Techno-Economic Assessment of Microalgae-Based Biofertilizer Production from Municipal Wastewater Using Scenedesmus sp.

Abstract

1. Introduction

2. Materials and Methods

2.1. Determination of Optimum Operational Conditions

2.1.1. Experimental Design

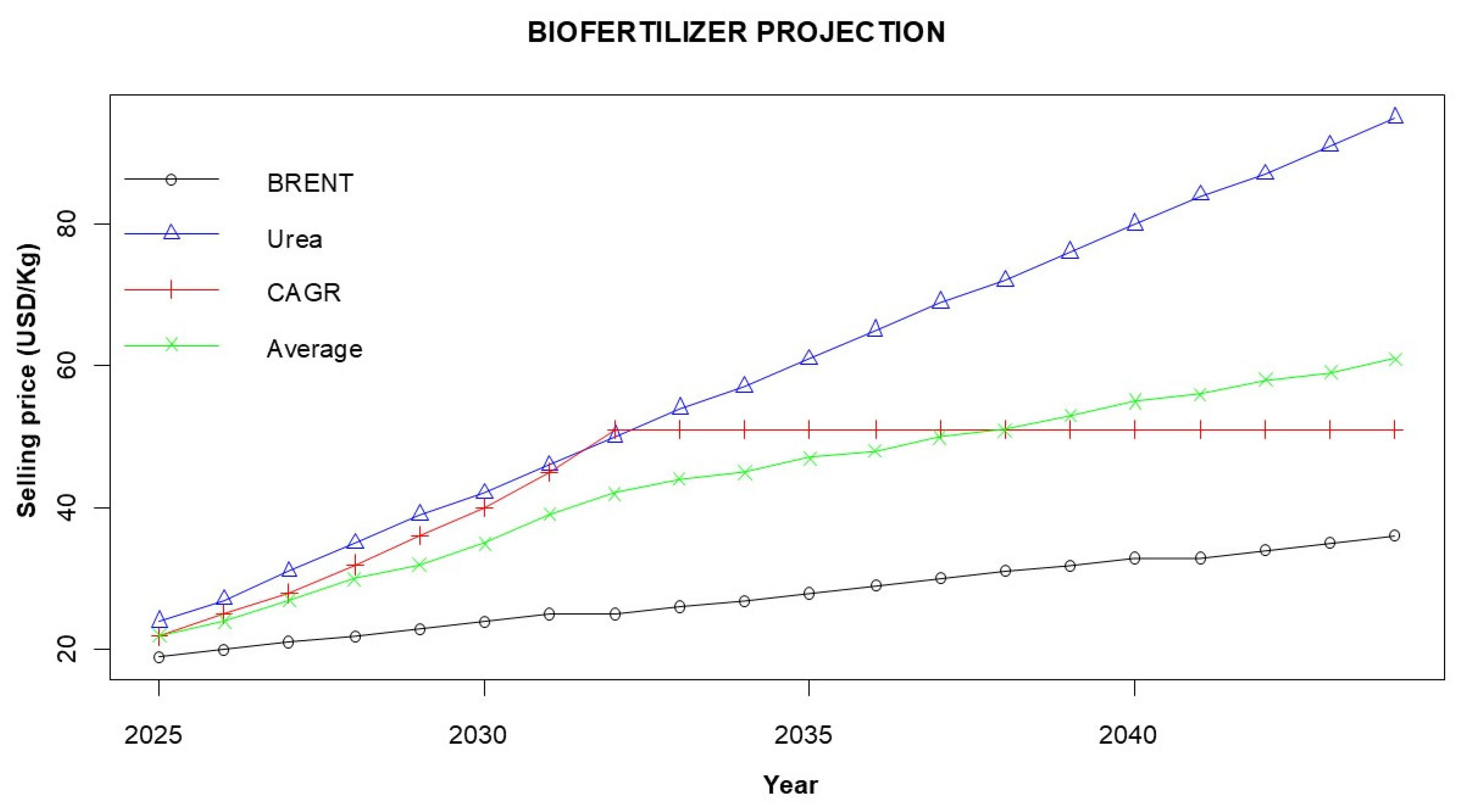

2.1.2. Selling Price Estimation for Microalgae Production

- = Average nutrients price in commercial biofertilizers (USD/Kg);

- = Nitrogen concentration (%wt./wt.);

- = Phosphorus concentration (%wt./wt.);

- = Market Price (USD/Kg);

- = Number of biofertilizers employed;

- = Theoretical biomass price (USD/Kg).

- = Regression coefficients (m = slope, b = intercept) according to historical data.

- = Market price for urea and oil at period n.

- = Biofertilizer price estimation at period n according to commodity i.

2.1.3. Operational Cost Estimation (OPEX)

- = Reactor volume dimension (m3);

- = Power required for aeration (KwH);

- = Required pressure for aeration (bar);

- = Density of water (Kg/m3);

- = Height of column water (m);

- = Air flow (L/min);

- = Wastewater flow (m3/s);

- = Harvesting time (s);

- = Amount of PBR required.

- = Raw materials cost (USD/year);

- = Labor costs at year n (USD/year);

- = Cost associated with raw material k at year 0 (USD/Kg);

- = Flow of raw material k at year n (Kg/year);

- = Market price of oil for period n (USD);

- = Energy costs at period 0 (USD/Kwh);

- = Energy costs per year at period “n” (USD/year).

2.1.4. Total Plant Costs and Financial Indexes

- = Capital expenditures required for plant production;

- = Surface/volume ratio for 40 L photobioreactors with 70.8 cm height;

- = Equipment cost at year “n”;

- = Required area for biomass production and services.

- = Other typical services contemplated in Table 7;

- = Total plant cost.

