Influence of a Diversion Pier on the Hydraulic Characteristics of an Inverted Siphon in a Long-Distance Water Conveyance Channel

Abstract

1. Introduction

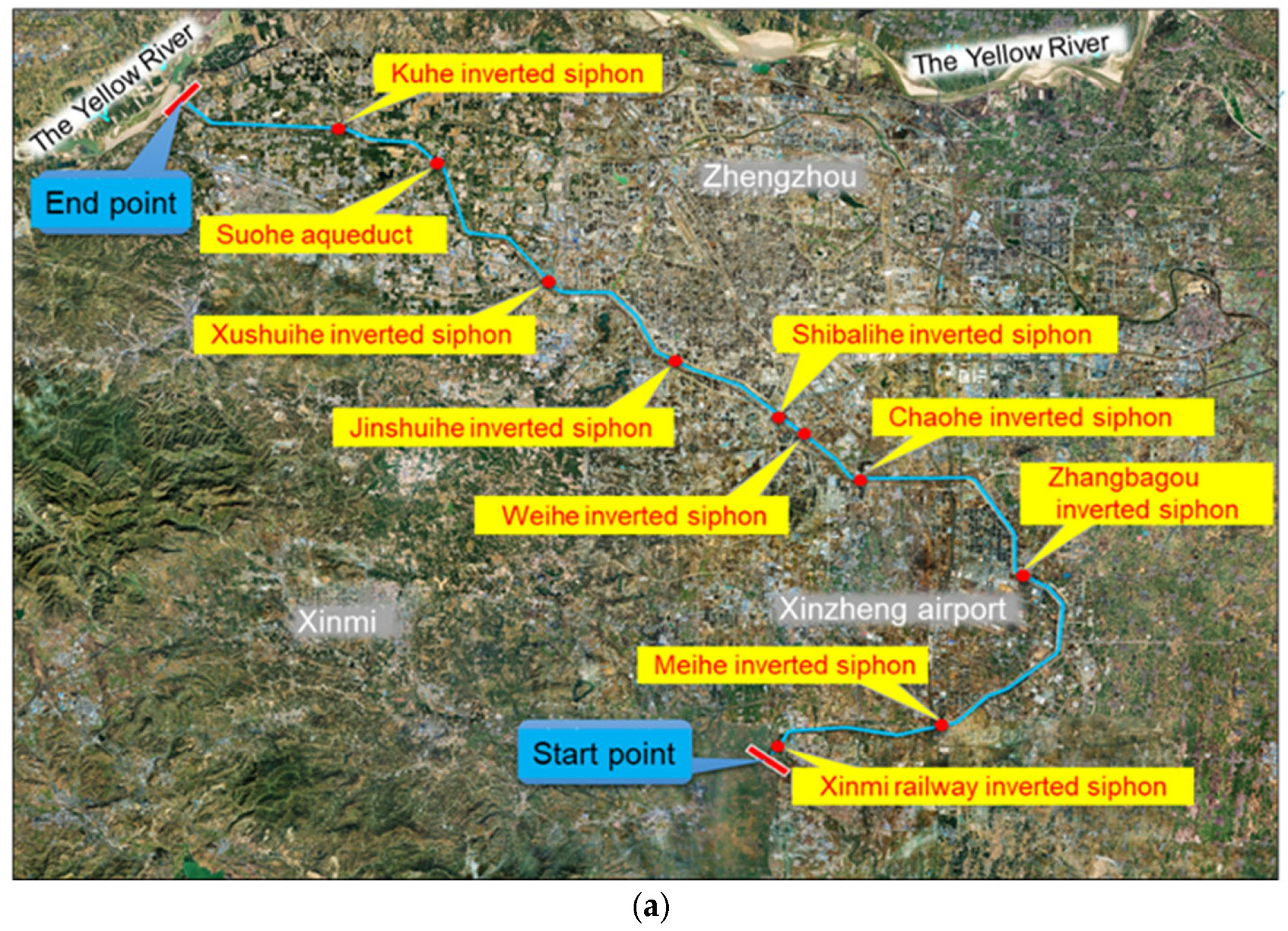

2. Background

3. Research on the Hydraulic Characteristics of Inverted Siphons in Water Conveyance Channels

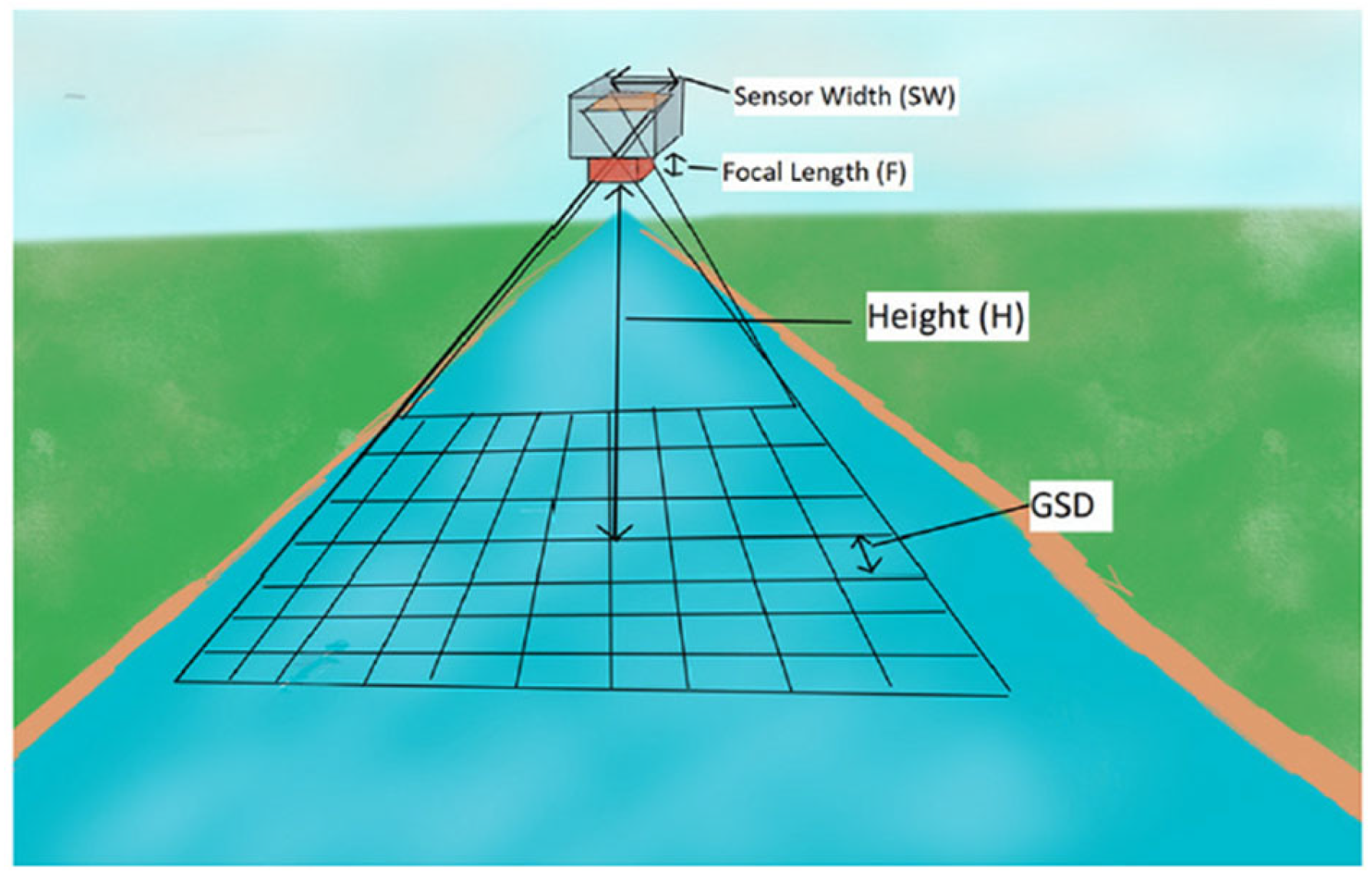

