Experimental Study on the Performance and Internal Flow Characteristics of Liquid–Gas Jet Pump with Square Nozzle

Abstract

1. Introduction

2. Experimental Design

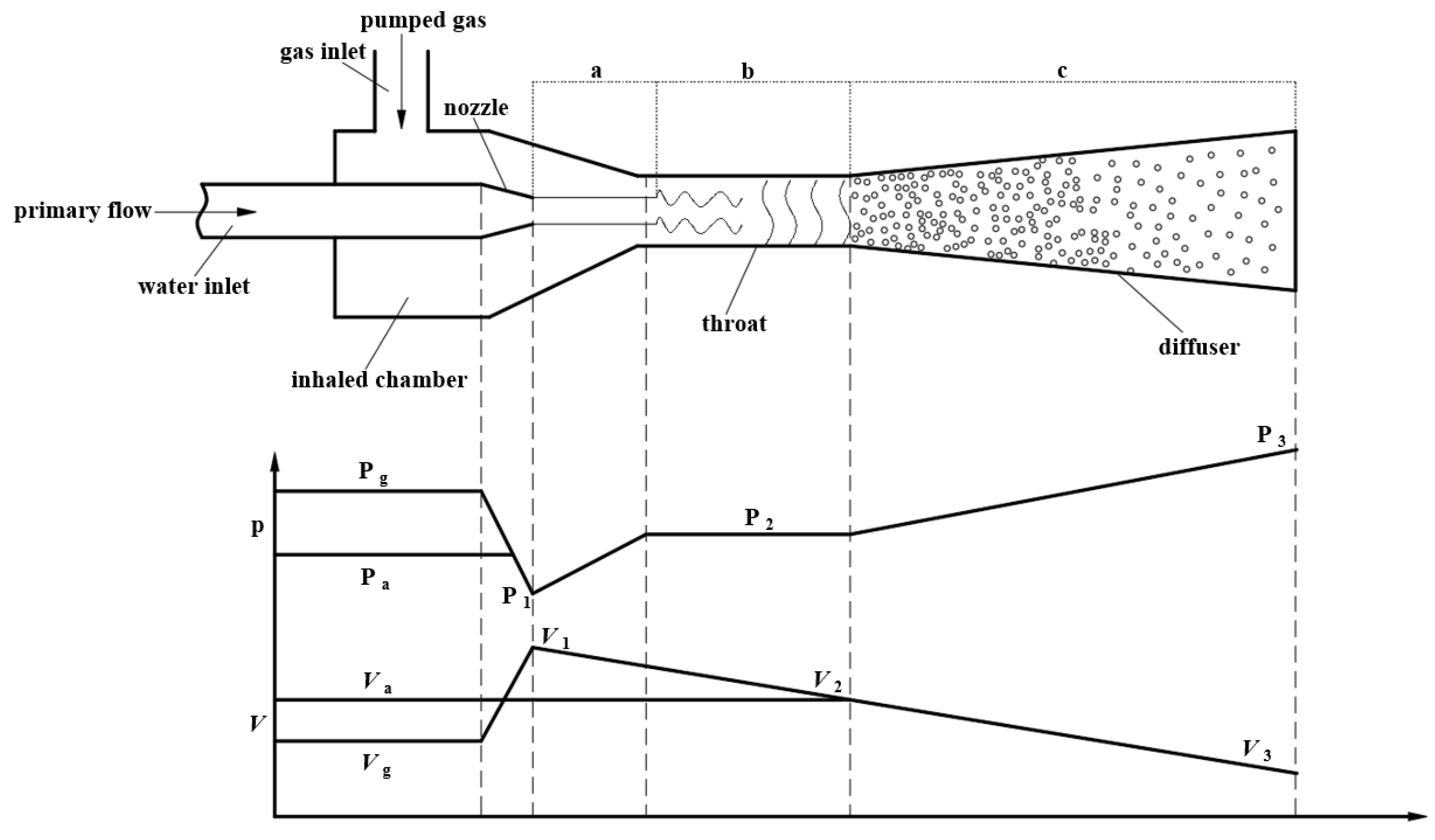

