Ground-Based Green Façade for Enhanced Greywater Treatment and Sustainable Water Management

Abstract

1. Introduction

2. Materials and Methods

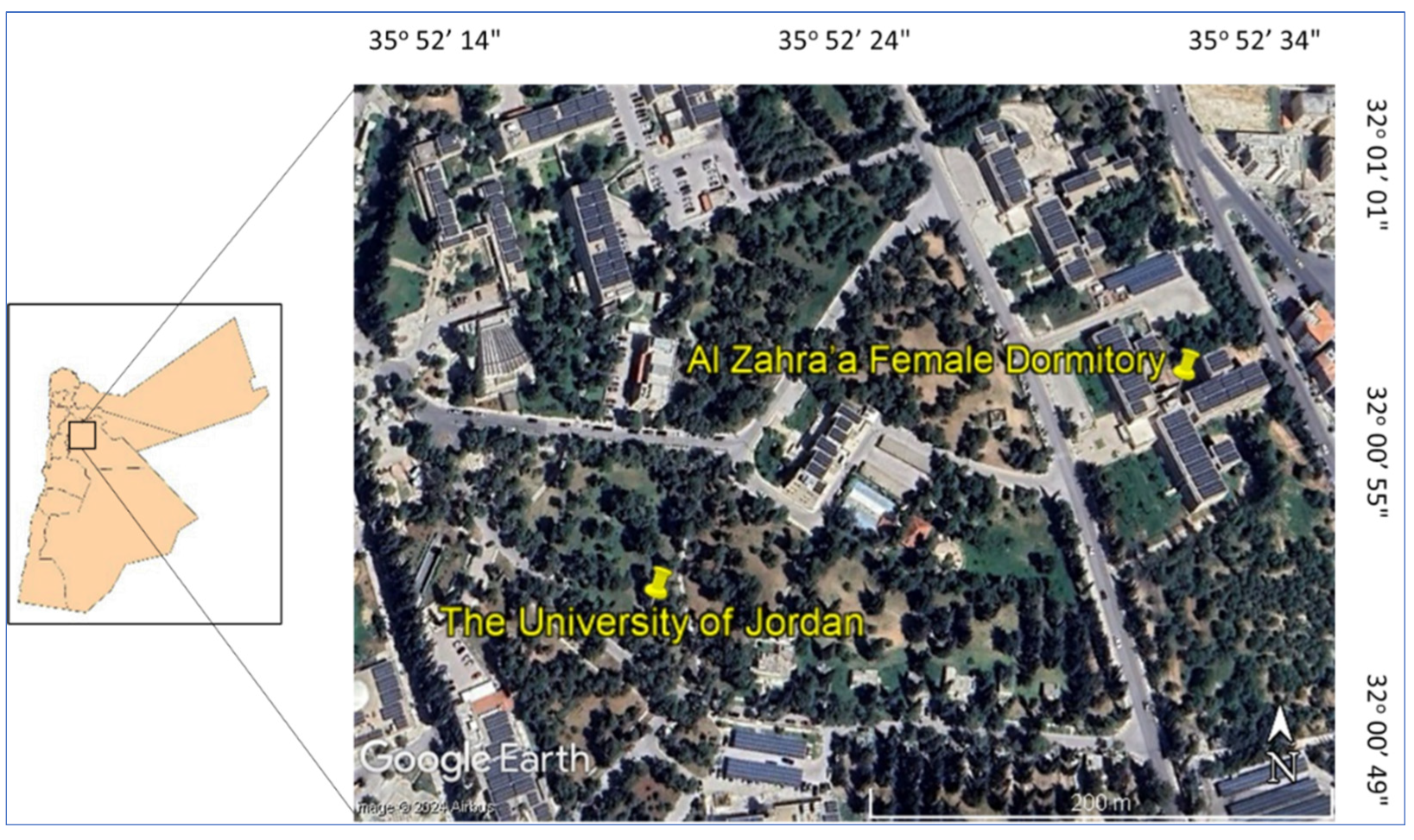

2.1. Study Site Description

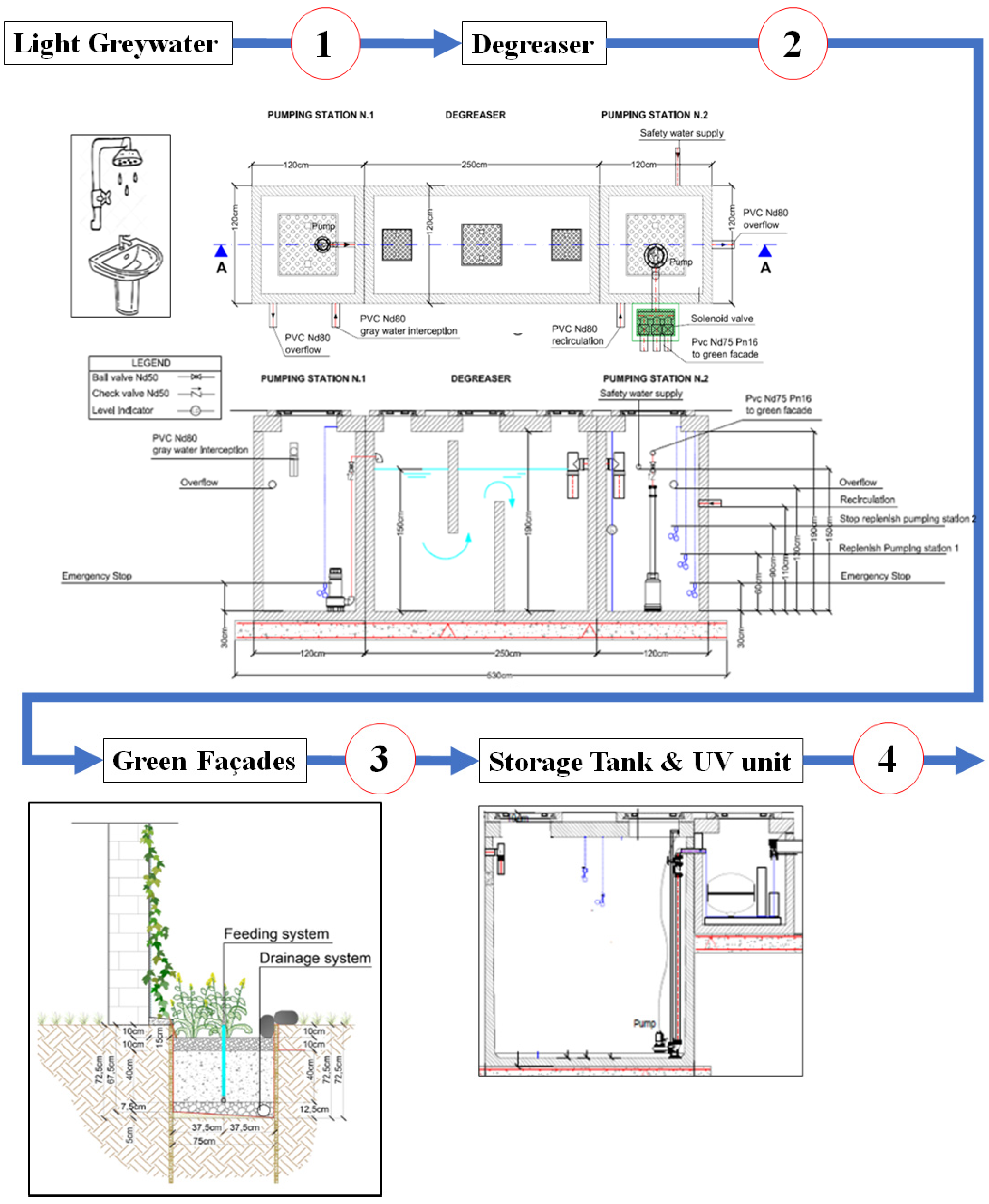

2.2. Description of the Decentralized Greywater Treatment System (DGWTS)

2.3. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Influent Greywater

3.2. Performance Evaluation of the On-Site Treatment System

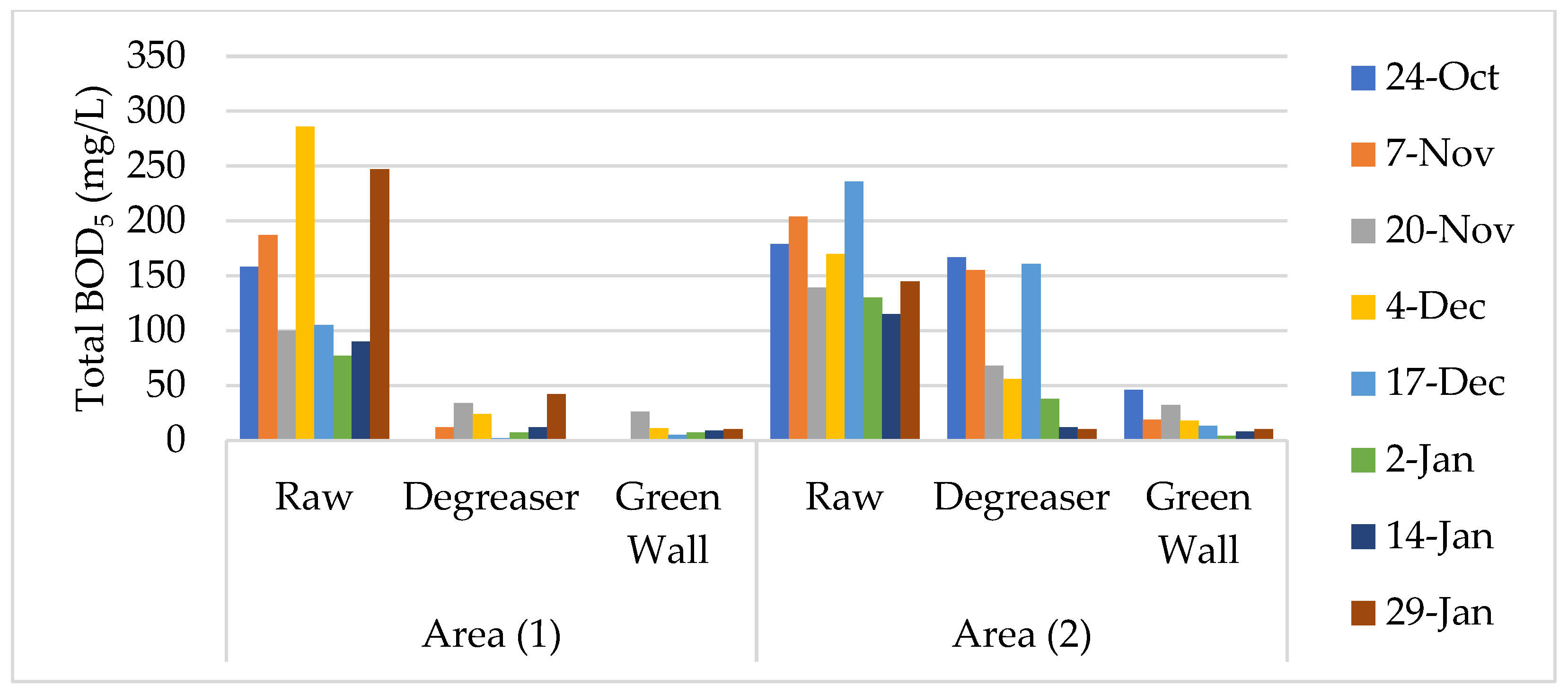

3.2.1. Total Chemical Oxygen Demand and Total Biochemical Oxygen Demand

3.2.2. pH and Dissolved Oxygen

3.2.3. Nutrients (Nitrogen and Phosphate)

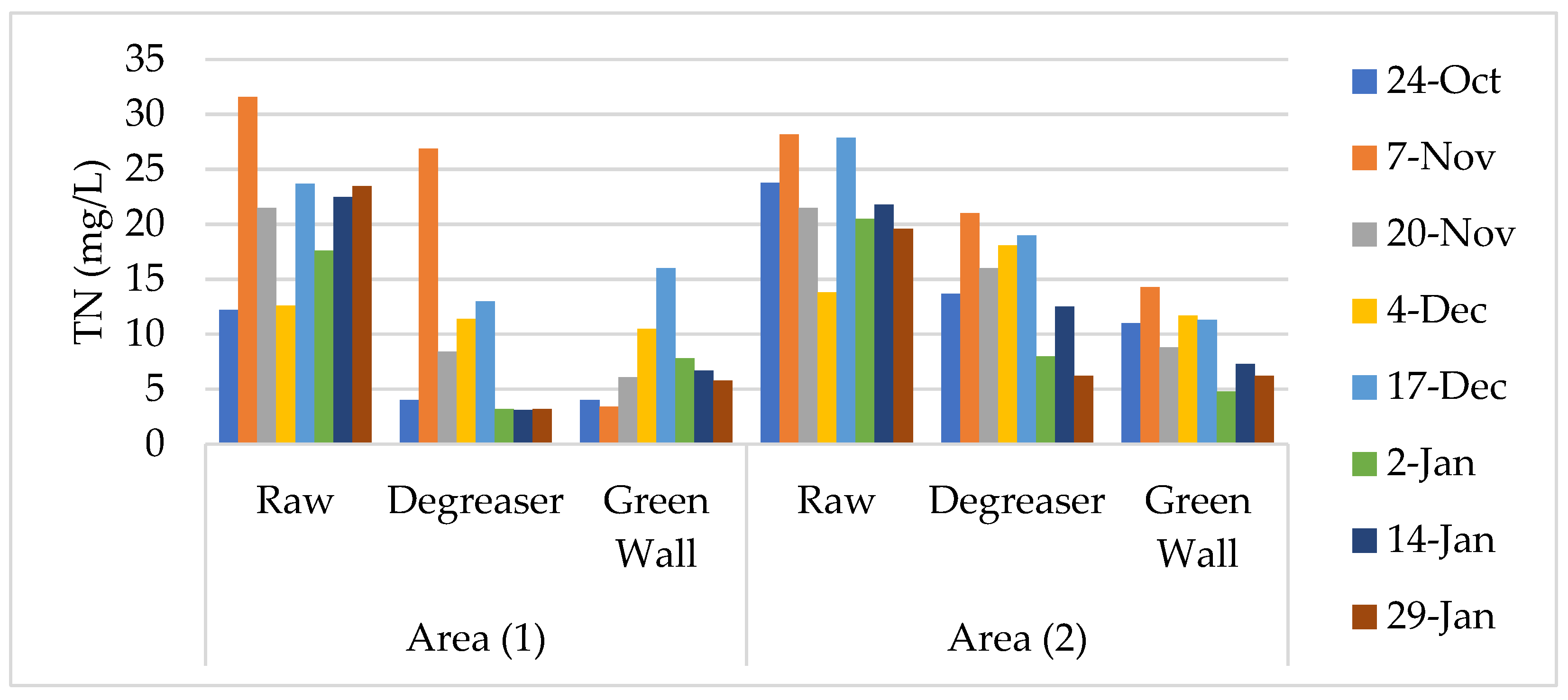

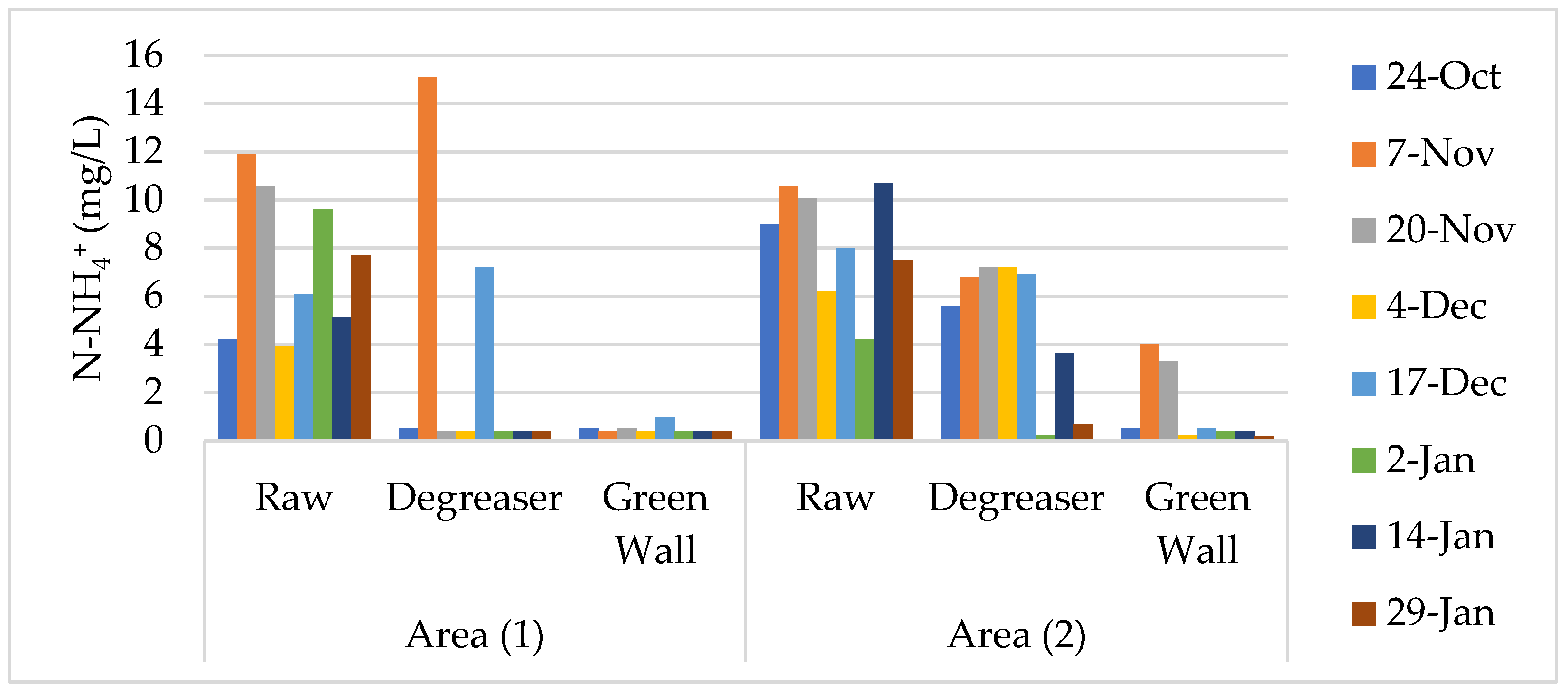

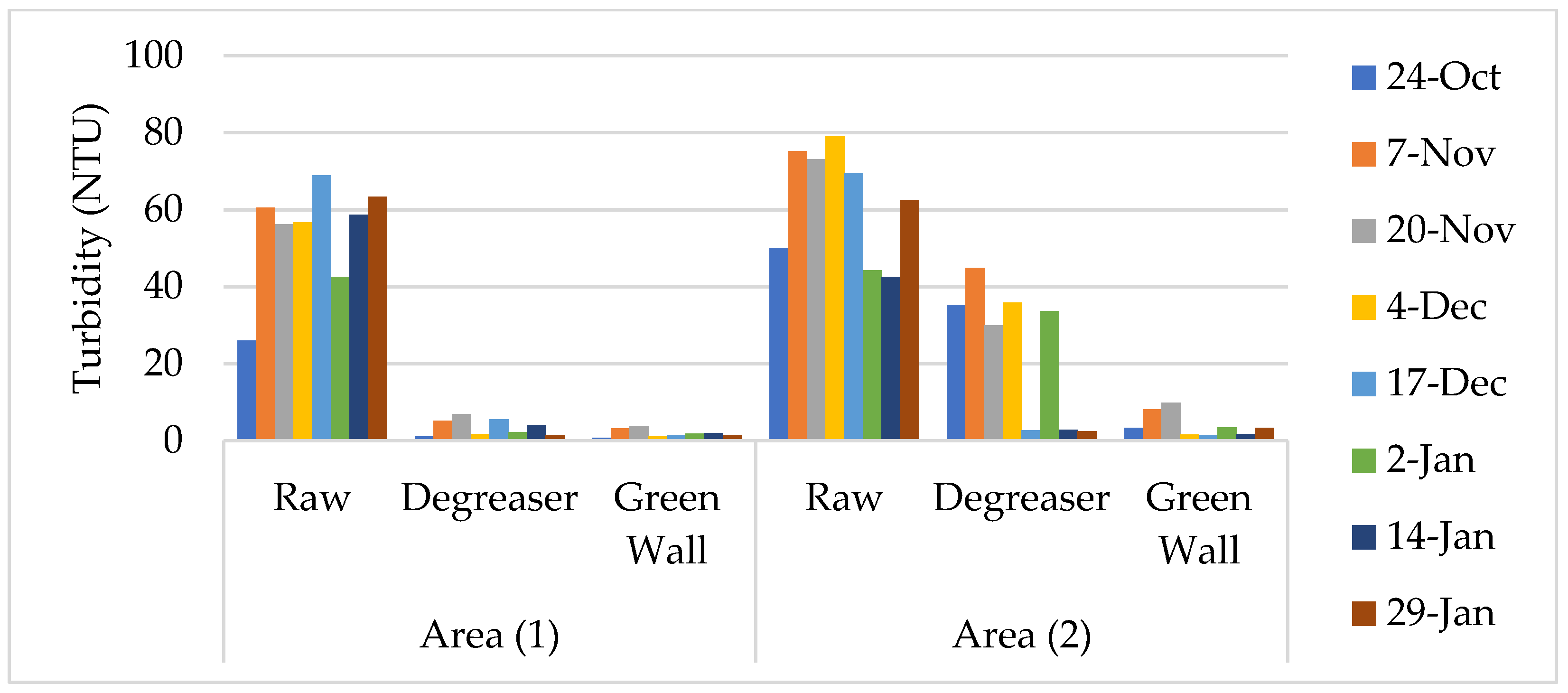

3.2.4. Total Dissolved Solids, Total Suspended Solids, and Turbidity

3.2.5. Biological Characteristics of the Treatment System

3.3. Performance Evaluation of Ground-Based Green Facades Systems

3.4. Effects of Treatment Phases on Greywater Quality

- pH: The raw greywater has the letter A, while both the degreaser and green wall systems have letter B. This indicates that the pH difference between raw greywater and the degreaser is significant. However, the pH difference between the degreaser and the green wall systems is not significant.

