Abstract

Given the relevance of sustainability, this study analyzed the impacts on water consumption in the production chain of ornamental stone pieces (marble and granite) and quartz-based composites. The goal was to compare the water demand throughout the process, from extraction to manufacturing, using 1 m3 blocks as the unit of analysis. This study was conducted in Bahia, a state with significant ornamental stone production, located in a semi-arid region with limited water availability. The methodology included data collection from participating companies, combined with sectorial information and the Ecoinvent version 3.3 database, modeled using the SimaPro 8.0 software. The impact assessment was carried out using the AWaRE (Water Scarcity Footprint) and ReCiPe Endpoint methods, following the guidelines of Life Cycle Assessment (LCA), as per ABNT NBR ISO 14040 standards. The results showed that marble and granite have lower water demand and environmental impact in the categories of particulate matter, human toxicity, ecotoxicity, eutrophication, and acidification when compared to quartz composites. The highest environmental impact occurred during the processing stage, which requires a large amount of water and generates effluents, losses, and particulate matter. The results indicate that marble and granite demand less water and exhibit lower environmental impacts—across categories like particulate matter, human toxicity, ecotoxicity, eutrophication, and acidification—than quartz composites. Notably, the processing stage incurred the highest environmental burden due to its intensive water use and consequent generation of effluents, losses, and particulate matter. These findings highlight the necessity of efficient water management and the adoption of circular economy principles—including water reuse and waste valorization—to promote long-term sustainability in the ornamental stone industry.

1. Introduction

According to Tazzini [1], the construction industry is one of the largest consumers of natural resources, being responsible for significant environmental impacts, especially related to the intensive use of water in different stages of the production process. During construction activities, water is widely used for material mixing, equipment cooling, cleaning, and various processes, highlighting the need for efficient water management [2].

The ornamental stone sector, for example, is water-intensive, both in the extraction stage and in primary and secondary processing. Additionally, this industry generates liquid effluents with high levels of solid particles and chemical agents from the use of abrasives and resins [3].

These wastes, when not treated properly, can compromise water bodies and adjacent ecosystems. In this context, the adoption of sustainable practices and technologies that promote the reduction, reuse, and treatment of effluents becomes essential to minimize environmental impacts [4].

The replacement of traditional materials such as marble and granite with alternatives of lower environmental impact, such as quartz-based synthetic stones, has proven to be a promising strategy. Materials like Silestone and Technistone, composed of 94% quartz and 6% acrylic resin and additives, offer significant advantages, including low water absorption, low porosity, and stain resistance. These features reduce the need for frequent maintenance, including the application of sealants, and make the material more suitable for humid areas, such as kitchens and bathrooms [5].

Furthermore, the use of synthetic stones contributes to reducing water consumption in industrial processes, as cutting and polishing these materials requires less water compared to marble and granite. Another advantage is the possibility of incorporating Industrial Ecology principles and cleaner production practices. This involves strategies to optimize resource use, reduce waste, and minimize environmental impacts. Specifically, water reuse in production cycles can be promoted through treatment and recovery technologies, reducing water consumption and operational costs. Additionally, encouraging industrial symbiosis practices allows different industries to share by-products and waste, creating a more efficient and sustainable system in which water used in one process can be repurposed in another, fostering a circular economy [6].

The Life Cycle Assessment (LCA) of synthetic stones compared to natural materials highlights the environmental benefits related to lower water use, reduced liquid effluent generation, and greater product durability [7]. Based on these principles, it is possible to promote a more sustainable and responsible construction industry in the use of this essential resource.

Thus, efficient water management, combined with technological innovation and material substitution, is crucial to addressing the environmental challenges of the construction industry, fostering sustainable economic development, and preserving water resources.

In light of this context, this study aimed to analyze and compare the impact on water consumption throughout the production chain of ornamental stone products—such as marble and granite—and quartz-based composites. For this, 1 m3 blocks were adopted as the functional unit, allowing a detailed assessment of water demand at each stage of the production process.

1.1. Water Availability in the Brazilian Semi-Arid Region

A key motivation for this study is the increasing concern regarding water availability in Brazil, particularly in regions with pronounced water scarcity. The semi-arid region of Brazil, which encompasses most of the Northeast, experiences irregular rainfall, high evapotranspiration, and chronic water shortages [8]. Bahia, the largest state in this region, has a strong presence in the ornamental stone industry, with significant production clusters supplying both domestic and international markets.

While the empirical data used in this study originate from industrial facilities in Salvador, the findings are relevant to the semi-arid region because many raw materials processed in urban centers, such as Salvador, originate from quarries located in the semi-arid interior. Additionally, water management practices adopted in these facilities can serve as benchmarks for industries operating in water-scarce areas.

The economic importance of the ornamental stone sector in the semi-arid region also justifies this focus. Several municipalities in Bahia, particularly in the semi-arid zone, depend on stone extraction and processing as a primary economic activity. However, the intensive water use in these operations presents challenges in a region where water scarcity is a persistent issue. By investigating water consumption in a major industrial center like Salvador, this study provides valuable insights applicable to the broader supply chain, including semi-arid production hubs.

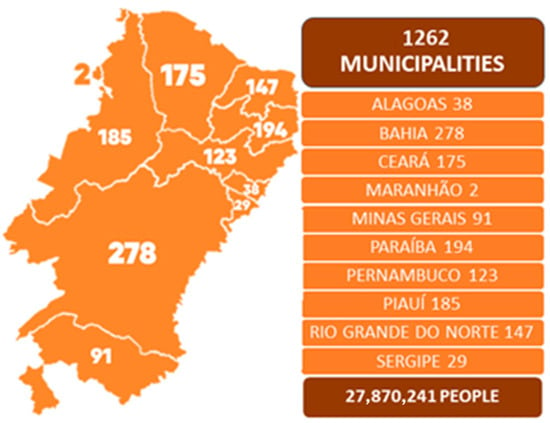

According to information from the National Institute of the Semi-arid Region [8], the Brazilian semi-arid region encompasses the nine states of the Northeast, as shown in Figure 1. Covering an area that represents 12% of the national territory, this region is home to approximately 27 million people, with 62% residing in urban areas and 38% in rural areas, making it one of the most populous semi-arid regions in the world.

Figure 1.

The municipalities of the Brazilian semi-arid region.

