Technology for Boosting Sustainability: A Web App-Based Information Model for Boosting Residual Biomass Recovery

Abstract

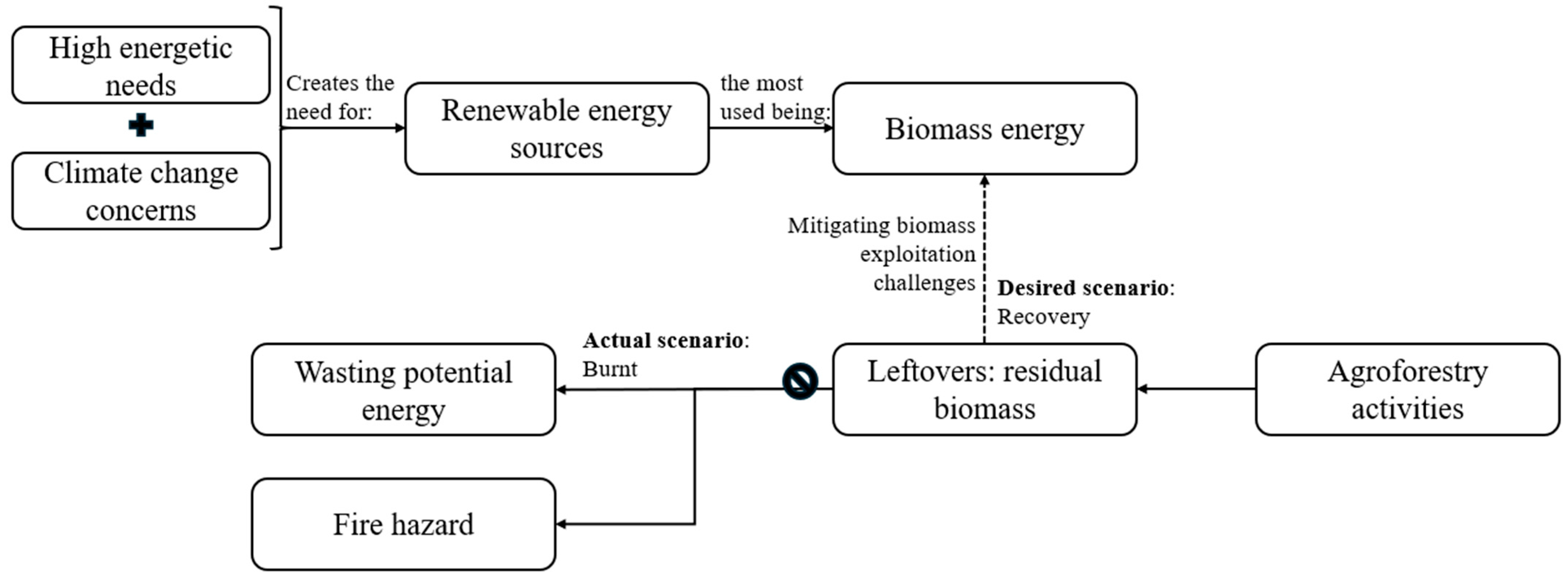

1. Introduction

2. Theoretical Framework

2.1. Residual Biomass Recovery: Concepts and Importance

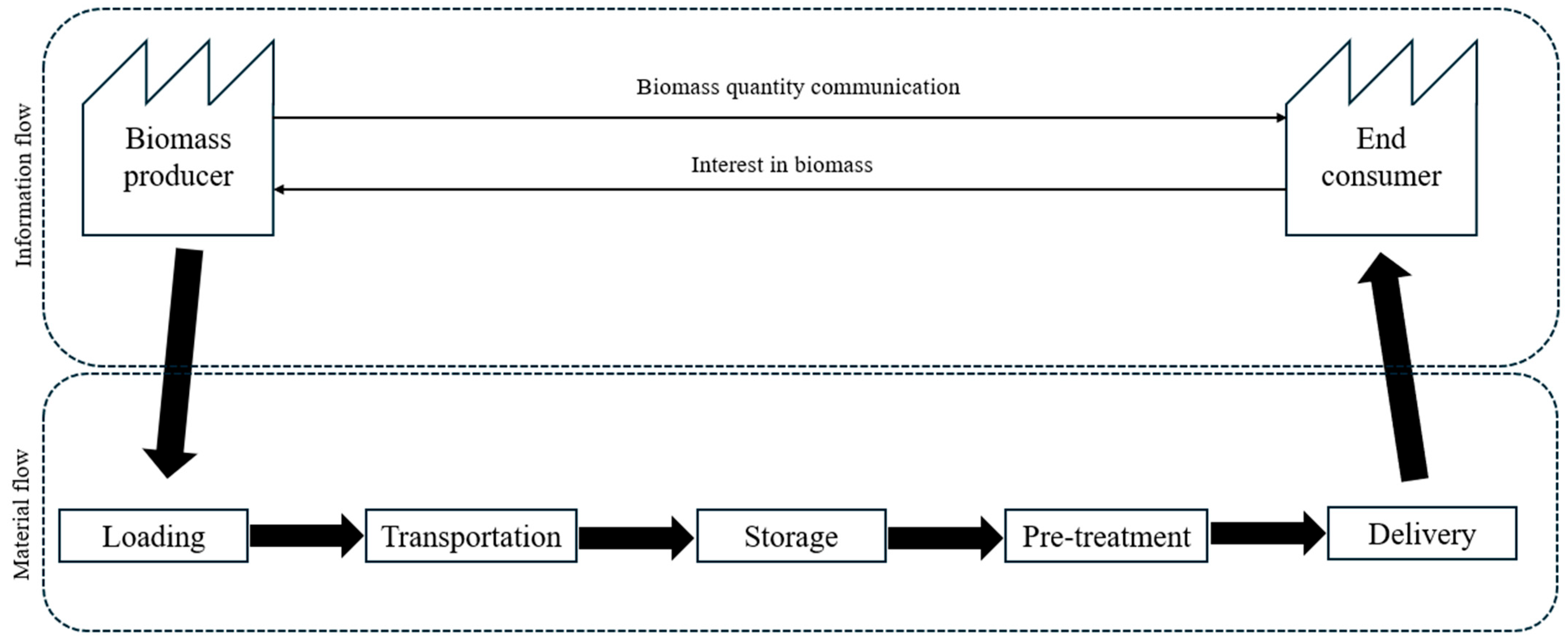

