An Overview of the Latest Developments and Potential Paths for Artificial Intelligence in Wastewater Treatment Systems

Abstract

1. Introduction

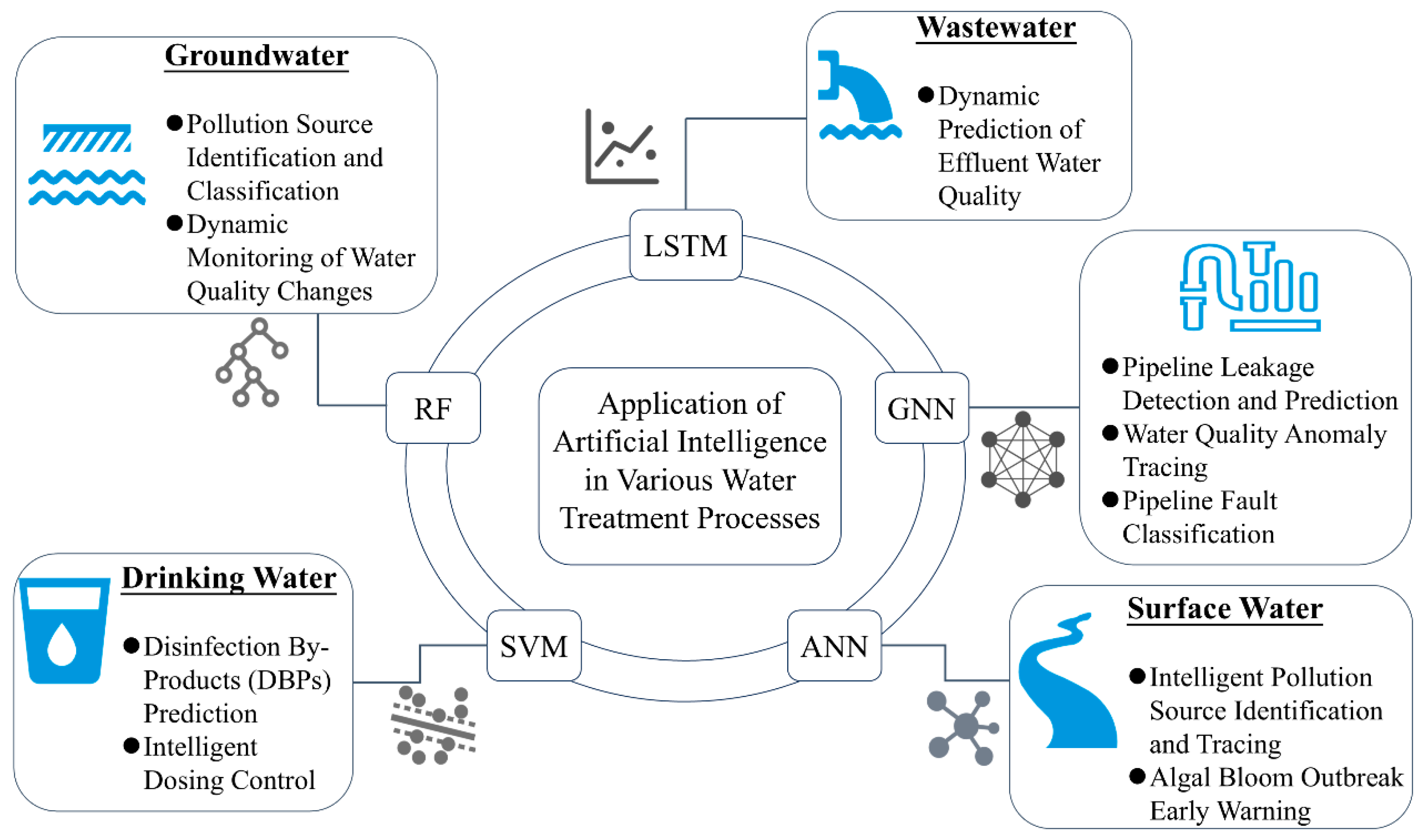

2. Artificial Intelligence in Wastewater Treatment Plants (WWTPs)

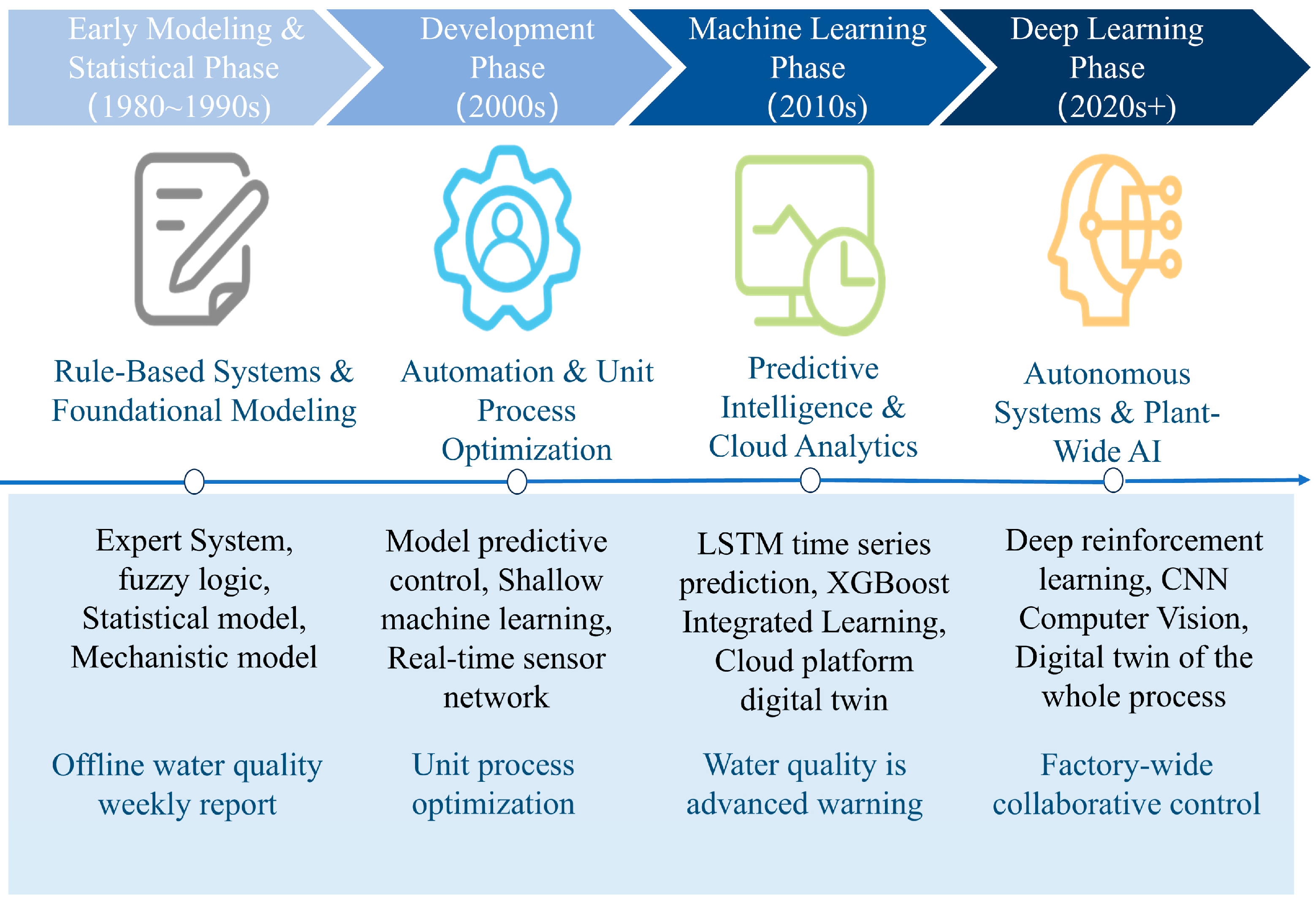

2.1. Evolution of Artificial Intelligence in Wastewater Treatment Plants

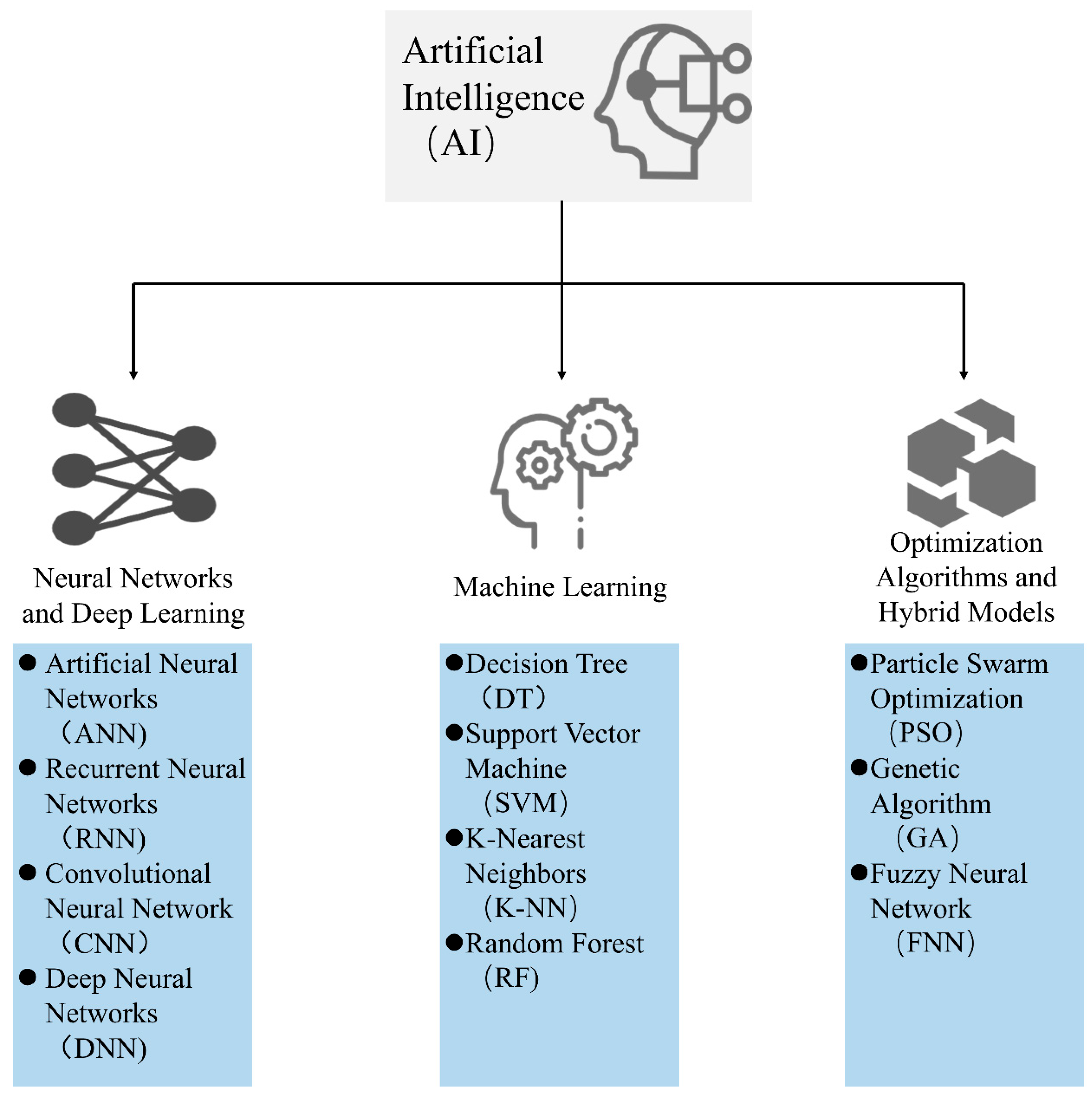

2.2. Commonly Used Algorithms and Models in Wastewater Treatment Plants

3. Artificial Intelligence in Wastewater Treatment Plants: State-of-the-Art and Progress

3.1. Water Quality Monitoring

3.2. Process Optimization and Energy Saving

3.3. Fault and Abnormality Diagnosis

3.4. Membrane Contamination Prediction and Control

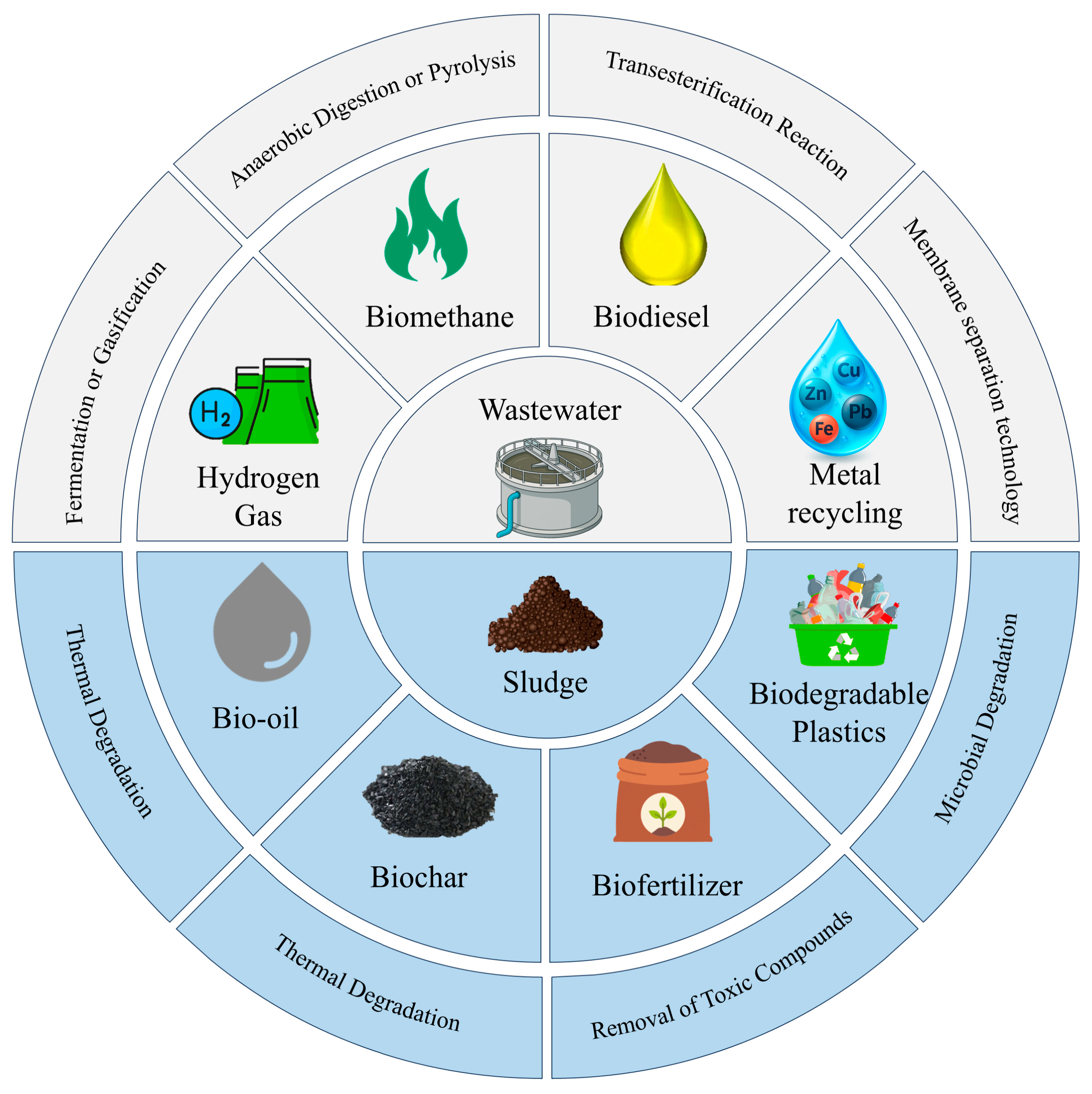

3.5. Resource Recovery and Utilization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| WWT | Wastewater treatment |

| ANN | Artificial neural networks |

| SVM | Support vector machines |

| DT | Decision trees |

| DL | Deep learning |

| IoT | Internet of Things |

| COD | Chemical oxygen demand |

| BOD | Biological oxygen demand |

| RO | Reverse osmosis |

| NF | Nanofiltration |

