Study on the Friction Coefficient of Pedestrian Instability Under Urban Road Flooding Conditions

Abstract

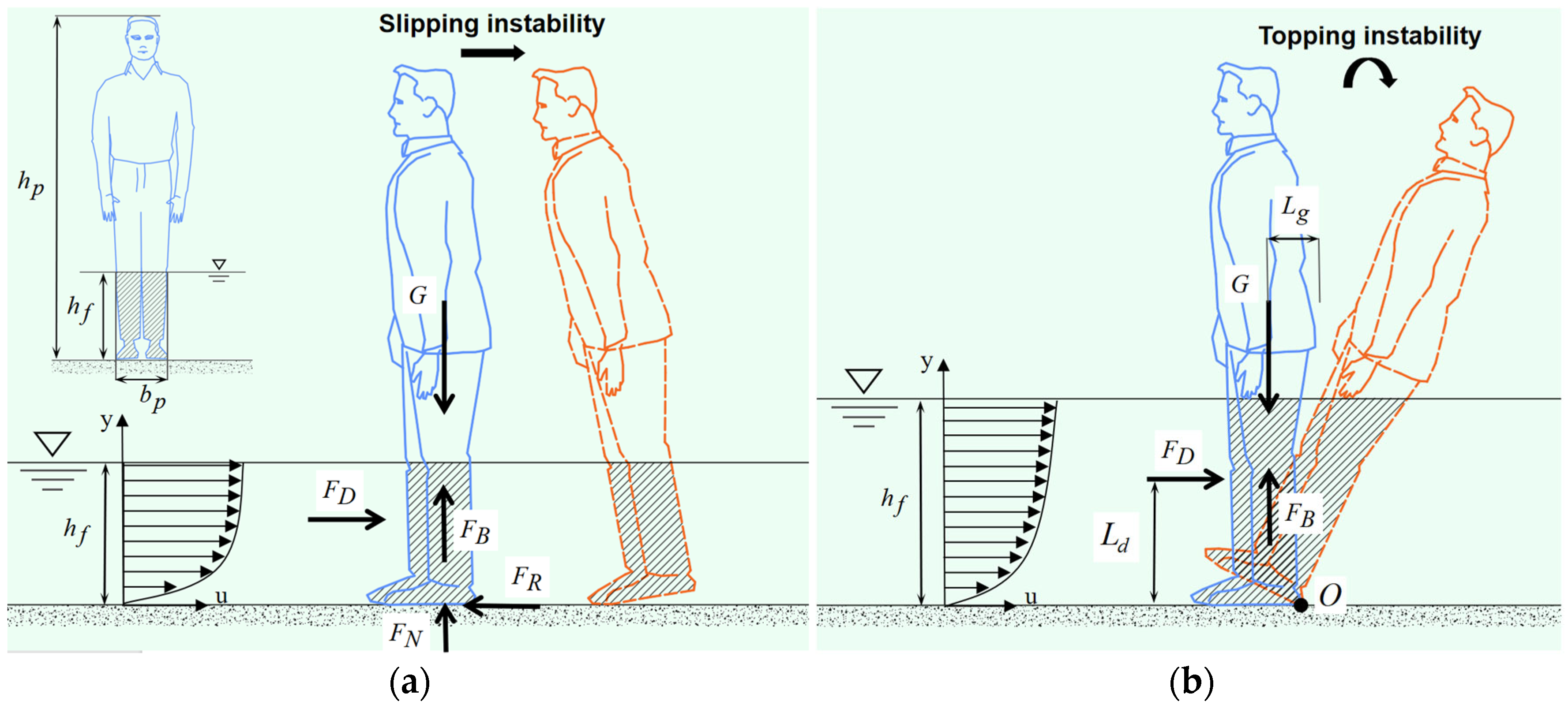

1. Introduction

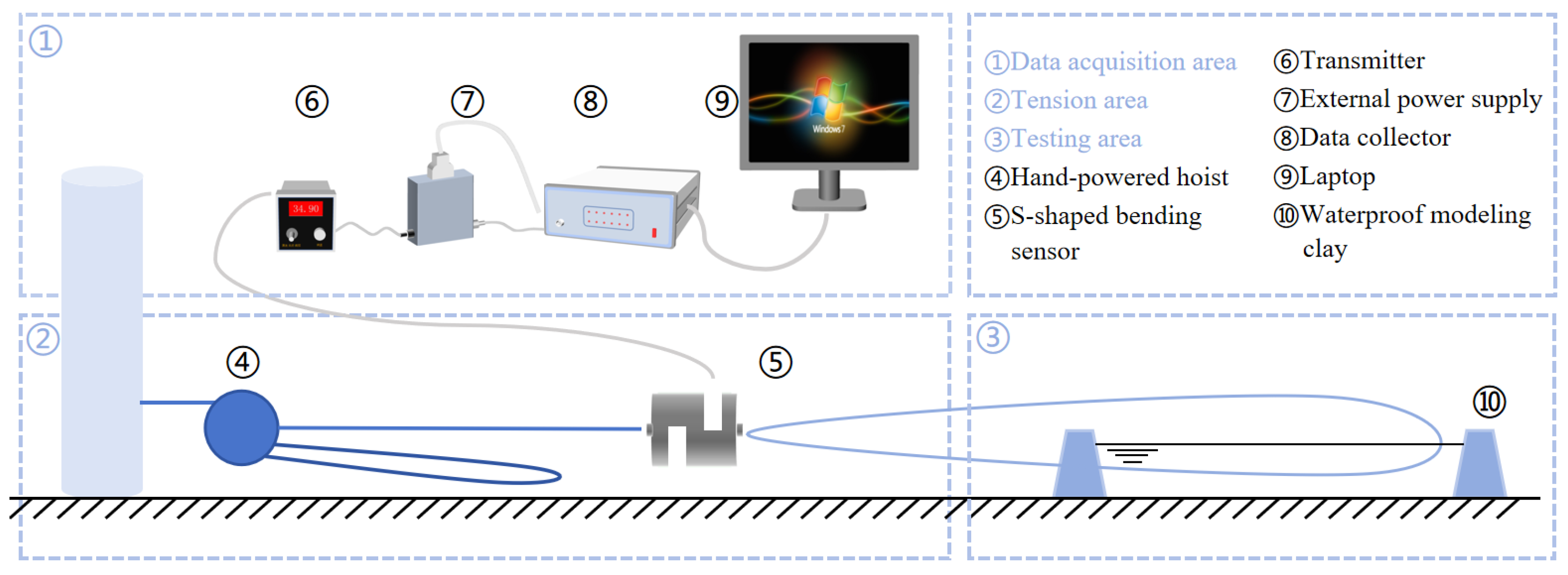

2. Materials and Methods

2.1. Experimental Setup

2.2. Subjects and Other Materials

2.3. Experimental Methods

2.3.1. Friction Coefficient of Different Footwear