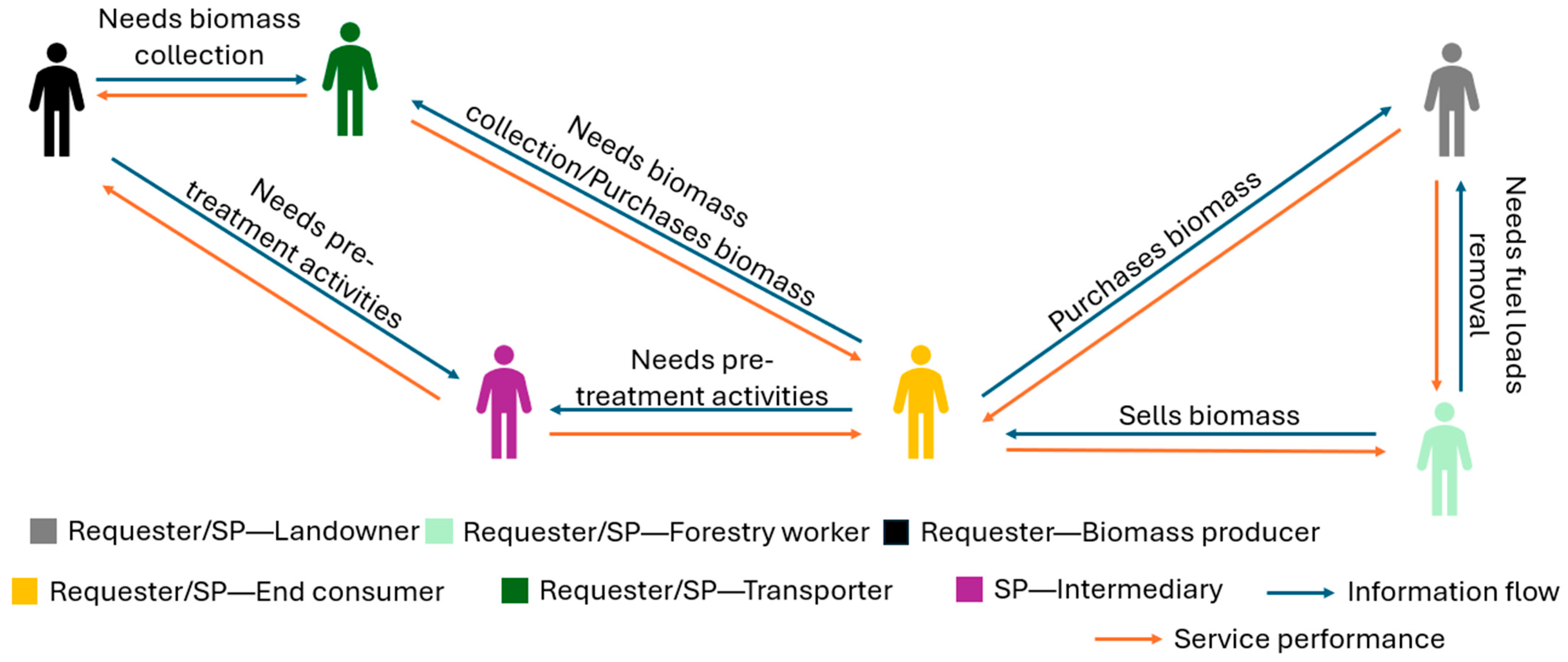

2.2. Residual Biomass Supply Chain: Actors, Stages, and Challenges

2.3. Lean Philosophy: Waste and Lean Information Management

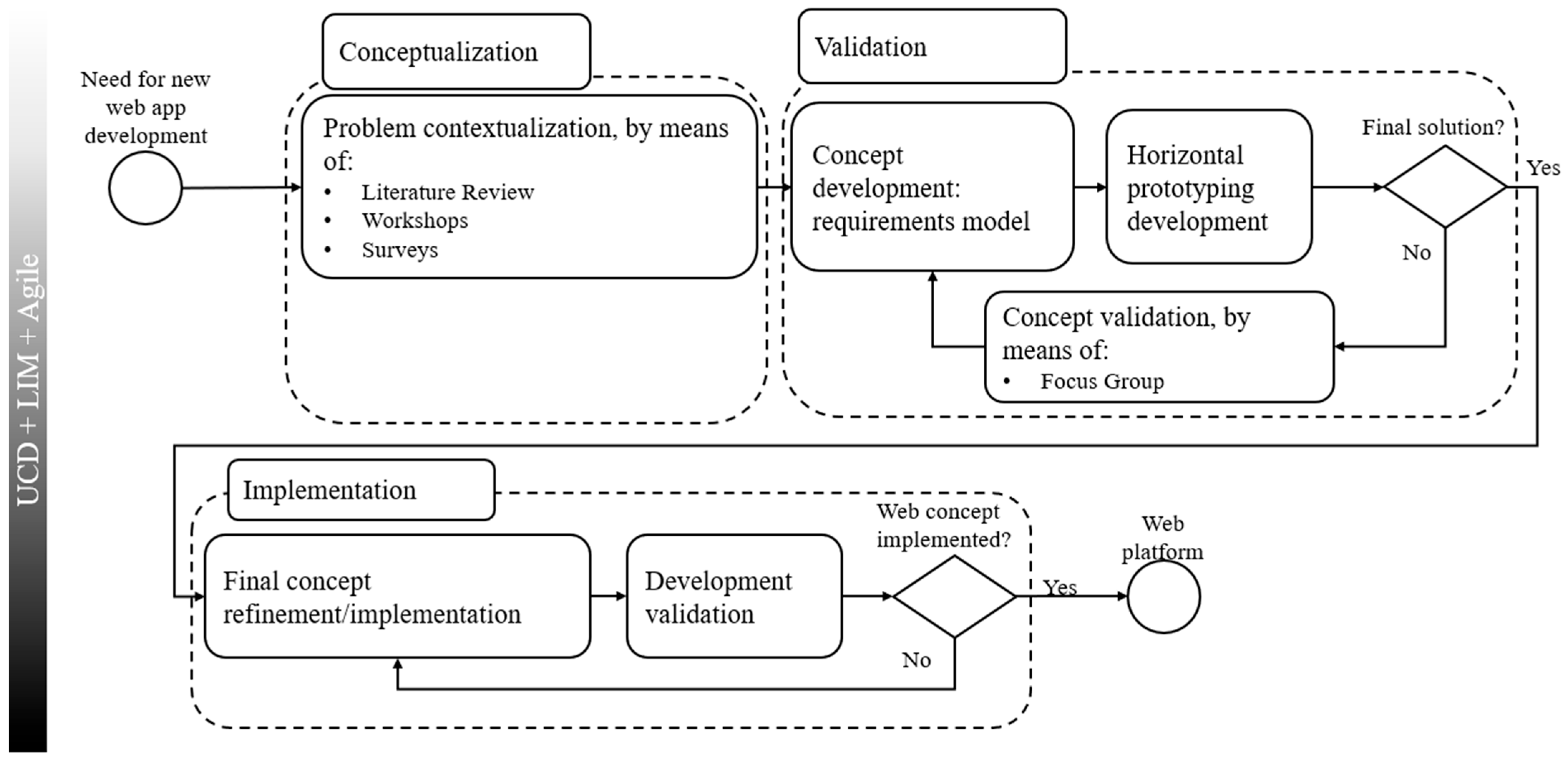

3. Methodological Approach

4. Results

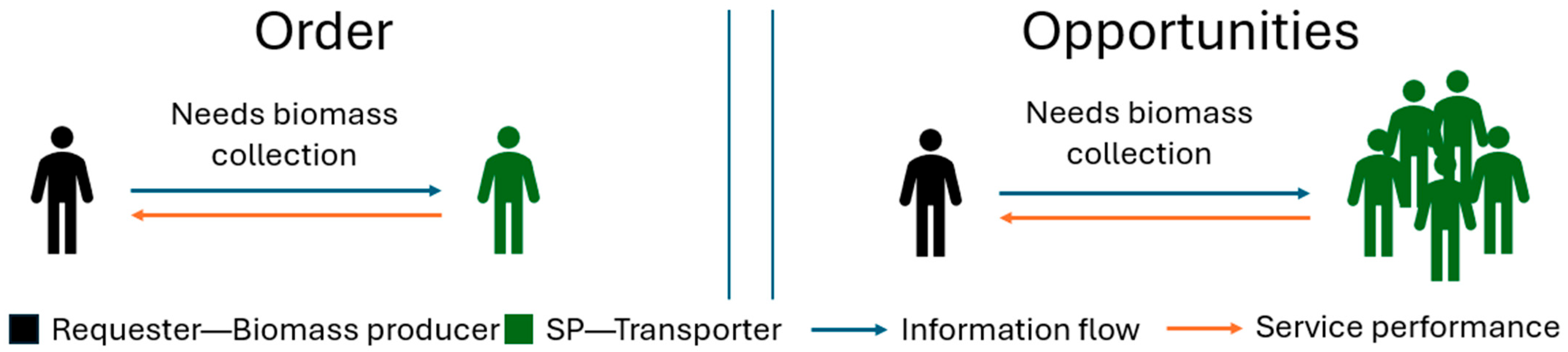

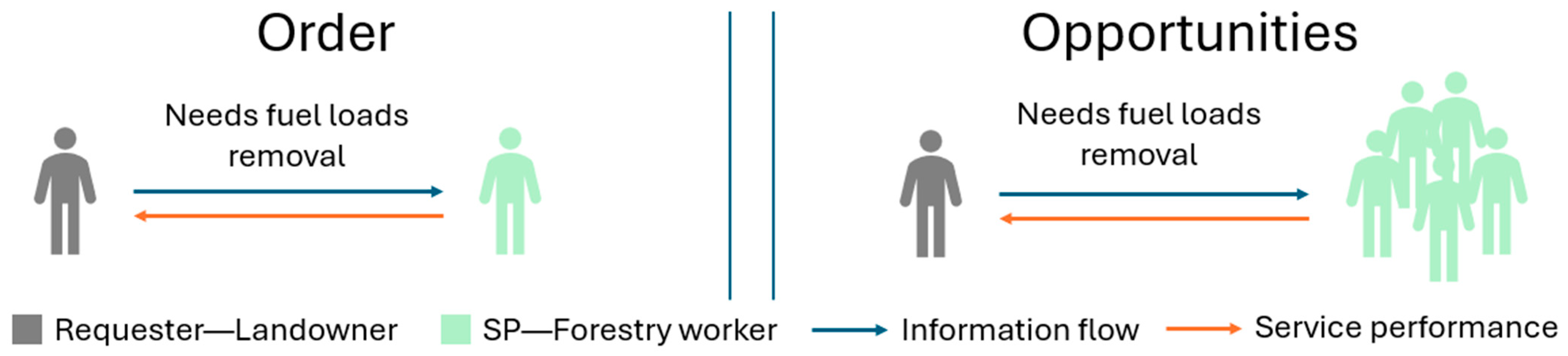

