Microstructural Evolution and Mechanical Properties of Fly-Ash-Based Grouting Materials in Different Aqueous Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection

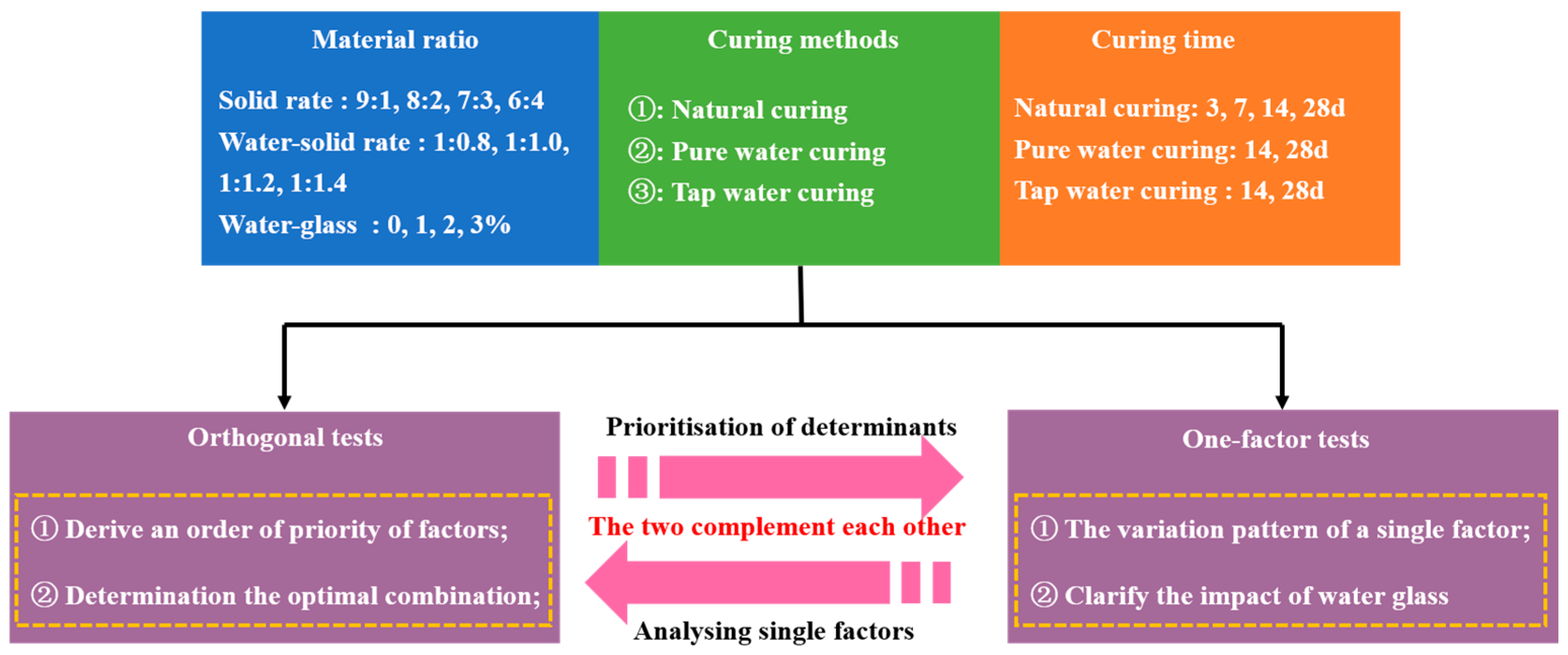

2.2. Experimental Design

- (a)

- One-factor tests

- (b)

- Orthogonal test

- (c)

