A.1. Calculations for Energy Balance

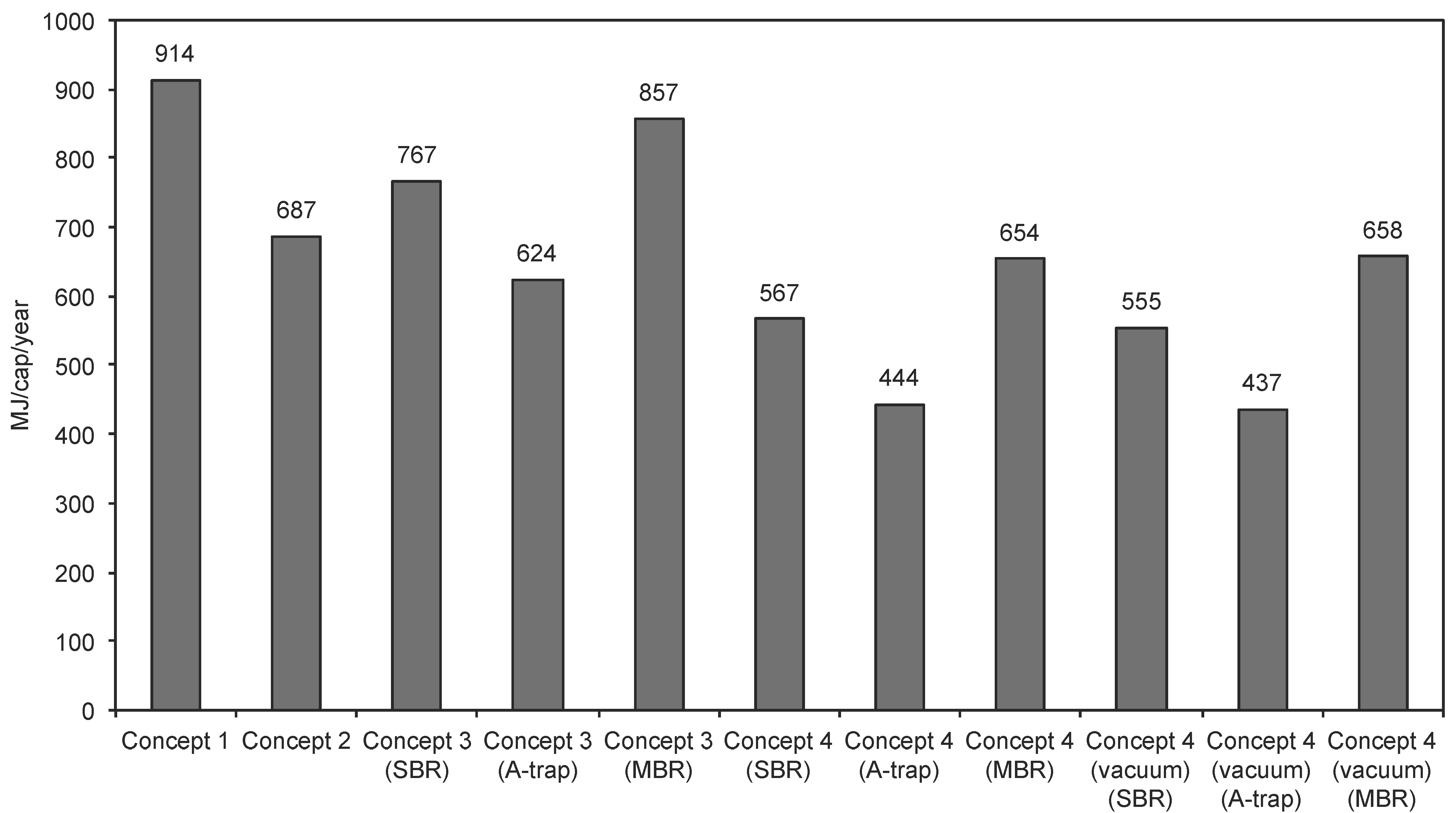

was the energy requirement for the gravity sewers with lifting stations (20 kWh/cap/y) [

50] in Concepts 1 and 2, for the vacuum collection and transport of black water and kitchen refuse (25 kWh/cap/y) [

4] in Concept 3 and for the vacuum collection and transport of feces and kitchen refuse (8 kWh/cap/y) in Concept 4 (assumed to be

of the energy requirement for the black water vacuum collection according to the water consumption ratio of

L). Urine separation in Concept 2 was assumed not to have a significant effect on the total wastewater flow and, thus, on the energy requirement for the collection. Due to short wastewater transport distances in semi-centralized sanitation, the energy requirement for the gravity urine diverting toilet was assumed to be insignificant. The collection also included the energy consumption for the kitchen grinder (5 kWh/cap/y) [

4] in all of the sanitation concepts.