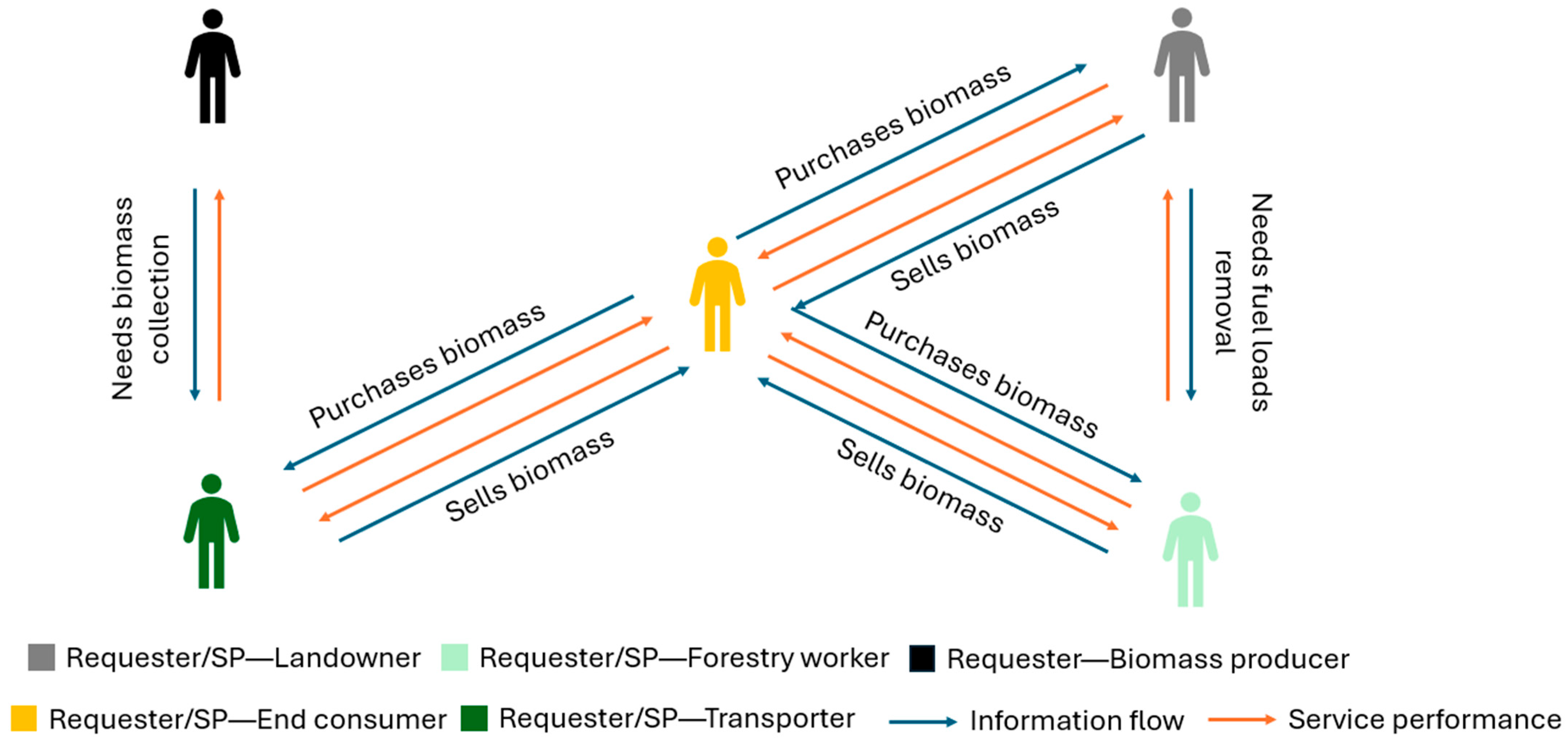

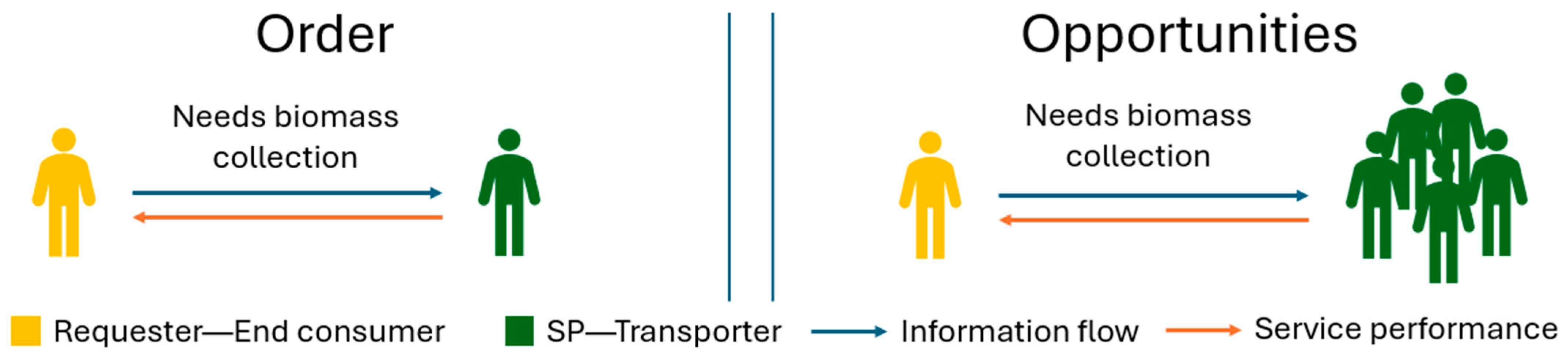

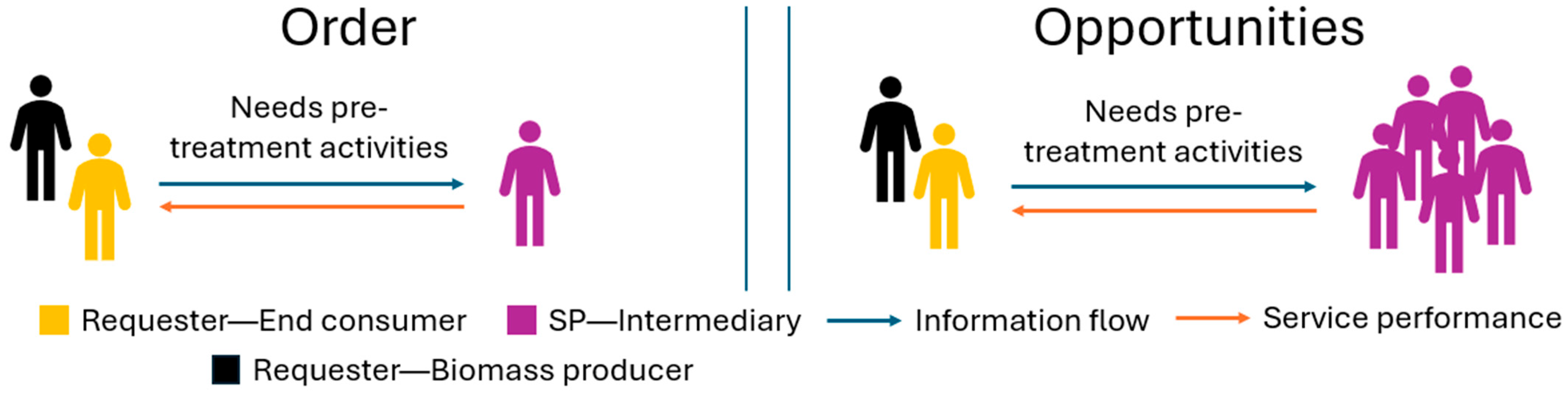

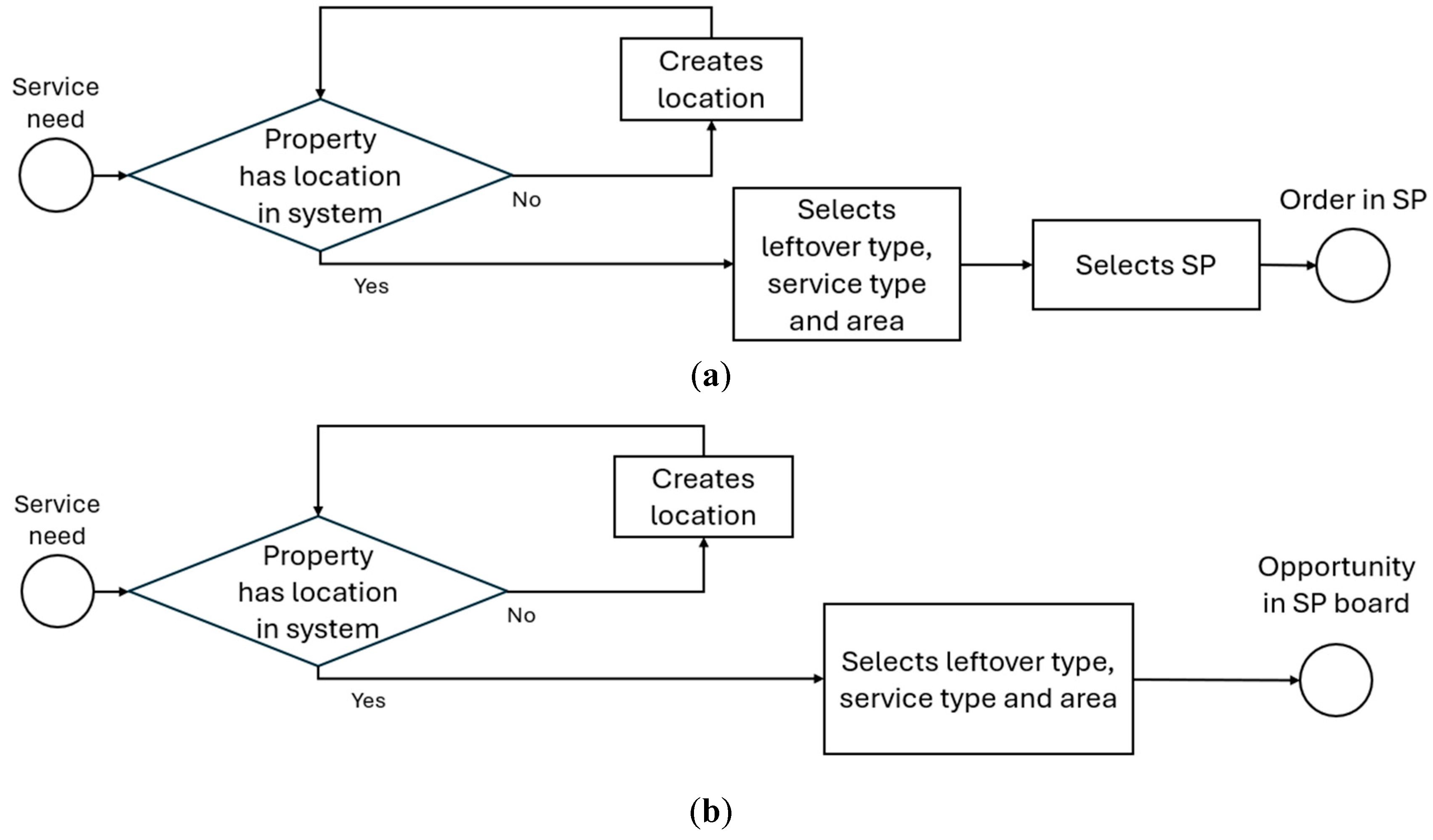

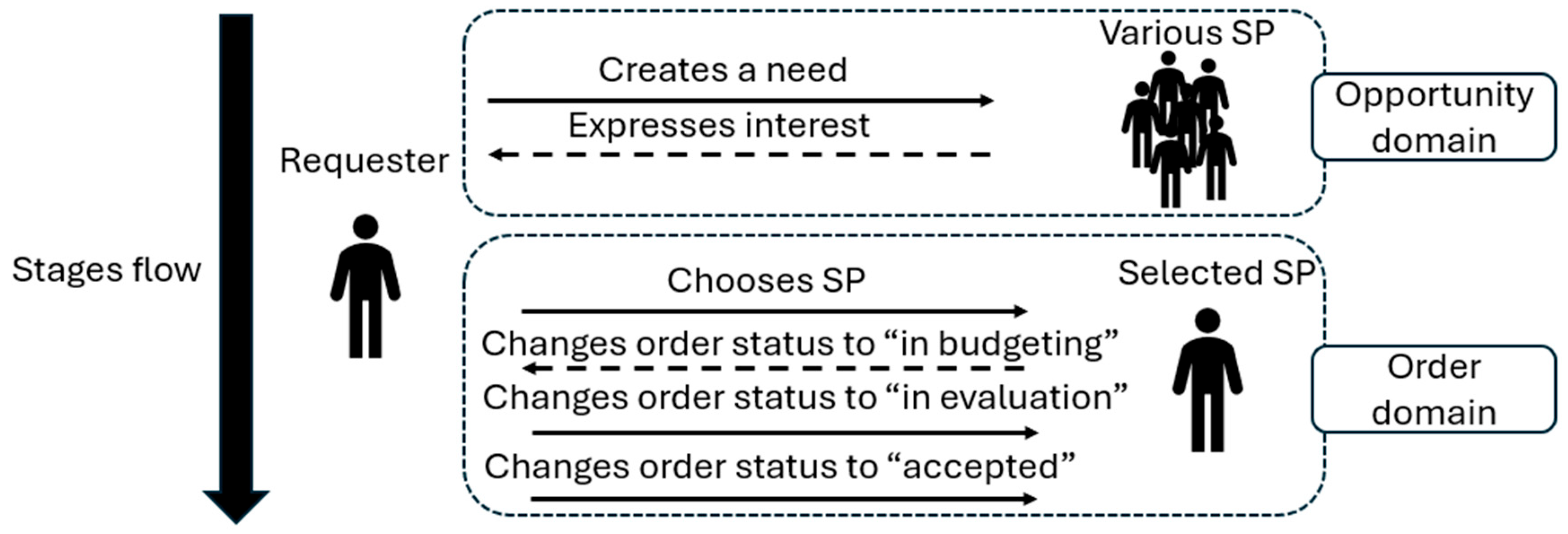

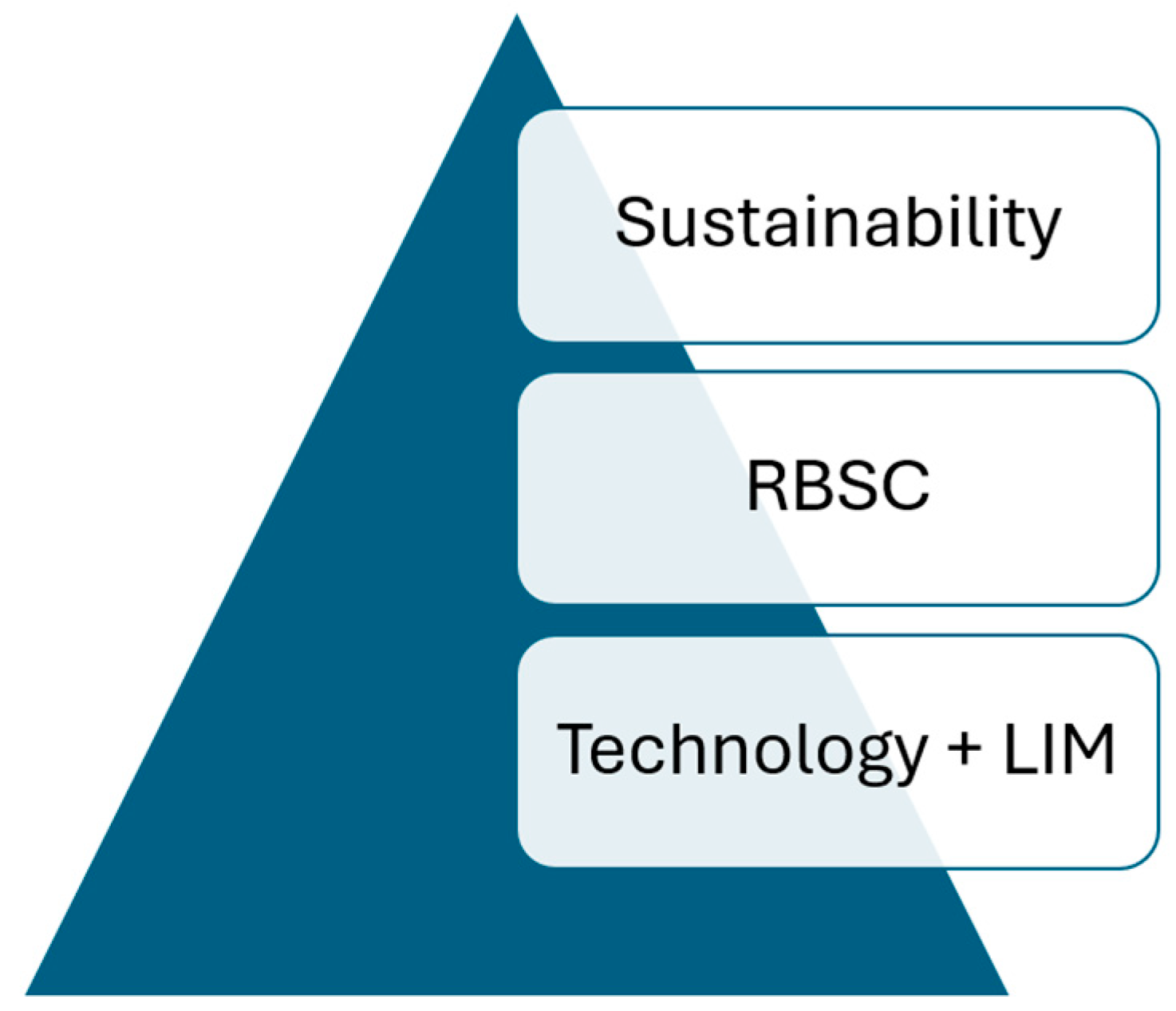

4.1. App-Based Information Model

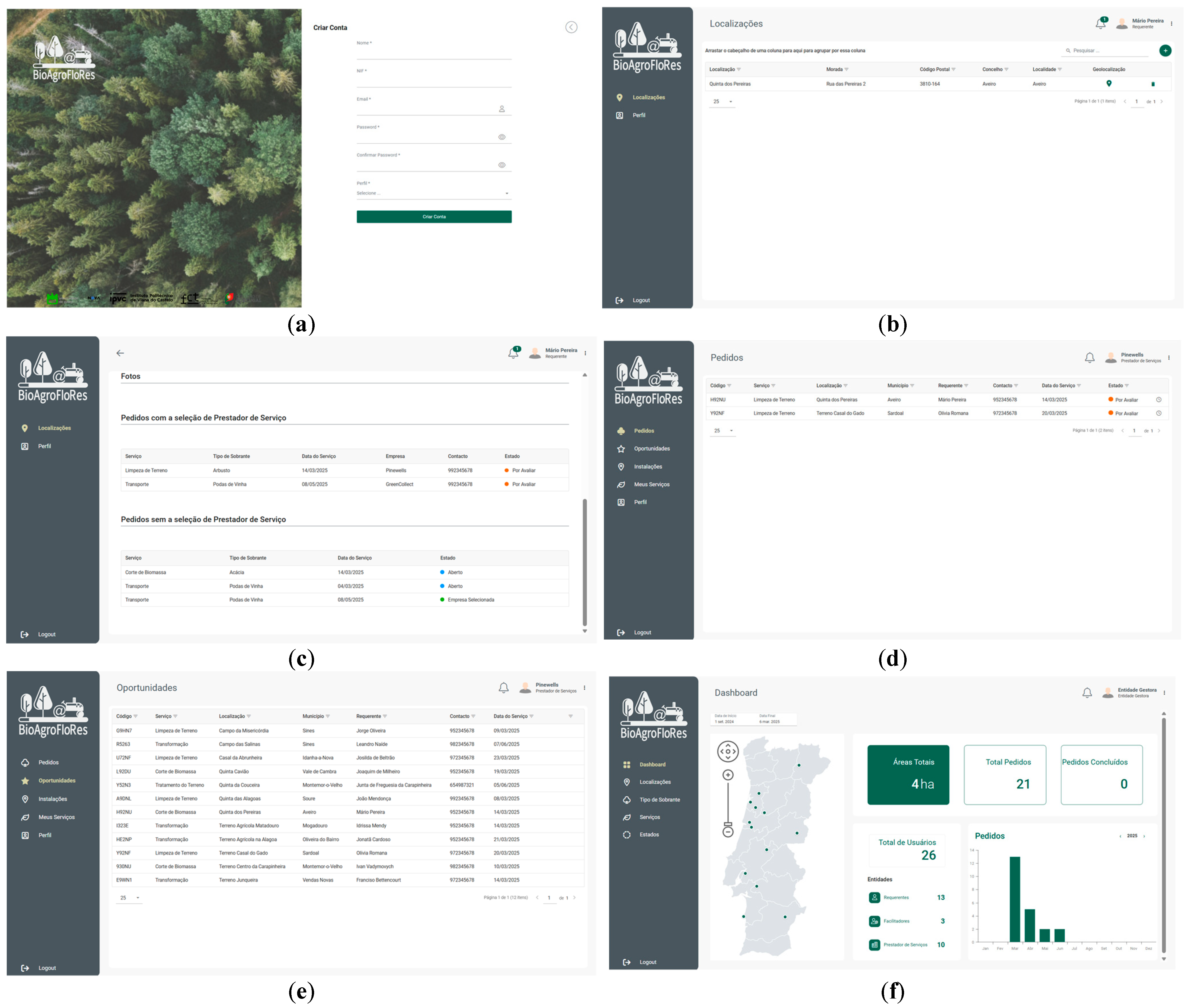

4.2. Web Application Concept

5. Discussion

6. Conclusions

- Presentation of an information management model based on a web application for a context marked by logistical challenges associated with a lack of information/knowledge;

- Presentation of a flexible model that can be adapted to different contexts (allowing different problems to be managed), enabling simple and targeted exchanges of information;

- Highlighting the flexibility and parameterizable nature of the solutions as signs of their increased robustness in the face of specific contexts;

- Highlighting the role of the LIM and HCD in the context of the RBSC.