| CV | Computer vision |

| NLP | Natural language processing |

| GNN | Graph neural network |

| RSM | Response surface method |

| CCD | Central composite design |

| RF | Random forest |

| ML | Machine learning |

| GBM | Gradient Boosting Machine |

| PSO | Particle Swarm Optimization |

| GA | Genetic Algorithm |

| BPNN | Back propagation neural network |

| IIoT | Industrial Internet of Things |

| CNN | Convolutional Neural Network |

| PCA | Principal components analysis |

| MB | Methylene Blue |

| TMP | Transmembrane Pressure |

| SMP | Soluble Microbial Products |

| EPS | Extracellular Polymeric Substances |

| VFA | Volatile Fatty Acids |

| ICA | Independent Component Analysis |

| MLP | Multilayer perceptron |

| PLS | Partial Least Squares |

| SADE | Stacked Denoising Auto Encoder |

| GBM | Gradient Boosting Machines |

References

- Ray, S.S.; Verma, R.K.; Singh, A.; Ganesapillai, M.; Kwon, Y.N. A holistic review on how artificial intelligence has redefined water treatment and seawater desalination processes. Desalination 2023, 546, 116221. [Google Scholar] [CrossRef]

- Tariq, A.; Mushtaq, A. Untreated wastewater reasons and causes: A review of most affected areas and cities. Int. J. Chem. Biochem. Sci. 2023, 23, 121–143. [Google Scholar]

- Chahal, C.; van den Akker, B.; Young, F.; Franco, C.; Blackbeard, J.; Monis, P. Pathogen and Particle Associations in Wastewater: Significance and Implications for Treatment and Disinfection Processes. In Advances in Applied Microbiology; Sariaslani, S., Gadd, G.M., Eds.; Advances in Applied Microbiology; Academic Press: Cambridge, MA, USA, 2016; Volume 97, pp. 63–119. [Google Scholar]

- Li, J.; Cheng, W.; Wang, H.R.; Luo, Y.W.; Liu, Q.L.; Wang, X.Y.; Wang, L.Y.; Zhang, T. Reverse osmosis and nanofiltration processes in industrial wastewater treatment: The recent progress, challenge, and future opportunity. Sep. Purif. Technol. 2025, 362, 131687. [Google Scholar] [CrossRef]

- Malviya, A.; Jaspal, D. Artificial intelligence as an upcoming technology in wastewater treatment: A comprehensive review. Environ. Technol. Rev. 2021, 10, 177–187. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y.H.; Liu, H.; Guo, Q.; Dai, C.J.; Zhao, M.; Liu, D.Z. A Review on Applications of Artificial Intelligence in Wastewater Treatment. Sustainability 2023, 15, 13557. [Google Scholar] [CrossRef]