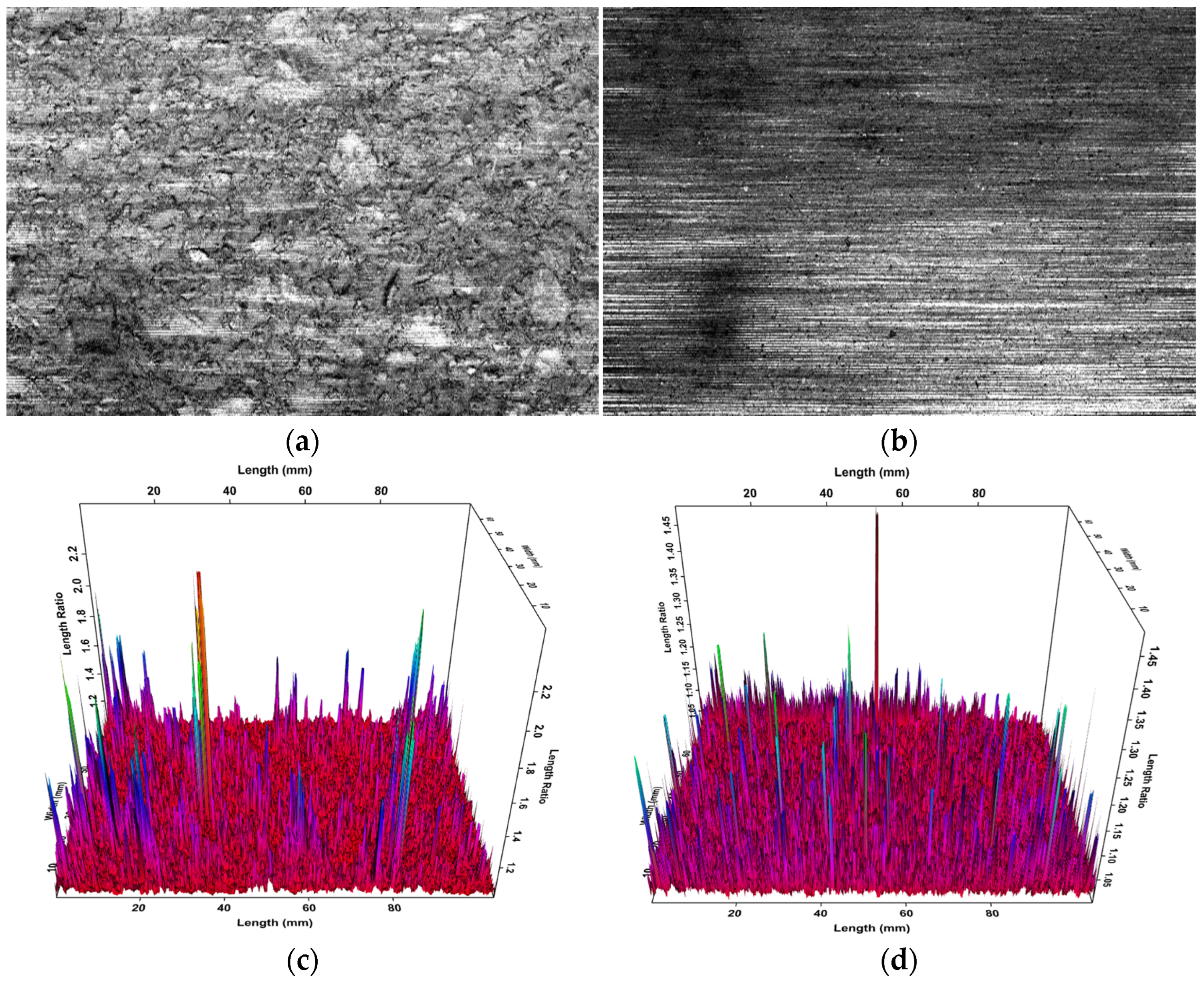

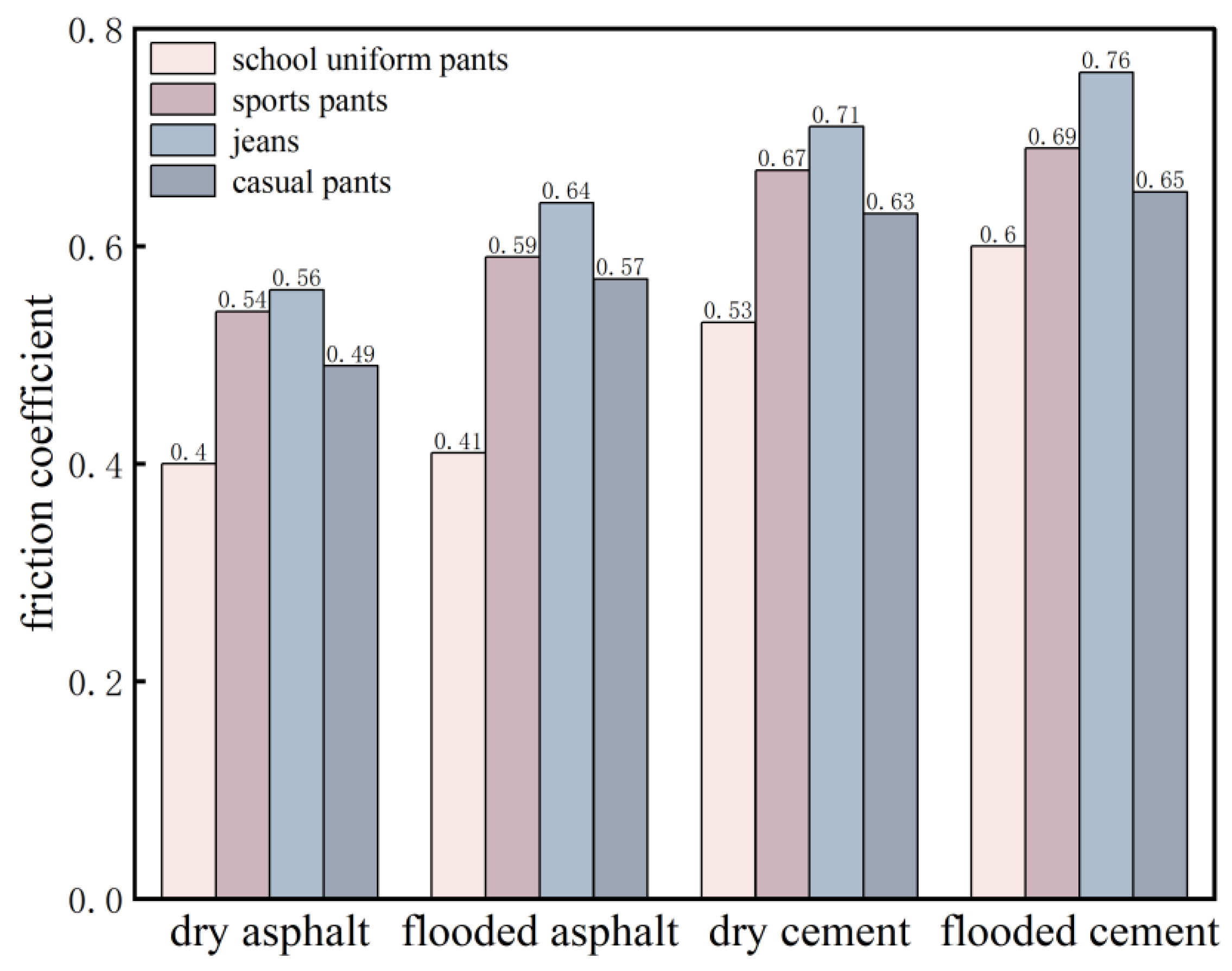

2.3.2. Friction Coefficient of Different Clothing

2.3.3. Relationship Between Pressure and Friction Coefficient

3. Discussion and Analysis

3.1. Friction Coefficients of Different Shoe Models

3.2. Friction Coefficients of Different Types of Clothing

