Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects

Abstract

1. Introduction

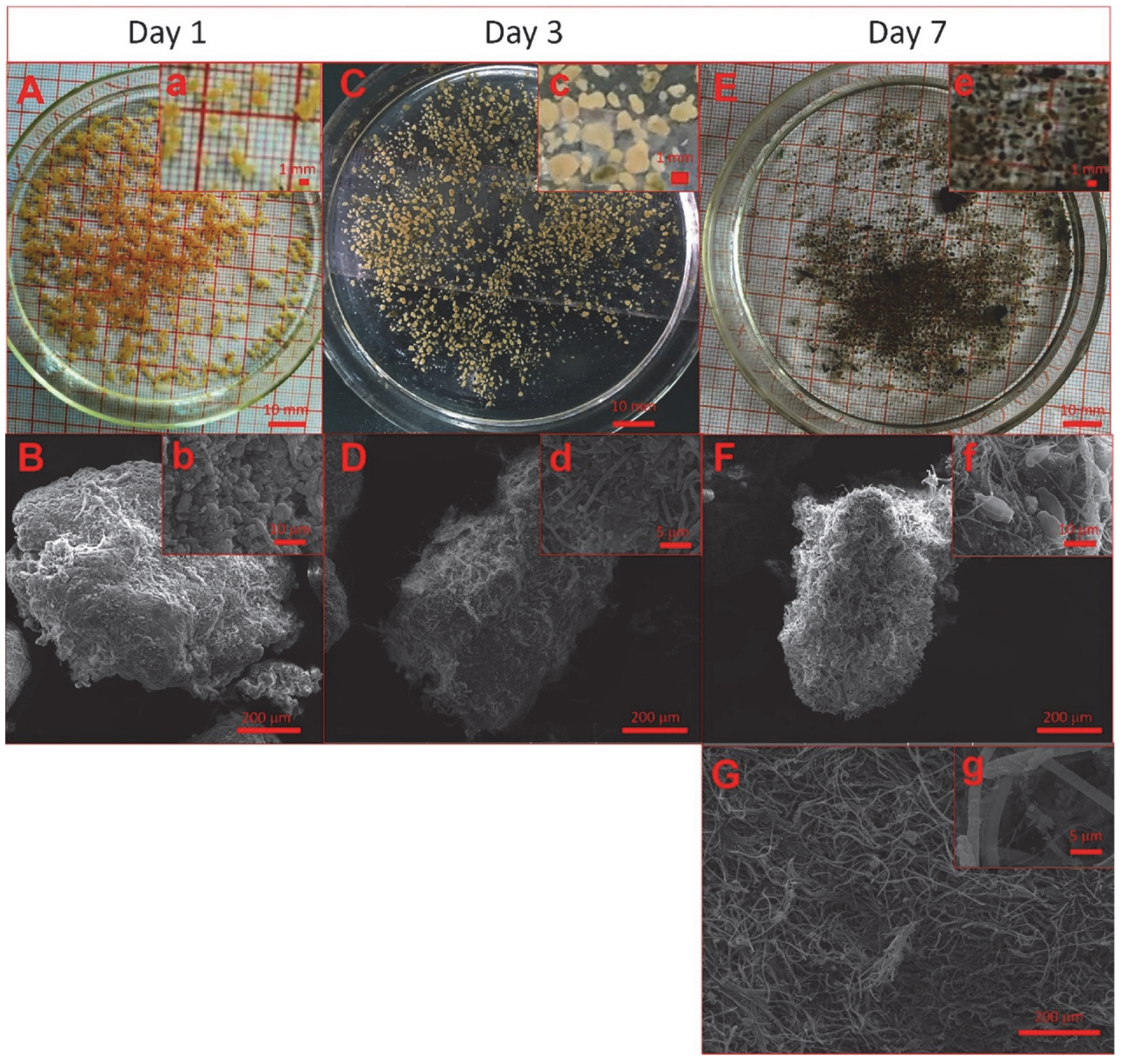

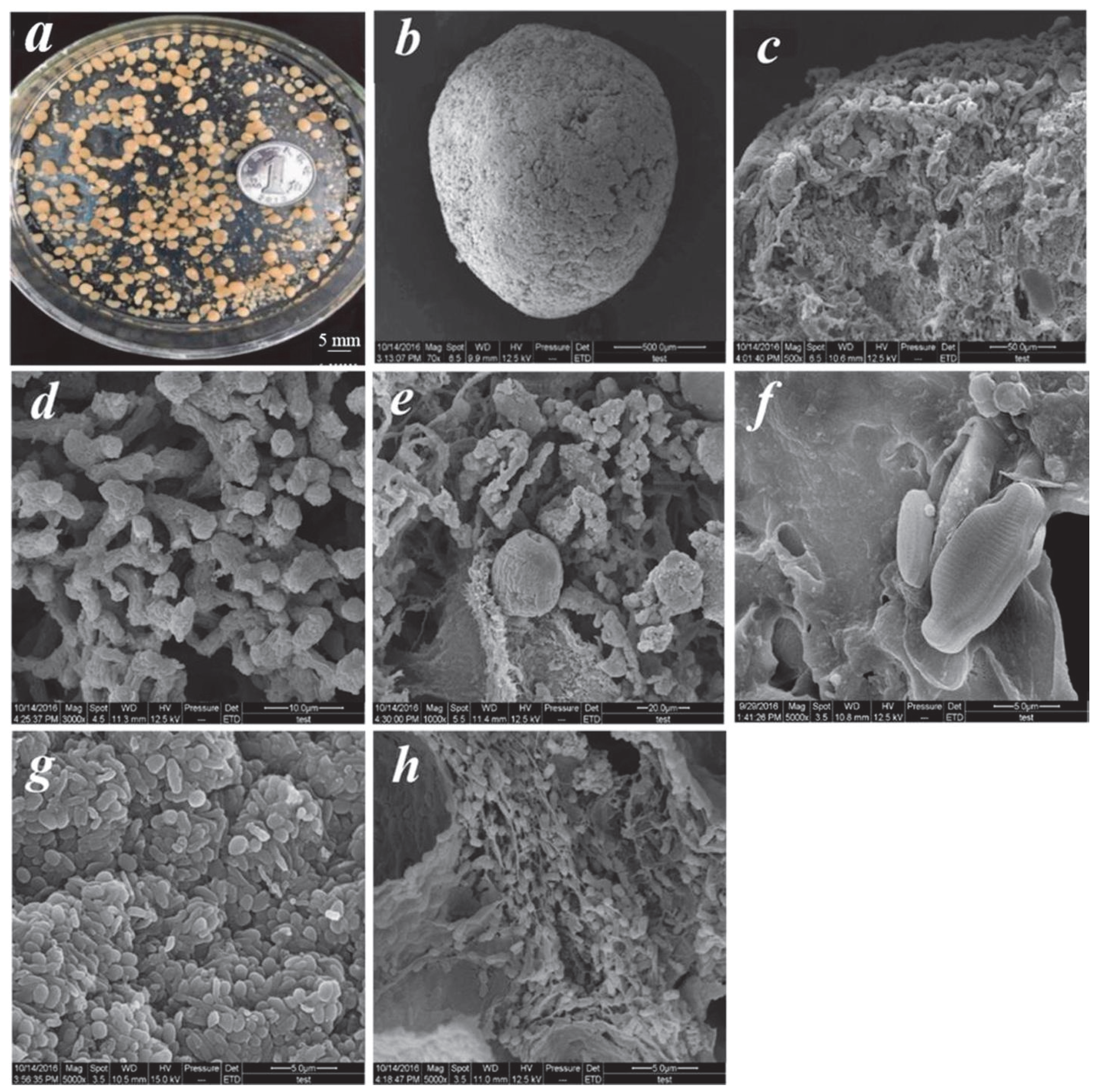

2. Formation Mechanism of Algal–Bacterial Granular Sludge

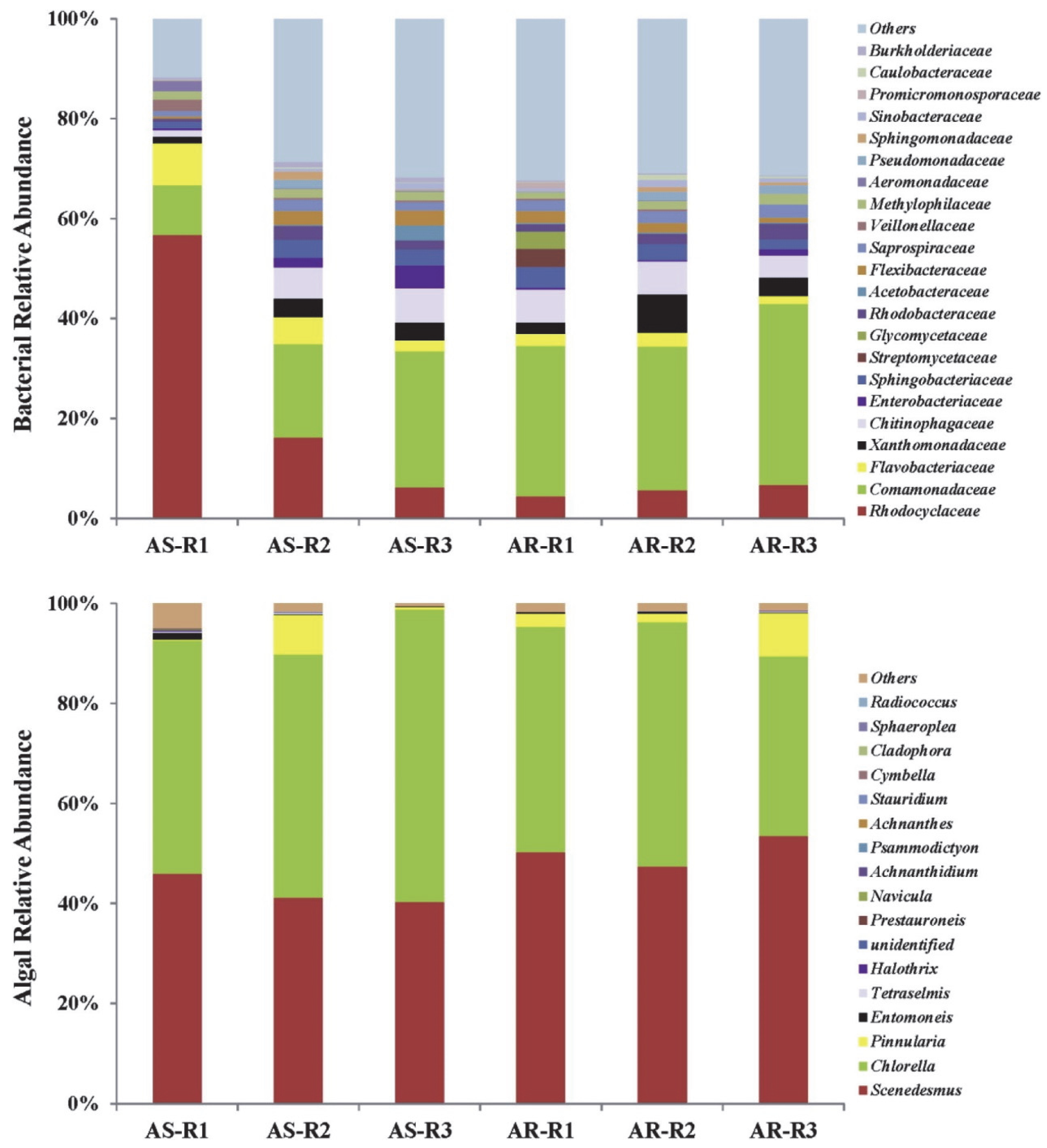

2.1. Characteristics of Microbial Community Composition

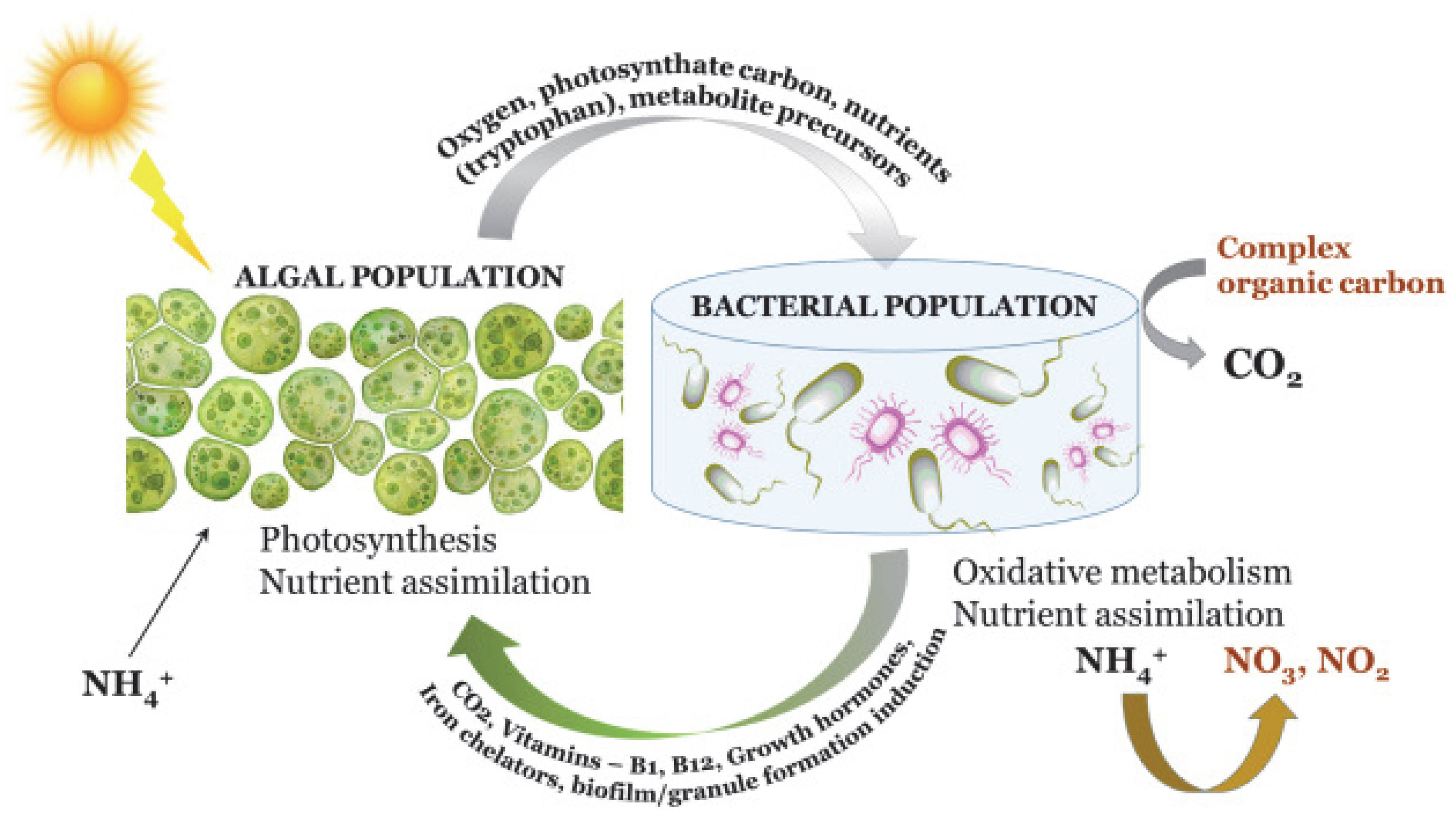

2.2. Synergistic Symbiosis Mechanism Between Algae and Bacteria

2.3. Key Factors Affecting the Granulation Process of Algal–Bacterial Granular Sludge

2.4. Stability Mechanism of Granular Sludge

3. Cultivation Methods and Optimization Strategies

3.1. Comparison of Different Types of Cultivation Reactors

3.2. Optimization of Key Operating Parameters

3.3. Challenges and Solutions in the Cultivation Process

3.4. Particle Size and Mass Transfer Diffusion Mechanism

4. Water Treatment Effect

4.1. Organic Matter Removal Performance

4.2. Nitrogen and Phosphorus Removal Efficiency

4.3. Treatment Effect of Special Pollutants

4.4. System Stability and Impact Load Resistance

5. Economic Evaluation and Prospects Analysis of Algae

6. Conclusions

Funding

Conflicts of Interest

References

