Digital Twin Applications in the Water Sector: A Review

Abstract

1. Introduction

2. Search Methodology

2.1. Scope and Search Strategy

2.2. Extraction and Coding

3. Definitions and Fundamentals

3.1. Model and Simulator

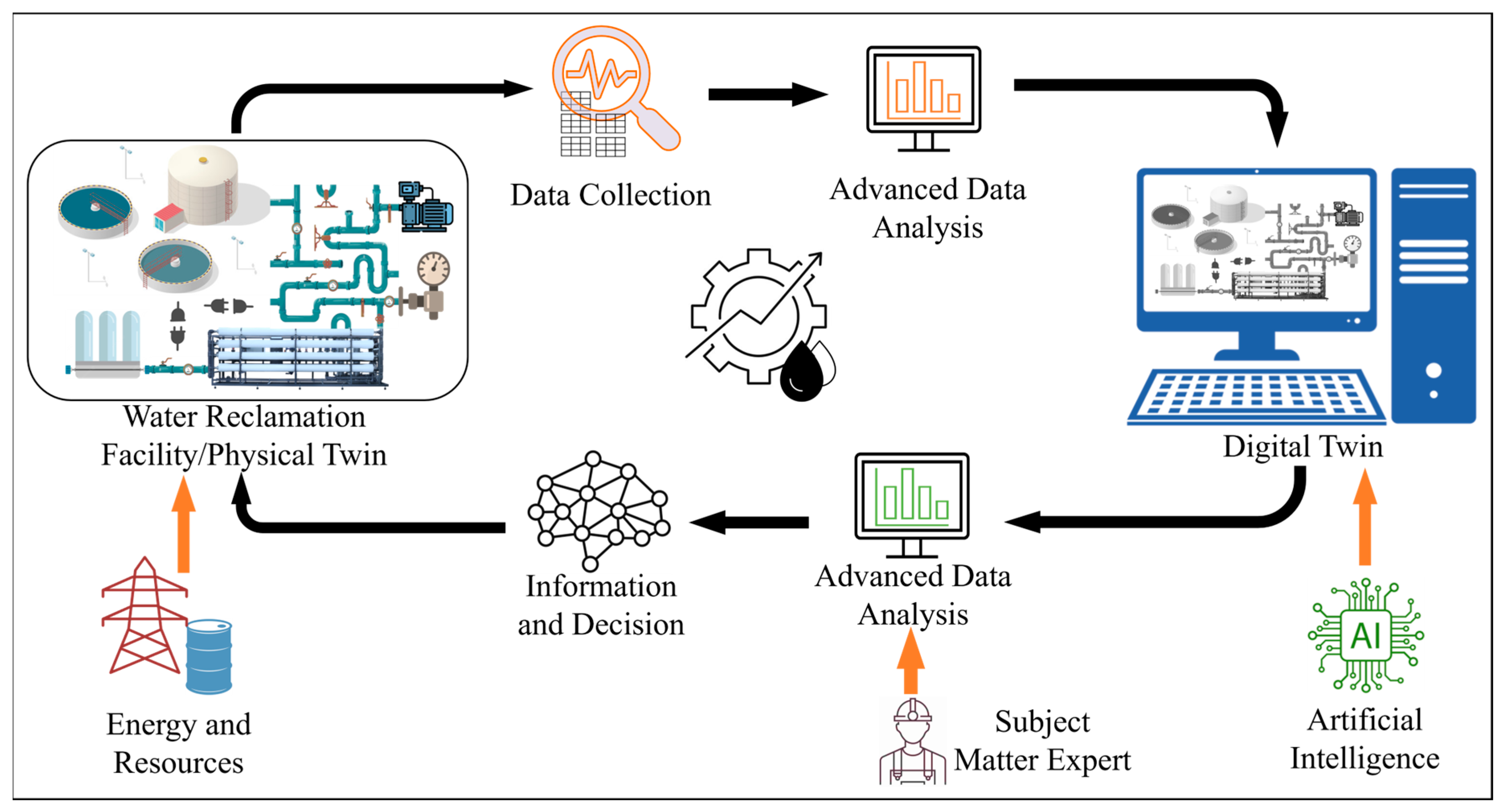

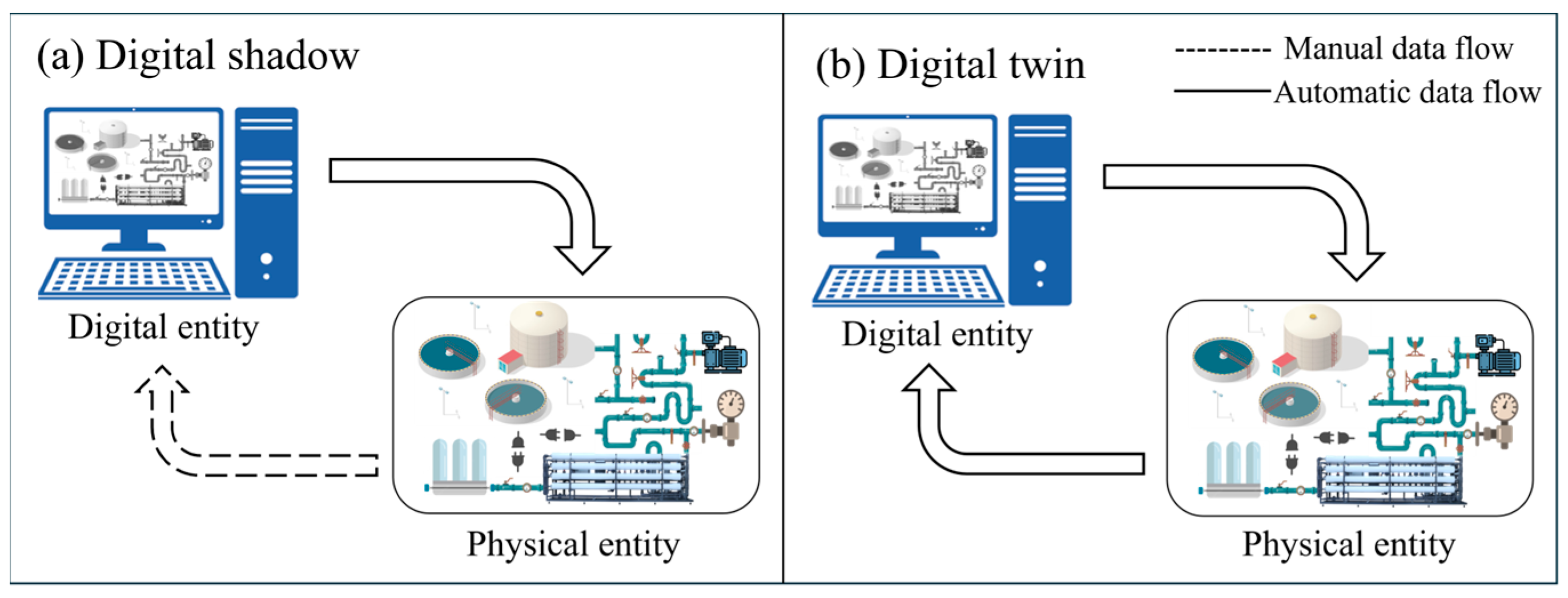

3.2. Digital Twin and Digital Shadow

4. System Integration

4.1. Variable Naming in Process Flow Diagram (PFD), Process and Instrumentation Diagram (P&ID), Data Acquisition and Control (DAC), and Model

4.2. Data Pipelines

4.3. Data Access Rights

- 1.

- Communication infrastructure: Is the physical infrastructure ready to enable communication to, and from, the DT? For example, can the laboratory data be accessed automatically?

- 2.

- Communication configuration: What are the requirements for granting read access to the information contained in the SCADA system, present as laboratory data, or produced by the DT?

- 3.

- Write-access rights: Can the DT manipulate variables (e.g., setpoints) in the physical entity? If so, which ones, at what frequency, and within what range?

4.4. Constraints for Optimization Based on a DT

5. Digital Twin Applications

6. Digital Twins in the Water Industry

7. Digital Twin Implementation in Real-World Systems

7.1. Full-Scale Implementation

7.2. Pilot-Scale Implementation

7.3. Cross-Case Synthesis

8. Challenges, Limitations, and Current Approaches

8.1. Data Quality Assessment and Control

8.2. Lack of a Framework for Developing Practical DT in the Water Industry

8.3. High Cost of Sensor Implementation and Computational Resources

8.4. Lack of Automated Bidirectional Data Transfer

- Hybrid Approaches with Manual Verification: One potential solution is the adoption of hybrid systems, where the DT generates operational recommendations based on real-time data, but these recommendations are subject to manual verification before implementation. This approach balances the need for safety and human oversight with the benefits of automation. Operators can review suggested changes from the DT and either approve or reject them based on additional safety checks or contextual factors that the DT may not fully account for.