2.1. The Structure and Working Principle of the LGJP

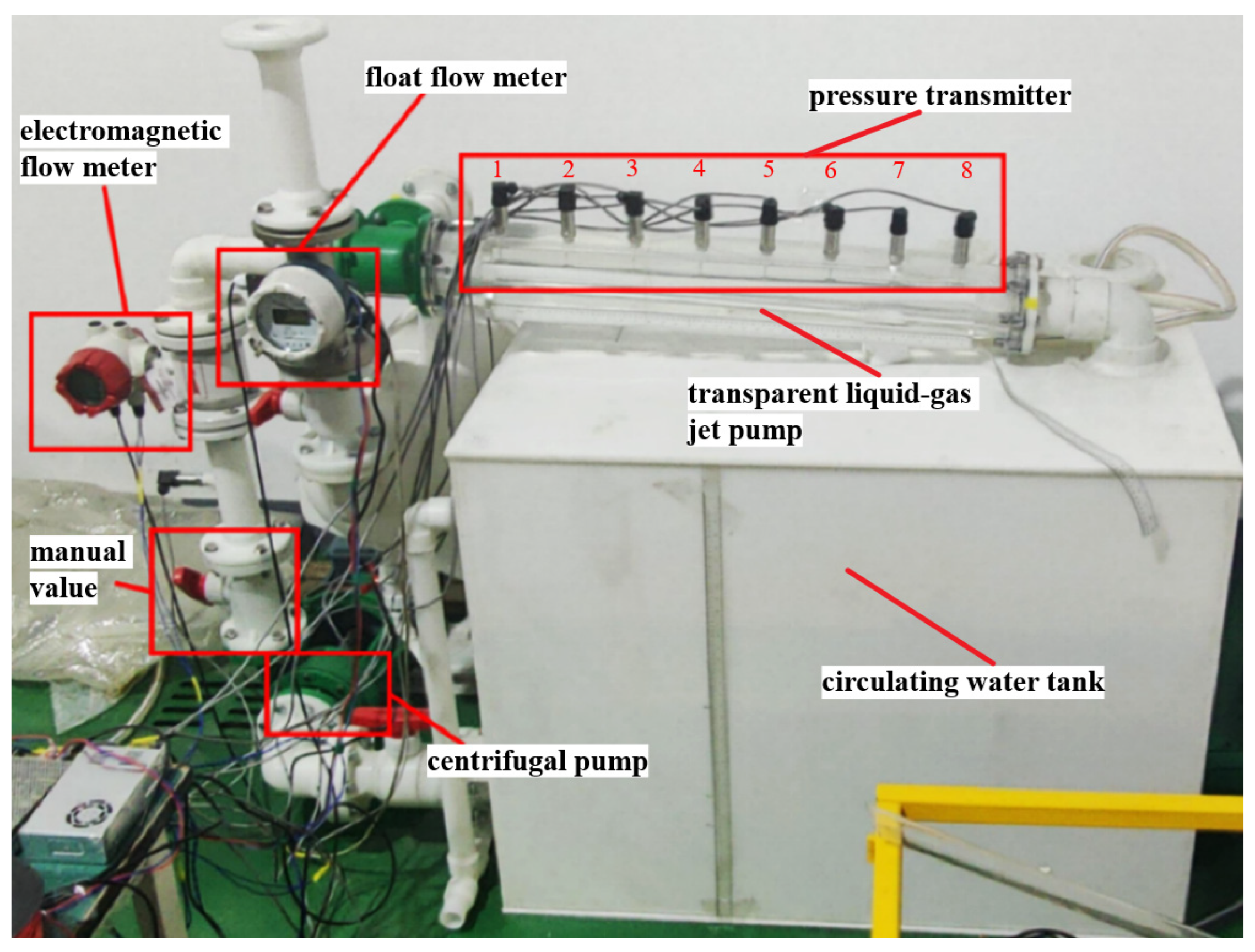