3.1. Unmanned Aerial Vehicle Photography Combined with Velocity Measurements of the Surface Flow Field of Traceless Particles

3.2. Acoustic Doppler Current Profiler (ADCP) Cross-Sectional Velocity Measurements

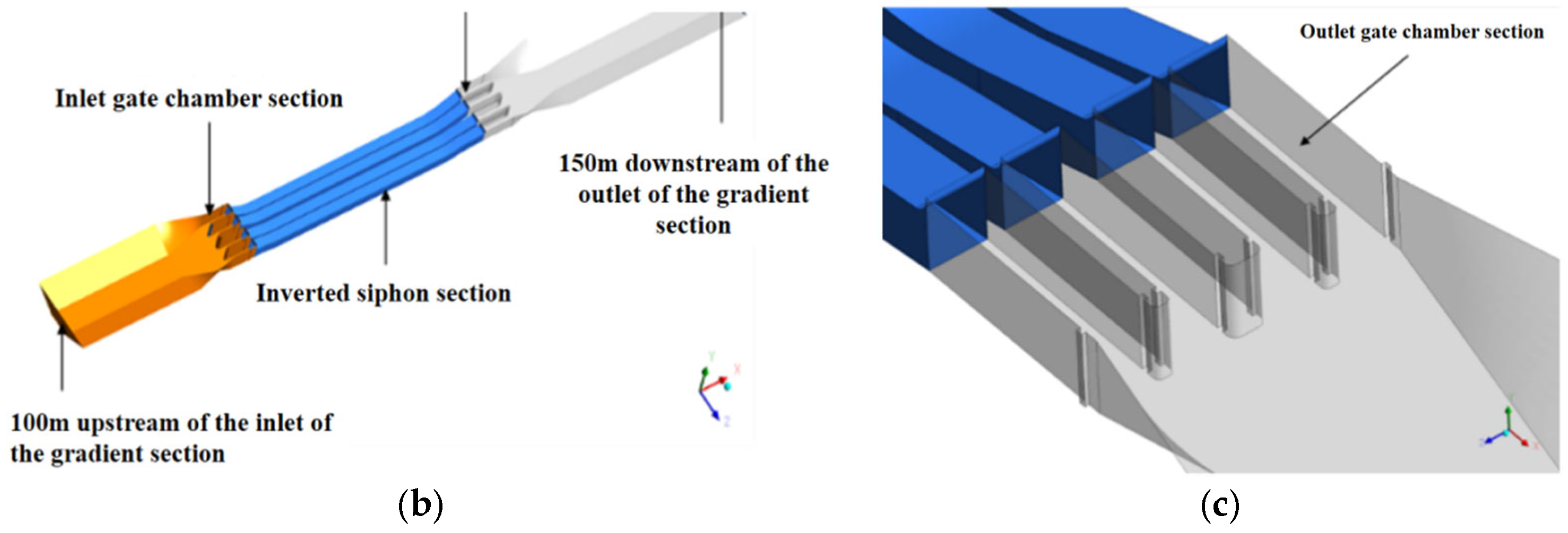

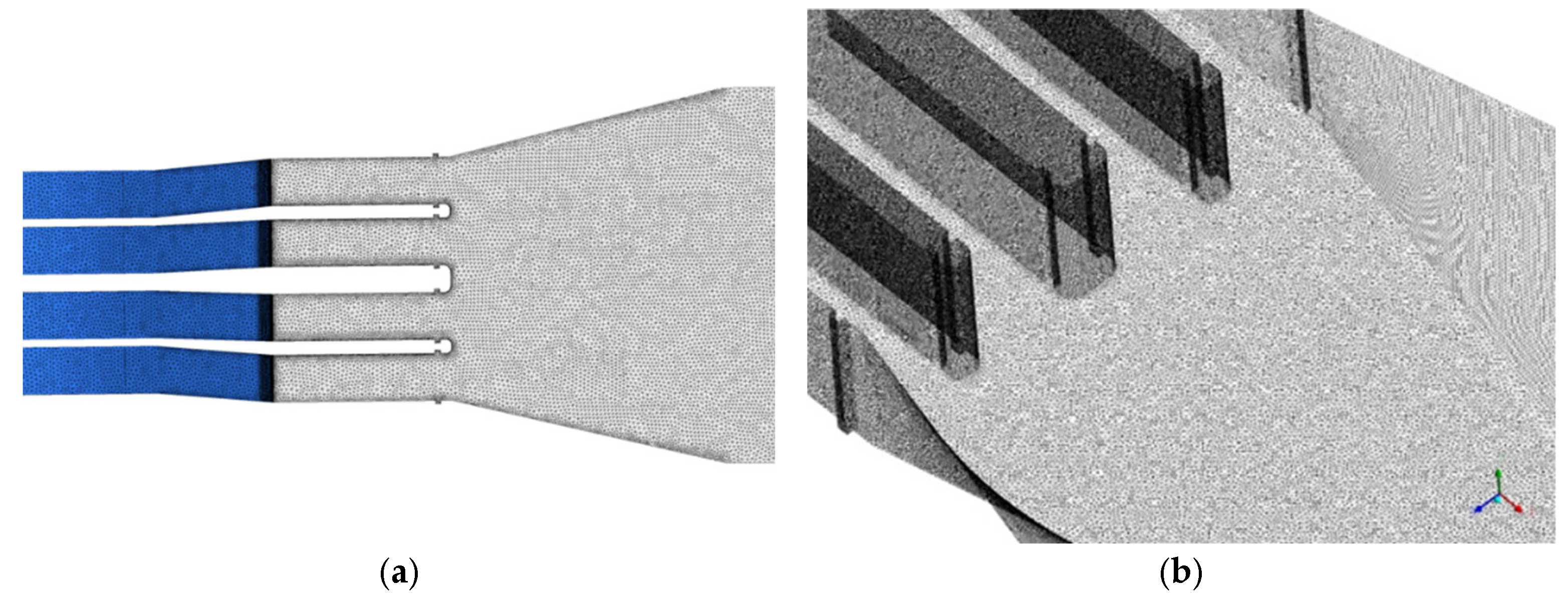

3.3. Geometric Modeling and Numerical Simulations

- (1)