According to the Superintendence of Economic and Social Studies of Bahia [9], the main characteristic of this territory is the irregularity of rainfall, combined with high evapotranspiration rates, factors that exacerbate water scarcity. Under these conditions, the available water supply for various purposes is insufficient to meet the demand. During prolonged periods of drought, the situation worsens even further, compromising water supply in 1262 municipalities and negatively impacting local economic activities [9]. Figure 1 presents the municipalities of the Brazilian semi-arid region.

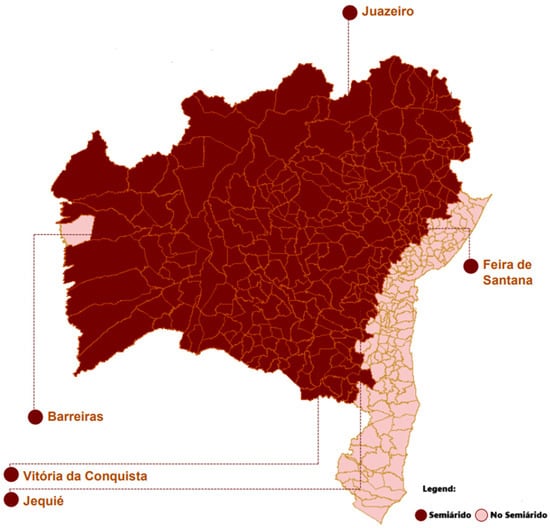

Bahia is the state with the largest number of municipalities in the Brazilian semi-arid region, as shown in Figure 2. The map highlights cities that exhibit semi-arid characteristics, defined by low rainfall, high temperatures, and water scarcity challenges. Of the 417 municipalities in Bahia, 278 fall within the boundaries of this region, representing 85.6% of the entire territory of Bahia. In 2022, the total population living in this area was 7.5 million people, which means half of the state’s population [9].

Figure 2.

The municipalities with more than 100,000 inhabitants in the Bahia semi-arid region.

In this context, the need to adopt effective practices for sustainable coexistence with drought becomes evident, prioritizing the strengthening of public policies focused on integrated water resource management [10]. These policies should consider the specificities of the semi-arid region and seek a balance between the demands of different user sectors. Strategies such as rational water use, reuse, and the utilization of wastewater are essential to minimize the impacts of water scarcity and ensure a more sustainable future for the region [10].

Among the traditional practices already established in the semi-arid region, rainwater harvesting stands out, having been adapted to local conditions through specific technologies and successful management experiences. These initiatives allow for the efficient storage and use of water during drought periods. Additionally, investing in new technologies for desalination and water conservation complements actions aimed at increasing water supply and optimizing its use.

1.2. Water Use in the Production of Marble Slabs, Granite, and Quartz Composites

The management and reuse of water in the processing of ornamental stones are essential topics for the sustainability of the sector. Recent studies highlight the importance of efficient water conservation practices, effluent treatment, and the optimization of water use to minimize environmental impacts. These studies emphasize that water is a critical input in this sector, mainly used in equipment cooling, cutting, and polishing of stones. Table 1 presents studies that address this topic.

Table 1.

Studies addressing water use in extraction and processing in the ornamental stone sector.

Ferraz et al. [11] analyzed the benefits of water reuse after treatment, demonstrating that an efficient recycling system can reduce up to 70% of new water consumption. This finding reinforces the need for more effective internal processes, corroborating the results of Zagoto et al. [18], who highlight the contribution of rainwater and process water reuse to a more sustainable industrial cycle. However, the efficiency of water reuse does not depend solely on recirculation. The quality of ornamental stone polishing is directly linked to the volume of water used, as pointed out by Altoé et al. [13]. These authors observed that an excessive reduction in water flow can compromise the shine and finish of the pieces. This indicates that water-saving strategies must be balanced with the technical requirements of stone processing.

Beyond consumption reduction, another challenge is the proper treatment of industrial effluents. A study by Silveira et al. [12] showed that scientific publications in this field emphasize the need for more effective technologies for impurity removal and water reuse. Fiorese et al. [15] complement this analysis by comparing different companies in the sector, revealing that the lack of standardization in water management policies remains an obstacle to industrial sustainability. Another critical factor is the environmental impact of the improper disposal of waste from stone processing. Neves and Raymundo [17] warn about the risk of groundwater contamination, a problem that can be mitigated by using advanced treatment technologies, such as centrifugation, analyzed by Ferreira et al. [16]. This method has proven effective in separating solids and purifying water, making it suitable for reuse in the production process.

Beyond water management, new strategies are being explored for reusing solid waste generated in the ornamental stone industry. Scolaro et al. [19] propose incorporating this waste into Portland cement pastes, demonstrating benefits in both reducing water demand and lowering CO2 emissions in cement production. This approach aligns with the study by Dalmora et al. [20], who confirmed the feasibility of using microfiltration as a complementary treatment for wastewater reuse in a marble industry in southern Brazil.

The studies presented in Table 1 demonstrate that sustainability in the ornamental stone sector depends on an integrated approach that combines

- Reducing water consumption through recirculation and process monitoring.

- Improving effluent treatment technologies to enable more efficient reuse of water.

- Reusing solid waste in new industrial processes, reducing overall environmental impact.

This study contributes directly to this scenario by proposing an integrated approach to efficient water management in the ornamental stone sector, focusing on reducing water consumption, improving effluent treatment, and enhancing solid waste valorization. Unlike previous studies that analyze these aspects in isolation, this research combines experimental analyses, circular economy concepts, Life Cycle Assessment (LCA), and computational modeling to evaluate the technical feasibility of water reuse and waste recovery in stone processing.

Advancing sustainability in the ornamental stone industry requires a joint effort among researchers, industries, and regulatory bodies, promoting technological innovation and more effective environmental regulations.

1.3. Life Cycle Assessment

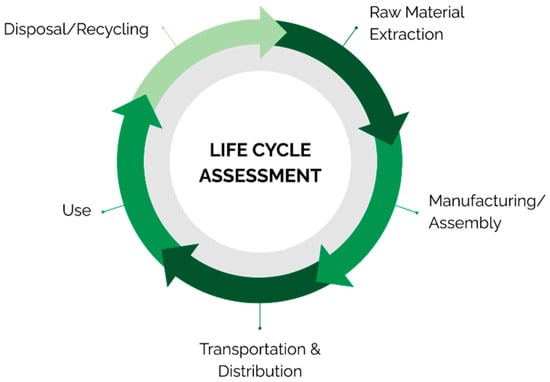

Life Cycle Assessment (LCA) is a widely used methodology to quantify the environmental impacts associated with a product or process throughout all its stages, from raw material extraction to final disposal [21]. Figure 3 presents the phases of a product’s life cycle.