In Concepts 1 and 2,

consisted of the following energy parameters.

was the aeration energy required to oxidize organic matter and nitrogen in the AS process, A-trap and post-nitrification step and was calculated based on an energy requirement of 2.2 MJ/kgCOD

converted and 14 MJ/kgN

converted [

7]. The aeration energy was calculated based on the fraction of oxidized COD of the total COD removed (43% in Concept 1 and 22% in Concept 2) and the fraction of nitrified N of the total N removed (94% in Concept 1 and 76% in Concept 2) [

22].

was the energy requirement for mixing of the biological reactors and the anaerobic digester, and

was the energy requirement for pumping of the internal flows, return activated sludge and excess sludge to the anaerobic digester [

22]. In Concept 1, additional mixing energy of 5 MJ/kg P

removed originated from the biological phosphorus removal [

7].

was the energy required to heat up the influent (excess sludge) to the operational temperature of the digester and to compensate heat loss through the digester walls. The primary energy required to heat up the influent was calculated according to Equation (A1):

where ΔQ is the required energy (J),

m is the mass of liquid (g),

C is the specific heat capacity of water (4.2 J/g °C) and ΔT is the temperature difference between the influent temperature and the operational temperature of the reactor. The influent temperature of the digester (Concept 1 and 2) was considered to be the tap water temperature (12 °C). The primary energy required to compensate heat loss was calculated according to Fourier’s law presented in Equation (A2):

where Φ is the heat transfer (W),

λ is the thermal conductivity of the isolation material (W/m*k),

A is the heat transfer area,

dT is the temperature difference across the isolation material (K) and

dx is the thickness of the isolation material (m). Mineral wool with thermal conductivity of 0.04 W/m*k and thickness of 0.05 m was considered to be used as isolation material [

5]. The area of heat transfer was considered to be the surface area of the reactor (calculated from the volume and dimensions of the reactor presented under the sub-chapter

Calculations for reactor dimensions and land area requirement), and the temperature difference was considered to be the difference between the environmental temperature (10 °C) and the operational temperature of the reactor (35 °C).

and

were the primary energy requirements for dewatering of the digested sludge and for incinerating the dewatered sludge according to the study of Wilsenach and van Loosdrecht [

22], from which they were recalculated to primary energy using an efficiency of 0.31. The heat production in the incineration of sludge was taken into account in the energy requirement.

E

sludge transport was the energy requirement for transporting of dewatered sludge to the incineration plant and was calculated based on a primary energy requirement of 4.8 MJ/t/km (including empty return trip) [

22]. E

urine transport was the energy requirement for transporting of urine from the on-site collection to agricultural land and was calculated based on the energy requirement of transporting described above.

was the energy produced as methane in the digestion of excess sludge and was calculated by taking into account the different excess sludge compositions in Concepts 1 and 2, originating from the different SRTs (12 d and 0.8 d, respectively). As presented in the study of Wilsenach and van Loosdrecht [

22], excess sludge from the A-trap was considered to consist of 25% adsorbed substrate and 75% biomass. The methanization level of the adsorbed substrate was assumed to be 73% [

51]. No adsorbed substrate was considered in Concept 1, due to the high SRT. The fraction of biodegradable biomass in Concept 1 was assumed to be 45% and in Concept 2 65%, and the methanization level of this fraction was considered to be 90% [

22]. The volume of the produced methane was calculated using a theoretical methane production of 0.35 L/gCOD, and the primary energy production from methane was calculated using the volume of methane and the calorific value of methane (35.8 MJ/m

3) [

28].

The sludge production in the AS process (Concept 1) and the A-trap (Concept 2) was calculated according to Tchobanoglous

et al. [

28] [Equation (A3)]:

where

P is the sludge production (kgVSS/d),

Y is the sludge yield (kgVSS/kg BOD

removed),

Q is the influent flow (m

3/d), S

0 is the influent BOD concentration (mg/L) and

S is the effluent BOD concentration (mg/L). A sludge yield of 0.58 kgVSS/kg BOD

removed was used for the AS process (SRT 12 d) and 0.85 kgVSS/kg BOD

removed for the A-trap (SRT 0.8 d) at 12 °C. The sludge production as total solids was calculated using a VSS/TSS ratio of 0.85 [

28]. The total wet sludge production was calculated using a dry solid content of 2.5%, and the total dry sludge production (after dewatering) was calculated using a dry solid content of 20% [

22]. In Concept 1, additional sludge production of 3.3 kgTSS/kg P

removed was assumed to originate from the biological phosphorus removal [

7].

