Abstract

Naturally occurring Fe(III) films with rainbow reflection iridescence have been observed floating on the water surface of various spots covered with shallow water (e.g., edges of wetlands and creeks, standing water over soils). This natural phenomenon has become a scenic attraction and stimulated much curiosity. We pursued an experimental inquiry aimed at probing this interesting, curious natural wonder. As the first critical task, floating Fe(III) films were successfully generated in an assessable, controllable setting in our laboratory. This enabled us to establish this phenomenon reproducibly under controlled conditions and characterize the phenomenon over the entire span of the formation and transformation of the Fe(III) films. Our film generation method requires a few things: fresh soil (source for Fe(III) and microbes), glucose (energy source), and water in a container. The floating Fe(III) films as observed in the field occurred in ~1–3 day(s) on the water surface of the inundated soil mixed with the sugar. The Fe(III) films then grew from initial very thin, colorless, somewhat transparent films with rainbow reflection iridescence to colored thicker films and then to orange/orange-red/red crusts over the time. A comprehensive mechanistic picture was formulated to depict the formation of the Fe(III) films. Several sequential processes are operative. First, the Fe(III) (oxides, oxyhydroxides) in the soil is reduced to Fe(II) by the Fe(III)-reducing microbes during their anerobic respiration with Fe(III) as the electron (e−) acceptor after depletion of dissolved O2 in the water as a result of aerobic microbial respiration with O2 as the e− acceptor. The Fe(II), being soluble, then diffuses to the water surface where it is oxidized to Fe(III). Subsequently, the Fe(III) hydrolyzes and various Fe(III) hydrolysis products polymerize to stabilize. A polymeric model was created to account for the Fe(III) film transformation. The Fe(III) films are considered to transform from the dimers and trimers and linear polymers of Fe(OH)3 to Fe(III) polymer sheets (e.g., Fe(OH)3, FeOOH), to 3D Fe(III) polymers, and eventually to Fe2O3 colloid particles. This floating Fe(III) film phenomenon boasts an environmental chemical drama of redox cycling of Fe(III)/Fe(II) at soil/water and water/air interfaces coupled with Fe(II) transport from the inundated soil to the water surface followed by ultimate mineralization of the Fe(III) polymers. Our Fe(III) film generation method can be readily scaled up to supply Fe(III) films of rich varieties in thickness, size, morphology, and structure over the entire span of various stages of their formation and transformation as desired for various uses. This setup offers a platform needed for further controlled studies on the kinetics, mechanism, and process of abiotic and biotic nature involved in the Fe(III) film phenomenon and for exploration of versatile roles of the Fe(III) films as nanofilms in Fe(III)/Fe(II)-surface catalyzed chemical and photochemical reactions involving various natural and synthetic compounds.

1. Introduction

Iron is unique and ubiquitous.

With the highest binding energy per nucleon, iron boasts the last chemical element with a stable nucleus (Fe(26)) that is generated in a star during its stellar nuclear fusion [1,2,3,4]. It has the highest cosmic abundance among the metal elements [5,6] and is the fourth most abundant element in the Earth’s crust [7,8]. As the most abundant element on Earth as a whole (~30% of Earth’s total mass) [7], iron is the major chemical component of the Earth’s core [5,7,9]. The Fe(III)/Fe(II) couple is considered to be intimately associated with the origin of life [10]. Biological systems have iron as their prominent member [7,11,12,13,14]. Hemoglobin, the pivotal blood biomolecule, finds iron occupying its magnificent protein assembly with a vital biochemical role to play [12,15,16].

Iron lends itself to everywhere in the environment. It commonly exists in water, soil, and air [17]. Iron binds humic substances, widely present in soils and waters [18,19,20]. Iron oxyhydroxides and oxides color soils in a spectrum of orange to red [20,21]. Airborne dusts containing iron originated from the Sahara Desert travel across the ocean, landing on another continent [22]. Oceanic scarcity of iron renders it to become a limiting nutrient for alga in oceans [23]. This oceanic ecological feature of iron inspired a novel attempt to boost oceanic algal bloom by artificial addition of iron to the ocean aimed at CO2 fixation (oceanic iron fertilization) [17,24].

Playing a pivotal role in environmental chemistry [25,26], iron can control a great number of environmental chemical reactions, especially reduction and oxidation (redox) reactions, and photochemical and surface reactions (e.g., see [26,27,28,29,30,31]). Iron plays a critical role in biogeochemical cycles of various nutrients and many other elements [26,32,33].

Fe ([Ar]3d64s2) has two stable redox species commonly found in the environments, ferric iron (Fe(III): Fe(Ar)3d5) and ferrous iron (Fe(II): Fe(Ar)3d6). The Fe(III) species are insoluble, existing as hydroxides (Fe(OH)3), oxyhydroxides (FeOOH), and oxides (e.g., Fe2O3) [11], while Fe(II) is soluble and thus mobile in soils, sediments, and waters. The Fe(III)/Fe(II) redox couple can undergo a redox cycling between Fe(III) and Fe(II):

Iron has a rich repertoire of redox reactions involving the Fe(III)/Fe(II) redox couple and cycling [26,33]. A prominent, important feature of Fe environmental chemistry lies at the coupling of Fe redox cycling with physical transport of Fe in waters and soils as a result of the soluble nature of Fe(II) species and insoluble nature of Fe(III) species.

Fe(III) + e− ↔ Fe(II)

Fe(II) can be readily oxidized to Fe(III) in soils and waters and then hydrolyze to form Fe(III) hydroxides, which further transform to Fe(III) oxyhydroxides and then oxides [26]. The oxidation of Fe(II) is especially active at redox interfaces such as water/air and soil/air interfaces where exists a redox potential change (redox gradient) [34]. Fe(III) species can be reduced to Fe(II) chemically (photochemical, surface reactions) and biotically (microbially via respiration) in soils and waters [26]. Anaerobes resort to other electron (e−) acceptors than O2 (e.g., Fe(III), Mn(IV), NO3−/NO2−, SO42−, etc.) for their anaerobic respiration [26,35,36] after dissolved oxygen (DO) is depleted [37]. Hence, Fe(III)/Fe(II) redox cycling is coupled not only with Fe transport but also with biotic activities in soils and waters.

Natural phenomenon of floating Fe(III) films and origin of the present study. The natural phenomenon of mysterious films floating on water surface delivers a marvelous highlight of the fascinating environmental redox chemistry of iron (Figure 1). Previously, oil-like floating thin films with rainbow shining were observed appearing on the surface of somewhat shallow water near the edge of a wetland; yet, a finger-poking of the film resulted in breaking of the films, instead of climbing onto one’s fingertip (see Figure 1b). This refutes the illusion of oily (hydrophobic) films and in turn suggests the hydrophilic nature of the films (Rich Bartlett, personal communication, 1993 [37,38,39]). It was thought that the films observed are composed of some forms of Fe(III) hydroxides/oxyhydroxides associated with microbially mediated redox transformation of Fe(III)/Fe(II) coupled with Fe(II) transport (Rich Bartlett, personal communication, 1993).

Figure 1.

Iridescent floating films naturally occurring on water at (a) Cane Creek Lake Park (2022, Cookeville, TN, USA) and (b) a wetland (1998, Tahquamenon River Watershed, MI, USA).

One can come across the floating Fe(III) films on a field trip, a leisure walk in a park with shallow streams or waters in sight, or various outdoor settings (Figure 1), and many other places around the world [37,39]. The floating films have also called the attention of a group of keen researchers with acute curiosity that led to investigations into the chemical nature of the films and the processes involved in their formation [37,38,39,40].

Yet, the mystery of this fascinating natural phenomenon remains to be fully unveiled. Because where and when the floating Fe(III) films may occur in our natural environments remain largely unpredictable, this phenomenon needs to be repeatably established under controlled conditions and fully characterized for its entire span from intimal thin films to thick films and crusts. Moreover, its complete environmental chemical picture still needs to be revealed. This necessitates full-scale experimental investigations. The research of such a sort calls for certain prerequisites, including (a) a film generation setup (method) that is conveniently operative and experimentally controllable and (b) the Fe(III) films that are repeatably available as desired.

Previously published studies on floating Fe(III) films resorted to the use of naturally occurring [37,39] or laboratory synthetic [39] films or the films formed in enriched media prepared by laboratory incubation of field-collected, selected natural sediment samples [40]. These sources of Fe(III) films bear some limitations. Naturally occurring Fe(III) films collected in the field might not be reproducible in their sampling location (site, spot) and environmental setting, their size, quantity, color, thickness, or structure, their chemical and mineralogical makeup and characteristics, or the stage (phase) of their growth and aging, which all appear to be more or less at the mercy of chance upon film sampling. The variation and non-reproducibility of film sampling could cast uncertainties on the representativeness of the films used in the previous studies. The synthetic films and those from the selected, incubated sediment media, on the other hand, involved a complicated series of highly technical laboratory operations that require well-trained hands in addition to certain specialty equipment [39,40]. Incidentally, these films thus produced may not necessarily reproducibly resemble naturally occurring Fe(III) films.

The lack of a reproducible, controllable supply of Fe(III) films ready in a laboratory setting challenged further in-depth full-scale controlled investigation. Hence, there is a compelling need to find a method to be able to generate Fe(III) films that is conveniently assessable and readily controllable and can repeatably deliver them. A discovery occurred in our laboratory, namely, that it was accomplishable to generate the Fe(III) films in our laboratory setting as desired [41,42], which then paved the way for a wide scope of novel research to fully establish and characterize this natural phenomenon and to reveal and understand the mechanism and process of the formation and transformation of the Fe(III) films, as described below in the objectives of this research.