- DO: The letters C, B, and A are associated with raw greywater, degreaser, and green wall systems, respectively. This suggests that DO values increase significantly at each treatment phase, from raw greywater to the degreaser and further to the green wall façade system.

- TSS and Turbidity: Both parameters show a similar trend with letter groups A, B, and C for raw greywater, degreaser, and green wall systems, respectively. This indicates a significant reduction in TSS and turbidity at each treatment phase, with the green wall showing the most effective removal.

- TDS: For TDS, raw greywater has the letter B, while both the degreaser and green wall systems have the letter A. This suggests that TDS values do not differ significantly between the degreaser and the green wall but do differ significantly between raw greywater and the degreaser.

- Total COD and total BOD5: These parameters follow the A, B, C trend, indicating significant reductions at each treatment step, with the green wall achieving the most notable reductions in total COD and total BOD5.

- Nutrients (TN, N-NH4+, and PO43−): These parameters also follow the A, B, C trend, reflecting significant reductions across all treatment phases, with the green wall being the most effective.

- N-NO3−: The letter groups C, B, and A are shown for raw greywater, degreaser, and green wall systems, respectively. This indicates significant increases in nitrate levels at each treatment stage, likely due to nitrification processes.

- TC and E. coli: The letter groups A, B, B, and B are associated with raw greywater, degreaser, green wall, and UV systems, respectively. This indicates that the TC and E. coli concentrations decrease significantly from raw greywater to the degreaser but do not differ significantly between the degreaser, green wall, and UV systems.

3.5. Sustainability Evaluation of the DGWTS System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilderer, P.A.; Schreff, D. Decentralized and Centralized Wastewater Management: A Challenge for Technology Developers. Water Sci. Technol. 2000, 41, 1–8. [Google Scholar] [CrossRef]

- Kujawa-Roeleveld, K.; Zeeman, G. Anaerobic Treatment in Decentralised and Source-Separation-Based Sanitation Concepts. Rev. Environ. Sci. BioTechnol. 2006, 5, 115–139. [Google Scholar] [CrossRef]

- Alrbaihat, M.R.; Abu-Afifeh, Q. Eco-Friendly Microplastic Removal through Physical and Chemical Techniques: A Review. Ann. Adv. Chem. 2023, 7, 14–24. [Google Scholar]

- Obeidat, N.; Shatanawi, K.; Kassab, G.; Halalsheh, M. Performance of Decentralized Wastewater Treatment System Employing Upflow Anaerobic Sludge Blanket and Vertical Flow Constructed Wetland. Case Stud. Chem. Environ. Eng. 2024, 9, 100695. [Google Scholar] [CrossRef]

- Al-Jayyousi, O.R. Greywater Reuse: Towards Sustainable Water Management. Desalination 2003, 156, 181–192. [Google Scholar] [CrossRef]