- Microscopic tests

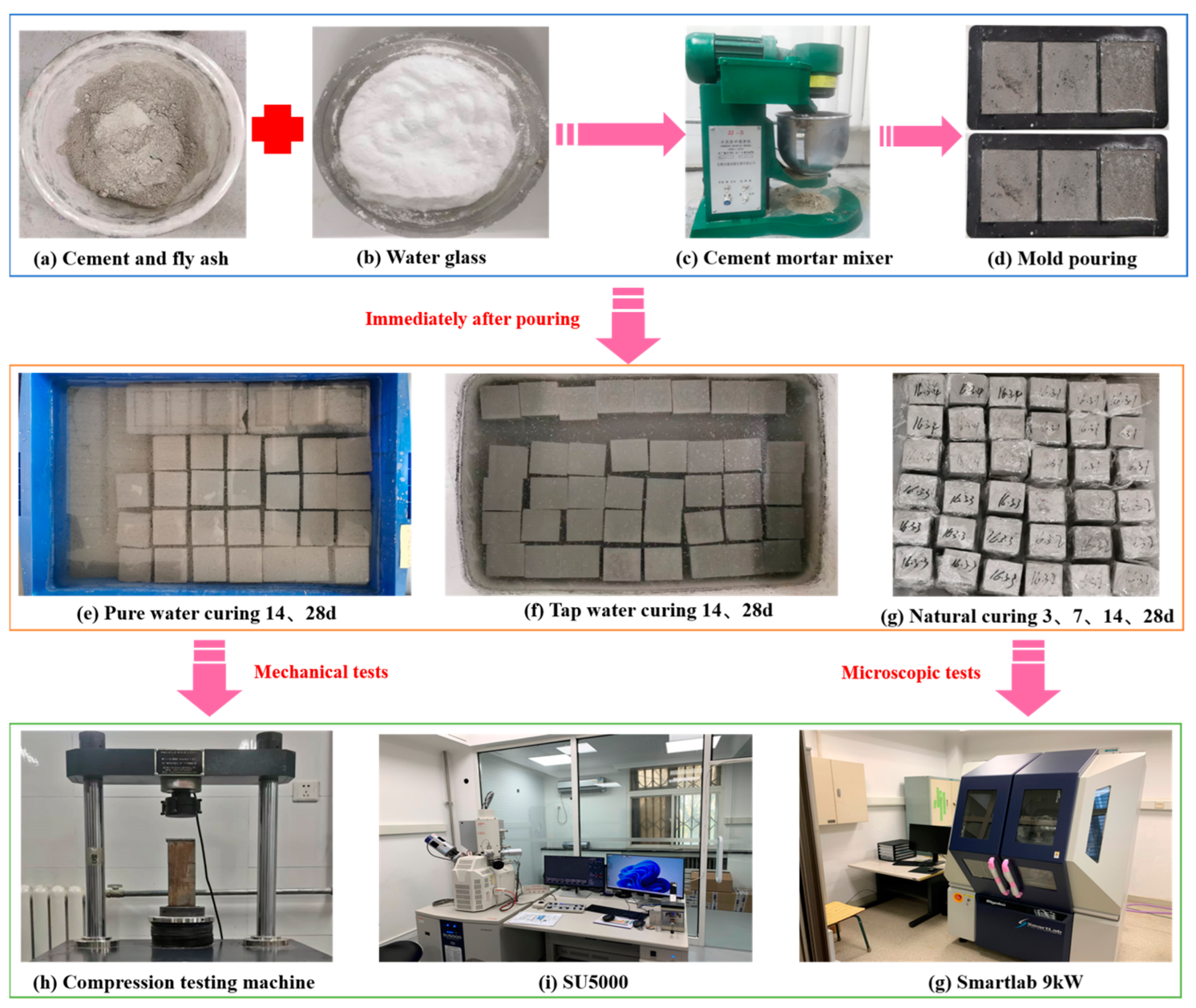

2.3. Experimental Procedure

3. Results and Discussion

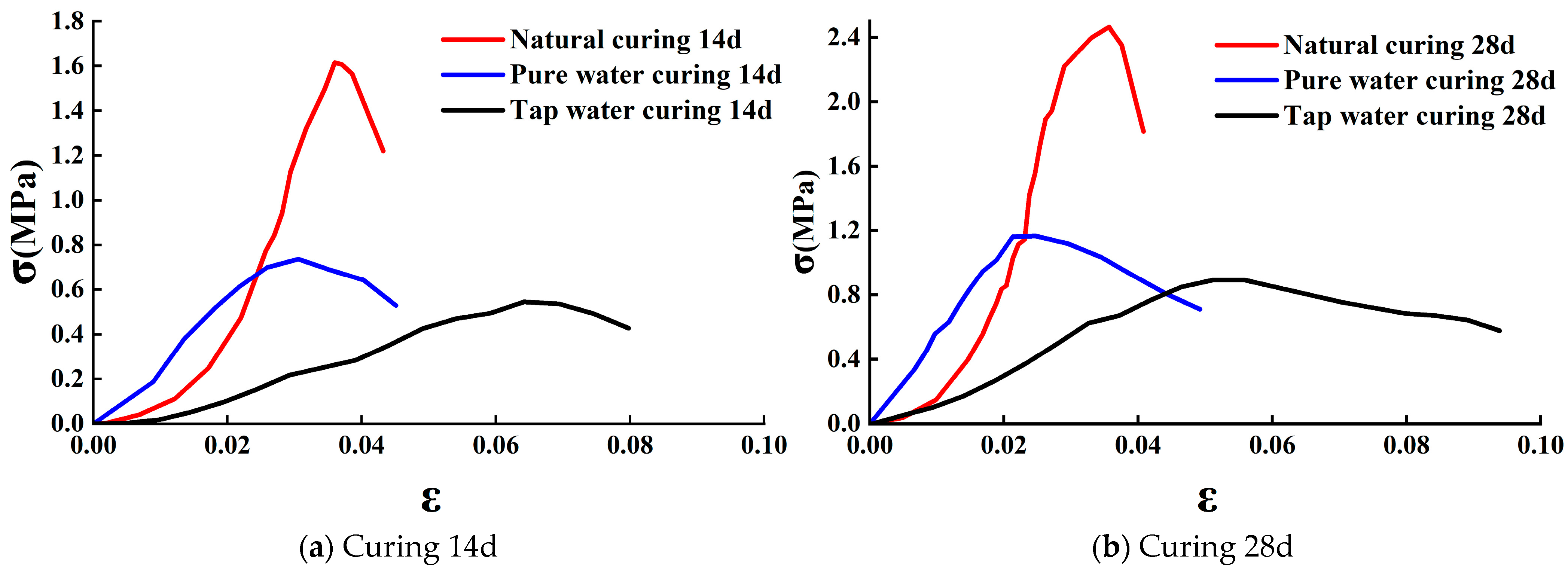

3.1. Deformation and Failure Characteristics

