Impact of Filtration Cycle Patterns on Both Water and Energy Footprints in Drip Irrigation Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

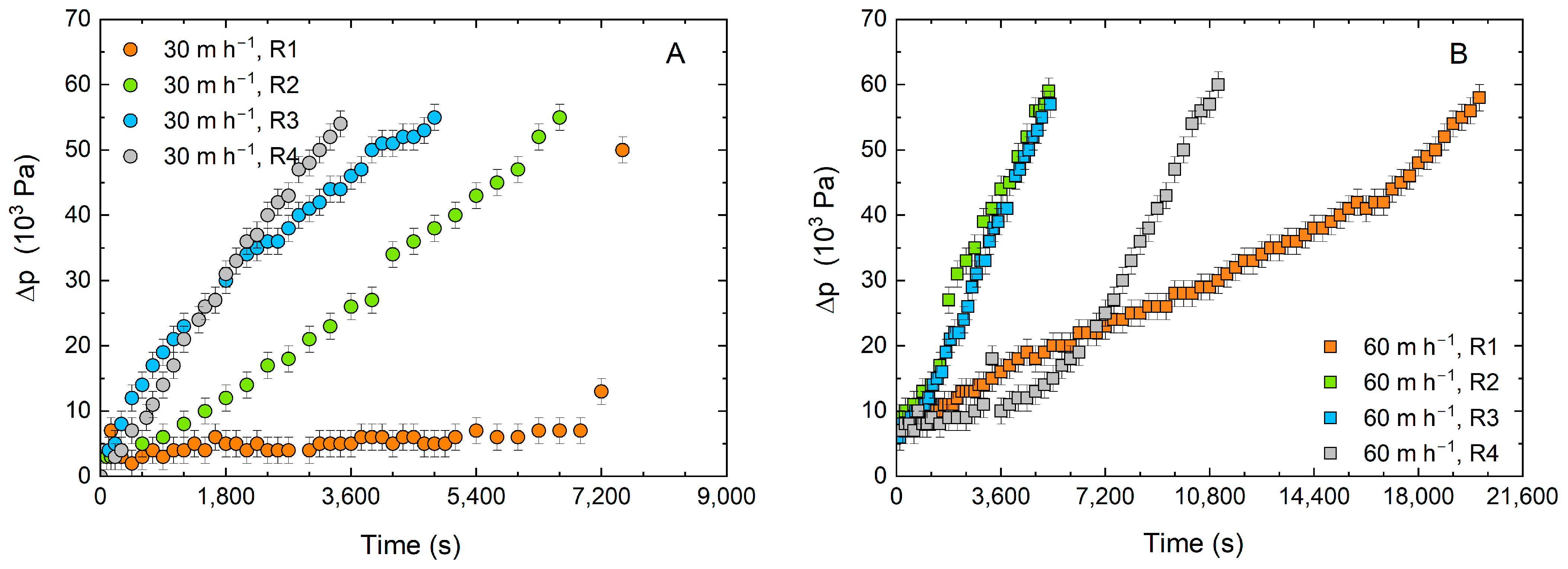

2.2. Experimental Results

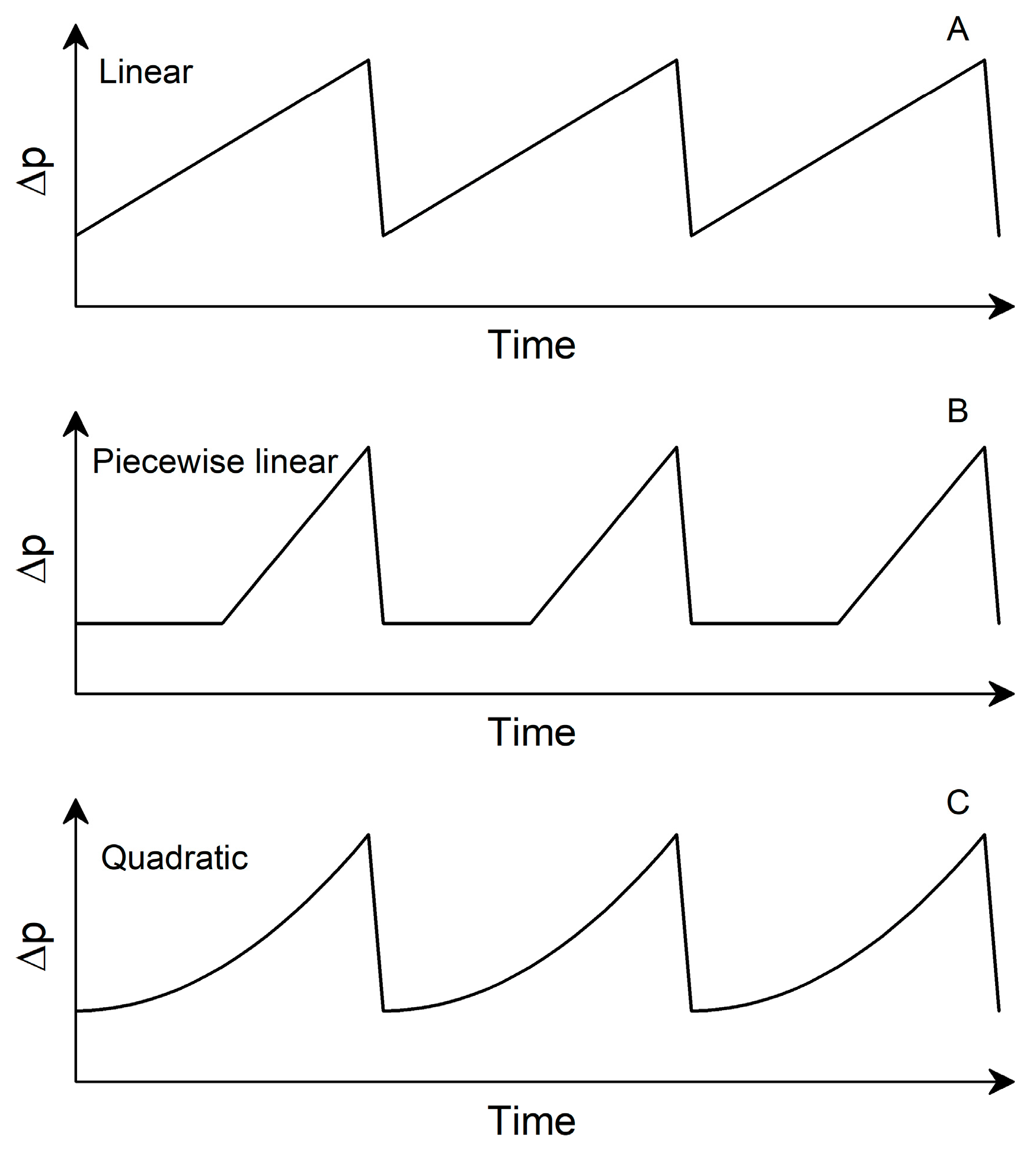