Figure 3.

Product life cycle [22].

In the context of water demand in the ornamental stone industry, LCA allows for the identification of key water consumption points, the evaluation of the efficiency of production processes, and the proposal of strategies to reduce the sector’s water footprint. The application of LCA in water demand considers not only the volume of water consumed directly in the extraction and processing of stones but also the indirect impacts, such as the contamination of water bodies due to improper effluent disposal and the energy used in water pumping and treatment [23]. This systemic approach enables a more comprehensive understanding of environmental impacts, facilitating decision-making to mitigate negative effects and optimize the use of natural resources.

In marble and granite extraction, LCA reveals that water consumption mainly occurs in cutting, cooling, and washing operations, with a large portion of the water used carrying solid waste particles and chemicals [24]. In processing, water use is associated with polishing and finishing the pieces, as well as the removal of impurities accumulated during processing. The contamination of water by fine sediments can significantly increase the pollutant load of effluents, which requires adequate treatment before reuse or disposal [25].

By applying LCA to compare different water management scenarios, studies indicate that practices such as water recirculation in the production process and waste filtration can reduce the need to extract new water sources by up to 80% [26]. Additionally, the incorporation of technologies like microfiltration membranes and particle separation by sedimentation can minimize environmental impacts and improve water quality for reuse.

Another relevant aspect identified by LCA is the water footprint of the waste generated in ornamental stone production. The sludge formed by the accumulation of solid particles in wastewater can become a significant environmental liability if not treated properly. Strategies for reusing this sludge, such as using it in the manufacture of building materials or in the recovery of degraded areas, can help reduce the environmental impact of the sector [24].

Thus, the application of LCA in the analysis of water demand in the ornamental stone industry not only quantifies environmental impacts but also guides the adoption of more sustainable solutions. The implementation of circular economy practices, combined with water reuse and treatment technologies, is essential to minimize negative impacts and promote sustainability in the marble, granite, and quartz composite processing sector.

2. Materials and Methods

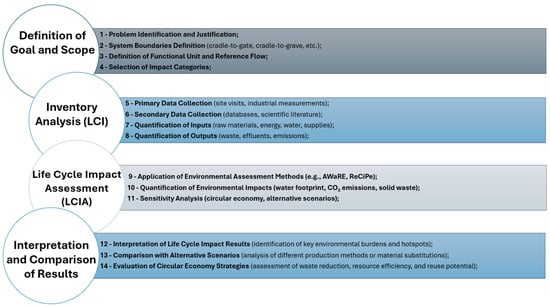

The Life Cycle Assessment (LCA) method was based on the ISO 14044 standard [27]. Figure 4 presents the steps followed in this research for the implementation of LCA, aligning with the four macro-phases: goal and scope definition, inventory analysis, impact assessment, and result interpretation. Each phase was divided into specific stages to ensure that the LCA objectives were achieved. Data were collected from the Brazilian Institute of Stones [28] and the Brazilian Association of the Ornamental Stone Industry [29].

Figure 4.

Methodology for LCA Implementation.

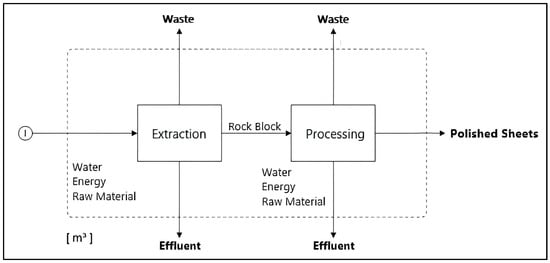

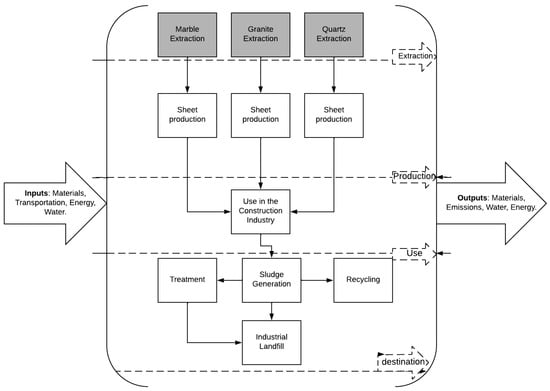

2.1. System Function

The function of the studied system is the processing of ornamental stones, considering a cradle-to-gate approach, as presented in Figure 5. This approach focuses on environmental impacts from raw material extraction to the point at which the product leaves the factory, excluding transportation and installation. The system boundary includes raw material extraction, the processing, and the polishing of marble, granite, and quartz-based composite slabs. The cradle-to-gate perspective allows for a detailed analysis of resource efficiency in production, such as water, energy, and chemical inputs, enabling the implementation of more sustainable practices.

Figure 5.

Product system studied.

The system does not include the transportation of the finished slabs to consumers or their installation, as the focus is on the environmental impacts associated with production.

2.2. Functional Unit and Reference Flow

The functional unit was defined as 1 m3 of polished slab, ensuring comparability between different types of stone materials. Each slab has an area of 5 m2, a thickness of 2.5 cm, and an estimated density of 2700 kg/m3. The reference flow for inventory calculations was based on 1 m3 of polished slab composed of marble, granite, or quartz composites.

2.3. Types and Sources of Data

Data were collected from primary and secondary sources.

Primary data: The primary data were obtained from direct visits to marble and granite processing companies in Salvador, Bahia, where approximately 130 marble shops operate. These visits provided specific data on material losses, energy consumption, water use, and production inputs.

Secondary data: The secondary data were extracted from the Brazilian Institute of Stones [28] and the Brazilian Association of the Ornamental Stone Industry [29]. Additional secondary data were obtained from the Ecoinvent 3.3 database within the SimaPro 8 software.

The collected data were normalized for production scale, ensuring that variations in regional inputs did not compromise the comparability of the results.

