Study on the Hydrogeological Characteristics of Roof Limestone Aquifers After Mining Damage in Karst Mining Areas

Abstract

1. Introduction

2. Materials and Methods

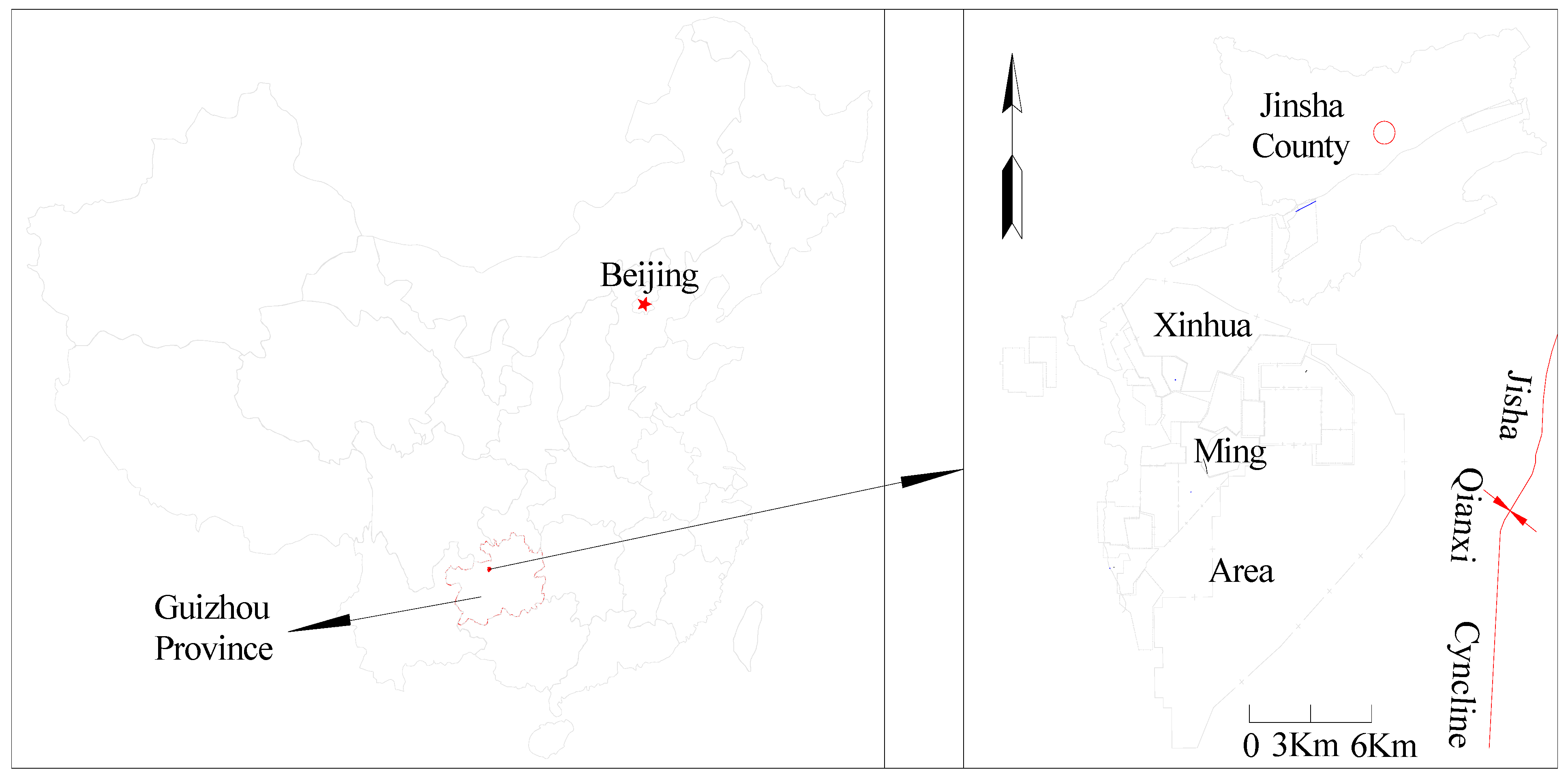

2.1. Overview of the Research Region

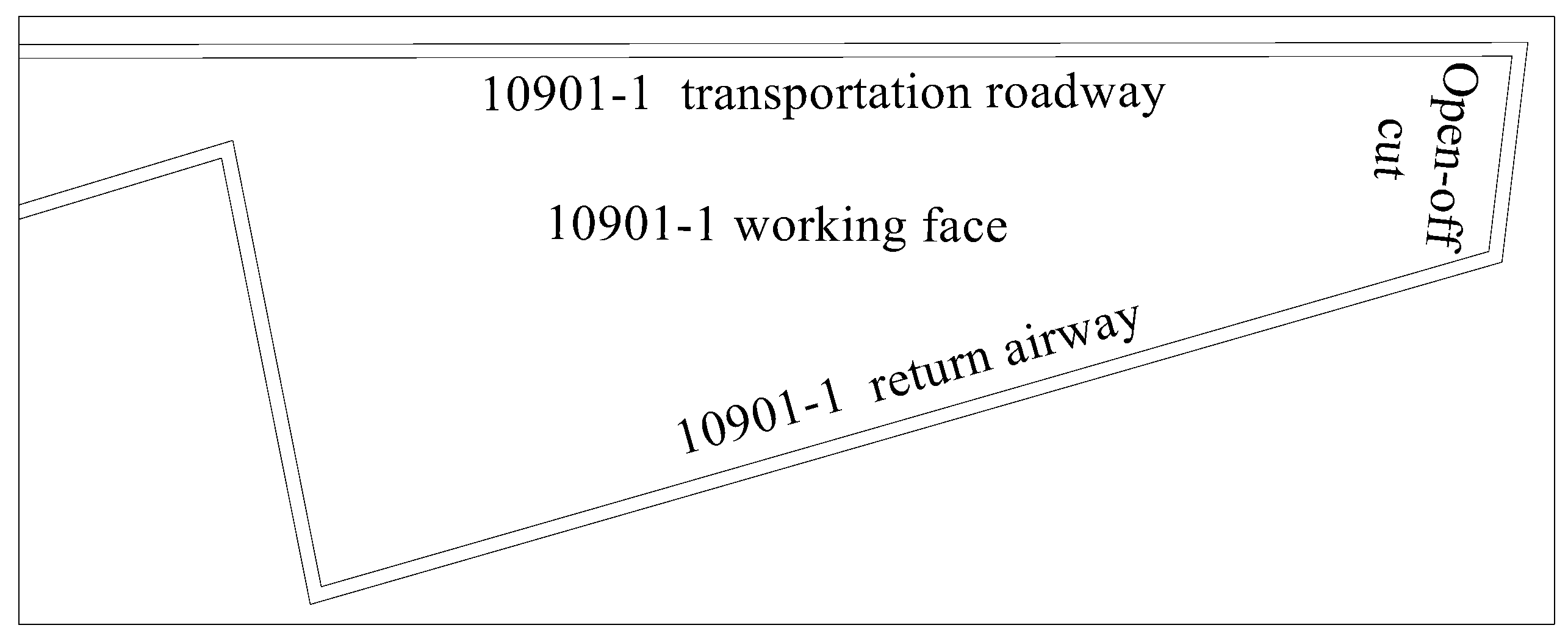

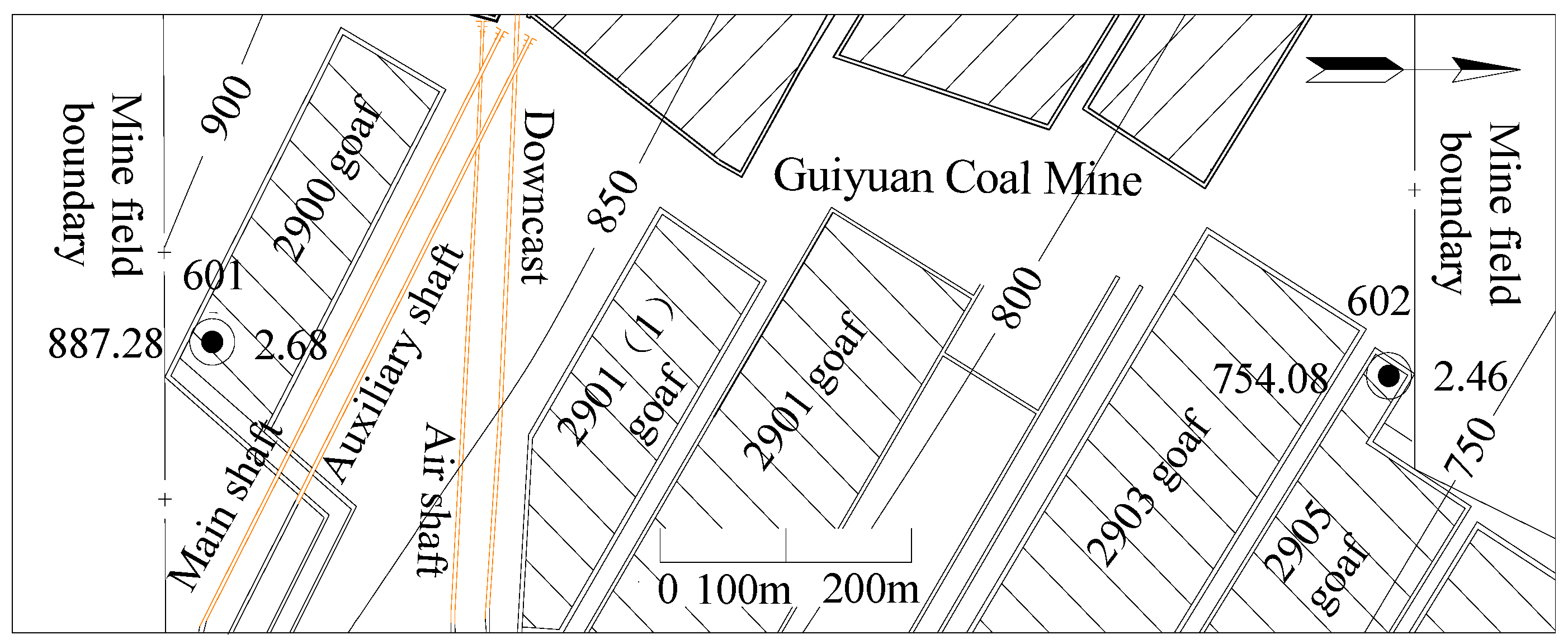

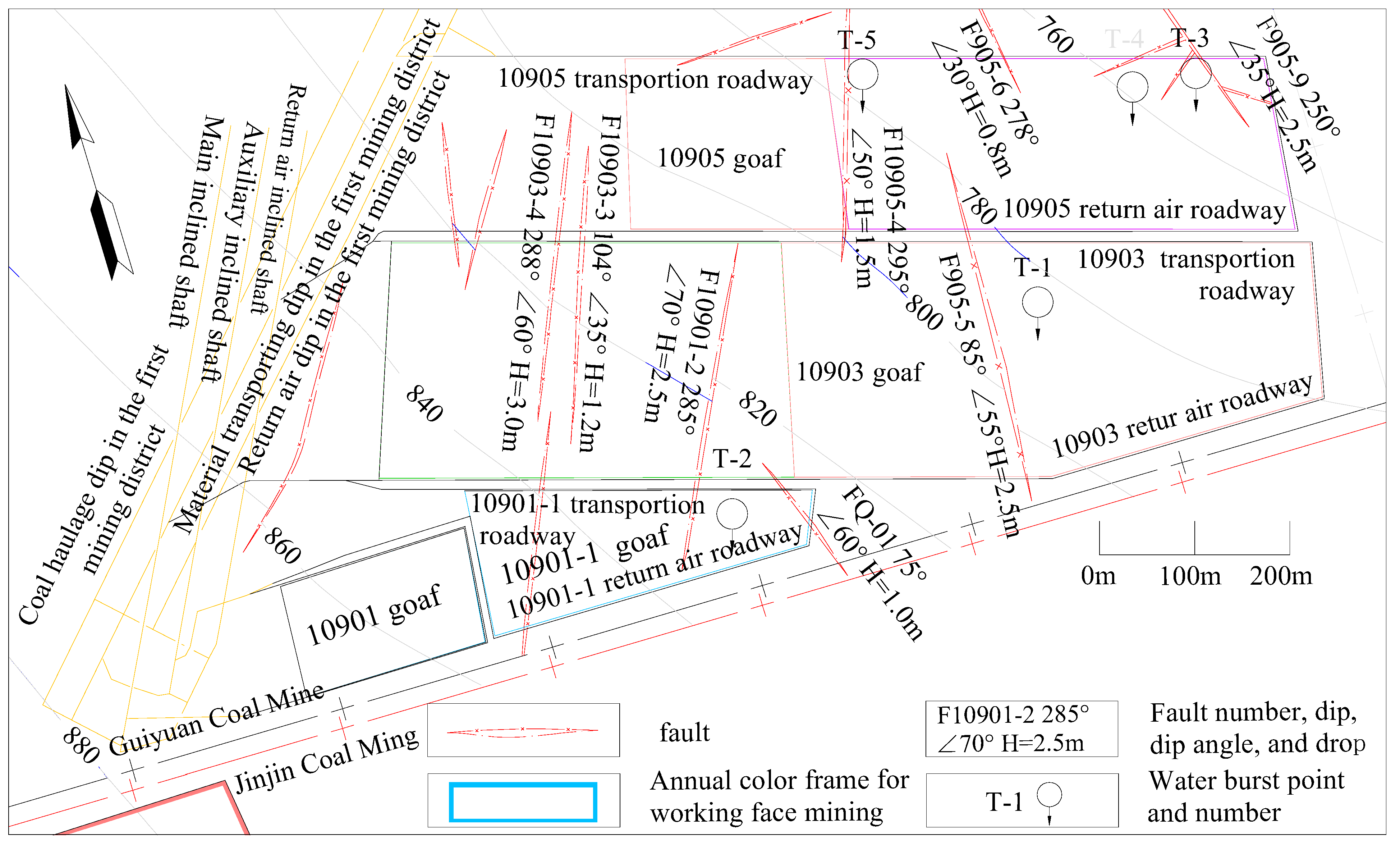

2.1.1. General Overview of the Mining Region

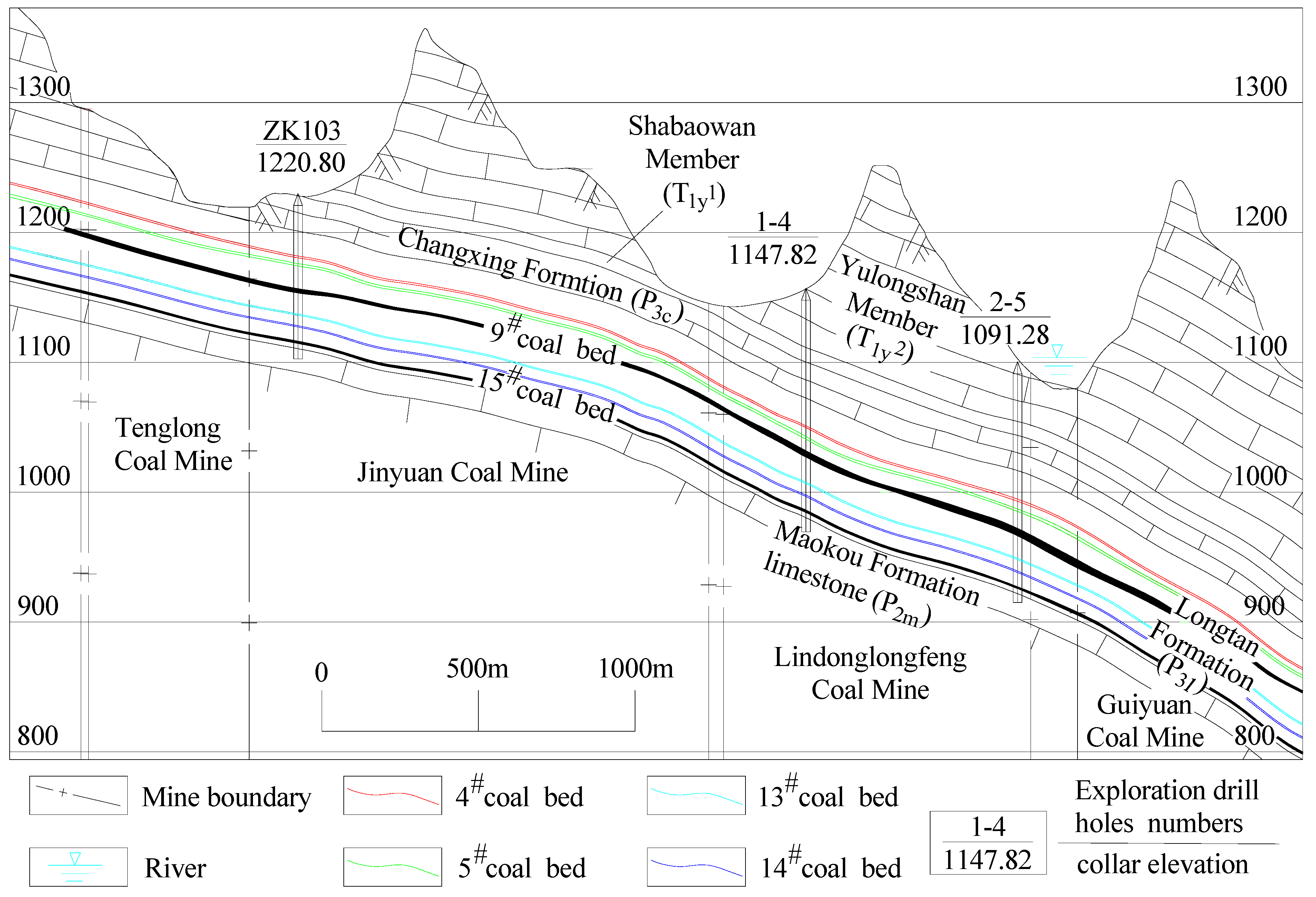

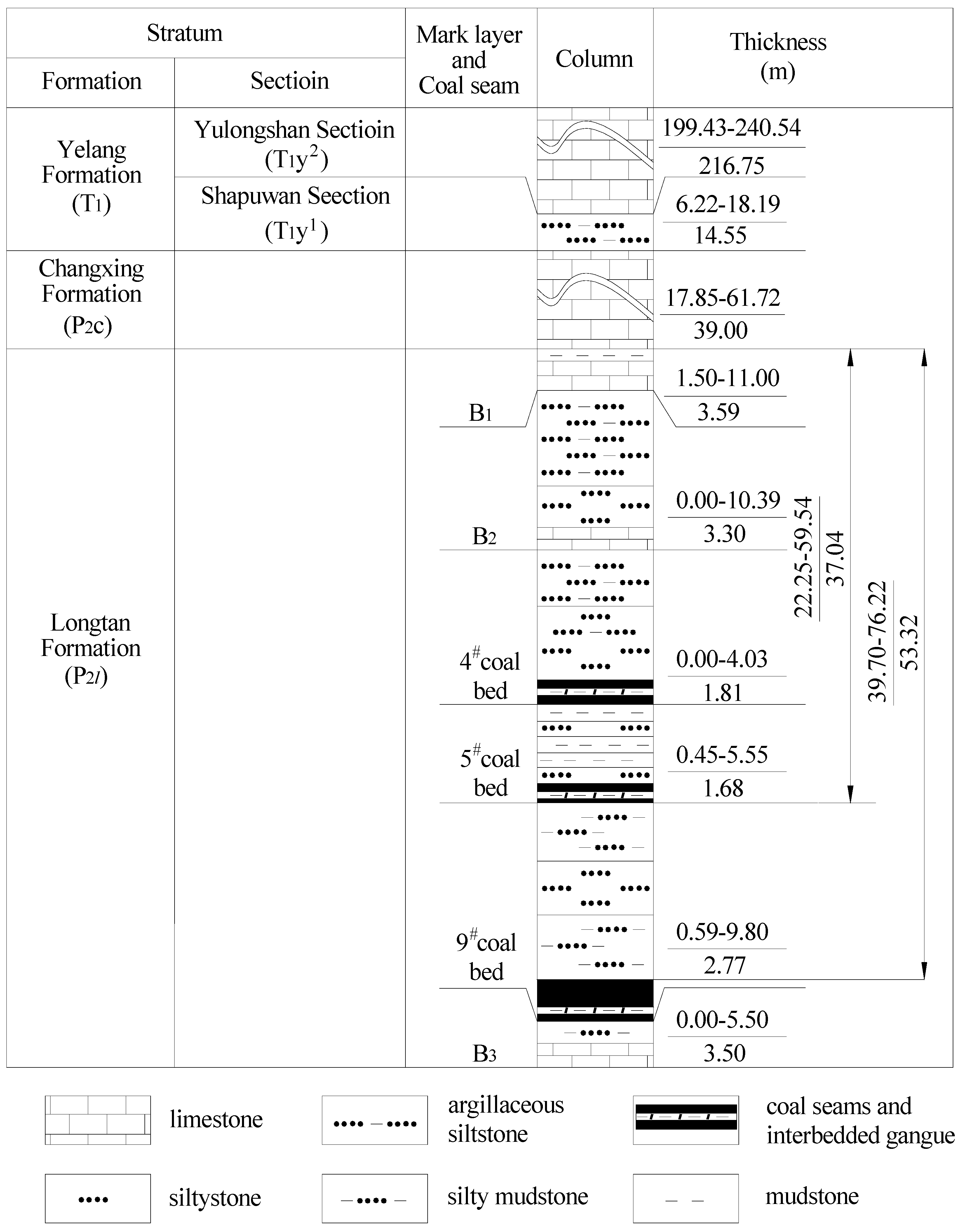

2.1.2. Geology of the Mining Region

2.1.3. Hydrogeological Conditions in the Mining Region

2.2. Geological Data Collection and Analysis

2.3. Research Methods for Analyzing the Roof Damage Height

2.3.1. Establishment of the Empirical Model

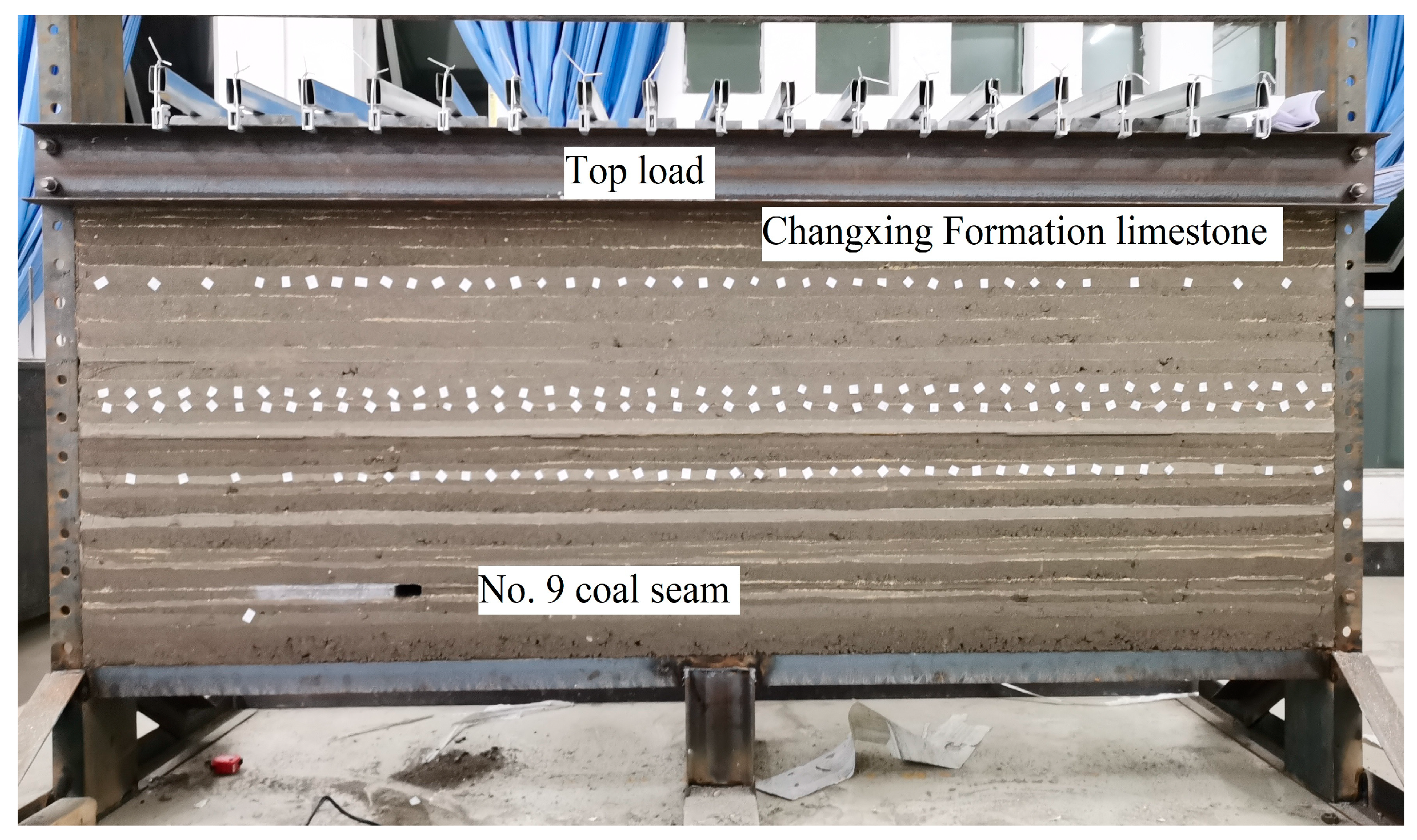

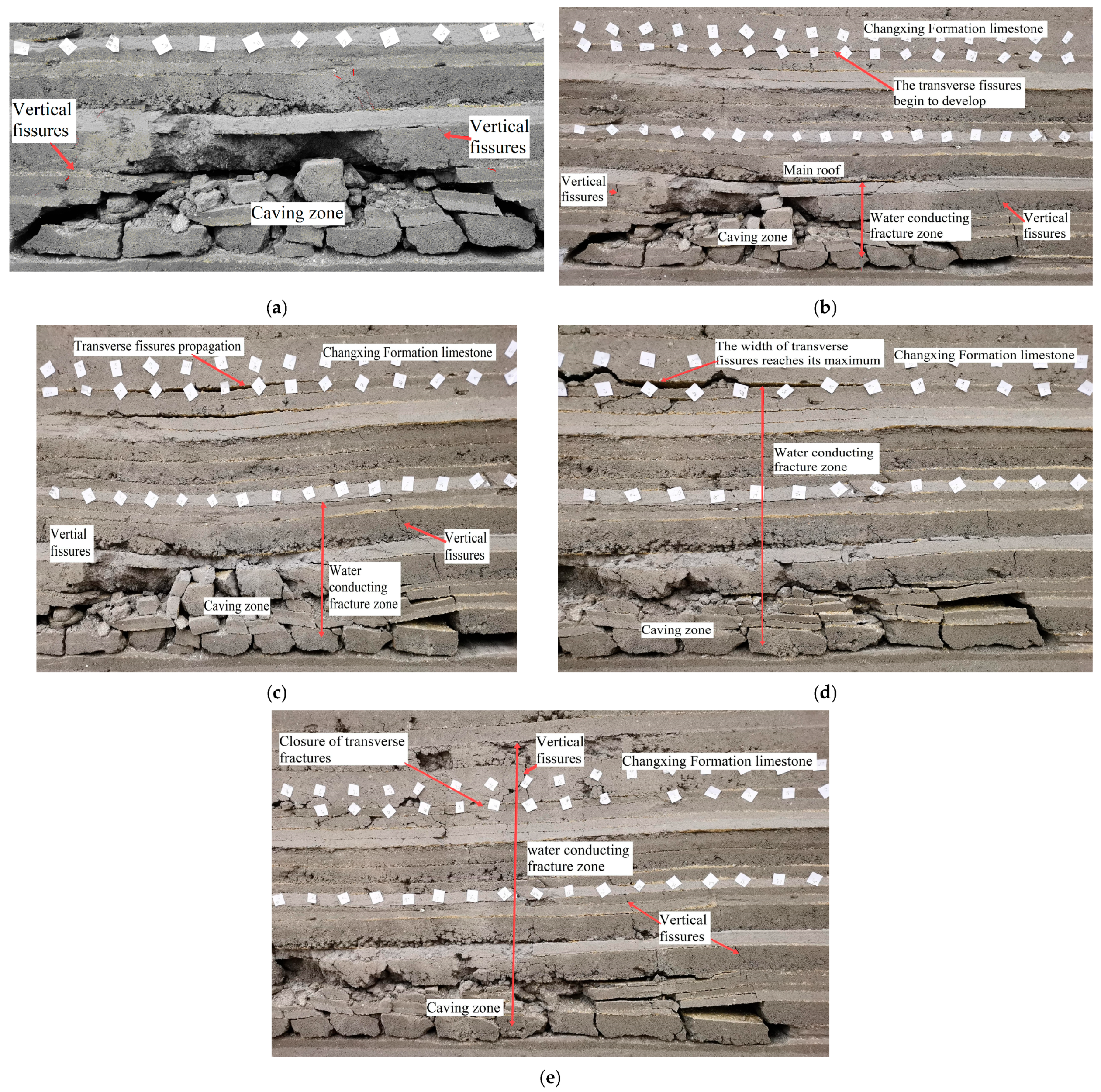

2.3.2. Simulation of the Water-Conducting Fracture Zone Height

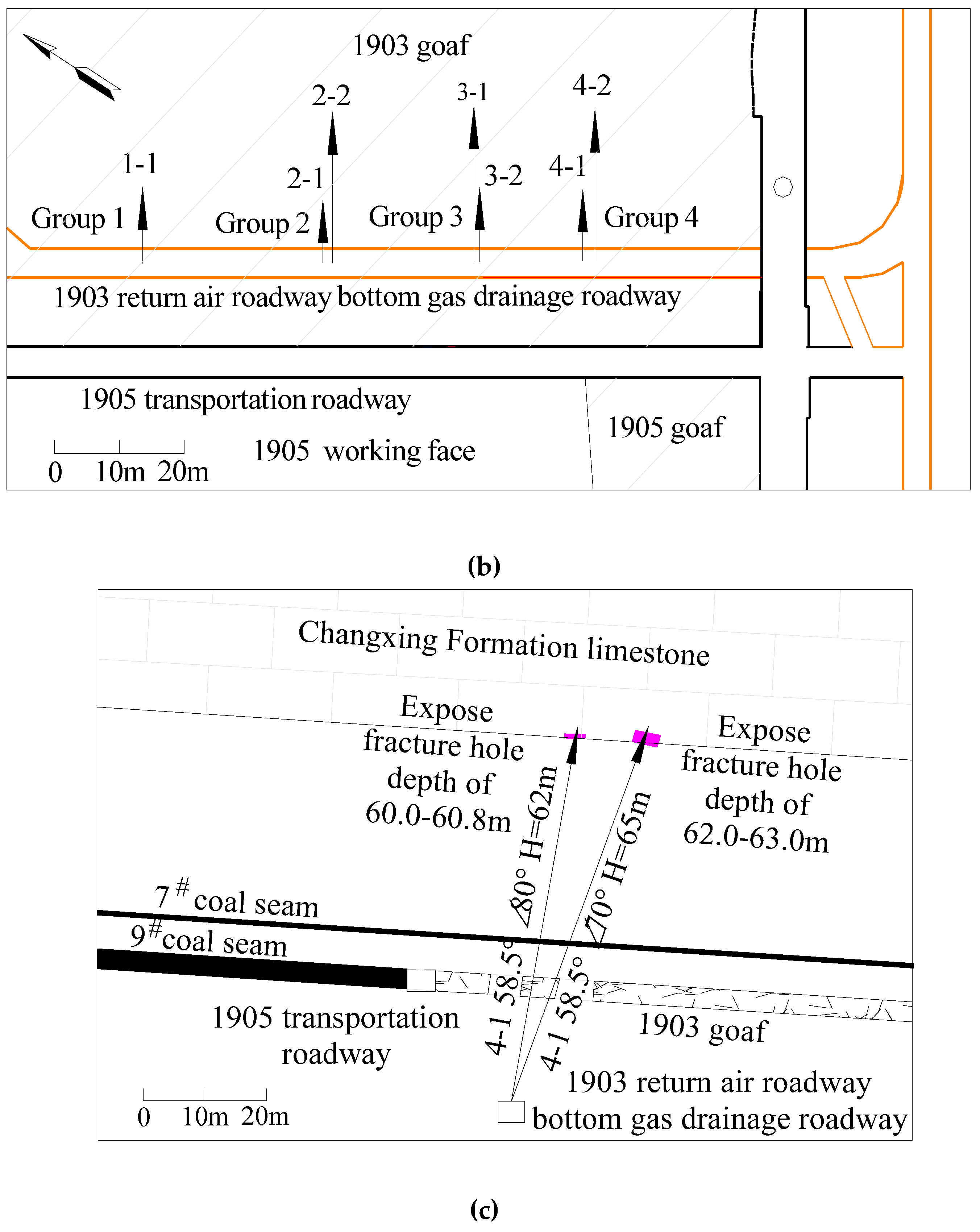

2.3.3. Ground Exploration via Drilling

3. Study on the Damage Characteristics of the Changxing Formation Limestone After Coalbed Mining

3.1. Research on the Height of the Mining-Induced Fracture Zone

3.1.1. Calculation of the Empirical Model

3.1.2. Results of the Simulation of Similar Materials

3.1.3. Ground Drilling-Based Measurement of the Height of the Water Conducting Fracture Zone

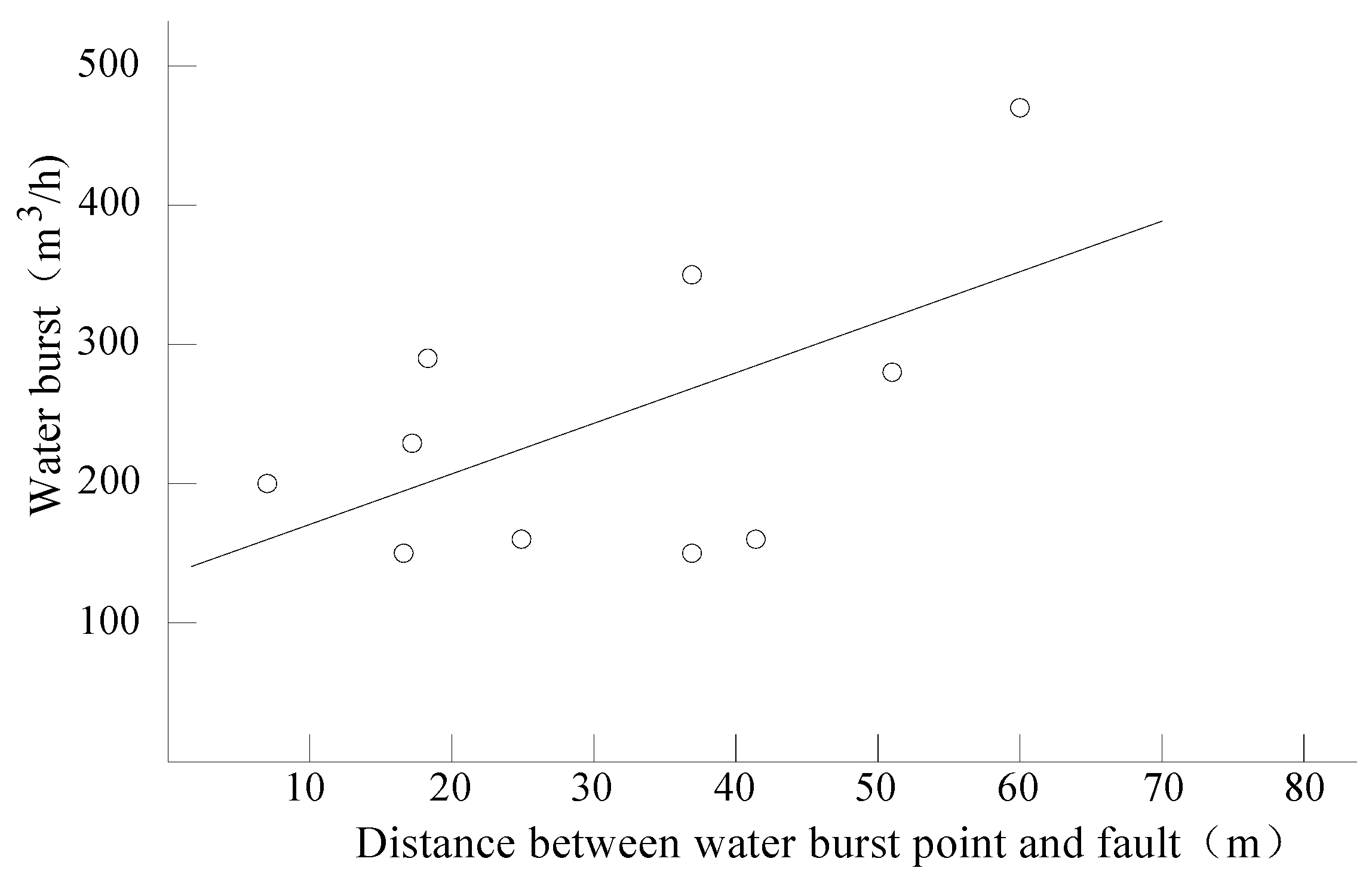

3.2. Fault Rerupture

4. Study on the Water-Rich Characteristics of the Changxing Formation Limestone After Mining Damage