2.3. Filtration Cycles

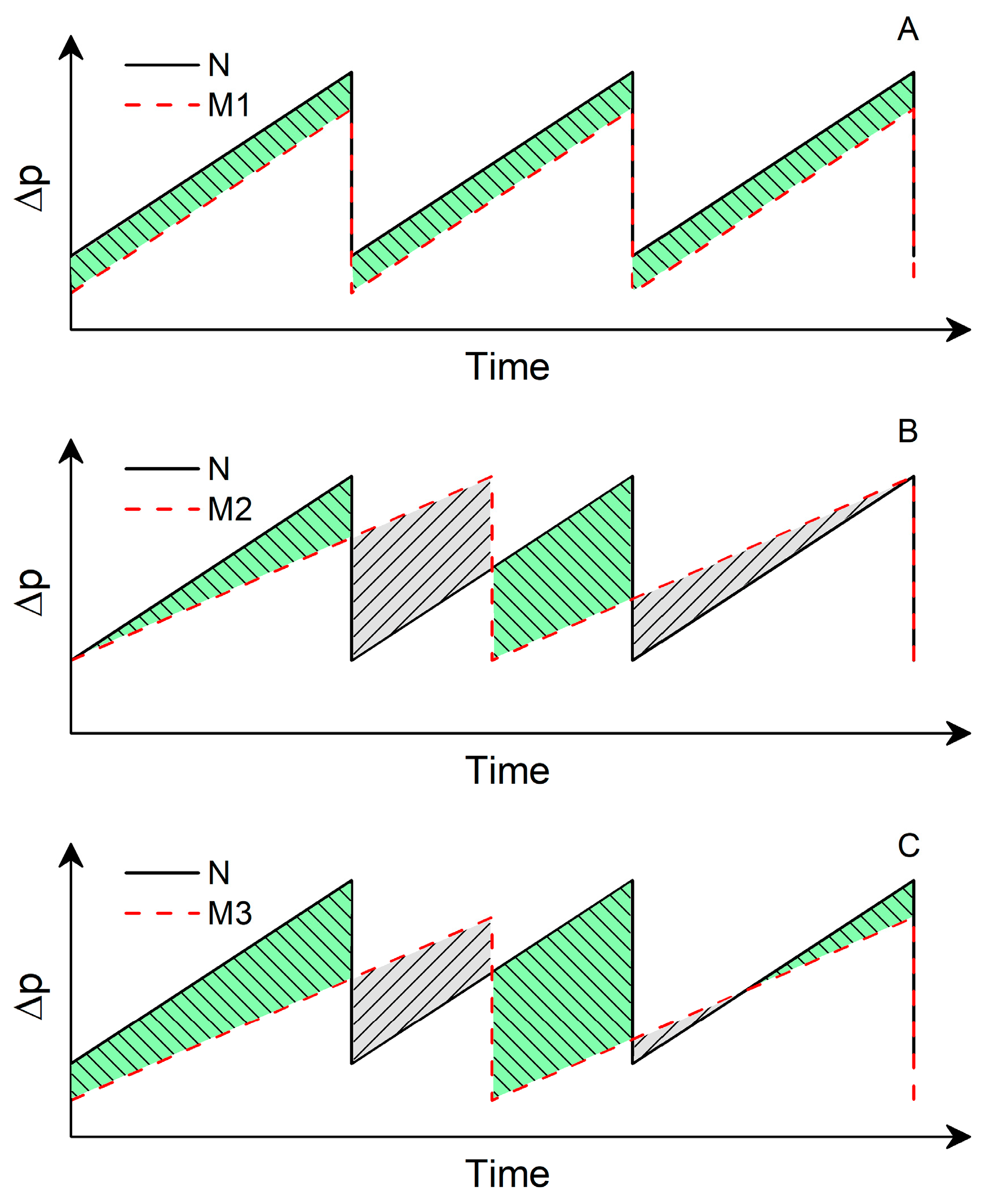

2.3.1. Linear Behavior

2.3.2. Piecewise Linear Behavior

2.3.3. Quadratic Behavior

2.4. Supporting Data

3. Results

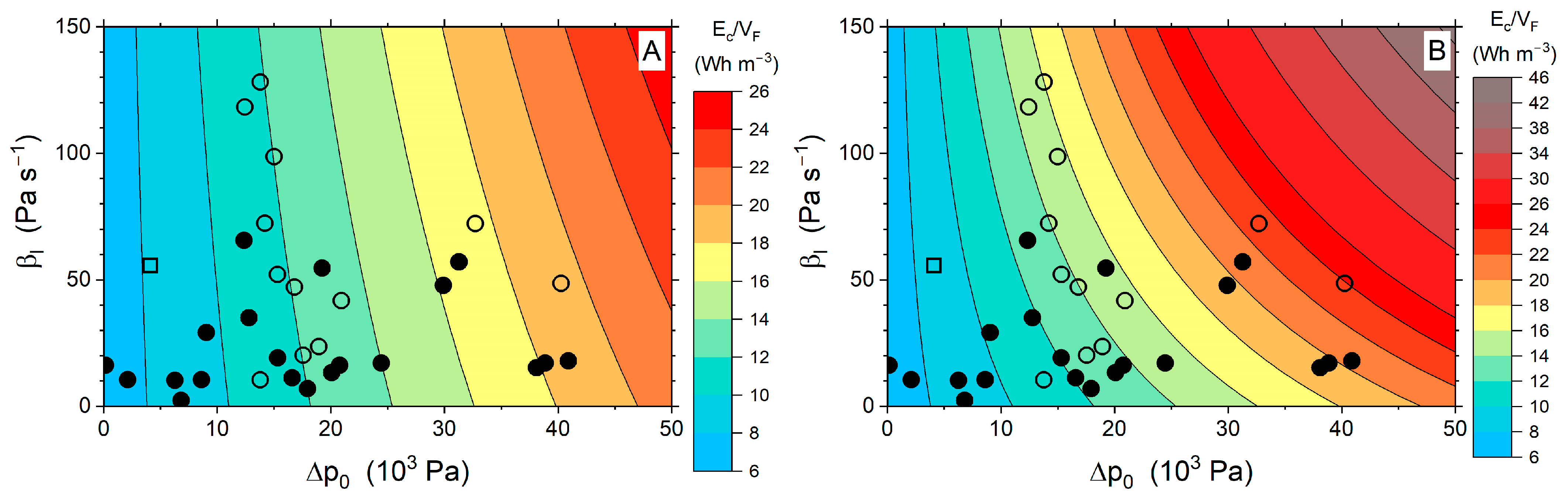

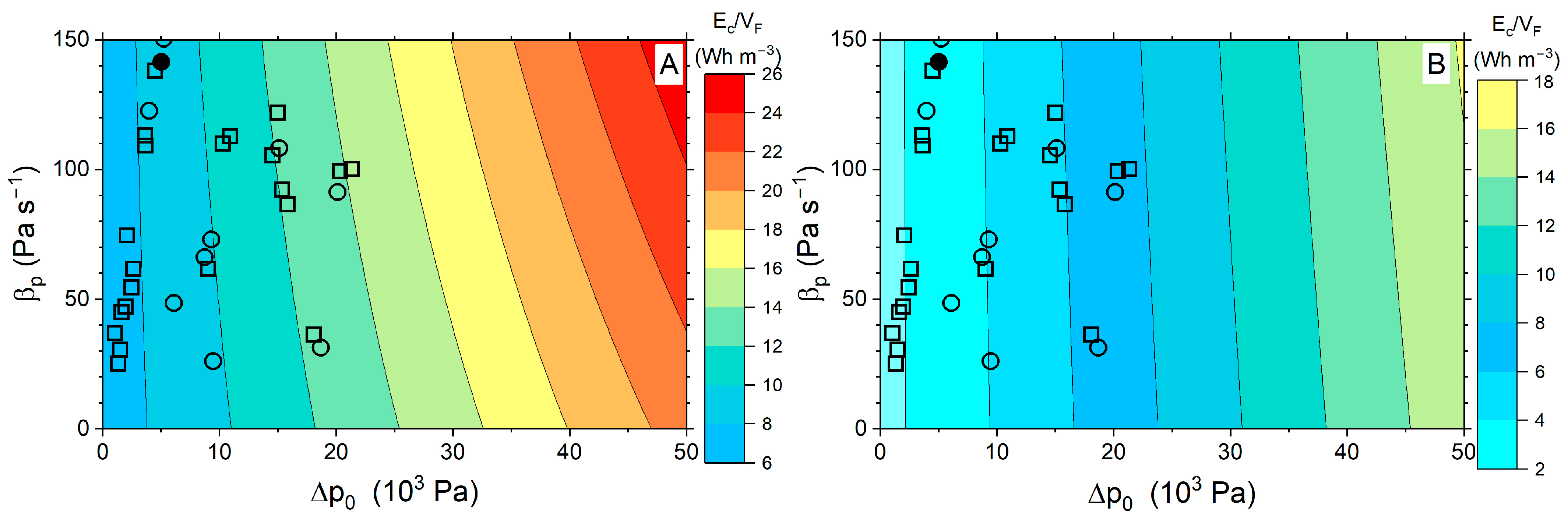

