Gravity-Driven Operation Mitigates Inorganic Fouling and Enables Low-Pressure Filtration in a Pilot-Scale Dynamic Membrane Bioreactor

Abstract

1. Introduction

2. Materials and Methods

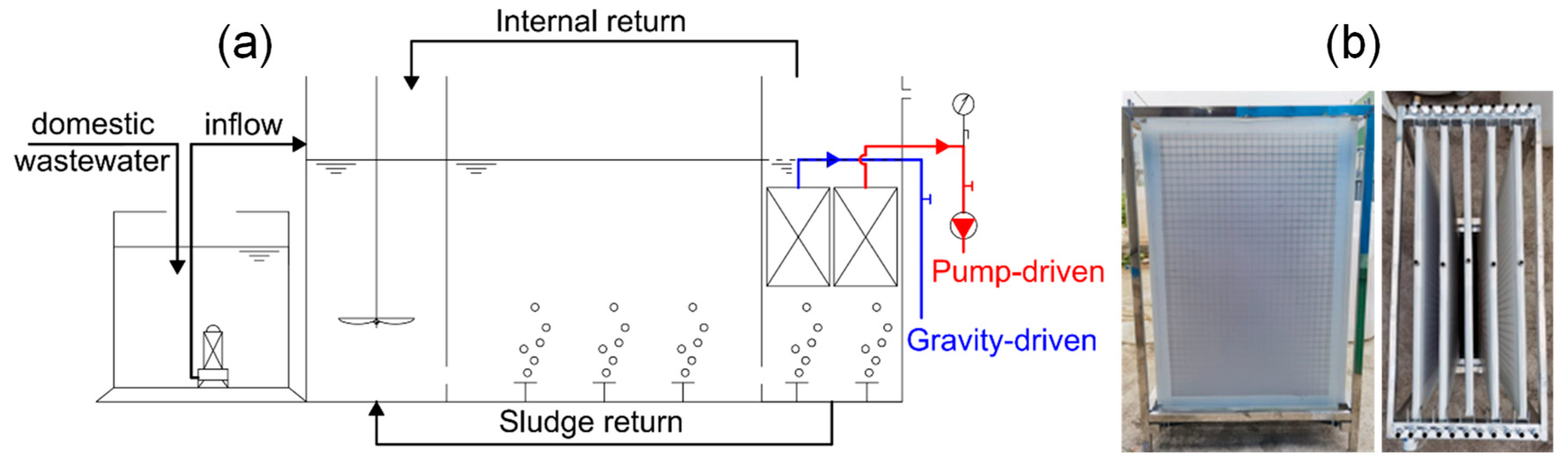

2.1. Pilot-Scale DMBR Setup and Wastewater

2.2. Operation and Monitoring of the Pilot-Scale DMBR

2.3. Filtration Resistance Calculation

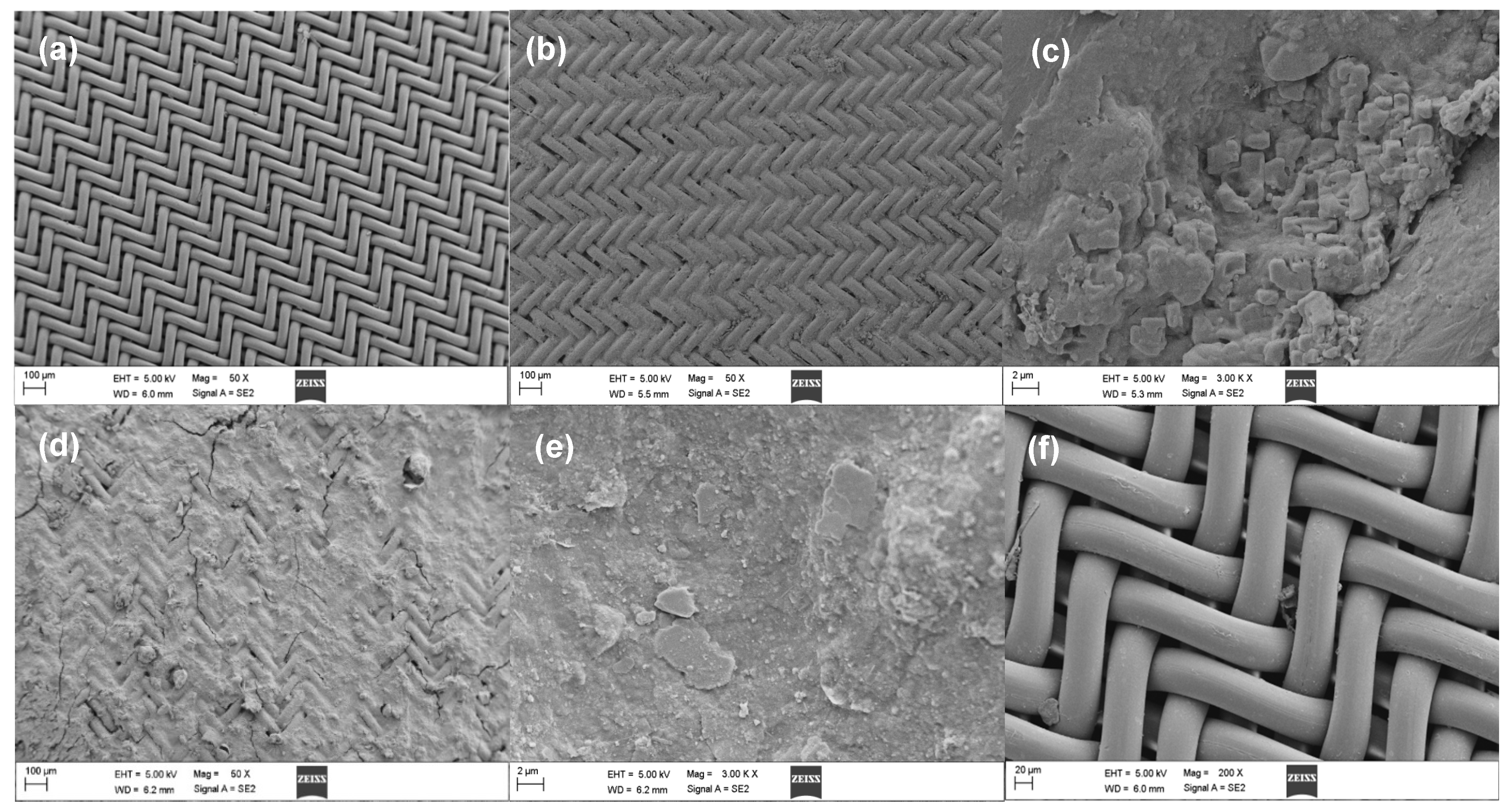

2.4. SEM and EDX/EDS Analysis

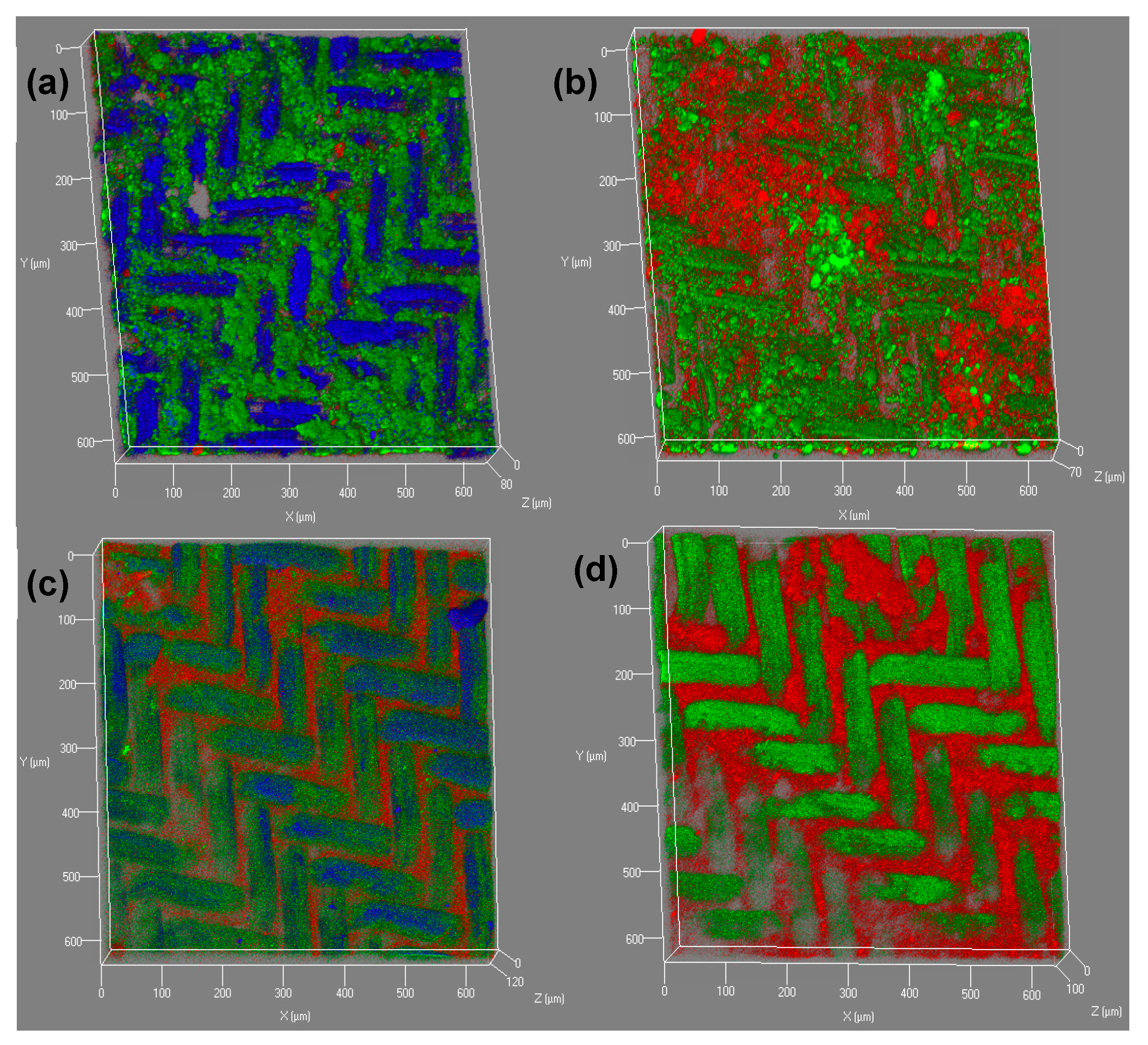

2.5. CLSM Analysis

3. Results and Discussion

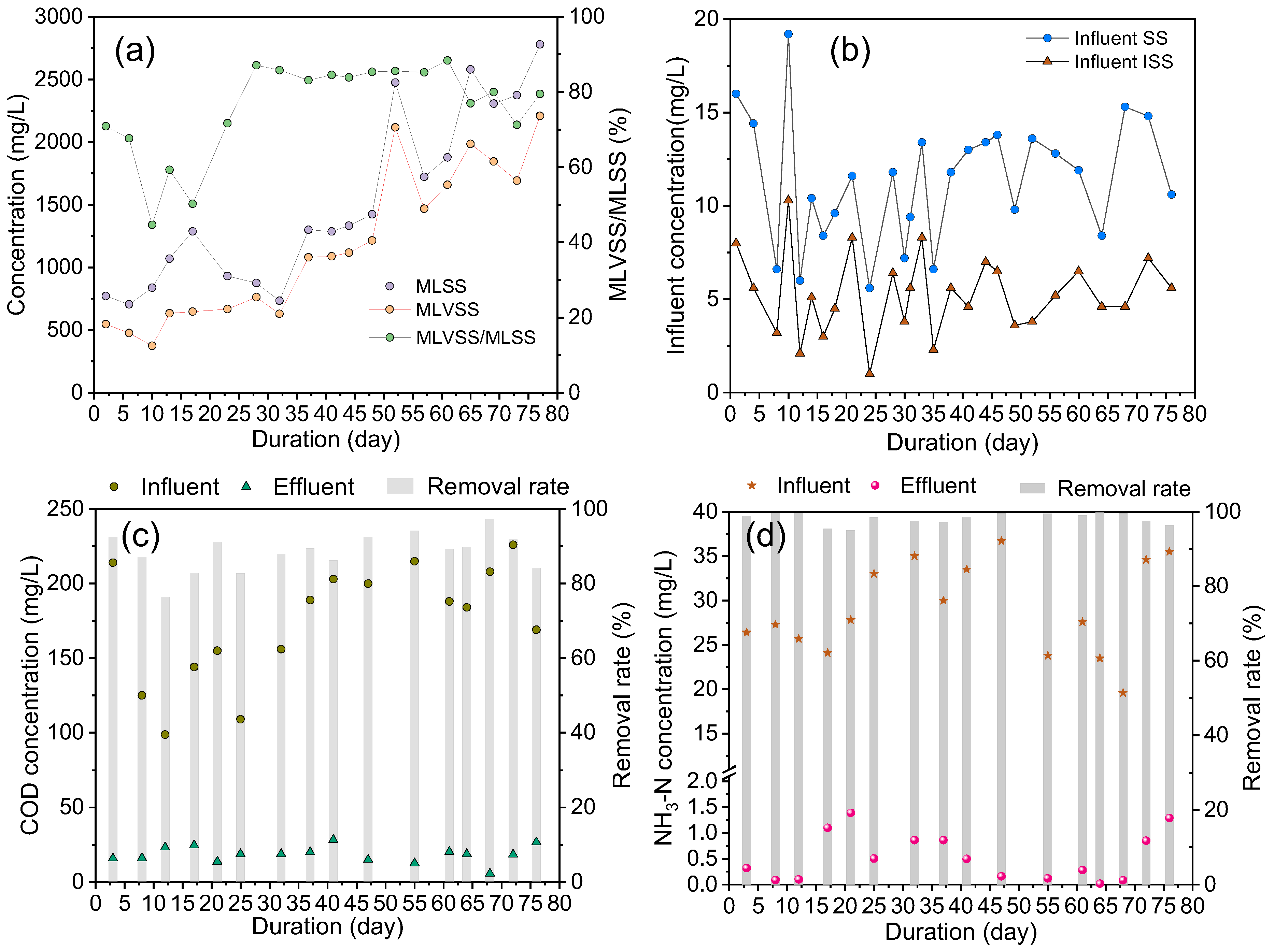

3.1. MLSS Concentration and the Removals of COD and Ammonia

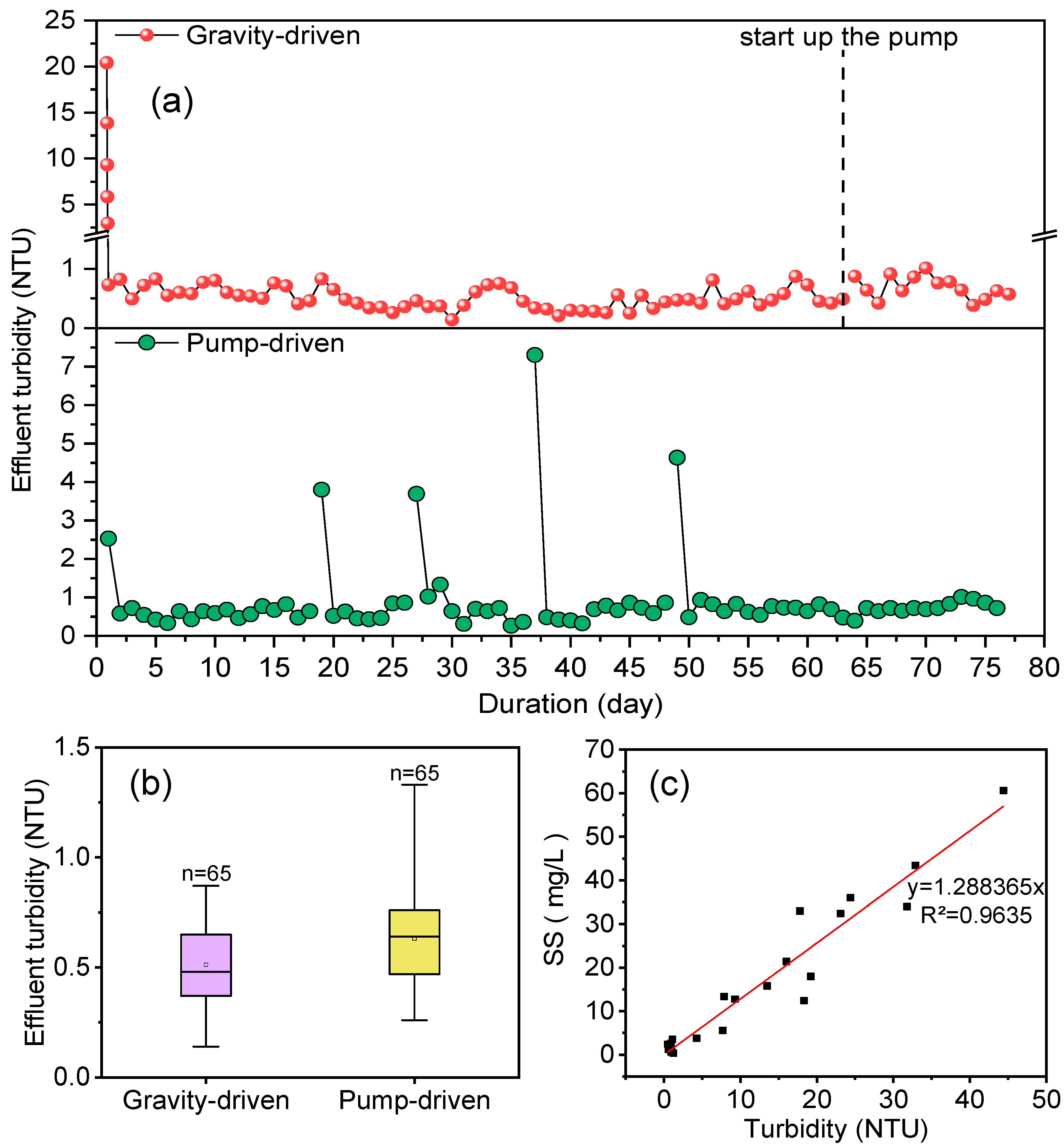

