Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation

Abstract

:1. Introduction

2. Materials and Methodology

2.1. As-Samra Wastewater Treatment Plant

2.2. Raw Material Preparation and Testing

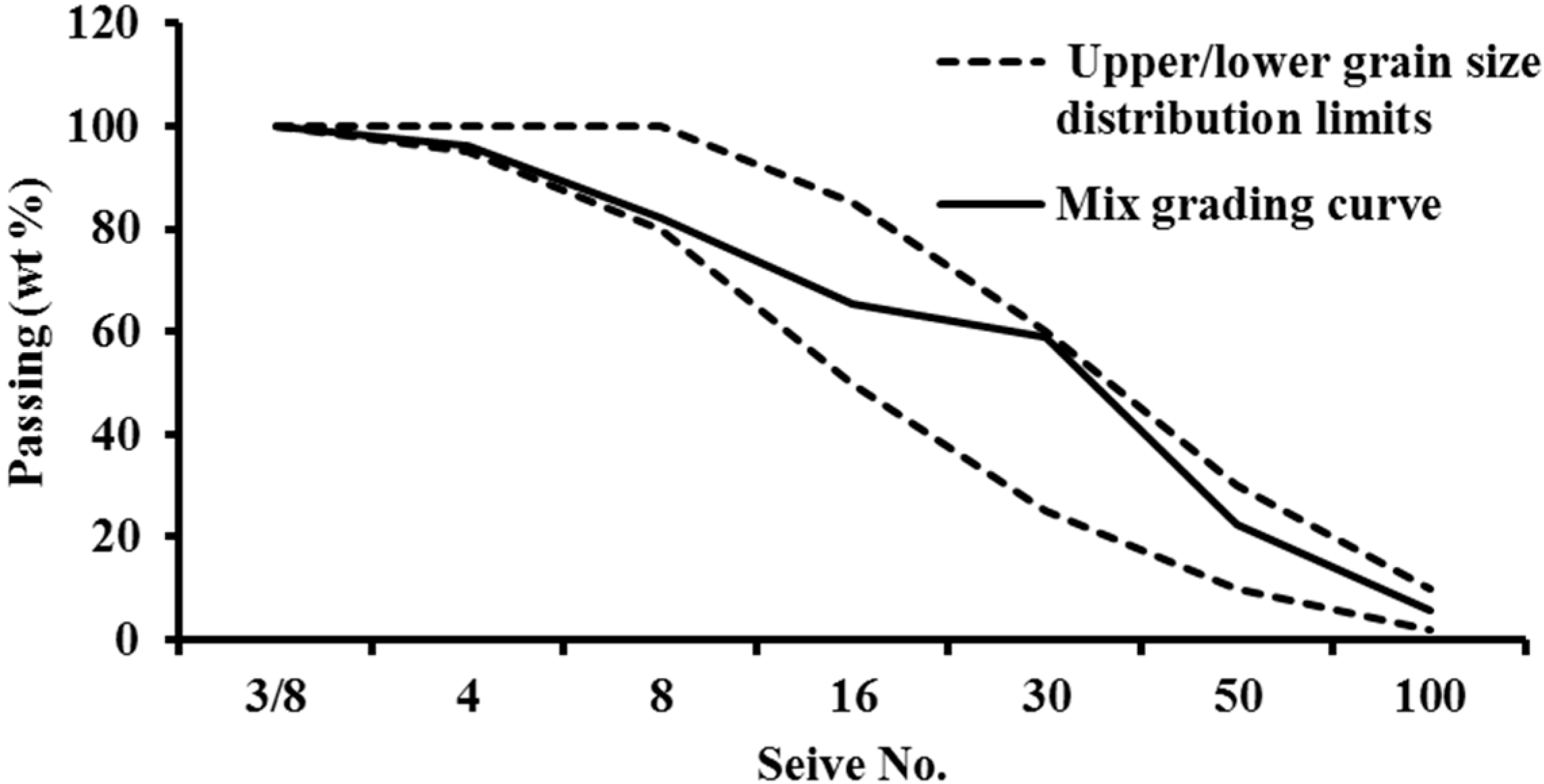

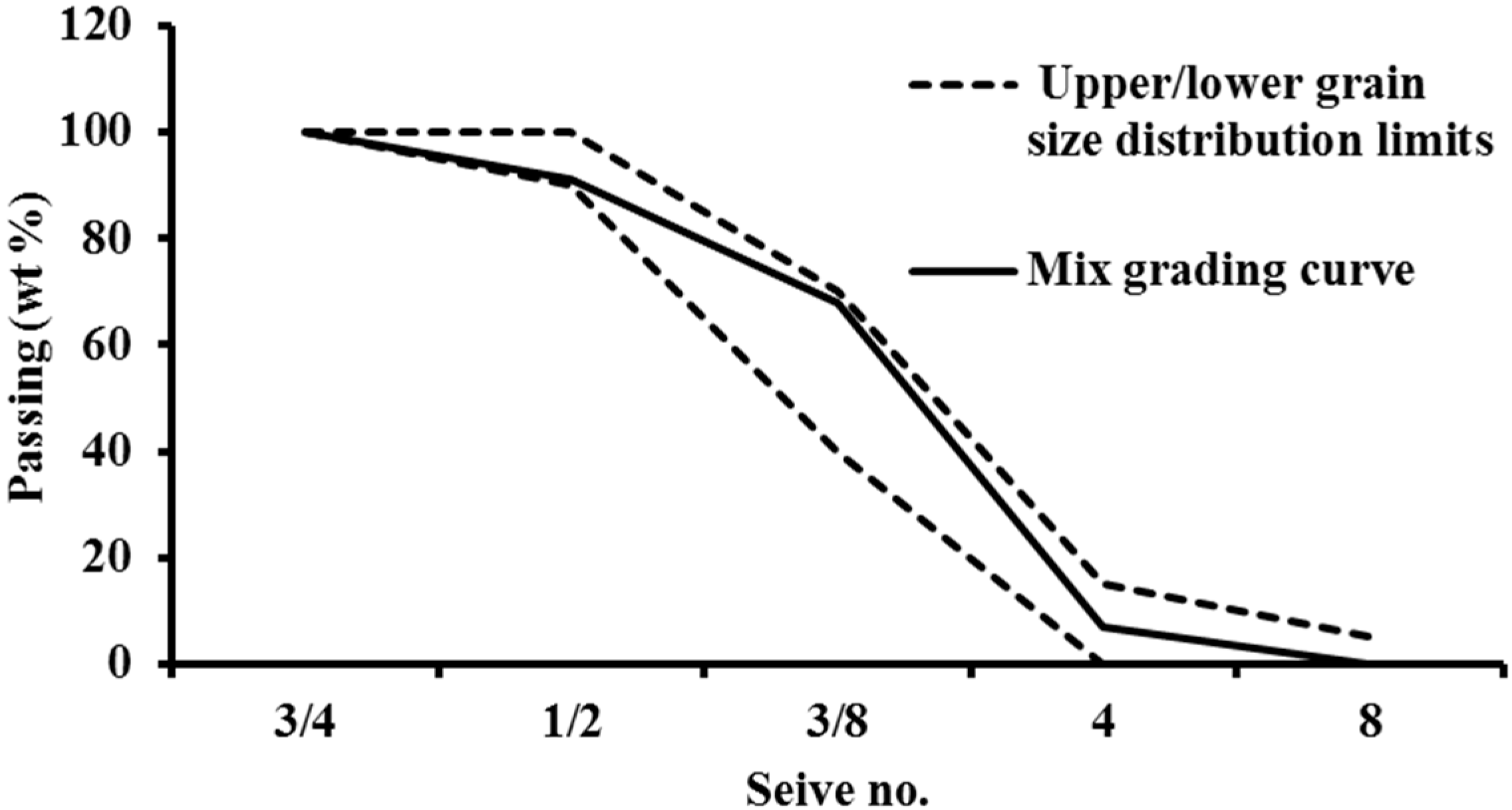

2.2.1. Aggregates

2.2.2. Cement

2.3. Experimental Work for Mortar

2.4. Mixes Experimental Work for Concrete

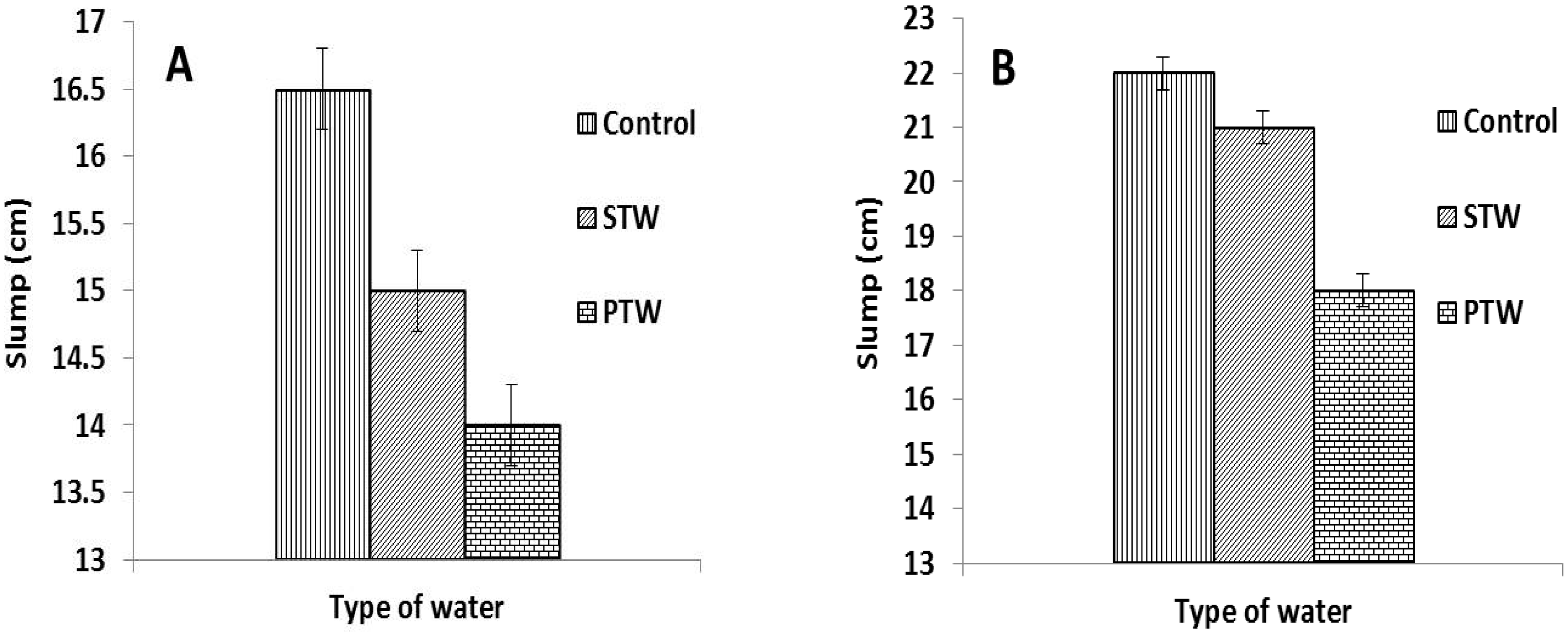

2.4.1. Concrete Trial Mixes

2.4.2. Scaling up to Real Concrete Production

