Correction of Pump Characteristic Curves Integrating Representative Operating Condition Recognition and Affine Transformation

Abstract

1. Introduction

2. Methodology

2.1. Representative Data Selection

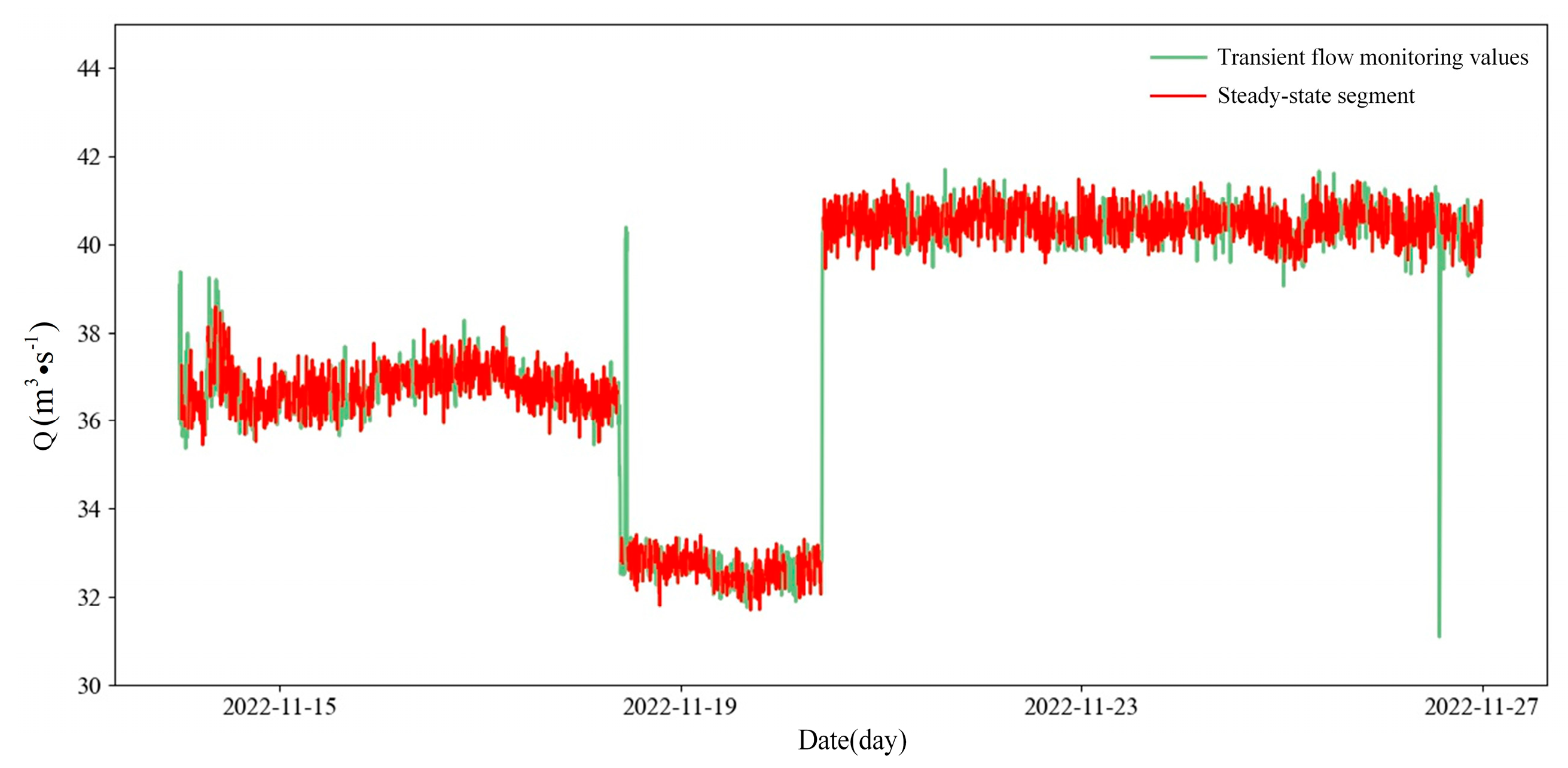

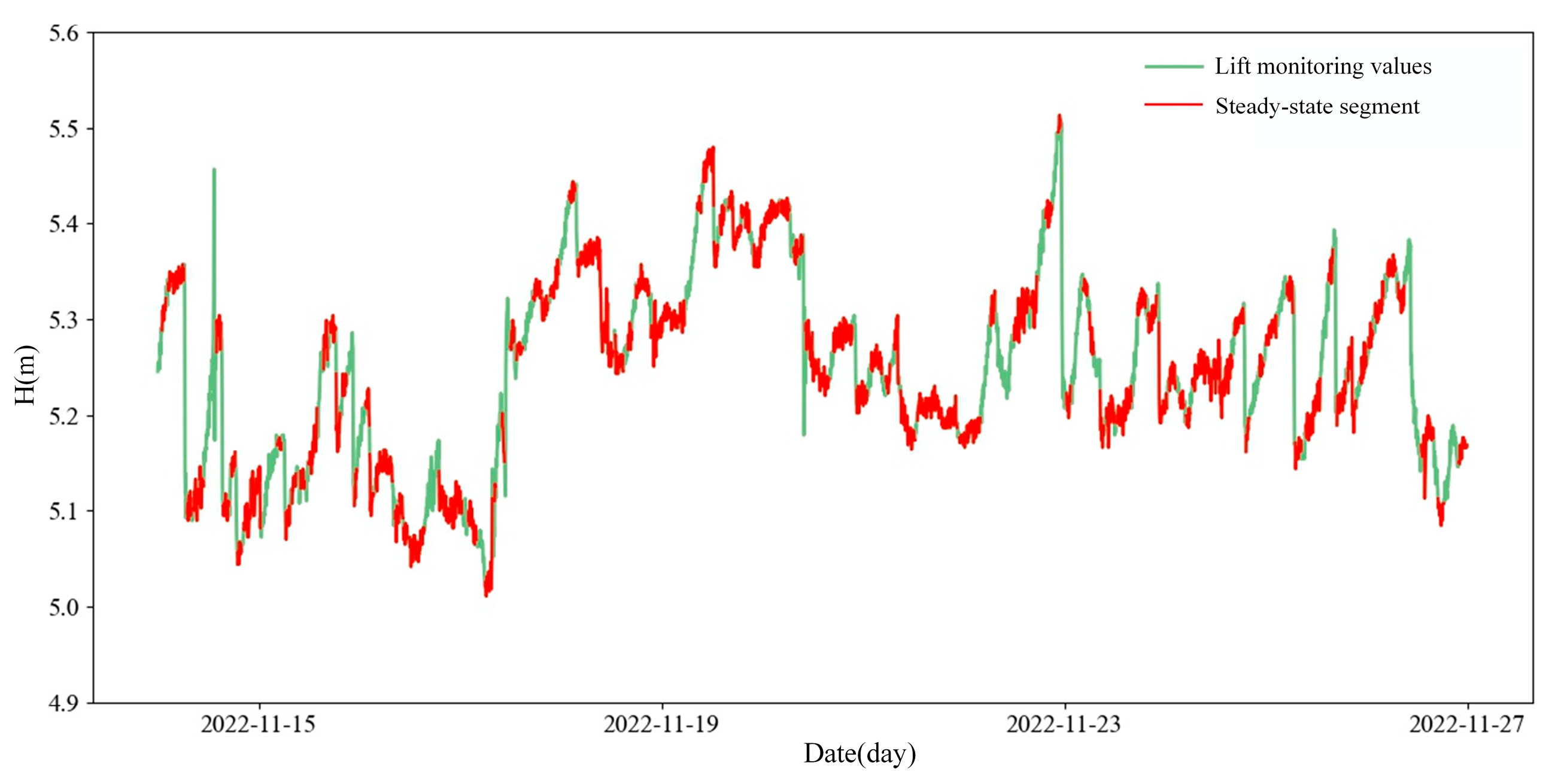

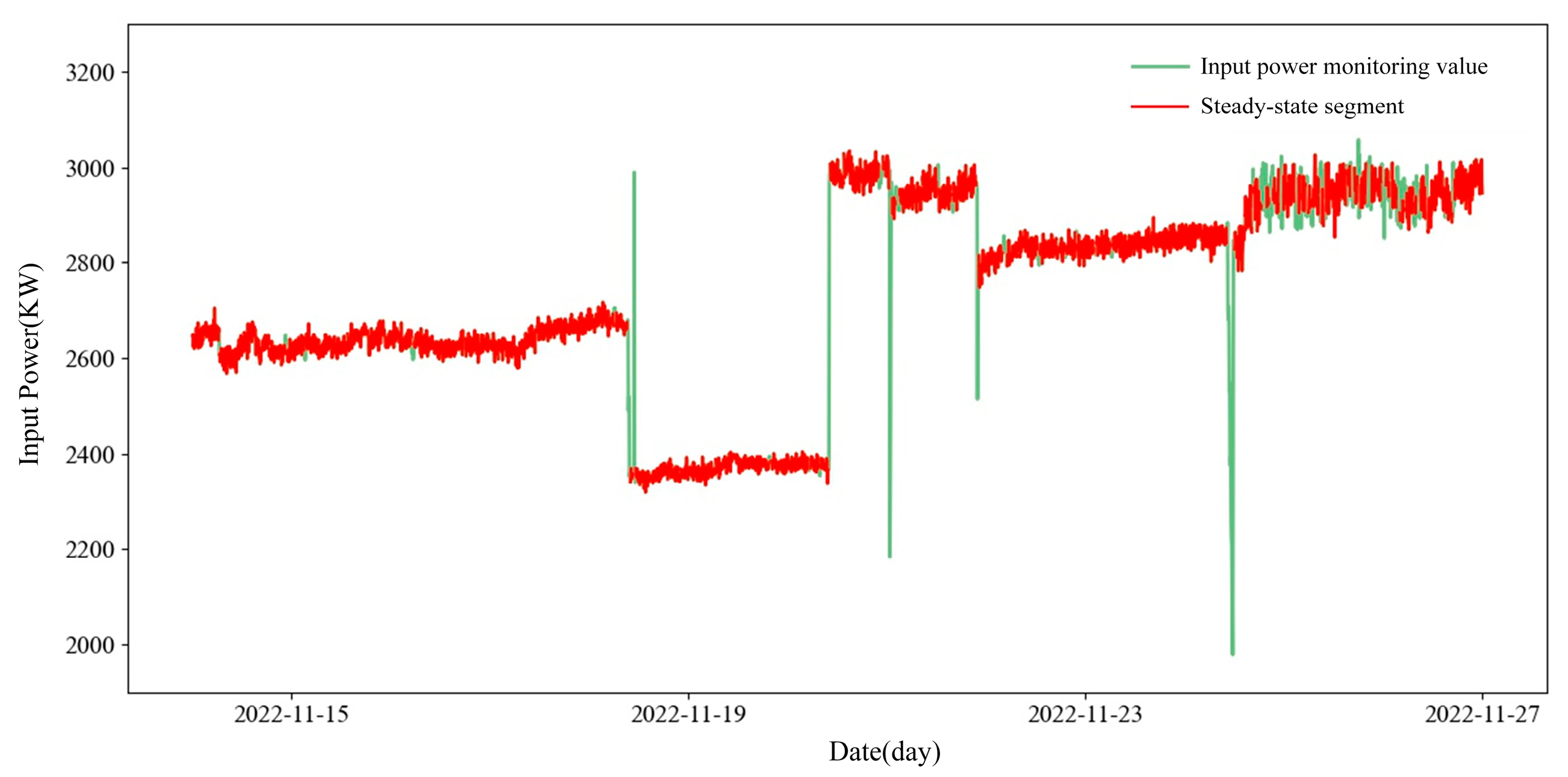

2.1.1. Steady-State Operating Condition Filtering

- (1)

- Noise Reduction of Raw Data:

- (2)

- Composite Statistical Test:

- ①

- The monitoring data are segmented into intervals, each containing N data points. The mean and variance of each segment are calculated. A T-distribution test statistic is then constructed based on the means and variances of two adjacent intervals, as expressed in Equation (1).

- ②

- Referring to the T-distribution table and a predefined significance level (typically 0.01 or 0.05), the critical value is obtained, and the confidence interval is defined as . If the test statistic falls within this interval, the system is considered to be in a steady state; otherwise, it is classified as dynamic.

