Displacement Interval Prediction Method for Arch Dam with Cracks: Integrated STL, MF-DFA and Bootstrap

Abstract

:1. Introduction

1.1. Literature Review

1.2. Problem Statement

- (1)

- Displacement monitoring data exhibit characteristics such as non-stationarity, temporal variability, and inevitably contain noise [20]. Hence, analysis based on a single algorithm struggles to accurately capture meaningful information from noisy monitoring data [29]. Previous displacement prediction studies mostly focus on statistical fitting, making it difficult to evaluate the trend of dam displacement [30,31]. Thus, combining time series decomposition techniques and fractal theory is needed for a deep analysis of the overall trend of arch dam displacement.

- (2)

- Previous studies have updated the HST model for displacement prediction, resulting in various variant models [10,32,33,34]. However, in existing arch dams, cracks often appear in the dam body. However, in the above literature, the influence of cracks on the displacement is rarely considered, and there is also less feature selection for the input factor set to exclude features that are irrelevant or redundant to the target variable [35]. Therefore, accurately selecting features for the model input factor set remains a challenge.

- (3)

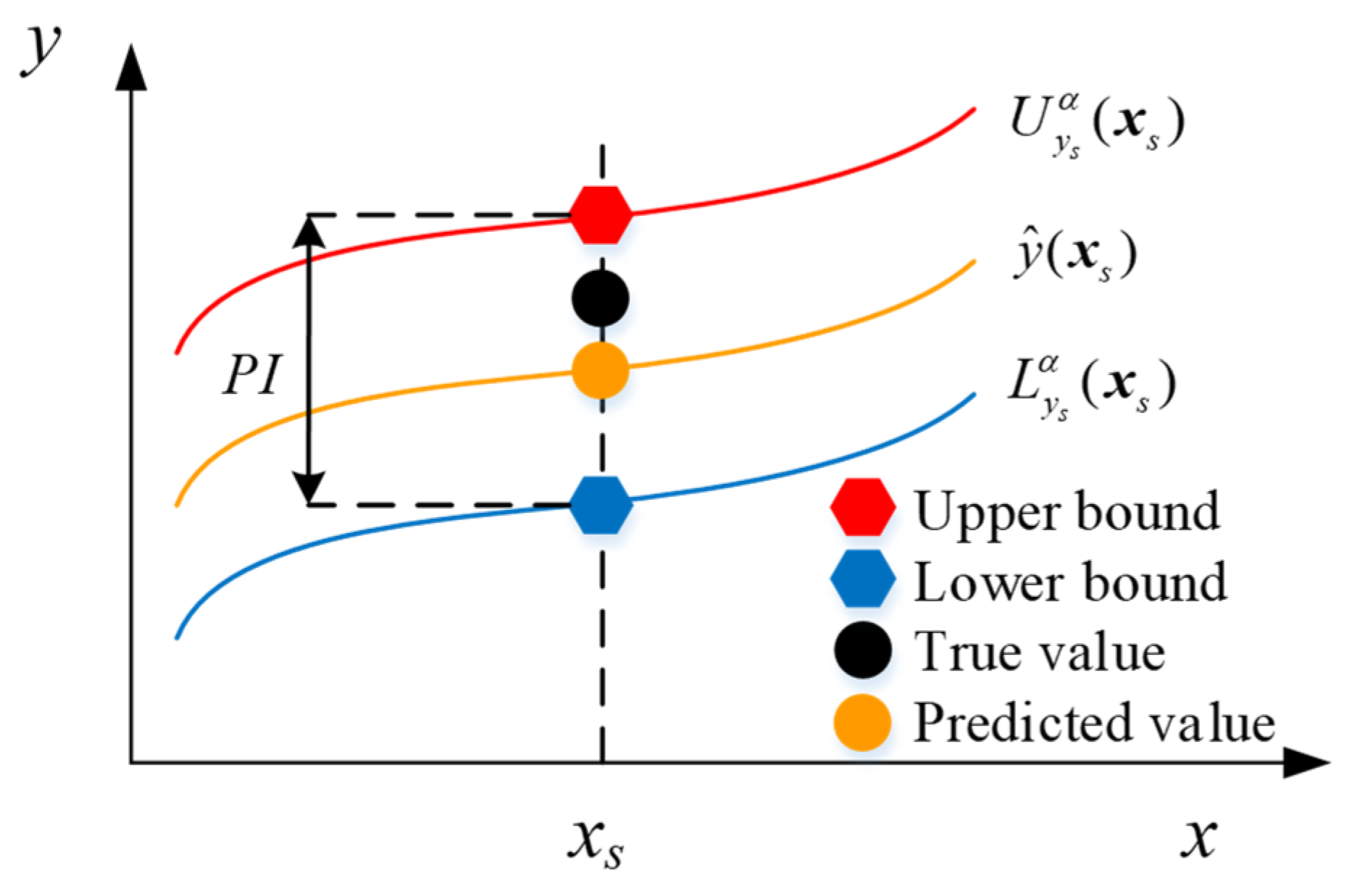

- In existing research on arch dam displacement monitoring models, scholars mostly obtain deterministic point estimates of the displacement through mathematical models, with limited consideration for the uncertainty and randomness of displacement changes [11]. Interval prediction contains more informative value compared to point prediction and can reflect the uncertainty based on the prediction interval [26,27]. Therefore, evaluating and quantifying the uncertainty in displacement prediction results is an urgent issue to address.

1.3. Proposed Solution

- (1)