3.2. Solids Separation Performance Indicated by Effluent Turbidity

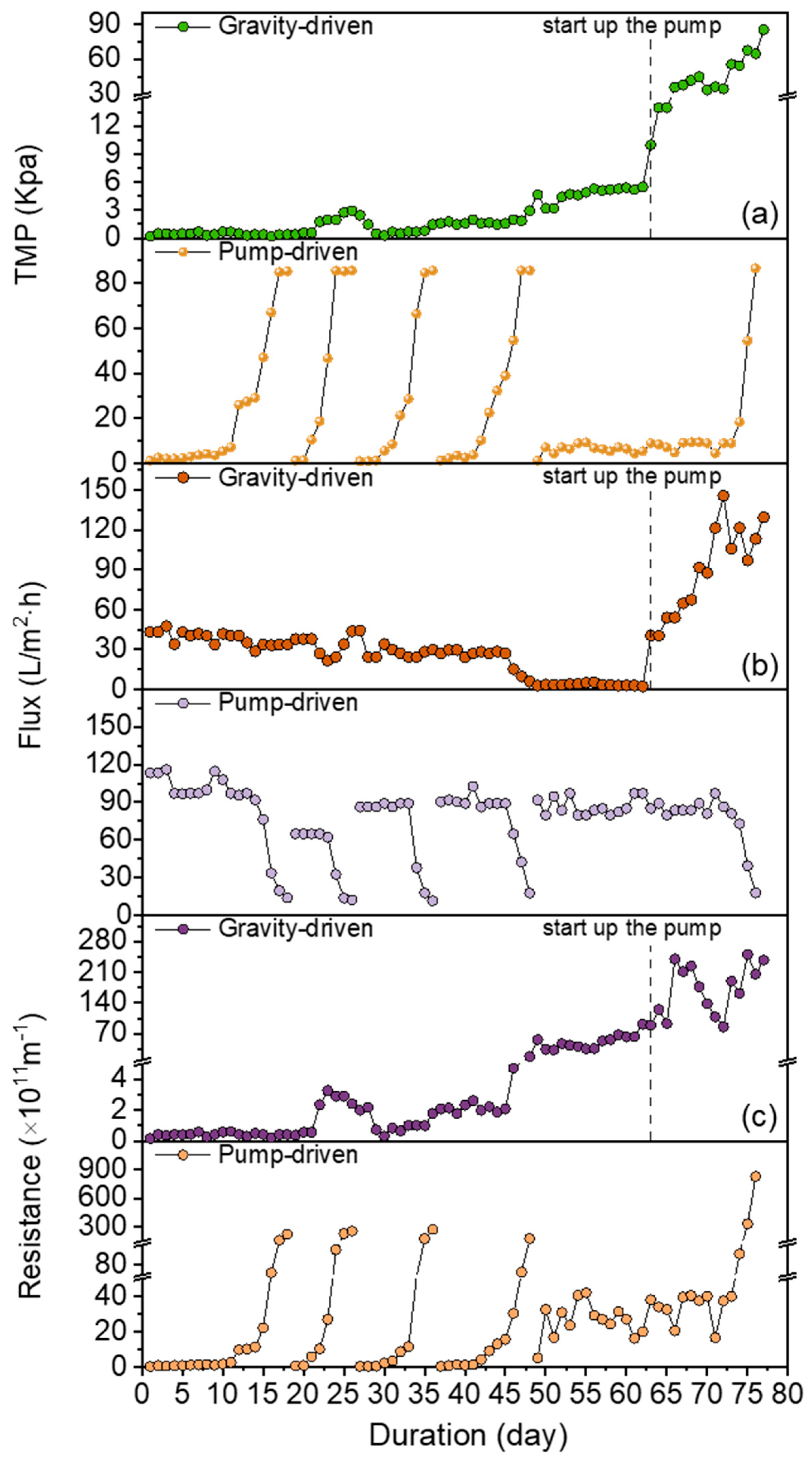

3.3. Changes in Operation Flux, TMP, and Resistance

3.4. DM Structures Characterized by SEM and CLSM

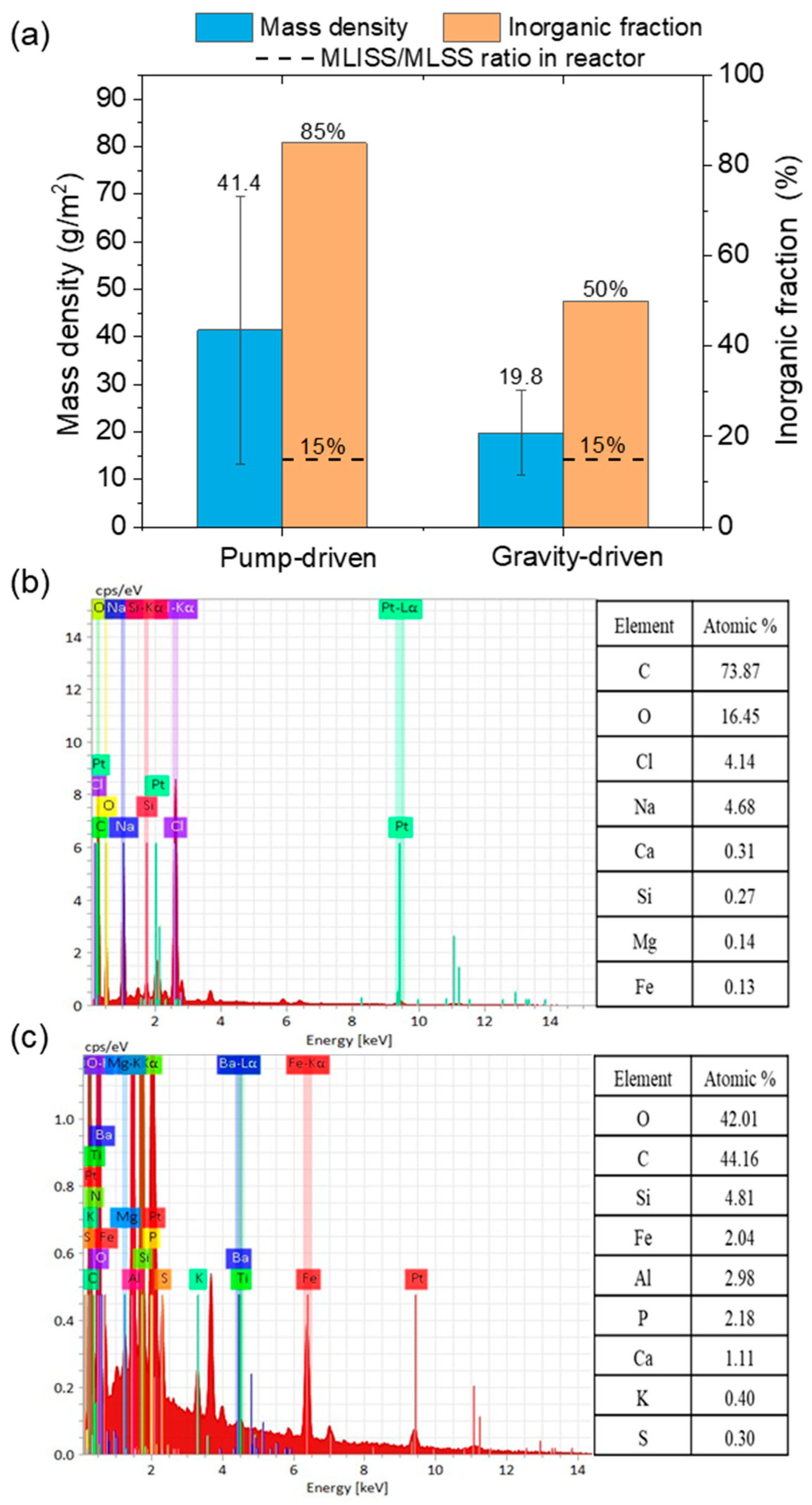

3.5. Inorganic and Elemental Composition of the DM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jeison, D.; Díaz, I.; Van Lier, J.B. Anaerobic membrane bioreactors: Are membranes really necessary? Electron. J. Biotechnol. 2008, 11, 1–2. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Wu, Z.; Lu, F.; Tong, J.; Zang, L. Formation of dynamic membrane in an anaerobic membrane bioreactor for municipal wastewater treatment. Chem. Eng. J. 2010, 165, 175–183. [Google Scholar] [CrossRef]