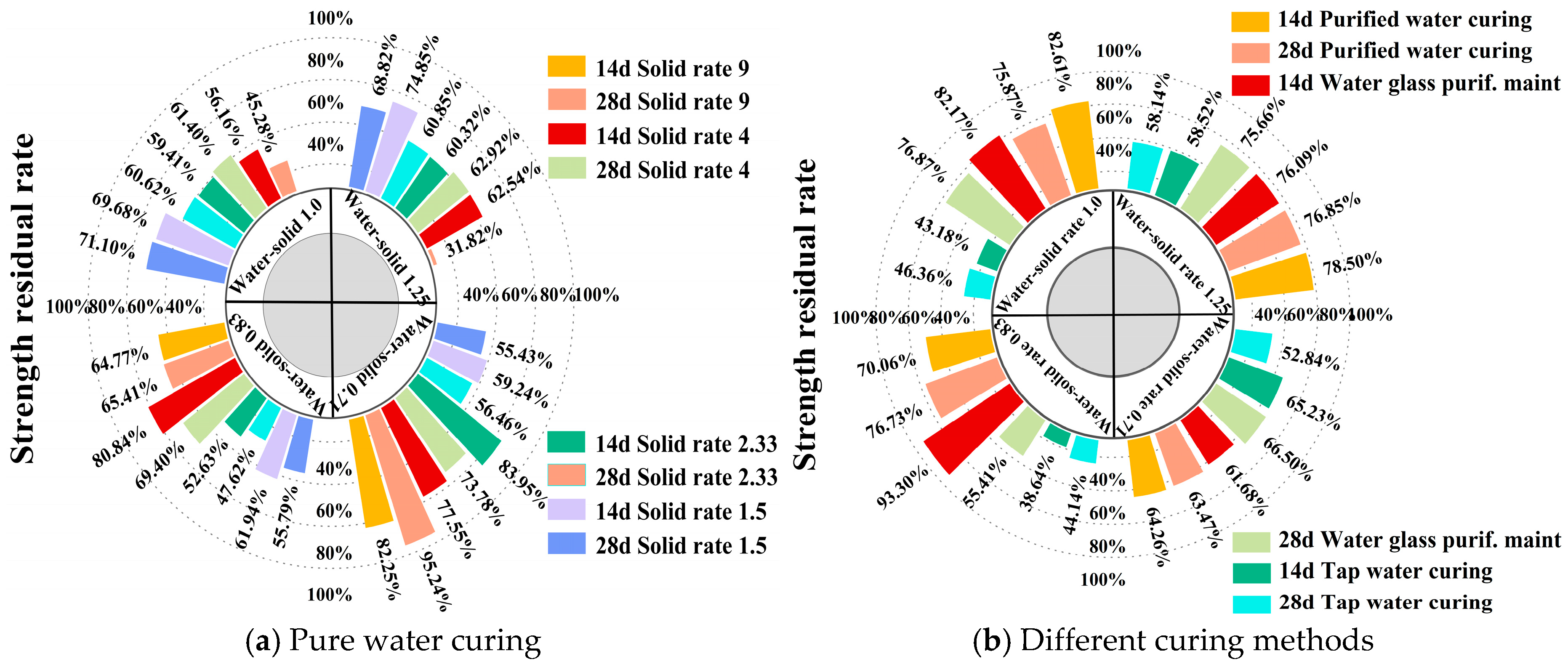

3.2. Uniaxial Compressive Strength (UCS)

- (1)

- The influence of solid rate and water solid rate on UCS

- (2)

- The influence of water glass on UCS

- (3)