- In practical terms, the following contributions stand out:

- Creation of centralized information and knowledge that will allow potential users to make better decisions;

- Creation of a liberalized market for services that will avoid the traditional values “imposed” by service providers;

- Resolution of sustainability concerns associated with the burning of leftovers that affect not only stakeholders but the population in general;

- Possibility of developing new business models, in line with the system’s needs;

- Improvements in the management of potential energy resources for nations.

7. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RBSC | Residual biomass supply chain |

| HCD | Human-centered design |

| LIM | Lean information management |

| VSM | Value stream mapping |

| SP | Service provider |

| ME | Management entity |

| BSC | Biomass supply chain |

| IoT | Internet of Things |

| SDG | Sustainable development goal |

References

- Zaman, K.; Khan, D.; Hassan, S.A.; Nassani, A.A.; Ahmad, E.; Anser, M.K. The influence of grid connectivity, electricity pricing, policy-driven power incentives, and carbon emissions on renewable energy adoption: Exploring key factors. Renew. Energy 2024, 232, 121108. [Google Scholar] [CrossRef]

- Cobos-Torres, J.-C.; Izquierdo, J.; Alvarez-Vera, M. Energy Efficiency of Lignocellulosic Biomass Pyrolysis in Two Types of Reactors: Electrical and with Primary Forest Biomass Fuel. Energies 2024, 17, 2943. [Google Scholar] [CrossRef]

- Spazzafumo, G.; Ongis, M.; Lanni, D.; D’antuono, G.; Raimondi, G.; Greco, G. Techno-Economical Assessment for Combined Production of Hydrogen, Heat, and Power from Residual Lignocellulosic Agricultural Biomass in Huesca Province (Spain). Energies 2024, 17, 813. [Google Scholar] [CrossRef]

- Tenório, J.A.S.; Chaar, J.S.; Araujo, R.O.; Lima, V.M.R.; Colpani, D.; Santos, V.O.; Santos, J.L.; Teixeira, L.L.A.; de Souza, L.K.C. Torrefaction of tucuma residual biomass: Kinetic analysis and energy enhancement. Emergent Mater. 2024. [Google Scholar] [CrossRef]

- Toscano, G.; Duca, D.; Ilari, A.; Boakye-Yiadom, K.A.; Gasperini, T. Carbon Footprint and Feedstock Quality of a Real Biomass Power Plant Fed with Forestry and Agricultural Residues. Resources 2022, 11, 7. [Google Scholar] [CrossRef]

- Meliana, Y.; Agustian, E.; Lisnawati; Fansuri, M.H.; Leonardus, M.; Susparini, N.T.; Putra, O.A.; Hanifah, Y.; Ardyani, T.; Simanungkalit, S.; et al. Valorization of corn cob waste for furfural production: A circular economy approach. Biomass Bioenergy 2025, 194, 107665. [Google Scholar] [CrossRef]

- Yadav, M.; Agrawal, S.; Sharma, C.; Singh, S.; Nara, R.; Kumar, A. Oil palm biomass: A potential feedstock for lignocellulolytic enzymes and biofuels production. Environ. Sci. Pollut. Res. 2025, 32, 11791–11814. [Google Scholar] [CrossRef]

- Rouboa, A.; Monteiro, E.; Ramos, A. Biomass pre-treatment techniques for the production of biofuels using thermal conversion methods—A review. Energy Convers. Manag. 2022, 270, 116271. [Google Scholar] [CrossRef]

- Ferreira, L.P.; Ramos, A.; Chidozie, B.; Vasconcelos, J. Development of a Residual Biomass Supply Chain Simulation Model Using AnyLogistix: A Methodical Approach. Logistics 2024, 8, 107. [Google Scholar] [CrossRef]

- Conrad, J.L.; Barrett, S.M.; Bolding, M.C.; Peduzzi, A.; Munro, H.L.; Bays, H.C. Assessing the sustainability of forest biomass harvesting practices in the southeastern US to meet European renewable energy goals. Biomass Bioenergy 2024, 186, 107267. [Google Scholar] [CrossRef]

- Vanoli, L.; Macaluso, A.; Fabozzi, S.; Di Fraia, S. Energy potential of residual biomass from agro-industry in a Mediterranean region of southern Italy (Campania). J. Clean. Prod. 2020, 277, 124085. [Google Scholar] [CrossRef]

- Romero, I.; Castro-Galiano, E.; Ruiz, E.; Galán-Martín, Á.; Eliche-Quesada, D.; Bueno-Rodríguez, S.; Contreras, M.d.M. The potential role of olive groves to deliver carbon dioxide removal in a carbon-neutral Europe: Opportunities and challenges. Renew. Sustain. Energy Rev. 2022, 165, 112609. [Google Scholar] [CrossRef]

- Gurgel, L.V.A.; Gomes, B.F.M.L.; Júnior, S.V. Production of activated carbons from technical lignin as a promising pathway towards carbon emission neutrality for second-generation (2G) ethanol plants. J. Clean. Prod. 2024, 450, 141648. [Google Scholar] [CrossRef]

- Rivaldi, J.D.; Martínez, K.; Rojas, O.; González, J.; Smidt, M.; Velázquez, E.; Sauer, C.; Shin, H.H.; Colmán, F. Thermochemical characterization and assessment of residual biomass energy in Paraguay. Biomass Convers. Biorefinery 2024, 14, 10115–10130. [Google Scholar] [CrossRef]

- García, C.A.; Alvarado-Flores, J.J.; López-Sosa, L.B.; Morales-Máximo, M.; Alcaraz-Vera, J.V.; Álvarez-Jara, M.; Rutiaga-Quiñones, J.G. Multifactorial Assessment of the Bioenergetic Potential of Residual Biomass of Pinus spp. in a Rural Community: From Functional Characterization to Mapping of the Available Energy Resource. Fire 2023, 6, 317. [Google Scholar] [CrossRef]

- Matias, J.; Dias, M.F.; Casau, M.; Nunes, L.J.; Teixeira, L.C. Agroforest woody residual biomass-to-energy supply chain analysis: Feasible and sustainable renewable resource exploitation for an alternative to fossil fuels. Results Eng. 2023, 17, 101010. [Google Scholar] [CrossRef]

- Piedra-Jimenez, F.; Torres, A.I.; Rodriguez, M.A. A robust disjunctive formulation for the redesign of forest biomass-based fuels supply chain under multiple factors of uncertainty. Comput. Chem. Eng. 2024, 181, 108540. [Google Scholar] [CrossRef]

- Ferreira, J.; Brás, I.; Silva, E.; Raimondo, R.; Mignano, V.; Saetta, R.; Fabbricino, M. Valorisation of Forest and Agriculture Residual Biomass—The Application of Life Cycle Assessment to Analyse Composting, Mulching, and Energetic Valorisation Strategies. Sustainability 2024, 16, 630. [Google Scholar] [CrossRef]

- Ma, C.; Lu, Y.; Yi, S.; Zhang, Y. Optimizing urban agricultural waste planning and management to enhance sustainability: Strategies for three types of cities. Sustain. Cities Soc. 2025, 120, 106168. [Google Scholar] [CrossRef]

- Teixeira, L.; Bastos, T.; Nunes, L.J.R. Fostering Circularity in Agroforestry Biomass: A Regulatory Framework for Sustainable Resource Management. Land 2025, 14, 362. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Silva, S. Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics 2023, 7, 48. [Google Scholar] [CrossRef]

- López-Díaz, I.; Aybar-Mejía, M.; Guzmán-Bello, H.; de Frias, J.A. A Review of Trends in the Energy Use of Biomass: The Case of the Dominican Republic. Sustainability 2022, 14, 3868. [Google Scholar] [CrossRef]

- Mehrjerdi, Y.Z.; Hosseini-Nasab, H.; Sadegheih, A.; Salehi, S. Designing a resilient and sustainable biomass supply chain network through the optimization approach under uncertainty and the disruption. J. Clean. Prod. 2022, 359, 131741. [Google Scholar] [CrossRef]