- Incremental Automation: Another approach is to gradually increase the level of automation within water systems. Starting with low-risk operations, such as adjustments to operational variables (e.g., flow rates that fluctuate in response to demand) or controllable parameters (e.g., chemical dosing setpoints), can build trust in the system’s ability to operate safely. Over time, as the reliability of the DT is demonstrated, utilities may become more comfortable, allowing DTs to handle higher-level, more critical operations. This incremental approach ensures that any potential risks are managed while allowing the system to evolve toward full automation.

- Enhanced Cybersecurity Measures: One of the primary concerns for water utilities in enabling bidirectional data flow is the potential vulnerability to cyberattacks. Therefore, implementing robust cybersecurity protocols is essential for protecting both the physical and digital entities. Encryption of data, secure communication channels, and stringent access controls are necessary to ensure that the DT’s instructions are both safe and reliable. By mitigating security risks, water utilities may be more inclined to allow autonomous adjustments based on real-time feedback from the DT.

- Regulatory Collaboration: To facilitate automated data transfer, water utilities must work closely with regulatory bodies to ensure compliance with safety and environmental standards. Clear guidelines and frameworks that define the operational boundaries of DTs can help alleviate concerns around safety and security. Regulatory agencies can develop policies that outline how and under what circumstances DTs can make automated changes to water systems, ensuring that all operations remain within acceptable risk thresholds.

8.5. The Challenge of Control Authority

8.6. Operational Realities for Closing the Loop

9. Future Direction and Summary

- Full-Scale Demonstrations. While pilot and subsystem implementations have illustrated DT value, there is an urgent need for end-to-end, full-scale deployments across diverse water infrastructures—treatment plants, distribution networks, and even consumer-side applications. Such real-world examples will shed light on scalability hurdles and inform best practices for translating DT capabilities into operational resilience.

- Advanced Analytics Integration. The incorporation of sophisticated data analytics, particularly ML and AI, will unlock new levels of DT performance. By embedding adaptive learning algorithms, DTs can evolve alongside system dynamics, enabling continuous optimization of operations and more reliable forecasting under both typical and extreme conditions.

- Standardized Development Frameworks. Widespread adoption demands harmonized guidelines for DT creation and maintenance. Standardization efforts should cover data schemas, metadata conventions, sensor deployment strategies, and model validation protocols. Establishing these frameworks will facilitate interoperability, reduce implementation complexity, and ensure consistent performance across the sector.

- Sustainability and Resource Efficiency. As water scarcity intensifies and energy costs rise, DTs will be instrumental in steering systems toward sustainable operation. By coupling robust data pipelines with operator-focused use cases, such as energy-aware control and demand forecasting, DTs can deliver both environmental and economic dividends. For instance, Changi’s FDT achieved up to five-day event forecasting accuracy [29], while EWE’s ODT yielded approximately 1.2 million kWh in annual aeration energy savings [40].

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABAC | Ammonia-Based Aeration Control |

| ADM1 | Anaerobic Digestion Model 1 |

| ADT | Autocalibrating Digital Twin |

| AI | Artificial Intelligence |

| AM | Asset Management |

| AMI | Advanced Metering Infrastructure |

| ANN | Artificial Neural Network |

| ASM | Activated Sludge Model |

| API | Application Programming Interface |

| BiLSTM | Bidirectional Long Short-Term Memory |

| BIM | Building Information Modeling |

| BOD | Biochemical Oxygen Demand |

| BP | Back Propagation |

| CFP | Computational Fluid Dynamics |

| CNN | Convolutional Neural Network |

| COBie | Construction Operation Building information exchange |

| COD | Chemical Oxygen Demand |

| CPS | Cyber-Physical System |

| CSO | Combined Sewer Overflow |

| DAC | Data Acquisition and Control |

| DD | Digital Dashboard |

| DO | Dissolved Oxygen |

| DS | Digital Shadow |

| DSS | Decision Support System |

| DNNs | Deep Neural Networks |

| DT | Digital Twin |

| FCF | Future City Flow |

| FDT | Forecasting Digital Twin |

| GBR | Gradient Boosting Regression |

| GHG | Greenhouse Gas |

| GIS | Geographic Information System |

| GRU | Gated Recurrent Unit |

| GUI | Graphical User Interface |

| HM | Hybrid Model |

| HRSD | Hampton Roads Sanitation District |

| IFC | Industrial Foundation Classes |

| IG | Influent Generator |

| IoT | Internet of Things |

| IWA | International Water Association |

| LSTM | Long Short-Term Memory |

| LTCM | Long-Term Continuous Monitoring |

| MABR | Membrane Aerated Biofilm Reactor |

| mCDI | Membrane Capacitive Deionization |

| MDT | Monitoring Digital Twin |

| ML | Machine Learning |

| MLE | Modified Ludzack-Ettinger |

| MLSS | Mixed Liquor Suspended Solids |

| NASA | National Aeronautics and Space Administration |

| O&M | Operation and Maintenance |

| ODT | Optimizing Digital Twin |

| PFD | Process Flow Diagram |

| PLC | Programmable Logic Controller |

| PUB | Public Utilities Board |

| P&ID | Process and Instrumentation Diagram |

| RBMs | Restricted Boltzmann Machines |

| ReLUs | Rectified Linear Units |

| RNN | Recurrent Neural Networks |

| RO | Reverse Osmosis |

| SAEs | Stacked Autoencoders |

| SCADA | Supervisory Control and Data Acquisition |

| SCIP | Solving Constraint Integer Programs |

| SDT | Sensitivity Digital Twin |

| SI | Système International |

| SVM | Support Vector Machine |

| SWRO | Seawater Reverse Osmosis |

| SWMM | Storm Water Management Model |

| TAN | Total Ammonia Nitrogen |

| T-GCN | Temporal Graph Convolutional Neural Network |

| TKN | Total Kjeldahl Nitrogen |

| TSS | Total Suspended Solids |

| UI | User Interface |

| US | United States |

| US EPA | United States Environmental Protection Agency |

| UTC | Coordinated Universal Time |

| VAE | Variational Autoencoder |

| VR | Virtual Reality |

| WDN | Water Distribution Network |

| WDS | Water Distribution System |

| WEF | Water Environment Federation |

| WEST | Wastewater Treatment Plant Expert Simulation Tool |

| WRRF | Water Resources Recovery Facility |

| WWTP | Wastewater Treatment Plant |

Appendix A. Digital Twin Components

- Physical Entity: A DT is a virtual replication of a subject or an object that is currently operational in full-scale. A physical entity in the water industry can be a wastewater WWTP, a desalination plant, or a water distribution network. Importantly, a DT is a model of a specific plant, process, or water stream and is thus distinct from general-purpose models used for benchmarking, education, or research (e.g., Jeppsson et al. [139]).

- High-Fidelity Simulator and Modelling: Fidelity in simulators corresponds to the degree of realism and acceptance of simulation results as representing the anticipated behavior of the physical system. It is a multi-dimensional concept that relates to several components of the simulation and is created through the selection of simulation settings, equipment, and scenarios. Fidelity can also refer to the degree of exactness that is achieved in the simulation [140,141]. A high-fidelity simulation model approximates the key processes that are involved in the physical system. As no model can capture every detail of reality, models are inherently simplifications and approximations of complex systems [142]. Thus, rather than representing the system in full detail, high-fidelity models focus on capturing essential physical and chemical processes, which are most relevant to the behavior of the system being simulated. Additionally, the simulator should provide a dynamic replication, so that the virtual entity can continuously update and synchronize with the physical system. Examples of simulators in the water industry are EPANET, SUMO, BioWin, InfoSWMM, WaterGEMS, and SewerCAD.

- Physical Sensors and Analyzers: Data streaming between the physical and virtual entities is one of the main elements in DT. Physical sensors enable the virtual entity to be informed of the real-time status of the physical twin. Additionally, physical sensors enable remote operation and automated control of the physical system. Examples of physical sensors are sensors for temperature, flow rate, and power meters. On the other hand, analyzers typically perform more complex assessments by processing and interpreting data collected from sensors to determine characteristics such as pH, turbidity, or dissolved oxygen levels. Both physical sensors and analyzers are critical for ensuring efficient, compliant, and safe water treatment operations.

- Actuators with virtual connections: Actuators with virtual connections such as switches, pump drives, and valves play a crucial role in automating and remotely controlling physical systems. Actuators are devices that convert control signals (often electrical) into physical action, such as opening or closing a valve or adjusting the speed of a pump. When connected virtually, these actuators can be operated remotely via supervisory control systems or digital interfaces. For example, pump drives with virtual connectivity allow operators to adjust the flow rate or pressure of pumps from a centralized control room or even off-site locations. This virtual connectivity not only enables remote operation but also facilitates automated process adjustments, reducing the need for manual intervention, enhancing system responsiveness, and improving overall operational efficiency.

- Physical-to-Virtual Connection: The physical and virtual twins should be equipped with continuous information flows to update each other. This not only enables the virtual entity to continuously synchronize itself with the physical entity but also provides the physical system with the ability to get feedback from the virtual entity to adjust and optimize its operations. The two-way connection in a DT is one of the main distinguished features that makes it a self-evolving representation model and separates DT from a simulator or a DS.