- Zhou, Y.; Zhou, Y.; Chen, S.; Guo, N.; Xiang, P.; Lin, S.; Bai, Y.; Hu, X.; Zhang, Z. Evaluating the role of algae in algal-bacterial granular sludge: Nutrient removal, microbial community and granular characteristics. Bioresour. Technol. 2022, 365, 128165. [Google Scholar] [CrossRef]

- Abouhend, A.S.; McNair, A.; Kuo-Dahab, W.C.; Watt, C.; Butler, C.S.; Milferstedt, K.; Hamelin, J.; Seo, J.; Gikonyo, G.J.; El-Moselhy, K.M.; et al. The Oxygenic Photogranule Process for Aeration-Free Wastewater Treatment. Environ. Sci. Technol. 2018, 52, 3503–3511. [Google Scholar] [CrossRef]

- Bindhu, B.K.; Madhu, G. Selection pressure theory for aerobic granulation—An overview. Int. J. Environ. Waste Manag. 2014, 13, 317–329. [Google Scholar] [CrossRef]

- Cai, W.; Jin, M.; Zhao, Z.; Lei, Z.; Zhang, Z.; Adachi, Y.; Lee, D.-J. Influence of ferrous iron dosing strategy on aerobic granulation of activated sludge and bioavailability of phosphorus accumulated in granules. Bioresour. Technol. Rep. 2018, 2, 7–14. [Google Scholar] [CrossRef]

- Cetin, E.; Karakas, E.; Dulekgurgen, E.; Ovez, S.; Kolukirik, M.; Yilmaz, G. Effects of high-concentration influent suspended solids on aerobic granulation in pilot-scale sequencing batch reactors treating real domestic wastewater. Water Res. 2018, 131, 74–89. [Google Scholar] [CrossRef]