Objectives of the present study. The objectives of the present research were to (1) generate naturally occurring floating Fe(III) films in a laboratory setting using a method that can deliver the films repeatably and controllably as desired across the entire span of the formation and transformation of the films; (2) fully establish the floating Fe(III) film phenomenon reproducibly and consistently; (3) characterize this phenomenon over the entire span of its formation and transformation; (4) experimentally investigate the Fe(III) film phenomenon using our film generation setting to understand this phenomenon; (5) formulate a comprehensive mechanistic picture of the Fe(III) film formation in terms of fundamental principles of environmental chemistry and established understanding of iron chemistry and environmental microbiology with fine technical details, especially in connection with the results of our own experimental work; and (6) create a polymeric model to account for the transformation of the Fe(III) films over its entire span. Hence, this research readily paves the way for further multi-faceted studies on the Fe(III) film phenomenon and for exploration of various potential applications of the Fe(III) films as nanofilms. The merit of our method for demonstration and investigation of the floating Fe(III) film phenomenon as a natural wonder may extend to general education in environmental science as well as environmental chemistry. Ample background information and elaborated presentation with technical details are thus provided for a broader range of readers, without the need of immediate access to the original references.

2. Materials and Methods

The laboratory setting and items needed for this research were common, and easily accessible or home-available. These include fresh soil, water, sugar, calcium carbonate, and a container. A pH meter/paper and Fe(II) test kit are needed for further mechanistic investigation. Generally, the occurrence of the floating Fe(III) film phenomenon requires the following necessities and conditions: (1) iron oxides/oxyhydroxides (Fe(III)) in the soil; (2) fresh, living functional microbes in the soil; (3) mild pH condition (~6–8) and favorable nutritional condition for microbes to flourish to reduce Fe(III) to Fe(II); and (4) inundation of the soil sample in the container (soil sample covered with shallow water) to facilitate the creation of an anoxic (anaerobic, reducing) condition in the submerged soil system.

2.1. Soils

To identify the soil samples needed to replicate the floating Fe(III) film phenomenon in a laboratory setting, fresh soil samples were collected in the field from a variety of places around the city of Cookeville (TN, USA) (Table 1). The samples collected were labeled and sealed in plastic bags and stored in a refrigerator (to keep them fresh) for further use.

Table 1.

Summary of the soil samples collected around Cookeville (TN, USA) and the results of the general demonstration tests (Expt.–1) for the floating Fe(III) film phenomenon.

Fresh soil samples. In order to replicate the floating Fe(III) film phenomenon, fresh soil samples collected in the field must be used. The requirement of fresh field soils stems from the need for fresh, living functional soil microbes co-existing in the soils. At present, it remains rather unclear exactly which groups of soil microbes are specifically responsible for the occurrence of floating Fe(III) films in a particular soil. Hence, the knowledge of which soil would carry and house the required soil microbes apparently appears to be in the hands of luck when a soil sample is taken. As a result, it could happen that some soil samples may not necessarily deliver the desired floating film phenomenon. Nevertheless, our experiences indicate that the required soils are widely and readily available in the field because the functional microbes are commonly present in soils.

Soil iron oxides and oxyhydroxides. Another indispensable component required for the occurrence of floating Fe(III) films is iron oxides and/or oxyhydroxides (as Fe(III) sources) present in soils. The best candidates for soils to be used are those with orange-to-red colors (or some parts of the soils with these colors), which are typical of and thus indicative of the presence of iron oxides/oxyhydroxides in the soils.

The requirement of soil iron oxides/oxyhydroxides suggests that the soils in the southern regions (humid, warm or hot; subtropical or tropical) may be favorable, with a higher chance for the films to occur because these soils commonly have plenty of iron oxides/oxyhydroxides, as shown by their soil color (red soils). Some layers (horizons) of soils in the northern regions may also have adequate iron oxides/oxyhydroxides. If a soil has few iron oxides/oxyhydroxides, as a remedy, some can be artificially added to the soil sample, followed by sufficient mixing. This may create an artificial simulation soil sample to test the film phenomenon (provided the soil sample has the required microbes and soil conditions).

The absence of visible orange-to-red colors in a soil does not necessarily lead to a ruling that the soil does not have iron oxides/oxyhydroxides. It could happen that the soil particles with iron oxides/oxyhydroxides may be covered (coated or wrapped) by organic matter (dark color), which thus can mask the colors of iron oxides/oxyhydroxides.

Soil sampling location and site (spot). The location and site of soil sampling are non-specific because, generally, the components required for the natural phenomenon of floating Fe(III) films to occur are widely present in soils. The specific spot in a soil profile for soil sample collection is not crucial. Any spot (site and location as well) of interest would warrant a collection. Except for the rule-of-thumb feature of orange-to-red colors to serve as a practical marker indicating the presence of iron oxides and/or oxyhydroxides in the soils, soil sampling in terms of geographical location and sampling site or spot can be quite arbitrary as desired. In other words, for the purpose of soil sampling to showcase the floating Fe(III) film phenomenon, the soils needed are not site-specific or spot-specific. Generally, the floating Fe(III) film phenomenon should be expected to occur in a wide range of samples among various soils collected from various places and spots.

Our experiences suggest that the soil samples that failed to deliver floating Fe(III) films may not possess the functional soil microbes, Fe(III) oxides and/or oxyhydroxides, or favorable soil conditions, in part or collectively, required for film occurrence. Freshly collected soil samples may be stored in a refrigerator for a prolonged period of time and the soil microbes seem to be able to sustain long-term survival in storage.

2.2. Chemicals

The chemicals needed for the present study are described below.

Glucose (C6H12O6): The sugar is added to boost the flourishing of soil microbes. The rationale for this procedure is that the organic matter originally present in a soil may not provide adequate microbial food (favorable, ready to be consumed) required to induce and sustain the flourishing growth of a variety of functional soil microbes on the scale required for full film occurrence. If glucose is not available, any common sugar should do.

Glucose is preferred since it is the simplest sugar (monosaccharide) that can serve as easy, fast food for the soil microbes to consume without need for initial digestion. This is why the soil organic matter present in a soil is usually not favored or useful, since it entails abundant metabolic activities to transform the organic substances (even the well-defined carbohydrates, fatty acids, and fats) first to the simplest sugars, ready for direct microbial use. Soil organic matter (mainly humic substances) bears a rich variety of (fused) aromatic compounds that can be highly resistant to microbial (enzymatic) attack. The soil organic matter may sustain the minimal survival of the soil microbes and other ordinary ecological activities, but it does not jump-start microbial flourishing in a manner that can quickly deliver a typical floating film occurrence.

Our research indicates that adding sugar turns out to be a critical measure; addition of sugar is responsible for jump-starting the soil microbial activities needed for the floating Fe(III) film phenomenon to occur. This is why the floating film may not commonly materialize readily in a setting only with a fresh field soil sample submerged in water.

Calcium Carbonate (CaCO3): The limestone chemical is used to modify soil pH to provide a mild system condition favored for microbial growth and film formation (pH: ~6–8 generally). Addition of calcium carbonate is especially beneficial for soils in the southern regions, which are commonly acidic (acidic soils or acid soils).

Water: Distilled water is sufficient. Other types of water can work as well. The type of water is not crucial (as long as the water used is clean).

Nitrogen (N2) gas: This was used to degas dissolved oxygen or expel oxygen in the headspace to create an anaerobic condition in the system tested.

Ferrous Ammonium Sulfate (Fe(NH4)2(SO4)26H2O, Baker, ACS Reagent): The ferrous salt was employed to artificially, abiotically generate floating Fe(III) films in a laboratory setting. Ferrous nitrate is not favorable because nitrate (i.e., NO3−) can be photochemically sensitive (a source of ·OH free radical in irradiated water) and induce photochemically mediated redox transformations involving Fe(III)/Fe(II).

It needs to be pointed out that throughout the present research, neither grade nor accuracy of quantification (weighing) of the above chemicals is critical.

2.3. Materials

The major material for generating floating Fe(III) films in a laboratory setting is a container with a size as desired. The container can be a glass beaker, a paper cup for drinks, a plastic food bowl, or a plastic box or tray. Our research shows that all containers can work just fine. The soil microbes seemed to feel at home in various containers.

2.4. Experimental Studies and Procedures

We conducted three sets of experimental work to create, demonstrate, and investigate the floating Fe(III) film phenomenon in a laboratory setting: (1) creation and general demonstration of the floating Fe(III) film phenomenon using various soils, (2) full-scale case study/demonstration and investigation of the Fe(III) film phenomenon, and (3) a set of experimental tests to probe and understand the process and mechanism involved in the Fe(III) film phenomenon. The experimental procedures and operational details for each particular set of the work are described below.

General experimental setup and procedures: To generate floating Fe(III) films in our laboratory setting, we prepared a mixture of (1) a fresh soil sample with (2) glucose (i.e., C6(H2O)6) powder, (3) calcium carbonate (CaCO3) powder (a natural, mild chemical used to mediate the pH), and (4) deionized water (DI-H2O) in a small beaker (Don Ross, Soil Redox Laboratory for Soil Chemistry), as these are favorable for microbial growth and mediation. Glucose provides fast food (easily accessible energy source) for soil microbes to engage in their biotic activities, while limestone and water help to nurture the mild soil pH condition needed for the microbes to flourish in a moist environment.

The field-collected fresh, moist soil samples (or stored in plastic bags in a refrigerator at ~4°, above freezing point) were used directly as they were, without any pretreatment needed (e.g., no need for grinding, selection, drying, or homogenizing). The exact amount of a soil sample used is not critical, as the soil microbes will grow to the level required for film generation under favorable conditions, even though the number of soil microbes or communities may not be identical from one soil sample to another at the beginning. The quantity of each of the other components needed (i.e., glucose, CaCO3, water) is not critical either and can be scaled up proportionally to the desired level.

After the three components (soil, glucose, and CaCO3) were placed in a container and sufficiently mixed, water was then gently added along the wall of the container until ~2–3 cm above the soil surface. If the mixing is performed after water is added, the solution above the soil may stay murky as a result of the soil particle suspension caused by mixing.

The size and shape of the container(s) are not critical. But, no matter what container is used, it is critical to ensure that the water level is ~2–3 cm above the soil surface for the specific treatment described (Table 2). Sufficient water height above the soil is important because it can secure an inundation condition with sufficient water coverage depth needed for dissolved oxygen control in the soil–water mixture.