- The influence of conservation methods on UCS

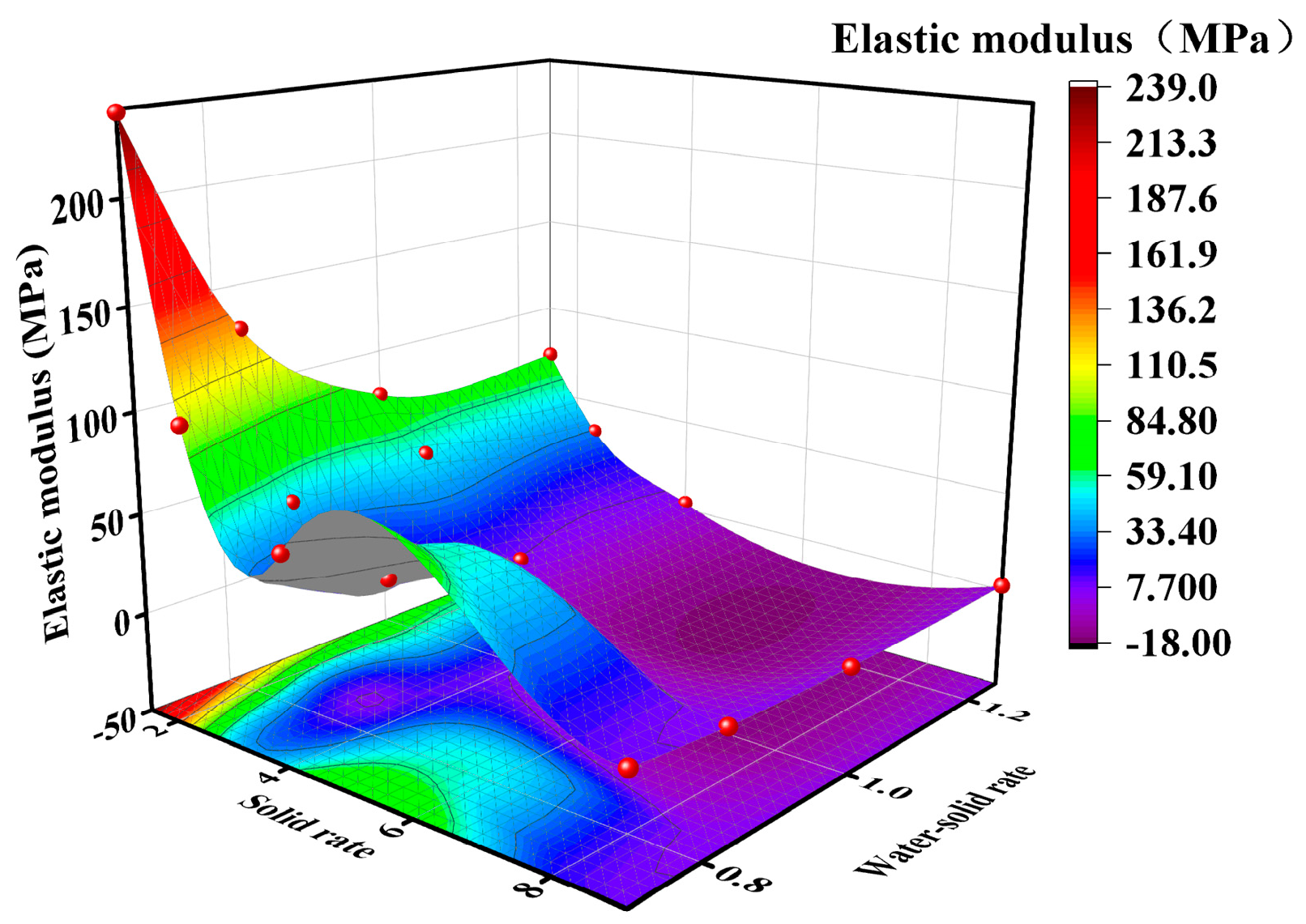

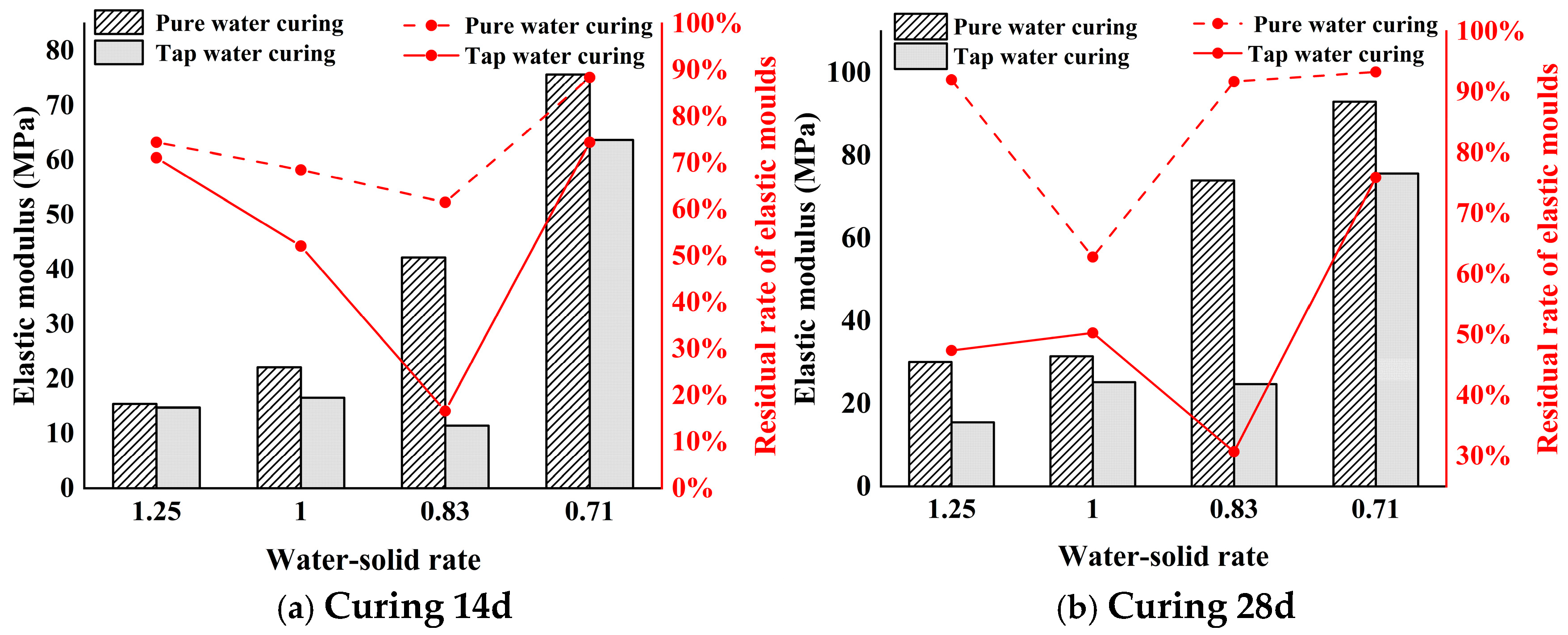

3.3. Elastic Modulus

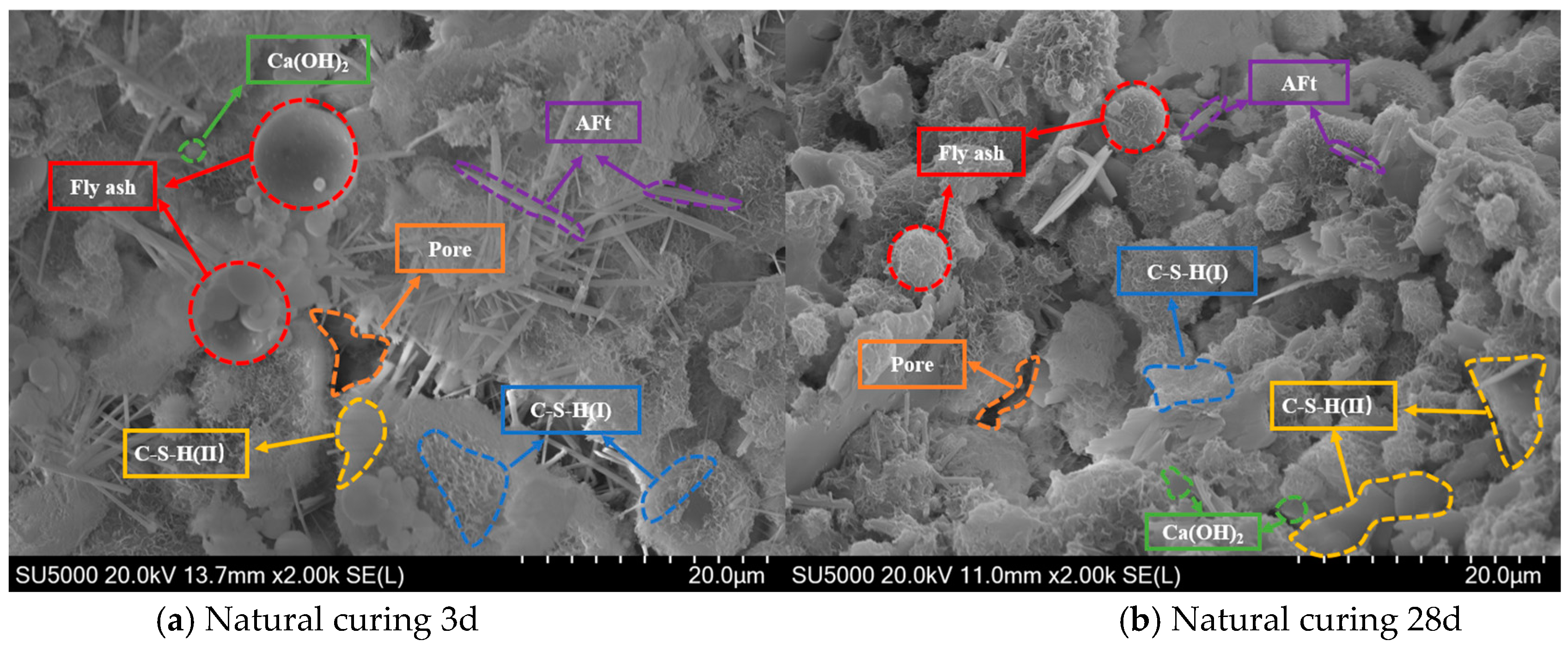

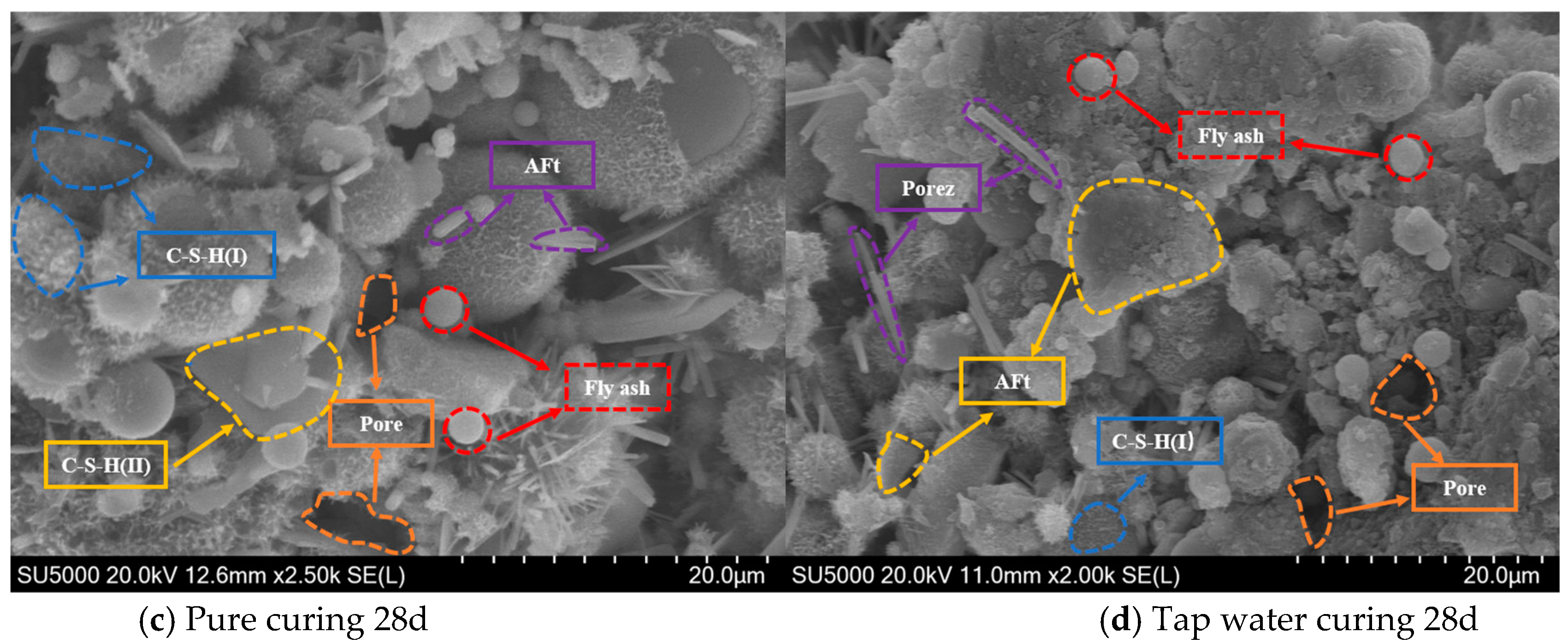

3.4. Microscopic Experiment

3.4.1. XRD

3.4.2. SEM

4. Conclusions

- The naturally conditioned specimens showed linear deformation before peak stress, and the modulus of elasticity was up to 238.6 MPa. Brittle damage occurred after reaching the peak, and the stress plummeted by 30% in a very short period of time; the pure-water- and tap-water-conditioned specimens showed a slow change of the stress with the strain before peak stress, and plastic damage occurred, and with the specimen’s residual strength remaining at around 45% of the peak strength; the tap-water-conditioned specimens showed the highest peak axial strain, which was 60% higher than that of the naturally cured specimens and 150% higher than that of the pure-water-cured specimens.

- The UCS of the stone body was closely related to the solid rate, water–solid rate, water–glass dosage, and maintenance time, and the solid rate was the main control factor. For the treatment of water-rich goaf, the water–solid rate should not be higher than 0.83; for the fly ash and silicate cement grouting materials, the fly ash dosage should not be higher than 80% in order to meet the strength requirements of the treatment project of water-rich goaf.