- Krittanawong, C. The rise of artificial intelligence and the uncertain future for physicians. Eur. J. Intern. Med. 2018, 48, e13–e14. [Google Scholar] [CrossRef]

- Lowe, M.; Qin, R.W.; Mao, X.W. A Review on Machine Learning, Artificial Intelligence, and Smart Technology in Water Treatment and Monitoring. Water 2022, 14, 1384. [Google Scholar] [CrossRef]

- Alprol, A.E.; Mansour, A.T.; Ibrahim, M.E.E.; Ashour, M. Artificial Intelligence Technologies Revolutionizing Wastewater Treatment: Current Trends and Future Prospective. Water 2024, 16, 314. [Google Scholar] [CrossRef]

- Safeer, S.; Pandey, R.P.; Rehman, B.; Safdar, T.; Ahmad, I.; Hasan, S.W.; Ullah, A. A review of artificial intelligence in water purification and wastewater treatment: Recent advancements. J. Water Process Eng. 2022, 49, 102974. [Google Scholar] [CrossRef]

- Dellana, S.A.; West, D. Predictive modeling for wastewater applications: Linear and nonlinear approaches. Environ. Model. Softw. 2009, 24, 96–106. [Google Scholar] [CrossRef]

- Rosen, C.; Lennox, J.A. Multivariate and multiscale monitoring of wastewater treatment operation. Water Res. 2001, 35, 3402–3410. [Google Scholar] [CrossRef]

- Chen, K.H.; Wang, H.C.; Valverde-Pérez, B.; Zhai, S.Y.; Vezzaro, L.; Wang, A.J. Optimal control towards sustainable wastewater treatment plants based on multi-agent reinforcement learning. Chemosphere 2021, 279, 130498. [Google Scholar] [CrossRef]

- Nair, A.T.; Makwana, A.R.; Ahammed, M.M. The use of response surface methodology for modelling and analysis of water and wastewater treatment processes: A review. Water Sci. Technol. 2014, 69, 464–478. [Google Scholar] [CrossRef]

- Alam, G.; Ihsanullah, I.; Naushad, M.; Sillanpaa, M. Applications of artificial intelligence in water treatment for optimization and automation of adsorption processes: Recent advances and prospects. Chem. Eng. J. 2022, 427, 130011. [Google Scholar] [CrossRef]

- Jin, L.L.; Huang, H.; Ren, H.Q. AI-driven transformation of water treatment technology and industry: Toward a new era of comprehensive innovation. Front. Environ. Sci. Eng. 2025, 19, 114. [Google Scholar] [CrossRef]

- Boutra, B.; Sebti, A.; Trari, M. Response surface methodology and artificial neural network for optimization and modeling the photodegradation of organic pollutants in water. Int. J. Environ. Sci. Technol. 2022, 19, 11263–11278. [Google Scholar] [CrossRef]

- Menkiti, M.C.; Ejimofor, M.I. Experimental and artificial neural network application on the optimization of paint effluent (PE) coagulation using novel Achatinoidea shell extract (ASE). J. Water Process Eng. 2016, 10, 172–187. [Google Scholar] [CrossRef]

- Sibiya, N.P.; Amo-Duodu, G.; Tetteh, E.K.; Rathilal, S. Model prediction of coagulation by magnetised rice starch for wastewater treatment using response surface methodology (RSM) with artificial neural network (ANN). Sci. Afr. 2022, 17, e01282. [Google Scholar] [CrossRef]

- Dutta, S.; Parsons, S.A.; Bhattacharjee, C.; Bandhyopadhyay, S.; Datta, S. Development of an artificial neural network model for adsorption and photocatalysis of reactive dye on TiO2 surface. Expert Syst. Appl. 2010, 37, 8634–8638. [Google Scholar] [CrossRef]

- Moreno-Pérez, J.; Bonilla-Petriciolet, A.; Mendoza-Castillo, D.I.; Reynel-Avila, H.E.; Verde-Gómez, Y.; Trejo-Valencia, R. Artificial neural network-based surrogate modeling of multi-component dynamic adsorption of heavy metals with a biochar. J. Environ. Chem. Eng. 2018, 6, 5389–5400. [Google Scholar] [CrossRef]

- Gadekar, M.R.; Ahammed, M.M. Modelling dye removal by adsorption onto water treatment residuals using combined response surface methodology-artificial neural network approach. J. Environ. Manag. 2019, 231, 241–248. [Google Scholar] [CrossRef]

- Choudhary, K.; Yildirim, T.; Siderius, D.W.; Kusne, A.G.; McDannald, A.; Ortiz-Montalvo, D.L. Graph neural network predictions of metal organic framework CO2 adsorption properties. Comput. Mater. Sci. 2022, 210, 111388. [Google Scholar] [CrossRef]

- An, T.; Feng, K.; Cheng, P.; Li, R.; Zhao, Z.; Xu, X.; Zhu, L. Adaptive prediction for effluent quality of wastewater treatment plant: Improvement with a dual-stage attention-based LSTM network. J. Environ. Manag. 2024, 359, 120887. [Google Scholar] [CrossRef] [PubMed]

- Bellamoli, F.; Di Iorio, M.; Vian, M.; Melgani, F. Machine learning methods for anomaly classification in wastewater treatment plants. J. Environ. Manag. 2023, 344, 118594. [Google Scholar] [CrossRef]

- Nam, K.; Heo, S.; Loy-Benitez, J.; Ifaei, P.; Yoo, C. An autonomous operational trajectory searching system for an economic and environmental membrane bioreactor plant using deep reinforcement learning. Water Sci. Technol. 2020, 81, 1578–1587. [Google Scholar] [CrossRef]

- Zaghloul, M.S.; Achari, G. Application of machine learning techniques to model a full-scale wastewater treatment plant with biological nutrient removal. J. Environ. Chem. Eng. 2022, 10, 107430. [Google Scholar] [CrossRef]

- Mihaly, N.-B.; Simon-Varhelyi, M.; Cristea, V.M. Data-driven modelling based on artificial neural networks for predicting energy and effluent quality indices and wastewater treatment plant optimization. Optim. Eng. 2022, 23, 2235–2259. [Google Scholar] [CrossRef]