4.1. Water-Rich Characteristics of the Limestone in Its Original State

4.2. Water-Rich Characteristics of the Changxing Formation Limestone After Mining Damage

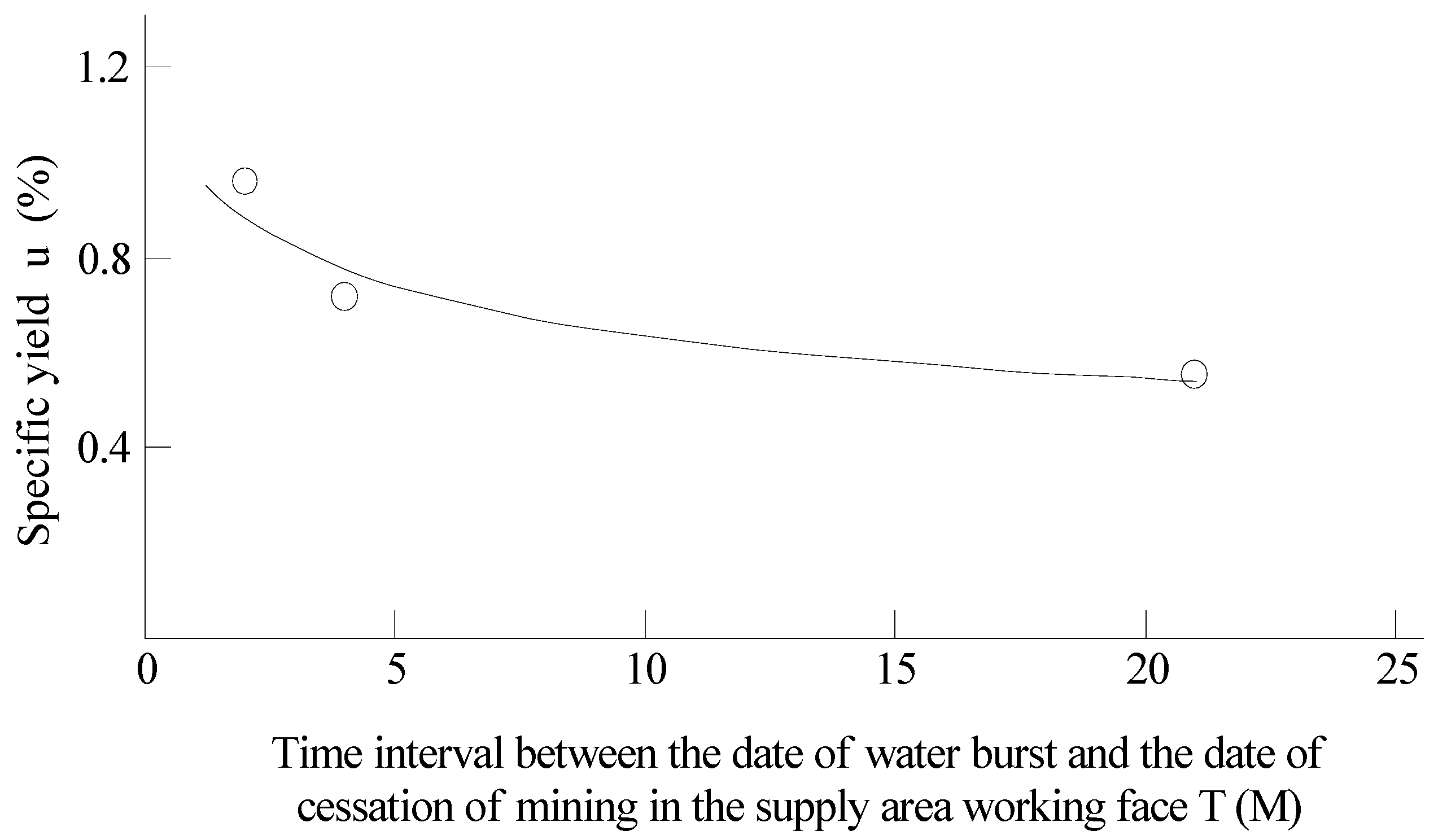

4.3. Characteristics of the Variation in the Specific Yield After Mining Damage

| Mine | Water Burst-Affected Working Face | Water Burst Inflow (Static Replenishment Quantity Qs) (m3) | Supply Goaf Area (m2) | Thickness of the Changxing Formation Limestone (m) | Changxing Formation Limestone Volume V (m3) | Water Burst Time of the Working Face (Day, Month, Year) | Latest Production Stoppage Time of the Goaf (Month, Year) |

|---|---|---|---|---|---|---|---|

| Anshenglongfeng Coal Mine | 1095 | 101,337 | 271,290 | 38.37 | 10,588,444 | 12 April 2023 | February 2023 |

| Guiyuan Coal Mine | 10901-1 | 76,000 | 10,630,885 | 44.11 | 10,635,885 | 25 February 2019 | August 2018 |

| Lindonglongfeng Coal Mine | 5914 | 43,260 | 195,521 | 40.00 | 7,820,840 | 24 March 2020 | May 2018 |

5. Application of the Research Results

5.1. Design Optimization of the Working Face

5.2. Enhancing the Disaster Resistance Capability of the Drainage System

5.3. Geophysical Exploration and Drilling Measures

6. Conclusions

- (1)