- Derlon, N.; Wagner, J.; da Costa, R.H.R.; Morgenroth, E. Formation of aerobic granules for the treatment of real and low-strength municipal wastewater using a sequencing batch reactor operated at constant volume. Water Res. 2016, 105, 341–350. [Google Scholar] [CrossRef]

- Shakoor, I.; Nazir, A.; Chaudhry, S.; Qurat-ul-Ain; Firdaus-e-Bareen; Capareda, S.C. Autochthonous Arthrospira platensis Gomont Driven Nickel (Ni) Phycoremediation from Cooking Oil Industrial Effluent. Molecules 2022, 27, 5353. [Google Scholar] [CrossRef]

- Abate, R.; Oon, Y.S.; Oon, Y.L.; Bi, Y. Microalgae-bacteria nexus for environmental remediation and renewable energy resources: Advances, mechanisms and biotechnological applications. Heliyon 2024, 10, e31170. [Google Scholar] [CrossRef]

- He, Q.; Chen, L.; Zhang, S.; Chen, R.; Wang, H.; Zhang, W.; Song, J. Natural sunlight induced rapid formation of water-born algal-bacterial granules in an aerobic bacterial granular photo-sequencing batch reactor. J. Hazard. Mater. 2018, 359, 222–230. [Google Scholar] [CrossRef]

- Shameem, K.S.; Sabumon, P.C. A Review on the Stability, Sustainability, Storage and Rejuvenation of Aerobic Granular Sludge for Wastewater Treatment. Water 2023, 15, 950. [Google Scholar] [CrossRef]