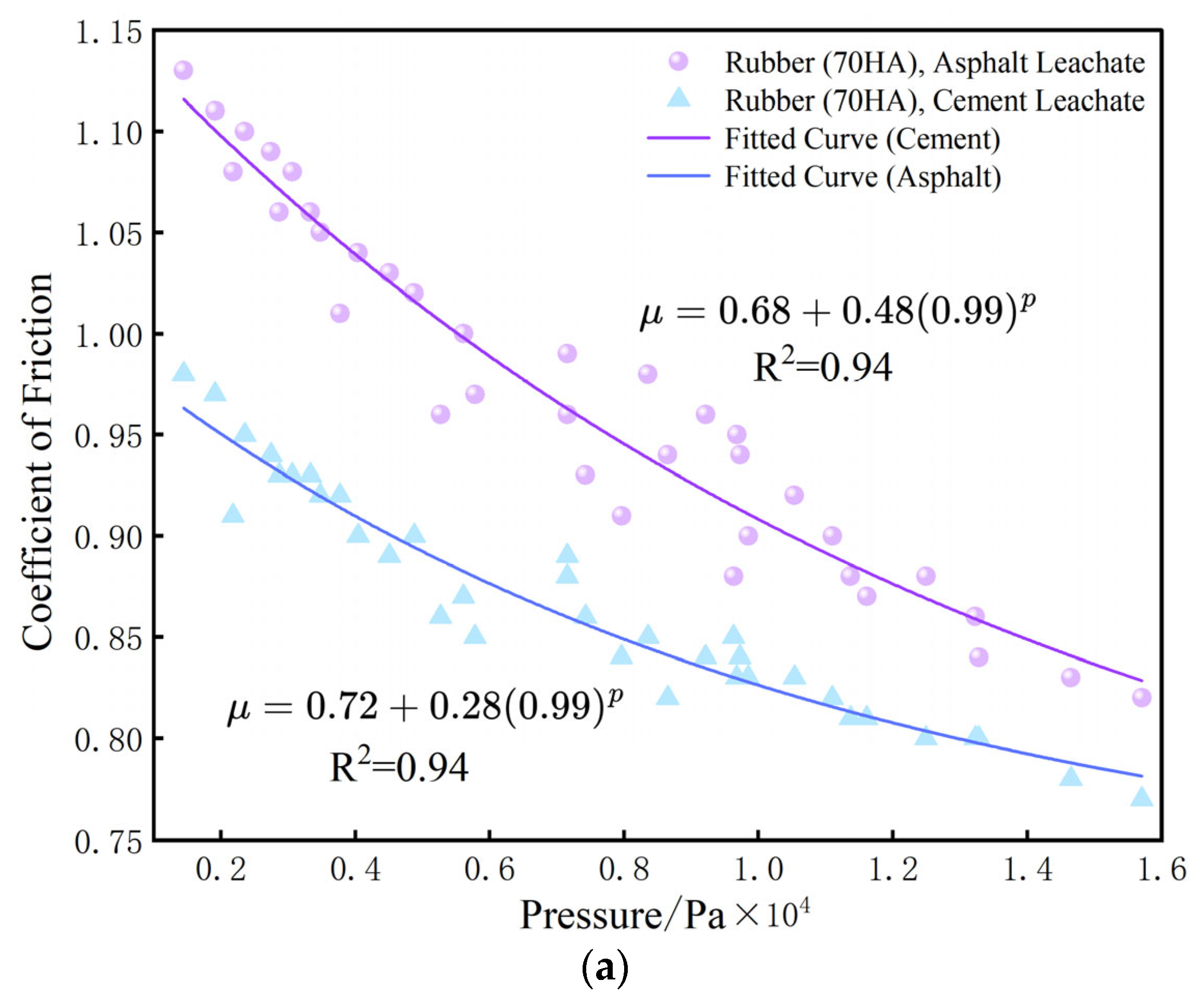

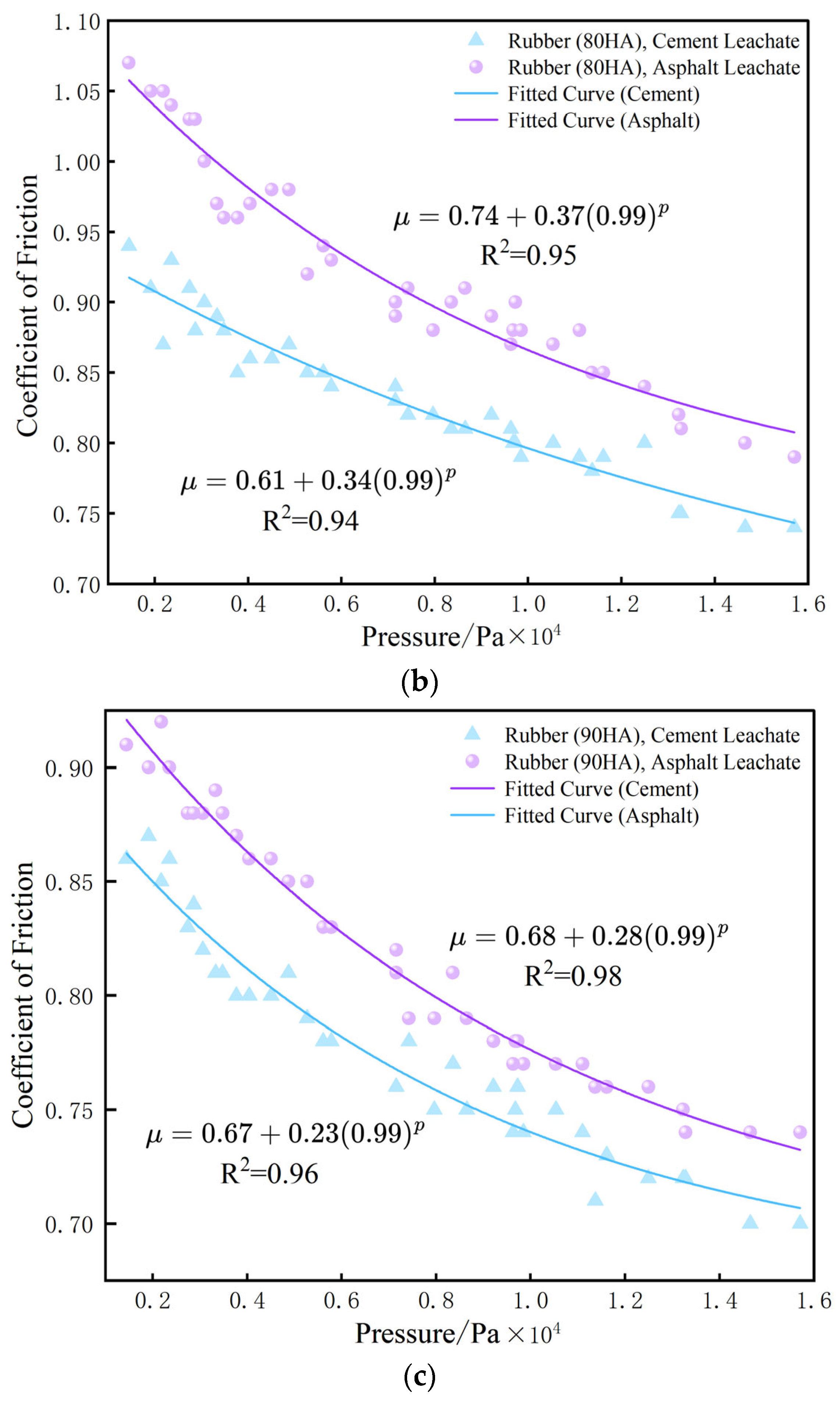

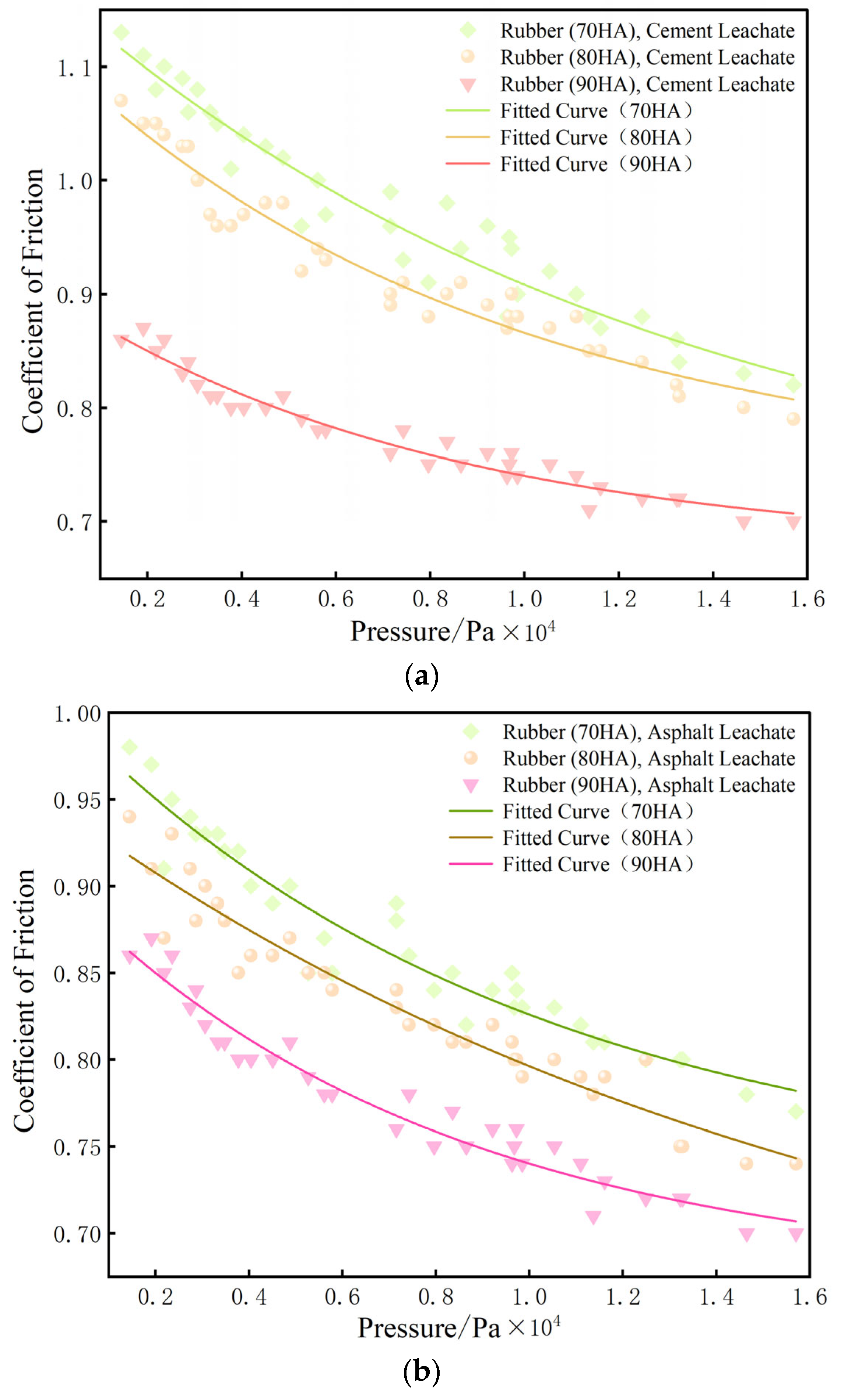

3.3. Relationship Between Pressure and Friction Coefficient

4. Conclusions and Future Research Directions

4.1. Conclusions

- (1)

- Friction Coefficient Measurement: Experiments determined that under waterlogged conditions, the friction coefficients for various shoe types and pants ranged from 0.59 to 0.80 and 0.53 to 0.76, respectively. In combinations of real-human testing, hydrophilic sole materials, and experimental pavement, the friction coefficient under waterlogged conditions was generally higher than under dry conditions. This result confirms that the traditional view—that the lubricating effect of water under wet conditions reduces the friction coefficient—is not absolute. Furthermore, this study innovatively measured the friction coefficient using resistance postures during floods, demonstrating that previous selections of friction coefficients at 0.3 or 0.4 yielded underestimated values.