- The similar-material simulation test results and ground measurement data verified that the height of the water-conducting fracture zone is not less than 25.78 times the mining height, which is much greater than the empirical calculation values (from 13.0–15.8). The height of the water-conducting fracture zone extends to the Changxing Formation limestone, leading to the development of fractures in this limestone.

- (2)

- The fractures caused by coalbed mining and the secondary fractures of faults were connected to the primary dissolution fissures and karst caves in the rock mass, resulting in the transformation of the Changxing Formation limestone from a weak water-rich (permeable) aquifer to a strong water-rich (permeable) aquifer, thereby serving as a water burst source in the mining region.

- (3)

- The specific yield of the Changxing Formation limestone after the occurrence of mining damage decreased with an increasing water burst time and interval after the cessation of mining in the supply area. The regression equation is u = 1.0513d−0.2189, which demonstrates a high degree of correlation between the variables.

- (4)

- This study provides a theoretical basis and practical experience for water hazard prevention and control in mining areas (wells) with similar hydrogeological conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, B.; Wu, H.; Wu, Q.; Zeng, Y.; Guo, X. Prediction technology of mine water inflow based on entropy weight method and multiple nonlinear regression theory and its application. Geomech. Geophys. Geo-Energ. Geo-Resour. 2024, 10, 127. [Google Scholar] [CrossRef]