- Under natural conservation conditions, with the growth of conservation time, the surface of fly ash particles was rough and gradually involved in the secondary hydration reaction, and the C-S-H gel moved gradually from (I) type low density accumulation to (II) type high density accumulation; conversely, under the conservation of pure water and tap water, the fly ash particles indicated a smoother surface, the distribution of the C-S-H (II) gel was less, and the structure was not dense.

- With tap water curing, chloride and Friedl’s appeared, leading to decalcification of the C-S-H gel; under the attack of ions, the pore size became larger, and the porosity increased, resulting in lower strength and higher strain in the specimens.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, S.Y.; Gao, C.F.; Yue, J.C.; Heng, P.G.; Guo, S.T.; Wang, X.Y. Evaluation of the effects of pre-grouting in combination with group holes on the risk of water inrush through coal seam floors. Water 2024, 16, 1160. [Google Scholar] [CrossRef]

- Deng, S.; Wang, X.; Yu, J.; Zhang, Y.; Liu, Z.; Zhu, Y. Simulation of grouting process in rock masses under a dam foundation characterized by a 3D fracture network. Rock Mech. Rock Eng. 2018, 51, 1801–1822. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, W.; Tan, X.; Yang, D.; Zhang, Q. New method to evaluate antiwashout performance of grout for preventing water-inrush disasters. Int. J. Geomech. 2020, 20, 0601902. [Google Scholar] [CrossRef]

- Merritt, P.; Power, C. Assessing the long-term evolution of mine water quality in abandoned underground mine workings using first-flush based models. Sci. Total Environ. 2022, 846, 157390. [Google Scholar] [CrossRef]

- Si, L.L.; Xi, Y.J.; Wei, J.P.; Li, B.; Wang, H.Y.; Yao, B.H.; Liu, Y. Dissolution characteristics of gas in mine water and its application on gas pressure measurement of water-intrusion coal seam. Fuel 2020, 3, 8866928. [Google Scholar] [CrossRef]

- Wang, H.; Xu, Y.; Yuan, L.; Sun, Y.; Cai, Y. Analysis of geothermal heat recovery from abandoned coal mine water for clean heating and cooling: A case from Shandong, China. Renew. Energy 2024, 228, 120659. [Google Scholar] [CrossRef]

- Kurukulasuriya, D.; Howcroft, W.; Moon, E.; Meredith, K.; Timms, W. Selecting Environmental Water Tracers to Understand Groundwater around Mines: Opportunities and Limitations. Mine Water Environ. 2022, 41, 357–369. [Google Scholar] [CrossRef]