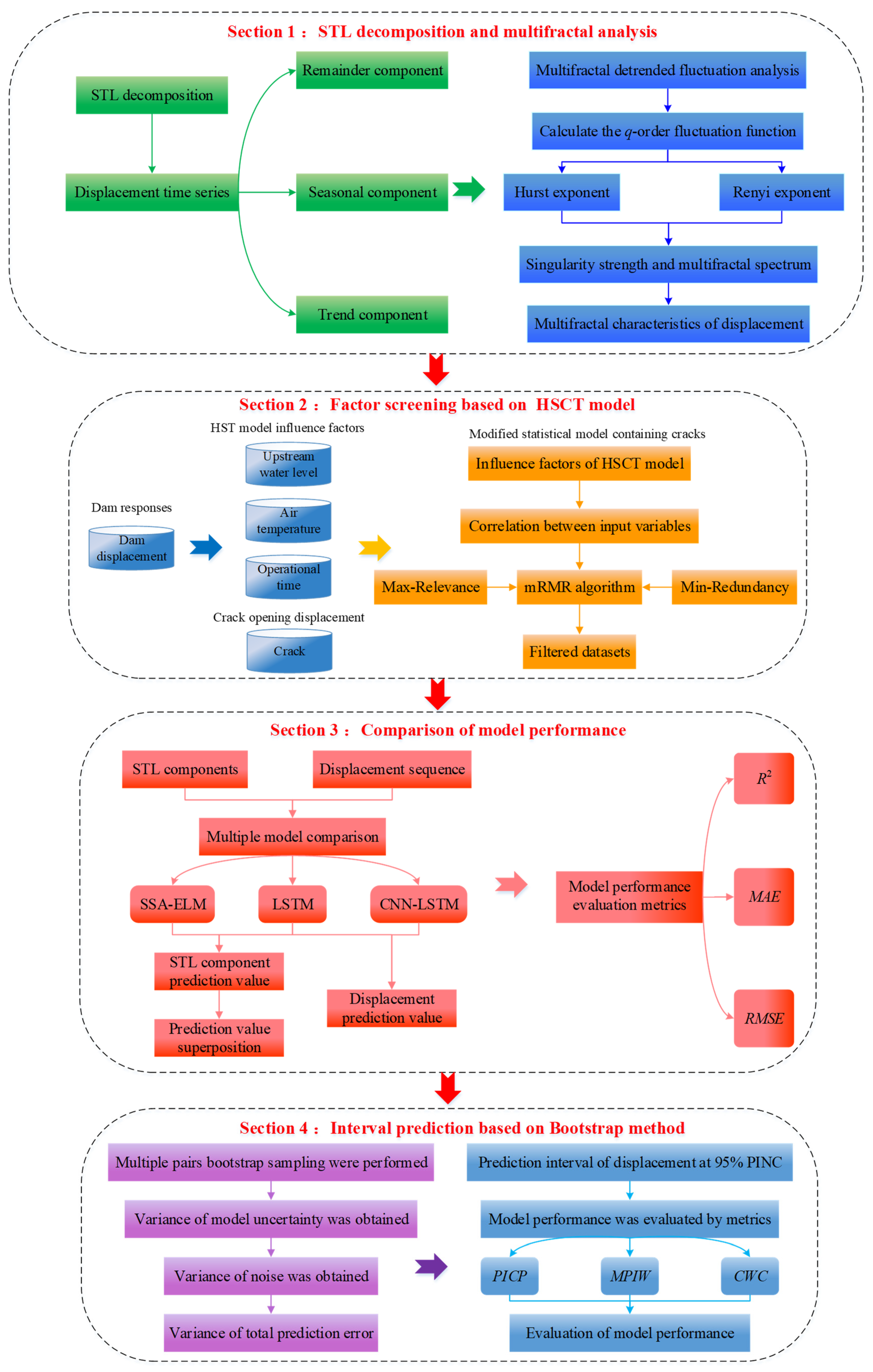

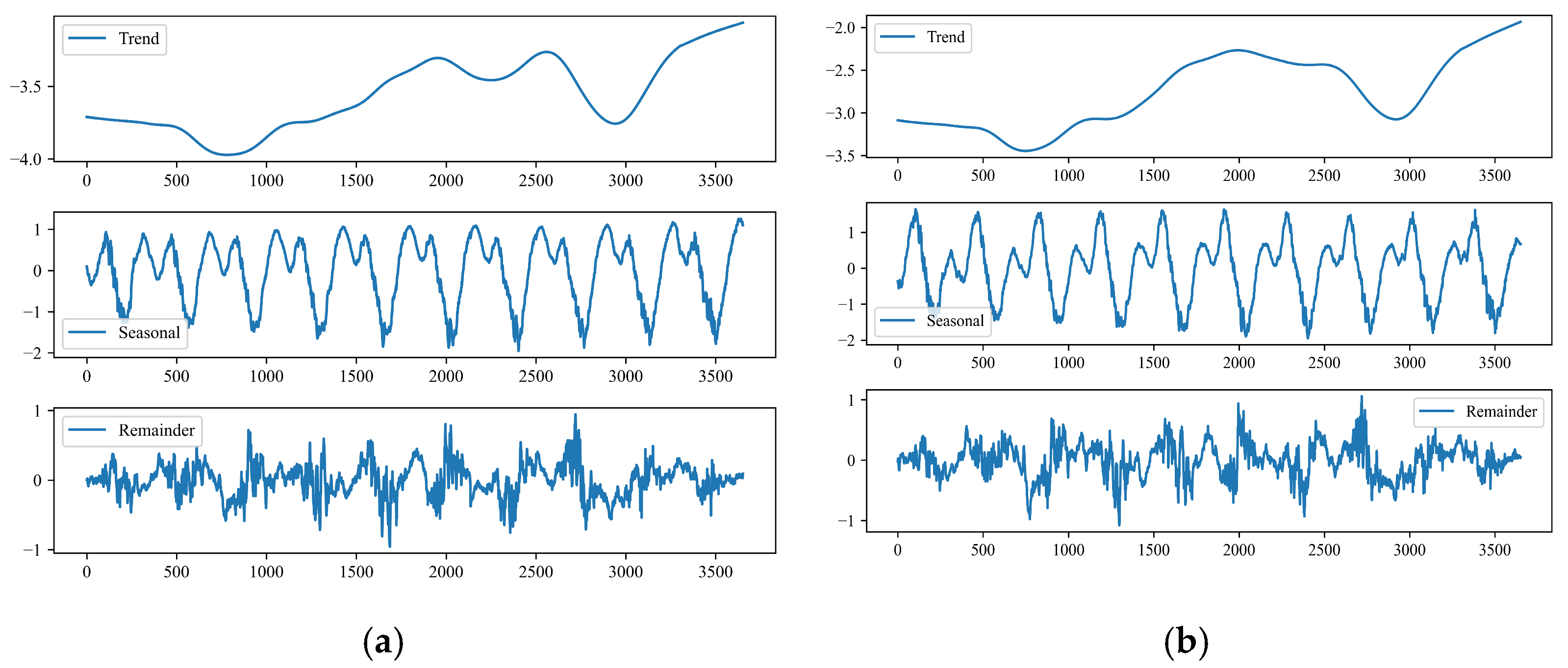

- Considering the non-stationarity and time-varying feature of displacement, the STL algorithm is employed to decompose displacement into trend components, seasonal components, and remainder components to implement separate modeling and effectively handle the non-linear characteristics of displacement. Furthermore, the MF-DFA based on multifractal theory is used to analyze the multifractal features of displacement for trend identification.

- (2)

- Introducing crack opening displacement as a factor that influences the displacement within the HST model, establishing the HSCT model. Utilizing the mRMR method to identify irrelevant variables in the HSCT model, resulting in a screened set.

- (3)

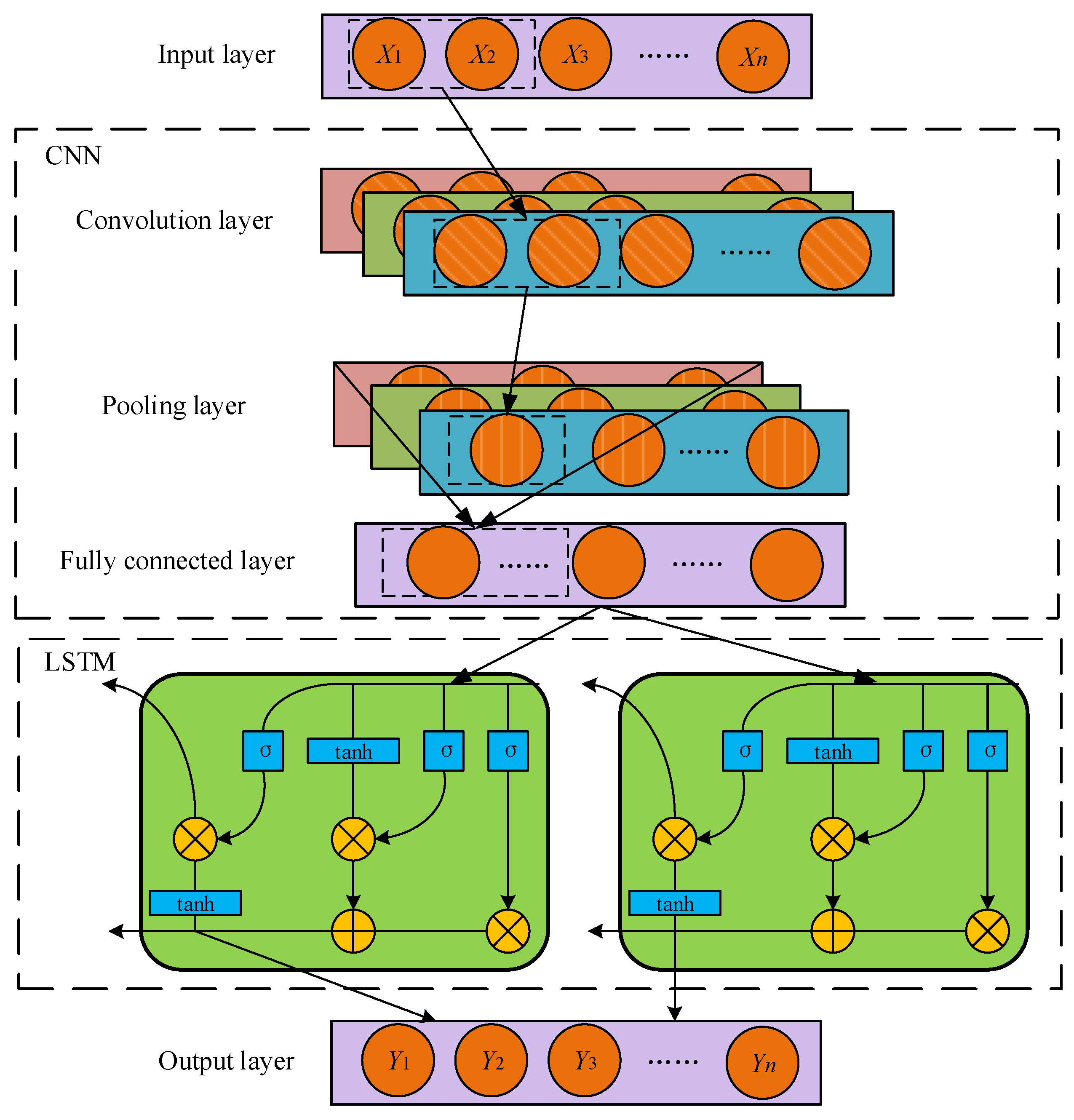

- To explore the uncertainty and randomness in displacement changes, and to account for errors in regression models and noise, the study introduces prediction intervals using the bootstrap method and a CNN-LSTM model to quantify the impact of these uncertainty factors and thereby enhance the reliability of displacement predictions.