- Wang, H.J. Prediction of water inflow in Huoshaopu Coal Mine in Panxian basin, Guizhou Province. China Coal Geol. 2019, 31, 44–51. [Google Scholar]

- Suo, J.; Qin, Q.; Wang, W.; Li, Z.; Huang, C.; Xu, Y.; Chen, Z.; Liu, J. Disastrous mechanism of water burst by karst roof channel in rocky desertification mining area in southwest China. Geofluids 2022, 2022, 7332182. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, W. Characteristics of an underground stope channel supplied by atmospheric precipitation and its water disaster prevention in the karst mining areas of Guizhou. Sci. Rep. 2023, 13, 15892. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Li, B.; Yang, Y.; Li, M.; Li, T.; Zhang, B.; Zheng, L.; Duan, H.; Liu, P.; Hu, X.; et al. Construction and application of optimized model for mine water inflow prediction based on neural network and ARIMA model. Sci. Rep. 2025, 15, 2009. [Google Scholar] [CrossRef]

- Li, Z.H.; Li, S.T.; Du, F.; Wang, W.Q.; Li, J.W.; Jiao, Y.; Fan, X. Research on the development law of karst caves on water conducting fractures under the influence of mining in southwest karst mining areas. Coal Sci. Technol. 2023, 51, 106–117. [Google Scholar]

- Wang, Y.; Kong, D.; Wu, G.; Cheng, Z.; Song, G.; Shang, Y. Failure mechanism and movement characteristics of overlying strata in longwall mining face with thick aquifer. Rock. Mech. Rock. Eng. 2024, 57, 6787–6809. [Google Scholar] [CrossRef]