- Geometric modeling and meshing

- (2)

- Computation method

- (3)

- Model validation

4. Results

4.1. Hydraulic Characteristics of Inverted Siphons in Water Conveyance Channels Before the Implementation of Flow Pattern Optimization Measures

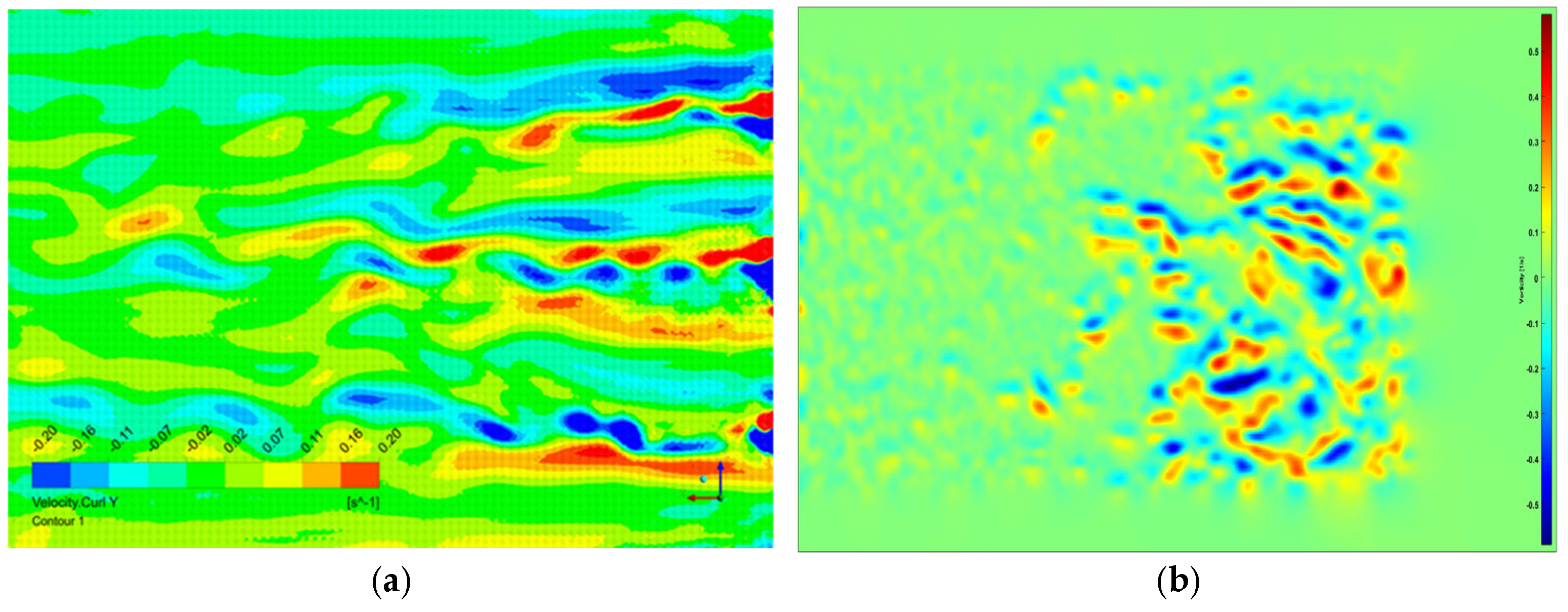

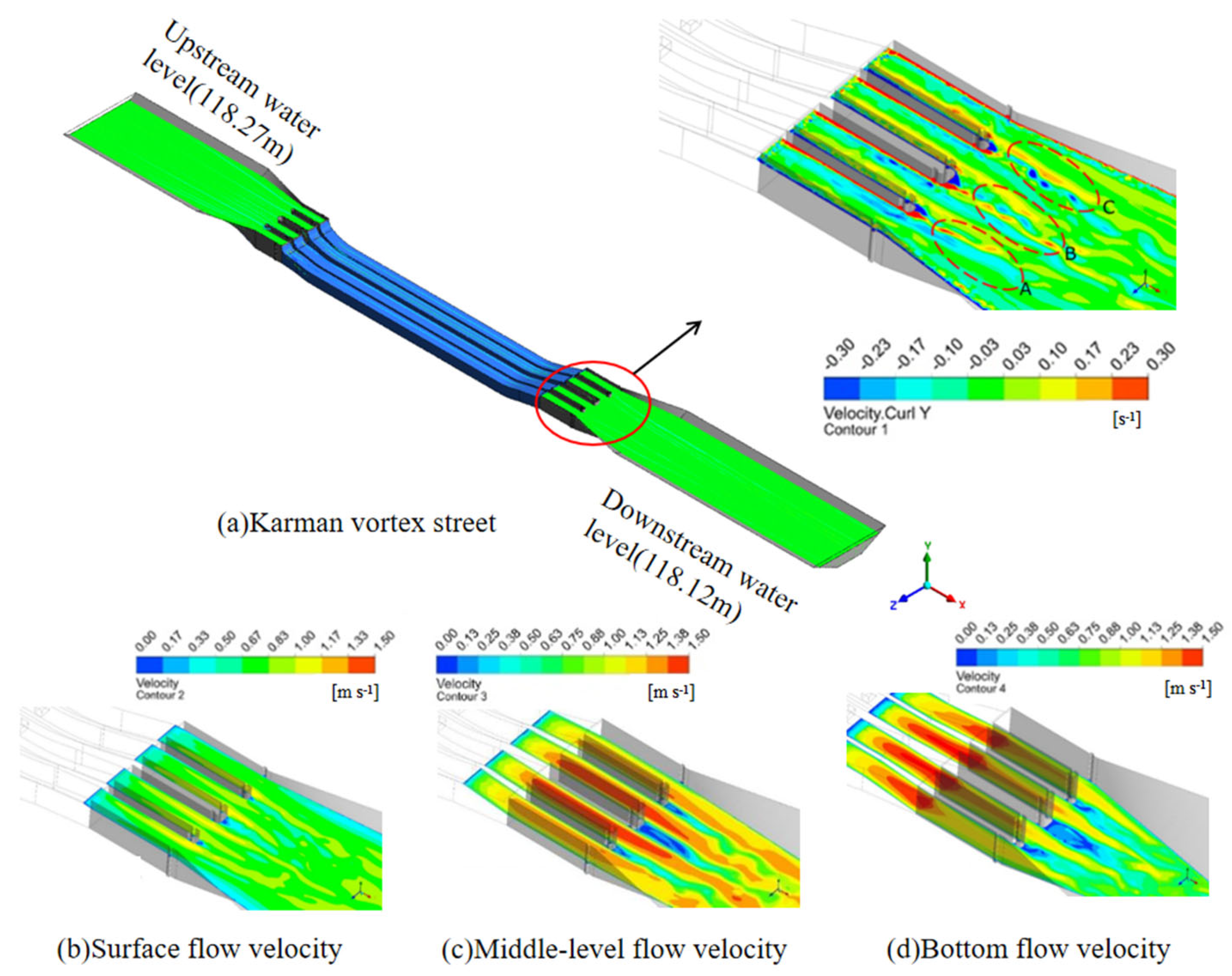

4.1.1. Flow Field Under the Dispatching Flow Condition

4.1.2. Flow-Field Results Under the Design Flow Condition

4.2. Hydraulic Characteristics of Inverted Siphons in Water Conveyance Channels After the Implementation of Flow Pattern Optimization Measures