2. Principles and Methodologies

2.1. Displacement STL Decomposition

- (1)

- Detrend time series by computing the sequence .

- (2)

- Smooth seasonal subseries by applying Loess smoothing to detrended subseries, resulting in a temporary seasonal series .

- (3)

- Low-pass filter for smoothing a subsequence. Obtained through the use of low-pass filters and the Loess process.

- (4)

- Compute the seasonal component for k + 1 iteration using the formula .

- (5)

- Remove the seasonal component pursuant to the expression .

- (6)

- Derive the trend component by applying Loess smoothing to the time series obtained in step (5) to obtain the k + 1 iteration’s trend component .

2.2. Multifractal Analysis of Displacement

2.3. Establishment of Displacement Factor Set of Arch Dam with Cracks

2.4. Displacement Prediction Based on CNN-LSTM

2.5. Displacement Interval Prediction Based on Bootstrap

2.6. Displacement Interval Prediction Method

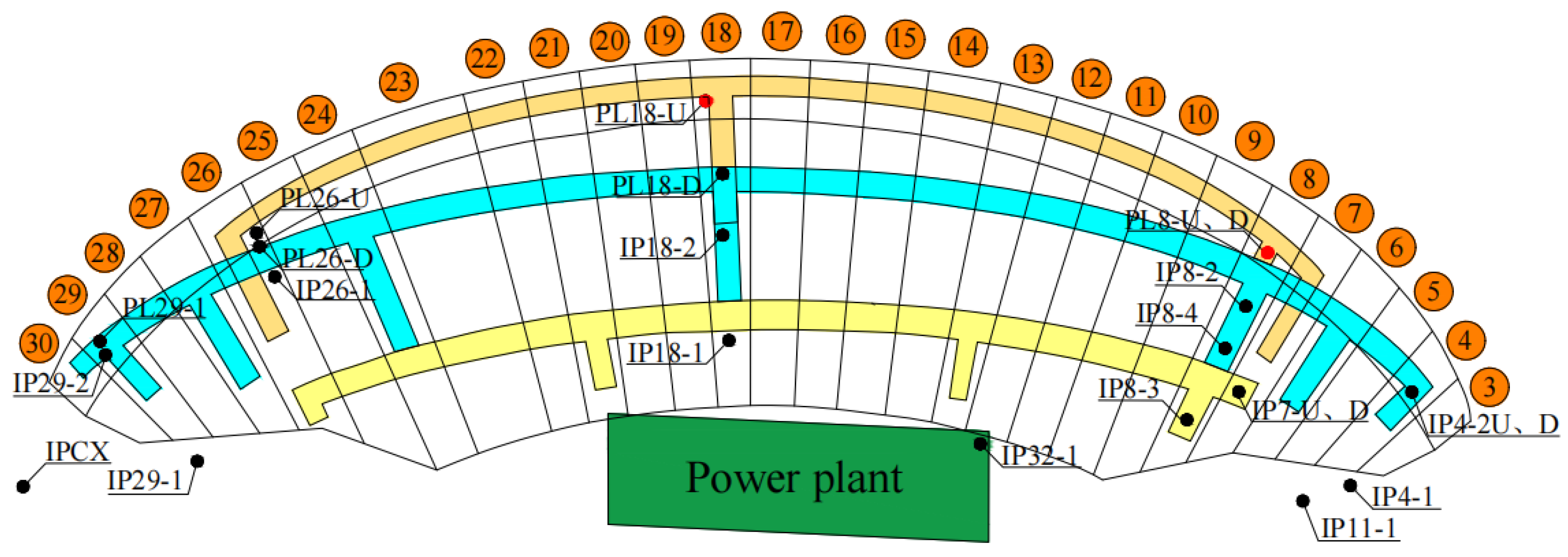

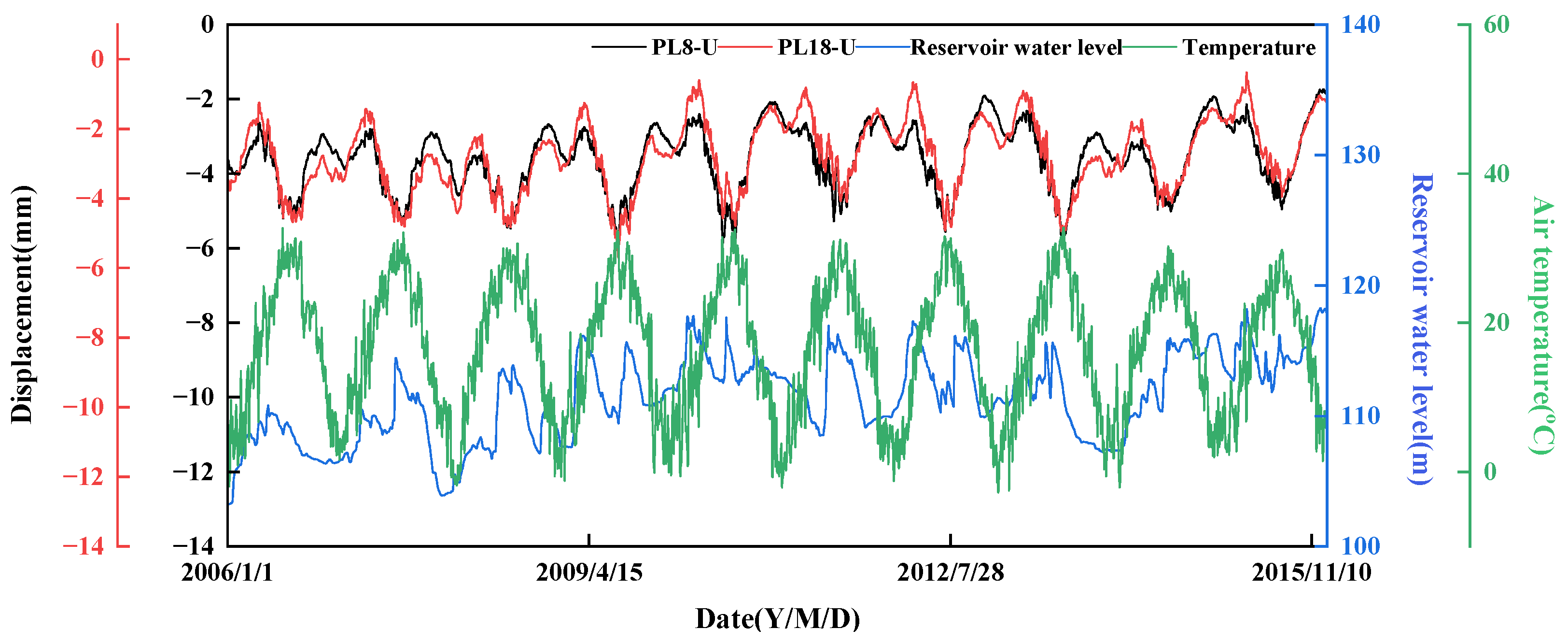

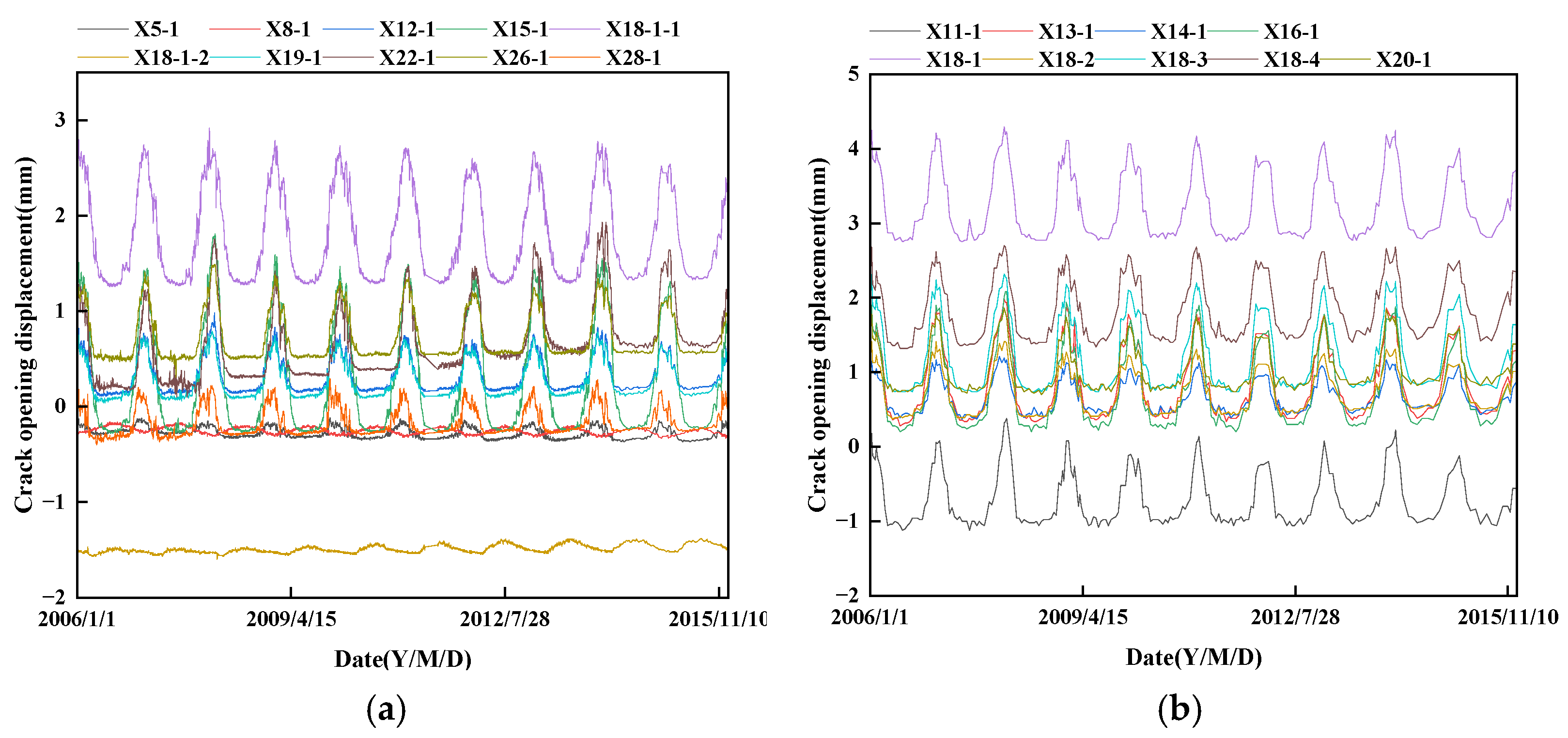