2.4. Inputs and Outputs (Inventory Analysis)

The inventories of the raw material extraction and stone processing stages are presented for marble and granite (Table 2) and quartz-based composites (Table 3).

Table 2.

The life cycle inventory from gate to gate for the extraction and processing stages of 1 m3 of polished marble or granite slabs.

Table 3.

The life cycle inventory from gate to gate for the extraction and processing stages of 1 m3 of polished quartz-based composite slabs.

The inventory quantifies the material and energy flows involved in the production of marble, granite, and quartz-based slabs. During raw material extraction, marble and granite operations generate approximately 18% waste, while the processing stage results in 31% material losses from cutting and polishing. Energy consumption primarily includes diesel and electricity usage in quarrying activities, and water is essential for cooling equipment and suppressing dust.

In the processing and polishing phases, electricity powers sawing, grinding, and polishing machines. Water consumption is managed through a recycling system that reduces overall freshwater intake. Diamond wires used for cutting are reused up to 10 times, influencing raw material demand in inventory calculations. Chemical inputs, including sealants and resins, are utilized in quartz-based slab production.

Regarding output and waste management, effluents consist of slurry-containing fine stone particles and chemical residues. Solid waste includes stone dust generated from cutting and polishing, along with spent diamond wires after multiple reuse cycles. Emissions from the production process include dust particles, CO2 from diesel combustion, and contaminants in wastewater.

2.5. Uncertainty Characterization

To account for variability and uncertainty, a combined approach was applied. Foreground data uncertainty was characterized using the Pedigree Matrix method, which assesses data quality indicators such as reliability, completeness, and temporal correlation. Background uncertainty, associated with processes from the Ecoinvent 3.3 database, was addressed through the Monte Carlo simulation model implemented in the LCA software SimaPro Craft 10.2, which uses the underlying Pedigree Matrix to derive standard deviations for input distributions. A lognormal distribution was assumed, and 10,000 iterations were performed to propagate uncertainty in water demand and environmental impact results, with outcomes reported at a 95% confidence interval.

2.6. Life Cycle Impact Assessment Methods and Selected Impact Categories

The environmental impacts of stone processing were assessed using the SimaPro® 8.4 software, one of the most widely used tools for LCA studies, particularly in water treatment and resource-intensive sectors. This platform offers an extensive set of life cycle impact assessment (LCIA) methods and access to comprehensive databases. The study employed an attributional LCA approach, and inventory data were modeled primarily using the Ecoinvent 3.3 database. For water use processes, the dataset “tap water production, conventional treatment, surface water [RoW]” was selected, as it best represents typical water supply systems in regions with limited local data.

Two LCIA methodologies were applied:

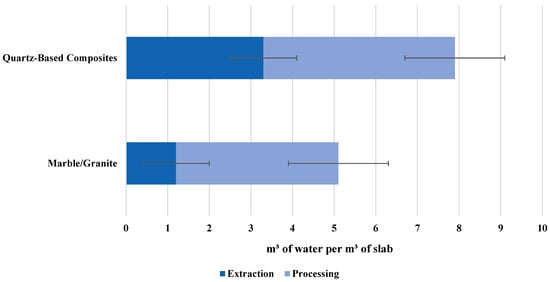

AWARE Method (Water Scarcity Footprint): Used to generate Figure 6, this method quantified the water scarcity footprint of the marble, granite, and quartz extraction stages. It evaluates the impact of water consumption on regional water availability and is essential for analyzing the sustainability of water reuse strategies.

Figure 6.

The water footprint in the extraction and processing for marble/granite and quartz-based composites.

ReCiPe Endpoint Method: This method was used to assess and compare broader environmental impacts, including climate change (CO2 emissions), human toxicity, and ecosystem degradation, helping identify opportunities to reduce impacts in the ornamental stone sector.

In addition to the above, other impact categories were evaluated using the following:

- Human Toxicity and Ecotoxicity: USETox 2 model [30].

- Eutrophication and Acidification: CML Baseline method [31].

- Particulate Matter Formation: ILCD method [32].

2.7. Sensitivity Analysis (Circular Economy Approach)

To evaluate the potential for circular economy strategies, a sensitivity analysis was performed by simulating alternative scenarios, including the following:

- Increased water recycling rates (from 70% to 90%) to assess the impact on water scarcity footprint reduction.

- Alternative reuse of stone dust in construction materials (e.g., cement composites) to measure its impact on waste reduction and CO2 emissions.

These analyses help quantify the environmental benefits of optimized resource use and waste valorization, reinforcing the feasibility of circular economy applications in the ornamental stone industry.

3. Results

3.1. Water Footprint Results

The water footprint in the extraction and processing of marble, granite, and quartz-based composites can vary significantly depending on the practices adopted by each company. This study shows that the average monthly water consumption of marble shops in Salvador is 25 m3. Of this total, approximately 8 m3 corresponds to reused water from the effluent treatment system by decantation. In addition, the companies use rainwater collected and stored in a reservoir with a capacity of 10 m3, supplementing their demand with water provided by the public water supply system.

It is important to note that these values are specific to the companies in the studied region and may not reflect the reality of other industries in the sector. The water footprint of a marble-, granite-, or quartz-based composite slab depends on various factors, including the efficiency of water reuse systems, the technology used in processing, and the environmental management practices adopted. Companies that invest in advanced technologies are able to optimize water usage and reduce waste generation, contributing to a smaller water footprint.

Therefore, to determine the specific water footprint of processing a marble or granite slab, a detailed analysis of the production processes and water resource management practices of each company is necessary.

Thus, Figure 6 presents the water footprint in the extraction and processing of marble/granite and quartz-based composites in this study.

As shown in Figure 6, the water footprint in the extraction of marble and granite exhibited significantly lower consumption compared to the extraction of quartz-based composites. The extraction of marble and granite involves removing stone blocks directly from quarries, with marble blocks typically cut using diamond wires or specialized saws. During this process, the amount of water used is relatively low, primarily serving to cool the cutting tools and control dust generation. Since these stones are extracted in large blocks that require less initial processing, water demand at this stage is reduced. On the other hand, quartz extraction involves more complex processes. Unlike marble and granite, quartz is not found in large homogeneous blocks but rather in smaller formations mixed with other minerals. To obtain pure quartz, a separation and purification process is required that demands a significant volume of water. Water is used both for washing and purifying the quartz and for cooling the machinery involved in crushing and grinding the material. As a result, this stage presents a considerably higher water impact.