- Advanced Data Analysis: The raw data exchanged between physical and DTs often contains noise, redundancies, or irrelevant information that can obscure valuable insights. This unprocessed data, if used directly, may lead to inaccuracies or inefficiencies in the functioning of either entity. Therefore, real-time data monitoring and collection results in a large dataset that must be refined and structured to ensure its relevance and accuracy. To make the data suitable for use by physical or virtual twins, it undergoes processing steps such as filtering and cleaning, followed by advanced data analysis techniques, including statistical approaches and AI algorithms. These steps transform raw data into actionable insights, allowing for precise decision-making and improved system performance.

- Interaction and Service: The DT should be able to interact with the users through a user interface (UI). The DT should be able to provide users with the real-time or near real-time status of the system, provide recommendations for operational settings and optimization, and enable remote and automated control of the physical entity. The major services that can be provided by the implementation of a full-scale DT are discussed in Section 5 and Appendix B of this review study.

Appendix B. Digital Twins Application

Appendix B.1. Monitoring DT (MDT)

Appendix B.2. Optimizing DT (ODT)

Appendix B.3. Forecasting DT (FGT)

Appendix B.4. Sensitivity DT (SDT)

Appendix B.5. Wrapper

Appendix C. Digital Twins in the Water Industry

Appendix C.1. Review and Conceptual Studies

Appendix C.2. Wastewater Treatment

Appendix C.3. Wastewater Collection Systems

Appendix C.4. Water Distribution Networks

Appendix C.5. Drinking Water Treatment

Appendix C.6. Water Reclamation

Appendix C.7. Water Desalination

References

- Taylor, J.E.; Law Olmsted, F.; Bennett, G.; Mohammadi, N. Engineering smarter cities with smart city digital twins. J. Manag. Eng. 2021, 37, 02021001. [Google Scholar] [CrossRef]

- Beji, H.; Lade, M. Impact of digital transformation on carbon emission reductions in the water industry. In Lecture Notes in Energy; Springer: Cham, Switzerland, 2022; Volume 86, pp. 117–127. [Google Scholar] [CrossRef]

- Conejos Fuertes, P.; Martínez Alzamora, F.; Hervás Carot, M.; Alonso Campos, J.C. Building and exploiting a digital twin for the management of drinking water distribution networks. Urban Water J. 2020, 17, 704–713. [Google Scholar] [CrossRef]

- Bolton, A.; Butler, L.; Dabson, I.; Enzer, M.; Evans, M.; Fenemore, T.; Harradence, F.; Keaney, E.; Kemp, A.; Luck, A.; et al. The Gemini Principles. In Guiding Values for the National Digital Twin and Information-Management Framework; Centre for Digital Built Britain: Cambridge, UK, 2018. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and Industry 4.0: 360-degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. Make more digital twins. Nature 2019, 573, 490–491. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital twin in industry: State of the art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- O’Dwyer, E.; Pan, I.; Charlesworth, R.; Butler, S.; Shah, N. Integration of an energy management tool and digital twin for coordination and control of multi-vector smart energy systems. Sustain. Cities Soc. 2020, 62, 102412. [Google Scholar] [CrossRef]

- Schrotter, G.; Hürzeler, C. The digital twin of the city of Zurich for urban planning. PFG J. Photogramm. Remote Sens. Geoinform. Sci. 2020, 88, 99–112. [Google Scholar] [CrossRef]

- Angjeliu, G.; Coronelli, D.; Cardani, G. Development of the simulation model for digital twin applications in historical masonry buildings: The integration between numerical and experimental reality. Comput. Struct. 2020, 238, 106282. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Xie, X.; Lu, Q.; Herrera, M.; Yu, Q.; Parlikad, A.K.; Schooling, J.M. Does historical data still count? Exploring the applicability of smart building applications in the post-pandemic period. Sustain. Cities Soc. 2021, 69, 102804. [Google Scholar] [CrossRef] [PubMed]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Gernaey, K.V.; Van Loosdrecht, M.C.M.; Henze, M.; Lind, M.; Jørgensen, S.B. Activated sludge wastewater treatment plant modelling and simulation: State of the art. Environ. Model. Softw. 2004, 19, 763–783. [Google Scholar] [CrossRef]

- Lund, N.S.V.; Falk, A.K.V.; Borup, M.; Madsen, H.; Steen Mikkelsen, P.S. Model predictive control of urban drainage systems: A review and perspective towards smart real-time water management. Crit. Rev. Environ. Sci. Technol. 2018, 48, 279–339. [Google Scholar] [CrossRef]

- Newhart, K.B.; Holloway, R.W.; Hering, A.S.; Cath, T.Y. Data-driven performance analyses of wastewater treatment plants: A review. Water Res. 2019, 157, 498–513. [Google Scholar] [CrossRef]

- Andrews, J.F. A mathematical model for the continuous culture of microorganisms utilizing inhibitory substrates. Biotechnol. Bioeng. 1968, 10, 707–723. [Google Scholar] [CrossRef]

- Schneider, M.Y.; Quaghebeur, W.; Borzooei, S.; Froemelt, A.; Li, F.; Saagi, R.; Wade, M.J.; Zhu, J.J.; Torfs, E. Hybrid modelling of water resource recovery facilities: Status and opportunities. Water Sci. Technol. 2022, 85, 2503–2524. [Google Scholar] [CrossRef]

- Takács, I.; Patry, G.G.; Nolasco, D. A dynamic model of the clarification-thickening process. Water Res. 1991, 25, 1263–1271. [Google Scholar] [CrossRef]

- Aliashrafi, A.; Zhang, Y.; Groenewegen, H.; Peleato, N.M. A review of data-driven modelling in drinking water treatment. Rev. Environ. Sci. Biotechnol. 2021, 20, 985–1009. [Google Scholar] [CrossRef]

- Solle, D.; Hitzmann, B.; Herwig, C.; Remelhe, M.P.; Ulonska, S.; Wuerth, L.; Prata, A.; Steckenreiter, T. Between the poles of data-driven and mechanistic modelling for process operation. Chem. Ing. Tech. 2017, 89, 542–561. [Google Scholar] [CrossRef]

- Berglund, E.Z.; Pesantez, J.E.; Rasekh, A.; Shafiee, M.E.; Sela, L.; Haxton, T. Review of modeling methodologies for managing water distribution security. J. Water Resour. Plan. Manag. 2020, 146, 03120001. [Google Scholar] [CrossRef]

- Berglund, E.Z.; Shafiee, M.E.; Xing, L.; Wen, J. Digital twins for water distribution systems. J. Water Resour. Plan. Manag. 2023, 149, 02523001. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Leng, J.; Chen, X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing systems. Int. J. Prod. Res. 2018, 57, 3903–3919. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Torfs, E.; Nicolaï, N.; Daneshgar, S.; Copp, J.B.; Haimi, H.; Ikumi, D.; Johnson, B.; Plosz, B.B.; Snowling, S.; Townley, L.R.; et al. The transition of WRRF models to digital twin applications. Water Sci. Technol. 2022, 85, 2840–2853. [Google Scholar] [CrossRef] [PubMed]

- ISA5.1, Instrumentation Symbols and Identification. Available online: https://www.isa.org/standards-and-publications/isa-standards/isa-standards-committees/isa5-1 (accessed on 22 June 2025).

- Corominas, L.l.; Rieger, L.; Takács, I.; Ekama, G.; Hauduc, H.; Vanrolleghem, P.A.; Oehmen, A.; Gernaey, K.V.; van Loosdrecht, M.C.M.; Comeau, Y. New framework for standardized notation in wastewater treatment modelling. Water Sci. Technol. 2010, 61, 841–857. [Google Scholar] [CrossRef]

- Dai, S.; Zhao, G.; Yu, Y.; Zheng, P.; Bao, Q.; Wang, W. Ontology-based information modelling method for digital twin creation of as-fabricated machining parts. Robot. Comput. Integr. Manuf. 2021, 72, 102173. [Google Scholar] [CrossRef]

- Villez, K.; Aguado, D.; Alferes, J.; Plana, Q.; Ruano, M.V.; Samuelsson, O. Metadata Collection and Organization in Wastewater Treatment and Wastewater Resource Recovery Systems; IWA Publishing: London, UK, 2024. [Google Scholar] [CrossRef]

- How Digital Twins Are Transforming the World of Water Management. Available online: https://smartwatermagazine.com/news/siemens/how-digital-twins-are-transforming-world-water-management (accessed on 22 June 2025).

- Daneshgar, S.; Polesel, F.; Borzooei, S.; Sørensen, H.R.; Peeters, R.; Weijers, S.; Nopens, I.; Torfs, E. A full-scale operational digital twin for a water-resource-recovery facility—A case study of Eindhoven water resource recovery facility. Water Environ. Res. 2024, 96, e11016. [Google Scholar] [CrossRef]

- Lumley, D.; Wanninger, D.J.; Magnusson, Å.; I’ons, D.; Gustafsson, L.G. Implementing a digital twin for optimized real-time control of Gothenburg’s regional sewage system. Water Pract. Technol. 2024, 19, 657–670. [Google Scholar] [CrossRef]

- Águas do Porto Combines Data from 22 Types of Sources into a Digital Twin to Monitor Its Water System in Real Time. Available online: https://www.bentley.com/wp-content/uploads/cs-aguas-do-porto-ltr-en-lr.pdf (accessed on 8 October 2025).