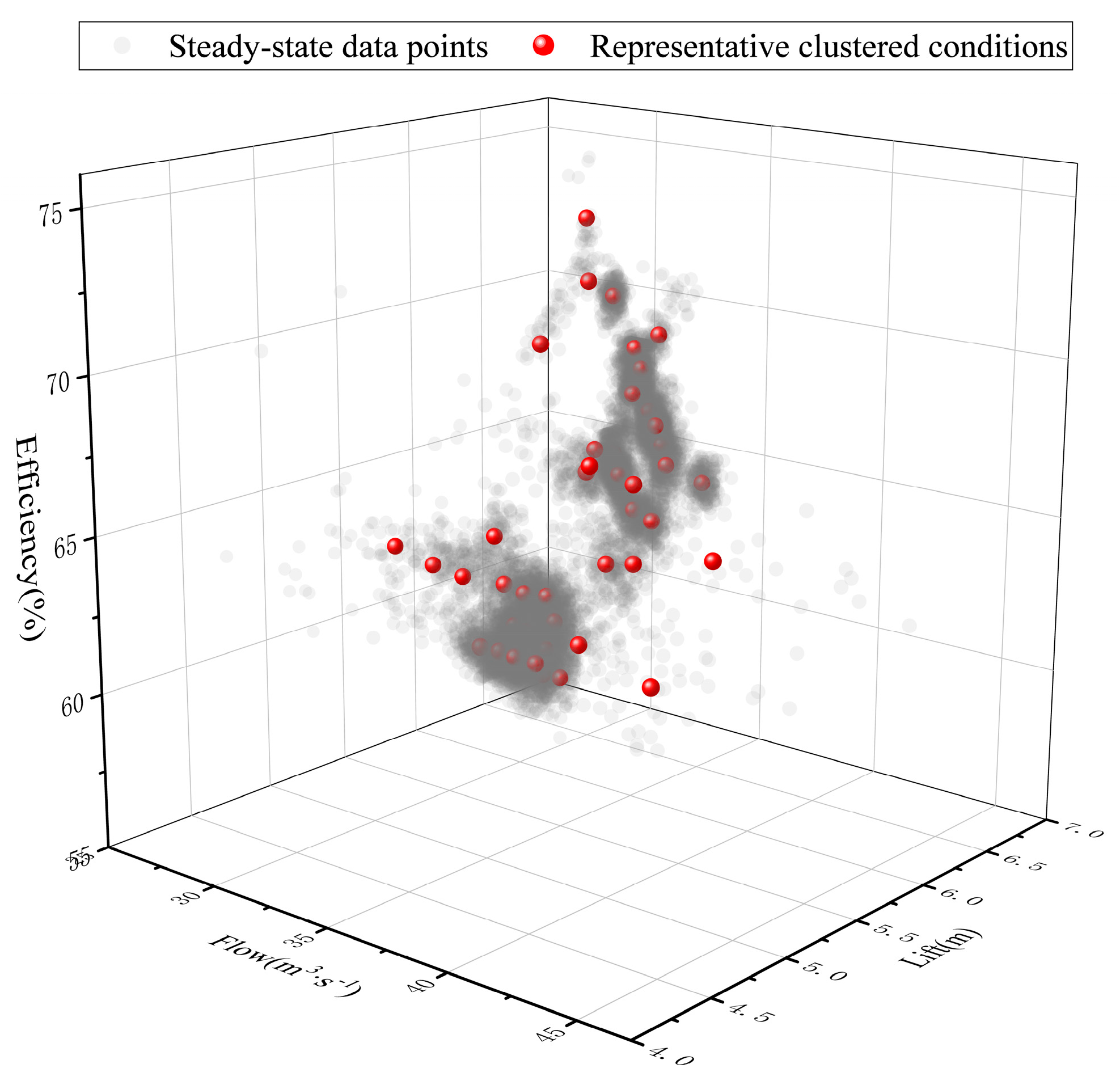

2.1.2. Construction of Representative Operating Datasets

- (1)

- To eliminate the impact of differing value magnitudes across features and ensure clustering performance, the steady-state data are first standardized. The standardization process is defined by Equation (2):where is the value of the th feature in the th sample, is the total number of samples, is the mean of the th feature, and is its standard deviation. represents the standardized value of the th feature in the th sample.

- (2)

- The standardized steady-state data are then clustered using the K-means algorithm according to the following steps:

- ①

- Initialize K cluster centers: Randomly select k initial points from the steady-state data as the initial cluster centroids.

- ②

- Assign samples to the nearest cluster: Compute the distance between each sample and the cluster centers, and assign each sample to the nearest cluster center.

- ③

- Update cluster centers: For each cluster, recalculate its centroid based on the newly assigned members.

- ④

- Repeat iteration: Repeat steps ② and ③ until convergence criteria are met.

- ⑤

- Cluster validity check: Evaluate the clustering performance using silhouette coefficients. If the clustering result is unsatisfactory, repeat steps ①–④.