Table 2.

Experimental setup and treatments for Expt.–1 and Expt.–2.

The submerged soil mixed with glucose and CaCO3 in the container was then left in open air without the need for special attention. The conditions thus set in the soil–water system in the container then triggered the processes. Floating Fe(III) films were expected to emerge gradually in ~24–48 h and keep evolving over time, depending on the particular soil sample in place. Some water was refilled as needed (along the container wall to avoid disturbing the solution as much as possible) occasionally to maintain the required water level.

Creation and demonstration of the floating Fe(III) film phenomenon in a laboratory setting (Expt.–1, General Demo): We used six fresh soil samples field-collected in Cookeville (TN, USA) (Table 1) to identify those that are able to deliver floating Fe(III) films in a laboratory setting and to generally demonstrate the floating film phenomenon. The specific treatments for Expt.–1 are detailed in Table 2. The setups were prepared as described preciously (see General experimental setup and procedures) and left alone at room temperature so that the films could generate (water was refilled to maintain its level). We also used disposable cups to explore the possibility of their use in place of glass beakers for future tests and found that the alternative containers served just as well.

Full-scale case study demonstration and investigation of the floating Fe(III) film phenomenon (Expt.–2, Primary Demo/Case Study): We selected one representative soil (R4, Table 1) with a typical film generation outcome based on the results from Expt.–1 and used a plastic tray (a larger container with a greater surface area than the small beakers) and identical procedures as for Expt.–1 to deliver full-scale, detailed demonstration and documentation of the floating Fe(III) film phenomenon. All the required components were employed at the proportionally scaled-up levels (Table 2, Expt.–2). We also conducted a set of tests to reveal the floating Fe(III) film phenomenon.

Experimental tests to probe the process and mechanism of the floating Fe(III) film phenomenon (Expt.–3, Process/Mechanism Study): We investigated the role of glucose, CaCO3, O2, and water (quantity, depth) in floating Fe(III) film generation to elucidate the environmental chemical and biological processes behind the floating film phenomenon. The same experimental setup and procedures were adopted as in Expt.–1, except that in some tests, glucose or CaCO3 was omitted, the water amount (level) was altered, the beaker headspace was first purged with N2 to remove O2, or the beakers were covered to cut O2 supply from the air (Table 3). Again, the R4 soil that delivered the typical floating Fe(III) film phenomenon was selected as the representative soil for all the tests in Expt.–3, Process/Mechanism Study (Table 3). Each test was accompanied by a control test without any treatment.

Table 3.

Experimental setup and treatments for Expt.–3 conducted in small beakers.

Monitoring of Fe(II) in the solution during Fe(III) film formation: During the last set of the experiment for Expt.–2, Primary Demo/Case Study, the solution above the soil in the large tray was sampled periodically to analyze Fe(II) and monitor its level variation. For this work, ~2 mL of the solution beneath the Fe(III) film was taken using a plastic dropper each time and placed in a 1 cm cuvette and then 5 drops of 10 mM 2,2′-Dipyridyl solution was added to generate an Fe(II) complex for spectrophotometric analysis. It can occur that sampling Fe(II) in the solution may result in Fe(III) film breakage. However, we observed that new, fresh films emerged later, restoring film coverage on the water surface at the spot disturbed.

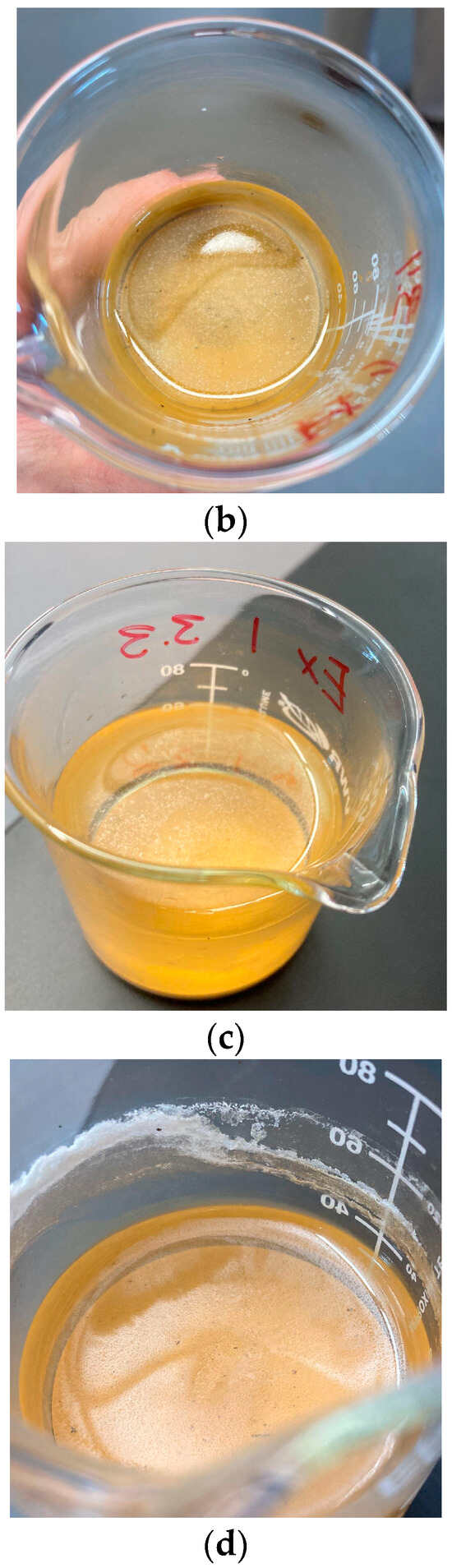

Experimental work to create Fe(III) films artificially and abiotically: To further test the mechanistic picture of the floating Fe(III) film phenomenon we proposed, efforts were made to artificially create floating Fe(III) films abiotically so as to simulate the natural floating film phenomenon in a laboratory setting. To this end, we used a ferrous salt (Fe(NH4)2(SO4)2·6H2O) to perform simulation experiments to induce abiotic generation of floating films using a setup that mimics the systems where biotically mediated formation of the films occurred in a laboratory setting (i.e., inundated fresh soil in a 100 mL glass beaker). The simulations were carried out by using a mixture of the Fe(II) salt and sand particles inundated with DI-H2O in a 100 mL glass beaker. Three sets of simulation tests (Simulations I, II, and III) were conducted.

For Simulation I (S1), a mixture of the Fe(II) salt and sand was added to deoxygenated H2O (by purging the water with N2 to remove O2) in a 100 mL beaker, and an additional portion of sand was poured to top the inundated mixture off. The beaker was sealed or kept open to air and then left at room temperature for observation of film generation (see Table 4 for S1 treatments). For Simulation II (S2) and Simulation III (S3) with control tests, similar procedures to those used for Simulation I were adopted, with some variations (see Table 5 and Table 6 for S2 and S3 treatments, respectively).

Table 4.

Experimental treatments for Simulation I (S1) for the abiotic generation of Fe(III) films.

Table 5.

Experimental treatments for Simulation II (S2) * for the abiotic generation of Fe(III) films.

Table 6.

Experimental treatments for Simulation III (S3) and the control tests (CT) * for the abiotic generation of Fe(III) films.

2.5. Experimental Measurements

pH measurement: pH was measured using a Mettler Toledo SevenEasy pH meter.

Spectrophotometric analysis of ferrous Fe (Fe(II)): Fe(II) generated in the tests was analyzed spectrophotometrically (Thermo Scientific Genesys 20 spectrophotometer, Thermo Electron Corporation, Madison, WI, USA) using 2,2′-Dipyridyl to form a pinkish-red Fe(II) coordination compound. Calibration was performed using a working Fe(II) standard series of 25, 50, 75, and 100 μM made by using a 100 μM Fe(II) standard stock solution (prepared by adding 0.05 mL (or one drop) of a standard stock solution of 50 mM FeCl3 in 0.8 M HCl to 25 mL DI-H2O (or distilled water) with 0.05 mL (or one drop) of 1.5 M NH2OH·HCl added to the water first).

The working Fe(II) standard solution series (25, 50, 75, and 100 μM) can be obtained by adding, to a 1 cm plastic cuvette, 0.5, 1.0, 1.5, and 2.0 of 100 μM Fe(II) stock solution plus 1.5, 1.0, 0.5, and 0.0 mL of H2O, respectively, to yield a total of 2.0 mL of one particular working Fe(II) standard solution in the cuvette. Then, 2 mL of water was added to a 1 cm cuvette to prepare the blank solution for the spectrophotometric analysis.

Then, to each of the working Fe(II) standard solutions and also the blank solution prepared in the cuvettes, or a sample solution placed in the cuvette, 5 drops (i.e., 0.25 mL) of the coloring agent solution (10 mM 2,2′-Dipyridyl solution prepared using Vermont Buffer (made of 71.6 mL 100% glacial acetic acid and 40.7 mL 29.5% ammonia, NH4OH)) was added. After 10 min, after complete formation of the pink-reddish Fe(II)-Dipyridyl complexes in the cuvettes, the absorbance was taken at 522 nm using the blank made [29]. Alternatively, 1,10-phenanthroline can be used to analyze Fe(II) spectrophotometrically after complete formation of orange-red Fe(II) complexes.

Measurement of floating Fe(III) film color: The colors of the floating Fe(III) films were measured using the Munsell Soil Color Book. A small piece of the Fe(III) film was collected using a flat-tip stick (or any appropriate tool) and the color of the fresh film sample was immediately compared with a matching color in the Munsell Soil Color Book to determine the color code for the film collected (the book provides instructions on its use as well as the color coding system). A delayed color measurement after the film is taken from the solution may give rise to a false color determination as a result of the drying of the film.

Collecting a film sample can disturb or break the films already formed and leave a small hole or an opening, where new films emerged. This observation led to the discovery of a way to obtain fresh, new films. Hence, clearing the water surface from film occupation can leave an opening for fresh, new films to form. By means of this technique, films in various formation and growth stages may be generated and harvested for further use as desired.