- Lim, K.Y.H.; Zheng, P.; Chen, C.H. A state-of-the-art survey of digital twin: Techniques, engineering product lifecycle management and business innovation perspectives. J. Intell. Manuf. 2019, 31, 1313–1337. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- EWE Wasser: Reducing Aeration Energy, Operational Expenses, and Compliance Risk in Cuxhaven. Available online: https://www.xylem.com/en-us/support/case-studies-white-papers/cuxhaven-germany-reduces-aeration-energy-use/ (accessed on 22 June 2025).

- Wang, K.J.; Lee, Y.H.; Angelica, S. Digital twin design for real-time monitoring-a case study of die cutting machine. Int. J. Prod. Res. 2020, 59, 6471–6485. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A new concept of digital twin supporting optimization and resilience of factories of the future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- dos Santos, C.H.; Lima, R.D.C.; Leal, F.; de Queiroz, J.A.; Balestrassi, P.P.; Montevechi, J.A.B. A decision support tool for operational planning: A digital twin using simulation and forecasting methods. Production 2020, 30, e20200018. [Google Scholar] [CrossRef]

- Yang, J.; Langley, R.S.; Andrade, L. Digital twins for design in the presence of uncertainties. Mech. Syst. Signal Process. 2022, 179, 109338. [Google Scholar] [CrossRef]

- Jedermann, R.; Lang, W. Wrapper functions for integrating mathematical models into digital twin event processing. Sensors 2022, 22, 7964. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer International Publishing: Cham, Switzerland, 2016; pp. 85–113. [Google Scholar] [CrossRef]

- Moser, A.; Appl, C.; Brüning, S.; Hass, V.C. Mechanistic mathematical models as a basis for digital twins. In Advances in Biochemical Engineering/Biotechnology; Springer: Cham, Switzerland, 2021; Volume 176, pp. 133–180. [Google Scholar] [CrossRef]

- Ciliberti, F.G.; Berardi, L.; Laucelli, D.B.; Ariza, A.D.; Enriquez, L.V.; Giustolisi, O. From digital twin paradigm to digital water services. J. Hydroinform. 2023, 25, 2444–2459. [Google Scholar] [CrossRef]

- Batarseh, F.A.; Kulkarni, A.; Sreng, C.; Lin, J.; Maksud, S. ACWA: An AI-driven cyber-physical testbed for intelligent water systems. Water Pract. Technol. 2023, 18, 3399–3418. [Google Scholar] [CrossRef]

- Dairi, A.; Cheng, T.; Harrou, F.; Sun, Y.; Leiknes, T.O. Deep learning approach for sustainable WWTP operation: A case study on data-driven influent conditions monitoring. Sustain. Cities Soc. 2019, 50, 101670. [Google Scholar] [CrossRef]

- Zhu, J.J.; Borzooei, S.; Sun, J.; Ren, Z.J. Deep learning optimization for soft sensing of hard-to-measure wastewater key variables. ACS EST Eng. 2022, 2, 1341–1355. [Google Scholar] [CrossRef]

- Verhaeghe, L.; Verwaeren, J.; Kirim, G.; Daneshgar, S.; Vanrolleghem, P.A.; Torfs, E. Towards good modelling practice for parallel hybrid models for wastewater treatment processes. Water Sci. Technol. 2024, 89, 2971–2990. [Google Scholar] [CrossRef] [PubMed]

- Heo, S.K.; Oh, T.; Woo, T.Y.; Kim, S.Y.; Choi, Y.; Park, M.; Kim, J.; Yoo, C.K. Real-scale demonstration of digital twins-based aeration control policy optimization in a partial nitritation/Anammox process: Policy iterative dynamic programming approach. Desalination 2025, 593, 118235. [Google Scholar] [CrossRef]

- Chen, K.J.; Kao, C.M. Optimization of municipal wastewater treatment plants management through digital twin modeling. J. Environ. Eng. 2025, 151, 04025001. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Fang, Y.; Winfrey, B.K. A digital twin framework for enhancing predictive maintenance of pumps in wastewater treatment plants. In Proceedings of the 38th International Symposium on Automation and Robotics in Construction (ISARC 2021), Dubai, UAE, 2–4 November 2021; IAARC: Auburn, AL, USA, 2021; pp. 88–93. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Fang, Y.; Winfrey, B.K. Predictive maintenance of pumps in civil infrastructure: State-of-the-art, challenges and future directions. Autom. Constr. 2022, 134, 104049. [Google Scholar] [CrossRef]

- Zhu, H.; Rui, T.; Wang, X.; Zhou, Y.; Fang, H. Fault diagnosis of hydraulic pumps based on stacked autoencoders. In Proceedings of the 12th IEEE International Conference on Electronic Measurement and Instruments (ICEMI 2015), Qingdao, China, 16–18 July 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 58–62. [Google Scholar] [CrossRef]

- Filipe, J.; Bessa, R.J.; Reis, M.; Alves, R.; Póvoa, P. Data-driven predictive energy optimization in a wastewater pumping station. Appl. Energy 2019, 252, 113423. [Google Scholar] [CrossRef]

- Eichenwald, Z.; McGrath, G.; Burchi, J.; Thomas, B.; Saparia, B.; Gee, S. Real-time Assessment of the GLWA’s Regional Operating Plan Using Digital Twin Technology. Water Environment Federation. 2021. Available online: https://www.accesswater.org/?id=-10044440 (accessed on 8 October 2025).

- Bartos, M.; Kerkez, B. Pipedream: An interactive digital twin model for natural and urban drainage systems. Environ. Model. Softw. 2021, 144, 105120. [Google Scholar] [CrossRef]

- Pedersen, A.N.; Borup, M.; Brink-Kjær, A.; Christiansen, L.E.; Mikkelsen, P.S. Living and prototyping digital twins for urban water systems: Towards multi-purpose value creation using models and sensors. Water 2021, 13, 592. [Google Scholar] [CrossRef]

- Li, J.; Mohamad, N.N.N.; Sharma, K.; Yuan, Z. Establishing boundary conditions in sewer pipe/soil heat transfer modelling using physics-informed learning. Water Res. 2023, 244, 120441. [Google Scholar] [CrossRef]

- Li, M.; Feng, X.; Hu, Q. 3D-laser point cloud-based geometric digital twin for condition assessment of large diameter pipelines. Tunn. Undergr. Space Technol. 2023, 142, 105430. [Google Scholar] [CrossRef]

- Hartmann, S.; Valles, R.; Schmitt, A.; Al-Zuriqat, T.; Dragos, K.; Gölzhäuser, P.; Jung, J.T.; Villinger, G.; Varela Rojas, D.; Bergmann, M.; et al. Digital-twin-based management of sewer systems: Research strategy for the KaSyTwin project. Water 2025, 17, 299. [Google Scholar] [CrossRef]

- Conejos, P.; Martínez Alzamora, F.; Hervás Carot, M.; Alonso Campos, J.C. Development and use of a digital twin for the water-supply and distribution network of Valencia (Spain). In Proceedings of the 17th International Computing & Control for the Water Industry Conference (CCWI 2019), Exeter, UK, 1–4 September 2019. [Google Scholar]

- Cody, R.A.; Tolson, B.A.; Orchard, J. Detecting leaks in water distribution pipes using a deep autoencoder and hydroacoustic spectrograms. J. Comput. Civ. Eng. 2020, 34, 04020001. [Google Scholar] [CrossRef]

- Morani, M.C.; Carravetta, A.; D’Ambrosio, C.; Fecarotta, O. A new mixed integer nonlinear programming model for optimal PAT and PRV location in water distribution networks. Urban Water J. 2021, 6, 394–409. [Google Scholar] [CrossRef]

- Chew, A.W.Z.; Wu, Z.Y.; Meng, X.; Kalfarisi, R. Pressure-based demand aggregation and calibration of normal and abnormal diurnal patterns for a smart water grid in near real-time. J. Water Resour. Plan. Manag. 2023, 149, 04023063. [Google Scholar] [CrossRef]

- Bonilla, C.A.; Zanfei, A.; Brentan, B.; Montalvo, I.; Izquierdo, J. A digital twin of a water distribution system by using graph convolutional networks for pump speed-based state estimation. Water 2022, 14, 514. [Google Scholar] [CrossRef]

- Ostfeld, A.; Abhijith, G.R. Digital twin for water distribution system management—Towards a paradigm shift. J. Pipeline Syst. Eng. Pract. 2023, 14, 02523001. [Google Scholar] [CrossRef]