- Niu, C.; Li, B.; Wang, Z. Using artificial intelligence-based algorithms to identify critical fouling factors and predict fouling behavior in anaerobic membrane bioreactors. J. Membr. Sci. 2023, 687, 122076. [Google Scholar] [CrossRef]

- Moretti, A.; Ivan, H.L.; Skvaril, J. A review of the state-of-the-art wastewater quality characterization and measurement technologies. Is the shift to real-time monitoring nowadays feasible? J. Water Process Eng. 2024, 60, 105061. [Google Scholar] [CrossRef]

- Guo, Y.; Kim, J.-Y.; Park, J.; Lee, J.-M.; Park, S.-G.; Lee, E.-J.; Lee, S.; Hwang, M.-H.; Zheng, G.; Ren, X.; et al. Predicting COD and TN in A2O+AO Process Considering Influent and Reactor Variability: A Dynamic Ensemble Model Approach. Water 2024, 16, 3212. [Google Scholar] [CrossRef]

- Karbassiyazdi, E.; Fattahi, F.; Yousefi, N.; Tahmassebi, A.; Taromi, A.A.; Manzari, J.Z.; Gandomi, A.H.; Altaee, A.; Razmjou, A. XGBoost model as an efficient machine learning approach for PFAS removal: Effects of material characteristics and operation conditions. Environ. Res. 2022, 215, 114286. [Google Scholar] [CrossRef]

- Lv, J.; Du, L.; Lin, H.; Wang, B.; Yin, W.; Song, Y.; Chen, J.; Yang, J.; Wang, A.; Wang, H. Enhancing effluent quality prediction in wastewater treatment plants through the integration of factor analysis and machine learning. Bioresour. Technol. 2024, 393, 130008. [Google Scholar] [CrossRef]

- Medvedev, I.; Kornaukhova, M.; Galazis, C.; Lóránt, B.; Tardy, G.M.; Losev, A.; Goryanin, I. Using AI and BES/MFC to decrease the prediction time of BOD5 measurement. Environ. Monit. Assess. 2023, 195, 1018. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, Y. Quantitative Modeling and Predictive Analysis of Chemical Oxygen Demand in Wastewater Treatment Systems Utilizing Long Short-Term Memory Neural Network. Sustainability 2024, 16, 10359. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, Y.; Huang, S.; Wang, R.; Wu, Y.; Zhou, H.; Li, X.; Tan, Z. Enhancing the effluent prediction accuracy with insufficient data based on transfer learning and LSTM algorithm in WWTPs. J. Water Process Eng. 2024, 62, 105267. [Google Scholar] [CrossRef]

- Singh, N.K.; Yadav, M.; Singh, V.; Padhiyar, H.; Kumar, V.; Bhatia, S.K.; Show, P.L. Artificial intelligence and machine learning-based monitoring and design of biological wastewater treatment systems. Bioresour. Technol. 2023, 369, 128486. [Google Scholar] [CrossRef] [PubMed]

- Haimi, H.; Mulas, M.; Corona, F.; Vahala, R. Data-derived soft-sensors for biological wastewater treatment plants: An overview. Environ. Model. Softw. 2013, 47, 88–107. [Google Scholar] [CrossRef]

- Carreres-Prieto, D.; García, J.T.; Carrillo, J.M.; Vigueras-Rodríguez, A. Towards highly economical and accurate wastewater sensors by reduced parts of the LED-visible spectrum. Sci. Total Environ. 2023, 871, 162082. [Google Scholar] [CrossRef]

- Minchala, L.I.; Peralta, J.; Mata-Quevedo, P.; Rojas, J. An Approach to Industrial Automation Based on Low-Cost Embedded Platforms and Open Software. Appl. Sci. 2020, 10, 4696. [Google Scholar] [CrossRef]

- Nair, A.M.; Gonzalez-Silva, B.M.; Haugen, F.A.; Ratnaweera, H.; Osterhus, S.W. Real-time monitoring of enhanced biological phosphorus removal in a multistage EBPR-MBBR using a soft-sensor for phosphates. J. Water Process Eng. 2020, 37, 101494. [Google Scholar] [CrossRef]

- Post, C.; Heyden, N.; Reinartz, A.; Foerderer, A.; Bruelisauer, S.; Linnemann, V.; Hug, W.; Amann, F. Possibilities of Real Time Monitoring of Micropollutants in Wastewater Using Laser-Induced Raman & Fluorescence Spectroscopy (LIRFS) and Artificial Intelligence (AI). Sensors 2022, 22, 4668. [Google Scholar] [CrossRef] [PubMed]

- Dai, W.; Pang, J.W.; Ding, J.; Wang, J.H.; Xu, C.; Zhang, L.Y.; Ren, N.Q.; Yang, S.S. Integrated real-time intelligent control for wastewater treatment plants: Data-driven modeling for enhanced prediction and regulatory strategies. Water Res. 2025, 274, 123099. [Google Scholar] [CrossRef]

- Picos-Benítez, A.R.; Martínez-Vargas, B.L.; Duron-Torres, S.M.; Brillas, E.; Peralta-Hernández, J.M. The use of artificial intelligence models in the prediction of optimum operational conditions for the treatment of dye wastewaters with similar structural characteristics. Process Saf. Environ. Prot. 2020, 143, 36–44. [Google Scholar] [CrossRef]

- De la Vega Manzano, M.; Tomás, P.; Jaramillo-Morán, M.A. Obtaining key parameters and working conditions of wastewater biological nutrient removal by means of artificial intelligence tools. Water 2018, 10, 685. [Google Scholar] [CrossRef]

- Aghilesh, K.; Kumar, A.; Agarwal, S.; Garg, M.C.; Joshi, H. Use of artificial intelligence for optimizing biosorption of textile wastewater using agricultural waste. Environ. Technol. 2023, 44, 22–34. [Google Scholar] [CrossRef]

- Miao, S.; Zhou, C.L.; AlQahtani, S.A.; Alrashoud, M.; Ghoneim, A.; Lv, Z.H. Applying machine learning in intelligent sewage treatment: A case study of chemical plant in sustainable cities. Sustain. Cities Soc. 2021, 72, 103009. [Google Scholar] [CrossRef]

- Li, X.Y.; Yi, X.H.; Liu, Z.H.; Liu, H.B.; Chen, T.; Niu, G.Q.; Yan, B.; Chen, C.; Huang, M.Z.; Ying, G.G. Application of novel hybrid deep leaning model for cleaner production in a paper industrial wastewater treatment system. J. Clean. Prod. 2021, 294, 126343. [Google Scholar] [CrossRef]