- Sushmitha, M.B.; Chanakya, H.N.; Khuntia, H.K. Efficient Grey Water Treatment and Reuse Options for India—A Review. In Proceedings of the Waste Water Recycling and Management: 7th IconSWM—ISWMAW 2017, Fairfield, OH, USA, 11–18 October 2017; Volume 3, pp. 143–149. Available online: https://link.springer.com/chapter/10.1007%2F978-981-13-2619-6_12 (accessed on 26 January 2022).

- Boano, F.; Caruso, A.; Costamagna, E.; Fiore, S.; Demichelis, F.; Galvão, A.; Pisoeiro, J.; Rizzo, A.; Masi, F. Assessment of the Treatment Performance of an Open-Air Green Wall Fed with Graywater under Winter Conditions. ACS EST Water 2020, 1, 595–602. [Google Scholar] [CrossRef]

- Castellar, J.A.C.; Torrens, A.; Buttiglieri, G.; Monclús, H.; Arias, C.A.; Carvalho, P.N.; Galvao, A.; Comas, J. Nature-Based Solutions Coupled with Advanced Technologies: An Opportunity for Decentralized Water Reuse in Cities. J. Clean. Prod. 2022, 340, 130660. [Google Scholar] [CrossRef]

- Tilley, E.; Ulrich, L.; Luethi, C.; Reymond, P.; Zurbruegg, Z. Compendium of Sanitation Systems and Technologies, 2nd ed.; SSWM, 2014; Available online: https://sswm.info/sites/default/files/reference_attachments/TILLEY%20et%20al%202014%20Compendium%20of%20Sanitation%20Systems%20and%20Technologies%202nd%20Revised%20Edition.pdf (accessed on 1 December 2024).