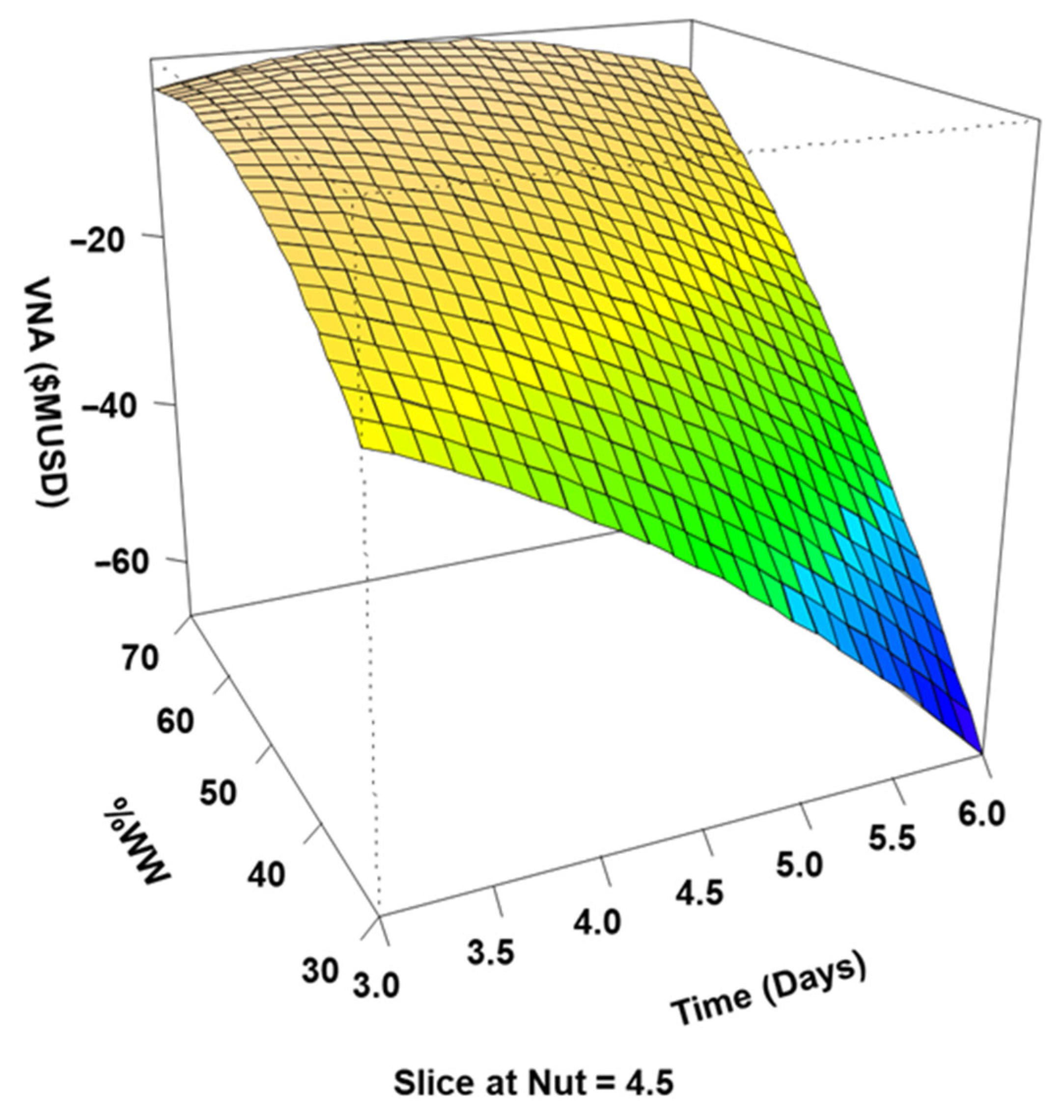

2.2. Sensitivity Analysis for Critical Variables

- = Base case biofertilizer biomass production.

- = New biomass production associated with wastewater flow.

- = Plant cost at base case.

- = Estimated plant cost according to new wastewater flow.