- Lozza, G.; Manzolini, G.; Basile, F.; Pilotti, L.; Ugolini, M. Supply chain optimization and GHG emissions in biofuel production from forestry residues in Sweden. Renew. Energy 2022, 196, 405–421. [Google Scholar] [CrossRef]

- Fujii, M.; Nakamura, S.; Matsui, T.; Haga, C.; Qian, T.; Ooba, M.; Namba, A. Estimation of Forest Residual Biomass for Bioelectricity Utilization towards Carbon Neutrality Based on Sentinel-2A Multi-Temporal Images: A Case Study of Aizu Region of Fukushima, Japan. Remote Sens. 2024, 16, 706. [Google Scholar] [CrossRef]

- Lobo-Do-Vale, R.; Colaço, M.C.; de Oliveira, E. Incident analysis of traditional burns in Portugal. Int. J. Disaster Risk Reduct. 2023, 95, 103852. [Google Scholar] [CrossRef]

- Oliva, P.; Casallas, A.; López-Barrera, E.A.; Quishpe-Vásquez, C. Wildfires impact on PM2.5 concentration in galicia Spain. J. Environ. Manag. 2024, 367, 122093. [Google Scholar] [CrossRef]

- Manzolini, G.; Moretti, L.; Milani, M.; Lozza, G.G. A detailed MILP formulation for the optimal design of advanced biofuel supply chains. Renew. Energy 2021, 171, 159–175. [Google Scholar] [CrossRef]

- Azcue, X.; Relvas, S.; Barbosa-Póvoa, A.P.; Paulo, H. Supply chain optimization of residual forestry biomass for bioenergy production: The case study of Portugal. Biomass Bioenergy 2015, 83, 245–256. [Google Scholar] [CrossRef]

- Teixeira, L.; Bastos, T.; Nunes, L.J.R. Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain. Fire 2024, 7, 263. [Google Scholar] [CrossRef]

- Hicks, B. Lean information management: Understanding and eliminating waste. Int. J. Inf. Manag. 2007, 27, 233–249. [Google Scholar] [CrossRef]

- Ahmed, S.; Rizvan, R.; Habib, M.A. Implementing lean manufacturing for improvement of operational performance in a labeling and packaging plant: A case study in Bangladesh. Results Eng. 2023, 17, 100818. [Google Scholar] [CrossRef]

- Li, H.; Xing, L.; Liu, M.; Xie, X.; Miao, L.; Huang, Y.; Wang, X.; Chang, W. Recent progress on the synergistic preparation of liquid fuels by co-pyrolysis of lignocellulosic biomass and plastic wastes. J. Energy Inst. 2025, 119, 102019. [Google Scholar] [CrossRef]

- Sbaffoni, S.; Rinaldi, C.; Fiorentino, G.; Cerbone, A.; Ansanelli, G.; Zucaro, A.; Beltrani, T.; Picarelli, A. Life Cycle Assessment of Electricity Production from Different Biomass Sources in Italy. Energies 2024, 17, 2771. [Google Scholar] [CrossRef]

- Tan, C.; Ma, C.; Hu, J.; Yu, Y.; Wang, H. Kinetics, reaction mechanism and product distribution of lignocellulosic biomass pyrolysis using triple-parallel reaction model, combined kinetics, Py-GC/MS, and artificial neural networks. Ind. Crop. Prod. 2025, 224, 120308. [Google Scholar] [CrossRef]

- Lombardelli, G.; Gatti, M.; Scaccabarozzi, R.; Conversano, A. Bio-methanol with negative CO2 emissions from residual forestry biomass gasification: Modelling and techno-economic assessment of different process configurations. Biomass Bioenergy 2024, 188, 107315. [Google Scholar] [CrossRef]

- Clough, Y.; Brady, M.V.; Singh, J.; Ek, H.T.; Winberg, J. Farmers’ motivations to cultivate biomass for energy and implications. Energy Policy 2024, 193, 114295. [Google Scholar] [CrossRef]

- Ghosh, S.K. Biomass & Bio-waste Supply Chain Sustainability for Bio-energy and Bio-fuel Production. Procedia Environ. Sci. 2016, 31, 31–39. [Google Scholar] [CrossRef]

- Toklu, E. Biomass energy potential and utilization in Turkey. Renew. Energy 2017, 107, 235–244. [Google Scholar] [CrossRef]

- Daud, W.M.A.W.; Patah, M.F.A.; Abdulyekeen, K.A.; Umar, A.A. Torrefaction of biomass: Production of enhanced solid biofuel from municipal solid waste and other types of biomass. Renew. Sustain. Energy Rev. 2021, 150, 111436. [Google Scholar] [CrossRef]

- Lora, E.E.S.; Palacio, J.C.E.; Jaén, R.L.; Venturini, O.J.; Filho, F.B.D. An approach to technology selection in bioelectricity technical potential assessment: A Brazilian case study. Energy 2023, 272, 126995. [Google Scholar] [CrossRef]

- Ferreira, J.V.; Ferreira, L.P.; Ramos, A.L.; Chidozie, B.C. Residual Agroforestry Biomass Supply Chain Simulation Insights and Directions: A Systematic Literature Review. Sustainability 2023, 15, 9992. [Google Scholar] [CrossRef]

- Milan, M.; de Almeida, B.O.; Romanelli, T.L.; Angnes, G. Energy and economic performances of stump and roots removal of eucalyptus for bioenergy. Biomass Bioenergy 2021, 153, 106229. [Google Scholar] [CrossRef]

- Pierobon, F.; Ganguly, I.; Sifford, C.; Velappan, H. Air quality impact of slash pile burns: Simulated geo-spatial impact assessment for Washington State. Sci. Total. Environ. 2022, 818, 151699. [Google Scholar] [CrossRef]

- Álvarez, C.; Moreno, A.D.; Manzanares, P.; Duque, A.; Doménech, P. Advanced Bioethanol Production: From Novel Raw Materials to Integrated Biorefineries. Processes 2021, 9, 206. [Google Scholar] [CrossRef]

- Kamperidou, V.; Terzopoulou, P. Anaerobic Digestion of Lignocellulosic Waste Materials. Sustainability 2021, 13, 12810. [Google Scholar] [CrossRef]

- Avino, P.; Ceci, P.; Mignogna, D.; Szabó, M. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability 2024, 16, 7036. [Google Scholar] [CrossRef]

- Penman, T.D.; Marshall, E.; Elliot-Kerr, S. Costs of preventing and supressing wildfires in Victoria, Australia. J. Environ. Manag. 2023, 344, 118606. [Google Scholar] [CrossRef]

- Brotons, L.; Aquilué, N.; Touza, J.; Chas-Amil, M.-L.; Sil, Â.; Regos, A.; Lecina-Diaz, J. Incorporating fire-smartness into agricultural policies reduces suppression costs and ecosystem services damages from wildfires. J. Environ. Manag. 2023, 337, 117707. [Google Scholar] [CrossRef]

- Ascoli, D.; Sirca, C.; Marchetti, M.; Salis, M.; Spano, D.; Scarpa, C.; Costa-Saura, J.M.; Bacciu, V. Estimating annual GHG and particulate matter emissions from rural and forest fires based on an integrated modelling approach. Sci. Total Environ. 2024, 907, 167960. [Google Scholar] [CrossRef]

- Oliveira, M.; Pereira, M.C.; Morais, S.; Delerue-Matos, C. Environmental particulate matter levels during 2017 large forest fires and megafires in the center region of Portugal: A public health concern? Int. J. Environ. Res. Public Health 2020, 17, 1032. [Google Scholar] [CrossRef] [PubMed]

- Kalfas, D.; Chatzitheodoridis, F.; Kalogiannidis, S.; Patitsa, C.; Papagrigoriou, A. Socio-Psychological, Economic and Environmental Effects of Forest Fires. Fire 2023, 6, 280. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Schuler, J.; Eisenbies, M.; Volk, T.; Hartley, D. Optimization of harvest and logistics for multiple lignocellulosic biomass feedstocks in the northeastern United States. Energy 2020, 197, 117260. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Gomes, C.J.P.; Meireles, C.I.R.; Ribeiro, N.M.C.A. Acacia dealbata Link. Aboveground Biomass Assessment: Sustainability of Control and Eradication Actions to Reduce Rural Fires Risk. Fire 2022, 5, 7. [Google Scholar] [CrossRef]