- Inoue, J.; Yamagata, Y.; Chen, Y.; Poskitt, C.M.; Sun, J. Anomaly detection for a water treatment system using unsupervised machine learning. In Proceedings of the 2017 IEEE International Conference on Data Mining Workshops (ICDMW), New Orleans, LA, USA, 18 November 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Chen, X.; Feng, F.; Wu, J.; Liu, W. Anomaly detection for drinking water quality via deep BiLSTM ensemble. In Proceedings of the Genetic and Evolutionary Computation Conference Companion (GECCO 2018), Kyoto, Japan, 15–19 July 2018; ACM: Kyoto, Japan, 2018; pp. 3–4. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, W.; Wang, K.; Wang, Y.; Hua, Q. Digital twins supported equipment maintenance model for intelligent water conservancy. Comput. Electr. Eng. 2022, 101, 108033. [Google Scholar] [CrossRef]

- Wei, Y.; Law, A.W.K.; Yang, C. Real-time data-processing framework with model updating for digital twins of water treatment facilities. Water 2022, 14, 3591. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Xiang, W.; Wang, T.; Otis, C.; Sarge, L.; Lei, Y.; Li, B. Forward-looking roadmaps for long-term continuous water quality monitoring: Bottlenecks, innovations, and prospects in a critical review. Environ. Sci. Technol. 2022, 56, 5334–5354. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, W.O. BIM and AM to manage critical and relevant water and wastewater utilities assets. In Lecture Notes in Civil Engineering; Springer: Singapore, 2021; Volume 98, pp. 697–720. [Google Scholar] [CrossRef]

- Quaranta, E.; Ramos, H.M.; Stein, U. Digitalisation of the European water sector to foster the green and digital transitions. Water 2023, 15, 2785. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, F.; Ma, J. Cutting-edge applications of multi-angle numerical simulations for capacitive deionization. Acta Phys. Chim. Sin. 2024, 40, 2311026. [Google Scholar] [CrossRef]

- Wang, H.; Guo, Y.; Li, L.; Li, S. Development of AI-based process controller of sour water treatment unit using deep reinforcement learning. J. Taiwan Inst. Chem. Eng. 2024, 157, 105407. [Google Scholar] [CrossRef]

- Rodríguez-Alonso, C.; Pena-Regueiro, I.; García, Ó. Digital twin platform for water treatment plants using microservices architecture. Sensors 2024, 24, 1568. [Google Scholar] [CrossRef]

- Sarshartehrani, F.; Lee, A.; Azab, M.; Watkins, T.; Gračanin, D. Towards immersive cybersecurity workforce development for mission-critical IoT systems. In Proceedings of the 2024 IEEE UEMCON, Yorktown Heights, NY, USA, 17–19 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 176–182. [Google Scholar] [CrossRef]

- Zhou, S.W.; Guo, S.S.; Xu, W.X.; Du, B.G.; Liang, J.Y.; Wang, L.; Li, Y.B. Digital twin-based pump station dynamic scheduling for energy-saving optimization in water-supply systems. Water Resour. Manag. 2024, 38, 2773–2789. [Google Scholar] [CrossRef]

- Zhang, J.; Taylor, N.; Zhao, W.; Rui, R.; He, C. Enhancing coagulation prediction in water treatment using a similarity score-based piecewise machine learning model. J. Environ. Eng. 2025, 151, 04023045. [Google Scholar] [CrossRef]

- Curl, J.M.; Nading, T.; Hegger, K.; Barhoumi, A.; Smoczynski, M. Digital twins: The next generation of water treatment technology. J. Am. Water Work. Assoc. 2019, 111, 44–50. [Google Scholar] [CrossRef]

- Yang, C.; Seiler, P.; Belia, E.; Daigger, G.T. An adaptive real-time grey-box model for advanced control and operations in WRRFs. Water Sci. Technol. 2021, 84, 2353–2365. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Vanrolleghem, P.A. Including snowmelt in influent generation for cold climate WRRFs: Comparison of data-driven and phenomenological approaches. Environ. Sci. Water Res. Technol. 2022, 8, 2087–2098. [Google Scholar] [CrossRef]

- Patriarca, R.; Simone, F.; Di Gravio, G. Modelling cyber resilience in a water treatment and distribution system. Reliab. Eng. Syst. Saf. 2022, 226, 108653. [Google Scholar] [CrossRef]

- Lian, B.; Zhu, Y.; Branchaud, D.; Wang, Y.; Bales, C.; Bednarz, T.; Waite, T.D. Application of digital twins for remote operation of membrane capacitive deionization (mCDI) systems. Desalination 2022, 525, 115482. [Google Scholar] [CrossRef]

- Serrao, M.; Jauzein, V.; Juran, I.; Tassin, B.; Vanrolleghem, P. Hybrid modelling of nitrogen removal by biofiltration using high-frequent operational data. Water Sci. Technol. 2024, 90, 1416–1432. [Google Scholar] [CrossRef]

- Molin, H.; Wärff, C.; Lindblom, E.; Arnell, M.; Carlsson, B.; Mattsson, P.; Bäckman, J.; Jeppsson, U. Automated data transfer for digital twin applications: Two case studies. Water Environ. Res. 2024, 96, e11074. [Google Scholar] [CrossRef] [PubMed]

- Khalil, M.; AlSayed, A.; Liu, Y.; Vanrolleghem, P.A. An integrated feature selection and hyper parameter optimization algorithm for balanced machine learning models predicting N2O emissions from wastewater treatment plants. J. Water Process Eng. 2024, 63, 105512. [Google Scholar] [CrossRef]

- Khalil, M.; Liu, Y.; Vanrolleghem, P.A. Modelling nitrous-oxide emissions from nitritation–denitritation IFAS-SBR treating sidestream wastewater. J. Environ. Chem. Eng. 2024, 15, 113458. [Google Scholar] [CrossRef]

- Alferes, J.; Desmet, N.; Kempeneers, S.; Latte, S.; Hitsov, I.; Jayaweera, C.; De Neve, K.; Wauman, J.; Bosch, R.; Dehaspe, J.; et al. Water-smart strategies to support decision-making for water resource management in the industrial context. Water Sci. Technol. 2024, 90, 2276–2290. [Google Scholar] [CrossRef]

- Rivas-Perez, R.; Sotomayor-Moriano, J.; Pérez-Zuñiga, G.; Soto-Angles, M.E. Real-time implementation of an expert model predictive controller in a pilot-scale reverse osmosis plant for brackish and seawater desalination. Appl. Sci. 2019, 9, 2932. [Google Scholar] [CrossRef]

- Alsarayreh, A.A.; Al-Obaidi, M.A.; Patel, R.; Mujtaba, I.M. Scope and limitations of modelling, simulation, and optimisation of a spiral-wound reverse osmosis process-based water desalination. Processes 2020, 8, 573. [Google Scholar] [CrossRef]

- Gunter, D.; Amusat, O.; Bartholomew, T.; Drouven, M. Santa Barbara Desalination Digital Twin Technical Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2021. [CrossRef]

- van Rooij, F.; Scarf, P.; Do, P. Planning the restoration of membranes in RO desalination using a digital twin. Desalination 2022, 519, 115214. [Google Scholar] [CrossRef]

- Remigi, E. Practical Application of a Model-Based Digital Twin for Monitoring and Scenario Analysis of a Water Resource Recovery Facility. Water Environment Federation, 2022. Available online: https://www.accesswater.org/?id=-10083930 (accessed on 22 September 2025).

- Siemens Digital Twin Set to Drive World’s First Carbon-Neutral Wastewater Treatment Plant. Available online: https://news.siemens.co.uk/news/siemens-digital-twin-set-to-drive-worlds-first-carbon-neutral-wastewater-treatment-plant (accessed on 22 June 2025).

- Komulainen, T.M.; Johansen, H. Possible concepts for digital twin simulator for WWTP. In Proceedings of the First SIMS EUROSIM Conference on Modelling and Simulation (SIMS EUROSIM 2021), Virtual Conference, Oulu, Finland, 21–23 September 2021; Linköping University Electronic Press: Linköping, Sweden, 2022; pp. 398–404. [Google Scholar] [CrossRef]

- Zekri, S.; Jabeur, N.; Gharrad, H. Smart water management using intelligent digital twins. Comput. Inform. 2022, 41, 135–153. [Google Scholar] [CrossRef]

- Gómez-Coronel, L.; Santos-Ruiz, I.; Torres, L.; López-Estrada, F.R.; Gómez-Peñate, S.; Escobar-Gómez, E. Digital twin of a hydraulic system with leak diagnosis applications. Processes 2023, 11, 3009. [Google Scholar] [CrossRef]

- Lumley, D.J.; Polesel, F.; Refstrup Sørensen, H.; Gustafsson, L.G. Connecting digital twins to control collection systems and water resource recovery facilities: From siloed to integrated urban (waste)water management. Water Pract. Technol. 2024, 19, 2267–2278. [Google Scholar] [CrossRef]

- You, J.; Wang, S.; Ha, M.; Kang, A.; Lei, X.; Chen, B.; Yu, Y.; Chai, B. Comparative hydrologic performance of cascading and distributed green-gray infrastructure: Experimental evidence for spatial optimization in urban waterlogging mitigation. J. Hydrol. 2025, 662, 133979. [Google Scholar] [CrossRef]