- Jin, B.; Wang, S.; Xing, L.; Li, B.; Peng, Y. The effect of salinity on waste activated sludge alkaline fermentation and kinetic analysis. J. Environ. Sci. 2016, 43, 80–90. [Google Scholar] [CrossRef]

- Hu, X.; Yin, R.; Jeong, J.; Matyjaszewski, K. Robust Miniemulsion PhotoATRP Driven by Red and Near-Infrared Light. J. Am. Chem. Soc. 2024, 146, 13417–13426. [Google Scholar] [CrossRef]

- Ray, A.; Nayak, M.; Ghosh, A. A review on co-culturing of microalgae: A greener strategy towards sustainable biofuels production. Sci. Total Environ. 2022, 802, 149765. [Google Scholar] [CrossRef]

- Kalendar, R.; Moriya, S. Simple mapping-based quantification of a mock microbial community using total RNA-seq data. PLoS ONE 2021, 16, e0254556. [Google Scholar] [CrossRef]

- Li, D.; Lv, Y.; Zeng, H.; Zhang, J. Effect of sludge retention time on continuous-flow system with enhanced biological phosphorus removal granules at different COD loading. Bioresour. Technol. 2016, 219, 14–20. [Google Scholar] [CrossRef]

- Arashiro, L.T.; Rada-Ariza, A.M.; Wang, M.; van der Steen, P.; Ergas, S.J. Modelling shortcut nitrogen removal from wastewater using an algal-bacterial consortium. Water Sci. Technol. 2017, 75, 782–792. [Google Scholar] [CrossRef]

- Liu, L.; Fan, H.; Liu, Y.; Liu, C.; Huang, X. Development of algae-bacteria granular consortia in photo-sequencing batch reactor. Bioresour. Technol. 2017, 232, 64–71. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, B.; Meng, J.; Zhou, A.; Yue, X.; Niu, Y.; Cui, Y. Efficiency, granulation, and bacterial populations related to pollutant removal in an upflow microaerobic sludge reactor treating wastewater with low COD/TN ratio. Bioresour. Technol. 2018, 270, 147–155. [Google Scholar] [CrossRef]

- Nani, G.; Sandoval-Herazo, M.; Martínez-Reséndiz, G.; Marín-Peña, O.; Zurita, F.; Sandoval Herazo, L.C. Influence of Bed Depth on the Development of Tropical Ornamental Plants in Subsurface Flow Treatment Wetlands for Municipal Wastewater Treatment: A Pilot-Scale Case. Plants 2024, 13, 1958. [Google Scholar] [CrossRef]

- Jakubska-Busse, A.; Kędziora, A.; Cieniuch, G.; Korzeniowska-Kowal, A.; Bugla-Płoskońska, G. Proteomics-based identification of orchid-associated bacteria colonizing the Epipactis albensis, E. helleborine and E. purpurata (Orchidaceae, Neottieae). Saudi J. Biol. Sci. 2021, 28, 4029–4038. [Google Scholar] [CrossRef]

- Li, Q.; Chen, J.; Liu, G.H.; Xu, X.; Zhang, Q.; Wang, Y.; Yuan, J.; Li, Y.; Qi, L.; Wang, H. Effects of biotin on promoting anammox bacterial activity. Sci. Rep. 2021, 11, 2038. [Google Scholar] [CrossRef] [PubMed]

- Chan, S.H.; Ismail, M.H.; Tan, C.H.; Rice, S.A.; McDougald, D. Microbial predation accelerates granulation and modulates microbial community composition. BMC Microbiol. 2021, 21, 91. [Google Scholar] [CrossRef]

- Rui, D.; Liu, K.; Ma, Y.; Huang, K.; Chen, M.; Wu, F.; Zhang, X.; Ye, L. Pilot-scale investigation of performance and microbial community in a novel system combining fixed and suspended activated sludge. Environ. Res. 2024, 246, 118141. [Google Scholar] [CrossRef]

- Raymond, J.; Siefert, J.L.; Staples, C.R.; Blankenship, R.E. The Natural History of Nitrogen Fixation. Mol. Biol. Evol. 2004, 21, 541–554. [Google Scholar] [CrossRef]

- Fallahi, A.; Rezvani, F.; Asgharnejad, H.; Khorshidi Nazloo, E.; Hajinajaf, N.; Higgins, B. Interactions of microalgae-bacteria consortia for nutrient removal from wastewater: A review. Chemosphere 2021, 272, 129878. [Google Scholar] [CrossRef]

- Nagarajan, D.; Lee, D.-J.; Varjani, S.; Lam, S.S.; Allakhverdiev, S.I.; Chang, J.-S. Microalgae-based wastewater treatment—Microalgae-bacteria consortia, multi-omics approaches and algal stress response. Sci. Total Environ. 2022, 845, 157110. [Google Scholar] [CrossRef]

- Yu, Q.; Chen, X.; Ai, S.; Wang, X.; He, J.; Gao, Z.; Meng, C.; Xi, L.; Ge, B.; Huang, F. Comprehensive transcriptomic and metabolomic insights into simultaneous CO2 sequestration and nitrate removal by the Chlorella vulgaris and Pseudomonas sp. consortium. Environ. Res. 2024, 259, 119540. [Google Scholar] [CrossRef]

- Liao, L.; Chen, B.; Deng, K.; He, Q.; Lin, G.; Guo, J.; Yan, P. Effect of the N-hexanoyl-L-homoserine Lactone on the Carbon Fixation Capacity of the Algae–Bacteria System. Int. J. Environ. Res. Public Health 2023, 20, 5047. [Google Scholar] [CrossRef]

- Guzmán-Fierro, V.; Arriagada, C.; Gallardo, J.J.; Campos, V.; Roeckel, M. Challenges of aerobic granular sludge utilization: Fast start-up strategies and cationic pollutant removal. Heliyon 2023, 9, e13503. [Google Scholar] [CrossRef]

- Liu, N.; Yun, Y.; Hu, L.; Xin, L.; Han, M.; Zhang, P. Study on Start-Up Membraneless Anaerobic Baffled Reactor Coupled with Microbial Fuel Cell for Dye Wastewater Treatment. ACS Omega 2021, 6, 23515–23527. [Google Scholar] [CrossRef]

- Fu, K.; Yang, W.; Fu, S.; Bian, Y.; Huo, A.; Guan, T.; Li, X.; Zhang, R.; Jing, H. Effective organic matter removal via bio-adsorption prior to anammox process and utilization of carbon-rich sludge. J. Environ. Manag. 2025, 373, 123777. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Xi, H.; Zhang, Z.; Zhang, Z.; He, X.; Wu, C.; Song, Y.; Wang, C.; Yu, Y. The response of nitrifying activated sludge to chlorophenols: Insights from metabolism and redox homeostasis. J. Environ. Manag. 2023, 346, 118942. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yuan, J.; Zhao, X.; Yin, J. Electrorheological Fluids of GO/Graphene-Based Nanoplates. Materials 2022, 15, 311. [Google Scholar] [CrossRef] [PubMed]