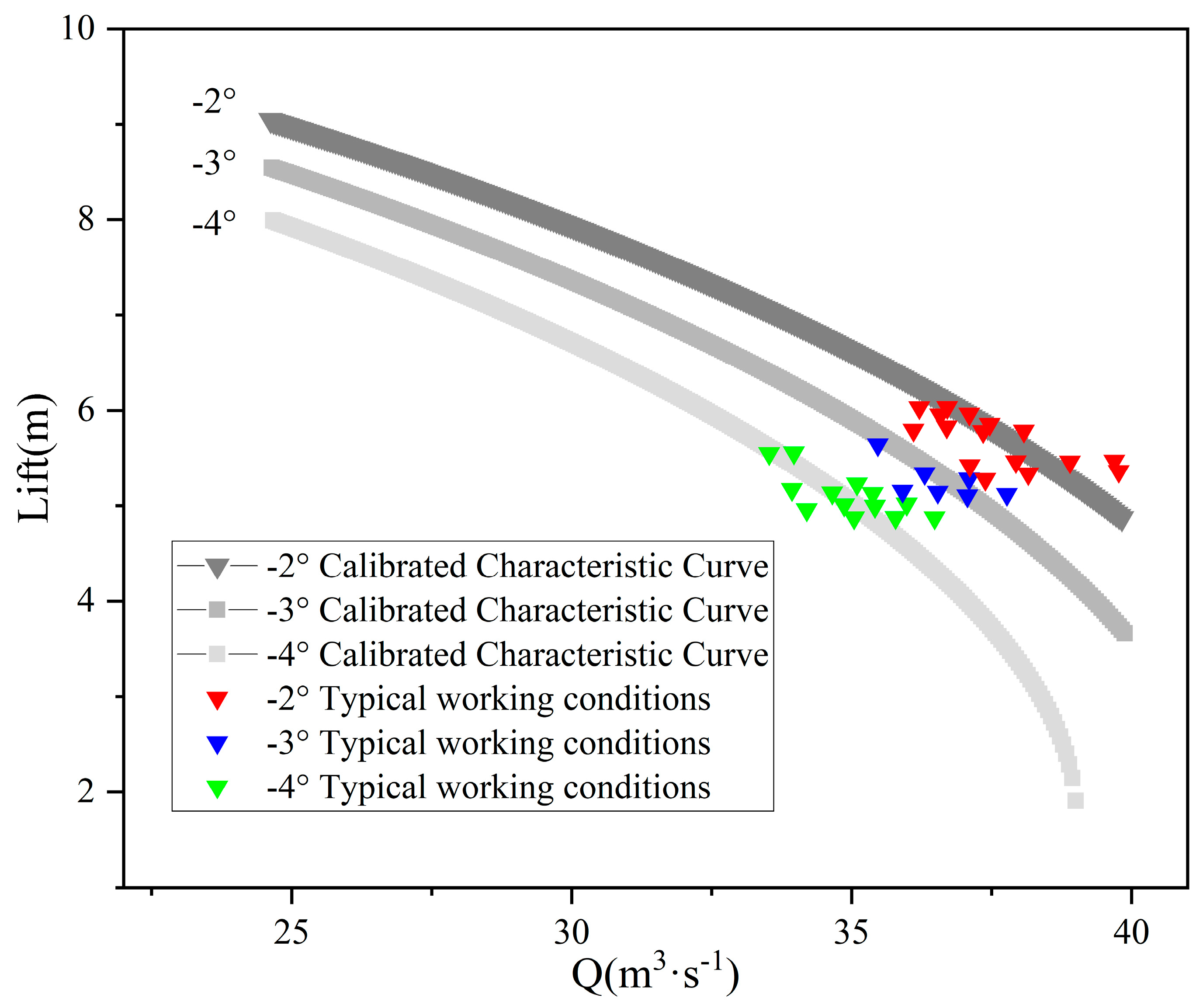

2.1.3. Modification of Characteristic Curve Equations

3. Results and Discussion

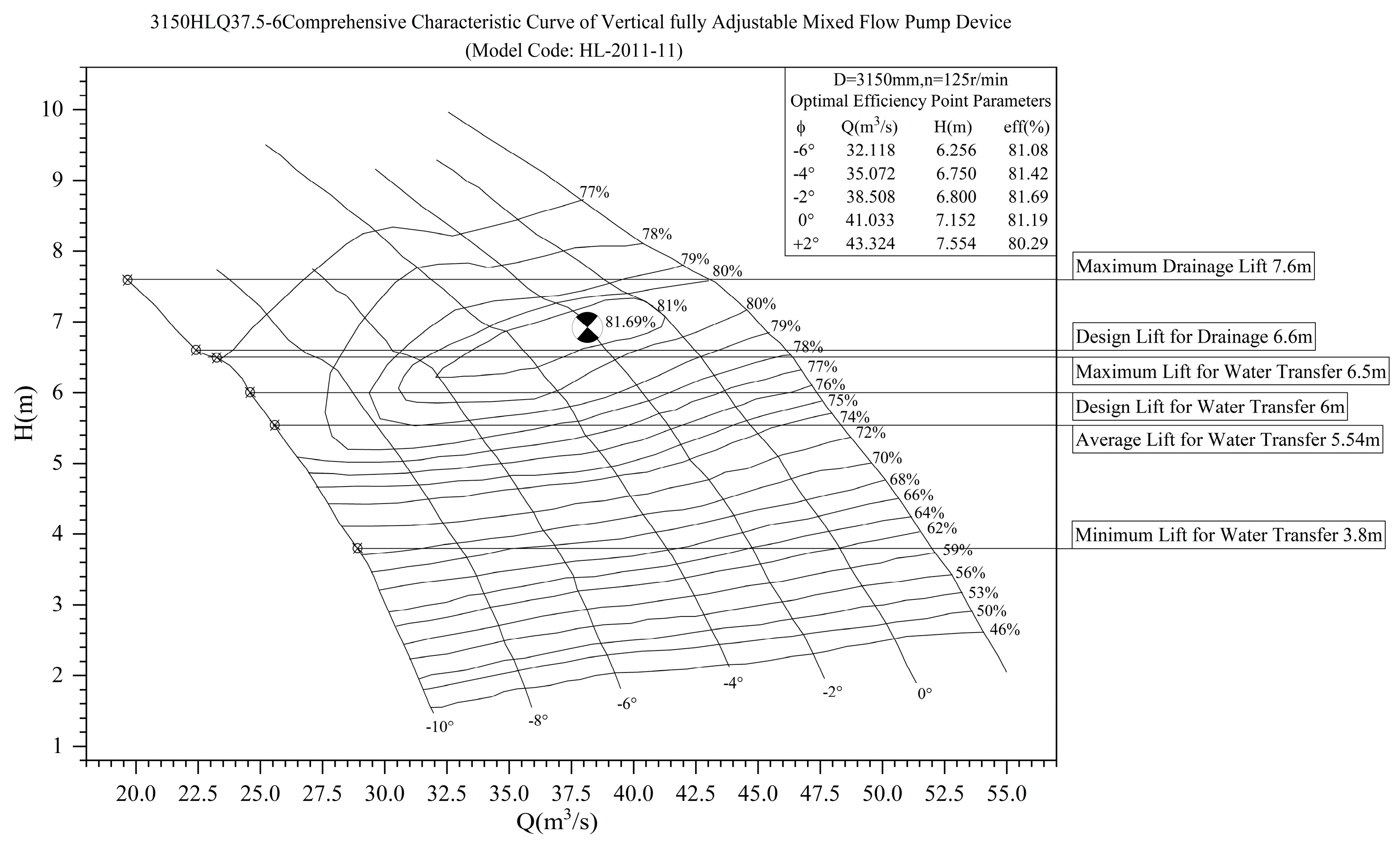

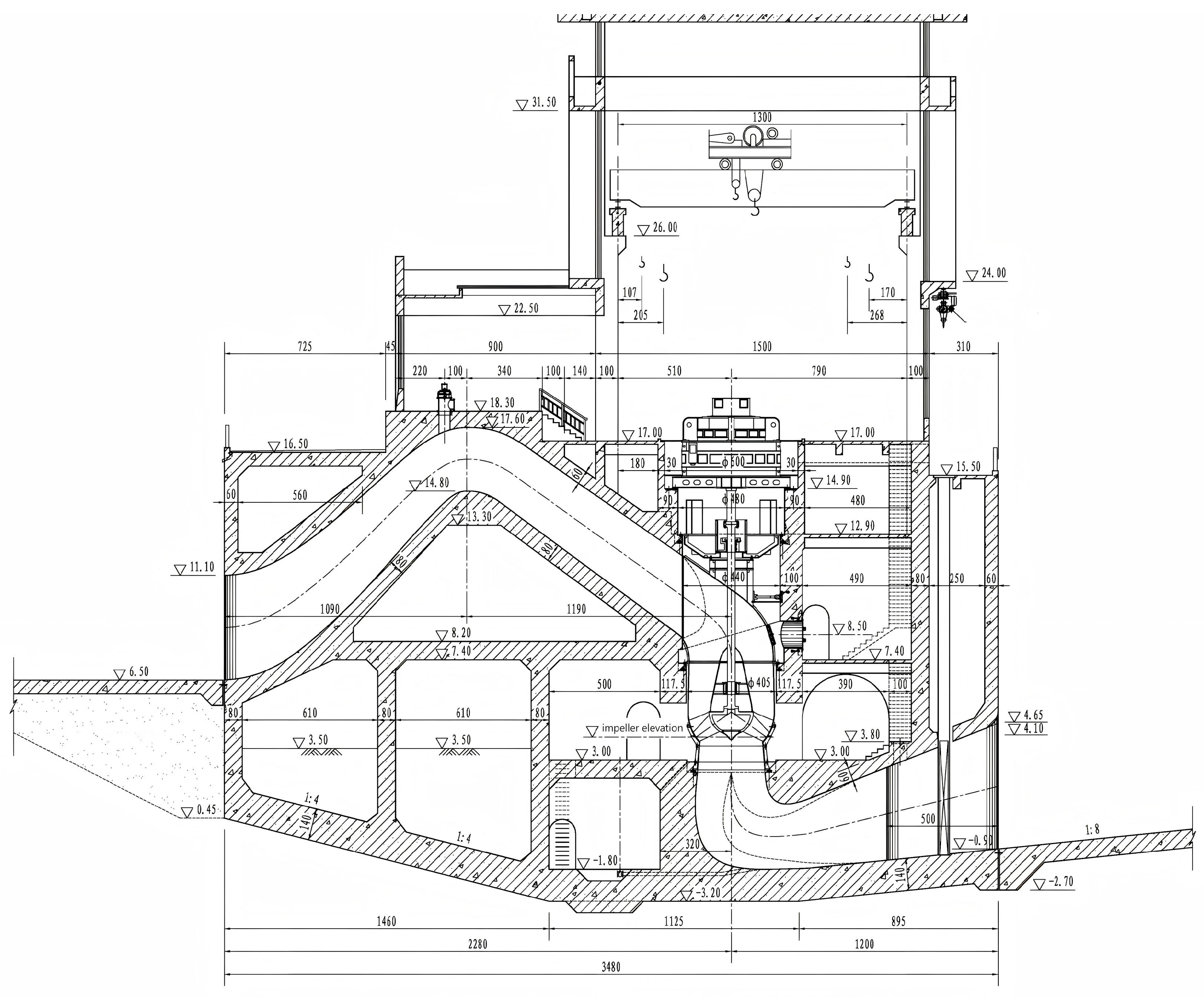

3.1. Study Area

3.2. Results of Representative Data Selection

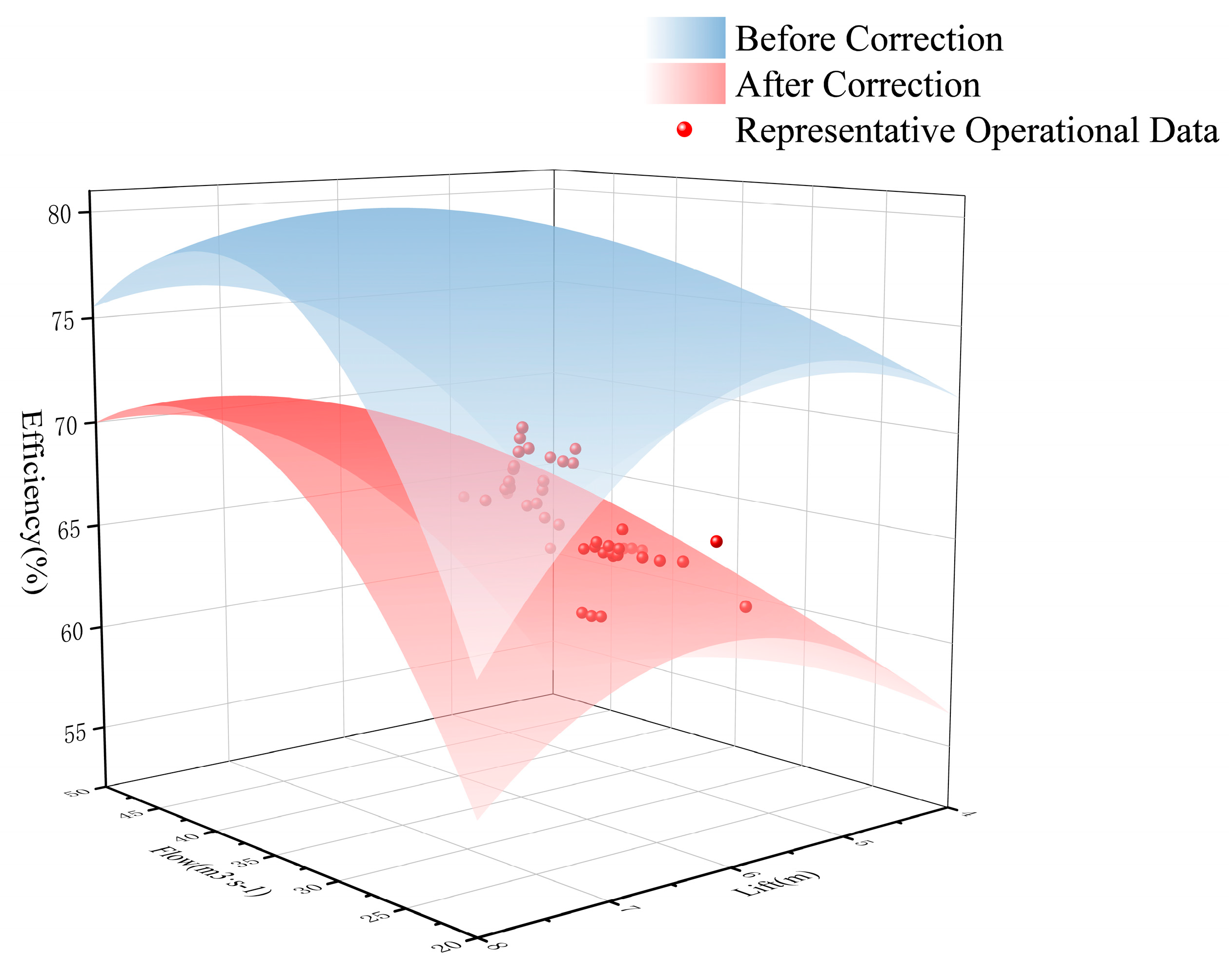

3.3. Results of Characteristic Curve Correction

4. Conclusions

- (1)