- Di, D.; Bai, Y.; Fang, H.; Sun, B.; Wang, N.; Li, B. Intelligent siltation diagnosis for drainage pipelines using weak-form analysis and theory-guided neural networks in geo-infrastructure. Autom. Constr. 2025, 176, 106246. [Google Scholar] [CrossRef]

- Du, K.; Yang, S.; Xu, W.; Zheng, F.; Duan, H. A novel optimization framework for efficiently identifying high-quality Pareto-optimal solutions: Maximizing resilience of water distribution systems under cost constraints. Reliab. Eng. Syst. Saf. 2025, 261, 111136. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, E.; Li, D.; Li, J.; Wang, Y.; Zhao, W.; Yang, Z. Annual multi-objective optimization model and strategy for scheduling cascade reservoirs on the Yellow River mainstream. J. Hydrol. 2025, 659, 133306. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants: A state of the art and proposals for improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Kim, M.; Kim, Y.; Kim, H.; Piao, W.; Kim, C. Evaluation of the k-nearest neighbor method for forecasting the influent characteristics of wastewater treatment plant. Front. Environ. Sci. Eng. 2016, 10, 299–310. [Google Scholar] [CrossRef]

- Cao, W.; Yang, Q. Online sequential extreme learning machine-based adaptive control for wastewater treatment plant. Neurocomputing 2020, 408, 169–175. [Google Scholar] [CrossRef]

- Cardillo Albarrán, J.; Chacón Ramírez, E.; Cruz Salazar, L.A.; Paredes Astudillo, Y.A. Digital twin in water supply systems to Industry 4.0: The holonic production unit. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Trentesaux, D., Borangiu, T., Leitão, P., Jimenez, J.F., Montoya-Torres, J.R., Eds.; Studies in Computational Intelligence; Springer: Cham, Switzerland, 2021; Volume 987. [Google Scholar] [CrossRef]

- Kijak, R. Application of Water 4.0 technologies and solutions. In Water Asset Management in Times of Climate Change and Digital Transformation; Palgrave Studies in Climate Resilient Societies; Palgrave Macmillan: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Yoon, N.; Kim, J.; Lim, J.-L.; Abbas, A.; Jeong, K.; Cho, K.H. Dual-stage attention-based LSTM for simulating performance of brackish water treatment plant. Desalination 2021, 512, 115107. [Google Scholar] [CrossRef]

- Qiao, J.-F.; Hou, Y.; Zhang, L.; Han, H.-G. Adaptive fuzzy neural network control of wastewater treatment process with multiobjective operation. Neurocomputing 2018, 275, 383–393. [Google Scholar] [CrossRef]

- Wei, Y.; Law, A.W.-K.; Yang, C.; Tang, D. Combined Anomaly Detection Framework for Digital Twins of Water Treatment Facilities. Water 2022, 14, 1001. [Google Scholar] [CrossRef]

- Pesantez, J.E.; Alghamdi, F.; Sabu, S.; Mahinthakumar, G.; Berglund, E.Z. Using a digital twin to explore water infrastructure impacts during the COVID-19 pandemic. Sustain. Cities Soc. 2022, 77, 103520. [Google Scholar] [CrossRef]

- Wallin, C.; Nordlander, E. Challenges in connecting a wastewater treatment plant to a machine learning platform. In Proceedings of the First SIMS EUROSIM Conference on Modelling and Simulation, SIMS EUROSIM 2021, and 62nd International Conference of Scandinavian Simulation Society, SIMS 2021, Virtual, 21–23 September 2021. [Google Scholar] [CrossRef]

- Kazała, R.; Luściński, S.; Strączyński, P.; Taneva, A. An Enabling Open-Source Technology for Development and Prototyping of Production Systems by Applying Digital Twinning. Processes 2022, 10, 21. [Google Scholar] [CrossRef]

- Ye, L.; Porro, J.; Nopens, I. (Eds.) Quantification and Modelling of Fugitive Greenhouse Gas Emissions from Urban Water Systems; IWA Publishing: London, UK, 2022. [Google Scholar] [CrossRef]

- Mihály, N.B.; Simon-Várhelyi, M.; Cristea, V.M. Data-driven modelling based on artificial neural networks for predicting energy and effluent quality indices and wastewater treatment plant optimization. Optim. Eng. 2022, 23, 2235–2259. [Google Scholar] [CrossRef]

- Cărbureanu, M.; Mihalache, S.F.; Zamfir, F. Machine learning methods applied for wastewater pH neutralization process modeling. In Proceedings of the 14th International Conference on Electronics, Computers and Artificial Intelligence (ECAI 2022), Ploiești, Romania, 30 June–1 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Pisani, J.; Cavone, G.; Giarré, L.; Pascucci, F. Industrial control systems attack detection by hybrid digital twin. In Proceedings of the 2023 European Control Conference (ECC), Bucharest, Romania, 13–16 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Isah, A.; Shin, H.; Oh, S.; Oh, S.; Aliyu, I.; Um, T.-W.; Kim, J. Digital Twins Temporal Dependencies-Based on Time Series Using Multivariate Long Short-Term Memory. Electronics 2023, 12, 4187. [Google Scholar] [CrossRef]

- Baena-Miret, S.; Puig, M.A.; Rodes, R.B.; Farran, L.B.; Durán, S.; Martí, M.G.; Valverde, A.C. Enhancing efficiency and quality control: The impact of digital twins in drinking water networks. Water Environ. Res. 2024, 96, e11139. [Google Scholar] [CrossRef] [PubMed]

- Mai, Z.; He, Y.; Feng, C.; Han, C.; Shi, Y.; Qi, W. Multi-objective modeling and optimization of water distribution for canal system considering irrigation coverage in artesian irrigation district. Agric. Water Manag. 2024, 301, 108959. [Google Scholar] [CrossRef]

- Mohammed, M.A.; Lakhan, A.; Abdulkareem, K.H.; Abd Ghani, M.K.; Marhoon, H.A.; Kadry, S.; Nedoma, J.; Martinek, R.; Garcia Zapirain, B. Industrial Internet of Water Things architecture for data standardization based on blockchain and digital twin technology. J. Adv. Res. 2024, 66, 1–14. [Google Scholar] [CrossRef]

- Singh, A.; Maheshwari, A.; Singh, S. Digital twin framework for leakages detection in large-scale water distribution systems: A case study of IIT-Jodhpur campus. IFAC-Pap. OnLine 2024, 57, 280–285. [Google Scholar] [CrossRef]

- Riyadh, A.; Peleato, N.M. Exploring spatial and temporal importance of input features and the explainability of machine learning-based modelling of water distribution systems. Digit. Chem. Eng. 2025, 14, 100202. [Google Scholar] [CrossRef]

- Truong, H.; Tello, A.; Lazovik, A.; Degeler, V. Graph neural networks for pressure estimation in water distribution systems. Water Resour. Res. 2024, 60, e2023WR036741. [Google Scholar] [CrossRef]

- Ukwuoma, H.C.; Dusserre, G.; Coatrieux, G.; Vincent, J.; Ahmed, N.B. Optimising intrusion detection in cyber-physical systems. In Proceedings of the 8th Cyber Security in Networking Conference (CSNet 2024), Paris, France, 4–6 December 2024; pp. 7–14. [Google Scholar] [CrossRef]

- Vitale, F.; Guarino, S.; Flammini, F.; Faramondi, L.; Mazzocca, N.; Setola, R. Process mining for digital twin development of industrial cyber-physical systems. IEEE Trans. Ind. Inf. 2025, 21, 866–875. [Google Scholar] [CrossRef]

- Jafari, I.; Luo, R.; Ng, E.; Corral, F., Jr.; Chua, Y.; Ng, S.H.; Hu, J. Robust prediction of residual chlorine decay in a drinking water distribution system integrating water quality sensing and predictive tools. ACS ES&T Water 2024, 4, 5506–5521. [Google Scholar] [CrossRef]

- Mobadersani, M.; Tokdemir, O.B.; Candaş, A.B. Optimizing water quality in urban distribution networks: Leveraging digital twin technology for real-time demand management. J. Constr. Eng. Manag. Innov. 2024, 7, 144–156. [Google Scholar] [CrossRef]

- Moraitis, G.; Makropoulos, C. A hybrid dynamic graph neural network framework for real-time anomaly detection. J. Hydroinform. 2024, 26, 3172–3191. [Google Scholar] [CrossRef]

- Preite, L.; Solari, F.; Vignali, G. Water management optimization in agriculture: A digital model development. Water Resour. Manag. 2025, 39, 1261–1279. [Google Scholar] [CrossRef]

- Tan, S.; Rapaport, A.; Vanrolleghem, P.A.; Dochain, D.; Passeport, E.; Taylor, J.A. Predictive control of flow rates and concentrations in sewage transport and treatment systems. J. Process Control 2025, 147, 103386. [Google Scholar] [CrossRef]