- Gim, G.H.; Ryu, J.; Kim, M.J.; Kim, P.I.; Kim, S.W. Effects of carbon source and light intensity on the growth and total lipid production of three microalgae under different culture conditions. J. Ind. Microbiol. Biotechnol. 2016, 43, 605–616. [Google Scholar] [CrossRef]

- Liu, C.; Shi, X.; Wu, F.; Ren, M.; Gao, G.; Wu, Q. Genome analyses provide insights into the evolution and adaptation of the eukaryotic Picophytoplankton Mychonastes homosphaera. BMC Genom. 2020, 21, 477. [Google Scholar] [CrossRef]

- Cai, Y.M. Non-surface Attached Bacterial Aggregates: A Ubiquitous Third Lifestyle. Front. Microbiol. 2020, 11, 557035. [Google Scholar] [CrossRef]

- Adler, A.; Holliger, C. Multistability and Reversibility of Aerobic Granular Sludge Microbial Communities Upon Changes From Simple to Complex Synthetic Wastewater and Back. Front. Microbiol. 2020, 11, 574361. [Google Scholar] [CrossRef]

- Truong, H.T.B.; Bui, H.M. Potential of aerobic granular sludge membrane bioreactor (AGMBR) in wastewater treatment. Bioengineered 2023, 14, 2260139. [Google Scholar] [CrossRef]

- Zhang, H.; Song, B.; Long, Y.; Liao, G.; Chen, M.; Qin, L.; Chen, X.; Zhu, F. Preparation of Emamectin Benzoate·Hexaflumuron Granules Based on Response Surface Methodology. ACS Omega 2024, 9, 15065–15073. [Google Scholar] [CrossRef]

- Al-Dhabi, N.A.; Esmail, G.A.; Valan Arasu, M. Enhanced Production of Biosurfactant from Bacillus subtilis Strain Al-Dhabi-130 under Solid-State Fermentation Using Date Molasses from Saudi Arabia for Bioremediation of Crude-Oil-Contaminated Soils. Int. J. Environ. Res. Public Health 2020, 17, 8446. [Google Scholar] [CrossRef]

- Yang, A.; Luo, Y.; Yang, J.; Xie, T.; Wang, W.; Wan, X.; Wang, K.; Pang, D.; Yang, D.; Dai, H.; et al. Quantitation of Enterovirus A71 Empty and Full Particles by Sedimentation Velocity Analytical Ultracentrifugation. Viruses 2024, 16, 573. [Google Scholar] [CrossRef]

- Tarlak, F. Machine Learning-Based Software for Predicting Pseudomonas spp. Growth Dynamics in Culture Media. Life 2024, 14, 1490. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Yu, Y.; Li, X.; Jia, H.; Ma, X.; Opoku, P.A. Research progress of anaerobic ammonium oxidation (Anammox) process based on integrated fixed-film activated sludge (IFAS). Environ. Microbiol. Rep. 2024, 16, e13235. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Lens, P.N.L.; Shi, W.; Zhang, R.; Zhang, Z.; Guo, Y.; Bao, X.; Cui, F. The attachment potential and N-acyl-homoserine lactone-based quorum sensing in aerobic granular sludge and algal-bacterial granular sludge. Appl. Microbiol. Biotechnol. 2018, 102, 5343–5353. [Google Scholar] [CrossRef]

- M’Hir, S.; Ayed, L.; De Pasquale, I.; Fanizza, E.; Tlais, A.Z.A.; Comparelli, R.; Verni, M.; Latronico, R.; Gobbetti, M.; Di Cagno, R.; et al. Comparison of Milk Kefirs Obtained from Cow’s, Ewe’s and Goat’s Milk: Antioxidant Role of Microbial-Derived Exopolysaccharides. Antioxidants 2024, 13, 335. [Google Scholar] [CrossRef]

- Yu, H.Q. Molecular Insights into Extracellular Polymeric Substances in Activated Sludge. Environ. Sci. Technol. 2020, 54, 7742–7750. [Google Scholar] [CrossRef]

- Wang, M.; Keeley, R.; Zalivina, N.; Halfhide, T.; Scott, K.; Zhang, Q.; van der Steen, P.; Ergas, S.J. Advances in algal-prokaryotic wastewater treatment: A review of nitrogen transformations, reactor configurations and molecular tools. J. Environ. Manag. 2018, 217, 845–857. [Google Scholar] [CrossRef]

- Cheng, R.; Song, X.; Song, W.; Yu, Z. A New Perspective: Revealing the Algicidal Properties of Bacillus subtilis to Alexandrium pacificum from Bacterial Communities and Toxins. Mar. Drugs 2022, 20, 624. [Google Scholar] [CrossRef]

- Cai, W.; Hu, P.; Li, Z.; Kang, Q.; Chen, H.; Zhang, J.; Zhu, S. Effect of high ammonia on granular stability and phosphorus recovery of algal-bacterial granules in treatment of synthetic biogas slurry. Heliyon 2022, 8, e09844. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Lan, G.H.; Zeng, P. Excessive precipitation of CaCO3 as aragonite in a continuous aerobic granular sludge reactor. Appl. Microbiol. Biotechnol. 2015, 99, 8225–8234. [Google Scholar] [CrossRef]

- Henry, R.J.; Furtado, A.; Rangan, P. Pathways of Photosynthesis in Non-Leaf Tissues. Biology 2020, 9, 438. [Google Scholar] [CrossRef] [PubMed]

- Oruganti, R.K.; Katam, K.; Show, P.L.; Gadhamshetty, V.; Upadhyayula, V.K.K.; Bhattacharyya, D. A comprehensive review on the use of algal-bacterial systems for wastewater treatment with emphasis on nutrient and micropollutant removal. Bioengineered 2022, 13, 10412–10453. [Google Scholar] [PubMed]

- Liu, J.; Li, J.; Tao, Y.; Sellamuthu, B.; Walsh, R. Analysis of bacterial, fungal and archaeal populations from a municipal wastewater treatment plant developing an innovative aerobic granular sludge process. World J. Microbiol. Biotechnol. 2017, 33, 14. [Google Scholar]

- Santos-Pascual, R.; Campoy, I.; Sanz Mata, D.; Martínez, M.J.; Prieto, A.; Barriuso, J. Deciphering the molecular components of the quorum sensing system in the fungus Ophiostoma piceae. Microbiol. Spectr. 2023, 11, e0029023. [Google Scholar] [CrossRef]