3. Results and Analysis

3.1. Optimum Operational Condition Determination

3.1.1. Plant Effluent Characterization and Selling Price Determination

3.1.2. Operational Cost Results

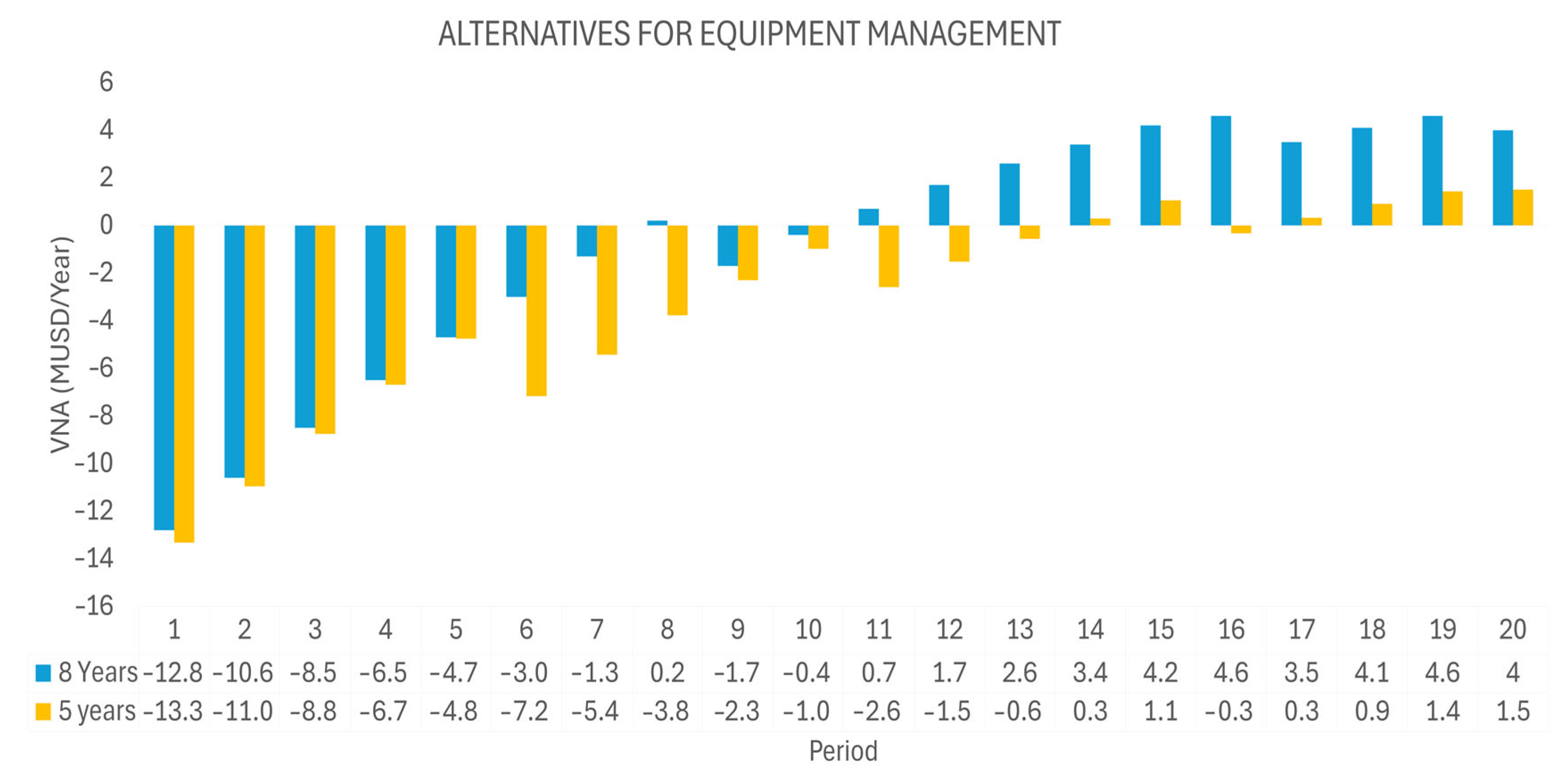

3.1.3. Equipment Acquisition, Land Requirements, and Cash Flow Results

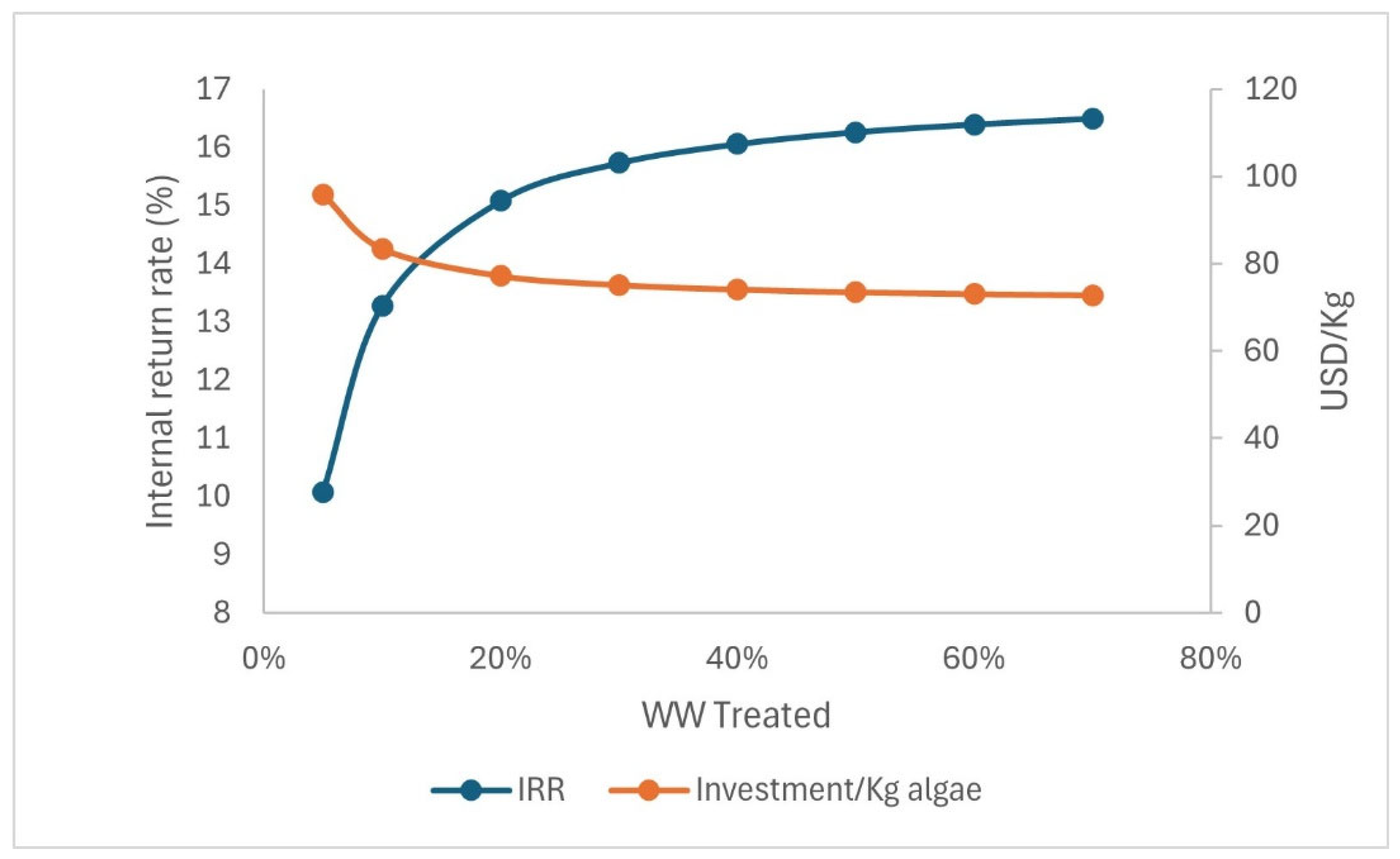

3.2. Sensibility Analysis for Optimal Operational Conditions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Obaideen, K.; Shehata, N.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Olabi, A.G. The role of wastewater treatment in achieving sustainable development goals (SDGs) and sustainability guideline. Energy Nexus 2022, 7, 100112. [Google Scholar] [CrossRef]

- Eurostat. Environmental Protection Expenditure Accounts-Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Environmental_protection_expenditure_accounts (accessed on 15 February 2025).

- Franceschini, G.; Slompo, N.D.M.; Rodrigues, S.A.; Sarnighausen, V.C.R.; Junior, J.L. The efficiency of the economic septic tank in the treatment of domestic wastewater and black water in rural areas. Res. Soc. Dev. 2021, 10, e22910817232. [Google Scholar] [CrossRef]

- Mesa, A.P.; Molina, J.C.S.; Ríos, L.A.; Echeverri, E.O.; Echeverri, D.O. Diagnosis of Nutrient Discharges and Management Alternatives in Developing Countries and the Use of Microalgae as a Potential Solution: A Case Study from Different Provinces in Antioquia, Colombia. Water 2024, 16, 2215. [Google Scholar] [CrossRef]

- United Nations. Indicator 6.3.1 ‘Proportion of Domestic and Industrial Wastewater Flow Safely Treated’. Available online: https://www.unwater.org/our-work/sdg-6-integrated-monitoring-initiative/indicator-631-proportion-domestic-and-industrial (accessed on 23 September 2025).

- Mazo, C.G.; Mejía, K.A.; Naranjo-Fernández, D.; Vargas, T.B.; Valencia, J.O.; Cardona, P.A.V. Alternativas de Tratamiento Terciario de Aguas Residuales Domésticas para Viviendas Dispersas Rurales en Zonas de Interés Hidrogeológico. Rev. EIA 2025, 22, 4428. [Google Scholar] [CrossRef]

- Miranda, A.M.; Hernandez-Tenorio, F.; Ocampo, D.; Vargas, G.J.; Sáez, A.A. Trends on CO2 Capture with Microalgae: A Bibliometric Analysis. Molecules 2022, 27, 4669. [Google Scholar] [CrossRef] [PubMed]

- Schmid, B.; Navalho, S.; Schulze, P.S.C.; Van De Walle, S.; Van Royen, G.; Schüler, L.M.; Maia, I.B.; Bastos, C.R.V.; Baune, M.-C.; Januschewski, E.; et al. Drying Microalgae Using an Industrial Solar Dryer: A Biomass Quality Assessment. Foods 2022, 11, 1873. [Google Scholar] [CrossRef]

- Benemann, J. Microalgae for Biofuels and Animal Feeds. Energies 2013, 6, 5869–5886. [Google Scholar] [CrossRef]