- Shi, X.; Xu, G.; Zhu, S. Water-filling characteristics and water source of weakly rich aater and weakly conducting water aquifers in the Changxing Formation after mining damages. Appl. Sci. 2024, 14, 4018. [Google Scholar] [CrossRef]

- Jin, M.F.; Yao, X.S.; Zhang, W.P.; Qin, X.F.; Yang, X. Technical study on formation mechanism and comprehensive prevention and control of separated layer water in Changxing Formation of Qianbei Coal Field. Coal Technol. 2023, 42, 128–132. [Google Scholar]

- Zheng, G. Analysis of the formation mechanism of water and gangue collapse accidents in Tenglong Coal Mine, Guizhou Province. China Coal Geol. 2024, 36, 43–46+5. [Google Scholar]

- Xu, J.; Zheng, L.; Lan, H.; Zuo, Y.; Li, B.; Tian, S.; Tian, Y. Research on an identification model for mine water inrush sources based on the HBA-CatBoost algorithm. Sci. Rep. 2024, 14, 23508. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Shi, H.; Wang, K.; Geng, Y.; Chen, J. Physical simulation of strata failure and its impact on overlying unconsolidated aquifer at various mining depths. Water 2018, 10, 650. [Google Scholar] [CrossRef]

- Xiao, L.; Li, F.; Niu, C.; Dai, G.; Qiao, Q.; Lin, C. Evaluation of water inrush hazard in coal seam roof Based on the AHP-CRITIC composite weighted method. Energies 2023, 16, 114. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, X.; Ke, F.; Liu, J.; Yao, Q.; Luo, H.; Li, X.; Xu, Y. Evolution of Overlying Strata Bed Separation and Water Inrush Hazard Assessment in Fully Mechanized Longwall Top-Coal Caving of an Ultra-Thick Coal Seam. Water 2025, 17, 850. [Google Scholar] [CrossRef]