4.2.1. Flow-Field Results of the Dispatching Flow Condition

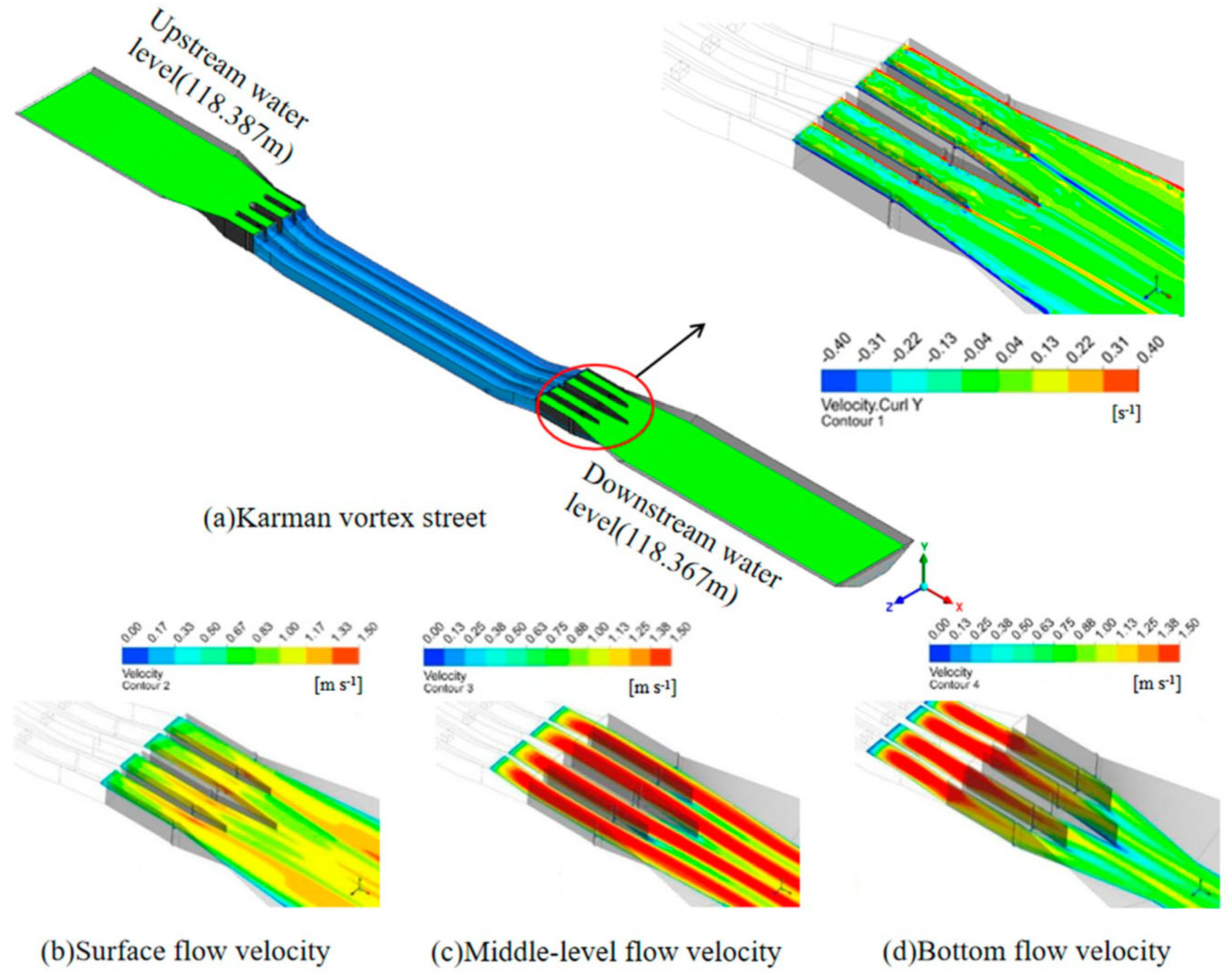

4.2.2. Flow Field Under the Design Flow Condition

4.3. Improvement in Hydraulic Characteristics of Inverted Siphons in Water Conveyance Channels

4.3.1. Improvement of the Hydraulic Loss

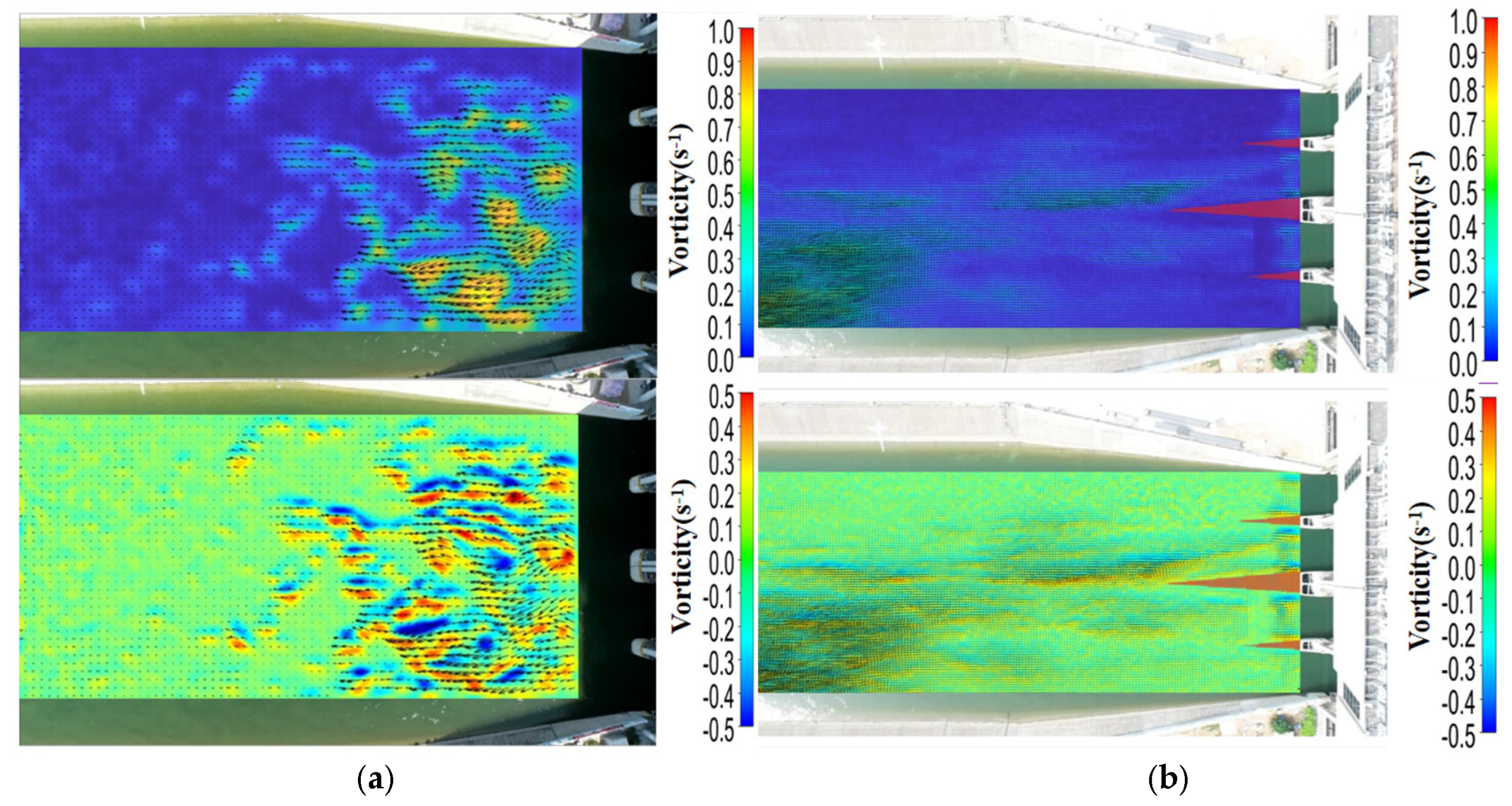

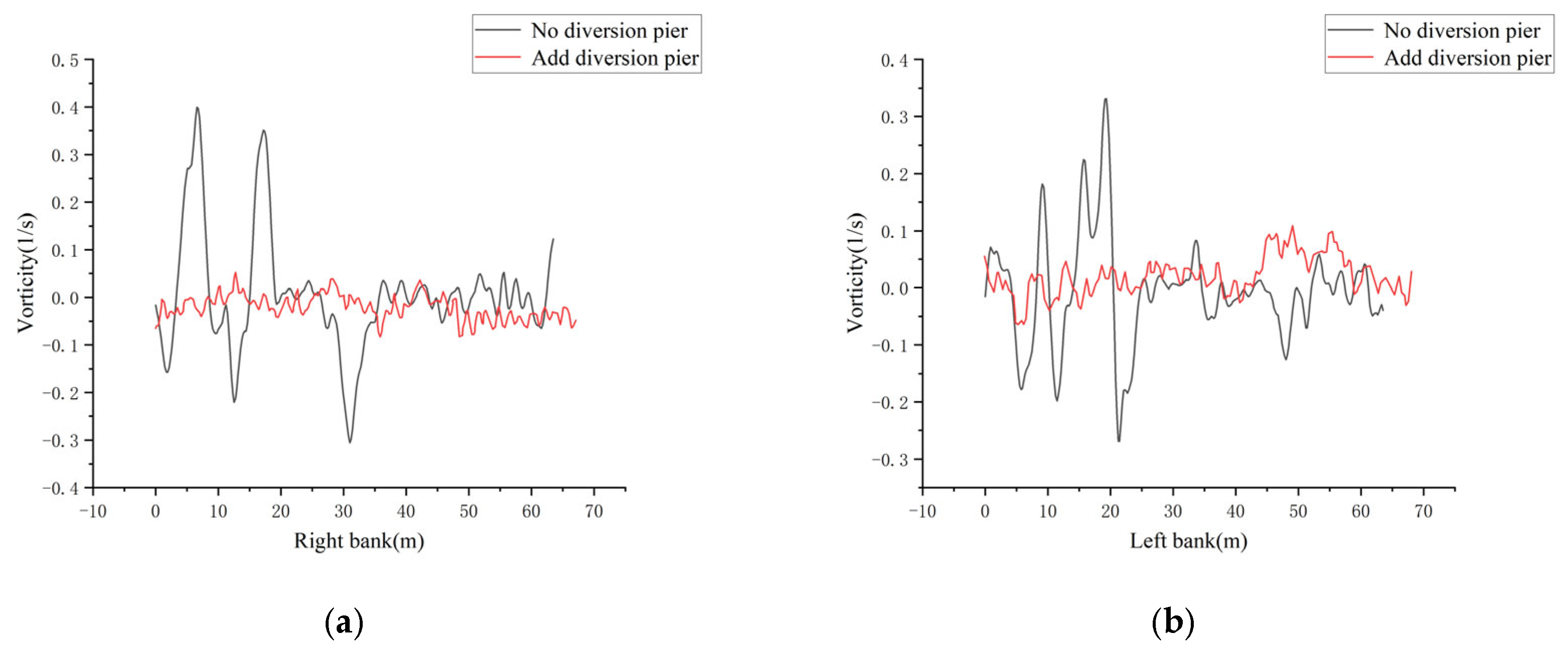

4.3.2. Improvement of the Surface Flow-Field Flow Pattern

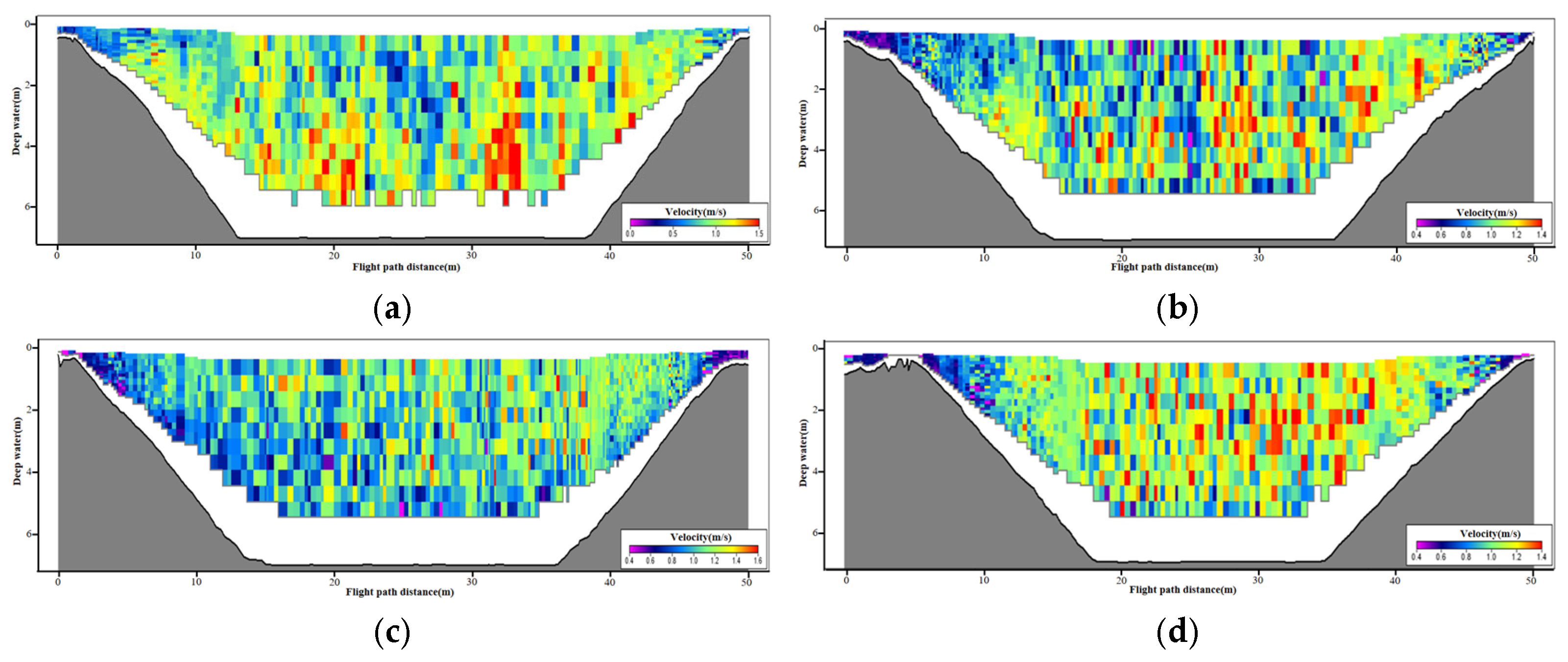

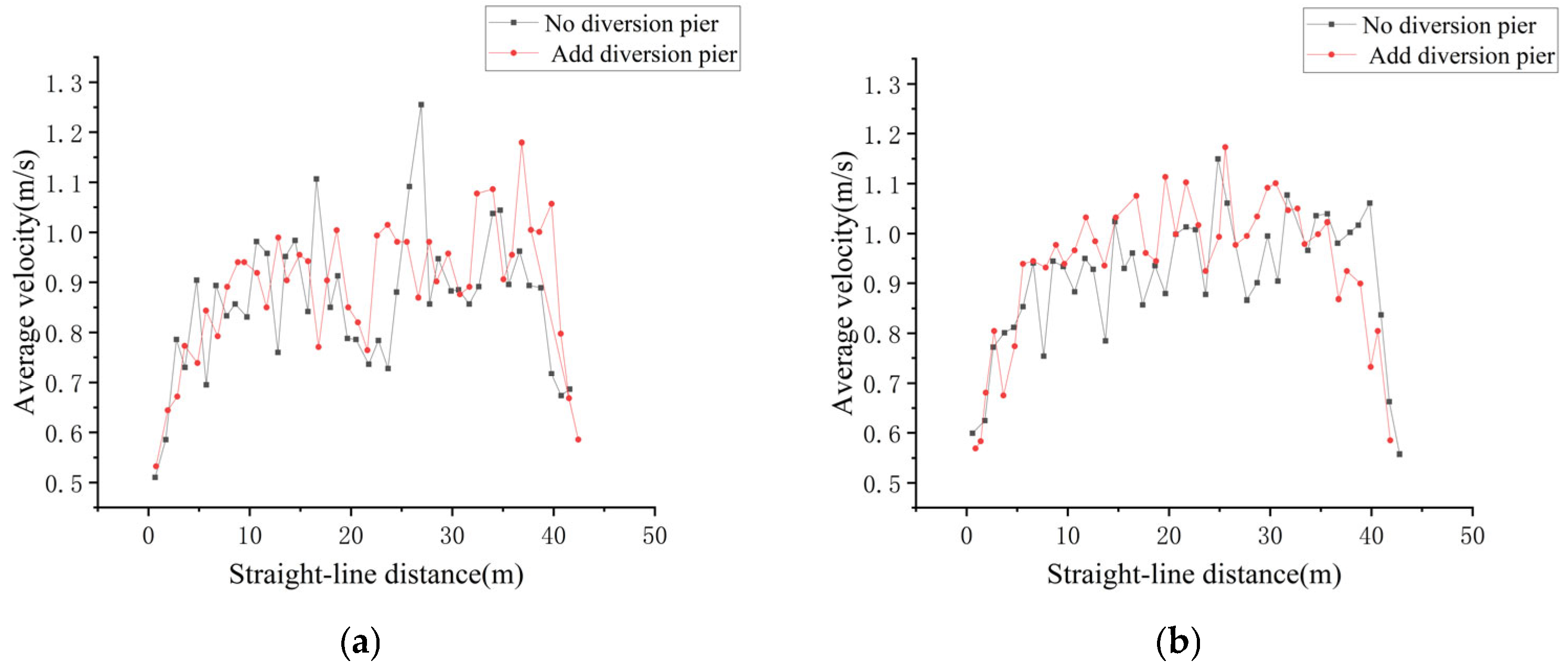

4.3.3. Improvement of the Flow Velocity Distribution on the Outlet Side

5. Discussion

5.1. Comparison of Hydraulic Characteristics of Inverted Siphons in Water Conveyance Channels Before and After the Implementation of Flow Pattern Optimization Measures

5.2. Improvement in Hydraulic Characteristics After the Implementation of Flow Pattern Optimization Measures

6. Conclusions

- (1)