- Chu, H.Q.; Zhang, Y.L.; Zhou, X.F.; Zhao, Y.Y.; Dong, B.Z.; Zhang, H. Dynamic membrane bioreactor for wastewater treatment: Operation, critical flux, and dynamic membrane structure. J. Membr. Sci. 2014, 450, 265–271. [Google Scholar] [CrossRef]

- Yu, Z.Z.; Hu, Y.S.; Dzakpasu, M.; Wang, X.C.C.; Ngo, H.H. Dynamic membrane bioreactor performance enhancement by powdered activated carbon addition: Evaluation of sludge morphological, aggregative and microbial properties. J. Environ. Sci. 2019, 75, 73–83. [Google Scholar] [CrossRef]

- Chu, H.-q.; Cao, D.-w.; Jin, W.; Dong, B.-z. Characteristics of bio-diatomite dynamic membrane process for municipal wastewater treatment. J. Membr. Sci. 2008, 325, 271–276. [Google Scholar] [CrossRef]

- Meng, F.; Zhang, S.; Oh, Y.; Zhou, Z.; Shin, H.-S.; Chae, S.-R. Fouling in membrane bioreactors: An updated review. Water Res. 2017, 114, 151–180. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ma, J.; Tang, C.Y.; Kimura, K.; Wang, Q.; Han, X. Membrane cleaning in membrane bioreactors: A review. J. Membr. Sci. 2014, 468, 276–307. [Google Scholar] [CrossRef]

- Yamamoto, K.; Hiasa, M.; Mahmood, T.; Matsuo, T. Direct solid-liquid separation using hollow fiber membrane in an activated sludge aeration tank. In Water Pollution Research and Control