- Fallahi, A.; Rezvani, F.; Asgharnejad, H.; Khorshidi, E.; Hajinajaf, N.; Higgins, B. Interactions of microalgae-bacteria consortia for nutrient removal from wastewater: A review. Chemosphere 2021, 272, 129878. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.K.; Sharma, S.; Dixit, G.; Shah, E.; Patel, A. Techno-economic analysis of microalgae production with simultaneous dairy effluent treatment using a pilot-scale High Volume V-shape pond system. Renew. Energy 2020, 145, 1620–1632. [Google Scholar] [CrossRef]

- Nagarajan, D.; Varjani, S.; Lee, D.J.; Chang, J.S. Sustainable aquaculture and animal feed from microalgae–Nutritive value and techno-functional components. Renew. Sustain. Energy Rev. 2021, 150, 111549. [Google Scholar] [CrossRef]

- Satiro, J.; Neto, A.G.d.S.; Marinho, T.; Sales, M.; Marinho, I.; Kato, M.T.; Simões, R.; Albuquerque, A.; Florencio, L. The Role of the Microalgae–Bacteria Consortium in Biomass Formation and Its Application in Wastewater Treatment Systems: A Comprehensive Review. Appl. Sci. 2024, 14, 6083. [Google Scholar] [CrossRef]

- Faruque, M.O.; Uddin, S.; Hossain, M.M.; Hossain, S.M.Z.; Shafiquzzaman, M.; Razzak, S.A. A comprehensive review on microalgae-driven heavy metals removal from industrial wastewater using living and nonliving microalgae. J. Hazard. Mater. Adv. 2024, 16, 100492. [Google Scholar] [CrossRef]

- Mesa, A.P.; Grattz, P.A.C.; Vargas, J.J.V.; Ríos, L.A.; Echeverri, D.O.; Parra, A.M.M. Feasibility of nitrogen and phosphorus removal from treated wastewater using microalgae and potential microalgae use as biofertilizer. J. Water Process Eng. 2025, 70, 107023. [Google Scholar] [CrossRef]

- Hossain, S.M.Z.; Alnoaimi, A.; Razzak, S.A.; Ezuber, H.; Al-Bastaki, N.; Safdar, M.; Alkaabi, S.; Hossain, M.M. Multiobjective optimization of microalgae (Chlorella sp.) growth in a photobioreactor using Box-Behnken design approach. Can. J. Chem. Eng. 2018, 96, 1903–1910. [Google Scholar] [CrossRef]

- IDEAM. Atlas de Radiación Solar, Ultravioleta y Ozono de Colombia. 2017. Available online: https://www.andi.com.co/uploads/radiacion.compressed.pdf (accessed on 24 March 2025).

- Stein, J.R. Handbook of Phycological methods. In Culture Methods and Growth Measurements, 1st ed.; Cambridge University Press: Cambridge, UK, 1973. [Google Scholar]

- Amorim, M.L.; Soares, J.; Vieira, B.B.; Batista-Silva, W.; Martins, M.A. Extraction of proteins from the microalga Scenedesmus obliquus BR003 followed by lipid extraction of the wet deproteinized biomass using hexane and ethyl acetate. Bioresour. Technol. 2020, 307, 123190. [Google Scholar] [CrossRef]

- Wilkinsonpc. Commodities-Materias Primas. Available online: https://commodities.wilkinsonpc.com.co/?petroleo-brent.html (accessed on 15 February 2025).

- IndexMundi. Urea-Monthly Price-Commodity Prices-Price Charts, Data, and News. Available online: https://www.indexmundi.com/commodities/?commodity=urea (accessed on 15 February 2025).

- BIS Research-Market Intelligence on Emerging Technologies. BIS Research is Your Go-To Place for Market Intelligence on Deep Tech. Available online: https://bisresearch.com/ (accessed on 18 February 2025).

- Vijayavenkataraman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Columbia, B.; Alabi, A.O.; Tampier, M. Microalgae Technologies & Processes for Biofuels-Bioenergy Production in British Columbia: Microalgae Technologies and Processes for Biofuels-Bioenergy Production in British Columbia: Current Technology, Suitability and Barriers to Implementation: Final Report; Canadian Electronic Library: Ottawa, ON, Canada, 2009; Available online: https://books.google.com.co/books?id=0zDczwEACAAJ (accessed on 6 November 2024).

- Wang, H.; Garcia, P.V.; Ahmed, S.; Heggerud, C.M. Mathematical comparison and empirical review of the Monod and Droop forms for resource-based population dynamics. Ecol. Modell. 2022, 466, 109887. [Google Scholar] [CrossRef]

- Aguilar-Savén, R.S. Business process modelling: Review and framework. Int. J. Prod. Econ. 2004, 90, 129–149. [Google Scholar] [CrossRef]

- Chemical Engineering. The Chemical Engineering Plant Cost Index. Available online: https://www.chemengonline.com/pci-home (accessed on 14 February 2025).

- Peters, M.S.; Timmerhaus, K.D. Diseño de Plantas y Su Evaluación Económica Para Ingenieros Químicos, 2nd ed.; McGraw & Hill: Columbus, OH, USA, 1991. [Google Scholar]

- DANE. Comunicado de Prensa; DANE: Bogotá, Colombia, 2024. Available online: https://incp.org.co/wp-content/uploads/2024/10/Comunicado-de-prensa-IPC-septiembre-2024-%E2%80%93-DANE.pdf (accessed on 23 March 2025).

- Satiro, J.; Gomes, A.; Florencio, L.; Simões, R.; Albuquerque, A. Effect of microalgae and bacteria inoculation on the startup of bioreactors for paper pulp wastewater and biofuel production. J. Environ. Manag. 2024, 362, 121305. [Google Scholar] [CrossRef]

- Yirgu, Z.; Leta, S.; Hussen, A.; Khan, M.M. Nutrient removal and carbohydrate production potential of indigenous Scenedesmus sp. grown in anaerobically digested brewery wastewater. Environ. Syst. Res. 2020, 9, 40. [Google Scholar] [CrossRef]

- Nordio, R.; Viviano, E.; Sánchez-Zurano, A.; Hernández, J.G.; Rodríguez-Miranda, E.; Guzmán, J.L.; Acién, G. Influence of pH and dissolved oxygen control strategies on the performance of pilot-scale microalgae raceways using fertilizer or wastewater as the nutrient source. J. Environ. Manag. 2023, 345, 118899. [Google Scholar] [CrossRef]

- Blanes, M.V.; Pérez-Hermosillo, I.J.; Rueda, A.R.; Sánchez, A.G. Biogas Purification through the use of a Microalgae-Bacterial System in Semi-Industrial High Rate Algal Ponds. J. Vis. Exp. 2024, 205, e65968. [Google Scholar] [CrossRef]

- Wu, R.S.S. Eutrophication, Water Borne Pathogens and Xenobiotic Compounds: Environmental Risks and Challenges. Mar. Pollut. Bull. 1999, 39, 11–22. [Google Scholar] [CrossRef]

- Departamento Administrativo de la Función Pública. Decreto 2667 de 2012; Departamento Administrativo de la Función Pública: Bogotá, Colombia, 2012.