- This study proposes a representative operating condition data selection method that combines adaptive Kalman filtering for noise reduction with a composite statistical testing approach to identify steady-state data. The resulting steady-state dataset is then clustered to construct a representative operating condition dataset, providing a reliable data foundation for subsequent pump characteristic curve correction.

- (2)

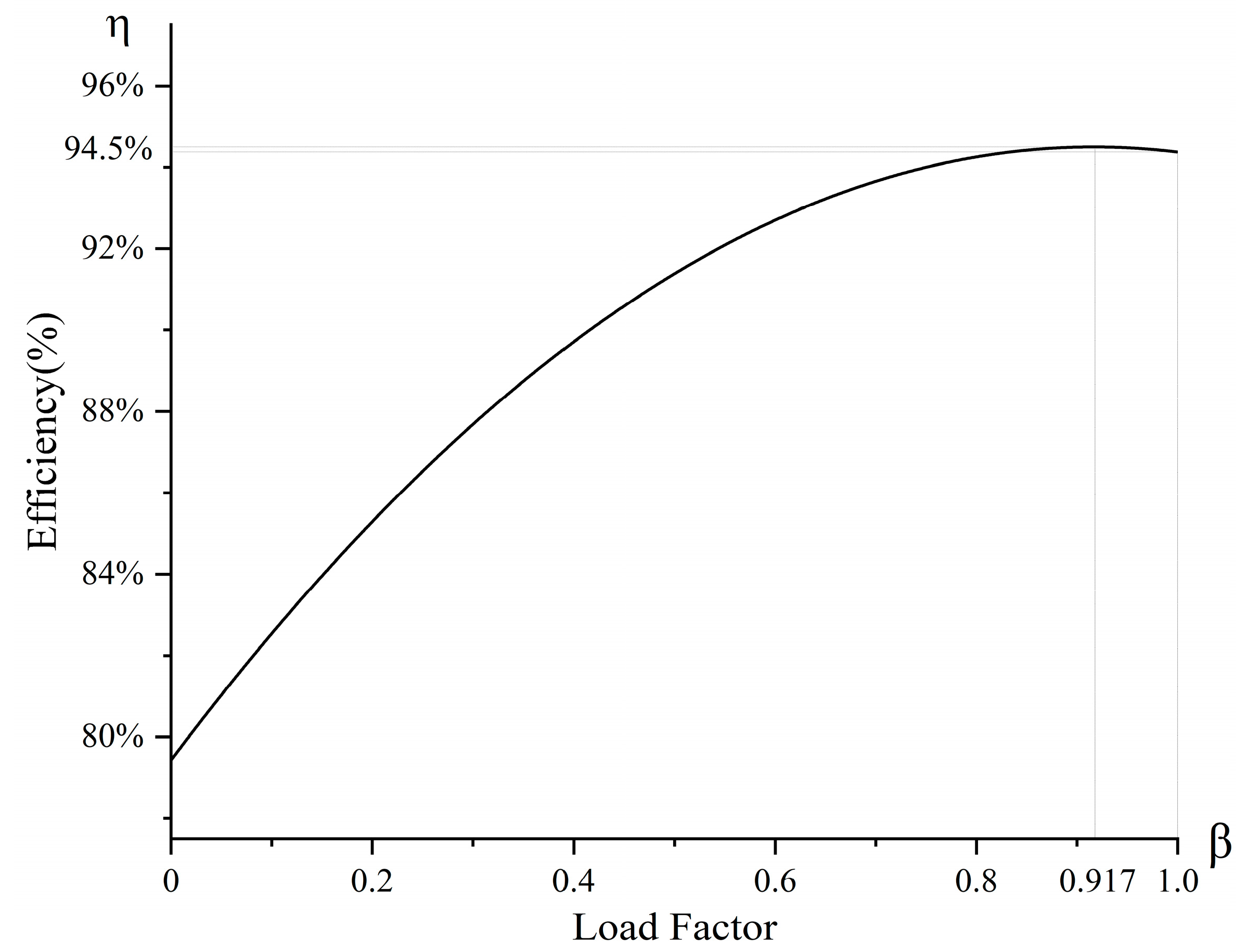

- A comprehensive pump characteristic curve correction method based on affine transformation is developed. By introducing appropriate parameters to modify the original characteristic equations, a three-dimensional affine transformation is implemented. Parameter optimization is subsequently performed based on the representative steady-state dataset. Validation results confirm that the corrected characteristic curves maintain high computational accuracy under typical operating conditions.