Brighton, Proceedings of the Fourteenth Biennial Conference of the International Association on Water Pollution Research and Control, Brighton, UK, 18–21 July 1988; Elsevier: Amsterdam, The Netherlands, 1988; pp. 43–54. [Google Scholar] [CrossRef]

- Judd, S. The status of industrial and municipal effluent treatment with membrane bioreactor technology. Chem. Eng. J. 2016, 305, 37–45. [Google Scholar] [CrossRef]

- Seo, G.T.; Moon, B.H.; Park, Y.M.; Kim, S.H. Filtration characteristics of immersed coarse pore filters in an activated sludge system for domestic wastewater reclamation. Water Sci. Technol. 2007, 55, 51–58. [Google Scholar] [CrossRef]

- Xiong, J.L.; Fu, D.F.; Singh, R.P. Self-adaptive dynamic membrane module with a high flux and stable operation for the municipal wastewater treatment. J. Membr. Sci. 2014, 471, 308–318. [Google Scholar] [CrossRef]

- Chen, G.C.; Wen, J.L.; Yu, Y.; Liu, M.; Liu, G.Q. Dynamic membranes with sparse nanofibers as the skeletons yield better and more stable effluent quality without sacrificing the flux in bioreactors. J. Membr. Sci. 2022, 650, 120414. [Google Scholar] [CrossRef]

- Loderer, C.; Worle, A.; Fuchs, W. Influence of Different Mesh Filter Module Configurations on Effluent Quality and Long-Term Filtration Performance. Environ. Sci. Technol. 2012, 46, 3844–3850. [Google Scholar] [CrossRef] [PubMed]