- Rysulova, M.; Kaposztasova, D.; Vranayova, Z. Green Walls as an Approach in Grey Water Treatment. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 072049. [Google Scholar] [CrossRef]

- Dal Ferro, N.; De Mattia, C.; Gandini, M.A.; Maucieri, C.; Stevanato, P.; Squartini, A.; Borin, M. Green Walls to Treat Kitchen Greywater in Urban Areas: Performance from a Pilot-Scale Experiment. Sci. Total Environ. 2021, 757, 144189. [Google Scholar] [CrossRef]

- Lakho, F.H.; Vergote, J.; Ihsan-Ul-Haq Khan, H.; Depuydt, V.; Depreeuw, T.; Van Hulle, S.W.H.; Rousseau, D.P.L. Total Value Wall: Full Scale Demonstration of a Green Wall for Grey Water Treatment and Recycling. J. Environ. Manag. 2021, 298, 113489. [Google Scholar] [CrossRef]

- Aicher, A.; Boermel, M.; Londong, J.; Beier, S. Vertical Green System for Gray Water Treatment: Analysis of the VertiKKA-Module in a Field Test. Front. Environ. Sci. 2022, 10, 976005. [Google Scholar] [CrossRef]

- Galvão, A.; Martins, D.; Rodrigues, A.; Manso, M.; Ferreira, J.; Silva, C.M. Green Walls with Recycled Filling Media to Treat Greywater. Sci. Total Environ. 2022, 842, 156748. [Google Scholar] [CrossRef] [PubMed]

- Pucher, B.; Zluwa, I.; Spörl, P.; Pitha, U.; Langergraber, G. Evaluation of the Multifunctionality of a Vertical Greening System Using Different Irrigation Strategies on Cooling, Plant Development and Greywater Use. Sci. Total Environ. 2022, 849, 157842. [Google Scholar] [CrossRef] [PubMed]

- Abu Qdais, H.; Abdulla, F.; Kurbatova, A. Wastewater Reuse in Jordan and Its Potential as an Adaptation Measure to Climate Change. J. Environ. Eng. Sci. 2019, 14, 203–211. [Google Scholar] [CrossRef]

- AlBtoosh, J.; Abu-Awwad, A.; Obeidat, N. A Statistical Approach to the Water Scarcity Implications on Food Security. Global J. Environ. Sci. Manag. 2024, 10, 201–218. [Google Scholar]

- Al-Mashaqbeh, O.; Alsafadi, D.; Dalahmeh, S.; Bartelt-Hunt, S.; Snow, D. Removal of Selected Pharmaceuticals and Personal Care Products in Wastewater Treatment Plant in Jordan. Water 2019, 11, 2004. [Google Scholar] [CrossRef]

- Ibrahim, M. Effluent Quality Assessment of Selected Wastewater Treatment Plant in Jordan for Irrigation Purposes: Water Quality Index Approach. J. Ecol. Eng. 2019, 20, 206–216. [Google Scholar] [CrossRef]

- Al Hadidi, N.; Al Hadidi, M. Suitability of Reclaimed Wastewater Effluent from Decentralized Wastewater Plant for Irrigation. Appl. Water Sci. 2021, 11, 173. [Google Scholar] [CrossRef]

- Abu-Afifeh, Q.; Rahbeh, M.; Al-Afeshat, A.; Al-Omari, S.; Qutishat, T.A.; Brezat, A.; Alkayed, A. Dam Sustainability’s Interdependency with Climate Change and Dam Failure Drivers. Sustainability 2023, 15, 16239. [Google Scholar] [CrossRef]

- Al-Afeshat, A.; Zoubi, M.M.; Abu Afifeh, Q.Y.; Al-Jawaldeh, H.; Qutishat, T.A.; Masoud, A.M.N.; Rahbeh, M. Interrelation of Dams Sustainability with the Local Communities and Water Quality. Global J. Environ. Sci. Manag. 2025, 11, 1–20. [Google Scholar]

- Hroub, H.A.; Rahbeh, M.; Zoubi, M.M.; Abu-Afifeh, Q.Y.; Al-Jawaldeh, H.; Obeidat, N. Projection of Future Temperature Variations in River Basins under Climate Change Scenarios Using General Circulation Models. Global J. Environ. Sci. Manag. 2025, 11. [Google Scholar] [CrossRef]

- MWI. Annual Reports; Ministry of Water and Irrigation: Amman, Jordan, 2022.

- Langergraber, G.; Castellar, J.A.C.; Pucher, B.; Baganz, G.F.M.; Milosevic, D.; Andreucci, M.-B.; Kearney, K.; Pineda-Martos, R.; Atanasova, N. A Framework for Addressing Circularity Challenges in Cities with Nature-Based Solutions. Water 2021, 13, 2355. [Google Scholar] [CrossRef]

- Bustami, R.A.; Belusko, M.; Ward, J.; Beecham, S. Vertical Greenery Systems: A Systematic Review of Research Trends. Build. Environ. 2018, 146, 226–237. [Google Scholar] [CrossRef]

- Kotsia, D.; Deligianni, A.; Fyllas, N.M.; Stasinakis, A.S.; Fountoulakis, M.S. Converting Treatment Wetlands into “Treatment Gardens”: Use of Ornamental Plants for Greywater Treatment. Sci. Total Environ. 2020, 744, 140889. [Google Scholar] [CrossRef] [PubMed]

- Stefanatou, A.; Lagkadas, M.; Petousi, I.; Schiza, S.; Stasinakis, A.S.; Fyllas, N.; Fountoulakis, M.S. Vertical Flow Constructed Wetlands as Green Facades and Gardens for On-Site Greywater Treatment in Buildings: Two-Year Mesocosm Study on Removal Performance. Sci. Total Environ. 2024, 906, 167362. [Google Scholar] [CrossRef]

- Stefanatou, A.; Vouzi, L.; Petousi, I.; Koukoura, A.; Gatidou, G.; Stasinakis, A.S.; Fountoulakis, M.S. Treatment of Real Laundry Wastewater Using Vertical Flow Constructed Wetland Planted with the Ornamental Climbing Plant Trachelospermum Jasminoides: Assessing the Removal of Conventional Pollutants and Benzotriazoles. Environ. Sci. Pollut. Res. 2024, 31, 43281–43291. [Google Scholar] [CrossRef]

- Platzer, C. Design Recommendations for Subsurface Flow Constructed Wetlands for Nitrification and Denitrification. Water Sci. Technol. 1999, 40, 257–263. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Tsihrintzis, V.A. Performance of Pilot-Scale Vertical Flow Constructed Wetlands Treating Simulated Municipal Wastewater: Effect of Various Design Parameters. Desalination 2009, 248, 753–770. [Google Scholar] [CrossRef]