3. Engineering Instance

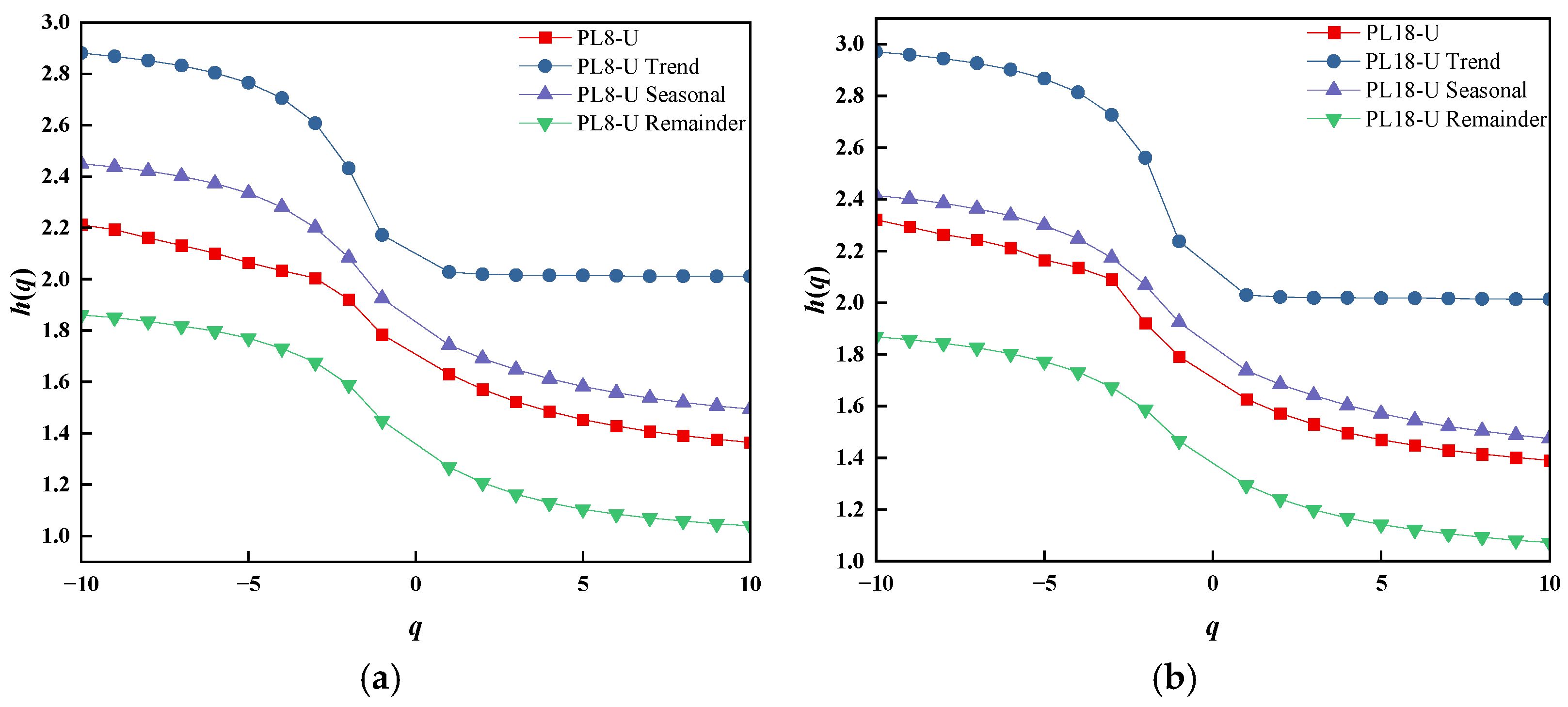

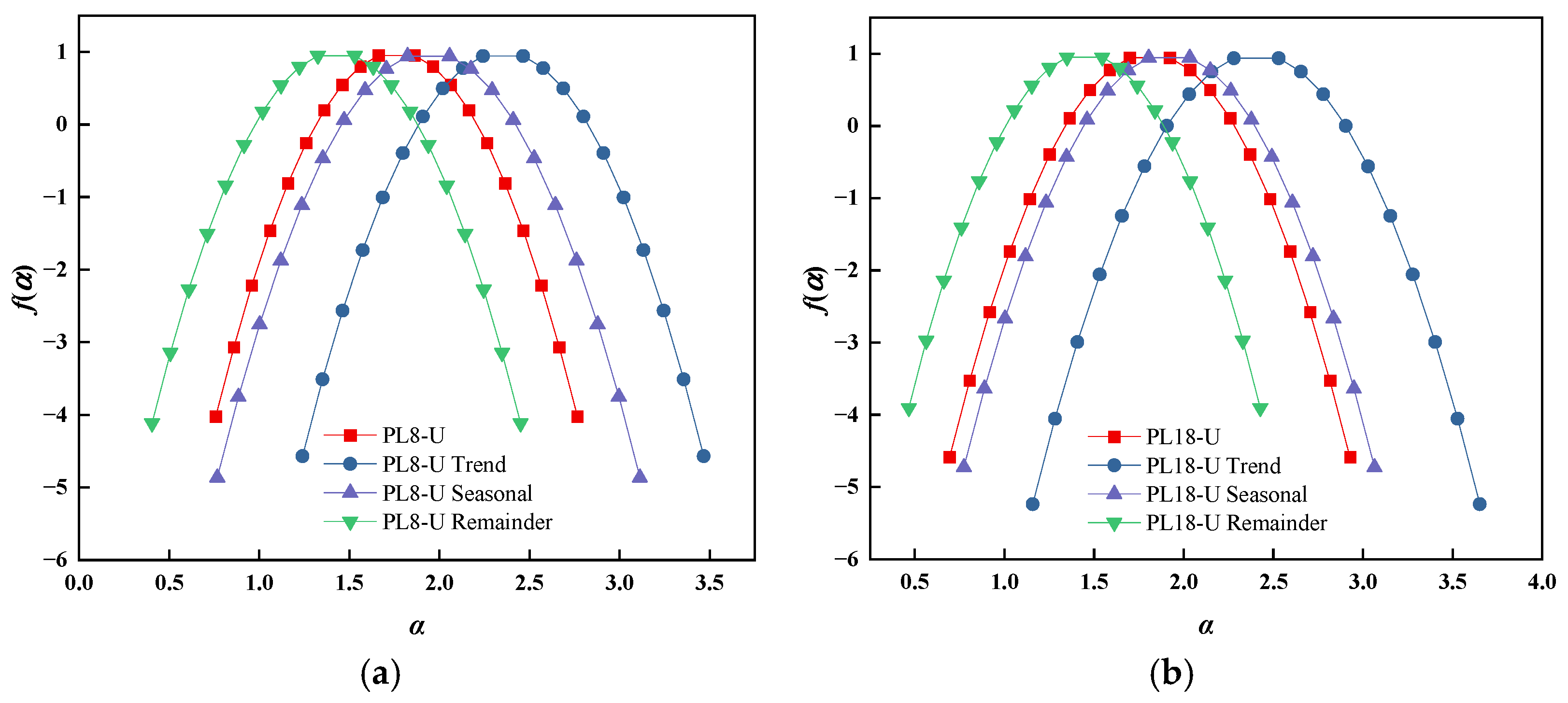

4. Multifractal Characteristics Analysis

5. Results and Analysis

5.1. Construction of Influencing Factor Set

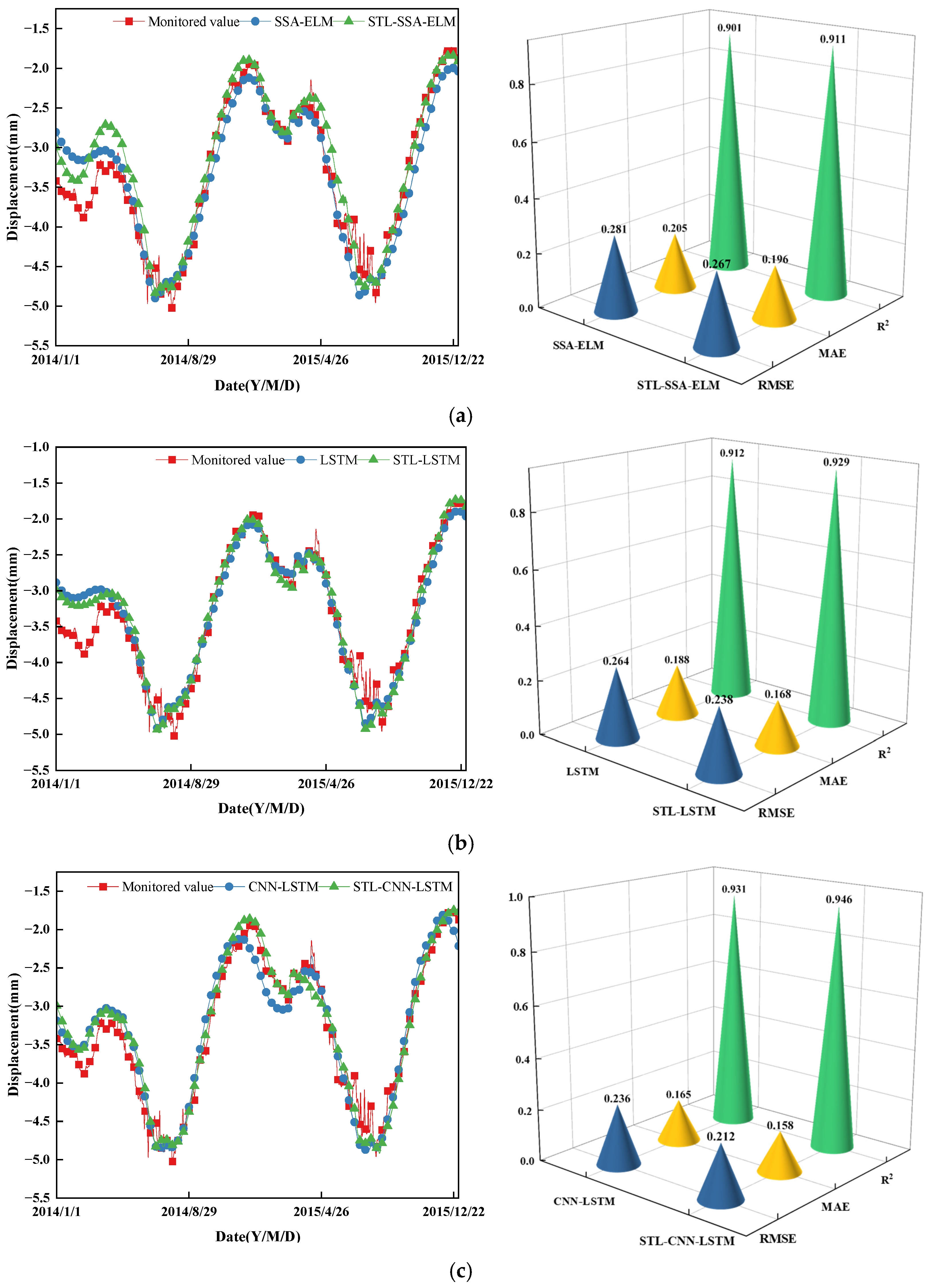

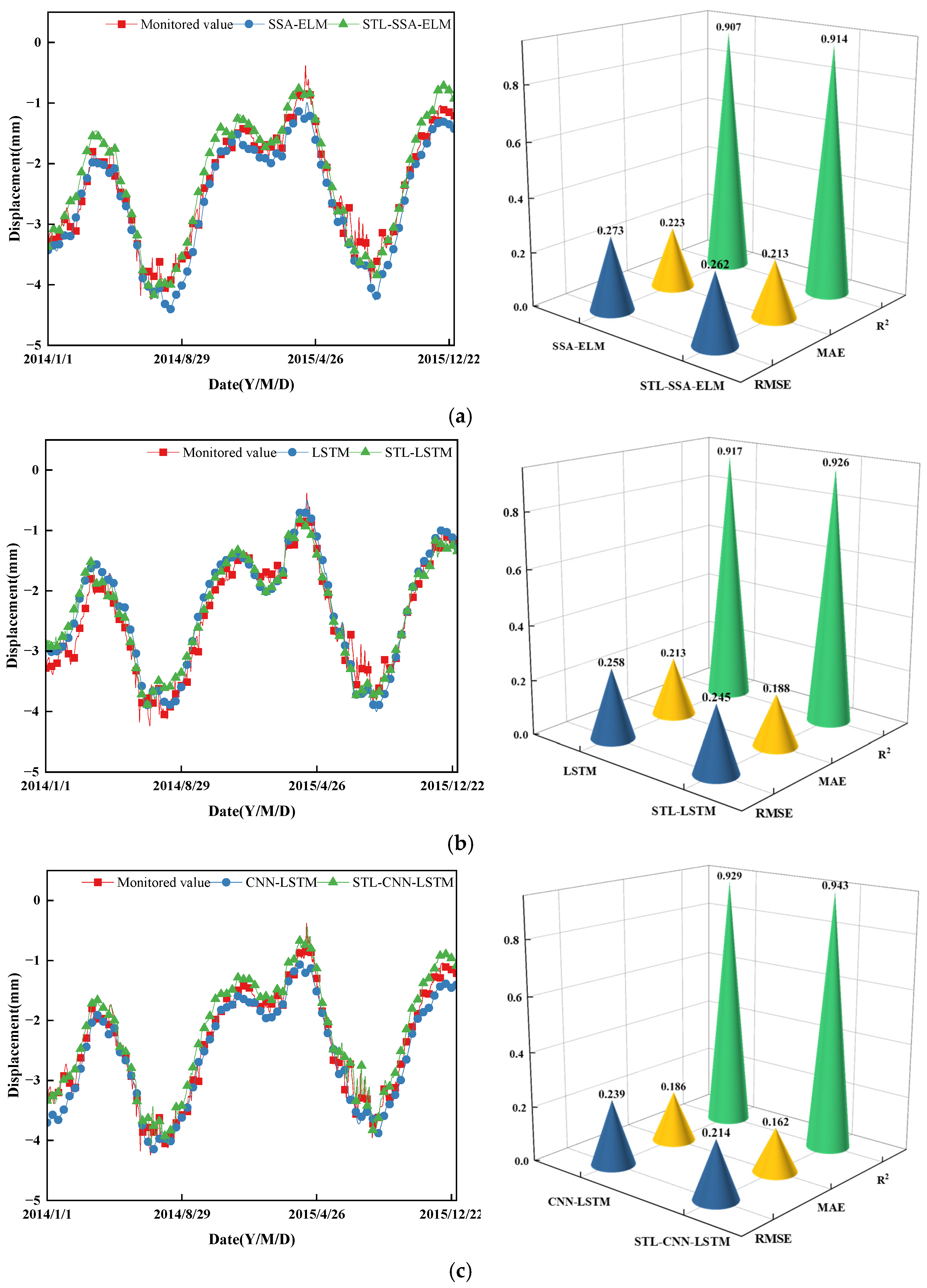

5.2. Comparison of Prediction Model Performance

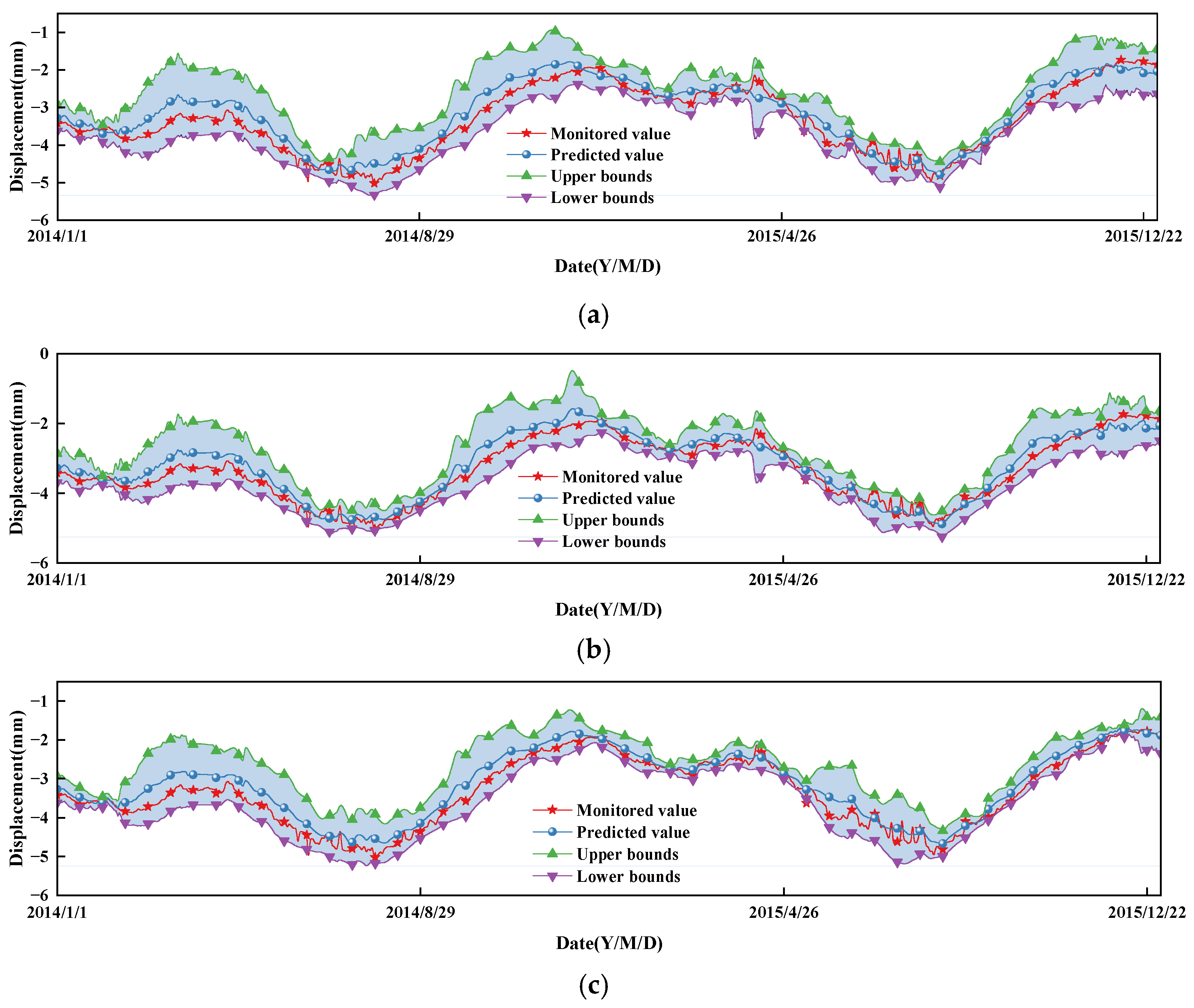

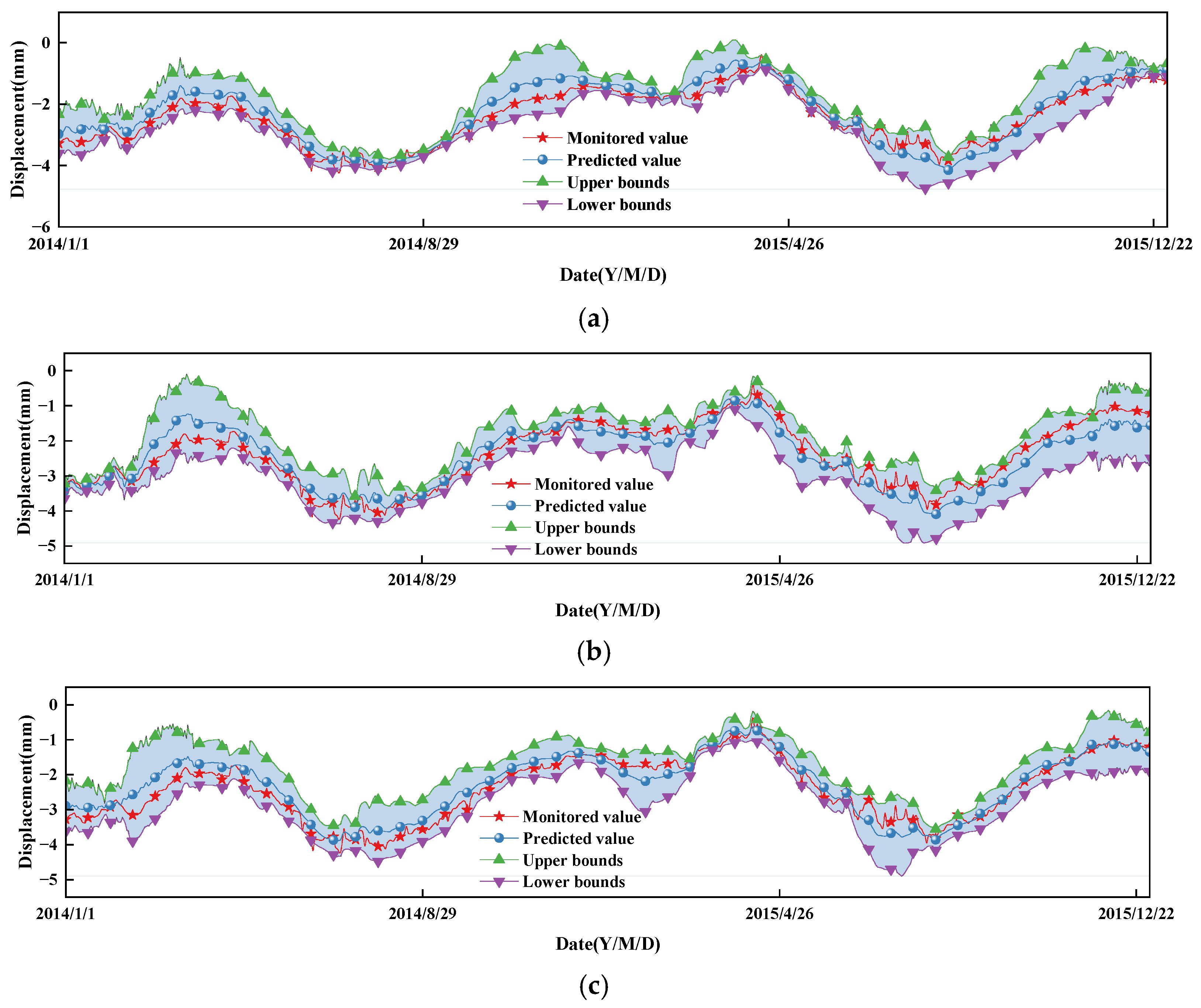

5.3. Displacement Interval Prediction Analysis

6. Conclusions

- (1)

- Noise in data often degrades the quality of displacement monitoring sequences and masks actual patterns in displacement sequences. By decomposing displacement sequences into trend components, seasonal components, and remainder components using the STL algorithm, growth trends in trend components, strong periodicity in seasonal components, and irregularity in remainder components are identified. By separating modeling, enabling better handling of the non-linear features of displacement in subsequent prediction and improving prediction accuracy.