3. Results and Discussion

Our research encompasses three major sets of experimental work: (1) the creation and demonstration of floating Fe(III) films in a laboratory setting so as to fully establish this phenomenon and create a method for film generation in a laboratory setting, (2) a full-scale case study of the floating film phenomenon in a laboratory setting to characterize the entire span of film formation and transformation, and (3) an experimental investigation into the mechanistic processes of the phenomenon. The benefit of the first set of work is twofold: first, it accomplished the creation of a film generation method in a laboratory setting; second, it resulted in the emergence and selection of the tested soil, delivering a typical case of the floating film phenomenon for further use in the following two sets of the research.

The floating Fe(III) film phenomenon can be viewed from the perspective of two chronological stages: (1) formation of initial Fe(III) films and (2) transformation of the Fe(III) films. Accordingly, we first formulated a comprehensive mechanistic picture of the Fe(III) film formation followed by a presentation of our experimental work to probe its mechanism and process. Next, we created a polymeric model to depict and understand the transformation of the Fe(III) films followed by a discussing of the film formation and transformation in real environments.

3.1. Creation and Demonstration of the Floating Fe(III) film Phenomenon in a Laboratory Setting

Four (P1, R2, R3, and R4) out of the six tested soils (Table 1) delivered the floating Fe(III) film phenomenon (Figure 2) over a span of ~1–3 days or longer, depending on the soil sample used. This demonstrates our success in creating the natural floating Fe(III) film phenomenon in a laboratory setting. This further indicates that this film phenomenon can occur readily and widely. Our findings point to the notion that the floating Fe(III) film occurrence is indeed a natural phenomenon that involves certain chemical and biological processes orchestrated by a group of natural components in the environment. The results of Expt.–1, General Demo demonstrate that the natural floating Fe(III) film phenomenon observed in the field can be readily generated in a laboratory setting using fresh soils. It then follows that instead of observing it in the field, we can now study this phenomenon in a controllable laboratory setting, which paves the way for various further studies.

Figure 2.

Examples of the Fe(III) film occurrence on water surface of submerged soils in small glass beakers in a laboratory setting for (a) three tested soil samples, P1, R2, and R4 (Table 1), and (b) an amplified image of the R4 soil with reflective rainbow iridescence and fractal film morphology.

The lack of film occurrence for two of the soils tested (R1 and P2) (Table 1) suggests that there are certain conditions required for the films to materialize. Since all the soils tested received identical treatment, the absence of Fe(III) film in these two soils was likely due to an absence of the required microbial communities and/or their favorable niche. This absence could also stem from a lack of Fe(III) species in the soils tested. If this would be the case, artificially adding Fe(III) oxides/oxyhydroxides to the soil(s) may offer a remedy, especially in the case of northern region soils, which usually possess less Fe(III) oxides and oxyhydroxides than those of southern regions.

The thickness, size, morphology, color, and reflecting iridescence of these films and the speed of their development contribute to their most important physical features. If thin and uniform, they are referred to as films, and if dry and cracked, they are referred to as crusts. The film’s color is represented either by iridescence, which means the oil-like coloration in the initial and early stages of formation, or by the color that it produces in later stages. The color of the films and crusts offers a reflection of the chemical makeup of the Fe(III) species and the stage of development, as discussed in subsequent sections.

In the early stages of formation and growth, the films (Figure 2) were thin, colorless with reflective rainbow iridescence, and in separate small patches with various fractal morphologies (Figure 2). The individual patches eventually fused together to a single piece of apparently uniform thin film, as displayed in the subsequent section.

3.2. Full-Scale Case Study and Characterization of the Floating Fe(III) Film Phenomenon

After the proper soils were first identified for delivery of the films, an amplified demonstration was performed to showcase the phenomenon on a larger scale, followed by a detailed case study to further investigate the Fe(III) film phenomenon. This study was implemented by setting a large plastic tray with all the required components in place at proportionally scaled up levels (Table 2).

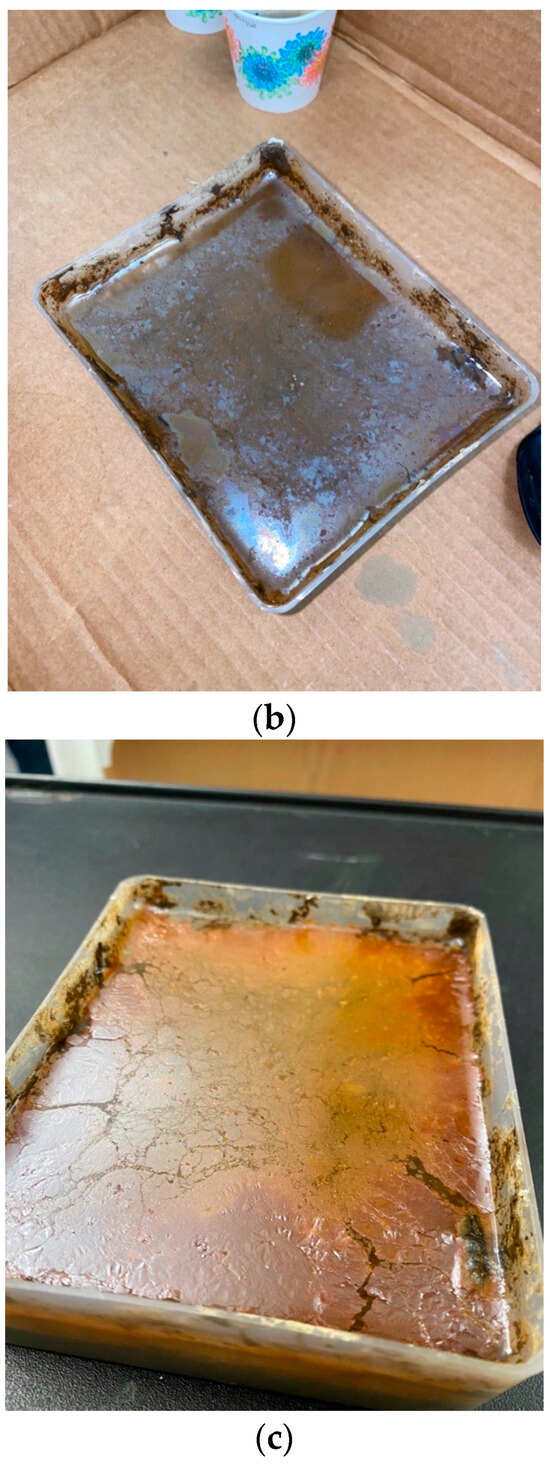

Clearly, the Fe(III) film generation in the large tray started with individual, separate small patches of floating, colorless (or somewhat blue reflection) thin films with reflective rainbow iridescence (Figure 3a) and continued to grow and change gradually to thicker films (Figure 3b) and orange/red crusts (Figure 3c) thicker than the initial thin films over a span of ~2 weeks (Table 7, First Test of Case Study).

Figure 3.

Primary demonstration of the floating Fe(III) films (Expt.–2, Primary Demo/Case Study) at water surface of the inundated soil (R4) in a large tray (Table 2) for the First Test of Case Study (February–April 2022) as (a) initial thin films in the early stage of the film formation, (b) separate, small patches of films with pronounced rainbow reflection iridescence in the intermediate stage, and (c) orange/red colored crusts in the later stage of film development.

Table 7.

The results of Expt.–2, Primary Demo/Case Study (First Test of Case Study, 2022) with a detailed documentation of Fe(III) film generation and growth in a large tray.

Shortly after water was added to the setup, a large amount of bubbles appeared in the tray, accompanied by a strong odor typical of anaerobic activities, which indicated strong microbial activities in the tray. The bubbles carried some Fe(II) and some bubbles soon turned orange, as can be seen on the left side/edge of the solution in the tray (Figure 3a), thus indicating oxidation of the Fe(II) present in the bubbles.

The occurrence of typical floating Fe(III) films in the large tray on an amplified scale (Figure 3, Table 7) not only offers a solid confirmation of the observations and results gained in Expt.–1, General Demo, but also points to a convenient, accessible way in which the floating Fe(III) films can be generated and readily collected at will in larger quantities across various stages of film formation with respect to various physical features (e.g., size, thickness, color, etc.). It follows that this film generation setup and its modification and adaptation can provide a satisfactory, useful means to manufacture the floating Fe(III) films in a laboratory setting.

It was curious how robust and reproducible this large tray setup could be for film manufacture. To explore the capability and potential of our film generation setup, we left the films together with the soil to dry up after the First Test of Case Study was conducted in February–March of 2022 (Figure 3, Table 7) with the tray unattended ever since, and then in early April of 2023 (one year later), we initiated a renewed, identical film test in the same tray from the first test (Figure 3, First Test of Case Study) by freshly adding 1.3 g of glucose (same amount as in the first test shown in Table 2) and required amount of water (Table 2) to the same water level. Amazingly, an identical recurrence of floating Fe(III) films materialized, as shown in Figure 4 and Table 8 (Second Test of Case Study) in the same manner as in the first test in February–March of 2022 (Figure 3 for First Test of Case Study).

Figure 4.

Primary demonstration of the floating Fe(III) films (Expt.–2, Primary Demo/Case Study) at water surface of the inundated soil (R4) in a large tray (Table 2) for the Second Test of Case Study (April–May 2023) (a) on 19 April 2023, ~two weeks after the second test was started for the film formation, and (b) on 27 April 2023, ~three weeks after the second test was started.

Table 8.

The results of Expt.–2, Primary Demo/Case Study (Second Test of Case Study, 2023) with a detailed documentation of the reoccurring floating Fe(III) film generation and growth in the large tray.

The First and Second Tests of Case Study with intermittent drying up of the films and soil delivered the same recurring floating Fe(III) film phenomenon in the same tray and setting. It appears that drying failed to eliminate or compromise the microbes in the soil and they survived the drying; once moisture was restored, the functions and activities of the soil microbes were switched on, which delivered the Fe(III) film phenomenon again.