- Zhou, N.; Dong, C.; Zhang, J.; Meng, G.; Cheng, Q. Influences of mine water on the properties of construction and demolition waste-based cemented paste backfill. Constr. Build. Mater. 2021, 313, 125492. [Google Scholar] [CrossRef]

- Lu, L.; Yang, Z.; Li, K.; Zhang, K.; Yan, X.; Marano, G.C.; Briseghella, B. Synergy of inert granite powder and active mineral admixture in manufactured sand mortar: The effect on mechanical properties, chloride permeability and water absorption properties. Constr. Build. Mater. 2023, 408, 133660. [Google Scholar] [CrossRef]

- Oggeri, C.; Fenoglio, T.M.; Vinai, R. Tunnel spoil classification and applicability of lime addition in weak formations for muck reuse. Tunn. Undergr. Space Technol. 2014, 44, 97–107. [Google Scholar] [CrossRef]

- Liang, X.; Feng, K.; Hu, Z.; Wang, C.; He, C. Study on grout rate and performance of backfill grouting in water-rich strata. Constr. Build. Mater. 2024, 443, 137766. [Google Scholar] [CrossRef]

- Sha, F.; Bu, M.; Fan, R.; Yang, N.; Zhang, L. Development and application of novel microfine cement-based grout. Case Stud. Constr. Mater. 2024, 20, e03167. [Google Scholar] [CrossRef]

- Wu, W.; Wang, R.; Zhu, C.; Li, Y.; Luo, Y.; Chen, Q.; Xing, F. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Song, W.; Du, C.; Fu, H. High-volume ultrafine fly ash-cement slurry mechanical properties and strength development model establishment. Constr. Build. Mater. 2021, 277, 122350. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.X.; Song, W.D. Mechanical model and strength development evolution of high content fly ash–cement grouting material. Constr. Build. Mater. 2023, 398, 132492. [Google Scholar] [CrossRef]

- Fu, J.X.; Wang, K.; Wang, J. Internal pore evolution and early hydration characterization of fly ash cement backfill. J. Build. Eng. 2023, 72, 106716. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Wang, X.Y.; Chu, S.Z.; Zeng, J.Y.; Mu, Y.D.; Li, Y.Q.; Luo, Z.T.; Ye, G.T. Effect of water loss during curing on hydration reaction and hydrates conversion in calcium aluminate cement-bonded castables. J. Iron Steel Res. Int. 2024, 31, 2133–2141. [Google Scholar] [CrossRef]

- Chong, L.; Yang, J.; Shi, C. Effect of curing regime on water resistance of magnesium–potassium phosphate cement. Constr. Build. Mater. 2017, 151, 43–51. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Zhang, Q.; Li, Z. Performance of typical cement suspension-sodium silicate double slurry grout. Constr. Build. Mater. 2019, 200, 408–419. [Google Scholar] [CrossRef]

- Feng, H.; Liang, J.; Pang, Y.; Zhao, X.; Wang, Y.; Sheikh, S.A. Effects of the fly ash and water glass on the mechanical properties and water stability of the high ductile magnesium phosphate cement-based composite. Constr. Build. Mater. 2022, 333, 127395. [Google Scholar] [CrossRef]

- Zheng, D.D.; Ji, T.; Wang, C.Q.; Sun, C.J.; Lin, X.J.; Hossain, K.M.A. Effect of the combination of fly ash and silica fume on water resistance of Magnesium–Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Yang, X.Z.; Lei, J.S.; Zhang, Y.Q.; Liu, Y.; Kang, J.; Liu, J. Study of the orthogonal test of modified cement-water glass grouting material under the curing condition of Karst water. J. Railw. Sci. Eng. 2019, 16, 2999–3004. [Google Scholar]

- Liu, W.; Du, H.; Yi, P.; Li, Y.; Luo, Y.; Chen, Q. The early hydration and rheological characteristics of cement paste containing co-combustion fly ash. J. Build. Eng. 2023, 78, 107736. [Google Scholar] [CrossRef]

- Termkhajornkit, P.; Nawa, T.; Kurumisawa, K. Effect of water curing conditions on the hydration degree and compressive strengths of fly ash–cement paste. Cem. Concr. Compos. 2006, 28, 781–789. [Google Scholar] [CrossRef]

- Yi, F.; Jiang, X.T.; Li, J.; Jin, H.S. An analysis of the deterioration mechanism of a grouting stone under the ion erosion. Hydrogeol. Eng. Geol. 2022, 49, 200–208. [Google Scholar]

- Jonchhe, P.; Yu, H.; Lau, C.; Ng, K. A comprehensive investigation of new coal char-based cement grouts: Impact of curing temperature, environment, and duration. Transp. Infrastruct. Geotechnol. 2024, 11, 3469–3495. [Google Scholar] [CrossRef]

- Huang, F.; Hu, Z.; Li, H.; Wang, Y.; Liu, J. Deformation mechanisms of cement paste with ultra-low water-to-cement rates under different curing conditions at early ages. Constr. Build. Mater. 2023, 364, 129951. [Google Scholar] [CrossRef]

- Wang, B.; Li, B.; Huang, L.S.; Zhang, J.X. Study on the mechanical properties and microstructure of a rich-watered grouting material. Mater. Today Commun. 2023, 35, 106261. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, H.Y.; Wang, P.F.; Chen, X.; Qian, J.S. Study on the performance of Ternesite-Ye’elimite cement at different curing conditions. Mater. Rep. 2021, 36, 110–115. [Google Scholar]

- MOT JTG/T 3331-2024; Technical Specifications for Design and Construction of Highway Engineering in Mined-out Area. Ministry of Transport: Beijing, China, 2024.