- (3)

- The proposed correction and optimization framework, though specifically developed and validated based on the mixed-flow pump system of the Hongze Pump Station, exhibits a degree of universality in its methodological design. In principle, the steady-state identification, characteristic curve correction via affine transformation, and multi-objective scheduling approach can be extended to other types of pumping units, including axial-flow and centrifugal pumps, provided that sufficient operational monitoring data are available. These pumps, despite structural differences, also exhibit performance deviations under long-term operation and deteriorating conditions. Therefore, the presented framework holds potential for broader application in performance calibration and energy-efficient dispatching across various pumping systems. Future work may focus on validating the generalizability of this method in multi-type or composite pump stations to further enhance its engineering value and practical applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, C.; Hou, J.; Li, X.; Song, G.; Yang, Y.; Liang, X.; Zhou, Q.; Imran, M.; Chen, G.; Wang, Z.; et al. Efficient urban flood control and drainage management framework based on digital twin technology and optimization scheduling algorithm. Water Res. 2025, 282, 123711. [Google Scholar] [CrossRef] [PubMed]

- Hunt, J.D.; Silva, C.V.; Fonseca, E.; de Freitas, M.A.V.; Brandão, R.; Wada, Y. Role of pumped hydro storage plants for flood control. J. Energy Storage 2024, 104, 114496. [Google Scholar] [CrossRef]

- Wu, Y.; She, D.; Xia, J.; Song, J.; Xiao, T.; Zhou, Y. The quantitative assessment of impact of pumping capacity and LID on urban flood susceptibility based on machine learning. J. Hydrol. 2023, 617, 129116. [Google Scholar] [CrossRef]

- Zuo, Z.; Tan, L.; Shi, W.; Chen, C.; Ye, J.; Francis, E.M. Transient Characteristic Analysis of Variable Frequency Speed Regulation of Axial Flow Pump. Sustainability 2022, 14, 11143. [Google Scholar] [CrossRef]

- Reeh, N.; Manthei, G.; Klar, P.J. Physical Modelling of the Set of Performance Curves for Radial Centrifugal Pumps to Determine the Flow Rate. Appl. Syst. Innov. 2023, 6, 111. [Google Scholar] [CrossRef]

- Wang, Z. Flow Channel Optimization and Hydraulic Characteristics on Pump Sets of Xifei Pumping Station. Master’s Thesis, Yangzhou University, Yangzhou, China, 2016. [Google Scholar] [CrossRef]

- Kandi, A.; Moghimi, M.; Tahani, M.; Derakhshan, S. Optimization of pump selection for running as turbine and performance analysis within the regulation schemes. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 560. [Google Scholar] [CrossRef]

- Zhang, J. Study on Optimal Operation Methods of Hongze pumping Station in Eastern First-Stage Route of South-to-North Water Transfer Project. Master’s Thesis, Yangzhou University, Yangzhou, China, 2014. [Google Scholar] [CrossRef]

- He, B.; Fu, Z.; Wu, W.; Zhao, Z.; Zhou, B.; Wang, G. Daily Optimal Scheduling of Pump Station Based on Improved Genetic Algorithm and Dynamic Programming. Water Resour. Power 2023, 41, 128–132. [Google Scholar] [CrossRef]

- Sun, T.; Wang, Z.; Zhu, B. Optimization study on the operation of No. Five Pumping Station in the Yanhuan Dingyang Yellow River irrigation district. J. China Inst. Water Resour. Hydropower Res. 2024, 22, 97–107. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, P.; Pu, Y.; Lei, H.; Zheng, X. Unit Operation Combination and Flow Distribution Scheme of Water Pump Station System Based on Genetic Algorithm. Appl. Sci. 2023, 13, 11869. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, J.; Zhu, B. Optimal operation of a single unit in a pumping station based on a combination of orthogonal experiment and 0-1 integer programming algorithm. Water Supply 2022, 22, 7905–7915. [Google Scholar] [CrossRef]

- Zhang, B.; Cheng, L.; Xu, C.; Wang, M. The Influence of Geometric Parameters of Pump Installation on the Hydraulic Performance of a Prefabricated Pumping Station. Energies 2021, 14, 1039. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, Y.; Kusiak, A. Minimizing pump energy in a wastewater processing plant. Energy 2012, 47, 505–514. [Google Scholar] [CrossRef]

- Eaton, A.; D’Alessandro, F.; Ahmed, W.; Hassan, H. On the performance degradation of centrifugal pumps. In Proceedings of the International Conference on Fluid Flow, Heat and Mass Transfer, Niagara Falls, ON, Canada, 7–9 June 2018; pp. 7–9. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, Y.; Chen, T. Analysis of Hydrodynamic Performance of Mixed-flow Pump Based on Fluent Numercial Simulation. Mach. Tool Hydraul. 2018, 46, 139–142. [Google Scholar] [CrossRef]

- Shen, X.; Li, R.; Han, W.; Chen, D.; Sun, J.; Tian, Y. Progressive Erosion and Pump Performance Prediction of Double Suction Centrifugal Pump Vane Based on Dynamic Boundary. Trans. Chin. Soc. Agric. Mach. 2024, 55, 212–220. [Google Scholar] [CrossRef]

- Zhu, J. Optimal Scheduling of Water Supply Pump Station Based on Calibration and Renewal of Pumps’ Characteristic Curves. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2017. [Google Scholar] [CrossRef]

- Bing, H.; Cao, S.L. Effects of blade rotation angle deviations on mixed-flow pump hydraulic performance. Sci. China Technol. Sci. 2014, 57, 1372–1382. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z.; Wei, W.; Si, Q.; Li, Y.; Xue, P.; Gao, Z.; Du, M. Optimization and regulation control of pump units based on differential characteristics. J. Drain. Irrig. Mach. Eng. 2024, 42, 256–264. [Google Scholar]

- Mao, J.; Zhang, R.; Wang, W.; Cheng, X. Extension correction method for dynamic characteristics of large and medium-sized irrigation pumps. J. Hydroelectr. Eng. 2015, 34, 98–105. [Google Scholar] [CrossRef]

- Le Marre, M.; Mandin, P.; Lanoisellé, J.-L.; Bezuglov, R. Experimental study on performance predictions of pumps as turbine. Energy Convers. Manag. 2023, 292, 117235. [Google Scholar] [CrossRef]