- Lv, L.; Li, W.; Zheng, Z.; Li, D.; Zhang, N. Exogenous acyl-homoserine lactones adjust community structures of bacteria and methanogens to ameliorate the performance of anaerobic granular sludge. J. Hazard. Mater. 2018, 354, 72–80. [Google Scholar]

- Zhang, Z.; Cao, R.; Jin, L.; Zhu, W.; Ji, Y.; Xu, X.; Zhu, L. The regulation of N-acyl-homoserine lactones (AHLs)-based quorum sensing on EPS secretion via ATP synthetic for the stability of aerobic granular sludge. Sci. Total Environ. 2019, 673, 83–91. [Google Scholar] [CrossRef]

- Chen, B.; Shen, Y.; Zhang, X.; Ji, B. Influence mechanism of sludge bed position on microalgal-bacterial granular sludge process. Sci. Total Environ. 2024, 907, 168118. [Google Scholar] [CrossRef]

- Yin, F.F.; Liu, W.R.; Wang, J.F.; Wu, P.; Shen, Y.L. Research on change process of nitrosation granular sludge in continuous stirred-tank reactor. Huan Jing Ke Xue = Huanjing Kexue 2014, 35, 4230–4236. [Google Scholar]

- Gao, J.F.; Zhang, L.F.; Zhang, S.J.; Gao, Y.Q.; Wang, S.J.; Fan, X.Y.; Pan, K.L. Microbial Community Dynamics During Two Sludge Granulation Processes. Huan Jing Ke Xue = Huanjing Kexue 2018, 39, 2265–2273. [Google Scholar]

- Lenton, I.C.D.; Scott, E.K.; Rubinsztein-Dunlop, H.; Favre-Bulle, I.A. Optical Tweezers Exploring Neuroscience. Front. Bioeng. Biotechnol. 2020, 8, 602797. [Google Scholar]

- Zahra, S.A.; Purba, L.D.A.; Abdullah, N.; Yuzir, A.; Iwamoto, K.; Lei, Z.; Hermana, J. Characteristics of algal-bacterial aerobic granular sludge treating real wastewater: Effects of algal inoculation and alginate-like exopolymers recovery. Chemosphere 2023, 329, 138595. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Yang, Z.-H.; Li, C.; Zeng, G.-M.; Ma, D.-H.; Zhou, L. A novel algal biofilm membrane photobioreactor for attached microalgae growth and nutrients removal from secondary effluent. Bioresour. Technol. 2015, 179, 8–12. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Guo, H.; Ma, F.; Zhang, J.; Ma, X.; You, S. New insights into mycelial pellets for aerobic sludge granulation in membrane bioreactor: Bio-functional interactions among metazoans, microbial communities and protein expression. Water Res. 2023, 228, 119361. [Google Scholar] [CrossRef]

- Li, D.; Zhang, S.; Li, S.; Zeng, H.; Zhang, J. Aerobic granular sludge operation and nutrients removal mechanism in a novel configuration reactor combined sequencing batch reactor and continuous-flow reactor. Bioresour. Technol. 2019, 292, 122024. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.J.; Chen, F.M.; Zuo, J.E. Development of a dynamic feeding strategy for continuous-flow aerobic granulation and nitrogen removal in a modified airlift loop reactor for municipal wastewater treatment. Sci. Total Environ. 2020, 714, 136764. [Google Scholar] [CrossRef]

- Smaoui, S.; Barkallah, M.; Ben Hlima, H.; Fendri, I.; Mousavi Khaneghah, A.; Michaud, P.; Abdelkafi, S. Microalgae Xanthophylls: From Biosynthesis Pathway and Production Techniques to Encapsulation Development. Foods 2021, 10, 2835. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.; Cai, S.; Lin, L.; Huang, G.; Hu, Z.; Jin, W.; Zheng, Y. Effects of light intensity and salinity on formation and performance of microalgal-bacterial granular sludge. Bioresour. Technol. 2023, 386, 129534. [Google Scholar] [CrossRef]

- van den Berg, L.; Toja Ortega, S.; van Loosdrecht, M.C.M.; de Kreuk, M.K. Diffusion of soluble organic substrates in aerobic granular sludge: Effect of molecular weight. Water Res. X 2022, 16, 100148. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Zhang, X.; Zhang, R.; Liu, W.T.; Tay, J.H. Effects of hydraulic retention time on aerobic granulation and granule growth kinetics at steady state with a fast start-up strategy. Appl. Microbiol. Biotechnol. 2016, 100, 469–477. [Google Scholar] [CrossRef]

- Khan, N.A.; Majumder, A.; Singh, S.; Ramamurthy, P.C.; Prakash, S.K.; Farooqi, I.H.; Mozaffari, N.; Lawal, D.U.; Aljundi, I.H. C/N ratio effect on oily wastewater treatment using column type SBR: Machine learning prediction and metagenomics study. Sci. Rep. 2024, 14, 22950. [Google Scholar] [CrossRef]

- Onadeji, A.; Sani, B.S.; Abubakar, U.A. Response surface methodology optimization of the effect of pH, contact time, and microbial concentration on chemical oxygen removal potential of vegetable oil industrial effluents. Water Environ. Res. 2024, 96, e10963. [Google Scholar] [CrossRef] [PubMed]

- Zhou, P.; Yang, L.; Yang, W.; Hou, J.; Liao, Z. Optimization of H2O2 Production in Biological Systems for Design of Bio-Fenton Reactors. Microorganisms 2024, 12, 1488. [Google Scholar] [CrossRef] [PubMed]

- Qian, W.; Yang, Y.; Chou, S.; Ge, S.; Li, P.; Wang, X.; Zhuang, L.L.; Zhang, J. Effect of N/P ratio on attached microalgae growth and the differentiated metabolism along the depth of biofilm. Environ. Res. 2024, 240, 117428. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Yue, Y.; Cai, S.; Li, X.; Chen, C.; Zhao, H.; Li, T. A comprehensive survey of the application of swarm intelligent optimization algorithm in photovoltaic energy storage systems. Sci. Rep. 2024, 14, 17958. [Google Scholar] [CrossRef]

- Liu, L.; Yu, X.; Wu, D.; Su, J. Antibiotic resistance gene profile in aerobic granular reactor under antibiotic stress: Can eukaryotic microalgae act as inhibiting factor? Environ. Pollut. 2022, 304, 119221. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Lan, G.H.; Zeng, P. Resistance and resilience of nitrifying bacteria in aerobic granules to pH shock. Lett. Appl. Microbiol. 2015, 61, 91–97. [Google Scholar] [CrossRef]