2.2. Experimental Setup

3. Results and Discussions

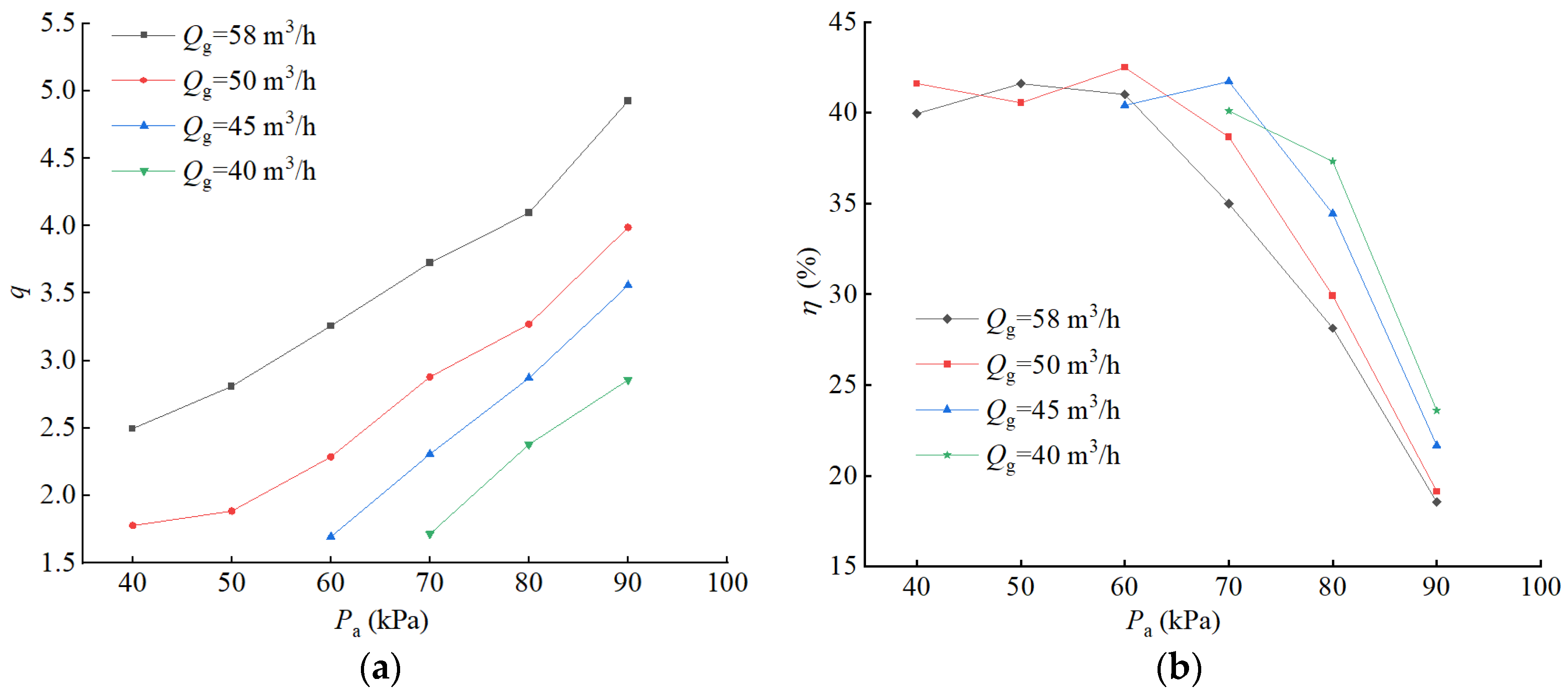