- Zhu, J.R.; Jiang, Z.Z.; Feng, L. Improved neural network with least square support vector machine for wastewater treatment process. Chemosphere 2022, 308, 136116. [Google Scholar] [CrossRef]

- Jin, W.J.; Wang, F.Z.; Chen, L.; Zhang, W.W. Machine learning-assisted synthetic biology of cyanobacteria and microalgae. Algal Res. 2025, 86, 103911. [Google Scholar] [CrossRef]

- Seshan, S.; Poinapen, J.; Zandvoort, M.H.; van Lier, J.B.; Kapelan, Z. Forecasting nitrous oxide emissions from a full-scale wastewater treatment plant using LSTM-based deep learning models. Water Res. 2025, 268, 122754. [Google Scholar] [CrossRef]

- Qi, J.M.; Hou, Y.; Hu, J.W.; Ruan, W.Q.; Xiang, Y.Q.; Wei, X.H. Decontamination of methylene Blue from simulated wastewater by the mesoporous rGO/Fe/Co nanohybrids: Artificial intelligence modeling and optimization. Mater. Today Commun. 2020, 24, 100709. [Google Scholar] [CrossRef]

- Li, H.Z.; Xu, S.H.; Teng, J.H.; Jiang, X.H.; Zhang, H.; Qin, Y.Z.; He, Y.S.; Fan, L. Deep learning assisted ATR-FTIR and Raman spectroscopy fusion technology for microplastic identification. Microchem. J. 2025, 212, 113224. [Google Scholar] [CrossRef]

- Newhart, K.B.; Holloway, R.W.; Hering, A.S.; Cath, T.Y. Data-driven performance analyses of wastewater treatment plants: A review. Water Res. 2019, 157, 498–513. [Google Scholar] [CrossRef]

- Haimi, H.; Mulas, M.; Corona, F.; Marsili-Libelli, S.; Lindell, P.; Heinonen, M.; Vahala, R. Adaptive data-derived anomaly detection in the activated sludge process of a large-scale wastewater treatment plant. Eng. Appl. Artif. Intell. 2016, 52, 65–80. [Google Scholar] [CrossRef]

- Elshenawy, L.M.; Yin, S.; Naik, A.S.; Ding, S.X. Efficient Recursive Principal Component Analysis Algorithms for Process Monitoring. Ind. Eng. Chem. Res. 2010, 49, 252–259. [Google Scholar] [CrossRef]

- Kazemi, P.; Giralt, J.; Bengoa, C.; Masoumian, A.; Steyer, J.P. Fault detection and diagnosis in water resource recovery facilities using incremental PCA. Water Sci. Technol. 2020, 82, 2711–2724. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Shi, H.B. Multivariate statistical process monitoring using an improved independent component analysis. Chem. Eng. Res. Des. 2010, 88, 403–414. [Google Scholar] [CrossRef]

- Xiao, H.J.; Huang, D.P.; Pan, Y.P.; Liu, Y.Q.; Song, K. Fault diagnosis and prognosis of wastewater processes with incomplete data by the auto-associative neural networks and ARMA model. Chemom. Intell. Lab. Syst. 2017, 161, 96–107. [Google Scholar] [CrossRef]

- Picabea, J.; Maestri, M.; Cassanello, M.; Horowitz, G. Hybrid model for fault detection and diagnosis in an industrial distillation column. Chem. Prod. Process Model. 2021, 16, 169–180. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, Y.; Huang, D.; Xu, C.; Wu, J. A novel ensemble adaptive sparse Bayesian transfer learning machine for nonlinear large-scale process monitoring. Sensors 2020, 20, 6139. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Zhao, X.; Xie, M. A mixture of variational canonical correlation analysis for nonlinear and quality-relevant process monitoring. IEEE Trans. Ind. Electron. 2017, 65, 6478–6486. [Google Scholar] [CrossRef]

- McLamore, E.S.; Huffaker, R.; Shupler, M.; Ward, K.; Datta, S.P.A.; Katherine Banks, M.; Casaburi, G.; Babilonia, J.; Foster, J.S. Digital Proxy of a Bio-Reactor (DIYBOT) combines sensor data and data analytics to improve greywater treatment and wastewater management systems. Sci. Rep. 2020, 10, 8015. [Google Scholar] [CrossRef] [PubMed]

- Torfs, E.; Nicolaï, N.; Daneshgar, S.; Copp, J.B.; Haimi, H.; Ikumi, D.; Johnson, B.; Plosz, B.B.; Snowling, S.; Townley, L.R.; et al. The transition of WRRF models to digital twin applications. Water Sci. Technol. 2022, 85, 2840–2853. [Google Scholar] [CrossRef]

- Meng, F.G.; Chae, S.R.; Drews, A.; Kraume, M.; Shin, H.S.; Yang, F.L. Recent advances in membrane bioreactors (MBRs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef]

- Sim, L.N.; Chong, T.H.; Taheri, A.H.; Sim, S.T.V.; Lai, L.; Krantz, W.B.; Fane, A.G. A review of fouling indices and monitoring techniques for reverse osmosis. Desalination 2018, 434, 169–188. [Google Scholar] [CrossRef]

- Han, H.G.; Zhang, S.; Qiao, J.F.; Wang, X.S. An intelligent detecting system for permeability prediction of MBR. Water Sci. Technol. 2018, 77, 467–478. [Google Scholar] [CrossRef]

- Shi, S.; Xu, G.R. Novel performance prediction model of a biofilm system treating domestic wastewater based on stacked denoising auto-encoders deep learning network. Chem. Eng. J. 2018, 347, 280–290. [Google Scholar] [CrossRef]

- Wang, T.J.; Li, Y.Y. Predictive modeling based on artificial neural networks for membrane fouling in a large pilot-scale anaerobic membrane bioreactor for treating real municipal wastewater. Sci. Total Environ. 2024, 912, 169164. [Google Scholar] [CrossRef]

- Hazrati, H.; Moghaddam, A.H.; Rostamizadeh, M. The influence of hydraulic retention time on cake layer specifications in the membrane bioreactor: Experimental and artificial neural network modeling. J. Environ. Chem. Eng. 2017, 5, 3005–3013. [Google Scholar] [CrossRef]