- After implementation of the diversion piers, the water level fluctuation in the gate chamber of the channel inverted siphon significantly reduced, the head loss decreased, and the water conveyance capacity of the building was improved to a certain extent. Before implementation of the flow-state optimization measures, the water level difference of the Kuhe inverted siphon was 14.71 cm; after implementation of the flow pattern optimization measures, the water level difference was 13.56 cm. Thus, the hydraulic loss of the Kuhe inverted siphon was decreased by 11.5 mm, or approximately 7.8%. The flow capacity of the water conveyance structure was thus improved to a certain extent. Under the dispatching flow condition, the water conveyance flow of the Kuhe inverted siphon was increased by approximately 4.11%.

- (2)

- The surface flow-field and cross-sectional analysis of the water flow in the characteristic area showed that before implementation of the flow pattern optimization measures, the three groups of vortex streets behind the three piers at the outlet of the Kuhe inverted siphon influenced each other, and the flow pattern was disorderly. After implementation of the flow pattern optimization measures, the Karman vortex street phenomenon downstream of the Kuhe inverted siphon was eliminated. The maximum vortex on the left side decreased from 0.34 s−1 to −0.062 s−1, whereas that on the right side decreased from 0.4 s−1 to 0.051 s−1. The average vortex along the channel was significantly reduced, the distribution tended to be uniform, and the pattern of the water flow was significantly improved. ADCP measurements in typical sections showed that the flow velocity distribution in the section downstream of the Kuhe inverted siphon near the tail of the pier was more uniform, the sudden flow velocity drop in the central area of the section disappeared, and the Karman vortex street was eliminated.

