google Scholar] [CrossRef]

- ISTAT. 6° Censimento Generale dell’ Agricoltura: Dati Definitivi; ISTAT: Rome, Italy, 2012. [Google Scholar]

- Sallustio, L.; Pettenella, D.; Merlini, P.; Romano, R.; Salvati, L.; Marchetti, M.; Corona, P. Assessing the economic marginality of agricultural lands in Italy to support land use planning. Land Use Policy 2018, 76, 526–534. [Google Scholar] [CrossRef]

- Cattivelli, V. The motivation of urban gardens in mountain areas. The case of South Tyrol. Sustainability 2020, 12, 4304. [Google Scholar] [CrossRef]

- Basso, M. Land-use changes triggered by the expansion of wine-growing areas: A study on the Municipalities in the Prosecco’s production zone (Italy). Land Use Policy 2019, 83, 390–402. [Google Scholar] [CrossRef]

- Dalpez, A.; Zanoni, M.; Marcantoni, M.; Leveghi, M.; Bona, E.; Tonon, C.; Del Frate, M.; Zanotelli, A.; Clementel, G.; Davidovich, L.; et al. La Vitivinicoltura in Trentino Dati 2010; Camera di Commercio I.A.A. di Trento: Trento, Italy, 2011. [Google Scholar]

- Pascuzzi, S.; Guarella, P.; Percoco, A.; Guario, A.; Ganzelmeier, H.; Wehmann, H. Test-bench and computer-aided measurement sys-tem for checking and calibrating spraying machines used in “tendone”-trained vineyards. In Proceedings of the First European Workshop on Standardised Procedure for the Inspection of Sprayers in Europe-SPISE, Mitt Biol Bundesanst Land- Forstwirtsch, Braunschweig, Germany, 27–29 April 2004; pp. 133–142. [Google Scholar]

- Giorio, P.; Nuzzo, V. Leaf area, light environment, and gas exchange in Montepulciano grapevines trained to Tendone trellising system. Plant Biosyst. 2012, 146, 322–333. [Google Scholar] [CrossRef]

- Fraga, H.; Amraoui, M.; Malheiro, A.C.; Moutinho-Pereira, J.; Eiras-Dias, J.; Silvestre, J.; Santos, J.A. Examining the relationship between the Enhanced Vegetation Index and grapevine phenology. Eur. J. Remote Sens. 2014, 47, 753–771. [Google Scholar] [CrossRef]

- Townsend, C.G. Viticulture and the Role of Geomorphology: General Principles and Case Studies. Geogr. Compass 2011, 5, 750–766. [Google Scholar] [CrossRef]

- Jobbágy, J.; Krištof, K.; Schmidt, A.; Križan, M.; Urbanovičová, O. Evaluation of the mechanized harvest of grapes with regards to harvest losses and economical aspects. Agron. Res. 2018, 16, 426–442. [Google Scholar] [CrossRef]

- Barrena-González, J.; Rodrigo-Comino, J.; Gyasi-Agyei, Y.; Fernández, M.P.; Cerdà, A. Applying the RUSLE and ISUM in the Tierra de Barros Vineyards (Extremadura, Spain) to estimate soil mobilisation rates. Land 2020, 9, 93. [Google Scholar] [CrossRef]

| Slope (°) | Class Ranking (%) |

|---|---|

| 0–5 | 100 |

| 5–10 | 80 |

| 10–15 | 60 |

| >15 | 40 |

| Length-Width Ratio | Class Ranking (%) |

|---|---|

| <0.8 | 90 |

| 0.8–2.0 | 100 |

| >2.0 | 110 |

| Headland Size (m) | Class Ranking (%) |

|---|---|

| <2.0 | 40 |

| 2.0–3.0 | 80 |

| 3.0–4.5 | 90 |

| >4.5 | 100 |

| Training System | Class Ranking (%) |

|---|---|

| Vertical System | 100 |

| Alberello | 70 |

| Horizontal system | 40 |

| Row Spacing (m) | Class Ranking (%) |

|---|---|

| <1.4 | 10 |

| 1.4–1.7 | 40 |

| 1.7–2.0 | 90 |

| >2.0 | 100 |

| Mechanisability Potential | ||||

|---|---|---|---|---|

| Parameter | High | Medium | Low | Very low |

| Slope (%) | 0–10 | 10–20 | 20–30 | >30 |

| Block Shape | Regular | Not regular | ||

| Length/Width ratio | 0.8–2.0 | <0.8 | ||

| Headland size (m) | >4.5 | 3.0–4.5 | 2.0–3.0 | <2.0 |

| Training system | Vertical system | Alberello | Horizontal system | |

| Row spacing (m) | >2.0 | 1.7–2.0 | <1.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cogato, A.; Pezzuolo, A.; Sørensen, C.G.; De Bei, R.; Sozzi, M.; Marinello, F. A GIS-Based Multicriteria Index to Evaluate the Mechanisability Potential of Italian Vineyard Area. Land 2020, 9, 469. https://doi.org/10.3390/land9110469

Cogato A, Pezzuolo A, Sørensen CG, De Bei R, Sozzi M, Marinello F. A GIS-Based Multicriteria Index to Evaluate the Mechanisability Potential of Italian Vineyard Area. Land. 2020; 9(11):469. https://doi.org/10.3390/land9110469

Chicago/Turabian StyleCogato, Alessia, Andrea Pezzuolo, Claus Grøn Sørensen, Roberta De Bei, Marco Sozzi, and Francesco Marinello. 2020. "A GIS-Based Multicriteria Index to Evaluate the Mechanisability Potential of Italian Vineyard Area" Land 9, no. 11: 469. https://doi.org/10.3390/land9110469

APA StyleCogato, A., Pezzuolo, A., Sørensen, C. G., De Bei, R., Sozzi, M., & Marinello, F. (2020). A GIS-Based Multicriteria Index to Evaluate the Mechanisability Potential of Italian Vineyard Area. Land, 9(11), 469. https://doi.org/10.3390/land9110469