- Álvarez-González, A.; Castro, I.M.; Ortiz, A.; Díez-Montero, R.; Passos, F.; Garfí, M.; Uggetti, E. Environmental and economic benefits of using microalgae grown in wastewater as biofertilizer for lettuce cultivation. Bioresour. Technol. 2025, 424, 132230. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Bera, S. Revisiting nitrogen utilization in algae: A review on the process of regulation and assimilation. Bioresour. Technol. Rep. 2020, 12, 100584. [Google Scholar] [CrossRef]

- Priyadharsini, P.; Nirmala, N.; Dawn, S.; Baskaran, A.; SundarRajan, P.; Gopinath, K.; Arun, J. Genetic improvement of microalgae for enhanced carbon dioxide sequestration and enriched biomass productivity: Review on CO2 bio-fixation pathways modifications. Algal Res. 2022, 66, 102810. [Google Scholar] [CrossRef]

- Parra, Z.R.; Apaza, M.G.; Agramont, A.A. Estimacion de factores de emision de gases de efecto invernadero en una planta de tratamiento de aguas residuales. Rev. Boliv. Quím. 2010, 27, 81–87. Available online: http://www.scielo.org.bo/scielo.php?script=sci_arttext&pid=S0250-54602010000200002&lng=es&nrm=iso&tlng=es (accessed on 6 November 2024).

- Meier, L.; Stará, D.; Bartacek, J.; Jeison, D. Removal of H2S by a continuous microalgae-based photosynthetic biogas upgrading process. Process. Saf. Environ. Prot. 2018, 119, 65–68. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, X.-D.; Miao, M.-S.; Chen, Q.-F.; Kong, Q.; Shang, D.-W.; Yu, J.-N.; Fu, X.-M. Effects of urban wastewater dilution on growth and biochemical properties of Scenedesmus sp. Desalin. Water Treat. 2016, 57, 29363–29370. [Google Scholar] [CrossRef]

- Ammar, E.E.; Aioub, A.A.; Elesawy, A.E.; Karkour, A.M.; Mouhamed, M.S.; Amer, A.A.; El-Shershaby, N.A. Algae as Bio-fertilizers: Between current situation and future prospective. Saudi J. Biol. Sci. 2022, 29, 3083–3096. [Google Scholar] [CrossRef]

- Díaz, L.E.; Gonzalez, J.D.; Morales-Gonzalez, M.P.; Garzón-Castro, C.L. Harnessing the power of microalgae consortia for sustainable crop production: Case study on lettuce (Lactuca sativa L.). J. Appl. Phycol. 2024, 36, 3273–3286. [Google Scholar] [CrossRef]

- Machado, A.A.; Valiaparampil, J.G.; Lavanya, M. Unlocking the Potential of Algae for Heavy Metal Remediation. Water Air Soil Pollut. 2024, 235, 629. [Google Scholar] [CrossRef]

- Tchounwou, P.B.; Yedjou, C.G.; Patlolla, A.K.; Sutton, D.J. Heavy Metal Toxicity and the Environment. Mol. Clin. Environ. Toxicol. 2012, 101, 133–164. [Google Scholar] [CrossRef]

- Instituto Colombiano Agropecuario (ICA). Resolución 00150 de 2003. Por la Cual se Adopta el Reglamento Técnico de Fertilizantes y Acondicionadores de Suelos para Colombia; Instituto Colombiano Agropecuario (ICA): Bogotá, Colombia, 2003. [Google Scholar]

- Rather, S.U.; Davoodbasha, M.; Bamufleh, H.S.; Alhumade, H.; Saeed, U.; Taimoor, A.A.; Sulaimon, A.A.; Al-Alaya, W.; Shariff, A.M. Utilization of Wastewater as a Nutritional Source for the Production of Algal Biomass. Int. J. Energy Res. 2023, 2023, 9939252. [Google Scholar] [CrossRef]

| Element | Assumptions |

|---|---|

| Plant lifetime (years) | 20 |

| Flow (L/s) | 10 |

| Operating days per year | 333 |

| Inflation | 5.81% |

| Discount rate (TES) | 11.62% |

| Depreciation period (years) | |

| Pumps and PBR | 5 |

| Storage tanks | 15 |

| Construction period (years) | 1 |

| Fraction of investment in year 1 | 100% |

| Start-up time (years) | 1 |

| Code | Function | Type | Material | Related Stream | Lifetime |

|---|---|---|---|---|---|

| B-1 | KOH Solution | Centrifugal pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS304 | In: KOH Out: S19 | 5 |

| B-2 | Nutritive Solution | Centrifugal pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS | In: NUT Out: C4 | 5 |

| B-3 | H2SO4 Solution pump | ANSI Plastic pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | ANSI PLASTIC | In: H2SO4 Out: C11 | 5 |

| B-4 | Raw Wastewater pump | Sanitary pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS316 | In: WW Out: C1 | 5 |

| B-5 | Reactor filling | Sanitary pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS316 | In: S1 Out: IN | 5 |

| B-6 | Reactor emptying | Sanitary pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS316 | In: OUT, Out: S4 | 5 |

| B-7 | Biomass transport | Rotatory lobe pump (Ningbo Bonve Pumps Co., Ltd., Ningbo, China) | SS | In: S3, Out: S5 | 5 |

| C-1 | Air | Vaneaxialfan (Blauberg Motoren, JiangSu, China) | CS | In: AIR Out: C16 | 15 |

| T-1 | KOH Solution | Storage tank ( Zhangjiagang King Machine Tech Co., Ltd., Jiangsu, China) | SS | Out: KOH | 15 |

| T-2 | Nutritive Solution | Storage tank ( Zhangjiagang King Machine Tech Co., Ltd., Jiangsu, China) | CS | Out: NUT | 15 |

| T-3 | H2SO4 Solution | Storage tank ( Zhangjiagang King Machine Tech Co., Ltd., Jiangsu, China) | SS | Out: H2SO4 | 15 |

| D-1 | Inoculum divider | Split Flow 1 | CS | In: S4, Out: S12, INOCULUM | 15 |

| D-2 | KOH Solution divider | Split Flow 2 | CS | In: S19 Out: S2, S8 | 15 |

| CE-1 | Biomass concentration | Atmospheric basket centrifuge (Dolphin centrifuge, Warren, Michigan) | CS | In: S12 Out: S7, EFFLUENT | 15 |