- Jin, D.W.; Li, C.F.; Liu, Y.F.; Cao, H.T.; Ren, D.J.; Wang, H.L.; Zhang, J.K.; Huang, Y.; Yang, G.D.; Guo, K.; et al. Characteristics of roof water hazard of coal seam in Huanglong Coalfield and key technologies for prevention and control. Coal Geol. Explor. 2023, 51, 205–213. [Google Scholar] [CrossRef]

- Shi, X.; Zhu, S.; Zhang, W. Study on the mechanisms and prevention of water inrush events in a deeply buried high-pressure coal seam-a case study of the Chensilou Coal Mine in China. Arab. J. Geosci. 2019, 12, 614. [Google Scholar] [CrossRef]

- Wu, Y.J. Key technology for double-layer hole treatment of water inrush disasters in high pressure aquifers. Coal Eng. 2024, 56, 86–92. [Google Scholar]

- Li, Y.; Zhang, Y.; Ma, Y.; Meng, F.; Guo, S. Risk analysis of coal seam floor water inrush based on GIS and combined weight TOPSIS method. All Earth 2024, 36, 2410108. [Google Scholar] [CrossRef]

- Zhang, W.J. Analysis of water drilling technology for exploring top plate sandstone in the 1013 working face of Yushuquan Coal Mine. Shandong Ind. Technol. 2015, 21, 41. [Google Scholar]

- Li, J.; He, Z.; Piao, C.; Chi, W.; Lu, Y. Research on subsidence prediction method of water-conducting fracture zone of overlying strata in coal mine based on grey theory model. Water 2023, 15, 4177. [Google Scholar] [CrossRef]