Based on these results, if the choice of material were based solely on the water footprint of the extraction stage, marble and granite would be the most advantageous options, as they require less water compared to quartz. However, a complete environmental analysis cannot be based on a single stage of the material’s life cycle. The water impact of stone processing and finishing must also be considered to determine which material ultimately has the lowest overall water consumption. The finishing stage can significantly alter the initial results, as different materials require varying amounts of water for cutting, polishing, and surface treatment. Additionally, factors such as the efficiency of water reuse systems and the adoption of sustainable technologies in processing can directly influence the final environmental impact of each material.

Therefore, for a more comprehensive and well-founded evaluation, it is essential to consider the entire life cycle of the materials, analyzing not only the extraction but also the processing stages. This approach enables more informed decisions aligned with principles of sustainability and efficient water resource management.

As in the extraction stage assessment, the water footprint of quartz-based composites also showed higher consumption in the processing phase compared to marble and granite. Therefore, if the material selection is based solely on the lowest water footprint, marble and granite demonstrate superior performance compared to quartz composites. In the processing of marble and granite, water is primarily used in cutting, polishing, and washing the slabs. Cutting these stones requires continuous cooling of the saw blades to prevent overheating and potential damage. Additionally, during polishing, water helps remove dust and residues, resulting in a smooth and glossy surface. Although water use is essential, the volume required in these processes tends to be relatively lower compared to the processing of other materials.

On the other hand, the processing of quartz, especially in the production of quartz composites, demands a significantly higher water footprint. This process involves mixing quartz powder with resins and other additives, whereby water is used to cool and clean the machinery. Furthermore, during the cutting and polishing of composites, water is essential for cooling the tools and removing residues. While these requirements are similar to those for marble and granite, the complexity of composite production considerably increases water consumption. Given this scenario, efficient water management in the processing stage becomes crucial, especially for quartz composites, to minimize environmental impacts such as water scarcity. The implementation of water recirculation systems can significantly reduce water consumption, while the proper treatment of wastewater generated during processing prevents contamination of water bodies and ensures environmentally responsible disposal. Filtration and decantation technologies can be employed to remove particles and residues, allowing water to be reused within the production cycle, thus promoting greater sustainability in the sector.

3.2. Life Cycle Assessment Results

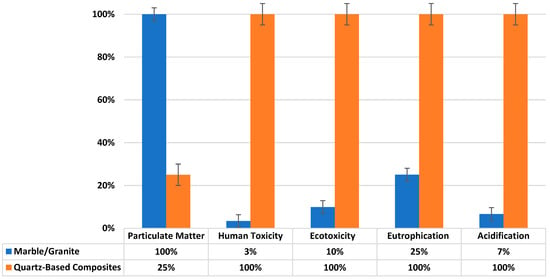

Figure 7 presents the contribution share of the total environmental impacts attributed exclusively to the extraction processes for marble/granite and quartz-based composites, based on inventory data, including water consumption.

Figure 7.

The environmental impacts of the extraction processes for marble/granite and quartz-based composites.

As presented in the inventory of Table 2, the use of water in the extraction processes for marble, granite, and quartz-based composites is associated with various stages, which consequently lead to environmental impacts affecting both aquatic ecosystems and human health. In Figure 7, it is possible to observe that for the particulate matter impact category, marble and granite exhibit worse environmental performance. This is due to the release of fine dust particles during the cutting and extraction of blocks, which, when transported by water, contaminate rivers and lakes, degrading water quality and impacting aquatic organisms. On the other hand, for other impact categories, quartz-based composites showed worse environmental performance. The water used in the quartz extraction process may contain heavy metals and chemical compounds from the additives used, increasing the risks of human toxicity. Exposure to these substances, either through the consumption of contaminated water or the inhalation of suspended particles, can pose serious health risks to populations near mining areas.

In terms of ecotoxicity, the improper disposal of wastewater containing sediments and chemicals used in quartz extraction can harm aquatic ecosystems, reducing biodiversity and altering the natural dynamics of water bodies. Eutrophication is another significant impact, as the presence of organic matter and nutrients in wastewater can stimulate excessive algae growth. This phenomenon reduces the concentration of dissolved oxygen, directly affecting aquatic fauna and potentially leading to the death of fish and other organisms. Additionally, water acidification can occur due to the release of chemical compounds during quartz extraction, altering the pH of water bodies and negatively impacting both aquatic organisms and soil quality in the extraction area.

After this assessment, it is evident that quartz-based composites have a worse environmental performance in water bodies, as they performed worse in most analyzed categories. When deciding which product to use with the least impact during the extraction stage, marble and granite are the most recommended options. However, the choice of the best material should also take into account its availability in nature, as quartz is more abundant than the others. A decision on the best material should always be based on a thorough technical and environmental assessment.

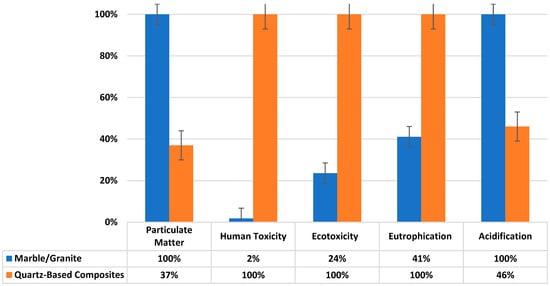

Figure 8 presents the contribution share of the total environmental impacts attributed exclusively to the processing of marble/granite and quartz-based composites, based on inventory data, including water consumption.

Figure 8.

Environmental impacts from the marble/granite and quartz-based composite processing.

As presented in Table 3, water use in the processing stage of marble, granite, and quartz is extensive, and the associated environmental impacts are diverse. Figure 8 indicates that the generation of particulate matter, for example, is a common issue, with both materials showing similar impacts in this category. During the cutting and polishing processes, fine dust particles are produced, and water is used to control their dispersion. Without proper treatment, this water can turn into contaminated sludge, requiring adequate treatment before disposal.