- (2)

- To identify the non-linear dynamic evolution patterns of displacement, the Hurst exponent, Renyi exponent, and multifractal spectrum of displacement and its components are computed using MF-DFA based on multifractal theory. These calculations verify the distinct multifractal features and long-range correlations of displacement and its components, with components exhibiting fractal features consistent with those of displacement. The evolution of displacement is highly complex, and MF-DFA can characterize fractal features at different time scales to effectively identify changing trends in displacement and its components.

- (3)

- In comparison to deterministic point value predictions, interval predictions contain more information and reflect uncertainty based on the predicted interval. To study the performance of different prediction algorithms in quantifying uncertainty, SSA-ELM, LSTM, and CNN-LSTM models are implemented for interval prediction based on STL decomposition, separate modeling, and superposition. The prediction intervals constructed by these models at a 95% confidence level are effective (PICP ≥ PINC), with CNN-LSTM showcasing the highest performance, achieving a PICP of 98% and the smallest MPIW. This precise quantification of displacement uncertainty through interval prediction enhances the understanding of displacement variations.

- (4)

- The proposed displacement interval prediction method for arch dams with cracks presents an effective and feasible approach for concrete dam displacement monitoring and health diagnosis. It facilitates both qualitative analysis of displacement trends and quantitative assessment of displacement prediction accuracy, offering a novel perspective for displacement analysis and prediction in hydraulic structures. This method provides valuable insights for operational management personnel, thereby enhancing the reliability of dam risk management.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, Q.; Li, M.; Kong, T.; Ma, J. Multi-sensor real-time monitoring of dam behavior using self-adaptive online sequential learning. Autom. Constr. 2022, 140, 104365. [Google Scholar] [CrossRef]

- Lin, C.; Chen, S.; Hariri-Ardebili, M.A.; Li, T. An explainable probabilistic model for health monitoring of concrete dam via optimized sparse bayesian learning and sensitivity analysis. Struct. Control Health Monit. 2023, 2023, 2979822. [Google Scholar] [CrossRef]

- Huang, B.; Kang, F.; Li, J.; Wang, F. Displacement prediction model for high arch dams using long short-term memory based encoder-decoder with dual-stage attention considering measured dam temperature. Eng. Struct. 2023, 280, 115686. [Google Scholar] [CrossRef]

- Qin, X.; Guo, J.; Gu, C.; Chen, X.; Xu, B. A discrete-continuum coupled numerical method for fracturing behavior in concrete dams considering material heterogeneity. Constr. Build. Mater. 2021, 305, 124741. [Google Scholar] [CrossRef]

- Zhao, E.; Li, B. Evaluation method for cohesive crack propagation in fragile locations of RCC dam using XFEM. Water 2020, 13, 58. [Google Scholar] [CrossRef]

- Zheng, C. Numerical Simulation of Interfaces in Concrete Dams and Its Application; China Institute of Water Resources and Hydropower Research: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Zhang, G.; Liu, Y.; Zheng, C.; Feng, F. Simulation of influence of multi-defects on long-term working performance of high arch dam. Sci. China Technol. Sci. 2011, 54 (Suppl. S1), 1–8. [Google Scholar] [CrossRef]

- Chen, S.; Gu, C.; Lin, C.; Hariri-Ardebili, M.A. Prediction of arch dam deformation via correlated multi-target stacking. Appl. Math. Model. 2021, 91, 1175–1193. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Y.; Gu, C.; Xia, Q.; Hu, K. Two spatial association-considered mathematical models for diagnosing the long-term balanced relationship and short-term fluctuation of the deformation behaviour of high concrete arch dams. Struct. Health Monit. 2020, 19, 1421–1439. [Google Scholar] [CrossRef]

- Wu, Z. Safety Monitoring Theory and Its Application of Hydraulic Structures; Higher Education Press: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Chen, H.; Chen, X.; Guan, J.; Zhang, X.; Guo, J.; Yang, G.; Xu, B. A combination model for evaluating deformation regional characteristics of arch dams using time series clustering and residual correction. Mech. Syst. Signal Process. 2022, 179, 109397. [Google Scholar] [CrossRef]

- Zhou, Y.; Bao, T.; Li, G.; Shu, X.; Li, Y. Multi-expert attention network for long-term dam displacement prediction. Adv. Eng. Inform. 2023, 57, 102060. [Google Scholar] [CrossRef]

- Hu, J.; Li, X. A novel prediction model construction and result interpretation method for slope deformation of deep excavated expansive soil canals. Expert Syst. Appl. 2024, 236, 121326. [Google Scholar] [CrossRef]

- Li, M.; Shen, Y.; Ren, Q.; Li, H. A new distributed time series evolution prediction model for dam deformation based on constituent elements. Adv. Eng. Inform. 2019, 39, 41–52. [Google Scholar] [CrossRef]

- Lei, W.; Wang, J. Dynamic Stacking ensemble monitoring model of dam displacement based on the feature selection with PCA-RF. J. Civ. Struct. Health Monit. 2022, 12, 557–578. [Google Scholar] [CrossRef]

- Ren, Q.; Li, H.; Li, M.; Kong, T.; Guo, R. Bayesian incremental learning paradigm for online monitoring of dam behavior considering global uncertainty. Appl. Soft Comput. 2023, 143, 110411. [Google Scholar] [CrossRef]

- Ren, Q.; Li, H.; Li, M.; Zhang, J.; Kong, T. Towards online monitoring of concrete dam displacement subject to time-varying environments: An improved sequential learning approach. Adv. Eng. Inform. 2023, 55, 101881. [Google Scholar] [CrossRef]

- Chen, S.; Gu, C.; Lin, C.; Zhang, K.; Zhu, Y. Multi-kernel optimized relevance vector machine for probabilistic prediction of concrete dam displacement. Eng. Comput. 2021, 37, 1943–1959. [Google Scholar] [CrossRef]

- Ren, Q.; Li, M.; Li, H.; Shen, Y. A novel deep learning prediction model for concrete dam displacements using interpretable mixed attention mechanism. Adv. Eng. Inform. 2021, 50, 101407. [Google Scholar] [CrossRef]

- Yuan, D.; Gu, C.; Wei, B.; Qin, X.; Xu, W. A high-performance displacement prediction model of concrete dams integrating signal processing and multiple machine learning techniques. Appl. Math. Model. 2022, 112, 436–451. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Gong, J.; Shu, X.; Zhang, K. The prediction of dam displacement time series using STL, extra-trees, and stacked LSTM neural network. IEEE Access 2020, 8, 94440–94452. [Google Scholar] [CrossRef]

- Su, H.; Hu, J.; Wu, Z. A study of safety evaluation and early-warning method for dam global behavior. Struct. Health Monit. 2012, 11, 269–279. [Google Scholar]

- Su, H.; Wen, Z.; Wang, F.; Hu, J. Dam structural behavior identification and prediction by using variable dimension fractal model and iterated function system. Appl. Soft Comput. 2016, 48, 612–620. [Google Scholar] [CrossRef]

- Wu, Y.; He, Y.; Wu, M.; Lu, C.; Gao, S.; Xu, Y. Multifractality and cross-correlation analysis of streamflow and sediment fluctuation at the apex of the Pearl River Delta. Sci. Rep. 2018, 8, 16553. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Wen, Z.; Wang, F.; Wei, B.; Hu, J. Multifractal scaling behavior analysis for existing dams. Expert Syst. Appl. 2013, 40, 4922–4933. [Google Scholar] [CrossRef]

- Ren, Q.; Li, M.; Kong, R.; Shen, Y.; Du, S. A hybrid approach for interval prediction of concrete dam displacements under uncertain conditions. Eng. Comput. 2023, 39, 1285–1303. [Google Scholar] [CrossRef]

- Ren, Q.; Li, M.; Shen, Y. A new interval prediction method for displacement behavior of concrete dams based on gradient boosted quantile regression. Struct. Control Health Monit. 2022, 29, e2859. [Google Scholar] [CrossRef]