- Xu, J.; Yang, D.; Zhang, Z.; Sun, Y.; Zhao, L. Study on fracture evolution and water-conducting fracture zone height beneath the sandstone fissure confined aquifer. Sustainability 2024, 16, 6006. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, X.; Lan, H.; Ren, W.; Tian, Y.; Xu, J.; Tian, S. Study of the development patterns of water-conducting fracture zones under karst aquifers and the mechanism of water inrush. Sci. Rep. 2024, 14, 20790. [Google Scholar] [CrossRef]

- Gao, Z.; Xu, G.; Li, H.; Su, D.; Liu, Y. Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform. Processes 2023, 11, 3413. [Google Scholar] [CrossRef]

- Zhao, B.; He, S.; Bai, K.; Lu, X.; Wang, W. Elastic wave prospecting of water-conducting fractured zones in coal mining. Sci. Rep. 2024, 14, 7036. [Google Scholar] [CrossRef]

- Yang, T.; Deng, J.; Peng, B.; Zhang, J.; Zhang, Y.; Yan, Y. Simulated Prediction of Roof Water Breakout for High-Intensity Mining under Reservoirs in Mining Areas in Western China. Appl. Sci. 2023, 13, 9902. [Google Scholar] [CrossRef]

- State Administration of Work Safety; National Coal Mine Safety Supervision Bureau; National Energy Administration. Regulations for the Setting of Coal Pillars and Coal Mining in Buildings, Water Bodies, Railways, and Main Mines; Coal Industry Press: Sydney, Australia, 2017. [Google Scholar]

- Van Dyke, M.A.; Zhang, P.; Dougherty, H.; Su, D.; Kim, B.H. Identifying Longwall-Induced Fracture Zone Height Through Core Drilling. Min. Metall. Explor. 2022, 39, 1345–1355. [Google Scholar] [CrossRef]

- Li, Y.C. Research on the Law of Water Inrush Disasters Caused by Water Conducting Faults During Deep Buried Tunnel Excavation; Henan University of Technology: Zhengzhou, China, 2023. [Google Scholar]

- Mu, W.; Wu, X.; Deng, R.; Hao, Q.; Qian, C. Mechanism of Water Inrush Through Fault Zones Using a Coupled Fluid–solid Numerical Model: A Case Study in the Beiyangzhuang Coal Mine, Northern China. Mine Water Env. 2020, 39, 380–396. [Google Scholar] [CrossRef]

- Zhong, Z.-L.; Shen, Z.; Qiao, H.-Y.; Li, Y.-P.; Zhu, K.-X. Study on Mechanism of Water and Mud Inrush in Deep-Buried Large-Section Tunnel Crossing Water-Rich Fault Fracture Zone. Rock. Mech. Rock. Eng. 2025, 58, 1147–1164. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, S.; Zhang, W.; Li, B. Research on the mechanism and evolution Law of delayed water inrush caused by fault activation with mining. Water 2023, 15, 4209. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, Q.; Zhang, W. Evolution of mining-induced water inrush disaster from a hidden fault in coal seam floor based on a coupled stress–seepage–damage model. Geomech. Geophys. Geo-Energ. Geo-Resour. 2024, 10, 1–21. [Google Scholar] [CrossRef]

- Sun, W.B.; Zhang, J.Y.; Wang, X.; Yang, H.; Fan, J.C.; Olimov, A. Staged sensing method of fault sudden water based on gray correlation analysis. China Saf. Sci. J. 2024, 34, 63–70. [Google Scholar]

- Sun, H.; Pan, R.; Li, J.; Yang, B.; Wang, X. Research on the mechanism of fault activation and water inrush across variable coal pillar widths. Dvances Civ. Eng. 2024, 2024, 8557425. [Google Scholar] [CrossRef]

- Tang, L.; Tu, S.; Tu, H.; Zhang, L.; Miao, K.; Zhao, H.; Ma, J. Interaction law between mining stress and fault activation and the effect of fault dip angle in longwall working face. Sci. Rep. 2024, 14, 25654. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Liu, Q.M.; Jiang, Z.H.; Ju, Q.D. Analysis of surrounding rock damage and fault activation characteristics in coal seam mining. Mod. Min. 2019, 35, 140–142. [Google Scholar]

- Gou, R.; Jiang, C.; Liu, Y.; Wang, C.; Li, Y. Study on fractal characteristics of evolution of mining-induced fissures in karst landform. Energies 2022, 15, 5372. [Google Scholar] [CrossRef]

- Lan, T.; Liu, Y.; Yuan, Y.; Fang, P.; Ling, X.; Zhang, C.; Li, Y.; Li, Y.; Feng, W. Determination of mine fault activation degree and the division of tectonic stress hazard zones. Sci. Rep. 2024, 14, 12419. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Huang, Q.; Ma, L. Study on the mechanism and control of strong ground pressure in the mining of shallow buried close-distance coal seam passing through the loess hilly region. Geomech. Geophys. Geo-Energ. Geo-Resour. 2025, 11, 11–14. [Google Scholar] [CrossRef]

- Micarelli, L.; Benedicto, A.; Wibberley, C. Structural evolution and permeability of normal fault zones in highly porous carbonate rocks. J. Struct. Geol. 2006, 28, 1214–1227. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.H.; Lu, Z.H.; Guo, J.T.; Fu, Z.Y.; Sun, J.K. Effects of underground coal mining disturbance on bacterial community diversity and its assembly processes. PLoS ONE 2025, 20, e0322014. [Google Scholar] [CrossRef]

- Barkin, J.L.; Dimmock, J.; Heenan, L.; Clancy, J.; Carr, H.; Pardon, M.K. Threat Severity and Threat Susceptibility Are Significantly Correlated with Climate Distress in Australian Mothers. Climate 2024, 12, 168. [Google Scholar] [CrossRef]

- Goldscheider, N.; Chen, Z.; Auler, A.; Bakalowicz, M.; Broda, S.; Drew, D.; Hartmann, J.; Jiang, G.; Moosdorf, N.; Stevanovic, Z.; et al. Global distribution of carbonate rocks and karst water resources. Hydrogeol. J. 2020, 28, 1661–1677. [Google Scholar] [CrossRef]

- Xu, H.; Chen, C.; Liu, L.; Li, Q.; Wei, B.; Hu, X. Response of Surface Runoff Evolution to Landscape Patterns in Karst Areas: A Case Study of Yun–Gui Plateau. Sustainability 2024, 16, 7338. [Google Scholar] [CrossRef]

- Lu, Q.; Zhao, C.; Huang, H. Comparative study on the temporal and spatial evolution of the ecosystem service value of different karst landform types: A case study in Guizhou Province, China. Appl. Sci. 2022, 12, 12801. [Google Scholar] [CrossRef]

- National Coal Mine Safety Supervision Bureau. Detailed Rules for Water Prevention and Control in Coal Mines; Coal Industry Press: Sydney, Australia, 2018. [Google Scholar]

- Vouillamoz, J.; Lawson, F.; Yalo, N.; Descloitres, M. The use of magnetic resonance sounding for quantifying specific yield and transmissivity in hard rock aquifers: The example of Benin. J. Appl. Geophys. 2014, 107, 16–24. [Google Scholar] [CrossRef]

- Liang, X.; Xie, Z.; Huang, M. A new parameterization for surface and groundwater interactions and its impact on water budgets with the variable infiltration capacity (VIC) land surface model. J. Geophys. Res. 2003, 108, 8613. [Google Scholar] [CrossRef]

- Lv, M.; Xu, Z.; Yang, Z.; Lu, H.; Lv, M. A comprehensive review of specific yield in land surface and groundwater studies. J. Adv. Model. Earth Syst. 2021, 13, e2020MS002270. [Google Scholar] [CrossRef]

- Udosen, N.I.; George, N.J. Evaluation of specific retention, specific yield, and storage-dependent drainability efficiency in a coastal milieu via geo-electrical technology. Water Pract. Technol. 2024, 19, 3654. [Google Scholar] [CrossRef]

- Shi, X.; Al-Arifi, N.; Abdelkareem, M.; Abdalla, F. Application of remote sensing and GIS techniques for exploring potential areas of hydrothermal mineralization in the central Eastern Desert of Egypt. J. Taibah Univ. Sci. 2020, 14, 1421–1432. [Google Scholar] [CrossRef]