3.1. Linear Behavior

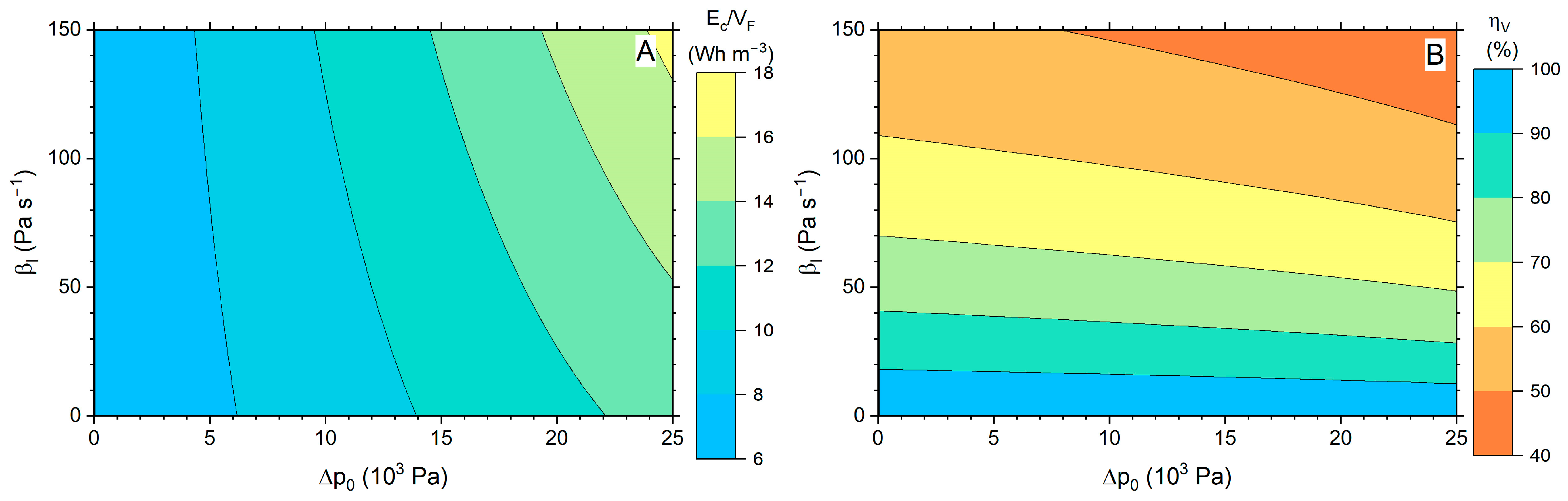

3.2. Piecewise Linear Behavior

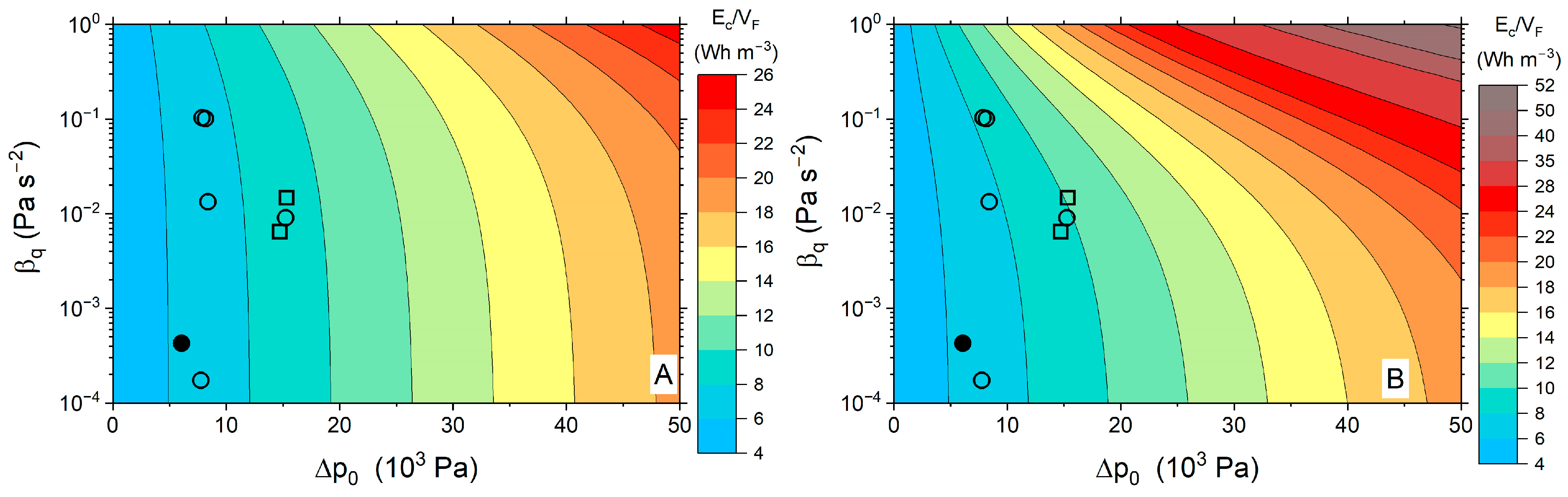

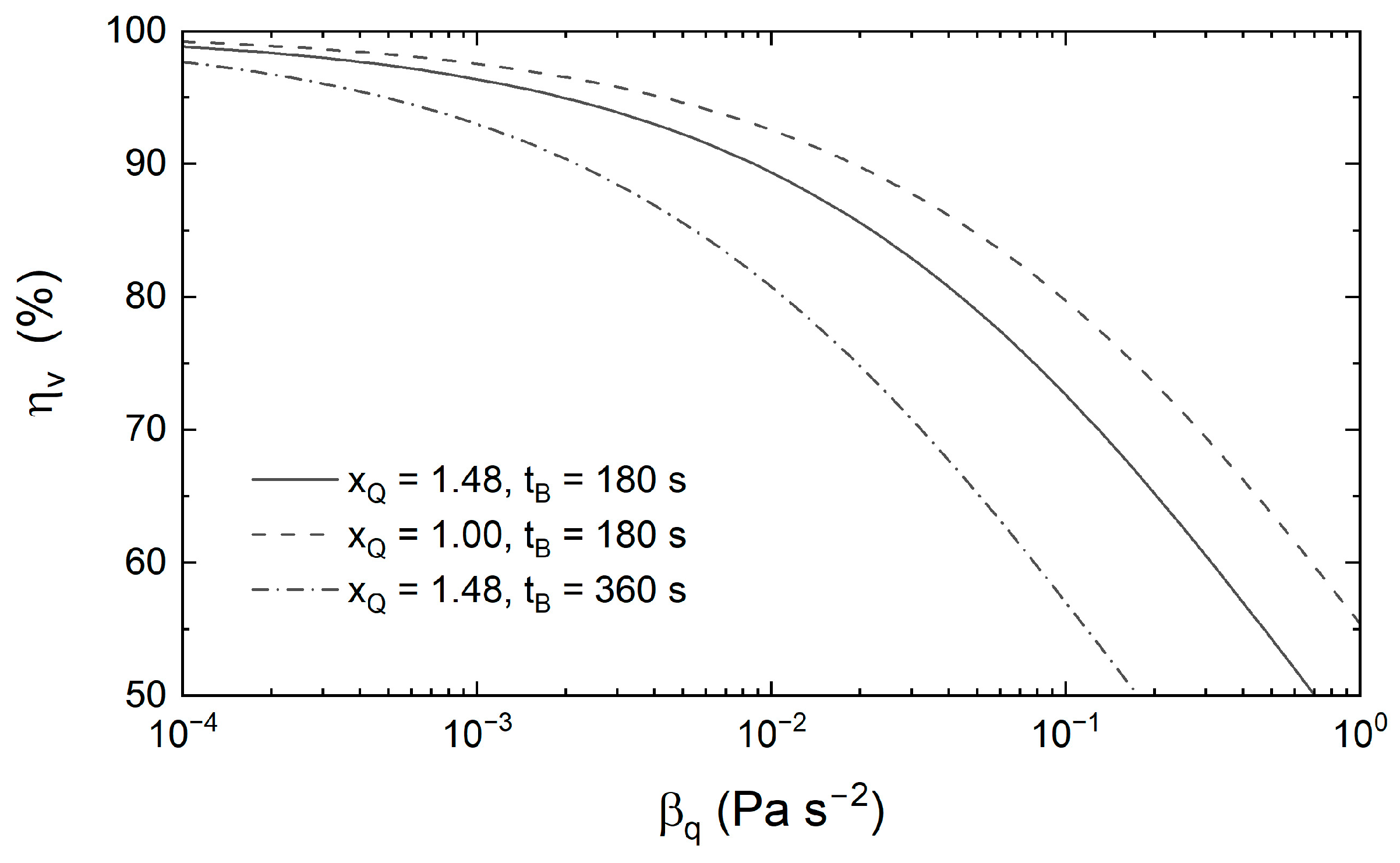

3.3. Quadratic Behavior

4. Discussion

5. Conclusions

- It is better to propose a redesign that decreases the filter pressure drop with tap water than another that extends the duration of the filtration cycle .

- The effect of the backwashing regime appears as a product of three contributions: (1) volumetric flow rate normalized by its filtration value, (2) filter pressure drop normalized by the initial value in filtration mode, and (3) backwashing time span tB. All of these three terms clearly depend on the filter design, although the type and concentration of particles may also affect them.