- Pang, Z.; Zhang, P.; Chen, X.; Dong, F.; Deng, J.; Li, C.; Liu, J.; Ma, X.; Dietrich, A.M. Occurrence and modeling of disinfection byproducts in distributed water of a megacity in China: Implications for human health. Sci. Total Environ. 2022, 848, 157674. [Google Scholar] [CrossRef]

- Pouzet, S.; Banderas, A.; Le Bec, M.; Lautier, T.; Truan, G.; Hersen, P. The Promise of Optogenetics for Bioproduction: Dynamic Control Strategies and Scale-Up Instruments. Bioengineering 2020, 7, 151. [Google Scholar] [CrossRef]

- Klein, S.G.; Alsolami, S.M.; Arossa, S.; Ramos-Mandujano, G.; Parry, A.J.; Steckbauer, A.; Duarte, C.M.; Li, M. In situ monitoring reveals cellular environmental instabilities in human pluripotent stem cell culture. Commun. Biol. 2022, 5, 119. [Google Scholar] [CrossRef]

- Lunn, R.; Baumhardt, P.E.; Blackwell, B.F.; Freyssinier, J.P.; Fernández-Juricic, E. Light wavelength and pulsing frequency affect avoidance responses of Canada geese. PeerJ 2023, 11, e16379. [Google Scholar] [CrossRef]

- de Graaff, D.R.; van Loosdrecht, M.C.M.; Pronk, M. Stable granulation of seawater-adapted aerobic granular sludge with filamentous Thiothrix bacteria. Water Res. 2020, 175, 115683. [Google Scholar] [CrossRef] [PubMed]

- Sarvajith, M.; Nancharaiah, Y.V. De novo granulation of sewage-borne microorganisms: A proof of concept on cultivating aerobic granular sludge without activated sludge and effective enhanced biological phosphorus removal. Environ. Res. 2023, 224, 115500. [Google Scholar] [CrossRef]

- Noev, A.; Morozova, N.; Suvorov, N.; Vasil’ev, Y.; Pankratov, A.; Grin, M. Development of a Dosage form for a Photoswitchable Local Anesthetic Ethercaine. Pharmaceuticals 2023, 16, 1398. [Google Scholar] [CrossRef]

- Iqbal, A.; Ullah, H.; Iqbal, M.; Khan, M.S.; Ullah, R.S.; Gul, Z.; Rehman, R.; Altaf, A.A.; Ullah, S. MOF UiO-66 and its composites: Design strategies and applications in drug and antibiotic removal. Environ. Sci. Pollut. Res. 2025, 1–28. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Y.; Zhang, Y.; Liu, Y. Exploring key factors in anaerobic syntrophic interactions: Biomass activity, microbial community, and morphology. Bioresour. Technol. 2022, 363, 127852. [Google Scholar] [CrossRef]

- Wang, J.; Liang, J. Insight: High intensity and activity carrier granular sludge cultured using polyvinyl alcohol/chitosan and polyvinyl alcohol/chitosan/iron gel beads. Bioresour. Technol. 2021, 326, 124778. [Google Scholar] [CrossRef]

- Fan, S.; Ji, B.; Abu Hasan, H.; Fan, J.; Guo, S.; Wang, J.; Yuan, J. Microalgal-bacterial granular sludge process for non-aerated aquaculture wastewater treatment. Bioprocess Biosyst. Eng. 2021, 44, 1733–1739. [Google Scholar] [CrossRef]

- Fan, W.-W.; Yuan, L.-J. The effect of bubble sizes on air-liquid-sludge flow pattern and aerobic sludge granulation. China Environ. Sci. 2020, 40, 3859–3870. [Google Scholar]

- Zhang, B.; Guo, Y.; Lens, P.N.L.; Zhang, Z.; Shi, W.; Cui, F.; Tay, J.H. Effect of light intensity on the characteristics of algal-bacterial granular sludge and the role of N-acyl-homoserine lactone in the granulation. Sci. Total Environ. 2019, 659, 372–383. [Google Scholar] [CrossRef]

- Wang, X.X.; Wang, W.L.; Dao, G.H.; Xu, Z.B.; Zhang, T.Y.; Wu, Y.H.; Hu, H.Y. Mechanism and kinetics of methylisothiazolinone removal by cultivation of Scenedesmus sp. LX1. J. Hazard. Mater. 2020, 386, 121959. [Google Scholar] [CrossRef]

- Xiong, W.; Jin, Y.; Wang, Y.; Wang, S.; Chen, B.; Su, H. Novel insights into the biological state in algal-bacterial granular sludge granulation: Armor-like protection provided by the algal barrier. Water Res. 2024, 262, 122087. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Lee, B.; Hur, J.; Min, J.O.; Ha, S.Y.; Ra, K.; Kim, K.T.; Shin, K.H. Biodegradability of algal-derived organic matter in a large artificial lake by using stable isotope tracers. Environ. Sci. Pollut. Res. Int. 2016, 23, 8358–8366. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, L.; Guo, Y.; Lens, P.N.L.; Shi, W. Rapid establishment of algal-bacterial granular sludge system by applying mycelial pellets in a lab-scale photo-reactor under low aeration conditions: Performance and mechanism analysis. Environ. Pollut. 2023, 322, 121183. [Google Scholar] [CrossRef]

- Qi, F.; Jia, Y.; Mu, R.; Ma, G.; Guo, Q.; Meng, Q.; Yu, G.; Xie, J. Convergent community structure of algal-bacterial consortia and its effects on advanced wastewater treatment and biomass production. Sci. Rep. 2021, 11, 21118. [Google Scholar] [CrossRef]

- Haaksman, V.A.; Mirghorayshi, M.; van Loosdrecht, M.C.M.; Pronk, M. Impact of aerobic availability of readily biodegradable COD on morphological stability of aerobic granular sludge. Water Res. 2020, 187, 116402. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Liu, Q.; Li, Y.; Yan, J. Mechanism of HMBR in Reducing Membrane Fouling under Different SRT: Effect of Sludge Load on Microbial Properties. Membranes 2022, 12, 1242. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, J.; Liu, J. Preparation of a New Iron-Carbon-Loaded Constructed Wetland Substrate and Enhanced Phosphorus Removal Performance. Materials 2020, 13, 4739. [Google Scholar] [CrossRef] [PubMed]

- Misra, S.K.; Kumar, A.; Pathak, K.; Kumar, G.; Virmani, T. Role of Genetically Modified Microorganisms for Effective Elimination of Heavy Metals. BioMed Res. Int. 2024, 2024, 9582237. [Google Scholar] [CrossRef]