- Chen, Y.H.; Wang, G.W.; Mou, N.N.; Huang, L.L.; Mei, R.; Zhang, M.Y. Machine-Learning-Based Integrated Mining Big Data and Multi-Dimensional Ore-Forming Prediction: A Case Study of Yanshan Iron Mine, Hebei, China. Appl. Sci. 2025, 15, 4082. [Google Scholar] [CrossRef]

| Serial Number | Mine | Water Burst-Affected Working Face | Location of the Water Burst | Mining Height (m) | Structure of the Water Burst Point and Working Face Conditions | Water Burst Time (Day, Month, Year) | Elevation (Burial Depth) of the Water Burst Point (m) | Maximum Water Burst Influx (m3/h) | Notes |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Linhua Coal Mine | 2093 | Stop mining line location | 3.3 | Fault | 17 March 2012 | 1041.3 (338.7) | 200 | |

| 2 | 20910 | 673 m from the open-off cut | 3.4 | Normal stratigraphic block | 10 October 2017 | 916 (374.8) | 96 | ||

| 3 | 20912 | 523 m from the open-off cut | 3.4 | Normal stratigraphic block | 10 January 2016 | 866 (379.1) | 210 | ||

| 4 | 20917 | 232 m from the open-off cut | 3.3 | Normal stratigraphic block | 10 January 2019 | 833.6 (491.6) | 86 | ||

| 5 | 10901 | 89 m from the open-off cut | 3.3 | Normal stratigraphic block | 17 November 2019 | 829.5 (447.5) | 310 | ||

| 6 | Guiyuan Coal Mine | 10903 | 276 m from the open-off cut | 3.0 | Near the fault | 16 June 2016 | 783 (367) | 280 | T-1 |

| 7 | 10901-1 | 80 m from the open-off cut | 2.5 | Between two faults | 25 February 2019 | 833 (415) | 160 | T-2 | |

| 8 | 10905 | 74 m from the open-off cut | 3.0 | Near the fault | 30 March 2020 | 747 (421) | 229 | T-3 | |

| 9 | 143 m from the open-off cut | 3.0 | Near the fault | 12 May 2020 | 751 (436) | 150 | T-4 | ||

| 10 | 425 m from the open-off cut | 3.0 | Near the fault | 8 November 2020 | 776 (433) | 290 | T-5 | ||

| 11 | 10908 | 247 m from the open-off cut | 3.0 | Normal stratigraphic block | 13 October 2021 | 808 (394) | 210 | ||

| 12 | 341 m from the open-off cut | 3.0 | Normal stratigraphic block | 14 February 2022 | 807 (439) | 80 | |||

| 13 | 2093 | 161 m from the open-off cut | 2.5 | Near the fault | 15 July 2019 | 728.5 (431.5) | 150 | ||

| 14 | 237 m from the open-off cut | 2.5 | Near the fault | 23 November 2019 | 729.8 (432.6) | 470 | |||

| 15 | 270 m from the open-off cut | 2.5 | Near the fault | 10 December 2019 | 730.9 (439.4) | 350 | |||

| 16 | Jinji Coal Mine | 1905 | 41 m from the open-off cut | 2.8 | Normal stratigraphic block | 20 December 2018 | 877.5 (366.1) | 200 | |

| 17 | Lindonglongfeng Coal Mine | 5914 | 202 m from the open-off cut | 2.4 | Expose faults | 22 July 2019 | 979.3 (146.2) | 160 | |

| 18 | 365 m from the open-off cut | 2.4 | Normal stratigraphic block | 24 March 2020 | 977.8 (127.4) | 210 | |||

| 19 | Tenglong Coal Mine | 10901 | 163 m from the open-off cut | 2.3 | 40 m from the nearby working face | 19 April 2020 | 1047.3 (342.7) | 80 | |

| 20 | 536 m from the open-off cut | 2.3 | 27 m from the nearby working face | 11 November 2020 | 1047.4 (350.1) | 800 | |||

| 21 | 10903 | 465 m from the open-off cut | 2.5 | Normal stratigraphic block | 19 June 2022 | 993.4 (274.1) | Influx of water and yellow mud | ||

| 22 | Anshenglongfeng Coal Mine | 10905 | 27.8 m from the open-off cut | 2.8 | Normal stratigraphic block | 12 April 2023 | 774 (335.5) | 578 |

| Lithology | Compressive Strength of the Model (kPa) | Designated Material Mix Ratio | Proportion of Material Used (%) | ||

|---|---|---|---|---|---|

| Fine Sand | Calcium Carbonate | Gypsum | |||

| Siltstone | 136 | 737 | 70 | 9 | 21 |

| Limestone | 154 | 455 | 40 | 30 | 30 |

| Silty mudstone | 100 | 755 | 70 | 15 | 15 |

| Mudstone | 91 | 473 | 40 | 42 | 18 |

| Fine sandstone | 113 | 373 | 30 | 49 | 21 |

| Coal | 45 | 773 | 70 | 21 | 9 |

| Argillaceous siltstone | 104 | 746 | 70 | 12 | 18 |

| Coal Mine | Linhua Coal Mine | Guiyuan Coal Mine | Jinji Coal Mine | Lindong Longfeng Coal Mine | Tenglong Coal Mine | Ansheng Longfeng Coal Mine |

|---|---|---|---|---|---|---|

| Water burst-affected working face | 10901 | 10908 | 1905 | 2914 | 10903 | 1905 |

| Mining height (m) | 3.3 | 3.0 | 2.8 | 2.4 | 2.5 | 2.8 |

| Height of the water-conducting fracture zone (m) | 42.8 | 41.3 | 40.3 | 37.9 | 38.5 | 40.3 |

| Fracture zone height to mining height ratio | 13.8 | 13.0 | 14.4 | 15.8 | 15.4 | 14.4 |

| Distance between coalbed 9 and the Changxing Formation limestone (m) | 54.84 | 50.68 | 49.81 | 55.59 | 49.09 | 41.78 |

| Serial Number | 1 | 6 | 7 | 8 | 9 | 10 | 13 | 14 | 15 | 17 |

|---|---|---|---|---|---|---|---|---|---|---|

| Mine | Linhua Coal Mine | Guiyuan Coal Mine | Lindonglongfeng Coal Mine | |||||||

| Water burst-affected working face | 2093 | 10903 | 10901-1 | 10905 | 2093 | 5914 | ||||

| Distance from the water burst points to faults (m) | 7.0 | 51.0 | 41.4 | 17.2 | 29.0 | 18.3 | 16.6 | 60.0 | 36.9 | 24.9 |

| Maximum water burst influx (m3/h) | 200 | 280 | 160 | 229 | 150 | 290 | 150 | 470 | 350 | 160 |

| Water-Rich Anomaly Zone | Length (m) | Width (m) | Height (m) | Height of Development in the Changxing Formation Limestone (m) |

|---|---|---|---|---|

| 1 | 326.3 | 13.1 | 37.8 | 32.6 |

| 2 | 36.1 | 31.5 | 38.5 | 22.3 |

| 3 | 63.9 | 48.0 | 34.4 | 20.2 |

| 4 | 131.7 | 79.3 | 21.6 | 18.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Xu, G.; Qian, Z.; Zhang, W. Study on the Hydrogeological Characteristics of Roof Limestone Aquifers After Mining Damage in Karst Mining Areas. Water 2025, 17, 2264. https://doi.org/10.3390/w17152264

Shi X, Xu G, Qian Z, Zhang W. Study on the Hydrogeological Characteristics of Roof Limestone Aquifers After Mining Damage in Karst Mining Areas. Water. 2025; 17(15):2264. https://doi.org/10.3390/w17152264

Chicago/Turabian StyleShi, Xianzhi, Guosheng Xu, Ziwei Qian, and Weiqiang Zhang. 2025. "Study on the Hydrogeological Characteristics of Roof Limestone Aquifers After Mining Damage in Karst Mining Areas" Water 17, no. 15: 2264. https://doi.org/10.3390/w17152264

APA StyleShi, X., Xu, G., Qian, Z., & Zhang, W. (2025). Study on the Hydrogeological Characteristics of Roof Limestone Aquifers After Mining Damage in Karst Mining Areas. Water, 17(15), 2264. https://doi.org/10.3390/w17152264