- Jun, S.; Jung, D. Exploration of deep learning leak detection model across multiple smart water distribution systems: Detectable leak sizes with AMI meters. Water Res. X 2025, 29, 100332. [Google Scholar] [CrossRef]

- Singh, A.; Singh, S.; Maheshwari, A. A proof-of-concept study towards developing digital twins for operational excellence in large-scale water distribution networks. Urban Water J. 2025, 22, 507–525. [Google Scholar] [CrossRef]

- Jeppsson, U.; Pons, M.N. The COST benchmark simulation model—Current state and future perspective. Control Eng. Pract. 2004, 12, 299–304. [Google Scholar] [CrossRef]

- Adamson, K. A systematic review of the literature related to the NLN/Jeffries simulation framework. Nurs. Educ. Perspect. 2015, 36, 281–291. [Google Scholar] [CrossRef]

- Choi, Y.F.; Wong, T.W. High-fidelity simulation training programme for final-year medical students: Implications from the perceived learning outcomes. Hong Kong Med. J. 2019, 25, 392. [Google Scholar] [CrossRef]

- Gujer, W. Systems Analysis for Water Technology; Springer: Berlin, Germany, 2008. [Google Scholar] [CrossRef]

- Vilarinho, S.; Lopes, I.; Sousa, S. Design procedure to develop dashboards aimed at improving the performance of productive equipment and processes. Procedia Manuf. 2017, 11, 1634–1641. [Google Scholar] [CrossRef]

- Bellalouna, F. Case study for design optimization using the digital twin approach. Procedia CIRP 2021, 100, 595–600. [Google Scholar] [CrossRef]

- Teng, S.Y.; Touš, M.; Leong, W.D.; How, B.S.; Lam, H.L.; Máša, V. Recent advances on industrial data-driven energy savings: Digital twins and infrastructures. Renew. Sustain. Energy Rev. 2021, 135, 110208. [Google Scholar] [CrossRef]

- Huynh, T.A.; Zondervan, E. Process intensification and digital twin—The potential for the energy transition in process industries. Phys. Sci. Rev. 2022, in press. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterizing the digital twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Brooks, S.; Yasin, A.; Alatishe, K.; Roy, R. Design and implementation of a self-cleaning heat exchanger using a digital twin. In Proceedings of the 10th International Conference on Through-Life Engineering Services 2021 (TESConf 2021), Online, 16–18 November 2021. [Google Scholar] [CrossRef]

- Shafiee, M.E.; Rasekh, A.; Sela, L.; Preis, A. Streaming smart meter data integration to enable dynamic demand assignment for real-time hydraulic simulation. J. Water Resour. Plan. Manag. 2020, 146, 06020008. [Google Scholar] [CrossRef]

- Saddiqi, M.M.; Zhao, W.; Cotterill, S.; Dereli, R.K. Smart management of combined sewer overflows: From an ancient technology to artificial intelligence. WIREs Water 2023, 10, e1635. [Google Scholar] [CrossRef]

- Kretschmer, F.; Franziskowski, S.; Huber, F.; Ertl, T. Chances and barriers of building information modelling in wastewater management. Water Sci. Technol. 2023, 87, 1630–1643. [Google Scholar] [CrossRef]

- Ramos, H.M.; Kuriqi, A.; Besharat, M.; Creaco, E.; Tasca, E.; Coronado-Hernández, O.E.; Pienika, R.; Iglesias-Rey, P. Smart water grids and digital twins for management of system efficiency in water distribution networks. Water 2023, 15, 1129. [Google Scholar] [CrossRef]

- Laucelli, D.B.; Enriquez, L.V.; Ariza, A.D.; Ciliberti, F.G.; Berardi, L.; Giustolisi, O. A digital water strategy based on the digital water service concept to support asset management in a real system. J. Hydroinform. 2023, 25, 2004–2016. [Google Scholar] [CrossRef]

- Boogaard, J.R.; Prabhakara Rao, S.; Abayankar Balaji, S.R.; Ranganathan, P. Digital-twin models for cybersecurity use cases in water utilities and SCADA systems. In Proceedings of the 2024 IEEE 5th Cyber Awareness and Research Symposium (CARS), Grand Forks, ND, USA, 28–29 October 2024; IEEE: Piscataway, NJ, USA, 2024. [Google Scholar] [CrossRef]

- Sheik, A.G.; Kumar, A.; Ansari, F.A.; Raj, V.; Peleato, N.M.; Patan, A.K.; Kumari, S.; Bux, F. Reinvigorating algal cultivation for biomass production with digital-twin technology–a smart sustainable infrastructure. Algal Res. 2024, 84, 103779. [Google Scholar] [CrossRef]

- Cairone, S.; Hasan, S.W.; Choo, K.H.; Lekkas, D.F.; Fortunato, L.; Zorpas, A.A.; Korshin, G.; Zarra, T.; Belgiorno, V.; Naddeo, V. Revolutionizing wastewater treatment toward circular-economy and carbon-neutrality goals: Pioneering sustainable and efficient solutions for automation and advanced process control with smart and cutting-edge technologies. J. Water Process Eng. 2024, 63, 105486. [Google Scholar] [CrossRef]

- Dehghani Tafti, A.; Houweling, D.; Perron, J.M.; Bencsik, D.; Johnson, T.; Vanrolleghem, P.A.; Comeau, Y. Towards a modelling framework for nature-based solutions in wastewater treatment. Water Sci. Technol. 2024, 90, 758–776. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Fan, Y.; Gao, Z.; Chen, H.; Kang, Y. Research progress on operation control and optimal scheduling of irrigation-canal systems. Irrig. Drain. 2024, 74, 861–879. [Google Scholar] [CrossRef]

- Villinger, G.; Reiterer, A. Robotic systems for sewer inspection and monitoring tasks: Overview and novel concepts. IEEE Sens. J. 2025, 25, 8786–8796. [Google Scholar] [CrossRef]

- Alex, J.; Hübner, C.; Förster, L. Planning, testing and commissioning of automation solutions for wastewater treatment plants using simulation. IFAC PapersOnLine 2020, 53, 16665–16670. [Google Scholar] [CrossRef]

- Matheri, A.N.; Mohamed, B.; Ntuli, F.; Nabadda, E.; Ngila, J.C. Sustainable circularity and intelligent empirical operations and control of wastewater treatment plants. Phys. Chem. Earth 2022, 126, 103152. [Google Scholar] [CrossRef]

- Mihaly, N.B.; Simon-Varhelyi, M.; Luca, A.V.; Cristea, V.M. Optimization of the wastewater treatment plant recycle flowrates using artificial neural networks. In Proceedings of the IEEE International Conference Automation, Quality and Testing, Robotics (AQTR 2022), Cluj-Napoca, Romania, 19–21 May 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar] [CrossRef]

- Cheng, T.; Harrou, F.; Kadri, F.; Sun, Y.; Leiknes, T. Forecasting of wastewater-treatment-plant key features using deep-learning-based models: A case study. IEEE Access 2020, 8, 184475–184485. [Google Scholar] [CrossRef]

- Yang, C.; Belia, E.; Daigger, G.T. Automating process design by coupling genetic algorithms with commercial simulators: A case study for hybrid MABR processes. Water Sci. Technol. 2022, 86, 672–689. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Lobur, M.; Jaworski, N.; Ciula, J.; Mzyk, T. Optimization of biological wastewater-treatment processes by hierarchical adaptive control. In Proceedings of the International Conference on Perspective Technologies and Methods in MEMS Design (MEMSTECH 2019), Polyana, Ukraine, 22–26 May 2019; IEEE: Polyana, Ukraine, 2019; pp. 119–122. [Google Scholar] [CrossRef]

- Fomenkova, A.A.; Klucharev, A.A.; Kolesnikova, S.I. Formalization of target invariants and design of an adaptive-control system for anaerobic biological wastewater treatment. J. Phys. Conf. Ser. 2021, 2099, 012035. [Google Scholar] [CrossRef]

- Laing, H.; O’Malley, C.; Browne, A.; Rutherford, T.; Baines, T.; Willis, M.J. Development of a biogas-distribution model for a wastewater-treatment plant: A mixed-integer linear-programming approach. Water Sci. Technol. 2020, 82, 2761–2775. [Google Scholar] [CrossRef]

- Therrien, J.D.; Nicolaï, N.; Vanrolleghem, P.A. A critical review of the data pipeline: How wastewater-system operation flows from data to intelligence. Water Sci. Technol. 2020, 82, 2613–2634. [Google Scholar] [CrossRef] [PubMed]

- Moretta, F.; Rizzo, E.; Manenti, F.; Bozzano, G. Enhancement of anaerobic-digestion digital twin through aerobic simulation and kinetic optimization for co-digestion scenarios. Bioresour. Technol. 2021, 341, 125845. [Google Scholar] [CrossRef]

- Li, J.L.; Chen, L.M.; Xu, H. Intelligent construction, operation and maintenance of a large wastewater-treatment plant based on BIM. Adv. Civ. Eng. 2021, 2021, 6644937. [Google Scholar] [CrossRef]