- APHA; AWWA; WEF. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Al Arni, S.; Elwaheidi, M.; Salih, A.A.M.; Ghernaout, D.; Matouq, M. Greywater Reuse: An Assessment of the Jordanian Experience in Rural Communities. Water Sci. Technol. 2022, 85, 1952–1963. [Google Scholar] [CrossRef]

- Ghunmi, L.A.; Zeeman, G.; van Lier, J.; Fayyed, M. Quantitative and Qualitative Characteristics of Grey Water for Reuse Requirements and Treatment Alternatives: The Case of Jordan. Water Sci. Technol. 2008, 58, 1385–1396. [Google Scholar] [CrossRef]

- Hernández Leal, L.; Temmink, H.; Zeeman, G.; Buisman, C.J.N. Comparison of Three Systems for Biological Greywater Treatment. Water 2010, 2, 155–169. [Google Scholar] [CrossRef]

- Noutsopoulos, C.; Andreadakis, A.; Kouris, N.; Charchousi, D.; Mendrinou, P.; Galani, A.; Mantziaras, I.; Koumaki, E. Greywater Characterization and Loadings—Physicochemical Treatment to Promote Onsite Reuse. J. Environ. Manag. 2018, 216, 337–346. [Google Scholar] [CrossRef] [PubMed]

- Roshan, A.; Kumar, M. Water End-Use Estimation Can Support the Urban Water Crisis Management: A Critical Review. J. Environ. Manag. 2020, 268, 110663. [Google Scholar] [CrossRef] [PubMed]

- Van de Walle, A.; Kim, M.; Alam, M.K.; Wang, X.; Wu, D.; Dash, S.R.; Rabaey, K.; Kim, J. Greywater Reuse as a Key Enabler for Improving Urban Wastewater Management. Environ. Sci. Ecotechnol. 2023, 16, 100277. [Google Scholar]

- Jamrah, A.; Ayyash, S. Greywater Generation and Characterization in Major Cities in Jordan. Jordan J. Civ. Eng. 2008, 2, 376–390. [Google Scholar]

- Al-Mashaqbeh, O.A.; Ghrair, A.M.; Megdal, S.B. Grey Water Reuse for Agricultural Purposes in the Jordan Valley: Household Survey Results in Deir Alla. Water 2012, 4, 580–596. [Google Scholar] [CrossRef]

- Sonune, N.; Mungal, N.; Kamble, S. Study of Physico-Chemical Characteristics of Domestic Wastewater in Vishnupuri, Nanded, India. Int. J. Curr. Microbiol. Appl. Sci. 2015, 4, 533–536. [Google Scholar]

- Metcalf and Eddy; Tchobanoglous, G. Wastewater Engineering: Treatment and Resource Recovery, 4th ed.; Mcgraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Albalawneh, A.; Chang, T.-K. Review of the greywater and proposed greywater recycling scheme for agricultural irrigation reuses. Int. J. Res. Granthaalayah 2015, 3, 16–35. [Google Scholar]

- Boyjoo, Y.; Pareek, V.K.; Ang, M. A Review of Greywater Characteristics and Treatment Processes. Water Sci. Technol. 2013, 67, 1403–1424. [Google Scholar] [CrossRef]

- Ghaly, A.; Mahmoud, N.; Ibrahim, M.; Mostafa, E.; Abdelrahman, E.; Emam, R.; Kassem, M.; Hatem, M. Greywater Sources, Characteristics, Utilization and Management Guidelines: A Review. Adv. Environ. Waste Manag. Recycl. 2021, 4, 2795–2809. [Google Scholar]

- Oteng-Peprah, M.; de Vries, N.K.; Acheampong, M.A. Greywater Characterization and Generation Rates in a Peri Urban Municipality of a Developing Country. J. Environ. Manag. 2018, 206, 498–506. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Mousavi, S.A.; Darvishi, P. Greywater as a Sustainable Source for Development of Green Roofs: Characteristics, Treatment Technologies, Reuse, Case Studies and Future Developments. J. Environ. Manag. 2021, 295, 112991. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Shafy, H.I.; El-Khateeb, M.A.; Shehata, M. Greywater Treatment Using Different Designs of Sand Filters. Desalin. Water Treat. 2013, 52, 5237–5242. [Google Scholar] [CrossRef]

- Korkusuz, E.A.; Beklioǧlu, M.; Demirer, G.N. Treatment Efficiencies of the Vertical Flow Pilot-Scale Constructed Wetlands for Domestic Wastewater Treatment. Turk. J. Eng. Environ. Sci. 2004, 28, 333–344. [Google Scholar]

- Patil, Y.M.; Patki, V.K.; Jahagirdar, S.; Karale, R.; Angathekar, V. Greywater Treatment by Vegetated Vermifilter: A Low Cost Material for Rural Sanitation in India. Mater. Today Proc. 2021, 45, 6946–6950. [Google Scholar] [CrossRef]

- Samayamanthula, D.R.; Sabarathinam, C.; Bhandary, H. Treatment and Effective Utilization of Greywater. Appl. Water Sci. 2019, 9, 90. [Google Scholar] [CrossRef]

- Tusiime, A.; Solihu, H.; Sekasi, J.; Mutanda, H.E. Performance of Lab-Scale Filtration System for Grey Water Treatment and Reuse. Environ. Chall. 2022, 9, 100641. [Google Scholar] [CrossRef]

- Abunaser, S.G.; Abdelhay, A. Performance of a Novel Vertical Flow Constructed Wetland for Greywater Treatment in Rural Areas in Jordan. Environ. Technol. 2020, 1–11. [Google Scholar] [CrossRef]

- Chandran, N.; Nijam, S. Performance Evaluation of Pumice as Green Wall Medium for Grey Water Recycling. Int. J. Sci. Eng. Res. 2020, 11, 84–90. [Google Scholar]

- Boano, F.; Caruso, A.; Costamagna, E.; Ridolfi, L.; Fiore, S.; Demichelis, F.; Galvão, A.; Pisoeiro, J.; Rizzo, A.; Masi, F. A Review of Nature-Based Solutions for Greywater Treatment: Applications, Hydraulic Design, and Environmental Benefits. Sci. Total Environ. 2020, 711, 134731. [Google Scholar] [CrossRef]

- Alateeqi, M.; Khajah, M.; Abu-Arabi, M.; AlMansour, H. Greywater Treatment Using Vertical Subsurface Flow Constructed Wetland System. J. Eng. Res. 2023, 11, 100052. [Google Scholar] [CrossRef]

- Micek, A.; Jóżwiakowski, K.; Marzec, M.; Listosz, A.; Malik, A. Efficiency of Pollution Removal in Preliminary Settling Tanks of Household Wastewater Treatment Plants in the Roztocze National Park. J. Ecol. Eng. 2020, 21, 9–18. [Google Scholar]

- Mietto, A.; Borin, M. Performance of Two Small Subsurface Flow Constructed Wetlands Treating Domestic Wastewaters in Italy. Environ. Technol. 2013, 34, 1085–1095. [Google Scholar]