3. Results and Discussion

3.1. Treated Domestic Wastewater Quality

3.2. Effects of Treated Wastewater on Cement Paste

3.3. Effects of Treated Wastewater on Mortar Properties

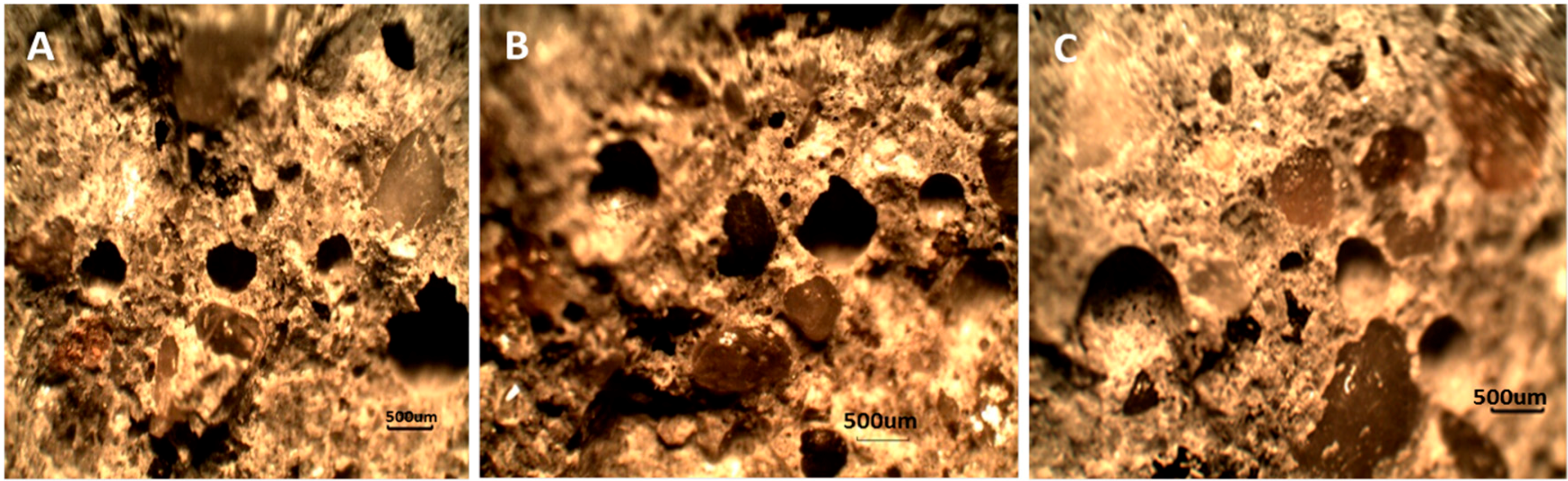

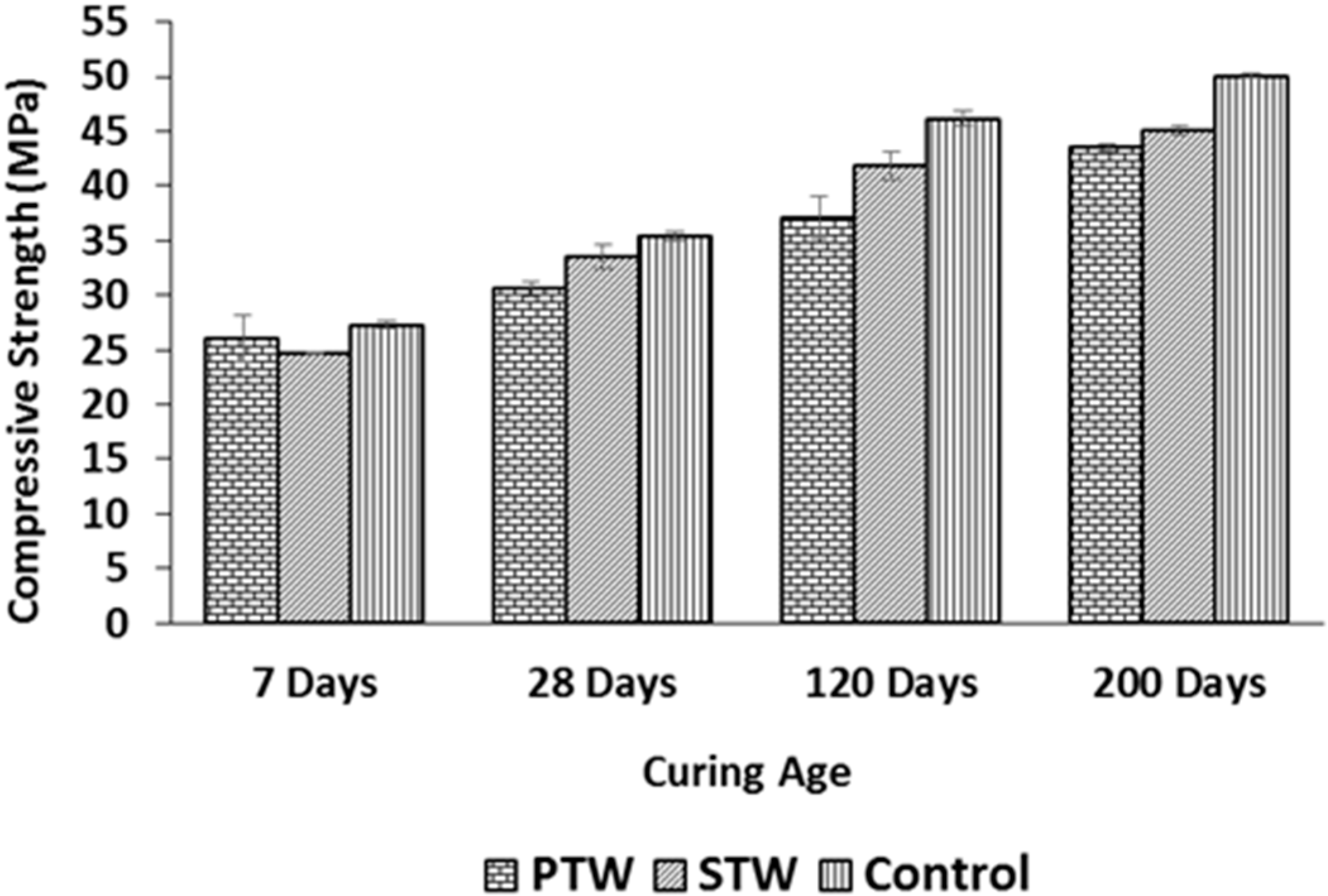

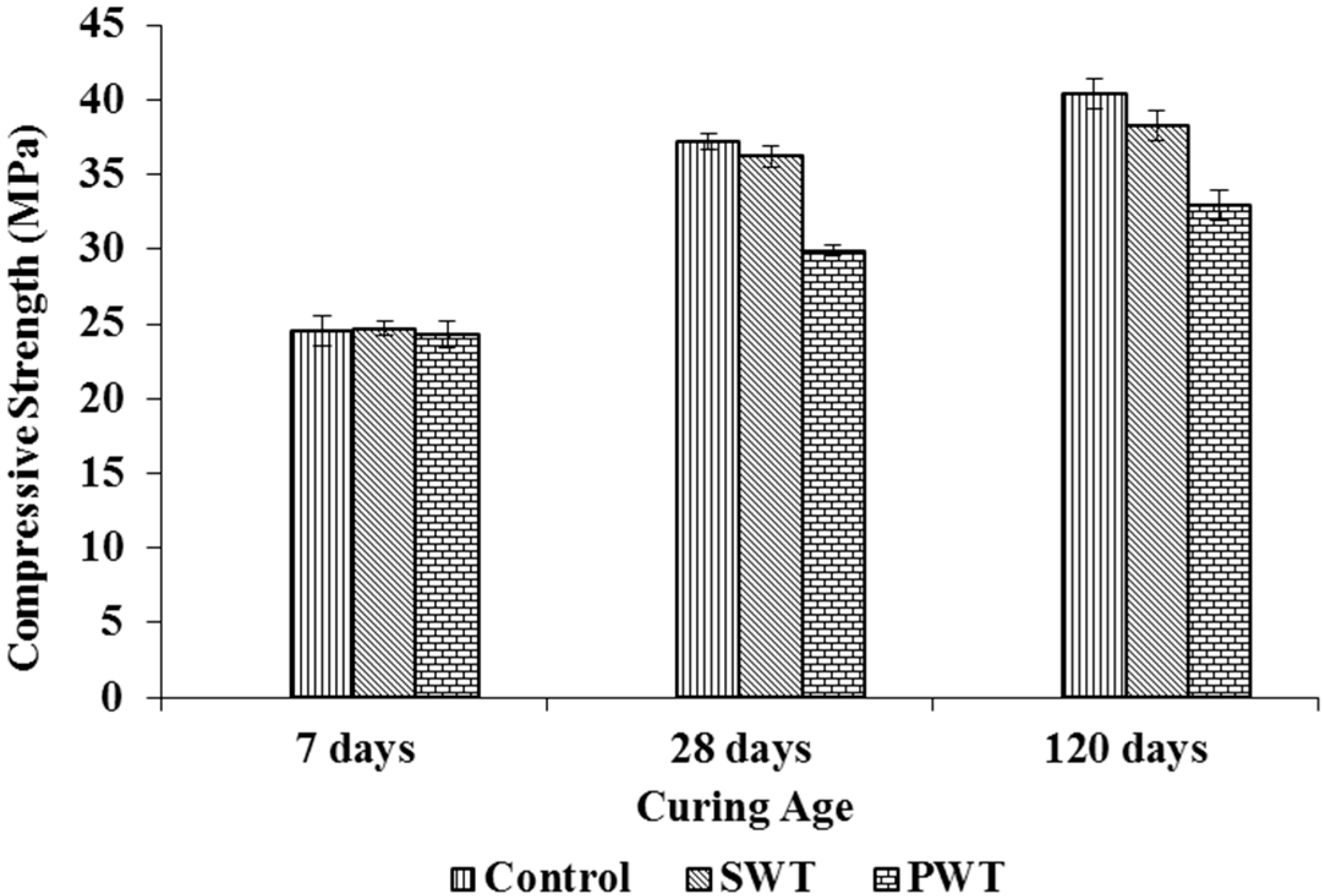

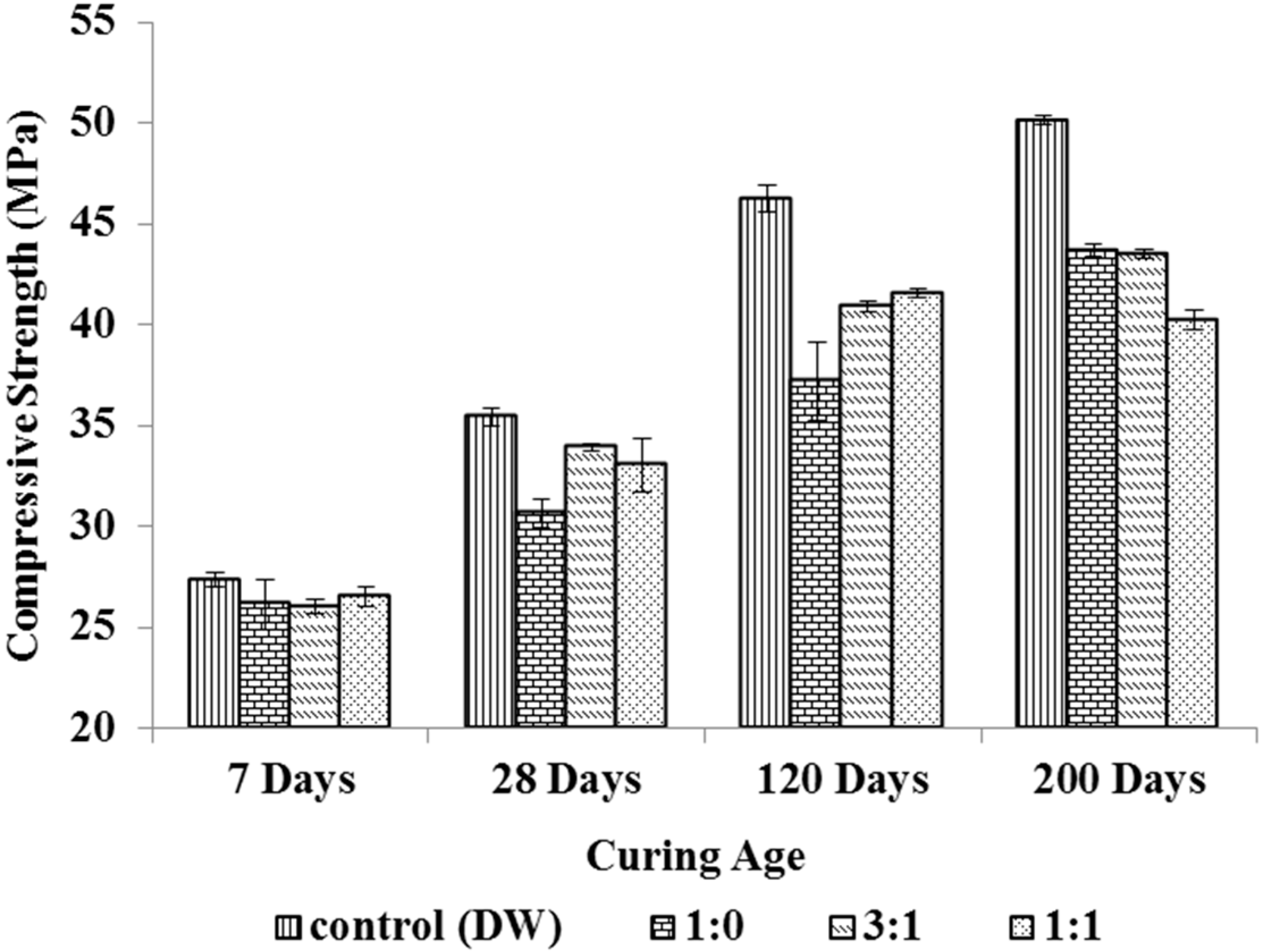

3.4. Effects on Concrete Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McCornick, P.G.; Hijazi, A.; Sheikh, B. From wastewater