- Feng, J.; Ge, Z.; Zhang, Y.; Zhu, G.; Wu, G.; Lu, J.; Luo, X. Numerical investigation on characteristics of transient process in centrifugal pumps during power failure. Renew. Energy 2021, 170, 267–276. [Google Scholar] [CrossRef]

- Briceño-León, C.X.; Iglesias-Rey, P.L.; Martinez-Solano, F.J.; Mora-Melia, D.; Fuertes-Miquel, V.S. Use of fixed and variable speed pumps in water distribution networks with different control strategies. Water 2021, 13, 479. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, J. Prediction of pump’s complete characteristic curves and its influence on further numerical analysis. J. Drain. Irrig. Mach. Eng. 2021, 39, 777–783. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.M.; Yu, G.P.; Hou, J.X. Modeling Characteristic Curves of Pump Station Using SCADA Operational Data. China Water Wastewater 2011, 27, 75–77. [Google Scholar] [CrossRef]

- Salomons, E.; Shamir, U.; Housh, M. Optimization Methodology for Estimating Pump Curves Using SCADA Data. Water 2021, 13, 586. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhang, Z.; Kusiak, A.; Tang, F.; Wei, X. Optimizing wastewater pumping system with data-driven models and a greedy electromagnetism-like algorithm. Stoch. Environ. Res. Risk Assess. 2016, 30, 1263–1275. [Google Scholar] [CrossRef]

- Ha, S.; Xu, H.; Tang, Z.; Zhu, C. Eigenvalue Extraction Method for Engine Steady-state Data Based on Gaussian Mixture Model. Aeroengine 2022, 48, 173–179. [Google Scholar] [CrossRef]

- Gao, M. Research on the Pretreatment Methods of Power Station Historical Data. Master’s Thesis, School of Control and Computer Engineering, North China Electric Power University, Beijing, China, 2014. [Google Scholar] [CrossRef]

- del Pilar Moreno, R. Steady State Detection, Data Reconciliation, and Gross Error Detection: Development for Industrial Processes. Master’s Thesis, University of New Brunswick, Department of Computer and Electrical Engineering, Fredericton, Canada, 2010. [Google Scholar]

- Tang, Y. Electric Machinery, 5th ed.; China Mechine Press: Beijing, China, 2014. [Google Scholar]

- Zhou, X. Research on National Water Resource Shortage Assessment Considering Inter-Basin Water Transfer. Master’s Thesis, Dalian University of Technology, Dalian, China, 2022. [Google Scholar] [CrossRef]

- Liu, Y.; Xin, Z.; Sun, S.; Zhang, C.; Fu, G. Assessing environmental, economic, and social impacts of inter-basin water transfer in China. J. Hydrol. 2023, 625, 130008. [Google Scholar] [CrossRef]

- Chen, X.; Jin, Y.; Xu, X.; He, W. Reflections on Intelligent Water Transfer Scheduling of the Middle Route of the South-to-North Water Transfer Project. J. Hohai Univ. (Nat. Sci.) 2023, 51, 46–55. [Google Scholar] [CrossRef]

| Value | −0.37 | 1.58 | 1.99 | −0.044 |

| Indicator | Before Correction | After Correction | Standard |

|---|---|---|---|

| Mean Absolute Error of Cluster Points (MAE) | 1.89° | 0.31° | Closer to 0 is better |

| Mean Absolute Error of All Points (MAE) | 1.73° | 0.51° | Closer to 0 is better |

| Coefficient of Determination (R-squared) | −2.83 | 0.67 | Closer to 1 is better |

| Value | −4.63 | −1.99 | −4.17 | 0.03 |

| Indicator | Before Correction | After Correction | Standard |

|---|---|---|---|

| Mean Absolute Error of Cluster Points (MAE) | 6.99% | 1.71% | Closer to 0 is better |

| Mean Absolute Error of All Points (MAE) | 7.32% | 1.30% | Closer to 0 is better |

| Coefficient of Determination (R-squared) | −5.78 | 0.76 | Closer to 1 is better |

| Flow (m3/s) | Lift (m) | Measured Efficiency (%) | Predicted Efficiency (%) | Absolute Efficiency Error (%) | Mean Efficiency Error (%) |

|---|---|---|---|---|---|

| 25.64 | 5.15 | 62.03 | 63.35 | 1.31 | 1.20 |

| 27.35 | 5.20 | 64.91 | 64.00 | 0.91 | |

| 29.57 | 5.22 | 63.65 | 64.53 | 0.88 | |

| 31.40 | 5.20 | 63.41 | 64.71 | 1.30 | |

| 33.71 | 5.26 | 64.67 | 65.19 | 0.52 | |

| 34.56 | 5.93 | 70.53 | 68.17 | 2.36 | |

| 36.28 | 4.99 | 62.78 | 63.68 | 0.90 | |

| 37.53 | 5.58 | 65.70 | 66.84 | 1.14 | |

| 38.70 | 4.75 | 62.54 | 61.88 | 0.66 | |

| 39.80 | 5.20 | 67.43 | 64.63 | 2.80 | |

| 42.27 | 5.31 | 65.39 | 64.92 | 0.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhao, Y.; Li, X.; Wu, C.; Zhao, J.; Ren, L. Correction of Pump Characteristic Curves Integrating Representative Operating Condition Recognition and Affine Transformation. Water 2025, 17, 1977. https://doi.org/10.3390/w17131977

Chen Y, Zhao Y, Li X, Wu C, Zhao J, Ren L. Correction of Pump Characteristic Curves Integrating Representative Operating Condition Recognition and Affine Transformation. Water. 2025; 17(13):1977. https://doi.org/10.3390/w17131977

Chicago/Turabian StyleChen, Yichao, Yongjun Zhao, Xiaomai Li, Chenchen Wu, Jie Zhao, and Li Ren. 2025. "Correction of Pump Characteristic Curves Integrating Representative Operating Condition Recognition and Affine Transformation" Water 17, no. 13: 1977. https://doi.org/10.3390/w17131977

APA StyleChen, Y., Zhao, Y., Li, X., Wu, C., Zhao, J., & Ren, L. (2025). Correction of Pump Characteristic Curves Integrating Representative Operating Condition Recognition and Affine Transformation. Water, 17(13), 1977. https://doi.org/10.3390/w17131977