- High pressure backwashing methods are only recommended when associated with very low backwashing times. In the case that high pressure procedures become inevitable for backwashing, designs that prolong the duration of the filtration cycle may be beneficial in terms of energy consumption, although it is still more advisable to reduce the value.

- The main filtration parameter is the slope of the function, with a lower slope corresponding to a higher water use efficiency.

- and values are irrelevant.

- The backwashing volumetric flow rate normalized by its filtration value and the duration time for backwashing tB are the unique backwashing parameters that contribute to variations in the water use efficiency.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Water Assessment Programme (UNESCO WWAP). The United Nations World Water Development Report 2017. In Wastewater: The Untapped Resource; UNESCO: Paris, France, 2017. [Google Scholar]

- National Plan for Wastewater Treatment, Sanitation, Efficiency, Savings and Reuse. General Water Directorate; Secretary of State for the Environment; Spanish Ministry for Ecological Transition and the Demographic Challenge, 2021. Available online: https://www.miteco.gob.es/content/dam/miteco/es/agua/temas/planificacion-hidrologica/dsear_plan_book_english_tcm30-538717.pdf (accessed on 10 March 2025).

- Doeser, B. Water policy under the European Grean Deal. In State Play and Key Challenges Ahead; Water Days 2021 Symposium: Lubljana, Slovenia, 2021. [Google Scholar]

- Hristov, J.; Barreiro-Hurle, J.; Salputra, G.; Blanco, M.; Witzke, P. Reuse of treated water in European agriculture: Potential to address water scarcity under climate change. Agric. Water Manag. 2021, 251, 106872. [Google Scholar] [CrossRef]

- Abi Saab, M.T.; Jomaa, I.; El Hage, R.; Skaf, S.; Fahed, S.; Rizk, Z.; Massaad, R.; Romanos, D.; Khairallah, Y.; Azzi, V.; et al. Are fresh water and reclaimed water safe for vegetable irritation? Empirical evidence from Lebanon. Water 2022, 14, 1437. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesa y Alimentación, 2024. Encuesta Sobre Superficies y Rendimientos de Cultivos. Análisis de Los Regadíos en España. 2023. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/boletin20231_tcm30-690544.pdf (accessed on 10 March 2025).

- Instituto Nacional de Estadística. Encuesta Sobre el uso del Agua en el Sector Agrario 2018 Estadísticas Sobre Agua. Available online: https://www.ine.es/dyngs/INEbase/operacion.htm?c=Estadistica_C&cid=1254736176839&menu=ultiDatos&idp=1254735976602 (accessed on 11 February 2025).

- ICID, International Comission on Irrigation and Drainage. Annual Report 2022-23. Available online: https://icid-ciid.org/icid_data_web/ar_2022-23.pdf (accessed on 10 February 2025).

- Trooien, T.P.; Hills, D.J. Application of Biological Effluent. In Microirrigation for Crop Production. Design, Operation and Management; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 329–356. [Google Scholar]

- Lv, C.; Niu, W.; Du, Y.; Sun, J.; Dong, A.; Wu, M.; Mu, F.; Zhu, J.; Siddique, H.M. A meta-analysis of labyrinth channel emitter clogging characteristics under Yellow River water drip tape irrigation. Agric. Water Manag. 2024, 291, 108634. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, C.; Li, M.; Zhangzhong, L.; Song, P.; Li, Y. Interaction and adaptation of phosphorus fertilizer and calcium ion in drip irrigation systems: The perspective of emitter clogging. Agric. Water Manag. 2023, 282, 108269. [Google Scholar] [CrossRef]

- Zhang, W.; Cai, J.; Zhai, G.; Song, L.; Lv, M. Experimental study on the filtration characteristics and sediment distribution influencing factors of sand media filters. Water 2023, 15, 4303. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Q.; Zhang, J.; Zong, R.; Liu, N.; Wang, Z. Experimental study of filtration performance of disc filter with discrete channel structure. J. Irrig. Drain. Eng. 2023, 149, 04023013. [Google Scholar] [CrossRef]

- Shi, K.; Liu, Z.; Xie, Y.; Li, M. Study on optimal start-up time and water usage volume of blowdown residue discharge of mesh filter. Water Supply 2021, 21, 2904–2915. [Google Scholar] [CrossRef]

- de Deus, F.P.; Testezlaf, R.; Mesquita, M. Assessment methodology of backwash in pressurized sand filters. Rev. Bras. Eng. Agric. Ambient. 2016, 20, 600–605. [Google Scholar] [CrossRef]

- de Deus, F.P.; Mesquita, M.; Salcedo Ramirez, J.C.; Testezlaf, R.; de Almeida, R.C. Hydraulic characterization of the backwash process in sand filters used in micro irrigation. Biosyst. Eng. 2020, 192, 188–198. [Google Scholar] [CrossRef]

- Burt, C.M. Hydraulics of Commercial Sand Media Filter Tanks Used for Agricultural Drip Irrigation. In ITRC Report No. R 10001. Irrigation Training and Research Center; California Polytechnic State University: San Luis Obispo, CA, USA, 2010. [Google Scholar]