reuse to water reclamation: Progression of water reuse standards in Jordan. In Wastewater Use in Irrigated Agriculture: Confronting the Livelihood and Environmental Realities; Scott, C.A., Faruqui, N.I., Raschid-Sally, L., Eds.; CABI Publishing: Wallingford, UK, 2004; pp. 113–125. [Google Scholar]

- Jordan Institution for Standards and Metrology. Water—Reclaimed Domestic Wastewater; Jordanian Standard JS 893; Jordan Institution for Standards and Metrology: Amman, Jordan, 2006.

- Ammary, B.Y. Wastewater reuse in Jordan: Present status and future plans. Desalination 2007, 211, 164–176. [Google Scholar] [CrossRef]

- Hashemite Kingdom of Jordan-Ministry of Water and Irrigation (MWI). Water for Life. Jordan’s Water Strategy 2008–2022; MWI: Amman, Jordan, 2009.

- Hashemite Kingdom of Jordan-Ministry of Water and Irrigation (MWI). National Water Strategy of Jordan 2016–2025. 2016. Available online: http://www.mwi.gov.jo/sites/en-us/Hot%20Issues/Strategic%20Documents%20of%20%20The%20Water%20Sector/National%20Water%20Strategy(%202016-2025)-25.2.2016.pdf (accessed on 25 June 2016). [Google Scholar]

- Economic and Commerce Bureau (ECB). Jordan’s Economic and Commerce Bureau—Construction and Building Materials; Embassy of the Hashemite Kingdom of Jordan: Washington, DC, USA, 2016; Available online: http://www.jordanecb.org/Public/English.aspx?Site_Id=1&Page_Id=555&menu_id=38 (accessed on 17 June 2016).

- Shekarchi, M.; Yazdian, M.; Mehrdadi, N. Use of biologically treated wastewater in concrete. Kuwait J. Sci. Eng. 2012, 39, 97–111. [Google Scholar]

- Naik, T.R. Sustainability of the cement and concrete industries. In Sustainable Construction Materials and Technologies; Chun, Y.M., Claisse, P., Naik, T.R., Ganjian, E., Eds.; Taylor and Francis: Coventry, UK, 2007; pp. 19–25. [Google Scholar]

- Silva, M.; Naik, T.R. Sustainable use of resources—Recycling of sewage treatment plant water in concrete. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28 June 2010.