| M-1 | Precondition mixer | Mixer 1 (Wenzhou Leno Machinery Co., Ltd., Zhejiang, China) | SS | In: S2, C1, C4 Out: S1 | 15 |

| M-2 | Biomass processing | Reversing anchor agitator (Ruian Xuanli Machinery Co., Ltd., Zhejiang, China) | SS | In: S7, C11, S8 Out: S3 | 15 |

| PBR | Reactor | 40L Vertical PBR (EIA Equipos Ingenieria Y Analisis S.A.S, Medellín, Colombia). | Acrylic | In: IN, INOCULUM C16 Out: AIR + W, OUT | 5 |

| Experiment | NUT A (%Vol/Vol.) | WW B (%Vol/Vol.) | Ht C (Days) | Desired Response (USD) |

|---|---|---|---|---|

| 1 | 2 | 70 | 4.5 | NPV |

| 2 | 7 | 50 | 6 | |

| 3 | 7 | 30 | 4.5 | |

| 4 | 2 | 30 | 4.5 | |

| 5 | 4.5 | 30 | 3 | |

| 6 | 4.5 | 50 | 4.5 | |

| 7 | 7 | 70 | 4.5 | |

| 8 | 2 | 50 | 3 | |

| 9 | 4.5 | 70 | 3 | |

| 10 | 2 | 50 | 6 | |

| 11 | 4.5 | 50 | 4.5 | |

| 12 | 4.5 | 70 | 6 | |

| 13 | 7 | 50 | 3 | |

| 14 | 4.5 | 50 | 4.5 | |

| 15 | 4.5 | 30 | 6 |

| Molecular Formula | Reactive | Concentration |

|---|---|---|

| Phosphorus stock solution (PSS): Transfer 100 mL to 1 L of medium | mg/L | |

| KH2PO4 | Monopotassium phosphate (Vizda industrial Co., limited, Shanxi, China) | 308 |

| K2HPO4 | Dipotassium phosphate (Jiangsu Kolod Food Ingredients Co., Ltd., Jiangsu, China) | 165 |

| Total phosphorus (mg P/L) | 100 | |

| Nitrogen stock solution (NSS): Transfer 200 mL to 1 L of medium | mg/L | |

| KNO3 | Potassium nitrate (Huaqiang Chemical Group Stock Co., Ltd., Hubei, China) | 1443.64 |

| SO4(NH4)2 | Ammonium sulphate (Aegle green fertilizer Co., Ltd., Shandong Province, China) | 943.405 |

| Total nitrogen (mg N/L) | 500 | |

| Micronutrients stock solution 1 (MSS1): Transfer 1 mL to 1 L of medium | g/L | |

| H3BO3 | Boric acid (Zhengzhou Langkou Chemical Products Co., Ltd., Henan, China) | 2.86 |

| MnCl2.4H2O | Chloride manganese (Shandong WorldSun Biological Technology Co., Ltd., Shandong, China) | 1.81 |

| ZnSO4.7H2O | Zinc sulfate heptahydrate (Jiangsu Kolod Food Ingredients Co., Ltd., Jiangsu, China) | 0.222 |

| (NH4)6Mo7O24.4H2O | Ammonium molybdate (Anhui Sincerely Titanium Industry Co., Ltd., Anhui, China) | 0.285 |

| CuSO4.5H2O | Copper sulfate (Jiangsu Kolod Food Ingredients Co., Ltd., Jiangsu, China) | 0.079 |

| CoCl2.6H2O | Cobalt chloride (Powder Pack Chem, Maharashtra, India) | 0.0404 |

| Micronutrients stock solution 2 (MSS2): Transfer 1 mL to 1 L of medium | g/L | |

| 2H2O.EDTA. Na2 | EDTA Disodium (Mingray Technology Group Co., Ltd., Hunan, China) | 10 |

| KOH | Potassium hydroxide (Guangxi Kunya Biological Technology Co., Ltd., Guangxi, China) | 6.2 |

| Micronutrients stock solution 3 (MSS3): Transfer 1 mL to 1 L of medium | g/L | |

| FeSO4.7H2O | Iron sulphate (Hebei Jinchangsheng Chemical Technology Co., Ltd., Hebei, China) | 4.98 |

| H2SO4 | Sulfuric acid (98%) (Shijiazhuang Xinlongwei Chemical Co., Ltd., Hebei, China) | 0.1 mL/L |