- Xiao, X.; Li, W.; Jin, M.; Zhang, L.; Qin, L.; Geng, W. Responses and tolerance mechanisms of microalgae to heavy metal stress: A review. Mar. Environ. Res. 2023, 183, 105805. [Google Scholar] [CrossRef]

- Mojiri, A.; Baharlooeian, M.; Zahed, M.A. The Potential of Chaetoceros muelleri in Bioremediation of Antibiotics: Performance and Optimization. Int. J. Environ. Res. Public Health 2021, 18, 977. [Google Scholar] [CrossRef]

- Ashour, M.; Khairy, H.M.; Bakr, A.; Matter, M.; Alprol, A.E. Seaweed liquid extract AS novel sustainable solutions for phycobioremediation plant germination, and feed additive for marine invertebrate copepod. Sci. Rep. 2024, 14, 29553. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, Y.; Ge, H.; Hou, H.; Zhang, H.; Pi, K. Cultivation of algal-bacterial granular sludge and degradation characteristics of tetracycline. Water Environ. Res. 2023, 95, e10846. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Huang, W.; Cao, Z.; Ji, Y.; Liu, D.; Huang, W.; Zhu, Y.; Lei, Z. Microalgae simultaneously promote antibiotic removal and antibiotic resistance genes/bacteria attenuation in algal-bacterial granular sludge system. J. Hazard. Mater. 2022, 438, 129286. [Google Scholar] [CrossRef]

- Ma, Y.; Li, P.; Zhang, Y.; Guo, X.; Song, Y.; Yake, Z.; Guo, Q.; Li, H.; Wang, Y.; Wan, J. Characteristics and performance of algal-bacterial granular sludge in photo-sequencing batch reactors under various substrate loading rates. J. Environ. Manag. 2024, 368, 122216. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, J.; Zhang, S.; Hou, Y.; Wang, J.; Gao, M.; Chen, X.; Zhang, A.; Liu, Y.; Li, Z. Formation characteristics of algal-bacteria granular sludge under low-light environment: From sludge characteristics, extracellular polymeric substances to microbial community. Bioresour. Technol. 2023, 376, 128851. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, Z.; Zhang, G.; Hirayama, S.; Nguyen, B.V.; Lei, Z.; Shimizu, K.; Zhang, Z. Insight into Cr(VI) biosorption onto algal-bacterial granular sludge: Cr(VI) bioreduction and its intracellular accumulation in addition to the effects of environmental factors. J. Hazard. Mater. 2021, 414, 125479. [Google Scholar] [CrossRef]

- Zhi, M.; Zhao, Y.; Zeng, X.; Maddela, N.R.; Xiao, Y.; Chen, Y.; Prasad, R.; Zhou, Z. Filamentous cyanobacteria and hydrophobic protein in extracellular polymeric substances facilitate algae-bacteria aggregation during partial nitrification. Int. J. Biol. Macromol. 2023, 251, 126379. [Google Scholar] [CrossRef]

- Li, S.; Show, P.L.; Ngo, H.H.; Ho, S.H. Algae-mediated antibiotic wastewater treatment: A critical review. Environ. Sci. Ecotechnol. 2022, 9, 100145. [Google Scholar] [CrossRef]

- Hao, B.; Wu, H.; You, Y.; Liang, Y.; Huang, L.; Sun, Y.; Zhang, S.; He, B. Bacterial community are more susceptible to nanoplastics than algae community in aquatic ecosystems dominated by submerged macrophytes. Water Res. 2023, 232, 119717. [Google Scholar] [CrossRef]

- Meng, W.; Qiao, K.; Liu, F.; Gao, X.; Hu, X.; Liu, J.; Gao, Y.; Zhu, J. Construction and application of a new CRISPR/Cas12a system in Stenotrophomonas AGS-1 from aerobic granular sludge. Biotechnol. J. 2023, 18, e2200596. [Google Scholar] [CrossRef]

| Reactor Type | Main Features | Advantage | Limitation | Treatment Efficiency |

|---|---|---|---|---|

| Column-type PSBR [61] | -Vertical configuration -External lighting -Height-to-diameter ratio > 5 | -Enhances transparency -Efficient mixing -A good settlement choice | -Difficulty in expanding scale -Large-scale light attenuation | COD: 85–95% Total nitrogen: 75–85% Total phosphorus: 70–80% |

| Traditional SBR [59] | -Loop operation -Internal lighting -Mechanical mixing | -High operational flexibility -Easy to process control -Mature technology | -Limited utilization of light -High energy consumption | COD: 80–90% TN: 70–80% Total phosphorus: 65–75% |

| Flat-plate photobioreactor [44] | -Large illumination area -Shallow depth -Continuous operation | -Maximum exposure -High biomass productivity -Uniform flow distribution | -High construction cost -Maintenance difficulties -Complex scaling up | COD: 75–85% Total nitrogen: 65–75% Total phosphorus: 60–70% |

| Membrane photobioreactor [62] | -Membrane separation -Hybrid power system -Continuous operation | -High biomass retention rate -Excellent effluent quality -Compact footprint | -Severe membrane fouling -High operating costs -Complex operation | COD: 90–95% TN: 80–90% Total phosphorus: 75–85% |

| Parameter | Best Range | Impact on the System | Performance Indicators |

|---|---|---|---|

| Light intensity [67] | 150–400 μmol/m2/s | -Photosynthetic efficiency -Biomass growth -Particle stability | -O2 productivity -Chlorophyll content -EPS production |

| Nutrient load [68] | Chemical oxygen demand: 400–800 mg/L N/P ratio: 5:1–8:1 | -Microbial growth -Particle formation -Treatment efficiency | -COD removal rate: >85% -Nitrogen removal rate: >75% -Phosphorus removal rate: >70% |

| HRT [69] | 12 to 48 h | -Biomass retention -Nutrient removal -Particle maturity | -Settlement velocity -Particle size -Effluent quality |

| Temperature and pH value [40] | Temperature: 20–30 °C PH value: 7.0–8.5 | -Metabolic activity -Community structure -System stability | -Specific growth rate -Removal efficiency -Particle strength |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Wang, J.; Feng, X.; Zhao, F. Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects. Water 2025, 17, 1647. https://doi.org/10.3390/w17111647

Chen S, Wang J, Feng X, Zhao F. Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects. Water. 2025; 17(11):1647. https://doi.org/10.3390/w17111647

Chicago/Turabian StyleChen, Shengnan, Jiashuo Wang, Xin Feng, and Fangchao Zhao. 2025. "Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects" Water 17, no. 11: 1647. https://doi.org/10.3390/w17111647

APA StyleChen, S., Wang, J., Feng, X., & Zhao, F. (2025). Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects. Water, 17(11), 1647. https://doi.org/10.3390/w17111647