- Cebeci, O.Z.; Saatci, A.M. Domestic sewage as mixing water in concrete. ACI Mater. J. 1989, 86, 503–506. [Google Scholar]

- Tay, J.; Yip, W. Use of reclaimed wastewater for concrete mixing. J. Environ. Eng. 1987, 113, 1156–1161. [Google Scholar] [CrossRef]

- Mahasneh, B.Z. Assessment of Replacing Wastewater and Treated Water with Tap Water in Making Concrete Mix. Research Gate Net. 2005. Available online: http://www.ejge.com/2014/Ppr2014.223mar.pdf (accessed on 22 August 2016).

- Saricimen, H.; Shameem, M.; Barry, M.; Ibrahim, M. Testing of Treated Effluent for Use in Mixing and Curing of Concrete. E-prints. 2008. Available online: http://eprints.kfupm.edu.sa/1745/1/91-104_Testing_of_Treated_Effluent_for_use_in_Mixing_and_Curing_of_Concrete_H-Saricimen_M-Shameem_M-Barry_and_M-Ibrahim.PDF (accessed on 11 May 2016).

- Al-Ghusain, I.; Terro, M.J. Use of treated wastewater for concrete mixing in Kuwait. Kuwait J. Sci. Eng. 2003, 30, 213–228. [Google Scholar]

- Lee, O.S.; Salim, M.R.; Ismail, M.; Ali, M.I. Reusing treated effluent in concrete technology. Jurnalteknologi 2001, 34, 1–10. [Google Scholar]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater; APHA: Washington, DC, USA, 2006. [Google Scholar]

- Moavenzadeh, F. Concise Encyclopedia of Building and Construction Materials; The MIT Press: Cambridge MA, USA, 1990; p. 689. [Google Scholar]

- ASTM International. Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM C230/C230M; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- European Committee for Standarization. Methods of Testing Cement. Determination of Strength; BS EN 196-1&2; European Committee for Standarization: Brussels, Belgium, 2005. [Google Scholar]

- American Society for Testing and Materials. Compressive Strength of Hydraulic Cement Mortar; ASTM C-109; American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- European Committee for Standarization. Methods of Test of Mortar for Masonry; BS EN 1015-11; European Committee for Standarization: Brussels, Belgium, 2007. [Google Scholar]

- Gambhir, M.L. Concrete Technology, 3rd ed.; Tata McGraw-Hill: New Delhi, India, 2004. [Google Scholar]

- Callister, W.D., Jr. Materials Science & Engineering an Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Jordan Institution for Standards and Metrology. Concrete—Testing Hardened Concrete, Part 2: Making and Curing Specimens for Strength Tests; JS 1652-1; Jordan Institution for Standards and Metrology: Amman, Jordan, 2004.

- European Committee for Standarization. Testing Fresh Concrete, Slump-Test; EN 12350-2; European Committee for Standarization: Brussels, Belgium, 2009. [Google Scholar]

- Kucche, K.J.; Jamkar, S.S.; Sadgir, P.A. Quality of water making concrete: A review of literature. Int. J. Sci. Publ. 2015, 5, 1–10. [Google Scholar]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C. Design and Control of Concrete Mixtures. Engineering Bulletin 001, 14th ed.; Portland Cement Association (PCA): Skokie, IL, USA, 2003. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: London, UK, 2011; p. 2833. [Google Scholar]

- Cement Concrete & Aggregates Australia. Use of Recycled Water in Concrete Production Report; Cement Concrete & Aggregates Australia: Sydney, Australia, 2007. [Google Scholar]

- ASTM International. Time of Setting of Hydraulic Cement by Vicat Needle; ASTM C 191; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Viessman, W.J.; Hammer, M.J. Water Supply and Pollution Control, 4th ed.; Harper and Row: New York, NY, USA, 1985. [Google Scholar]

- ASTM International. Standard Specification for Ready Mix Concrete; ASTM C94/C94M-14b; ASTM International: West Conshohocken, PA, USA, 1994. [Google Scholar]

- European Committee for Standardization. Mixing Water for Concrete—Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete; European Standard EN 1008; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- Environmental Protection Agency (EPA). Guidelines for Water Reuse Technical Issues in Planning Water Reuse Systems; EPA/625/R-04/108; U.S. Agency for International Development: Washington, DC, USA, 2004; Chapter 3.

- Jordan Institution for Standards and Metrology. Composition Specifications and Conformity Criteria for Common Cements; JS 30-1; Jordan Institution for Standards and Metrology: Amman, Jordan, 2007.