- Bolorinos, J.; Mauter, M.S.; Rajagopal, R. Integrated energy-flexibility management at wastewater-treatment facilities. Environ. Sci. Technol. 2023, 57, 18362–18371. [Google Scholar] [CrossRef]

- Schroer, H.W.; Just, C.L. Feature engineering and supervised machine learning to forecast biogas production during municipal anaerobic co-digestion. ACS EST Eng. 2023, 3, 660–672. [Google Scholar] [CrossRef]

- Fang, G.; Liu, Y. Twinning quality sensors in wastewater-treatment processes via optimized echo state network-based soft sensors. Appl. Soft Comput. 2024, 164, 111977. [Google Scholar] [CrossRef]

- Wang, D.; Ma, H.; Qiao, J. Multilayer adaptive-critic design with a digital twin for data-driven optimal tracking control and industrial applications. Eng. Appl. Artif. Intell. 2024, 133, 108228. [Google Scholar] [CrossRef]

- Machaka, V.; Figueroa-Lorenzo, S.; Arrizabalaga, S.; Hernantes, J. Comparative analysis of the standalone and hybrid SDN solutions for early detection of network channel attacks in industrial control systems: A WWTP case study. Internet of Things 2024, 28, 101413. [Google Scholar] [CrossRef]

- Akroyd, J. CReDo Methodology Papers: Implementation; Centre for Digital Built Britain: Cambridge, UK, 2022. [Google Scholar] [CrossRef]

- Dalla Vedova, M.D.L.; Berri, P.C. A new simplified fluid-dynamic model for digital twins of electrohydraulic servovalves. Aircr. Eng. Aerosp. Technol. 2022, 94, 79–88. [Google Scholar] [CrossRef]

- Lumley, D. Using a Digital Twin to Control Sewer Overflows—Sweden. Water Environment Federation, 2022. Available online: https://www.accesswater.org/?id=-10081497 (accessed on 8 October 2025).

- He, L.; Wen, K.; Gong, J.; Wu, C. A multi-model ensemble digital-twin solution for real-time unsteady-flow state estimation of a pumping station. ISA Trans. 2022, 126, 242–253. [Google Scholar] [CrossRef]

- Ramos, H.M.; Morani, M.C.; Carravetta, A.; Fecarotta, O.; Adeyeye, K.; López-Jiménez, P.A.; Pérez-Sánchez, M. New challenges towards smart-system efficiency using digital twins in water-distribution networks. Water 2022, 14, 1304. [Google Scholar] [CrossRef]

- Brahmbhatt, P.; Maheshwari, A.; Gudi, R.D. Digital-twin-assisted decision-support system for quality regulation and leak-localization tasks in large-scale water-distribution networks. Digit. Chem. Eng. 2023, 9, 100127. [Google Scholar] [CrossRef]

- Krejcik, J. Emerging Technologies Tackle Water Distribution Challenges. Water Environment Federation, 2020. Available online: https://www.accesswater.org?id=-10033006 (accessed on 8 October 2025).

- Mücke, N.T.; Pandey, P.; Jain, S.; Bohté, S.M.; Oosterlee, C.W. A probabilistic digital twin for leak localization in water-distribution networks using generative deep learning. Sensors 2023, 23, 6179. [Google Scholar] [CrossRef] [PubMed]

- Katulić, F.; Sumina, D.; Groš, S.; Erceg, I. Protecting Modbus/TCP-based industrial automation and control systems using message-authentication codes. IEEE Access 2023, 11, 60439–60454. [Google Scholar] [CrossRef]

- Fu, A.; Qiao, R.; Wu, Z. Decentralized periodic event-triggered control for smart-water-distribution systems via a digital twin approach. Int. J. Robust Nonlinear Control. 2024, 34, 9638–9653. [Google Scholar] [CrossRef]

- Menapace, A.; Zanfei, A.; Herrera, M.; Brentan, B. Graph neural networks for sensor placement: A proof of concept towards a digital twin of water-distribution systems. Water 2024, 16, 1835. [Google Scholar] [CrossRef]

- Kallesøe, C.S.; Wisniewski, R. Cyber-attack and fault detection using a digital twin of the controller software. IFAC PapersOnLine 2024, 58, 97–102. [Google Scholar] [CrossRef]

- Sinagra, M.; Creaco, E.; Morreale, G.; Tucciarelli, T. Energy-recovery optimization by means of a turbine in a pressure regulation node of a real network through a data-driven digital twin. Water Resour. Manag. 2023, 37, 3925–3943. [Google Scholar] [CrossRef]

- Travaš, V.; Gal, E.; Lučin, I.; Žic, E. Digital twin for real-time leakage detection and localization in pressurized piping systems. J. Hydroinform. 2025, 27, 755–770. [Google Scholar] [CrossRef]

- Fu, G.; Jin, Y.; Sun, S.; Yuan, Z.; Butler, D. The role of deep learning in urban water management: A critical review. Water Res. 2022, 223, 118973. [Google Scholar] [CrossRef]

- Savić, D. Digital water developments and lessons learned from automation in the car and aircraft industries. Engineering 2022, 9, 35–41. [Google Scholar] [CrossRef]

- Moradi, F.; Abbaspour Asadollah, S.; Pourvatan, B.; Moezkarimi, Z.; Sirjani, M. CRYSTAL framework: Cybersecurity assurance for cyber-physical systems. J. Log. Algebr. Methods Program. 2024, 139, 100965. [Google Scholar] [CrossRef]

- Belay, M.A.; Rasheed, A.; Rossi, P.S. Multivariate time-series anomaly detection via low-rank and sparse decomposition. IEEE Sens. J. 2024, 24, 34942–34952. [Google Scholar] [CrossRef]

- Quaghebeur, W.; Torfs, E.; De Baets, B.; Nopens, I. Hybrid differential equations: Integrating mechanistic and empirical techniques for modelling of water systems. Water Res. 2022, 213, 118166. [Google Scholar] [CrossRef]

| Facility Name | Location | Facility Type | Implementation | Reference |

|---|---|---|---|---|

| Changi Water Reclamation Plant | Singapore | Water Reclamation | DT: Operated in the advisory-only mode, but it has capability of bidirectional communication | [29] |

| Eindhoven Water Resource Recovery | Netherlands | Water Resource Recovery | DS: Advisory only | [35] |

| Bresso-Niguarda Water Resource Recovery | Italy | Water Resource Recovery | DS: Advisory only | [98] |

| Gothenburg Regional Sewage System | Sweden | Wastewater Collection | DS: Advisory only | [36] |

| EWE WASSER GmbH | Germany | Wastewater Treatment | DS: Advisory only | [40] |

| Águas do Porto | Portugal | Integrated Urban Water Cycle Management | DS: Advisory only | [37] |

| Lushan Water Supply Company | China | Water Supply System | DT: Advisory and process control | [34] |

| Water Distribution Network of Valencia | Spain | Water Supply System | DS: Advisory only | [3] |

| Strongford Wastewater Treatment Plant | United Kingdom | Wastewater Treatment | N/A * | [99] |

| Authors | Location | System Type | Implementation | Reference |

|---|---|---|---|---|

| Bartos & Kerkez | USA | Surface Water Systems | DS: Advisory only | [60] |

| Komulainen & Johansen | Norway | Wastewater Treatment | DS: Advisory only | [100] |

| Lian et al. | Various communities China and Australia | Pilot plants for desalination | DS (2) * + DT (2) | [88] |

| Zekri et al. | Oman | Water distribution | DT: Advisory and process control | [101] |

| Gomez-Coronel et al. | Mexico | Water distribution | DT: Advisory and process control | [102] |

| Lumley et al. | Sweden (7) + Norway | Wastewater Collection | DS: Advisory only | [103] |

| Lumley et al. | Denmark (4) + Netherlands + Italy | Water Treatment | DS: Advisory only | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbani Bam, P.; Rezaei, N.; Roubanis, A.; Austin, D.; Austin, E.; Tarroja, B.; Takacs, I.; Villez, K.; Rosso, D. Digital Twin Applications in the Water Sector: A Review. Water 2025, 17, 2957. https://doi.org/10.3390/w17202957

Ghorbani Bam P, Rezaei N, Roubanis A, Austin D, Austin E, Tarroja B, Takacs I, Villez K, Rosso D. Digital Twin Applications in the Water Sector: A Review. Water. 2025; 17(20):2957. https://doi.org/10.3390/w17202957

Chicago/Turabian StyleGhorbani Bam, Pooria, Nader Rezaei, Alexander Roubanis, Dana Austin, Elinor Austin, Brian Tarroja, Imre Takacs, Kris Villez, and Diego Rosso. 2025. "Digital Twin Applications in the Water Sector: A Review" Water 17, no. 20: 2957. https://doi.org/10.3390/w17202957

APA StyleGhorbani Bam, P., Rezaei, N., Roubanis, A., Austin, D., Austin, E., Tarroja, B., Takacs, I., Villez, K., & Rosso, D. (2025). Digital Twin Applications in the Water Sector: A Review. Water, 17(20), 2957. https://doi.org/10.3390/w17202957