Out of curiosity, after the First (February–March 2022) and Second (April–May 2023) Tests of Case Study, we again tested the same R4 soil in the original tray with the same setup following the same procedures three more times in 2023. Remarkably, the floating films reoccurred three times in a roll during August–November of 2023, each time in the same expected manner as described previously and shown in Figure 3 and Figure 4 and Table 7 and Table 8.

During drying, the Fe(III) films dropped to the dried soil surface. After a restoring of moisture (water added) and under the required conditions, the Fe(III) species in the films resting on the soil surface returned to the water surface (see Figure 4), closing a coupled cycling of Fe(III)/Fe(II) redox transformation with the Fe(III)/Fe(II) transport in the system in the tray (to be elaborated later in technical details). This reoccurring coupled cycling of the Fe(III)/Fe(II) redox and Fe(III)/Fe(II) transport mediated by the soil microbes provides a fine device for renewable manufacturing of the Fe(III) films, available for film harvest in various stages of formation and growth as desired.

During the Second Test of Case Study for the Fe(III) film phenomenon in April–May of 2023, several measurements were conducted to investigate the film phenomenon using the tray setting, which successfully provided a platform for this study. We measured the pH of the solution and the colors of the films in various stages of their development. Moreover, we monitored the Fe(II) level in the solution during film development.

Our measurement showed that the pH of the tested solution beneath the films was ~6–7 (Table 8) right in the circumneutral range, which is a favorable pH condition for soil microbes and Fe(II) oxidation. The pH measurement was discontinued because when the pH probe was inserted into the solution in the tray with the Fe(III) films covering or almost sealing the water surface in some cases, some Fe(III) film patches were stuck to the glass membrane of the pH probe bulb. The Fe(III) film patches can become strongly attached to the glass membrane and thus could potentially cause malfunction of the pH electrode. Hence, care needs to be taken when a pH measurement is made under such circumstances. The pH may also be measured by using a piece of pH paper.

The colors of the films in various stages of development are given in Table 8. The film color changed from initially being colorless (or blue with reflective rainbow iridescence) to orange to orange-red to red. These results suggest that the chemical makeup of the Fe(III) films was evolving with continuous speciation change. Our Fe(II) monitoring test showed that Fe(II) was present at quite high levels with some mild variation, which was sustained during the entire test. The results of the Fe(II) test will be presented in detail in a subsequent section.

The experimental work of Expt.–1 and Expt.–2, conducted in a laboratory setting, demonstrates that the floating Fe(III) film phenomenon is indeed a reproducible, well-established natural phenomenon. This work also successfully provides a characterization of the Fe(III) film phenomenon over the entire span of its formation and transformation from initially thin films to subsequently thicker films and crusts. These research outcomes would be challenging to achieve by in situ observation.

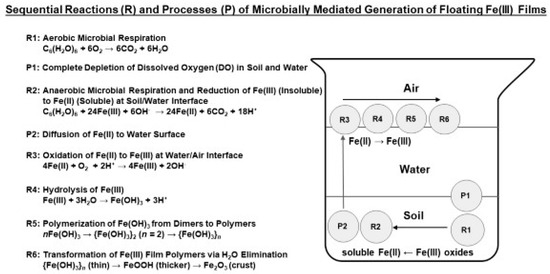

3.3. Floating Fe(III) Film Formation: A Mechanistic Picture

The occurrence of floating Fe(III) films in a laboratory setting as well as that observed in the field stands as a well-established natural phenomenon. This certainly invites an inclination to find out the mechanism behind this natural wonder. This environmental chemical drama, generally, has been considered to involve coupled Fe(III)/Fe(II) redox cycling and Fe(II) transport mediated by soil microbes. However, a full, comprehensive mechanistic picture of this phenomenon with necessary technical details still remains unavailable. We here provide a formulation of such a picture for Fe(III) film formation, as schematically depicted in Figure 5 and presented with elaborations below, integrated with the results of our own experimental work.

Figure 5.

A schematic presentation of the hypothesized mechanistic picture proposed to depict the microbially mediated generation of floating Fe(III) films in a laboratory setting and on the water surface of natural aquatic systems. The entire film generation phenomenon contains a sequence of six biotic and abiotic (chemical) reactions (R1–R6) coupled with two physical processes (P1–P2).

The entire chain of events for floating Fe(III) film formation contains a sequence of six biotic and abiotic (chemical) reactions (R1–R6) coupled with two physical processes (P1–P2) in the soil–water system, as shown in Figure 5. This view is consistent with the general conceptual model constructed for the redox transformation of the Fe(III)/Fe(II) couple at oxic/anoxic boundaries [26,34,37].

Chronologically, in a moist environment such as the inundated soils in our laboratory setting (Figure 2, Figure 3 and Figure 4), the glucose added (sugar or monosaccharide as fast food or a quick energy source) jump-starts the flourishing of the aerobic soil microbes present in the fresh soil samples. Microbial activities and growth at high speed sustained by an unusually high supply of energy (sugar) eventually deplete the dissolved oxygen (DO) in the water within and above the soil (P1: complete depletion of DO in soil and water) [43] as a result of aerobic microbial respiration (R1) with the DO as the electron acceptor:

- R1: Aerobic microbial respiration

C6(H2O)6 + 6O2 → 6CO2 + 6H2O

- P1: DO depletion in soil and water

The aerobic condition: In the presence of dissolved oxygen, O2 (aq) (i.e., the aerobic condition), the level of Fe(II) is negligible under the equilibrium condition involving the Fe(III)/Fe(II) redox couple. Considering a form of Fe(III) commonly present in natural aqueous environments, i.e., FeO(OH) (ferric oxyhydroxide), the level of Fe(II) is governed by the two equilibria shown below [17]:

FeO(OH)(s) + 3H3O+ ↔ Fe(III)(aq) + 5H2O K = 104

Fe(III) + e− ↔ Fe(II)(aq) K = 1013

The combination of R(3) and R(4) gives rise to the redox reaction for the Fe(III)/Fe(II) redox couple:

where the symbol aq denotes the aquo complex of the metal cation in an aqueous medium and s stands for the solid phase (by convention, the solid state (i.e., FeOOH(s)) and pure water do not appear in an equilibrium equation (Equation (6)), since these concentration items, being constants based on their densities, are included in the K value for the equation). The above equation (Equation(6)) for the overall Fe(III)/Fe(II) redox couple (half redox reaction) can be transformed into log form:

where pH = −log[H3O+], pe = −log[e−], and e− is for electron. At the pe level for air-saturated water (fully aerobic condition, pe = 12.5) and the circumneutral pH (~pH 7), we have log[Fe(II)(aq)] = −16.5 (log[Fe(II)(aq)] = 17 − 3 × 7 − 12.5), i.e., [Fe(II)(aq)] = 10−16.5 M [17]. It is clear that under aerobic conditions, Fe(III) is predominant and the Fe speciation and the levels of Fe(III) and Fe(II) are controlled by the level of DO.

FeO(OH)(s) + 3H3O+ + e− ↔ Fe(II)(aq) + 5H2O K = 1017

log[Fe(II)(aq)] = logK − 3pH − pe

The anaerobic condition: Presumably, with aerobic decomposition of organic matter in operation, only ~3.1 mg/L of dissolved organic carbon (DOC) is needed to consume 8.25 mg/L of dissolved O2 (note: under saturation of DO in water with atmospheric oxygen at a total atmospheric pressure of 1 atm and 25 °C, saturated DO level in water = 8.25 mg/L or 2.58 × 10−4 M mol O2/L water, or 258 μM, at the atmospheric O2 level = 286 mg O2/L air for 21% of O2 in the air). It was found that groundwater in a temperate climate region containing > ~4 mg/L of DOC (or total organic carbon (TOC), biochemical oxygen demand (BOD), chemical oxygen demand (COD)) will usually turn anaerobic. This finding (as a rule of thumb) generally applies to water in various places, such as stream-bottom muds, lake and reservoir bottoms, organic-rich waste ponds, water-logged soils, and deeper groundwater systems [43,44].

In our case, for example, ~0.1 g glucose was added to ~40 mL water, which amounts to a level of 1000 mg C/L in the system (i.e., 40 mg C in 40 mL water; molecular mass for glucose: MM = 180.156 g/mole; 6 C/glucose). This high level of glucose (or DOC) thus surely is destined to secure an anaerobic condition in the system at equilibrium.

According to Berner’s practical redox classification based on water DO level [45], a DO level above 30 μM dictates an oxic environment with various Fe(III) species present predominantly and the DO level below 1 μM DO for an anoxic environment (DO ≥ 1 μM: suboxic; DO < 1 μM: postoxic with Fe(II) present) [43].

At the beginning, the water above the soil sample contains some dissolved oxygen, which provides and sustains an aerobic condition under which the aerobic microbes are active. With glucose present, the aerobic microbial respiration becomes intensified to keep driving the consumption of DO. Eventually, the DO in the system is depleted, which then triggers the next steps in the chain of events:

- R2: Anaerobic microbial respiration

Anaerobic reduction of Fe(III) oxides (in inundated soil or sediment)

C6(H2O)6 + 24Fe(III) + 6OH− → 24Fe(II) + 6CO2 + 18H+

- P2: Fe(II) diffusion from soil to water surface

The depletion of DO shuts down the aerobic microbial activities and growth, which awakens the anaerobic microbes and their activities in the soil, as now, the conditions are anaerobically favorable [35,46]. Their respiration (R2) is running at full swing, and sooner or later comes to the stage of enlisting of ferric iron, Fe(III), present in the Fe oxides and oxyhydroxides of the soil, as the electron acceptor along the redox ladder coupled with anaerobic respiration in soil and water [19,26,33,43,47,48].

Ferrous iron, Fe(II), is then generated during anaerobic microbial respiration at the soil/water interface. Soluble and thus mobile, the Fe(II) then diffuses and migrates to the water surface, the water/air interface (P2: migration of Fe(II) from soil to water surface) as the building-up of Fe(II) around the soil Fe(III) oxides and oxyhydroxides (as coating on soil clay particles, or as whole particles) is establishing an upward Fe(II) gradient.