- Garrido, S.; Pimentel, C.; Matias, J.; Bras, P.; Rijal, P.; Inteligentes, L.L.A.d.S.; Carvalho, H. Residual Forestry Biomass Supply Chain: A Mapping Approach. Int. J. Ind. Eng. Manag. 2023, 14, 244–256. [Google Scholar] [CrossRef]

- Torres, C.A.V.; Freitas, F.; Marques, S.; Rodrigues, T.; Silva, C.J.; Dias, J.C.; Branco, P.C.; Evtyugin, D.V. Biopolymers Derived from Forest Biomass for the Sustainable Textile Industry. Forests 2025, 16, 163. [Google Scholar] [CrossRef]

- Jiang, P.; Yang, X.; Del Valle, T.M.; Zhu, J. Evaluation of straw and agricultural policy impacts on the sustainability of the straw-based bioeconomy with an agent-based model. Biomass Bioenergy 2024, 184, 107177. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Rusch, M.; Schöggl, J. Application of digital technologies for sustainable product management in a circular economy: A review. Bus. Strat. Environ. 2023, 32, 1159–1174. [Google Scholar] [CrossRef]

- Romaní, A.; Jesus, M.; Mata, F.; Domingues, L. Current Options in the Valorisation of Vine Pruning Residue for the Production of Biofuels, Biopolymers, Antioxidants, and Bio-Composites following the Concept of Biorefinery: A Review. Polymers 2022, 14, 1640. [Google Scholar] [CrossRef]

- Matias, J.C.O.; Nunes, L.J.R.; Bastos, T.; Teixeira, L.C. Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform. Logistics 2023, 7, 56. [Google Scholar] [CrossRef]

- Bastos, T.; Matias, J.; Nunes, L.J.; Teixeira, L.C. Optimizing the agroforestry residual biomass supply chain: A disruptive tool for mitigating logistic costs and enhancing forest management. Results Eng. 2023, 20, 101500. [Google Scholar] [CrossRef]

- Torralba, M.; Miqueo, A.; Yagüe-Fabra, J.A. Operator-centred Lean 4.0 framework for flexible assembly lines. Procedia CIRP 2021, 104, 440–445. [Google Scholar] [CrossRef]

- Holweg, M.; Staudacher, A.P.; Hoberg, K.; Cifone, F.D. ‘Lean 4.0’: How can digital technologies support lean practices? Int. J. Prod. Econ. 2021, 241, 108258. [Google Scholar] [CrossRef]

- Rosa, M.J.; Ávila, L.; Calçado, R. Combining business process management and lean manufacturing to improve information and documentation flows: A case study. Bus. Process. Manag. J. 2024, 30, 2564–2585. [Google Scholar] [CrossRef]

- Hokkanen, L.; da Silva, T.J.; de Assumpção, M.; Leal, G.C.L.; Balancieri, R.; Guerino, G.C. User Experience Practices in Software Startups: A Systematic Mapping Study. Adv. Human-Computer Interact. 2022, 2022. [Google Scholar] [CrossRef]

- Kose, B.O. Business process management approach for improving agile software process and agile maturity. J. Software Evol. Process. 2021, 33, e2331. [Google Scholar] [CrossRef]

- Darzi, A.; Mayer, E.; Klaber, R.; Symons, J.; Khanbhai, M.; Flott, K.; Harrison-White, S.; Spofforth, J.; Manton, D. Enriching the Value of Patient Experience Feedback: Web-Based Dashboard Development Using Co-design and Heuristic Evaluation. JMIR Hum. Factors 2022, 9, e27887. [Google Scholar] [CrossRef]

- Bastos, T.; Nunes, L.; Teixeira, L. Enhancing Agroforestry Residual Biomass Recovery: Developing and Validating a Supply Chain Management App-Based Model. Int. J. Ind. Eng. Manag. 2025, 16, 139–149. [Google Scholar] [CrossRef]

- Nunes, L.J.; Bastos, T.; Teixeira, L.C. Forest 4.0: Technologies and digitalization to create the residual biomass supply chain of the future. J. Clean. Prod. 2024, 467, 143041. [Google Scholar] [CrossRef]

- Dickens, M.; Hallett, S.H.; Dick, A.; Hardy, D.; Coulon, F.; Thomas, R.; Hammond, E.B.; Beriro, D.J.; Washbourn, E. The development of a novel decision support system for regional land use planning for brownfield land. J. Environ. Manag. 2024, 349, 119466. [Google Scholar] [CrossRef]

- Hrouga, M.; Sbihi, A. Logistics 4.0 for supply chain performance: Perspectives from a retailing case study. Bus. Process. Manag. J. 2023, 29, 1892–1919. [Google Scholar] [CrossRef]

- Lioutas, E.D.; Kamariotou, M.; Kitsios, F.; Talias, M.A.; Charatsari, C. Digital strategy decision support systems: Agrifood supply chain management in SMEs. Sensors 2022, 22, 274. [Google Scholar] [CrossRef]

- Pereira, J.A.M.; Berenguer, C.V.; Câmara, J.S.; Perestrelo, R. Management of Agri-Food Waste Based on Thermochemical Processes towards a Circular Bioeconomy Concept: The Case Study of the Portuguese Industry. Processes 2023, 11, 2870. [Google Scholar] [CrossRef]

- Carvalho, H.; Pimentel, C.; Matias, J.; Garrido, S.; Rijal, P. Drivers and barriers of residual agroforestry biomass valorization: A systematic literature review. Agrofor. Syst. 2025, 99, 81. [Google Scholar] [CrossRef]

- Tantiwatthanaphanich, T.; Zou, X. Empowering the Local Community Via Biomass Utilization: A Case Study In Thailand. Int. Rev. Spat. Plan. Sustain. Dev. 2016, 4, 30–45. [Google Scholar] [CrossRef]

- Milojković, J.; Šoštarić, T.; Dimitrijević, J.; Simić, M.; Petrović, J.; Koprivica, M.; Ercegović, M. Improvement of combustible characteristics of Paulownia leaves via hydrothermal carbonization. Biomass Convers. Biorefinery 2024, 14, 3975–3985. [Google Scholar] [CrossRef]

| Actor | Description |

|---|---|

| Requester | The person who has a need, which can be biomass transportation, fuel loads removal, or biomass acquisition. |

| Service Provider (SP) | The person who answers the need, which can be a transport provider, forestry operator, or biomass seller. |

| Facilitator | The person who acts for the requester. They do not have the need but have permission to communicate the need into the system. |

| Management Entity (ME) | The entity responsible for ensuring the platform functions well. It can change platform parametrization and assess information about the platform’s impact. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, T.; Matias, J.; Nunes, L.; Teixeira, L. Technology for Boosting Sustainability: A Web App-Based Information Model for Boosting Residual Biomass Recovery. Land 2025, 14, 1332. https://doi.org/10.3390/land14071332

Bastos T, Matias J, Nunes L, Teixeira L. Technology for Boosting Sustainability: A Web App-Based Information Model for Boosting Residual Biomass Recovery. Land. 2025; 14(7):1332. https://doi.org/10.3390/land14071332

Chicago/Turabian StyleBastos, Tiago, João Matias, Leonel Nunes, and Leonor Teixeira. 2025. "Technology for Boosting Sustainability: A Web App-Based Information Model for Boosting Residual Biomass Recovery" Land 14, no. 7: 1332. https://doi.org/10.3390/land14071332

APA StyleBastos, T., Matias, J., Nunes, L., & Teixeira, L. (2025). Technology for Boosting Sustainability: A Web App-Based Information Model for Boosting Residual Biomass Recovery. Land, 14(7), 1332. https://doi.org/10.3390/land14071332