- (3)

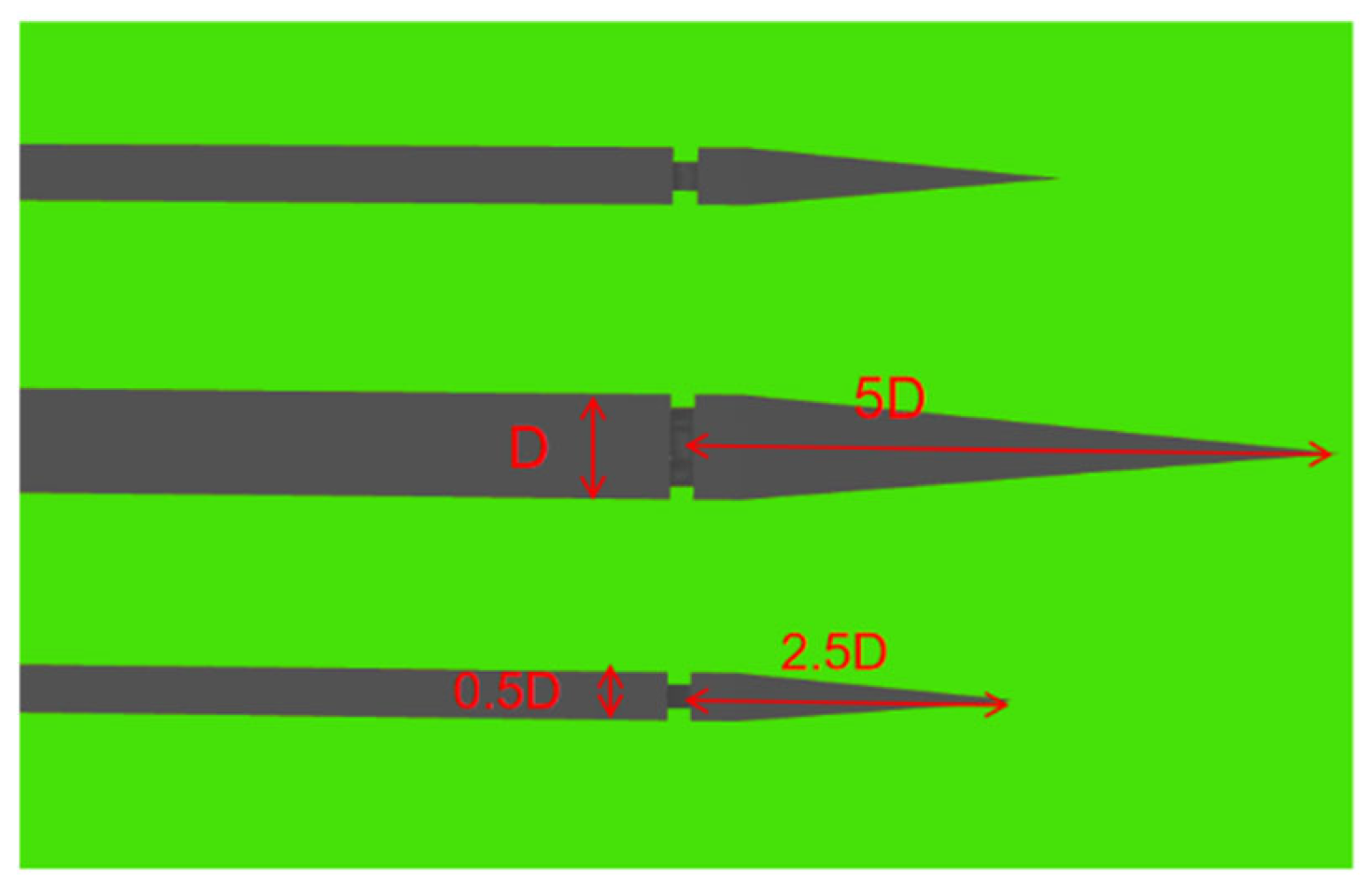

- Numerical simulations of the Kuhe inverted siphon were conducted. In the flow velocity distribution under the dispatching and design flow conditions, after adding the 5D diversion pier, the overall flow velocities of the surface and middle layers were increased, while the overall flow velocity of the bottom layer decreased slightly. Adding the 5D diversion pier showed that the flow pattern optimization measures had a significant inhibitory effect on the formation and development of the Karman vortex street behind the pier, and improvement in the flow pattern was evident.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, S.K.; Li, B.G. The huge comprehensive benefits of the South-to-North Water Diversion Project. South-North Water Transf. Water Sci. Technol. 2003, S1, 40–42. [Google Scholar]

- Qu, Z.G.; Li, Z.P. Causal analysis on water level abnormal fluctuation in aqueduct and improvement measures: Case of Lihe aqueduct in Middle Route of South to North Water Transfer Project. Yangtze River 2022, 53, 189–194. [Google Scholar]

- He, J.S.; Xu, X.J. An Empirical Study on the Economic Benefits of Water-Receiving Areas in Hebei Province by the Middle Route Project of the South-to-North Water Diversion Project. China Water Transp. 2022, 22, 39–41. [Google Scholar]

- Zhou, S.F.; Fu, Z.P.; Zhang, R.Y.; Lv, J.C. Experimental Study on Vortex Elimination Method of Inverted Siphon With Lateral Inlet. China Rural Water Hydropower 2022, 6, 54–59. [Google Scholar]

- Duan, W.G.; Huang, G.B.; Zhang, H.; Li, L. Experimental Research on Vortexes Eliminating of Several Typical Hydraulic Intakes. J. Chang. River Sci. Res. Inst. 2011, 28, 21–27. [Google Scholar]

- Shi, J.Y.; Tian, Z.Z. Experimental Study on the Reverse Siphon Hydraulics Model of the Qihe Canal, the Main Canal of the Middle Route of the South-to-North Water Diversion Project. Water Resour. Plan. Des. 2006, 1, 45–48. [Google Scholar]

- Li, S.P.; Zhao, Y.L.; He, F.C.; Zhao, X.P.; Wang, J.H.; Yuan, Q. Experimental Study on Optimization of Flow Pattern and Scouring of Xiaozhuanggou Inverted Siphon in the Middle Route of South to North Water Transfer Project. Yellow River 2021, 43, 131–146. [Google Scholar]

- Liu, M.X.; Wang, Z.Z.; Zhu, Y.J.; Hu, H.; Wang, P.; Sun, D. Unsteady Flow in Diffusion Section at the Outlet of Large Water Conveyance Tunnel. J. Irrig. Drain. 2023, 42, 107–116. [Google Scholar]

- Li, L.Q.; Chen, X.N.; Jiang, L.; Wang, S.T.; Xu, X.Y. Influence of the Tail Pier Lengthening on the Water Level Fluctuation Elimination in the South-to-North Water Diversion Aqueduct. China Rural Water Hydropower 2023, 1, 146–151. [Google Scholar]