The timespan for the chain of events of R1, P1, R2, and P2 kinetically amounts to the overall duration before the Fe(III) films start emerging at the water surface. This timespan sets the major kinetic limiting factor for floating Fe(III) film formation and can reach 1–2 days, depending on the specific microbial communities present and various conditions in the submerged soil system.

Hence, anerobic microbial reduction of Fe(III) to Fe(II) is a key step in the overall process (chain of events) of Fe(III) film formation. Microbial enzymatic metal reduction, including reduction of Fe(III) in Fe(III) oxyhydroxides and oxides in soils and waters, is widely recognized [10,35,36,47,48,49,50,51,52,53,54] and may account for much of various metal reductions that occur in soils and sediments [35,51,52].

Reduction of the Fe(III) of soil iron oxides/oxyhydroxides to Fe(II) by soil anaerobic microbes: The dissimilatory Fe(III) reduction microorganisms commonly metabolize the organic carbons generated from fermentable sugars (e.g., glucose in our study), but they mainly use Fe(III) as the terminal electron acceptor in anaerobic respiration (dissimilatory microbial Fe(III) reduction), rather than as an energy source, or for the benefit of usage (uptake) of iron as a nutrient (assimilatory microbial Fe(III) reduction) since they usually can survive and grow in the absence of Fe(III) [51]. Soils with sufficient organic matter exhibit Fe(III) reduction more commonly, and low pH seems to favor the reduction [35,36].

Dissimilatory Fe(III) reduction is not particular to a single genus. Microbial Fe(III) reducers encompass a variety of microbes, including a large heterogeneous group of the heterotrophic bacteria. Among known Fe(III) reducers are Alcaligenes, Bacillus, Clostridium, Desulfovibrio, Desulfuromonas acetoxidans, Geobacter metallireducens (or GS-15), Klebsiella, Proteus, Pseudomonas, Serratia, and Shewanella putrefaciens [10,35,49], and other microbes of bacterial and fungal genera [47]. In a study in which the Fe(III) films were generated by progressive enrichment and incubation of the field sediment samples, the heterotrophic bacteria of the genus Enterobacter were found to be the dominant bacteria responsible for the generation of floating films, and the bacteria represented only a minor part of those microbial communities in the field [40]. A variety of sulfate-reducing microbes, such as Desulfovibrio, are capable of reducing Fe(III) as well [10].

Shawanella putrefaciens and Geobacter metallireducan (GS-15) are widely present in the environment, but S. putrefaciens is more commonly found in sedimentary environments, while GS-15 is mostly predominant in soils [10,55]. Both S. putrefaciens and GS-15, like sulfur-reducing bacteria, utilize the metabolic products of other microorganisms, e.g., amino acids, formate, acetate, butyrate, propionate, and some long-chain fatty acids, to oxidize food to CO2 to harvest energy, meanwhile using Fe(III) as the electron acceptor by reducing Fe(III) to Fe(II) [10,46]. Some microbes (e.g., Micrococcus lactilyticus) can even use molecular hydrogen (H2) to reduce ferric hydroxide and ferricyanide [36,56].

Metabolic studies of glucose in sediments with Fe(III) as the electron acceptor for respiration showed that glucose was fermented first to organic acids (primarily acetate), then followed by oxidation of these acids to CO2. Fermentative microbes first metabolize available sugars (and amino acids) to short-chain fatty acids and H2 and the products of the fermentation are then consumed by the Fe(III)-reducing microbes accompanied by Fe(III) reduction via anaerobic respiration [46,51]. Generally, anaerobic activities (called anaerobiosis) of fermentative microbes can result in accumulation of organic acids, with acetic, formic, and butyric acids as the dominant acids (lactic and succinic acids as the minor ones) [35,48].

Our study showed that shortly after the tested system with added glucose was set to run, many bubbles, together with a fermentation odor, occurred, as described before. These observations echo the microbial and metabolic processes described above. The gases in the bubbles are considered to be CO2 from the fermentation. Hence, fermentation serves as a signal for the subsequent formation of Fe(II) via microbial Fe(III) reduction.

Anaerobic reduction of Fe(III) by metal-reducing bacteria using endogenous Fe(III) oxides as the primary electron acceptor source occurs widely in the environment ([51,57,58]. Bacteria (e.g., Bacillus) and fungi (e.g., Alternaria and Fusarium) were found to be able to reduce Fe(III) enzymatically [58] (for more examples, see [51]). In a kinetic study in which Fe(III) reduction was followed using synthetic crystalline Fe(III) oxide (goethite) and two southern Fe(III) oxide-rich subsoils from Tennessee and North Carolina (USA) in the cultures of the Fe(III)-reducing bacterium Shewanella alga strain BrY, significant Fe(III) reduction to Fe(II) was found, and removal of Fe(II) through aqueous phase transport was shown to prominently control the rate and extent of Fe(III) reduction [57]. As a result of the assistance of the advective removal of Fe(II), crystalline Fe(III) oxides were found to be consumed nearly completely within a shallow subsurface landfill leachate plume in Denmark [57,59]. In our study, the upward migration of the generated Fe(II) towards the water surface should also serve as an effective aqueous transport venue to enhance the biotic reduction of solid-phase Fe(III) species.

It is clear that a group of players are at the center of this activity, including (1) water (as O2 barrier), (2) Fe(III) oxides/oxyhydroxides (Fe(III) source), (3) Fe(III) reducers and other microbes to generate acetate as food for the Fe(III) reducers, and (4) sugar (food for fermentation microbes). They work collectively in a chain of biotic and chemical events to stage the biotic Fe(III) reduction. The role of sugar is critical. It is the acetate generated by fermentative microbes using sugar, which triggers the activity and flourishing of the Fe(III) reducers. Our study showed that in the absence of sugar, absence of Fe(III) film or little film was observed, and no bubbles or odor occurred.

Electron transfer during anaerobic microbial reduction of Fe(III) to Fe(II): Electron transfer occurs during anaerobic respiration, involving microbial reduction of Fe(III) to Fe(II), as depicted by a biotic mechanistic model for the processes and pathways operative in Fe(III) reduction [51,52]. Three mechanisms were revealed to account for the electron transfer between microbial cells and Fe(III)-containing solid particles: (1) direct physical contact between the cells and the Fe(III) particles (or particle surfaces, or both) in addition to cellular Fe(III) reductase(s), (2) extracellular (external) electron shuttles either generated microbially or available environmentally to transfer the electron(s) from electron donor (organics in cells) to Fe(III) in the solid particles, and (3) dissolution of Fe(III) solids by complexing Fe(III) with microbially generated ligands. Different species of microbial Fe(III) reducers may use different mechanisms [48,51,52,60].

Regarding direct physical contact between microbial cells and Fe(III) particles, the actual transfer of electrons from cells involves an electron transfer chain that may enlist one (or more) electron carrier(s) (e.g., some metal ion(s)) [51]. Actually, the microbes can also be adsorbed on the Fe(III) particle surfaces, in addition to the case where the microbes are simply physically mixed with Fe(III) particles. The adsorption of the microbes can provide close, or closer, contact between the microbial cells and Fe(III) solid particles and thus enhance the electron transfer.

Insoluble Fe(III) species can pose a challenge to Fe(III) reducers during the transfer of reducing equivalents from microbial cells to Fe(III) solids in anaerobic respiration by means of Fe(III) solids serving as the ultimate electron acceptors [50,60]. The Shewanella species was found to evolve to tackle this challenge by enlisting quinones or flavins as electron shuttles between cells and substrates. However, some distance is still inevitable between the cells and Fe(III) particles. For the Geobacter species, direct physical contact that allows for the passing of electrons from a bacterial biofilm directly to the Fe(III) is necessary between the cells and substratum. This biofilm–mineral contact could also be facilitated by pili or microbial nanowires, which can provide metallic-like conductivity and mediate electron transfer [48,50,52,61].

Two types of electron shuttles have been recognized as being capable of facilitating microbial Fe(III) reduction: (1) exogenous electron shuttles and (2) endogenous electron shuttles. Exogenous shuttles are already present in the environment outside cells. One of these extracellular shuttles are humic substances with a variety of aromatic structures and other quinone-like organic compounds in the reduced form of hydro-quinones. It is known that the endogenous shuttles are produced by microbes and then released to the surrounding environment to serve as electron transfer facilitators. For example, Geothrix fermentans can supply a quinone-like electron shuttle for their growth on lactate (electron donor or food for the microbes) mixed with Fe(III) particles (electron acceptor) [53,62].

Additional features of microbial reduction of Fe(III) species to Fe(II): The degree of crystalline structure formation plays a special role in microbial Fe(III) reduction. The Fe(III)-reducing microbes appear to favor less crystalline Fe(III) oxides, and it seems that less crystalline structures are more amendable or vulnerable to enzymatic attack during microbial Fe(III) reduction [51]. Some Fe(III) species can be reduced enzymatically in cell-free systems or even reduced by metabolic end-products abiotically [47]. In addition to enzymatic reduction of Fe(III) in soils and sediments, non-enzymatic Fe(III) reduction may also contribute to the overall anaerobic microbial Fe(III) reduction. Yet, the enzymatic reduction is more predominant than the non-enzymatic reduction and it can oxidize the organic compounds completely to CO2 [51].

It needs to be pointed out that the chemical reaction equation for the Fe(III)/glucose couple (R(8)) does not suggest a reaction actually occurring between Fe(III) and glucose. It instead offers a stoichiometric estimation of the electrons transferred from glucose to Fe(III) during anaerobic respiration by assuming all glucose added and all electrons from the oxidation of the added glucose are consumed solely by Fe(III) in the oxidation. In our study, some of the added glucose was first consumed by aerobic microbes to deplete DO to create an anaerobic condition for the subsequent fermentation to occur.