- Satyawali, Y.; Balakrishnan, M. Treatment of distillery effluent in a membrane bioreactor (MBR) equipped with mesh filter. Sep. Purif. Technol. 2008, 63, 278–286. [Google Scholar] [CrossRef]

- Huang, J.; Wu, X.W.; Cai, D.L.; Chen, G.F.; Li, D.Y.; Yu, Y.; Petrik, L.F.; Liu, G.Q. Linking solids retention time to the composition, structure, and hydraulic resistance of biofilms developed on support materials in dynamic membrane bioreactors. J. Membr. Sci. 2019, 581, 158–167. [Google Scholar] [CrossRef]

- Isik, O.; Batyrow, M.; Abdelrahman, A.M.; Orman, I.; Ozgun, H.; Ersahin, M.E.; Pasaoglu, M.E.; Demir, I.; Koyuncu, I. Dynamic membrane bioreactor performance for treatment of municipal wastewaters at different sludge concentrations. Environ. Technol. Innov. 2021, 22, 101452. [Google Scholar] [CrossRef]

- Chuang, S.-H.; Lin, P.-K.; Chang, W.-C. Dynamic fouling behaviors of submerged nonwoven bioreactor for filtration of activated sludge with different SRT. Bioresour. Technol. 2011, 102, 7768–7776. [Google Scholar] [CrossRef]

- Yu, Z.Z.; Hu, Y.S.; Dzakpasu, M.; Wang, X.C.C. Thermodynamic prediction and experimental investigation of short-term dynamic membrane formation in dynamic membrane bioreactors: Effects of sludge properties. J. Environ. Sci. 2019, 77, 85–96. [Google Scholar] [CrossRef]

- Imai, A.; Fukushima, T.; Matsushige, K.; Kim, Y.H.; Choi, K. Characterization of dissolved organic matter in effluents from wastewater treatment plants. Water Res. 2002, 36, 859–870. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Deng, W.; Hu, Y.; Chen, R.; Wang, X.C. Gravity-driven high flux filtration behavior and microbial community of an integrated granular activated carbon and dynamic membrane bioreactor for domestic wastewater treatment. Sci. Total Environ. 2022, 825, 153930. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, X.C.; Tian, W.; Ngo, H.H.; Chen, R. Towards stable operation of a dynamic membrane bioreactor (DMBR): Operational process, behavior and retention effect of dynamic membrane. J. Membr. Sci. 2016, 498, 20–29. [Google Scholar] [CrossRef]

- Wang, Y.K.; Sheng, G.P.; Li, W.W.; Yu, H.Q. A pilot investigation into membrane bioreactor using mesh filter for treating low-strength municipal wastewater. Bioresour. Technol. 2012, 122, 17–21. [Google Scholar] [CrossRef]

- Xiong, J.; Fu, D.; Singh, R.P.; Ducoste, J.J. Structural characteristics and development of the cake layer in a dynamic membrane bioreactor. Sep. Purif. Technol. 2016, 167, 88–96. [Google Scholar] [CrossRef]

- Huang, J.; Wu, X.W.; Liang, Z.H.; Yu, Y.; Liu, G.Q. Water flushing irremovable biofilms on support material in dynamic membrane bioreactor: Formation, composition, and microbial community. Chemosphere 2021, 271, 129813. [Google Scholar] [CrossRef]

- Lin, H.J.; Xie, K.; Mahendran, B.; Bagley, D.M.; Leung, K.T.; Liss, S.N.; Liao, B.Q. Sludge properties and their effects on membrane fouling in submerged anaerobic membrane bioreactors (SAnMBRs). Water Res. 2009, 43, 3827–3837. [Google Scholar] [CrossRef]

- Jiang, L.G.; Yu, Y.; Liu, G.Q. Effects of inorganic particles and their interactions with biofilms on dynamic membrane structure and long-term filtration performance. Sci. Total Environ. 2021, 780, 146639. [Google Scholar] [CrossRef]

- Abd Mutalib, M.; Rahman, M.; Othman, M.; Ismail, A.; Jaafar, J. Scanning electron microscopy (SEM) and energy-dispersive X-ray (EDX) spectroscopy. In Membrane Characterization; Elsevier: Amsterdam, The Netherlands, 2017; pp. 161–179. [Google Scholar]

- Quintas, V.; Prada-López, I.; Tomás, I. Analyzing the oral biofilm using fluorescence-based microscopy: What’s in a dye. In Microscopy: Advances in Scientific Research and Education; Méndez-Vilas, A., Ed.; Formatex Research Center: Badajoz, Spain, 2014; pp. 226–238. [Google Scholar]

- Yuan, B.; Wang, X.H.; Tang, C.Y.; Li, X.F.; Yu, G.H. In situ observation of the growth of biofouling layer in osmotic membrane bioreactors by multiple fluorescence labeling and confocal laser scanning microscopy. Water Res. 2015, 75, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.L.; Huang, J.; Liu, G.Q.; Li, M.Y.; Yu, Y.; Meng, F.G. Effect of support material pore size on the filtration behavior of dynamic membrane bioreactor. Bioresour. Technol. 2018, 255, 359–363. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.B.; Li, Y.J.; Yang, C.Z.; Pu, W.H.; He, L.; Bo, F. Stable aerobic granules in continuous-flow bioreactor with self-forming dynamic membrane. Bioresour. Technol. 2012, 121, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Sreeda, P.; Sathya, A.B.; Sivasubramanian, V. Novel application of high-density polyethylene mesh as self-forming dynamic membrane integrated into a bioreactor for wastewater treatment. Environ. Technol. 2018, 39, 51–58. [Google Scholar] [CrossRef]