Also highlighted in Figure 8 is human toxicity, another major concern, with quartz composites exhibiting a higher impact in this category. This occurs because water contaminated with chemicals such as lubricants and resins can pose health risks if not properly treated, affecting both workers and local communities. It is possible to observe that the categories of ecotoxicity and eutrophication presented critical impacts to be considered in this study, especially in processes involving quartz-based composites. Water used in production processes can become toxic to aquatic life if contaminated with heavy metals and chemicals, harming entire ecosystems. The release of nutrients such as phosphorus and nitrogen can lead to eutrophication, resulting in excessive algae growth and a reduction in dissolved oxygen levels in the water, negatively impacting biodiversity.

Acidification also presented similar levels for marble, granite, and quartz. The release of acidic substances in wastewater can alter the pH of water bodies, harming sensitive aquatic organisms and causing corrosion in structures.

These analyses provide a clear and well-founded basis for decision-making, allowing the identification of which product generates the least environmental impact throughout its life cycle, both in the extraction and processing stages. According to the results of this study, quartz-based composites exhibited significantly worse performance in 90% of the evaluated impact categories, highlighting their greater potential for environmental degradation. Additionally, their extraction process requires a considerably higher volume of water, reinforcing the need to seek more sustainable alternatives for the production and use of these materials. To mitigate these impacts, sustainable water management is essential. This includes water recycling and reuse, proper wastewater treatment, and the adoption of practices that reduce contaminant generation.

Optimizing water use in the processing of marble, granite, and quartz-based composites can significantly reduce environmental impacts, particularly in the categories of ecotoxicity, eutrophication, and human toxicity. The implementation of water recirculation and wastewater treatment systems helps minimize the contamination of water bodies and reduces the demand for potable water. However, even with efficient water management, quartz-based composites continue to exhibit higher environmental impacts compared to marble and granite due to the use of resins and chemical additives in their composition and processing. Therefore, the decision on which material to use should consider not only the water footprint but also an integrated sustainability approach, assessing the feasibility of circular economy practices and the mitigation of impacts throughout the entire product life cycle.

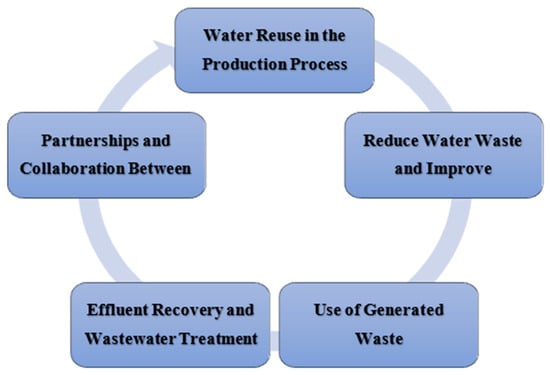

3.3. Circular Economy Proposal

The results of the Life Cycle Assessment (LCA) demonstrate that the choice of ornamental stone significantly impacts the water footprint and other analyzed environmental indicators. However, beyond material selection, the way resources are managed throughout the production process plays a crucial role in reducing these impacts. Efficient water management, for example, can significantly mitigate the identified negative effects by reducing water demand and minimizing the pollutant load in the generated effluents. This aspect is essential for transitioning from a linear to a circular model in the ornamental stone industry, where strategies such as water reuse, the optimization of cutting and polishing processes, and solid waste recovery can substantially modify the environmental impact associated with each type of material.

Thus, the analysis of LCA results not only highlights which materials perform better in their conventional form but also provides insights for developing more sustainable solutions for the entire production chain. The following section discusses how the circular economy can be applied in this sector, bringing both environmental and economic benefits while promoting a more responsible approach to natural resource use.

Figure 9 represents the linear economy model as observed in the ornamental stone sector companies studied.

Figure 9.

The linear economy model observed in the studied ornamental stone sector companies.

Figure 9 represents the linear economy model observed in the ornamental stone sector companies studied. This linear economy model follows the traditional “extract, produce, discard” approach, whereby resources are extracted from nature, transformed into products, and, after use, discarded as waste. This cycle creates a significant environmental impact, especially in the context of water use and waste generation.

In the linear economy model, the extraction of raw materials such as marble, granite, and quartz consumes a substantial amount of water. During the processing of these materials, water is used to cool tools, polish surfaces, and control dust. However, the water used becomes contaminated with fine particles, chemicals, and solid waste, resulting in effluents that are often improperly discarded without adequate treatment.

This model is detrimental for several reasons. First, there is a high consumption of natural resources. The continuous extraction of raw materials depletes natural resources and requires large amounts of water, which can be unsustainable in the long term. Second, there is the generation of waste. The linear model generates a significant amount of solid waste and liquid effluents, which can pollute the environment and harm ecosystem health. Third, there is the waste of water. The water used in the extraction and processing processes is often not recycled or reused, leading to the wastage of this essential and scarce resource. Finally, there is the environmental impact. The contamination of water bodies with chemicals and fine particles resulting from the processing of ornamental stones can cause ecotoxicity, eutrophication, and acidification, harming biodiversity and water quality.

To mitigate these impacts, transitioning to a circular economy model is essential. The circular economy promotes the reuse and recycling of resources, minimizing waste and optimizing the use of water and raw materials. This includes the implementation of water recirculation systems, proper wastewater treatment, and the reuse of solid waste in the production of quartz composites. By adopting circular economy practices, companies in the ornamental stone sector can significantly reduce their environmental impact, conserve natural resources, and promote more sustainable and efficient production. Figure 10 presents the proposed circular economy model.

Figure 10.

Economy model proposed in this study.

The first and most immediate circular economy proposal observed in this study is the implementation of water reuse systems. Currently, large volumes of water are used in the cutting, polishing, and processing of ornamental stones, but a significant portion of this water is discarded after being contaminated with rock particles, oils, and other chemicals. In a circular model, wastewater could be treated and reused within the production process itself, reducing the need to capture new water sources. Water treatment can be achieved through filtration, separation, and purification systems. Technologies like reverse osmosis or decantation and centrifugation systems can be applied to remove suspended solids and chemicals, making the water suitable for recirculation in the processing stages. Furthermore, rainwater collection could be adopted, stored, and treated to supplement the industry’s water supply, especially in regions where water availability is limited.

Circular economy also implies the more efficient use of resources, which, in the case of water, means reducing waste during the cutting and polishing operations. The use of precision technologies, such as laser cutting systems and water jets, can reduce the amount of water needed for these processes. In addition, adjustments in water flow control and the use of automated monitoring systems can ensure that only the necessary amount of water is used at each stage.