After being microbially generated, at the end of the upward transport, Fe(II) finds itself at the water/air interface (a redox interface, or redox front, across which a rather abrupt or steep change in redox potential Eh occurs [43]), now in a favorable niche for its oxidation back to Fe(III), i.e., a wealth of DO and a circumneutral pH condition (~pH 7, mediated by CaCO3 added). There, Fe(II) is readily oxidized back to Fe(III) rather quickly (R3) [63]:

- R3: Fe(II) oxidation

Fe(III) + e− → Fe(II) E0 = 0.771 V

Under acidic conditions:

or

4Fe(II) + O2 + 2H+ → 4Fe(III) + 2OH−

4Fe(II) + O2 + 4H+ → 4Fe(III) + 2H2O E0 = 0.46 V

Under basic conditions, for example, the oxidation is still readily favorable:

Fe2O3·3H2O + 2e− → 2Fe(OH)2(s) + 2OH− E0 = −0.56 V

The hexaaquo ferrous ion Fe(II)(H2O)62+ bears a high spin and a transition around 1000 nm, with an absorption band tail extended to the visible region towards the red end, which is responsible for the pale blue-green color of the Fe(II) solution. Aqueous Fe(II) hydrolyzes only slightly [64].

Kinetics of Fe(II) oxidation: The rate of Fe(II) oxidation depends on the level of DO (i.e., O2(aq.)) and pH, as well as the concentration of Fe(II) in the system. The oxidation of Fe(II) was shown to exhibit the first-order kinetics with respect to both the Fe(II) and O2 concentrations, and second-order with respect to [OH]. This points to a 100-fold rise in the Fe(II) oxidation rate upon a rise in pH by one unit. The detailed kinetics of Fe(II) oxidation has been revealed [26]. The oxidation is strongly pH-dependent kinetically; it is slow at pH < 6. The oxidation of Fe(II) was found to follow the kinetics shown below [65,66,67]:

where k = 8.2 ± 2.5 × 1013 min−1 atm−1 mol−2 L2 at 20 °C. An alternative form of the kinetic rate equation can be obtained below:

where kH = 3 × 10−12 min−1 mol L−1 at 20 °C.

−d[Fe(II)]/dt = k[Fe(II)][OH−]2pO2

−d[Fe(II)]/dt = kH([O2(aq)]/[H+]2)[Fe(II)]

An elaboration of the Fe(II) oxidation and its kinetic picture is given as follows: in the presence of DO and at circumneutral pH, oxidation can proceed at a fairly fast rate. For a general redox half reaction, red1 + ox2 → red2 + ox1, its rate law equation takes the general form of rate = k[red1][ox2]. For a simplified general conceptual redox half reaction for Fe(II) oxidation, Fe(II) + O2 → Fe(III), likewise, the oxidation thus can be expressed as rate = k[Fe(II)][O2]. Hence,

rate = −d[Fe(II)]/dt = k′[Fe(II)][O2]

At a fixed level of oxygen, which can occur in natural environments, [O2] can be treated as a constant; thus, combining k′ and [O2] yields pseudo first-order kinetics:

where kobs = k′[O2]. Wehrli et al. [68] showed that the Fe(II) oxidation kinetics also depends on solution pH, as they found a logarithmic relationship between kobs and [H+] (i.e., logkobs vs. pH being linear). This pH dependence is a manifestation of the effect of pH-dependent aqueous Fe(II) speciation, since Fe(II) exists in several hydrolyzed forms in water (total [Fe(II)] = [Fe2+] + [FeOH+] + [Fe(OH)2]):

rate = kobs[Fe(II)]

rate = kobs[Fe(II)] = k0[Fe2+] + k1[FeOH+] + k2[Fe(OH)2]

A kinetic equation for Fe(II) oxidation with oxygen incorporated (in addition to the effect of pH) can thus be given:

where kobs = k′[O2], k0 = k0′[O2], k1 = k1′[O2], and k2 = k2′[Fe(OH)2][O2] [33].

rate = −d[Fe(II)]/dt = k′[Fe(II)][O2] = kobs[Fe(II)]

=k0′[Fe2+][O2] + k1′[FeOH+][O2] + k2′[Fe(OH)2][O2]

=k0′[Fe2+][O2] + k1′[FeOH+][O2] + k2′[Fe(OH)2][O2]

The pH dependence of Fe(II) oxidation can be explained by the following theory: first, hydrolyzed Fe(II) species are more favored, with faster Fe(II) oxidation rates than nonhydrolyzed ones; second, the OH− ligands associated with Fe(II) in the hydrolyzed Fe(II) species can donate electron density to Fe(II), which makes Fe(II) more reducing.

Mechanism of Fe(II) oxidation: Mechanistically, oxidation of Fe(II) to Fe(III) involves an outer-sphere electron transfer through both σ and π systems of O2 and Fe(II) species. The OH− ligands associated with the hydrolyzed Fe(II) can stabilize the oxidized Fe, i.e., the Fe(III) species [26,28,69], as detailed in a mechanistic scheme for Fe(II) oxidation by Schneider and Schwyn [11]. Fe(II) oxidation involves several active oxygenated species, including the following: superoxide (·O2−), hydroxide free radical (·OH), and hydrogen peroxide (H2O2), catalytically as well as non-catalytically. H2O2 is relatively stable and thus a detectable product during Fe(II) oxidation [70,71].

The Haber–Weiss mechanism has been adopted to formulate the mechanism for aqueous Fe(II) oxidation by oxygen, which is the most accepted mechanistic model for Fe(II) oxidation [67,72]:

Fe(II) + O2 → Fe(III) + ·O2−

Fe(II) + ·O2− + 2H+ → Fe(III) + H2O2

Fe(II) + H2O2 → Fe(III) + ·OH + OH−

Fe(II) + ·OH → Fe(III) + OH−

The Fenton reaction is shown below (i.e., R(23) and R(24); the Fenton reagent Fe(II) + H2O2) [73] also plays a notable role in Fe(II) oxidation [26]:

or

Fe(II) + H2O2 + H+ → Fe(III) + ·OH + H2O

Fe(II) + H2O2 → Fe(III) + ·OH + OH−

Both H2O2 and ·O2− can be considerably active during Fe(II) oxidation, since they can be generated at significant levels, especially at oxic–anoxic interfaces (air/water interfaces) where O2 is readily available [70].

Immediately after the oxidation of Fe(II) to Fe(III), under the favorable condition of circumneutral pH, Fe(III) can readily hydrolyze to form Fe(III) hydroxides (R4):

- R4: Fe(III) hydrolysis

Fe(III) + 3H2O → Fe(OH)3 + 3H+

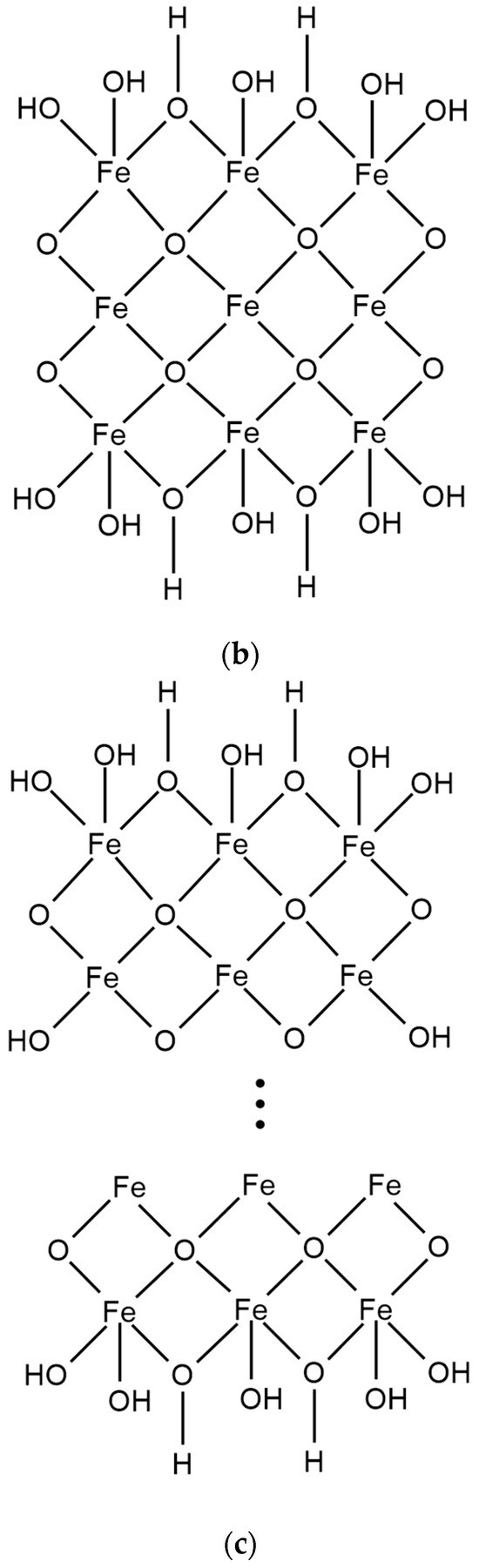

Hydration of Fe3+ cation: In an aqueous solution, like any cation to be stabilized in the highly polar medium of water, cation Fe3+ (generally represented by Fe(III) without its actual form(s) present in water being specified) actually stays as a hydrated cation, also called aquated cation [74], bound to six water molecules (i.e., [Fe(H2O)6]3+) [17,75]. Hence, [Fe(H2O)6]3+ is an octahedral coordination compound with water as the ligand bound to the central metal cation Fe3+ (Figure 6).

Figure 6.