- Li, L.C.; Xu, G.R.; Yu, H.R.; Xing, J. Dynamic membrane for micro-particle removal in wastewater treatment: Performance and influencing factors. Sci. Total Environ. 2018, 627, 332–340. [Google Scholar] [CrossRef]

- Xue, N.T.; Xia, J.L.; Huang, X. Fouling control of a pilot scale self-forming dynamic membrane bioreactor for municipal wastewater treatment. Desalination Water Treat. 2010, 18, 302–308. [Google Scholar] [CrossRef]

- Fuchs, W.; Resch, C.; Kernstock, M.; Mayer, M.; Schoeberl, P.; Braun, R. Influence of operational conditions on the performance of a mesh filter activated sludge process. Water Res. 2005, 39, 803–810. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.Q.; Zhang, Y.L.; Zhou, X.F.; Dong, B.Z. Bio-enhanced powder-activated carbon dynamic membrane reactor for municipal wastewater treatment. J. Membr. Sci. 2013, 433, 126–134. [Google Scholar] [CrossRef]

- Hu, Y.S.; Wang, X.C.C.; Sun, Q.Y.; Ngo, H.H.; Yu, Z.Z.; Tang, J.L.; Zhang, Q.H. Characterization of a hybrid powdered activated carbon-dynamic membrane bioreactor (PAC-DMBR) process with high flux by gravity flow: Operational performance and sludge properties. Bioresour. Technol. 2017, 223, 65–73. [Google Scholar] [CrossRef]

- Zhang, J.S.; Loong, W.L.C.; Chou, S.R.; Tang, C.Y.; Wang, R.; Fane, A.G. Membrane biofouling and scaling in forward osmosis membrane bioreactor. J. Membr. Sci. 2012, 403, 8–14. [Google Scholar] [CrossRef]

- Ou, S.H.; You, S.J.; Chang, W.Y.; Damodar, R.A. Effect of sludge retention time on sludge properties and membrane fouling of different hydrophobic PTFE membranes. Desalination Water Treat. 2011, 30, 105–113. [Google Scholar] [CrossRef]

- Chen, Y.-P.; Guo, J.-S.; Wang, J.; Yan, P.; Ji, F.-Y.; Fang, F.; Dong, Y. A grit separation module for inorganic matter removal from activated sludge: Investigation on characteristics of split sludge from the module. Environ. Technol. 2016, 37, 3168–3176. [Google Scholar] [CrossRef]

- Bayo, J.; López-Castellanos, J.; Martínez-García, R.; Alcolea, A.; Lardín, C. Hydrocyclone as a cleaning device for anaerobic sludge digesters in a wastewater treatment plant. J. Clean. Prod. 2015, 87, 550–557. [Google Scholar] [CrossRef]

- Chen, G.F.; Cai, D.L.; Huang, J.; Lu, Z.C.; Yu, Y.; Liu, G.Q. Biofilm as a live and in-situ formed membrane for solids separation in bioreactors: Biofilm succession governs resistance variation demonstrated during the start-up period. J. Membr. Sci. 2020, 608, 118197. [Google Scholar] [CrossRef]

- Zhou, L.J.; Ye, B.; Xia, S.Q. Assessment of membrane bioreactor fouling with the addition of suspended aluminum nitride nanoparticles. Chemosphere 2019, 237, 124473. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Lv, D.; Jiang, L.; Liu, G. Gravity-Driven Operation Mitigates Inorganic Fouling and Enables Low-Pressure Filtration in a Pilot-Scale Dynamic Membrane Bioreactor. Water 2025, 17, 2799. https://doi.org/10.3390/w17192799

Liu X, Lv D, Jiang L, Liu G. Gravity-Driven Operation Mitigates Inorganic Fouling and Enables Low-Pressure Filtration in a Pilot-Scale Dynamic Membrane Bioreactor. Water. 2025; 17(19):2799. https://doi.org/10.3390/w17192799

Chicago/Turabian StyleLiu, Xuechun, Dezheng Lv, Lugao Jiang, and Guoqiang Liu. 2025. "Gravity-Driven Operation Mitigates Inorganic Fouling and Enables Low-Pressure Filtration in a Pilot-Scale Dynamic Membrane Bioreactor" Water 17, no. 19: 2799. https://doi.org/10.3390/w17192799

APA StyleLiu, X., Lv, D., Jiang, L., & Liu, G. (2025). Gravity-Driven Operation Mitigates Inorganic Fouling and Enables Low-Pressure Filtration in a Pilot-Scale Dynamic Membrane Bioreactor. Water, 17(19), 2799. https://doi.org/10.3390/w17192799