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient Water and Energy Use in Irrigation Modernization: Lessons from Spanish Case Studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Grafton, R.Q.; Williams, J.; Perry, C.J.; Molle, F.; Ringler, C.; Steduto, P.; Udall, B.; Wheeler, S.A.; Wang, Y.; Garrick, D.; et al. The paradox of irrigation efficiency. Science 2018, 361, 6404. [Google Scholar] [CrossRef]

- Ripperger, S.; Gösele, W.; Alt, C. Filtration, 1. Fundamentals. In Ullmann’s Enciclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Col KGaA: Weinheim, Germany, 2012; Volume 14, pp. 677–709. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, K.; Xie, Y.; Li, M. Hydraulic performance of self-priming mesh filter for microirrigation in Northwest China. Agric. Res. 2022, 11, 58–67. [Google Scholar] [CrossRef]

- Long, Y.; Liu, Z.; Zong, Q.; Jing, H.; Lu, C. Study on the structural characteristics of mesh filter cake in drip irrigation: Based on the growth stage of filter cake. Agriculture 2024, 14, 1296. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, N.; Zhang, J.; Wang, Z.; Liang, W.; Li, M.; Zhang, J. Development and performance evaluation of novel jet self-cleaning for screen filters in drip irrigation systems: More efficient, water-saving, and cleaner. Agric. Water Manag. 2025, 312, 109424. [Google Scholar] [CrossRef]

- Li, L.; Zhu, D.; Zhang, R.; Zheng, C.; Zhao, Z.; Hong, M.; Nazarov, K.; Liu, C. Enhanced experimental study on the head loss and filtration performance of annular flow disc filter. Trans. CSAE 2024, 40, 140–148. [Google Scholar] [CrossRef]

- Song, L.; Cai, J.; Zhai, G.; Feng, J.; Fan, Y.; Han, J.; Hao, P.; Ma, N.; Miao, F. Comparative study and evaluation of sediment deposition and migration characteristics of new sustainable filter media in micro-irrigation sand filters. Sustainability 2024, 16, 3256. [Google Scholar] [CrossRef]

- Alcon, G.D.; de Deus, F.P.; Diotto, A.V.; Thebaldi, M.S.; Mesquita, M.; Nana, Y.; Baptistella Zueleta, N.A. Influence of the diffuser plate construction design on the filtration hydraulic behaviour in a pressurized sand filter. Biosyst. Eng. 2023, 233, 114–124. [Google Scholar] [CrossRef]

- Pujol, T.; Puig-Bargués, J.; Arbat, G.; Duran-Ros, M.; Solé-Torres, C.; Pujol, J.; Ramírez de Cartagena, F. Effect of wand-type underdrains on the hydraulic performance of pressurised sand media filters. Biosyst. Eng. 2020, 192, 176–187. [Google Scholar] [CrossRef]

- Schroeder, A.; Marshall, L.; Trease, B.; Becker, A.; Laurie Sanderson, S. Development of helical, fish-inspired cross-step filter for collecting harmful algae. Bioinspired Biomim. 2019, 14, 56008. [Google Scholar] [CrossRef]

- Xu, Z.; Mao, X.Y.; Gu, Y.; Chen, X.; Kuang, W.; Wang, R.Z.; Shao, X.H. Analysis of hydrodynamic filtration performance in a cross-step filter for drip irrigation based on the CFD-DEM coupling method. Biosyst. Eng. 2023, 232, 114–128. [Google Scholar] [CrossRef]

- Ghaffari, M.; Soltani, J. Evaluation and comparison of performance in the disc filter with sand filters of filtration equipment in micro irrigation systems. Mod. Appl. Sci. 2016, 10, 264–271. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, H.; Liao, D.; Deng, Y. Comparative experiments on the technological performance of disc filters. IOP Conf. Ser. Mater. Sci. Eng. 2017, 207, 12066. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Pujol, J.; Pujol, T.; Cufí, S.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Solid removal across the bed depth in media filters for drip irrigation systems. Agriculture 2023, 13, 458. [Google Scholar] [CrossRef]

- Hasani, A.M.; Aminpour, Y.; Nikmehr, M.; Puig-Bargués, J.; Maroufpoor, E. Performance of Sand Filter with Disc and Screen Filters in Irrigation with Rainbow Trout Fish Effluent. Irrig. Drain. 2023, 72, 317–327. [Google Scholar] [CrossRef]

- Zong, Q.; Liu, Z.; Liu, H.; Yang, H. Backwashing performance of self-cleaning screen filters in drip irrigation systems. PLoS ONE 2019, 14, e0226354. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, R.; Wang, W.; Hu, X.; Cheng, Y.; Liu, F. Effect of fertilizer solution concentrations on filter clogging in drip fertigation systems. Agric. Water Manag. 2021, 250, 106829. [Google Scholar] [CrossRef]