- Qamar, A.; Kerdi, S.; Amin, N.; Zhang, X.L.; Vrouwenvelder, J.; Ghaffour, N. A deep neural networks framework for in-situ biofilm thickness detection and hydrodynamics tracing for filtration systems. Sep. Purif. Technol. 2022, 301, 121959. [Google Scholar] [CrossRef]

- Schmitt, F.; Banu, R.; Yeom, I.T.; Do, K.U. Development of artificial neural networks to predict membrane fouling in an anoxic-aerobic membrane bioreactor treating domestic wastewater. Biochem. Eng. J. 2018, 133, 47–58. [Google Scholar] [CrossRef]

- Yokoyama, D.; Suzuki, S.; Asakura, T.; Kikuchi, J. Chemometric Analysis of NMR Spectra and Machine Learning to Investigate Membrane Fouling. Acs Omega 2022, 7, 12654–12660. [Google Scholar] [CrossRef]

- Mirbagheri, S.A.; Bagheri, M.; Bagheri, Z.; Kamarkhani, A.M. Evaluation and prediction of membrane fouling in a submerged membrane bioreactor with simultaneous upward and downward aeration using artificial neural network-genetic algorithm. Process Saf. Environ. Prot. 2015, 96, 111–124. [Google Scholar] [CrossRef]

- Ivnitsky, H.; Minz, D.; Kautsky, L.; Preis, A.; Ostfeld, A.; Semiat, R.; Dosoretz, C.G. Biofouling formation and modeling in nanofiltration membranes applied to wastewater treatment. J. Membr. Sci. 2010, 360, 165–173. [Google Scholar] [CrossRef]

- Maere, T.; Villez, K.; Marsili-Libelli, S.; Naessens, W.; Nopens, I. Membrane bioreactor fouling behaviour assessment through principal component analysis and fuzzy clustering. Water Res. 2012, 46, 6132–6142. [Google Scholar] [CrossRef]

- Jafari, M.; Tzirtzipi, C.; Castro-Dominguez, B. Applications of artificial intelligence for membrane separation: A review. J. Water Process Eng. 2024, 68, 106532. [Google Scholar] [CrossRef]

- Manisha, M.; Verma, K.; Chanakya, H.N.; Rao, L. Reuse of Treated Wastewater: A Key Driver for Achieving All Sustainable Development Goals. J. Indian Inst. Sci. 2024, 104, 989–1021. [Google Scholar] [CrossRef]

- Sundui, B.; Ramirez Calderon, O.A.; Abdeldayem, O.M.; Lázaro-Gil, J.; Rene, E.R.; Sambuu, U. Applications of machine learning algorithms for biological wastewater treatment: Updates and perspectives. Clean Technol. Environ. Policy 2021, 23, 127–143. [Google Scholar] [CrossRef]

- Sniatala, B.; Kurniawan, T.A.; Sobotka, D.; Makinia, J.; Othman, M.H.D. Macro-nutrients recovery from liquid waste as a sustainable resource for production of recovered mineral fertilizer: Uncovering alternative options to sustain global food security cost-effectively. Sci. Total Environ. 2023, 856, 159283. [Google Scholar] [CrossRef] [PubMed]

- Fisher, O.J.; Watson, N.J.; Escrig, J.E.; Witt, R.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Considerations, challenges and opportunities when developing data-driven models for process manufacturing systems. Comput. Chem. Eng. 2020, 140, 106881. [Google Scholar] [CrossRef]

- Torres, C.M.D.; Ciacci, L.; Passarini, F. Phosphorous flow analysis and resource circularity at the province level in north Italy. Sustain. Chem. Pharm. 2023, 33, 101133. [Google Scholar] [CrossRef]

- Lim, Y.J.; Goh, K.; Nadzri, N.; Wang, R. Thin-film composite (TFC) membranes for sustainable desalination and water reuse: A perspective. Desalination 2025, 599, 118451. [Google Scholar] [CrossRef]

- Xu, R.Z.; Cao, J.S.; Wu, Y.; Wang, S.N.; Luo, J.Y.; Chen, X.M.; Fang, F. An integrated approach based on virtual data augmentation and deep neural networks modeling for VFA production prediction in anaerobic fermentation process. Water Res. 2020, 184, 116103. [Google Scholar] [CrossRef] [PubMed]

- Yogeswari, M.K.; Dharmalingam, K.; Mullai, P. Implementation of artificial neural network model for continuous hydrogen production using confectionery wastewater. J. Environ. Manag. 2019, 252, 109684. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, S.R.; Tariq, R.; Hameed, Z.; Ali, I.; Taqvi, S.A.; Naqvi, M.; Niazi, M.; Noor, T.; Farooq, W. Pyrolysis of high-ash sewage sludge: Thermo-kinetic study using TGA and artificial neural networks. Fuel 2018, 233, 529–538. [Google Scholar] [CrossRef]

| Application Scenario | AI Models/Algorithms | Research Parameters & Ranges | Key Function | Applied Results | Reference |

|---|---|---|---|---|---|

| Water quality parameter prediction | DA-LSTM neural network | COD: 394–3000 mg/L; TP: 0.09–1 mg/L; etc. | Predicting effluent COD, TP, TN | COD validation set R2 improved from 0.93 to 0.98 | [24] |

| Anomaly detection and classification | Decision Tree (DT) | DO: 0–6 mg/L; NH3-N: 0–20 mg/L; etc. | Identify sensor faults and process anomalies | Achieved 92% recall and 61% precision | [25] |

| Aeration optimization control | Deep Reinforcement Learning (DRL) | Influent quality simulated from full-scale MBR plant; DO setpoint: 2–7 mg/L | Dynamically adjust aeration intensity | 33.18% reduction in energy consumption while maintaining treatment efficiency | [26] |

| Process parameter prediction | ANN + ANFIS + SVR hybrid model | 15 parameters (COD, TN, MLSS, etc.) | Predict 15 parameters, including MLSS, TN, and COD | 5% average accuracy increase over individual base models | [27] |

| Treatment process optimization | Artificial Neural Network (ANN) | Aeration Energy (AE), Effluent Quality (EQ), Pumping Energy (PE) | Optimize control setpoints based on predictive results | Total energy consumption reduced by 6.85% | [28] |

| Membrane fouling prediction | Random Forest (RF) | COD: 340 mg/L–20 g/L; VSS: 1.10–37.00 g/L; Pore size: 0.08–0.5 μm; Packing density: 1.53–35.71 m2/m3 | Predict the membrane fouling rate and quantify factors | Extended membrane lifespan by 30%, reduced maintenance costs by 25% | [29] |