- Nivala, J.; van Afferden, M.; Hasselbach, R.; Langergraber, G.; Molle, P.; Rustige, H.; Nowak, J. The New German Standard on Constructed Wetland Systems for Treatment of Domestic and Municipal Wastewater. Water Sci. Technol. 2018, 78, 2414–2426. [Google Scholar]

- Manga, M.; Ngobi, T.G.; Okeny, L.; Acheng, P.; Namakula, H.; Kyaterekera, E.; Nansubuga, I.; Kibwami, N. The Effect of Household Storage Tanks/Vessels and User Practices on the Quality of Water: A Systematic Review of Literature. Environ. Syst. Res. 2021, 10, 18. [Google Scholar]

- Subramanian, P.S.G.; Raj, A.V.; Jamwal, P.; Connelly, S.; Yeluripati, J.; Richards, S.; Ellis, R.; Rao, L. Decentralized Treatment and Recycling of Greywater from a School in Rural India. J. Water Process Eng. 2020, 38, 101695. [Google Scholar]

- Abou-Elela, S.I.; Hellal, M.S. Municipal Wastewater Treatment Using Vertical Flow Constructed Wetlands Planted with Canna, Phragmites and Cyprus. Ecol. Eng. 2012, 47, 209–213. [Google Scholar]

- Bakheet, B.; Prodanovic, V.; Deletic, A.; McCarthy, D. Effective Treatment of Greywater via Green Wall Biofiltration and Electrochemical Disinfection. Water Res. 2020, 185, 116228. [Google Scholar]

- Arden, S.; Ma, X. Constructed Wetlands for Greywater Recycle and Reuse: A Review. Sci. Total Environ. 2018, 630, 587–599. [Google Scholar]

- Winward, G.P.; Avery, L.M.; Stephenson, T.; Jefferson, B. Ultraviolet (UV) disinfection of grey water: Particle size effects. Environ. Technol. 2008, 29, 235–244. [Google Scholar]

- Ofori, S.; Abebrese, D.K.; Růžičková, I.; Wanner, J. Reuse of Treated Wastewater for Crop Irrigation: Water Suitability, Fertilization Potential, and Impact on Selected Soil Physicochemical Properties. Water 2024, 16, 484. [Google Scholar] [CrossRef]

- Yadav, R.K.; Sahoo, S.; Yadav, A.K.; Patil, S.A. Green Wall System Coupled with Slow Sand Filtration for Efficient Greywater Management at Households. npj Clean Water 2023, 6, 73. [Google Scholar]

- Prodanovic, V.; McCarthy, D.; Hatt, B.; Deletic, A. Designing Green Walls for Greywater Treatment: The Role of Plants and Operational Factors on Nutrient Removal. Ecol. Eng. 2019, 130, 184–195. [Google Scholar]

- Sami, M.; Hedström, A.; Kvarnström, E.; McCarthy, D.T.; Herrmann, I. Greywater Treatment in a Green Wall Using Different Filter Materials and Hydraulic Loading Rates. J. Environ. Manag. 2023, 340, 117998. [Google Scholar]

- Masi, F.; Bresciani, R.; Rizzo, A.; Edathoot, A.; Patwardhan, N.; Panse, D.; Langergraber, G. Green Walls for Greywater Treatment and Recycling in Dense Urban Areas: A Case-Study in Pune. J. Water, Sanit. Hyg. Dev. 2016, 6, 342–347. [Google Scholar]

- Obeidat, N.; Abu-Awwad, A.; Al-Salaymeh, A.S.; AlBtoosh, J.; Zoubi, M.M.; Abu-Afifeh, Q.Y.; Seif, M.A.; Hroub, H.; Arabiat, O. Social Acceptance of Water Quality through Decentralized Greywater Treatment Using Green Wall System. Global J. Environ. Sci. Manag. 2025, 11. [Google Scholar] [CrossRef]

| Parameter | Type I | Type II |

|---|---|---|

| Flow | 0.5 m3/d | 0.6 m3/d |

| Number of beds | 1 | 2 |

| Bottom surface area VF-trench per bed | 6.84 m2 | 3.78 m2 |

| L VF-trench per bed | 11.4 m | 6.3 m |

| W VF-trench per bed | 0.6 m | 0.60 m |

| Total VF surface | 6.84 m2 | 7.56 m2 |

| Hydraulic Loading Rate (HLR) | 73 mm | 79 mm |

| Flush volume | 250 L | 300 L |

| Flush duration | 60 s | 75 s |

| Average resting period | 12 h | 12 h |

| Total height of the filter media (from the bottom) | 0.6 m | 0.6 m |

| Height of the gravel—Ø 5–10 mm | 0.1 m | 0.1 m |

| Height of the sand—Ø 0.1–3 mm | 0.4 m | 0.4 m |

| Height of the gravel—Ø 5–10 mm | 0.1 m | 0.1 m |

| Plant species | Hedera, Bougainvillea, Passiflora, Jasmine, Lonicera, Nandina, Lily, Acorus, Tulbagh, and Peperomia | |

| Parameter | Irrigating Cooked Vegetables, Gardens, Green Lands, and Other Crops | Irrigating Raw Eaten | Parameter |

|---|---|---|---|

| Total BOD5 (mg/L) | 60 | 60 | ≤10 |

| Total COD (mg/L) | 120 | 120 | ≤20 |

| TSS (mg/L) | 100 | 50 | ≤10 |

| pH | 6–9 | 6–9 | 6–9 |

| (mg/L) | 70 | 70 | 70 |

| Total Nitrogen (TN) (mg/L) | 50 | 50 | 50 |

| Total Phosphorus (TP) (mg/L) | 15 | 15 | 15 |

| Turbidity (NTU) | - | - | ≤5 |

| E. coli (CFU/100 mL) | 104 | 103 | ≤10 |

| Fat, oil and grease, FOG (mg/L) | 8 | 8 | 8 |

| Parameter | Unit | Raw Greywater (Point 1) | Degreaser (Point 2) | Green Façade (Point 3) | |||

|---|---|---|---|---|---|---|---|

| A1 | A2 | A1 | A2 | A1 | A2 | ||

| pH | unit | 8.14 ± 0.3 | 8.24 ± 0.3 | 7.88 ± 0.2 | 7.99 ± 0.2 | 7.94 ± 0.2 | 8.02 ± 0.2 |

| DO | mg/L | 2.45 ± 1.44 | 2.15 ± 0.84 | 6.49 ± 2.87 | 2.38 ± 2.123 | 7.19 ± 1.73 | 5.64 ± 2.43 |