- Wang, S.; Xu, C.; Liu, Y.; Wu, B. A spatial association-coupled double objective support vector machine prediction model for diagnosing the deformation behaviour of high arch dams. Struct. Health Monit. 2022, 21, 945–964. [Google Scholar] [CrossRef]

- Wang, L.; Lee, R.S.T. Stock Index Return Volatility Forecast via Excitatory and Inhibitory Neuronal Synapse Unit with Modified MF-ADCCA. Fractal Fract. 2023, 7, 292. [Google Scholar] [CrossRef]

- Yao, K.; Wen, Z.; Yang, L.; Chen, J.; Hou, H.; Su, H. A multipoint prediction model for nonlinear displacement of concrete dam. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 1932–1952. [Google Scholar] [CrossRef]

- Li, M.; Ren, Q.; Li, M.; Fang, X.; Xiao, L.; Li, H. A separate modeling approach to noisy displacement prediction of concrete dams via improved deep learning with frequency division. Adv. Eng. Inform. 2024, 60, 102367. [Google Scholar] [CrossRef]

- Léger, P.; Leclerc, M. Hydrostatic, temperature, time-displacement model for concrete dams. J. Eng. Mech. 2007, 133, 267–277. [Google Scholar] [CrossRef]

- Yu, X.; Li, J.; Kang, F. A hybrid model of bald eagle search and relevance vector machine for dam safety monitoring using long-term temperature. Adv. Eng. Inform. 2023, 55, 101863. [Google Scholar] [CrossRef]

- Hu, J.; Wu, S. Statistical modeling for deformation analysis of concrete arch dams with influential horizontal cracks. Struct. Health Monit. 2019, 18, 546–562. [Google Scholar] [CrossRef]

- Xu, B.; Chen, Z.; Su, H.; Zhang, H. A deep learning method for predicting the displacement of concrete arch dams considering the effect of cracks. Adv. Eng. Inform. 2024, 62, 102574. [Google Scholar] [CrossRef]

- Wang, M.; Zhong, C.; Yue, K.; Zheng, Y.; Jiang, W.; Wang, J. Modified MF-DFA Model Based on LSSVM Fitting. Fractal Fract. 2024, 8, 320. [Google Scholar] [CrossRef]

- Gorjão, L.R.; Hassan, G.; Kurths, J.; Witthaut, D. MFDFA: Efficient multifractal detrended fluctuation analysis in python. Comput. Phys. Commun. 2022, 273, 108254. [Google Scholar] [CrossRef]

- Peng, H.; Long, F.; Ding, C. Feature selection based on mutual information criteria of max-dependency, max-relevance, and min-redundancy. IEEE Trans. Pattern Anal. Mach. Intell. 2005, 27, 1226–1238. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Q.; Hu, Y.; Wang, Y.; Zhu, X.; Tan, Y.; Liu, C.; Pei, L. Deformation prediction model based on an improved CNN+LSTM model for the first impoundment of super-high arch dams. J. Civ. Struct. Health Monit. 2023, 13, 431–442. [Google Scholar]

- Bera, S.; Shrivastava, V.K. Analysis of various optimizers on deep convolutional neural network model in the application of hyperspectral remote sensing image classification. Int. J. Remote Sens. 2020, 41, 2664–2683. [Google Scholar] [CrossRef]

- Flachaire, E. Bootstrapping heteroskedastic regression models: Wild bootstrap vs. pairs bootstrap. Comput. Stat. Data Anal. 2005, 49, 361–376. [Google Scholar] [CrossRef]

- Khosravi, A.; Nahavandi, S.; Creighton, D.; Atiya, A.F. Comprehensive review of neural network-based prediction intervals and new advances. IEEE Trans. Neural Netw. 2011, 22, 1341–1356. [Google Scholar] [CrossRef]

- Xu, X.; Yang, J.; Ma, C.; Qu, X.; Chen, J.; Cheng, L. Segmented modeling method of dam displacement based on BEAST time series decomposition. Measurement 2022, 202, 111811. [Google Scholar] [CrossRef]

- Yang, C.; Huang, R.; Liu, D.; Qiu, W.; Zhang, R.; Tang, Y. Analysis and warning prediction of tunnel deformation based on multifractal theory. Fractal Fract. 2024, 8, 108. [Google Scholar] [CrossRef]

| Monitoring Points | Models | RMSE | MAE | R2 |

|---|---|---|---|---|

| PL8−U | SSA-ELM | 0.264 (10.5%) | 0.188 (12.2%) | 0.912 (2.4%) |

| LSTM | 0.238 (15.3%) | 0.168 (18.1%) | 0.929 (3.1%) | |

| CNN-LSTM | 0.236 (11.6%) | 0.165 (15.8%) | 0.931 (2.2%) | |

| PL18−U | SSA-ELM | 0.267 (12.7%) | 0.214 (8.5%) | 0.912 (3.1%) |

| LSTM | 0.262 (6.1%) | 0.213 (5.3%) | 0.914 (1.3%) | |

| CNN-LSTM | 0.258 (5.5%) | 0.212 (4.5%) | 0.917 (1.1%) |

| Factor | PL8−U | PL18−U | Factor | PL8−U | PL18−U |

|---|---|---|---|---|---|

| x1 | 3.947 | 1.266 | J6 | 1.527 | 1.390 |

| x2 | 1.108 | 2.885 | J7 | 0.864 | 0.531 |

| x3 | 1.528 | 0.838 | J8 | 1.527 | 1.390 |

| x4 | 0.875 | 0.662 | J9 | 1.584 | 1.442 |

| x5 | 19.641 | 17.617 | J10 | 3.042 | 5.740 |

| x6 | 1.701 | 1.002 | J11 | 0.583 | 0.772 |

| x7 | 4.540 | 10.262 | J12 | 5.069 | 1.389 |

| x8 | 34.841 | 1.329 | J13 | 0.625 | 0.569 |

| x9 | 1.528 | 1.389 | J14 | 5.456 | 10.563 |

| x10 | 0.735 | 0.669 | J15 | 1.527 | 1.388 |

| J1 | 7.400 | 6.787 | J16 | 18.267 | 4.252 |

| J2 | 5.074 | 1.390 | J17 | 0.639 | 0.581 |

| J3 | 1.528 | 1.389 | J18 | 0.862 | 1.402 |

| J4 | 3.044 | 2.764 | J19 | 5.078 | 1.390 |

| J5 | 1.005 | 12.943 | - | - | - |

| Monitoring Points | Filtered Data Sets |

|---|---|

| PL8−U | {x1–x3, x5–x9, J1–J6, J8–J10, J12, J14–J16, J19} |

| PL18−U | {x1, x2, x5–x9, J1–J6, J8–J10, J12, J14–J16, J18, J19} |

| Measuring Points | Prediction Models | PINC 95% | ||

|---|---|---|---|---|

| PICP (%) | MPIW (mm) | CWC (mm) | ||

| PL8−U | STL-SSA-ELM | 98.22 | 1.10 | 1.10 |

| STL-LSTM | 98.89 | 0.98 | 0.98 | |

| STL-CNN-LSTM | 98.77 | 0.95 | 0.95 | |

| PL18−U | STL-SSA-ELM | 95.79 | 1.07 | 1.07 |

| STL-LSTM | 98.49 | 1.21 | 1.21 | |

| STL-CNN-LSTM | 98.90 | 1.11 | 1.11 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Xu, B.; Sun, L.; Wang, X.; Song, D.; Lu, W.; Li, Y. Displacement Interval Prediction Method for Arch Dam with Cracks: Integrated STL, MF-DFA and Bootstrap. Water 2024, 16, 2755. https://doi.org/10.3390/w16192755

Chen Z, Xu B, Sun L, Wang X, Song D, Lu W, Li Y. Displacement Interval Prediction Method for Arch Dam with Cracks: Integrated STL, MF-DFA and Bootstrap. Water. 2024; 16(19):2755. https://doi.org/10.3390/w16192755

Chicago/Turabian StyleChen, Zeyuan, Bo Xu, Linsong Sun, Xuan Wang, Dalai Song, Weigang Lu, and Yangtao Li. 2024. "Displacement Interval Prediction Method for Arch Dam with Cracks: Integrated STL, MF-DFA and Bootstrap" Water 16, no. 19: 2755. https://doi.org/10.3390/w16192755

APA StyleChen, Z., Xu, B., Sun, L., Wang, X., Song, D., Lu, W., & Li, Y. (2024). Displacement Interval Prediction Method for Arch Dam with Cracks: Integrated STL, MF-DFA and Bootstrap. Water, 16(19), 2755. https://doi.org/10.3390/w16192755