- (2)

- Friction Coefficient Variation: In contrast to previous studies that adopted a fixed friction coefficient for the entire pedestrian instability analysis, this research experimentally analyzed the effects of rubber hardness and load. Results indicate a clear trend: the greater the rubber hardness, the lower the friction coefficient. A dynamic process was observed where the friction coefficient decreases as the applied load increases. Consequently, we propose that future pedestrian instability risk assessments should dynamically select the friction coefficient by accounting for multiple influencing factors such as pressure and water depth, rather than relying on a single static value.

- (3)

- Friction Coefficient Selection Method: For the first time, buoyancy was incorporated into the friction coefficient selection framework. By referencing national human body standards to determine pressure ranges and analyzing the relationships between rubber hardness, two typical urban pavement types, and pressure levels, this study established exponential equations expressing the correlation between pressure and the friction coefficients for three types of rubber (70 HA, 80 HA, and 90 HA) on both asphalt and cement surfaces. These equations allow future researchers to consider key parameters—pavement type, sole hardness, and pressure at varying water depths—to dynamically select an appropriate friction coefficient. This advancement is expected to significantly improve the accuracy and reliability of pedestrian instability risk analysis.

4.2. Safety Protection Recommendations Based on Research Findings

- (1)

- Innovation in Personal Protective Equipment: During rainstorms, the public should select hydrophilic-material footwear and clothing (e.g., cotton jeans and rubber-soled anti-slip shoes). The capillary adhesion force generated upon water contact significantly enhances ground stability. Shoe soles should prioritize medium-hardness rubber (tactile flexibility), which optimally maintains friction performance under varying water pressure. Avoid daily wear of hydrophobic smooth materials (e.g., synthetic fiber school pants and plastic clogs), as these materials readily induce fluid lubrication leading to slippage.

- (2)

- Proactive Modification of High-Risk Environments: Municipal departments should prioritize modifying flood diversion channels: permeable pavements (e.g., porous asphalt) accelerate surface-water recession, shortening the duration of buoyancy hazards; texture optimization (e.g., micro-grooving on cement surfaces) disrupts continuous water film formation, maintaining effective interfacial friction. Renovation projects should focus on accident-prone areas (e.g., underpasses and sunken bridge zones) to establish “sponge-type disaster prevention corridors”.

- (3)

- Upgraded Intelligent Emergency Response: Establish a buoyancy-aware early warning system that dynamically assesses slip risk through real-time calculation of pedestrians’ effective plantar pressure (offsetting buoyancy effects). When the monitored water depth exceeds critical thresholds, issue tiered alerts to the public:“Yellow Alert” (recommend detouring low-lying sections) → ”Red Alert” (prohibit wading through water).

4.3. Future Research Directions

- (1)

- Future research requires in-depth coupling analysis of surface roughness and wear state for identical road materials: Prepare multi-level roughness specimens through differential processes (e.g., asphalt embossing/exposed aggregate cement), establishing a macro-meso morphological parameter system; simulate wheel rolling compaction and natural aging to quantify roughness attenuation caused by wear and its effect on thickening interfacial water films; develop a “initial roughness-wear progression-water film dynamics-friction coefficient” decay prediction model. Subsequently, propose the minimum roughness threshold ensuring pedestrian safety and critical pore clogging rate for permeable pavements, providing specifications for road design and maintenance in flood-prone areas.

- (2)

- Research on Multi-Control Parameter Collaborative Optimization: While existing experiments have addressed the impact of sole hardness, systematic investigations into sole tread design (e.g., groove depth, density, and orientation), material diversity (e.g., polyurethane, EVA foam, and TPU composites), and wear state remain insufficient. Subsequent studies should design orthogonal experiments to quantify the influence of geometric tread parameters (e.g., aspect ratio and curvature radius) on water film rupture capacity and contact area, employing high-speed imaging technology to capture microscopic contact behavior between soles and pavement under dynamic loading. Concurrently, measurements of water film thickness and contact angle will yield data with enhanced applicability.

- (3)

- Dynamic Load and Multi-Physics Coupling Mechanism Analysis: The current pressure testing is based on a static model and does not account for the spatiotemporal variation of plantar pressure during the gait cycle (e.g., differences between heel strike and toe-off phases). Future work should combine biomechanical simulation with pressure sensor arrays to develop a dynamic model linking gait, pressure, and friction coefficients. In addition, the coupling effects between hydrodynamic forces—such as water flow impact and vortex-induced disturbances—and frictional forces should be examined to better capture the transient instability processes experienced by pedestrians during urban flooding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, T.; Cui, X. Comparative Observation of Two Severe Rainstorms in Beijing. Atmos. Sci. 2022, 46, 111–132. [Google Scholar]

- Liu, J.; Liu, J.; Pei, Y.; Mei, C. Causes and Disaster Prevention of “7·20” Heavy Rainstorm and Waterlogging in Zhengzhou. J. Zhengzhou Univ. (Eng. Ed.) 2023, 44, 38–45. [Google Scholar]

- Tascón-González, L.; Ferrer-Julià, M.; Ruiz, M.; García-Meléndez, E. Social Vulnerability Assessment for Flood Risk Analysis. Water 2020, 12, 558. [Google Scholar] [CrossRef]