- GB5749-2022; Standards for Drinking Water Quality. National Health Commission of the People’s Republic of China: Beijing, China, 2022.

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar]

- Lu, B.; Zhang, Z.; Zhu, H.; Liu, K.; Zhang, Y.; Chen, W. Optimization design of recycled powder mortar mix ratio based on orthogonal test. Constr. Build. Mater. 2025, 474, 141145. [Google Scholar] [CrossRef]

- Wang, Z.; Abduljabbar, Y.Y.; Maekawa, K.; Leung, C.K.; Poon, C.S.; Li, Z. Performance assessment of seawater fly ash cement paste with integrated physicochemical-geochemical simulation platform and experimental validation. J. Build. Eng. 2023, 79, 107802. [Google Scholar] [CrossRef]

- Liu, J.; Sui, W. Determination of mechanical and microstructure properties of paste backfills to avoid overburden failure. J. Clean. Prod. 2023, 388, 135926. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, C.; Wang, B.; Han, J.; Guo, L.; Tang, N. Study on the micro-rheological properties of fly ash-based cement mortar. Constr. Build. Mater. 2024, 442, 137664. [Google Scholar] [CrossRef]

| Basic Chemical Composition/% | Density/ (g/cm3) | Water Demand Rate/% | Burnout /% | Moisture Content/% | ||

|---|---|---|---|---|---|---|

| SO3 | f-CaO | SiO2, Al2O3, Fe2O3 | ||||

| 1.2 | 2.9 | 88 | 2.0 | 101 | 7 | 0.2 |

| Index | Unit of Measure | “Standards for Drinking Water Quality” GB 5749-2022 [31] | Mentougou |

|---|---|---|---|

| Free chlorine | mg/L | The contact time with water ≥30min, Factory water and terminal water limits ≤2, The factory water balance ≥0.3, The residual water at the end ≥0.05. | 0.10~0.50 |

| Permanganate index (O2) | mg/L | 3 | 0.53~1.4 |

| Factors | Natural Curing | Water-Rich Curing | ||

|---|---|---|---|---|

| A | B | SS/% | Numbering | Numbering |

| 9:1 | 1:0.8, 1:1.0, 1:1.2, 1:1.4 | 0 | S1…S4 | SW1…SW4 |

| 8:2 | 1:0.8, 1:1.0, 1:1.2, 1:1.4 | 0 | S5…S8 | SW5…SW8 |

| 7:3 | 1:0.8, 1:1.0, 1:1.2, 1:1.4 | 0 | S9…S12 | SW9…SW12, SWT9...SWT12 |

| 7:3 | 1:0.8, 1:1.0, 1:1.2, 1:1.4 | 3 | SG9...SG12 | SWG9...SWG12 |

| 6:4 | 1:0.8, 1:1.0, 1:1.2, 1:1.4 | 0 | S13…S16 | SW13…SW16 |

| Level | Factors | ||

|---|---|---|---|

| A | B | SS/% | |

| 1 | 9:1 | 1:0.8 | 0 |

| 2 | 8:2 | 1:1.0 | 1 |

| 3 | 7:3 | 1:1.2 | 2 |

| 4 | 6:4 | 1:1.4 | 3 |

| Type of Curing | Natural Curing | Pure Water Curing | Tap Water Curing |

|---|---|---|---|

| Curing time/day | 3, 28 | 28 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Qin, Y.; Hu, F.; Xu, N.; Guo, Y.; Qin, J.; Ren, G. Microstructural Evolution and Mechanical Properties of Fly-Ash-Based Grouting Materials in Different Aqueous Environments. Water 2025, 17, 1407. https://doi.org/10.3390/w17101407

Chen J, Qin Y, Hu F, Xu N, Guo Y, Qin J, Ren G. Microstructural Evolution and Mechanical Properties of Fly-Ash-Based Grouting Materials in Different Aqueous Environments. Water. 2025; 17(10):1407. https://doi.org/10.3390/w17101407

Chicago/Turabian StyleChen, Jianwei, Yan Qin, Fengdan Hu, Nengxiong Xu, Yuxi Guo, Jiayu Qin, and Guangming Ren. 2025. "Microstructural Evolution and Mechanical Properties of Fly-Ash-Based Grouting Materials in Different Aqueous Environments" Water 17, no. 10: 1407. https://doi.org/10.3390/w17101407

APA StyleChen, J., Qin, Y., Hu, F., Xu, N., Guo, Y., Qin, J., & Ren, G. (2025). Microstructural Evolution and Mechanical Properties of Fly-Ash-Based Grouting Materials in Different Aqueous Environments. Water, 17(10), 1407. https://doi.org/10.3390/w17101407