| Model | Input Variables | Target Parameter | Results | Advantages/Limitations | Reference |

|---|---|---|---|---|---|

| Long Short-Term Memory (LSTM) | Inflow/outflow water parameters from a WWTP | COD | COD prediction error rate: 7% | Captures temporal features; requires long training time | [35] |

| TL-LSTM | Inflow indicators, operational parameters, and effluent data from WWTPs | NH3-N | Prediction performance: R2 = 0.811, RMSE = 0.627 mg/L | Transfer learning improves generalization; data-intensive | [36] |

| Artificial Neural Network (ANN) | Current/voltage in microbial fuel cell (MFC) biodegradation | BOD5 | Average error: 7% | Simple structure; moderate accuracy | [34] |

| Extreme Gradient Boosting (XGBoost) | 234 PFAS compounds from 64 studies | PFAS micropollutants | pH identified as the most critical predictor for PFAS removal | High accuracy; limited interpretability | [32] |

| Hybrid dynamic model | Two-year operational data from A2O + AO processes | TN | TN prediction error range: 9.4–15.5% | Integrates multiple model strengths; high | [31] |

| Backpropagation Neural Network (FBPNN) | Two-year water quality data from municipal WWTPs | NO3−-N | Prediction performance: R2 = 99.38%, RMSE = 0.12 mg/L | High precision; prone to overfitting | [33] |

| Model/Method | Application Scenario | Input Variables | Objective | Results/Performance | Reference |

|---|---|---|---|---|---|

| ANN-GA Hybrid Model | Dye Wastewater Treatment | Reaction time, flow rate, current density, pH, initial dye concentration | Optimize electro-oxidation parameters for enhanced decolorization efficiency | Achieved 88.8% decolorization (close to model-predicted 95.5%) | [44] |

| SOM + K-means Clustering | Activated Sludge Wastewater Treatment | Dissolved oxygen (DO), oxidation-reduction potential (ORP) | Identify operational modes for aeration control optimization | Extracted key parameters (ORAS, ORP, OUR) | [45] |

| ANN-ANFIS-RSM Hybrid Model | Textile Wastewater Biosorption | Temperature, pH, biosorbent dosage, dye concentration | Predict methylene blue (MB) adsorption performance and optimize conditions | Optimal MB removal: 74.49% (R2 > 0.9) | [46] |

| GRU Neural Network | Industrial Wastewater | Flow rate, pH, temperature, DO, real-time COD | Predict COD concentration for process stability | Superior accuracy over LSTM and SVR | [47] |

| CLSTMA Deep Learning Model | Papermaking Wastewater | Influent/effluent COD, suspended solids (SS), flow rate, pH, temperature, DO | High-precision BOD/COD prediction for reuse cost optimization | Prediction improvements: SS (8.29–11.86%), COD (15.13–37.21%) | [48] |

| IFFNN-LSSVM Hybrid Model | Effluent Quality Prediction in WWTPs | Temperature, conductivity, turbidity, total dissolved solids (TDS), other physical parameters | High-accuracy effluent prediction with low computational cost | Lower error vs. GWO/FFNN benchmarks | [49] |

| Model/Method | Study Object | Input Variables | Objective | Results/Performance | Reference |

|---|---|---|---|---|---|

| Feedforward Neural Network (FFNN) | Membrane Bioreactor (MBR) | MLSS, HRT, time | Predict COD removal efficiency and transmembrane pressure (TMP) | HRT reduction led to smaller sludge particles; MLSS showed the strongest correlation with TMP | [70] |

| Feedback Neural Network (FNN) | Desalination/WWTP filtration modules | Hydrodynamic parameters of the filtration process | Predict pressure drop and (bio)fouling growth on ultrafiltration membranes | Quantified biofilm thickness on membrane surface; correlated biofilm development with hydrodynamic parameters | [71] |

| Artificial Neural Network (ANN) | AO + MBR system | pH, alkalinity, DO, COD, TN, TP, nitrate | Identify the most relevant variables for TMP prediction | TN-TP-nitrate combination showed the strongest predictive power for TMP | [72] |

| Machine Learning (ML) + NMR spectroscopy | Aquaculture water membrane filters | NMR spectra of foulant components | Predict maximum TMP as a fouling indicator | Polysaccharides identified as primary foulants contributing to membrane clogging | [73] |

| MLP & RBF ANN | Submerged MBR (SMBR) | Time, COD, TSS, SRT, MLSS | Predict TMP and membrane permeability (Perm) under alternating aeration | TMP increased while Perm decreased with operation time; GA-optimized ANN showed higher accuracy | [74] |

| Decision Tree (DT) | Tertiary wastewater NF membrane | Pressure, TOC, pH, conductivity | Predict permeate flux decline | High TOC (>9.38 mg/L), high conductivity (>1564 mg/L), and high pressure caused significant flux decline | [75] |

| PCA + Fuzzy Clustering | MBR fouling assessment | TMP datasets from lab-scale MBR | Monitor and control membrane fouling | Successfully extracted fouling control parameters (filtration cycle status, aeration rate) from TMP data alone. | [76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Gao, Y.; Zhou, J.; Shah, K.J.; Sun, Y. An Overview of the Latest Developments and Potential Paths for Artificial Intelligence in Wastewater Treatment Systems. Water 2025, 17, 2432. https://doi.org/10.3390/w17162432

Sun W, Gao Y, Zhou J, Shah KJ, Sun Y. An Overview of the Latest Developments and Potential Paths for Artificial Intelligence in Wastewater Treatment Systems. Water. 2025; 17(16):2432. https://doi.org/10.3390/w17162432

Chicago/Turabian StyleSun, Wenquan, Yun Gao, Jun Zhou, Kinjal J. Shah, and Yongjun Sun. 2025. "An Overview of the Latest Developments and Potential Paths for Artificial Intelligence in Wastewater Treatment Systems" Water 17, no. 16: 2432. https://doi.org/10.3390/w17162432

APA StyleSun, W., Gao, Y., Zhou, J., Shah, K. J., & Sun, Y. (2025). An Overview of the Latest Developments and Potential Paths for Artificial Intelligence in Wastewater Treatment Systems. Water, 17(16), 2432. https://doi.org/10.3390/w17162432