Another important pillar of this proposal is the utilization of generated waste, such as the sludge produced during the processing stage. This sludge contains marble, granite, and quartz particles, which, after treatment, could be recycled and incorporated into new products, such as building materials, decorative pieces, or even raw materials for the production of new quartz-based composites.

Besides mitigating material waste, the reuse of waste also contributes to reducing pressure on natural resources, such as the extraction of new rocks. The proper disposal of sludge, through recycling and valorization processes, represents a significant opportunity for the industry to adopt a more sustainable model.

The use of wastewater treatment technologies can enable water recovery and the removal of contaminants. The use of biodigesters, bioreactors, and membrane systems for biological or physico-chemical treatment can ensure water quality before its reuse. Furthermore, effluents can be monitored to ensure that their disposal, when necessary, complies with environmental standards, preventing the contamination of water bodies and negative environmental impacts.

To enable an efficient circular model, it is essential to promote collaboration across different sectors of the production chain. Ornamental stone industries can partner with water treatment companies, waste recycling firms, and other stakeholders to develop integrated solutions. This collaboration can range from sharing technologies to the exchange of materials and resources between industries, forming an industrial symbiosis network that promotes the continuous reuse of water and materials.

4. Conclusions

The water footprint assessment in the ornamental stone sector revealed that, although all the materials studied present significant environmental impacts, quartz-based composites demonstrated inferior environmental performance in most analyzed categories. The Life Cycle Assessment (LCA) showed that this material requires higher water consumption both in extraction and processing, in addition to presenting risks associated with human toxicity and the contamination of aquatic ecosystems. On the other hand, marble and granite, despite causing a greater impact in the particulate matter category, showed lower water demand and relatively more manageable environmental impacts. The adoption of sustainable water management practices, such as recirculation and reuse, can significantly reduce these impacts, making the production process more efficient and environmentally responsible. However, even with these optimizations, the results indicate that quartz composites still present greater environmental challenges. This reinforces the need for a systemic approach based on the circular economy, whereby not only water but also processing waste is continuously reused, minimizing waste and reducing impacts throughout the product’s life cycle. Therefore, the decision on which material to use should go beyond technical and economic considerations to include its environmental feasibility within a more sustainable production model. The implementation of strategies based on LCA and the circular economy is essential to redefine industry standards, promoting a balance between economic development and the preservation of natural resources.

Author Contributions

Conceptualization, J.O.N.d.J., L.J.d.S., V.P., K.P.O.E., O.S. and W.C.d.A.; Methodology, J.O.N.d.J., L.J.d.S., V.P., K.P.O.E., O.S. and W.C.d.A.; Software, J.O.N.d.J., V.P. and W.C.d.A.; Validation, J.O.N.d.J., O.S. and W.C.d.A.; Investigation, J.O.N.d.J.; Writing—original draft, J.O.N.d.J., L.J.d.S., V.P., K.P.O.E., O.S. and W.C.d.A.; Writing—review & editing, J.O.N.d.J., L.J.d.S., V.P., O.S. and W.C.d.A.; Visualization, J.O.N.d.J. and L.J.d.S.; Supervision, K.P.O.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tazzini, A.; Gambino, F.; Casale, M.; Dino, G.A. Managing Marble Quarry Waste: Opportunities and Challenges for Implementing the Circular Economy. Sustainability 2024, 16, 3056. [Google Scholar] [CrossRef]

- Almeida, N.V. Avaliação do consumo e circulação de água no processo de beneficiamento de rochas ornamentais. Bachelor’s Thesis, Instituto Federal do Espirito Santo, Campus Cachoeiro de Itapemirim, Cachoeiro de Itapemirim, Brazil, 2022. [Google Scholar]

- Almada, B.S.; Melo, L.S.; Silva, G.J.B.; Santos, B.J.; Aguilar, M.T.P. Effect of the waste ornamental rocks on the hydration and life cycle of Portland cement composites. Constr. Build. Mater. 2023, 395, 132353. [Google Scholar] [CrossRef]

- Cobo-Ceacero, C.J.; Cotes-Palomino, M.T.; Martínez-García, C.; Moreno-Maroto, J.M.; Uceda-Rodríguez, M. Use of Marble Sludge Waste in the Production of Eco-friendly Materials: Applying the Principles of Circular Economy. Environ. Sci. Pollut. Res. 2019, 26, 35399–35410. [Google Scholar] [CrossRef] [PubMed]

- Marques, C.R.; Albertin, R.M.; Taboni, L.R.; Viotto, H.G.F.; Silva, F.F.; Angeoletto, F. Avaliação da Gestão de Resíduos Gerados em Marmoraria: Estudo de Caso Aplicado em Maringá. Rev. Téc. Cient. 2020, 24, 1–19. [Google Scholar]

- Oliveira, F.; Sousa, R.; Silva, P.; Lopes, P.; Moreira, G.; Leite, R.; Arruda, R. Analysis of the benefits of the addition of granite residues in the production of ecological brick. Int. J. Adv. Eng. Res. Sci. 2021, 8, 149–158. [Google Scholar] [CrossRef]

- Rezende Leite, F.; Antunes, M.; Silva, D.; Oliveira, P. Avaliação do ciclo de vida da produção de argamassas com resíduos de beneficiamento de rochas ornamentais (RBRO). In Proceedings of the Congresso Brasileiro Sobre Gestão do Ciclo de Vida, Brasilia, Brazil, 17–20 June 2018; pp. 567–571. [Google Scholar]

- INSA. Instituto Nacional do Semiarido—INSA. 2023. Available online: https://www.gov.br/insa/pt-br (accessed on 7 January 2025).

- SEI. Superintendência de Estudos Econômicos e Sociais da Bahia. 2024. Available online: https://sei.ba.gov.br/index.php?lang=pt (accessed on 10 December 2024).