| Parameter | Method | Municipal |

|---|---|---|

| Tracked parameters * | ||

| Total Kjeldahl Nitrogen (mg/L) | SM 4500 Norg B, SM 4500 NH3 B, C | 59.2 |

| Nitrite (mgN-NO2−/L) | SM. (4500 B) | <0.005 |

| Nitrate (mg N-NO3−/L) | Test 1–65 NANOCOLOR 918-65, MACHEREY NAGEL | <1 |

| Ammoniacal Nitrogen (mg/L) | S.M. (4500 NH3 B, C) | 50.3 |

| Phosphates (mg P-PO4/L) | S.M. (4500 P E) | 5.6 |

| Phosphorus (mg P/L) | S.M. (4500 P B, E) | 7.6 |

| COD (mg O2/L) | S.M. (5220 D) | 172 |

| pH (U pH) | S.M. (4500-H+ B) | 7.4 |

| Suspended solids (mg SST/L) | S.M. (2540 D) | 74.3 |

| Other chemical parameters | ||

| BOD5 (mg O2/L) | S.M. (5210 B) ASTM D888-18 | 39.7 |

| Total Hardness (mg CaCO3/L) | S.M. (2340 C) | 48.4 |

| Calcium Hardness (mg CaCO3/L) | S.M. (3500 Ca B) | 40.6 |

| Conductivity (µS/cm) | S.M. (2510 B) | 410 |

| Total Acidity (mg CaCO3/L) | S.M. (2310 B) | 21.6 |

| Total Alkalinity (mg CaCO3/L) | S.M. (2320 B) | 136.3 |

| Phenols (mg/L) | S.M. (5530 B, D) | <0.05 |

| Detergents (mg SAAM/L) | S.M. (5540 C) | 0.5 |

| Fluorides (mg F-/L) | Test 1–42 NANOCOLOR 918142, MACHEREY NAGEL | 1.1 |

| Total Solids (mg TS/L) | S.M. (2540 B) | 233 |

| Metals | ||

| Total Beryllium (mg Be/L) | EPA 200.7 | <0.010 |

| Boron (mg B/L) | <0.100 | |

| Cadmium (mg Cd/L) | <0.003 | |

| Total Calcium (mg Ca/L) | 16.3 | |

| Total Cobalt (mg Co/L) | <0.05 | |

| Copper (mg Cu/L) | <0.05 | |

| Tin (mg Sn/L) | <0.050 | |

| Strontium (mg Sr/L) | <0.050 | |

| Lithium (mg Li/L) | <0.01 | |

| Magnesium (mg Mg/L) | 2.1 | |

| Manganese (mg/L) | 0.1 | |

| Molybdenum (mg/L) | <0.05 | |

| Nickel (mg/L) | <0.02 | |

| Silver (mg Ag/L) | <0.05 | |

| Lead (mg Pb/L) | <0.01 | |

| Potassium (mg K/L) | 9.5 | |

| Selenium (mg Se/L) | <0.01 | |

| Total Silicon (mg Si/L) | 7.6 | |

| Sodium (mg Na/L) | 16.4 | |

| Total Titanium (mg Ti/L) | <0.05 | |

| Vanadium (mg V/L) | <0.01 | |

| Zinc (mg Zn/L) | 0.08 | |

| Chromium (mg Cr/L) | EPA 3015A | <0.05 |

| Antimony (mg Sb/L) | EPA 3015A-SM 3120B | <0.010 |

| Barium (mg Ba/L) | EPA 3015A-SM 3120B | 0.058 |

| Total Mercury (mg/L) | SM 3112 B | <0.001 |

| Arsenic (mg As/L) | SM 3030 K | <0.010 |

| Aluminum (mg Al/L) | SM 3030 B, SM. 3500 Al B | 4.7 |

| Total Iron (mg Fe/L) | SM 3030 G, SM 3500 Fe B | 1.9 |

| Commercial Fertilizer | N (CN) (%wt./wt.) | P (CP) (%wt./wt.) | Market Price (MP) (USD/Kg) | Nutrient Price (PN+P) (USD/Kg) |

|---|---|---|---|---|

| Biofertilizer A | 3.2% | 0.0% | 7.65 | 239.08 |

| Biofertilizer B | 2.0% | 1.1% | 9.26 | 299.65 |

| Biofertilizer C | 0.8% | 0.8% | 3.64 | 233.62 |

| Biofertilizer D | 6.0% | 1.4% | 17.14 | 232.42 |

| Average | 3% | 1% | 9.42 | 251.19 |

| Service Facilities | Typical CAPEX Value% |

|---|---|

| Electric distribution | 0.1 |

| Communications | 0.2 |

| Raw material storage | 0.5 |

| Finished-product storage | 1.5 |

| Fire protection system | 0.5 |

| Safety installations | 0.4 |

| AIU * | 25% |

| Experiment | Ht | N-NO3− | N-NO2− | N-NH3+ | NOrg | N | P-PO43− | COD | pH |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 4.5 | 0.0 | 6 × 10−3 | 1.2 | 6.1 | 7.3 | 7 × 10−3 | 79 | 8.0 |

| 2 | 6 | 0.1 | 9 × 10−3 | 4.5 | 5.2 | 9.8 | 3.0 × 10−3 | 168 | 9.7 |

| 3 | 4.5 | 0.0 | 8 × 10−3 | 1.0 | 3.1 | 4.1 | 1.5 × 10−2 | 89 | 8.7 |

| 4 | 4.5 | 0.0 | 4 × 10−3 | 0.4 | 3.6 | 4.1 | 1.9 × 10−2 | 196 | 8.8 |

| 5 | 3 | 0.2 | 3 × 10−4 | 0.0 | 3.9 | 4.2 | 0 | 79 | 8.4 |

| 6 | 4.5 | 0.0 | 4 × 10−3 | 0.3 | 3.8 | 4.1 | 0 | 61 | 8.8 |

| 7 | 4.5 | 0.0 | 9 × 10−3 | 0.6 | 2.8 | 3.4 | 1.5 × 10−2 | 92 | 8.7 |

| 8 | 3 | 0.1 | 4 × 10−3 | 0.0 | 1.5 | 1.5 | 1.6 × 10−2 | 104 | 8.5 |

| 9 | 3 | 0.5 | 6 × 10−4 | 0.0 | 2.2 | 2.7 | 0 | 147 | 8.1 |

| 10 | 6 | 0.2 | 5 × 10−3 | 0.0 | 3.8 | 4.0 | 1.0x−2 | 95 | 9.6 |

| 11 | 4.5 | 0.3 | 4 × 10−3 | 0.3 | 3.7 | 4.3 | 0 | 60 | 8.8 |

| 12 | 6 | 0.1 | 8 × 10−3 | 3.3 | 3.3 | 6.8 | 1.8x−2 | 171 | 9.7 |

| 13 | 3 | 0.0 | 4 × 10−3 | 0.2 | 3.3 | 3.5 | 0 | 153 | 8.3 |

| 14 | 4.5 | 0.3 | 4 × 10−3 | 0.3 | 3.7 | 4.3 | 0 | 64 | 8.8 |

| 15 | 6 | 0.1 | 9 × 10−3 | 4.2 | 4.9 | 9.3 | 1.3x−2 | 150 | 9.6 |

| Experiment | NUT (%Vol/Vol.) | WW (%Vol/Vol.) | Ht (Days) | Initial SST | Final SST | Biomass (Ton/Year) | N (%wt./wt.) | P (%wt./wt.) | Selling Price (Bp) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 70 | 4.5 | 405 | 746 | 239 | 7.2 | 0.5 | 19.19 |

| 2 | 7 | 50 | 6 | 567 | 1066 | 378 | 5.2 | 0.6 | 14.56 |

| 3 | 7 | 30 | 4.5 | 738 | 1058 | 406 | 5.1 | 0.5 | 14.00 |

| 4 | 2 | 30 | 4.5 | 744 | 1089 | 361 | 4.4 | 0.2 | 11.69 |

| 5 | 4.5 | 30 | 3 | 790 | 881 | 315 | 5.6 | 0.6 | 15.53 |

| 6 | 4.5 | 50 | 4.5 | 595 | 990 | 336 | 5.2 | 0.5 | 14.07 |

| 7 | 7 | 70 | 4.5 | 366 | 736 | 252 | 7.1 | 0.6 | 19.37 |

| 8 | 2 | 50 | 3 | 635 | 746 | 241 | 5.0 | 0.7 | 14.25 |

| 9 | 4.5 | 70 | 3 | 374 | 533 | 176 | 6.8 | 1.1 | 19.92 |

| 10 | 2 | 50 | 6 | 635 | 1003 | 324 | 5.0 | 0.5 | 13.79 |

| 11 | 4.5 | 50 | 4.5 | 595 | 990 | 336 | 5.1 | 0.5 | 13.95 |

| 12 | 4.5 | 70 | 6 | 374 | 942 | 312 | 5.5 | 0.5 | 15.00 |

| 13 | 7 | 50 | 3 | 577 | 627 | 222 | 4.1 | 0.6 | 11.86 |

| 14 | 4.5 | 50 | 4.5 | 595 | 990 | 336 | 5.3 | 0.5 | 14.33 |

| 15 | 4.5 | 30 | 6 | 781 | 1132 | 405 | 3.9 | 0.5 | 10.84 |

| Experiment | OPEX (Million USD/Year) | OPEX (USD/Kg) | Nutritive Solution (m3/Year) | KOH Solution (m3/Year) | H2SO4 (m3/Year) |