The composition of the sludge rejection water (COD, TN and TP) was defined as the difference between the digester influent (excess sludge from the AS process and A-trap) and the COD converted into methane and nitrogen and phosphorus incorporated into the anaerobic biomass. The amount of biomass produced in the digester was calculated using a biomass yield of 0.08 gVSS/g COD

converted, and the amount of nitrogen and phosphorus incorporated into the biomass was calculated using fractions of 0.12 gN/g VSS and 0.03 gP/g VSS, respectively [

28]. All of the nitrogen and phosphorus in the sludge rejection water was considered to be in the inorganic form of NH

4+ and PO

43−.

In Concepts 3 and 4,

consisted of the following energy parameters.

was the energy required to heat up the influent to the operational temperature of the reactor and to compensate heat loss through the reactor walls, calculated as described above with the digester in Concepts 1 and 2. The influent temperature of the UASB reactor was calculated from the mass proportions of the according wastewater sub-streams (

Table 2). In the case of grey water sludge co-digestion in the UASB reactor, the influent temperature was adjusted with the temperature of grey water sludge that was assumed to be the environmental temperature (10 °C). No heating energy for other treatment steps were taken into account.

was the energy requirement for the OLAND reactor and was derived from the rotating power requirement of the rotating biological contactor according to Fujie

et al. [

52] [Equation (A4)]).

where

A is the surface area of the discs (m

2),

λ1 is the frictional constant (8.6*10

−6 kWmin

2/min

4),

N is the rotational speed of a disc (min

−1) and

D is the disc diameter (m). The surface area of the discs was calculated from the total nitrogen load and the biofilm load (6300 mgN/m

2/d [

53]). The disc rotational speed of 3 min

−1 [

6] and the disc diameter of 1 m [

52] were selected.

was the energy requirement for the struvite precipitation and was calculated based on an electricity consumption of 3.8 kWh/kgN

influent [

53].

was the energy requirement for the trickling filter as a post-treatment step in both black water and grey water treatment lines and was calculated based on an average electricity consumption of 3 kW/1000 m

3influent [

28].

was the energy requirement for the MBR and was calculated based on an average electricity consumption of 0.3 kWh/m

3greywater [

54]. The electricity consumption for the OLAND reactor, struvite precipitator, TF and the MBR was converted to primary energy using an efficiency of 0.31 [

36].

and

were the energy requirements for grey water treatment in the SBR and the A-trap, respectively, consisting of energy consumption for pumping and aeration. Energy consumption for pumping was calculated with Equation (A5) according to Karassik

et al. [

55]:

where

Q is the flow rate,

H is the pump head and

η is the pump efficiency. For the SBR, the pump head was considered to be the height of wastewater in the reactor. For the A-trap, the pump head was considered to be the height of the buffer tank for influent pump and the height of the aerated grit chamber and settling tank for the two intermediate pumps (calculations for pump head are presented in the sub-chapter

Calculations for reactor dimensions and land area requirement). The specific gravity of fluid was considered to be one and

η was set to 0.68, according to the study of Wilsenach and van Loosdrecht [

22]. The total energy consumption for pumping in the SBR was calculated from the energy consumption for two pumps: influent and effluent pump, feeding and discharge time of 15 min each and a total cycle time of 360 min [

9]. The total energy consumption for pumping in the A-trap was calculated by assuming the pumping to be continuous. The energy requirement for pumping of the UASB influent was calculated to be insignificant and was not included in the energy balance. The energy consumption for aeration in the SBR and the A-trap was calculated according to the energy requirement of 2.2 MJ/kgCOD

converted [

7]. The amount of oxidized COD in the SBR was calculated by defining the total amount of biodegradable COD removed in the reactor using a COD

biodegradable/BOD

5 ratio of 1.6 g/g [

28] and excluding the amount of COD removed in the sludge using a sludge yield of 0.12 kgVSS/kgCOD [

9] and a COD/VSS ratio of 1.4. The amount of oxidized COD in the A-trap was assumed to be 11% of the incoming COD [

34]. Nitrogen removal in the SBR and A-trap was assumed to take place only through the excess sludge removal.

and

were the energy requirements for transporting of excess sludge from the UASB reactor and the SBR and urine, respectively, from the on-site collection to agricultural land, and was calculated based on the primary energy requirement of 4.8 MJ/t/km (including empty return trip) [

22].

was the energy produced as methane in the UASB reactor. The volume of produced methane was calculated from the COD load of the reactor, the methanization level of the influent and the theoretical methane production of 0.35 L/gCOD. The methanization level of the influent was calculated as a mass proportion of the methanization levels of the sub-streams (70% for black water with kitchen refuse, 78% for feces with kitchen refuse [

5] and 88% for grey water sludge [

12]). The primary energy production from methane was calculated using the volume of methane and the calorific value of methane (35.8 MJ/m

3) [

28].