| TSS | mg/L | 45 ± 15 | 50 ± 18 | 11± 5 | 25 ± 14 | 7 ± 3 | 7 ± 3 |

| Turbidity | NTU | 54 ± 14 | 62 ± 15 | 4 ± 2 | 23 ± 18 | 2 ± 1 | 4 ± 3 |

| TDS | mg/L | 611 ±1 68 | 644 ± 121 | 1192 ± 292 | 666 ± 179 | 986 ± 472 | 662 ± 107 |

| COD 2 | mg/L | 260 ± 79 | 348 ± 66 | 26 ± 16 | 165 ± 99 | 16 ± 14 | 39 ± 24 |

| BOD5 2 | mg/L | 156 ± 78 | 165 ± 41 | 17 ± 15 | 83 ± 67 | 9 ± 8 | 19 ±14 |

| TN | mg/L | 20.65 ± 6.4 | 22.14 ± 4.07 | 9.15 ± 8.19 | 14.31 ± 5.25 | 7.54 ± 4.07 | 9.43 ± 3.2 |

| N-NH4+ | mg/L | 7.39 ± 3.04 | 8.29 ± 2.29 | 3.10 ± 5.4 | 4.78 ± 2.92 | 0.5 ± 0.21 | 1.19 ± 0.53 |

| N-NO3− | mg/L | 0.19 ± 0.2 | 0.16 ± 0.18 | 4.94 ± 3.56 | 1.73 ± 2.19 | 6.43 ± 3.88 | 4.03 ± 1.85 |

| PO43− | mg/L | 1.96 ± 1 | 2.53 ± 2 | 1.24 ± 1.01 | 1.59 ± 0.84 | 0.65 ± 0.56 | 0.74 ± 0.86 |

| TC 3 | MPN/100 mL 4 | (5.2 ± 6.8) × 106 | (5.3 ± 6.9) × 106 | (1.2 ± 3.2) × 106 | (1.6 ± 3.1) × 106 | (1.9 ± 4.5) × 104 | (3.5 ± 6.2) × 104 |

| E. coli 3 | MPN/100 mL 4 | (2.3 ± 3.1) × 105 | (2.3 ± 1.7) × 105 | (1.1 ± 1.8) × 104 | (1.4 ± 2.8) × 105 | (4.1 ± 4.5) × 102 | (1.0 ± 1.1) × 102 |

| Study Reference | Monitoring Period | Substrate Used | Removal Efficiency (%) | Key Findings | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TSS | Turbidity | Total COD | Total BOD5 | TN | TP | TC | E. coli | ||||

| Current study in Jordan | 16 weeks | Sand and gravel | 84% | 95% | 92% | 92% | 58% | 71% | 4.3 log | 5.1 log | The decentralized green wall system is an effective alternative for greywater treatment in urban areas. |

| Stefanatou et al. [29] | Two Years | Sand and vermiculite | - | 82–98% | 86–95% | - | - | - | 5 log | 4 log | Planted VFCW for greywater treatment improve system efficiency and esthetics. |

| Yadav et al. [67] | 15 Weeks | Cocopeat and Granular activated charcoal | - | 90% | 85% | - | 73% | 61% | - | - | Affordable green wall solutions efficiently manage greywater while using fewer resources and utilizing up a smaller footprint. |

| Sami et al. [69] | 10 Months | Biochar, pumice, hemp fiber, spent coffee grounds, and composted fiber soil. | - | - | - | 96–99% | 58–82% | 57–85% | - | 2.2–4.0 log | Greywater treatment with green walls may have an impact on future urban greywater management developments. |

| Galvão et al. [14] | 4 Months | Tiles, Coconut mix and recycled fibers | 50–70% | - | 60–70% | - | - | - | - | - | Greywater treatment with green walls constructed using recycled materials can support the circular economy. |

| Boano et al. [7] | 3 Months | Mix of coconut fiber and perlite | - | - | 40% | 97% | 61% | 57% | - | 99% | Potential of an open-air green wall for greywater treatment, even in difficult conditions. |

| Chandran and Nijam [54] | - | Pumice and Sand | - | - | 56% | - | - | - | - | - | Additional research is required to identify the most appropriate media combinations for greywater recycling. |

| Kotsia et al. [27] | Two Years | Coarse gravel, Fine gravel, and washed sand. | 94% | - | 96% | 99% | - | - | 2.2 log | - | Green walls improve the attractiveness of urban, semi-urban, and touristic environments by providing a technically economically feasible option for greywater treatment. |

| Prodanovic, et al. [68] | 12 Months | Mix of Perlite and Coco coir | - | - | - | - | 88% | 27–53% | - | - | Greywater treatment and reuse perform effectively with well-designed green walls. |

| Masi et al. [70] | 9 Months | LECA plus sand and LECA plus coconut fibers. | - | - | 7–86% | 25–54% | - | - | - | - | Only Phase II samples were appropriate for flushing toilets, even though all samples satisfied irrigation reuse standards. |

| Parameter | Letter Group | |||

|---|---|---|---|---|

| Raw Greywater | Degreaser | Green Wall | UV | |

| pH | A | B | B | - |

| DO | C | B | A | - |

| TSS | A | B | C | - |

| Turbidity | A | B | C | - |

| TDS | B | A | A | - |

| Total COD | A | B | C | - |

| Total BOD5 | A | B | C | - |

| TN | A | B | C | - |

| N-NH4+ | A | B | C | - |

| N-NO3− | C | B | A | - |

| PO43− | A | B | C | - |

| TC | A | B | B | B |

| E. coli | A | B | B | B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obeidat, N.; Abu Awwad, A.; Al-Salaymeh, A.; Bresciani, R.; Masi, F.; Rizzo, A.; AlBtoosh, J.; Zoubi, M.M. Ground-Based Green Façade for Enhanced Greywater Treatment and Sustainable Water Management. Water 2025, 17, 346. https://doi.org/10.3390/w17030346

Obeidat N, Abu Awwad A, Al-Salaymeh A, Bresciani R, Masi F, Rizzo A, AlBtoosh J, Zoubi MM. Ground-Based Green Façade for Enhanced Greywater Treatment and Sustainable Water Management. Water. 2025; 17(3):346. https://doi.org/10.3390/w17030346

Chicago/Turabian StyleObeidat, Nisreen, Ahmad Abu Awwad, Ahmed Al-Salaymeh, Riccardo Bresciani, Fabio Masi, Anacleto Rizzo, Jomanah AlBtoosh, and Mutaz M. Zoubi. 2025. "Ground-Based Green Façade for Enhanced Greywater Treatment and Sustainable Water Management" Water 17, no. 3: 346. https://doi.org/10.3390/w17030346

APA StyleObeidat, N., Abu Awwad, A., Al-Salaymeh, A., Bresciani, R., Masi, F., Rizzo, A., AlBtoosh, J., & Zoubi, M. M. (2025). Ground-Based Green Façade for Enhanced Greywater Treatment and Sustainable Water Management. Water, 17(3), 346. https://doi.org/10.3390/w17030346