A schematic presentation (a) of the hydrolysis of Fe(III) cation (Note: The Fe(III) cation here is a general term adopted to refer to various representations for Fe(III) cation in an aqueous solution, e.g., hydrated Fe(III) cation, aquated Fe(III), Fe3+(aq), aquo Fe(III), or hexaquo Fe(III), with all the various denotations representing [Fe(H2O)6]3+ as an octahedral coordination compound with H2O molecules as the ligands bound to the central metal cation Fe3+ as shown by (b), specifically for the bonding between O and Fe in the octahedral geometry of the Fe(III)O6 unit in various Fe(III) polymers subsequently formed following Fe(III) hydrolysis. Only the first step of the hydrolysis of Fe(III) is shown here) and (c) of the polymerization of the Fe(III) hydrolysis products ([Fe(H2O)5(OH)]2+) to form an Fe(III) dimer ([(H2O)4Fe(OH)2Fe(H2O)4]4+) by the condensation polymerization via elimination of water molecules.

Hydrolysis of Fe(III) species: Aqueous multivalent metal ions are known to undergo a sequence of consecutive proton (H+) transfers and thus become Brønsted acids [26]. The aquo Fe(III) compound (hydrated Fe(III)) bears a shift in electron density to Fe3+ from the OH bonds of the coordinated water ligands. This shift leads the protons of the OH groups of the water molecules to become acidic and consequently results in their dissociation (i.e., hydrolysis) [17,75] (see Figure 6 for R(26)):

The above sequence depicts the hydrolysis reactions of Fe3+(aq) cation in aqueous media (aquo Fe(III)) readily occurring at pH > ~1 [8,63,64,75,76]). A charge increase and a size decrease in cations can enhance their polarizing power and tendency to hydrolyze [77].

[Fe(H2O)6]3+ + H2O ↔ [Fe(H2O)5(OH)]2+ + H3O+ Ka = 8.9 × 10−4

[Fe(H2O)5(OH)]2+ + H2O ↔ [Fe(H2O)4(OH)2]+ + H3O+ Ka = 5.5 × 10−4

[Fe(H2O)4(OH)2]+ + H2O ↔ [Fe(H2O)3(OH)3] + H3O+

At a higher solution pH, the Fe(III) species then hydrolyze (also called protolyze) further from R(26) up to R(28), faster and to a larger extent. Only at pH = ~0 (or pH < 1), ~99% of Fe(III)(aq) may be expected to stay as [Fe(H2O)6]3+, a pale purple hexaquo cation [63,74]. The Fe(III) hydrolysis products can exist first in various mononuclear complexes with a general formula of Fe(OH)x(H2O)yn+ (x = 1, 2, 3, and 4; n = −1, 0, 1, 2), for example, Fe(OH)(H2O)52+, Fe(OH)2(H2O)4+, Fe(OH)3(H2O)y, and Fe(OH)4(H2O)x− [11]. The first Fe(III) hydrolysis product from the purple hexaaquo [Fe(H2O)6]3+ cation (a complex) is the yellow [Fe(H2O)5(OH)]2+. This features charge-transfer UV absorption bands with an extended absorption tail in the visible region that gives it its yellow color [64].

The chemical formula (composition/stoichiometry) and actual structures of the Fe(III) species in liquid water solution also depend on the ionic strength and companion anions (or ligands and complexes of Fe(III) formed with the ligands) of the tested Fe(III) solution as well as the concentration of the Fe(III) in the solution [74,78,79]. The reactions of the hydrolysis and eventual precipitation of aqueous Fe(III) include formation, aging, and then agglomeration of a red cationic hydrolytic polymer [76].

The chemical term ferric hydroxide(s) (Fe(OH)3) by no means depicts chemically well-defined Fe(III) compounds. Instead, it represents a virtually unrestricted variety of Fe(III) species that differ in broad aspects, such as composition, structure, particle shape, size, distribution, interfacial characteristics, and thus chemical reactivity [11].

Various stages of Fe(III) hydrolysis: Hydrolysis of aqueous inorganic Fe(III) spans three sequential stages: (1) formation of low molecular mass hydrolysis species (e.g., Fe(OH)2+, Fe(OH)2+, Fe(OH)3, Fe2(OH)24+ dimmer), (2) formation of a red cationic polymer (general structural scheme: coordination number six for Fe(III) in an octahedral complex of Fe(O, OH, H2O)6 or Fe(III)L6, L = O, OH, or/and H2O; Fe(III)–O distance for crystals: 0.2 nm), and (3) aging of the Fe(III) polymers, followed by ultimate transformation to various Fe(III) oxides, and in various cases, to precipitation of the Fe(III) oxide phases directly from the low molecular mass precursors. It needs to be noted that most studies on Fe(III) hydrolysis have been conducted by adding bases to Fe(III) salts (e.g., nitrate, perchlorate, chloride, sulfate, etc.) [76].

Various kinds of Fe(III) hydrolysis: The companion anions (ligands) from the Fe(III) salts used in the Fe(III) hydrolysis studies that are inevitably present in the hydrolysis solutions are influential to the Fe(III) hydrolysis processes, formation of various particular hydrolysis products, and then subsequent polymerization of these products [76].

There are two kinds of Fe(III) hydrolysis: (1) hydrolysis occurring in inorganic Fe(III) salts exposed to a (strong) base (e.g., NaOH) added at (quite) high concentrations and (2) hydrolysis occurring in Fe(III) generated at around circumneutral pH from oxidation of Fe(II) microbially produced anaerobically. Hence, the Fe(III) hydrolysis processes and products, following polymerization of Fe(III) hydrolysis products, and the subsequent formation, growth, and aging of floating Fe(III) films may not resemble each other for these two kinds of Fe(III) hydrolysis. Fe(III) hydrolysis originating from oxidation of Fe(II) may differ kinetically and mechanistically from that via a direct interaction of an Fe(III) salt with a (strong) base in the presence of inorganic anions (e.g., chloride, perchlorate, bicarbonate, sulfate, nitrate), or organic ligands (e.g., acetate, lactate, oxalate), especially at high concentrations of Fe(III) salts and/or the companion anions or ligands [11,79].

In our study, two special conditions are notable: (1) the setting is natural, with fresh soil in water; (2) Fe(III) is generated via natural microbial Fe(III) reduction and subsequent re-oxidation of the Fe(II) thus slowly generated and supplied in the setting with natural companion components at natural levels (both Fe(II) and Fe(III) occurring at slow rates). The natural setting and conditions may collectively contribute to the occurrence of floating Fe(III) films, as observed in nature and in our laboratory.

In an aqueous solution at around circumneutral pH, individual Fe(OH)3 monomers become unstable and proceed to polymerize (R5):

- R5: Polymerization of Fe(OH)3 and various other Fe(III) hydrolysis products

nFe(OH)3 → {Fe(OH)3}(n=2) → {Fe(OH)3}(n>2)

General process of polymerization of Fe(III) hydrolysis products: Upon hydrolysis of Fe(III), polymerization of single, discrete molecules of its hydrolysis products occurs (R(26)–R(28)) with various Fe(III) polymers formed depending on pH [75]. One general, schematic representation of Fe(III) polymerization can be given [11]:

Fe(OH)i3−i + Fe(OH)j3−j → Fe2(OH)i + j i, j ≥ 1, i ≤ j

The polymeric hydrolysis products (iso-polycations) can be multinuclear, and their existence is common for most metal ions [26]. For example, a dimer can be formed for the first Fe(III) hydrolysis product (see R(26)) as shown below and in Figure 6 [16,17,79]:

Fe(III) dimer forms by condensation between the two monomers via elimination of H2O. This is why two H2O molecules are generated as products appearing on the right side of equation R(31). Another way to show Fe(III) dimer formation is as follows [63]:

2[Fe(H2O)5(OH)]2+ ↔ [(H2O)4Fe(OH)2Fe(H2O)4]4+ + 2H2O K = 1.2 × 10−3

2[Fe(H2O)6]3+ ↔ [(H2O)4Fe(OH)2Fe(H2O)4]4+ + 2H+ K = 10−2.91

The Fe(III) dimer Fe2(OH)24+, or [(H2O)4Fe(OH)2Fe(H2O)4]4+, is essentially diamagnetic [79,80]. In the symmetrical assembly of the Fe(III) dimer, the two Fe(III) cations are joined by a double bridge of Fe–O–Fe with each Fe bound to two oxygens of the two central OH groups (Figure 6, O shared between two Fe(III) ions). These polymer structures are called bridged polynuclear (multinuclear) polymer species. The existence of the Fe(III) dimer has been verified [26]. The hydroxoiron(III) dimer (Di-μ-hydroxo-octaaquodiiron(III), Fe2(OH)24+) has been characterized [81]. The dimerization of Fe(III) hydrolysis products was found to proceed kinetically as shown below, e.g., for a simple dimerization reaction:

with the dimerization rate constant reported at 450 (±50) M−1 s−1 and the decomposition (backward reaction) rate constant at 1 (±0.5) s−1 (25 °C, ionic strength I = 0.6) [81].

2FeOH2+ ↔ Fe2(OH)24+

Mechanism of polymerization of Fe(III) hydrolysis products: Hydroxo-aquacations polymerize to generate polynuclear hydroxo-bridged cations [82]. The polymerization of various Fe(III) hydrolysis products can proceed further to generate highly polymerized Fe(III) species with various intermediate products, depending on pH and time and thus more bridges of Fe–O–Fe can form through the OH groups by means of condensation via elimination of H2O. The terms “ol” and “oxo” are generally adopted to refer to the –OH– and –O– bridges. The formation processes of these bridges are called olation and oxalation. Olation then may be followed by oxolation in which the bridging OH group is turned into a bridging O group [26].

Ultimately, some water molecules and protons are split during Fe(III) hydrolysis [17]. The elimination of water molecules to form polymeric bridges (or links) during the polymerization is the condensation process [76]. Condensation (polymerization) occurs during the sequence of Fe(III) hydrolysis and the polymerization of various hydrolysis products from aquo- to hydroxo- to hydroxo-oxo to oxo complexes of Fe(III) [26].

This condensation via H2O elimination (Figure 6) is mechanistically fundamental and highly important in the polymerization of various Fe(III) hydrolysis products. Essentially, Fe(III) hydrolysis products can form various Fe(III) polymers from linear polymers (e.g., a dimer or a trimer, etc.) to 2D polymer sheets and finally to 3D Fe2O3 solids via this single fundamental mechanism alone.