- De Jesus, J.; Medeiros, D.L.; Esquerre, K.P.O.; Sahin, O.; de Araujo, W.C. Water Treatment with Aluminum Sulfate and Tannin-based Biocoagulant in a Petroleum Refinery: Technical, Environmental, and Economic Performance. Sustainability 2024, 16, 1191. [Google Scholar] [CrossRef]

- Ferraz, C.C.A.; Maurício, E.; Stradiotti, C.G.P. The Benefits of Water Reuse in the Ornamental Stone Processing Process. Bachelor’s Thesis, Faculdade Multivix, Vitória, Brazil, 2018. [Google Scholar]

- Silveira, R.P.; Carmo, S.L.V.; Paula, M.M.; Purificação, L.S.; Hora, H.R.M.; Oliveira, V.P.S. Tratamento de Efluentes da Indústria de Rochas Ornamentais: Uma Abordagem Bibliométrica. Sci. Tec Rev. Educ. Ciência Tecnol. Do IFRS 2017, 4, 42–59. [Google Scholar] [CrossRef]

- Altoé, C.R.; Silveira, L.L.L. Influência do Volume de Água Utilizado no Processo de Polimento de Rochas Ornamentais na qualidade do brilho total. Geociências 2020, 39, 875–884. [Google Scholar] [CrossRef]

- Almeida, N.V.; Gadioli, M.C.B. Avaliação da Circulação e Consumo de Água no Processo de Beneficiamento de Rochas Ornamentais. In Proceedings of the Nos Anais da XXVI Jornada de Iniciação Científica, Rio de Janeiro, Brazil, 31 July 2018. [Google Scholar]

- Fiorese, C.H.U.; Andrade, D.; Alves, G.B.; Monhol, V.A.; Torres HFilho, G.S. Management of effluents and water consumed in the marine and granite benefit industry: Case study. Braz. Dev. 2019, 5, 12320. [Google Scholar] [CrossRef]

- Ferreira, A.S.; Neto, R.S.; Manhães, A.C.P.M. Estudo de Alternativas para o Tratamento de Efluentes Líquidos do Setor de Rochas Ornamentais. In Proceedings of the Anais do V Seminário Regional Sobre Gestão de Recursos Hídricos: Recuperação, Conservação e Gestão Ambiental de Bacias Hidrográficas—Práticas e Técnicas Inovadoras, Rio de Janeiro, Brazil, 27 September 2016. [Google Scholar]

- Zagoto, J.; Faria, F.R.; Miotto, B.V. Use of Water in Production Chain of Ornamental Stones in Espírito Santo, Brazil. Bachelor’s Thesis, Instituto Federal do Espirito Santo, Campus de Nova Venécia, Vitória, Brazil, 2014. [Google Scholar]

- Neves, M.A.; Raymundo, V. Fine Waste Deposits from Ornamental Stone Processing: Groundwater Quality. Eng. Sanit. Ambient. 2022, 27, 257–267. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Silvestro, L.; Ruviaro, A.S.; de Azevedo, A.R.G.; Monteiro, S.N.; Pelisser, F. Effect of Ornamental Stone Waste Incorporation on the Rheology, Hydration, Microstructure, and CO2 Emissions of Ordinary Portland Cement. Materials 2022, 15, 401. [Google Scholar] [CrossRef] [PubMed]

- Dalmora, G.; Viero, E.; Diehl, T.; Hemkemeier, M. Uso de Microfiltração No Tratamento Para Reuso Do Efluente De Marmoraria. RECIMA21 Rev. Científica Multidiscip. 2023, 4, e412516. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Duarte, S.; Exenberger, H.; Flora, M. Integrando BIM-LCA para aprimorar avaliações de sustentabilidade de construções. Sustainability 2024, 16, 1172. [Google Scholar] [CrossRef]

- Eckelman, M.; Nunberg, S. Life Cycle Assessment Explained. Journal Tools for Sustainability in Cultural Heritage. Available online: https://stich.culturalheritage.org/life-cycle-assessment-explained/ (accessed on 16 December 2024).

- Ahmad, T.; Hussain, M.; Iqbal, M.; Ali, A.; Manzoor, W.; Bibi, H.; Ali, S.; Rehman, F.; Rashedi, A.; Amin, M.; et al. Environmental, energy and water footprints of the marble tile production chain from a life cycle perspective. Sustainability 2022, 14, 8325. [Google Scholar] [CrossRef]

- Sánchez, A.R.; Ramos, V.C.; Polo, M.S.; Ramón, M.V.L.; Utrilla, J.R. Avaliação do ciclo de vida da produção de cimento com lodos de resíduos de mármore. Int. J. Environ. Res. Public Health 2021, 18, 10968. [Google Scholar] [CrossRef]

- Oweh, S.O.; Aigba, P.A.; Samuel, O.D.; Oyekale, J.; Abam, F.I.; Veza, I.; Enweremadu, C.C.; Der, O.; Ercetin, A.; Sener, R. Improving productivity in a marble processing plant through energy and exergy analysis. Sustainability 2024, 16, 11233. [Google Scholar] [CrossRef]

- Ozcelik, M. Environmental Effects of Marble Quarry Operations in the Burdur Lake Basin (Burdur-Turquia). J. Degrad. Min. Lands Manag. 2023, 10, 4517–4525. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneve, Switzerland, 2006.

- IBRAM. Instituto Brasileiro de Rochas. Available online: https://ibram.org.br/ (accessed on 12 January 2025).

- ABIROCHAS—Associação Brasileira de Rochas Ornamentais. Available online: https://abirochas.com.br/ (accessed on 12 January 2025).

- Fantke, P.; McKone, T.E.; Tainio, M.; Jolliet, O.; Apte, J.S.; Stylianou, K.S.; Illner, N.; Marshall, J.D.; Choma, E.F.; Evans, J.S. Global effect factors for exposure to fine particulate matter. Environ. Sci. Technol. 2017, 53, 4289–4298. [Google Scholar] [CrossRef] [PubMed]

- Hauschild, M.Z.; Wenzel, H. Volume 2—Scientific Background. In Environmental Assessment of Products; Springer: London, UK, 1998. [Google Scholar]

- Tukker, A.; Huppes, G.; Guinée, J.B.; Heijungs, R.; de Koning, A.; van Oers, L.; Suh, S.; Geerken, T.; van Holderbeke, M.; Jansen, B.; et al. Environmental Impact of Products (EIPRO) Analysis of the Life Cycle Environmental Impacts Related to the Final Consumption of the EU-25. 2006. Available online: https://eaternity.org/assets/sci-pub/Tukker_2006_main.pdf (accessed on 9 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).