|---|---|---|---|---|---|

| 1 | 0.25 | 1.05 | 8220 | 1.4 | 107 |

| 2 | 0.46 | 1.21 | 40,280 | 2.2 | 169 |

| 3 | 0.56 | 1.38 | 67,133 | 2.4 | 182 |

| 4 | 0.45 | 1.25 | 19,181 | 2.1 | 162 |

| 5 | 0.40 | 1.26 | 43,157 | 1.9 | 141 |

| 6 | 0.37 | 1.10 | 25,894 | 2.0 | 150 |

| 7 | 0.29 | 1.15 | 28,771 | 1.5 | 113 |

| 8 | 0.25 | 1.04 | 11,508 | 1.4 | 108 |

| 9 | 0.20 | 1.14 | 18,496 | 1.1 | 79 |

| 10 | 0.38 | 1.17 | 11,508 | 1.9 | 145 |

| 11 | 0.37 | 1.10 | 25,894 | 2.0 | 150 |

| 12 | 0.34 | 1.08 | 18,496 | 1.8 | 140 |

| 13 | 0.29 | 1.29 | 40,280 | 1.3 | 100 |

| 14 | 0.37 | 1.10 | 25,894 | 2.0 | 150 |

| 15 | 0.58 | 1.44 | 43,157 | 2.4 | 181 |

| Equipment | Acquisition (Million USD) | Installation (Million USD) | Total (Million USD) |

|---|---|---|---|

| Pumps | 0.09 | 0.35 | 0.45 |

| Storage tanks | 0.10 | 0.63 | 0.73 |

| Centrifuge | 0.11 | 0.13 | 0.24 |

| Mixers | 0.09 | 0.20 | 0.28 |

| PBR | 3.63 | 3.63 | 7.27 |

| Total equipment cost | 8.97 |

| Experiment | Reactor Volume (m3) | Sales (Million USD) | Land Requirement (Ha) | CAPEX (Million USD) | Raw Utilities (MUSD) | VNA (Million USD) | IRR (%) | Plant Cost (Million USD) |

|---|---|---|---|---|---|---|---|---|

| 1 | 6171 | 4.6 | 10.2 | 16.2 | 1.4 | −0.8 | 11 | 20.97 |

| 2 | 11,520 | 5.5 | 19.0 | 28.8 | 0.6 | −20.5 | 0 | 37.24 |

| 3 | 14,400 | 5.7 | 23.8 | 35.6 | −0.1 | −33.3 | −5 | 46.00 |

| 4 | 14,400 | 4.2 | 23.8 | 35.6 | −1.4 | −44.2 | - | 46.00 |

| 5 | 9600 | 4.9 | 15.9 | 24.3 | 0.7 | −15.5 | 2 | 31.40 |

| 6 | 8640 | 4.7 | 14.3 | 22.1 | 0.8 | −12.1 | 4 | 28.48 |

| 7 | 6171 | 4.9 | 10.2 | 16.2 | 1.6 | 1.0 | 12 | 20.97 |

| 8 | 5760 | 3.4 | 9.5 | 15.3 | 0.7 | −7.0 | 5 | 19.72 |

| 9 | 4114 | 3.5 | 6.8 | 11.4 | 1.2 | 1.5 | 13 | 14.71 |

| 10 | 11,520 | 4.5 | 19.0 | 28.8 | −0.1 | −27.3 | −6 | 37.24 |

| 11 | 8640 | 4.7 | 14.3 | 22.1 | 0.8 | −12.4 | 3 | 28.48 |

| 12 | 8229 | 4.7 | 13.6 | 21.1 | 0.9 | −10.3 | 5 | 27.23 |

| 13 | 5760 | 2.6 | 9.5 | 15.3 | 0.1 | −12.9 | −3 | 19.72 |

| 14 | 8640 | 4.8 | 14.3 | 22.1 | 0.9 | −11.5 | 4 | 28.48 |

| 15 | 19,200 | 4.4 | 31.7 | 46.9 | −3.1 | −69.4 | - | 60.61 |

| Coefficients: | Estimate | Std. Error | t Value | Pr(>|t|) |

|---|---|---|---|---|

| (Intercept) | −29.358 | 34.688 | −0.846 | 0.419 |

| WW | 1.104 | 0.772 | 1.431 | 0.186 |

| Ht | −7.649 | 11.503 | −0.665 | 0.523 |

| WWx Ht | 0.331 | 0.0852 | 3.879 | 3.74 × 10−3 ** |

| WW2 | −0.017 | 0.007 | −2.516 | 0.033 * |

| Ht2 | −1.831 | 1.180 | −1.552 | 0.155 |

| Statistical Test | Result |

|---|---|

| Residual standard error: | 5.115 on 9 degrees of freedom |

| Model fitness: | Multiple R-squared: 0.9489, Adjusted R-squared: 0.9205 |

| F-statistic: | 33.43 on 5 and 9 degrees of freedom, p-value: 1.496 × 10−5 |

| Shapiro–Wilk normality test: | W = 0.96921, p-value = 0.8462 |

| Studentized Breusch–Pagan Test: | BP (Test Statistic) = 4.2727, p-value = 0.5109 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez Mesa, A.; Céspedes Grattz, P.A.; Vidal Vargas, J.J.; Ríos, L.A.; Ocampo Echeverri, D. Techno-Economic Assessment of Microalgae-Based Biofertilizer Production from Municipal Wastewater Using Scenedesmus sp. Water 2025, 17, 2941. https://doi.org/10.3390/w17202941

Pérez Mesa A, Céspedes Grattz PA, Vidal Vargas JJ, Ríos LA, Ocampo Echeverri D. Techno-Economic Assessment of Microalgae-Based Biofertilizer Production from Municipal Wastewater Using Scenedesmus sp. Water. 2025; 17(20):2941. https://doi.org/10.3390/w17202941

Chicago/Turabian StylePérez Mesa, Alejandro, Paula Andrea Céspedes Grattz, Juan José Vidal Vargas, Luis Alberto Ríos, and David Ocampo Echeverri. 2025. "Techno-Economic Assessment of Microalgae-Based Biofertilizer Production from Municipal Wastewater Using Scenedesmus sp." Water 17, no. 20: 2941. https://doi.org/10.3390/w17202941

APA StylePérez Mesa, A., Céspedes Grattz, P. A., Vidal Vargas, J. J., Ríos, L. A., & Ocampo Echeverri, D. (2025). Techno-Economic Assessment of Microalgae-Based Biofertilizer Production from Municipal Wastewater Using Scenedesmus sp. Water, 17(20), 2941. https://doi.org/10.3390/w17202941