- Alqedra, M.M.; Arafa, M.; Mattar, M. Influence of low and high organic wastewater sludge on physical and mechanical properties of concrete mixes. J. Environ. Sci. Technol. 2011, 4, 354–365. [Google Scholar] [CrossRef]

- Tang, F.J.; Gartner, E.M. Influence of Sulphate Source on Ponland Cement Hydration. Adv. Cem. Res. 1988, 1, 67–74. [Google Scholar] [CrossRef]

- Lawrence, C.D. Changes in Composition of the Aqueous Phase during Hydration of Cement Pastes and Suspensions. Highw. Res. Board Spec. Rep. 1966, 90, 378–391. [Google Scholar]

- AbdolChini, S.; Mbwambo, W.J. Environmentally friendly solutions for the disposal of concrete wash water from ready mixed concrete operations. In Proceedings of the CIB W89 Beijing International Conference, Beijing, China, 21–24 October 1996.

- Bureau of Indian Standard. Plain and Reinforced Concrete Code of Practice; IS 456; Bureau of Indian Standard: New Delhi, India, 2000. [Google Scholar]

| Aggregate Type | Median Particle Size (mm) | Bulk Specific Gravity (SSD) | Absorption (%) |

|---|---|---|---|

| Coarse Aggregate (Fouleyeh) | 12.50 | 2.50 | 3.6 |

| Coarse Aggregate (Hemseyeh) | 9.50 | 2.67 | 0.9 |

| Coarse Aggregate (Adaseyeh) | 4.73 | 2.67 | 1.2 |

| Fine Aggregate (Semsmeyeh) | 2.36 | 2.65 | 1.5 |

| Fine Aggregate (Swealeh sand) | 0.30 | 2.62 | 1.0 |

| Property | Test Result (%) | Limitations | Test Method |

|---|---|---|---|

| Chloride Content (Cl) | 0.031 | ≤0.10 | [16] |

| Sulfate Content (SO3) | 3.20 | ≤3.5 | [16] |

| Insoluble Residue | 11.93 | --- | [16] |

| Quantit (kg/m3) | ||

|---|---|---|

| Mix Contents | Bench-scale | Full-scale |

| Fouleyehy * | - | 463 |

| Hemseyeh * | 514.728 | - |

| Adaseyeh * | 370.3 | 520 |

| Semsmeyeh * | 252.1 | 318 |

| Swealeh Sand * | 502.7 | 574 |

| Cement | 418.18 | 280 |

| Total Water | 233 | 190 |

| Superplasticizer | Zero | 5 |

| Parameter | Unit | PTW | STW | FW | DW | * Maximum Concentration |

|---|---|---|---|---|---|---|

| TSS | mg/L | 148 | 10.5 | <2 | <2 | 2000 |

| TDS | mg/L | 900 | 974 | 499 | <2 | 2000 |

| COD | mg/L | 538 | 46.9 | <5 | <5 | 500 |

| BOD | mg/L | 226 | 2.6 | <2 | <2 | - |

| Cl | mg/L | 251 | 291 | 107 | <5 | 500 |

| SO4 | mg/L | 106 | 106.2 | 78.4 | <5 | 2000 |

| NH3 | mg/L | 54.4 | <4.5 | <0.08 | <0.08 | No specific limit |

| pH | - | 7.2 | 7.5 | 7.59 | 6 | 6–8 |

| E. coli | MPN/100 mL | 1.70 × 107 | ˂1 | <1 | <1 | ** ˂200 |

| Water Type | Wt. of Cement (gm) | Water (CC) | Water/Cement (%) | Initial Setting Time (min) | * Needle Penetration (mm) | Soundness (mm) |

|---|---|---|---|---|---|---|

| PTW | 500 | 149 | 29.8 | 210 | 4 | 1 |

| STW | 500 | 148 | 29.6 | 185 | 4 | 1 |

| Control | 500 | 146 | 29.2 | 180 | 6 | 1 |

| Curing Age (Day) | Mortar Relative Strength Index (%) | Concrete Relative Strength Index (%) | ||

|---|---|---|---|---|

| PTW | STW | PTW | STW | |

| 7 | −14.9 | −3.7 | −4.5 | −9.8 |

| 28 | −16.2 | +0.7 | −13.5 | −5.1 |

| 120 | −13.6 | −5.3 | −19.6 | −7.2 |

| 200 | −12.9 | −2.24 | −13.2 | −10.1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghrair, A.M.; Al-Mashaqbeh, O. Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation. Water 2016, 8, 366. https://doi.org/10.3390/w8090366

Ghrair AM, Al-Mashaqbeh O. Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation. Water. 2016; 8(9):366. https://doi.org/10.3390/w8090366

Chicago/Turabian StyleGhrair, Ayoup M., and Othman Al-Mashaqbeh. 2016. "Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation" Water 8, no. 9: 366. https://doi.org/10.3390/w8090366

APA StyleGhrair, A. M., & Al-Mashaqbeh, O. (2016). Domestic Wastewater Reuse in Concrete Using Bench-Scale Testing and Full-Scale Implementation. Water, 8(9), 366. https://doi.org/10.3390/w8090366