- Li, J.; Mu, Z.W.; He, Z.Q.; Li, X. Numerical Simulation of Head Loss of Small-trough and Long-distance Inverted Siphon. South-North. Water Transf. Water Sci. Technol. 2013, 11, 70–73. [Google Scholar]

- Li, J.; Mu, Z.W.; Qi, S.L.; Li, X. Numerical Simulation of Hydraulic Performance of Filling Process in Long Inverted Siphon of Sangequan. Water Resour. Power 2014, 32, 86–89. [Google Scholar]

- Su, H.T.; Shi, D.L.; Yang, Q.Y.; Yan, W.; Chen, Z.B. Numerical simulation of two-phase flow during inverted siphon filling. Yangtze River 2021, 52, 220–227. [Google Scholar]

- Zhang, S.K.; Han, L.; Ye, K.H.; Hu, S. Study of Hydraulic Characteristics of Inverted Siphons with Large Flows. Water Resour. Power 2024, 8, 114–118. [Google Scholar]

- Jin, T.; Liao, Q. Application of large scale PIV in river surface turbulence measurements and water depth estimation. Flow. Meas. Instrum. 2019, 67, 142–152. [Google Scholar] [CrossRef]

- Muste, M.; Fujita, I.; Hauet, A. Large-scale particle image velocimetry for measurements in riverine environments. Water Resour. Res. 2008, 44, W00D19. [Google Scholar] [CrossRef]

- Lewis, Q.W.; Rhoads, B.L. Resolving two-dimensional flow structure in rivers using large-scale particle image velocimetry: An example from a stream confluence. Water Resour. Res. 2015, 51, 7977–7994. [Google Scholar] [CrossRef]

- Stamhuis, E.; Thielicke, W. PIVlab–towards user-friendly, affordable and accurate digital particle image velocimetry in MATLAB. J. Open Res. Softw. 2014, 2, 30. [Google Scholar]

- Thielicke, W.; Sonntag, R. Particle Image Velocimetry for MATLAB: Accuracy and enhanced algorithms in PIVlab. J. Open Res. Softw. 2021, 9, 12. [Google Scholar] [CrossRef]

- Cao, Z.Y.; Sun, D.J.; Zhang, Z.X.; Zhang, D.L.; Yong, J. Acoustic Doppler velocimetry technology and equipment. J. Harbin Eng. Univ. 2023, 44, 1914–1926. [Google Scholar]

- Deng, K.; Zhang, Z.W.; Yu, J.L.; Lu, S. Development of Acoustic Doppler Current Profiler at Home and Aboard. J. Mar. Inf. Technol. Appl. 2019, 34, 8–11. [Google Scholar]

- Xue, Y.Z.; Gu, J.H.; Wei, T.Y. The working principle of the acoustic doppler profiler and its applications in the middle and lower reaches of the Yangtze River. Mar. Sci. 2004, 10, 24–28. [Google Scholar]

- Hirsch, C. Numerical Computation of Internal and External Flows: Fundamentals of Computational Fluid Dynamics, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2007. [Google Scholar]

- Versteeg, H.; Malalasekra, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd ed.; Prentice Hall: London, UK, 2007. [Google Scholar]

- Moukalled, F.; Mangani, L.; Darwish, M. The Finite Volume Method in Computational Fluid Dynamics: An Advanced Introduction with OpenFOAM and Matlab; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Luo, C.; He, Y.; Shang, Y.; Cong, X.; Ding, C.; Cheng, L.; Lei, S. Flow Characteristics and Anti-Vortex in a Pump Station with Laterally Asymmetric Inflow. Processes 2022, 10, 2398. [Google Scholar] [CrossRef]

- Cong, G.H.; Wang, F.J. Applicability of turbulence models in numerical simulation of vortex flow in pump sump. Trans. Chin. Soc. Agric. Eng. 2008, 6, 31–35. [Google Scholar]

- Cheng, J.R. Turbulence Model and Finite Analysis Method; Shanghai Jiao Tong University Press: Shanghai, China, 1989. [Google Scholar]

- He, Z.Q.; Mu, Z.W.; Li, X.; Xu, L.L. Numerical Simulation of 3-D Flow Field of Inverted Siphon Imports and Exports Based on VOF Method. China Rural Water Hydropower 2012, 3, 94–96. [Google Scholar]

- Ge, J.J.; Ma, S.Y.; Li, Z.P.; Fan, M.S.; Wang, Y.F. Study on flow optimization in large transmission channel with siphon. China Rural Water Hydropower 2025, 1–20, in press. [Google Scholar]

| 100 m Upstream | 200 m Downstream | Water Level Difference (cm) | |

|---|---|---|---|

| On-site test period 1 | 118.304 | 118.1551 | 14.89 |

| On-site test period 2 | 118.2853 | 118.1378 | 14.75 |

| On-site test period 3 | 118.2901 | 118.1423 | 14.78 |

| On-site test period 4 | 118.2729 | 118.1258 | 14.71 |

| On-site test period 5 | 118.2735 | 118.1274 | 14.61 |

| On-site test period 6 | 118.2555 | 118.1127 | 14.28 |

| 100 m Upstream | 200 m Downstream | Water Level Difference (cm) | |

| On-site test period 7 | 118.2179 | 118.0806 | 13.73 |

| On-site test period 8 | 118.2179 | 118.0809 | 13.7 |

| On-site test period 9 | 118.2169 | 118.0819 | 13.9 |

| On-site test period 10 | 118.2189 | 118.0833 | 13.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Hu, J.; Yang, X.; Lou, L.; Mu, T.; Wang, D.; Hu, T. Influence of a Diversion Pier on the Hydraulic Characteristics of an Inverted Siphon in a Long-Distance Water Conveyance Channel. Water 2025, 17, 2378. https://doi.org/10.3390/w17162378

Wang J, Hu J, Yang X, Lou L, Mu T, Wang D, Hu T. Influence of a Diversion Pier on the Hydraulic Characteristics of an Inverted Siphon in a Long-Distance Water Conveyance Channel. Water. 2025; 17(16):2378. https://doi.org/10.3390/w17162378

Chicago/Turabian StyleWang, Jian, Jingyu Hu, Xiaoli Yang, Lifang Lou, Tong Mu, Dongsheng Wang, and Tengfei Hu. 2025. "Influence of a Diversion Pier on the Hydraulic Characteristics of an Inverted Siphon in a Long-Distance Water Conveyance Channel" Water 17, no. 16: 2378. https://doi.org/10.3390/w17162378

APA StyleWang, J., Hu, J., Yang, X., Lou, L., Mu, T., Wang, D., & Hu, T. (2025). Influence of a Diversion Pier on the Hydraulic Characteristics of an Inverted Siphon in a Long-Distance Water Conveyance Channel. Water, 17(16), 2378. https://doi.org/10.3390/w17162378