The sludge production in the UASB reactor was calculated according to Zeeman and Lettinga [

56] [Equation (A6)]:

where

Xp is the sludge production (kgCOD/m

3/d),

O is the organic loading rate (2.98 kgCOD/m

3/d [

33]),

SS is the fraction of suspended solids in the influent (COD

ss/COD

total) (0.76 with a mixture of black water and kitchen refuse, and 0.88 with a mixture of feces and kitchen refuse [

5]),

R is the fraction of COD

ss removed (0.96 [

33]) and

H is the level of hydrolysis of the removed solids (0.7 [

5]). The total wet sludge production was calculated using the volume of the UASB reactor (calculations for the reactor volume are presented in the sub-chapter

Calculations for reactor dimensions and land area requirement) and the sludge concentration (34 gCOD/L [

27]). The sludge production in the SBR was calculated using a sludge yield of 0.12 kgVSS/kgCOD

removed and a sludge concentration of 5.5 gVSS/L [

9]. The sludge production in the A-trap was calculated using a sludge yield of 0.73 kgVSS/kgCOD

removed and a sludge concentration of 6.3 gVSS/L [

34]. The sludge production in the MBR was calculated from the flow mass balance of the system using a SRT of 1 d and HRT of 1.9 h [

12].

A.3. Calculations for Reactor Dimensions and Land Area Requirement

The volume of the biological reactors and secondary settling tanks were according to Wilsenach and van Loosdrecht [

22], and the volume of the buffer tanks, urine storage tank and reactors (digester/UASB, struvite, MBR and A-trap) were determined using the influent flow rate and the storage time or the HRT. The volume of the A-trap consisted of three parts: aerated grit chamber, A-trap reactor and settling tank. The storage time was 1 d for the UASB buffer tank (assumed), 0.3 d for the SBR, A-trap and MBR buffer tanks (assumed) and six months for the urine collection tank [

7]. The HRT was 15 d for the digester [

22], 0.08 d for the struvite reactor [

35], 1.9 h for the MBR [

12], 4 min and 54 min for the aerated grit chamber and settling tank, respectively [

57], and 1.9 h for the A-trap reactor [

34]. The HRT of the UASB reactor was calculated according to Zeeman and Lettinga [

56] [Equation (A8)]:

where

C is the influent, COD

total concentration (gCOD/L),

X is the sludge concentration in the reactor (34 gCOD/L [

27]),

SS is the fraction of suspended solids in the influent (COD

ss/COD

total) (0.76 with a mixture of black water and kitchen refuse and 0.88 with a mixture of feces and kitchen refuse [

5]),

R is the fraction of COD

ss removed (0.96 [

33]),

H is the level of hydrolysis of the removed solids (0.7 [

5]), and

SRT is the sludge retention time (d) calculated from the sludge production (kgCOD/m

3/d) and the sludge concentration in the reactor.

The volume of the biogas storage tank was calculated using the volume of produced methane, the fraction of methane in biogas (65% [

28]) and storage time of 1 d [

5]. The volume of the SBR was calculated using the volume of wastewater per cycle (360 min) and a volume

wastewater/volume

total ratio of 0.3 m

3/m

3 [

28]. The volume of a single-stage TF was determined according to Tchobanoglous

et al. [

28] [Equation (A9)]:

where

W is the BOD

5 loading and

e is the BOD

5 removal efficiency. The depth of the filter was set to 2.1 m as the average depth in standard rate filters.

The volume of the OLAND reactor was determined from the length, width and height of the reactor. The length of the reactor was determined by the length of the shaft and the width and height by the disc diameter. To calculate the length of the shaft, the total number of discs was defined from the total surface area of discs and the disc diameter (determined previously with the energy requirement of OLAND). The length of the shaft was calculated using a disc thickness of 0.5 cm and a disc interspace of 1 cm [

6]. The length, width and height of the reactor was then determined using the length of the shaft and the disc diameter, respectively, with 15% of the disc diameter as extra space.

Height of the buffer tanks, digester, UASB reactor and SBR was calculated using Equation (A10), which was derived from the equation for cylinder volume using

f as a height/diameter ratio.

where

Vcylinder is the volume of the reactor and

f is the height/diameter ratio that was assumed to be three with the exception of the SBR with a ratio of 1. The diameter was calculated using an assumed maximum height of 5 m as a boundary condition.

The height of the aerated grit chamber and settling tank of the A-trap was calculated using Equation (A11), which was derived from the sum of cube volume and pyramid volume using f as the height

pyramid/height

vessel ratio:

Vvessel is the volume of the aerated grit chamber and settling tank,

A is the surface area and

f is the height

pyramid/height

vessel ratio of 0.1 for the aerated grit chamber and 0.5 for the settling tank. The surface area of the aerated grit chamber was calculated using a maximum surface loading of 30 m

3/(m

2h), and the surface area of the settling tank was calculated using a maximum surface loading of 1.5 m

3/(m

2h) [

57]. The height of the A-trap reactor was considered to be the difference between the height of the vessel and the height of the pyramid.