- Salazar-Briones, C.; Ruiz-Gibert, J.M.; Lomelí-Banda, M.A.; Mungaray-Moctezuma, A. An Integrated Urban Flood Vulnerability Index for Sustainable Planning in Arid Zones of Developing Countries. Water 2020, 12, 608. [Google Scholar] [CrossRef]

- Metangley, S.; Middey, A.; Kadaverugu, R. Modern methods to explore the dynamics between aerosols and convective precipitation: A critical review. Dyn. Atmos. Oceans 2024, 106, 101465. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, W.; Wang, W. Block-level spatial integration of population density, social vulnerability, and heavy precipitation reveals intensified urban flooding risk. Sustain. Cities Soc. 2024, 117, 105984. [Google Scholar] [CrossRef]

- Pickering, N.; Nassiri, S. Stormwater management and roadways. In Oxford Research Encyclopedia of Environmental Science; Oxford Research Encyclopedias: Oxford, UK, 2021. [Google Scholar]

- Bernardini, G.; Romano, G.; Soldini, L.; Quagliarini, E. How Urban Layout and Pedestrian Evacuation Behaviours Can Influence Flood Risk Assessment in Riverine Historic Built Environments. Sustain. Cities Soc. 2021, 70, 102906. [Google Scholar] [CrossRef]

- Zhu, Z.; Gou, L.; Liu, S.; Peng, D. Effect of Urban Neighbourhood Layout on the Flood Intrusion Rate of Residential Buildings and Associated Risk for Pedestrians. Sustain. Cities Soc. 2023, 92, 104485. [Google Scholar] [CrossRef]

- Wang, W.; Li, Y.; Zhang, Y.; Wu, Z. Pedestrian Evacuation Planning under Dam-Break Flood Disaster Considering Road Risk and Road Pedestrian Demand. Int. J. Disaster Risk Reduct. 2024, 104, 104355. [Google Scholar] [CrossRef]

- Xia, J.; Falconer, R.A.; Wang, Y.; Xiao, X. New Criterion for the Stability of a Human Body in Floodwaters. J. Hydraul. Res. 2014, 52, 93–104. [Google Scholar] [CrossRef]

- Jonkman, S.N.; Penning-Rowsell, E. Human Instability in Flood Flows. JAWRA J. Am. Water Resour. Assoc. 2008, 44, 1208–1218. [Google Scholar] [CrossRef]

- Yee, M. Human Stability in Floodways. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 2003. [Google Scholar]

- Keller, R.J.; Mitsch, B. Safety Aspects of Design Roadways as Floodways; Research Report, No. 69; Urban Water Research Association of Australia: Melbourne, Australia, 1993; p. 51. [Google Scholar]

- Takahashi, S.; Endoh, K.; Muro, Z.I. Experimental Study on People’s Safety Against Overtopping Waves on Breakwaters. Port Harb. Inst. Rep. 1992, 34, 4–31. [Google Scholar]

- Martínez-Gomariz, E.; Gómez, M.; Russo, B. Experimental Study of the Stability of Pedestrians Exposed to Urban Pluvial Flooding. Nat. Hazards 2016, 82, 1259–1278. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, Y.; Gou, L.; Peng, D.; Pang, B. On the Physical Vulnerability of Pedestrians in Urban Flooding: Experimental Study of the Hydrodynamic Instability of a Human Body Model in Floodwater. Urban Clim. 2023, 48, 101420. [Google Scholar] [CrossRef]

- Guo, X.; Wang, W.; Fang, X.; Gong, Y.; Li, J.; Wang, M.; Li, X. Analysis of Self-Rescue Possibilities for Pedestrians in the Aftermath of Destabilization during a Flood Event. Water 2024, 16, 1218. [Google Scholar] [CrossRef]

- He, X.; Wang, Y. Preliminary Measurement and Discussion on the Friction Coefficient of Anti-Slip Shoes. Qual. World 2002, 6, 49. [Google Scholar]

- Liu, L.; Li, K.W.; Lee, Y.H.; Chen, C.C.; Chen, C.Y. Friction Measurements on “Anti-Slip” Floors under Shoe Sole, Contamination, and Inclination Conditions. Saf. Sci. 2010, 48, 1321–1326. [Google Scholar] [CrossRef]

- Derler, S.; Gerhardt, L.C. Tribology of Skin: Review and Analysis of Experimental Results for the Friction Coefficient of Human Skin. Tribol. Lett. 2012, 45, 1–27. [Google Scholar] [CrossRef]

- Ye, Z. Study on Experimental Methods for Slip Resistance Performance of Footwear. Chin. Pers. Prot. Equip. 2013, 4, 35–38. [Google Scholar]

- China Steel Group Wuhan Safety and Environmental Protection Research Institute Co., Ltd.; National Labor Protection Products Quality Supervision and Testing Center (Wuhan); Dongguan Xinhuhui Industrial Co., Ltd.; Hunan Valin Xiangtan Iron and Steel Co., Ltd.; Yangzhou Jianbu Footwear Co., Ltd.; Intertek (Guangzhou) Quality Technology Service Co., Ltd.; Qingdao Shanfang Instrument Co., Ltd. Test Method for Slip Resistance of Foot Protection Shoes; General Administration of Quality Supervision: Beijing, China; Inspection and Quarantine of the People’s Republic of China: Beijing, China; Standardization Administration of China: Beijing, China, 2012; p. 20.