- Jiao, Y.; Feng, J.; Liu, Y.; Yang, L.; Han, M. Sustainable operation mode of a sand filter in a drip irrigation system using Yellow River water in an arid area. Water Supply 2020, 20, 3636–3644. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Qiu, X.; Wang, J.; Wang, S.; Wang, H.; Shen, T. Study on the performance of filters under biogas slurry drip irrigation systems. Agriculture 2025, 15, 30. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Pujol, J.; Pujol, T.; Cufí, S.; Graciano-Uribe, J.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Efficiency of backwashing in removing solids from sand media filters for drip irrigation systems. Agriculture 2024, 14, 1570. [Google Scholar] [CrossRef]

- Mesquita, M.; Testezlaf, R.; Ramirez, J.C.S. The effect of media bed characteristics and internal auxiliary elements on sand filter head loss. Agric. Water Manag. 2012, 115, 178–185. [Google Scholar] [CrossRef]

- Graciano-Uribe, J.; Pujol, T.; Duran-Ros, M.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Hydraulic performance analysis of new versus commercial nozzle design for pressurized porous media filters. Irrig. Sci. 2024, 1–18. [Google Scholar] [CrossRef]

- Ravina, I.; Paz, E.; Sofer, Z.; Marcu, A.; Schischa, A.; Sagi, G.; Yechialy, Z.; Lev, Y. Control of clogging in drip irrigation with stored treated municipal sewage effluent. Agric. Water Manag. 1997, 33, 127–137. [Google Scholar] [CrossRef]

- Pujol, T.; Duran-Ros, M.; Arbat, G.; Cufí, S.; Pujol, J.; Ramírez de Cartagena, F.; Puig-Bargués, J. Pressurised sand bed filtration model: Set up and energy requirements for a filtration cycle. Biosyst. Eng. 2024, 238, 62–77. [Google Scholar] [CrossRef]

- Salmasi, F.; Abraham, J.; Salmasi, A. Evaluation of variable speed pumps in pressurized water distribution systems. Appl. Water Sci. 2022, 12, 51. [Google Scholar] [CrossRef]

- Graciano-Uribe, J.; Pujol, T.; Duran-Ros, M.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Effects of porous media type and nozzle design on the backwashing regime of pressurised porous media filters. Biosyst. Eng. 2024, 247, 77–90. [Google Scholar] [CrossRef]

- Buys, F.; Stevens, J.B.; Smal, S. Training material for extension advisors in irrigation water management. Volume 2: Technical Learner Guide. Part 5: Irrigation engineering. Water Res. Comm. Rep. NO. TT 2012, 540, 104. [Google Scholar]

- Mesquita, M.; de Deus, F.P.; Testezlaf, R.; Diotto, A.V. Removal efficiency of pressurized sand filters during the filtration process. Desalination Water Treat. 2019, 161, 132–143. [Google Scholar] [CrossRef]

- White, F.M. Fluid Mechanics, 7th ed.; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Ostad-Ali-Askari, K.; Sadeghi, F.; Vanani, H.R.; Monem, M.J.; Kianmehr, P. Evaluation of variable frequency drive system in pumping stations of irrigation networks using INACSEM model. Irrig. Drain. 2025, 1–11. [Google Scholar] [CrossRef]

- de Deus, F.P.; Testezlaf, R.; Mesquita, M. Efficiency of pressurized sand filters in removing different particle sizes from irrigation water. Pesqui. Agropecu. Bras. 2015, 50, 939–948. [Google Scholar] [CrossRef]

- Netafim. Drip Irrigation Understanding the Basics: Handbook. 2022. Available online: https://www.netafim.com/globalassets/local/uae/irrigating-the-future-pdfs/drip-irrigation---understanding-the-basics.pdf (accessed on 19 February 2025).

| Filter Type (Number) | Linear (%) | Piecewise Linear (%) | Quadratic (%) |

|---|---|---|---|

| Disc (39) | 53.8 | 25.6 | 20.5 |

| Porous media (23) | 91.2 | 4.4 | 4.4 |

| Screen (46) | 6.5 | 73.9 | 19.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pujol, T.; Castells, A.; Duran-Ros, M.; Graciano-Uribe, J.; Arbat, G.; Puig-Bargués, J. Impact of Filtration Cycle Patterns on Both Water and Energy Footprints in Drip Irrigation Systems. Water 2025, 17, 1440. https://doi.org/10.3390/w17101440

Pujol T, Castells A, Duran-Ros M, Graciano-Uribe J, Arbat G, Puig-Bargués J. Impact of Filtration Cycle Patterns on Both Water and Energy Footprints in Drip Irrigation Systems. Water. 2025; 17(10):1440. https://doi.org/10.3390/w17101440

Chicago/Turabian StylePujol, Toni, Aniol Castells, Miquel Duran-Ros, Jonathan Graciano-Uribe, Gerard Arbat, and Jaume Puig-Bargués. 2025. "Impact of Filtration Cycle Patterns on Both Water and Energy Footprints in Drip Irrigation Systems" Water 17, no. 10: 1440. https://doi.org/10.3390/w17101440

APA StylePujol, T., Castells, A., Duran-Ros, M., Graciano-Uribe, J., Arbat, G., & Puig-Bargués, J. (2025). Impact of Filtration Cycle Patterns on Both Water and Energy Footprints in Drip Irrigation Systems. Water, 17(10), 1440. https://doi.org/10.3390/w17101440