- GB/T 10000-2023; Chinese Adult Anthropometric Dimensions. China National Institute of Standardization (CNIS): Beijing, China, 2023.

- GB/T 26158-2010; Chinese Minor Anthropometric Dimensions. China National Institute of Standardization (CNIS): Beijing, China, 2010.

- Xia, J.Q.; Gu, A.C.; Shu, C.W.; Guo, P. Theoretical Analysis and Experimental Study on Human Stability Conditions in Floods. Disaster Sci. 2014, 29, 4–11. [Google Scholar]

- Barquins, M.; Roberts, A.D. Rubber Friction Variation with Rate and Temperature: Some New Observations. J. Phys. D Appl. Phys. 1986, 19, 547. [Google Scholar] [CrossRef]

- Foster, D.N.; Cox, R.J. Stability of Children on Roads Used as Floodways; University of New South Wales, Water Research Laboratory: Beijing, China, 1973; Volume 73, p. 12. [Google Scholar]

- Guo, X. Study on Human Stability under Urban Road Flooding Conditions and Development of Risk Early Warning Equipment. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2024. [Google Scholar]

- Grönqvist, R. Mechanisms of Friction and Assessment of Slip Resistance of New and Used Footwear Soles on Contaminated Floors. Ergonomics 1995, 38, 224–241. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Yang, Y.; Zhao, H.; Jelagin, D.; Chen, F.; Gilabert, F.A.; Guarin, A. Effects of Surface Texture Deterioration and Wet Surface Conditions on Asphalt Runway Skid Resistance. Tribol. Int. 2021, 153, 106589. [Google Scholar] [CrossRef]

| Weight Standard | Load at 15 cm Depth (kg) | Load at 35 cm Depth (kg) | Load at 35 cm Depth (kg) | Load at 75 cm Depth (kg) | Load at 95 cm Depth (kg) | Load at 115 cm Depth (kg) |

|---|---|---|---|---|---|---|

| ① | 45.32 | 42.98 | 39.68 | 35.34 | 29.17 | 21.36 |

| ② | 64.10 | 59.81 | 54.24 | 47.36 | 39.34 | 30.32 |

| ③ | 39.54 | 37.62 | 34.13 | 29.23 | 22.94 | 15.39 |

| ④ | 54.02 | 51.09 | 46.42 | 40.2 | 32.5 | 23.62 |

| ⑤ | 13.59 | 12.54 | 11.18 | 9.55 | 7.76 | 5.93 |

| ⑥ | 19.94 | 18.39 | 16.47 | 14.22 | 11.66 | 8.85 |

| Pavement Type Types of Shoes | Crocodile Shoes | High Heels | Nike Skate Shoes | Asics Sports Shoes | NB Sports Shoes | Adidas Sports Shoes | Rubber Sole Shoes |

|---|---|---|---|---|---|---|---|

| Concrete Pavement. | 0.65 | 0.68 | 0.70 | 0.71 | 0.73 | 0.74 | 0.67 |

| Asphalt Pavement. | 0.61 | 0.61 | 0.72 | 0.73 | 0.74 | 0.77 | 0.70 |

| Pavement Type Types of Shoes | Crocodile Shoes | High Heels | Nike Skate Shoes | Asics Sports Shoes | NB Sports Shoes | Adidas Sports Shoes | Rubber Sole Shoes |

|---|---|---|---|---|---|---|---|

| Concrete Pavement. | 0.74 | 0.72 | 0.75 | 0.78 | 0.79 | 0.80 | 0.74 |

| Asphalt Pavement. | 0.59 | 0.65 | 0.73 | 0.77 | 0.75 | 0.76 | 0.72 |

| Pavement Type Types of Pants | Glossy Track Pants | Casual Pants | Gray Sweatpants | Jeans |

|---|---|---|---|---|

| Concrete Pavement. | 0.60 | 0.65 | 0.69 | 0.76 |

| Asphalt Pavement. | 0.53 | 0.63 | 0.67 | 0.71 |

| Rubber Hardness/(HA) | Formula | Remarks |

|---|---|---|

| 70 | Cement Waterlogged Surface | |

| Asphalt Waterlogged Surface | ||

| 80 | Cement Waterlogged Surface | |

| Asphalt Waterlogged Surface | ||

| 90 | Cement Waterlogged Surface | |

| Asphalt Waterlogged Surface |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Li, J.; Li, X.; Liu, D.; Wang, Y.; Si, Q.; Wang, H. Study on the Friction Coefficient of Pedestrian Instability Under Urban Road Flooding Conditions. Water 2025, 17, 1963. https://doi.org/10.3390/w17131963

Guo J, Li J, Li X, Liu D, Wang Y, Si Q, Wang H. Study on the Friction Coefficient of Pedestrian Instability Under Urban Road Flooding Conditions. Water. 2025; 17(13):1963. https://doi.org/10.3390/w17131963

Chicago/Turabian StyleGuo, Junjie, Junqi Li, Xiaojing Li, Di Liu, Yu Wang, Qin Si, and Hui Wang. 2025. "Study on the Friction Coefficient of Pedestrian Instability Under Urban Road Flooding Conditions" Water 17, no. 13: 1963. https://doi.org/10.3390/w17131963

APA StyleGuo, J., Li, J., Li, X., Liu, D., Wang, Y., Si, Q., & Wang, H. (2025). Study on the Friction Coefficient of Pedestrian Instability Under Urban Road Flooding Conditions. Water, 17(13), 1963. https://doi.org/10.3390/w17131963