3.1. External Characterization

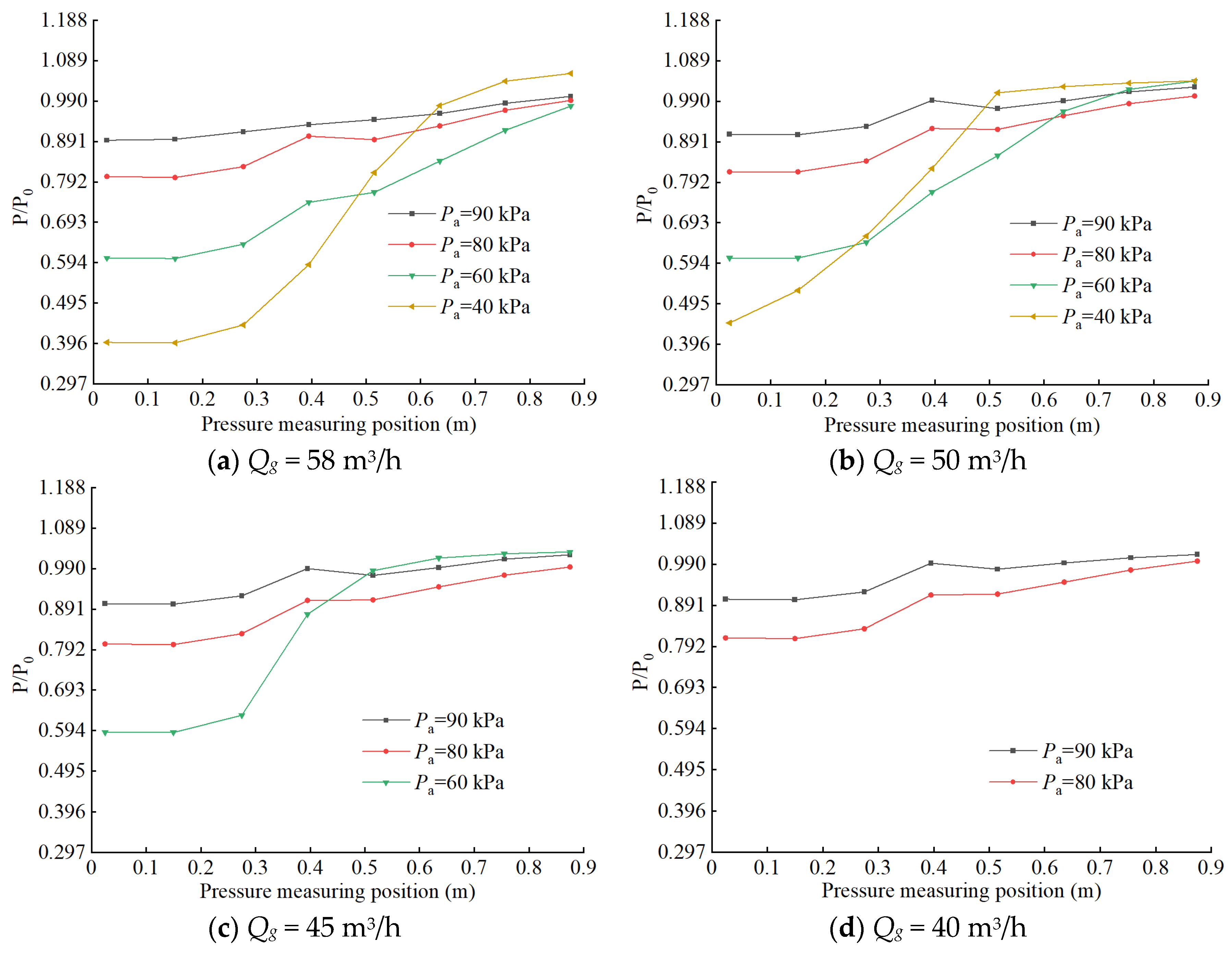

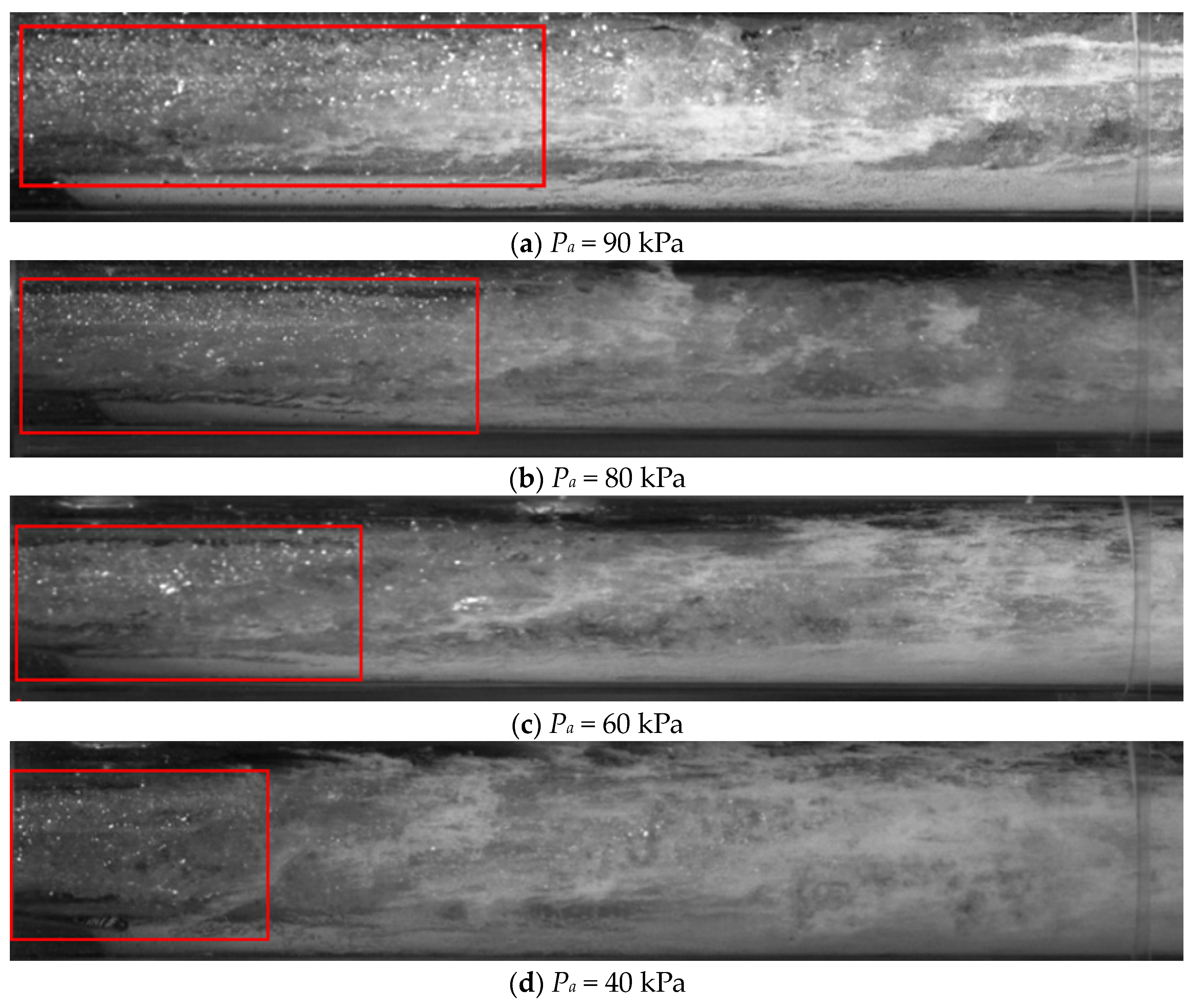

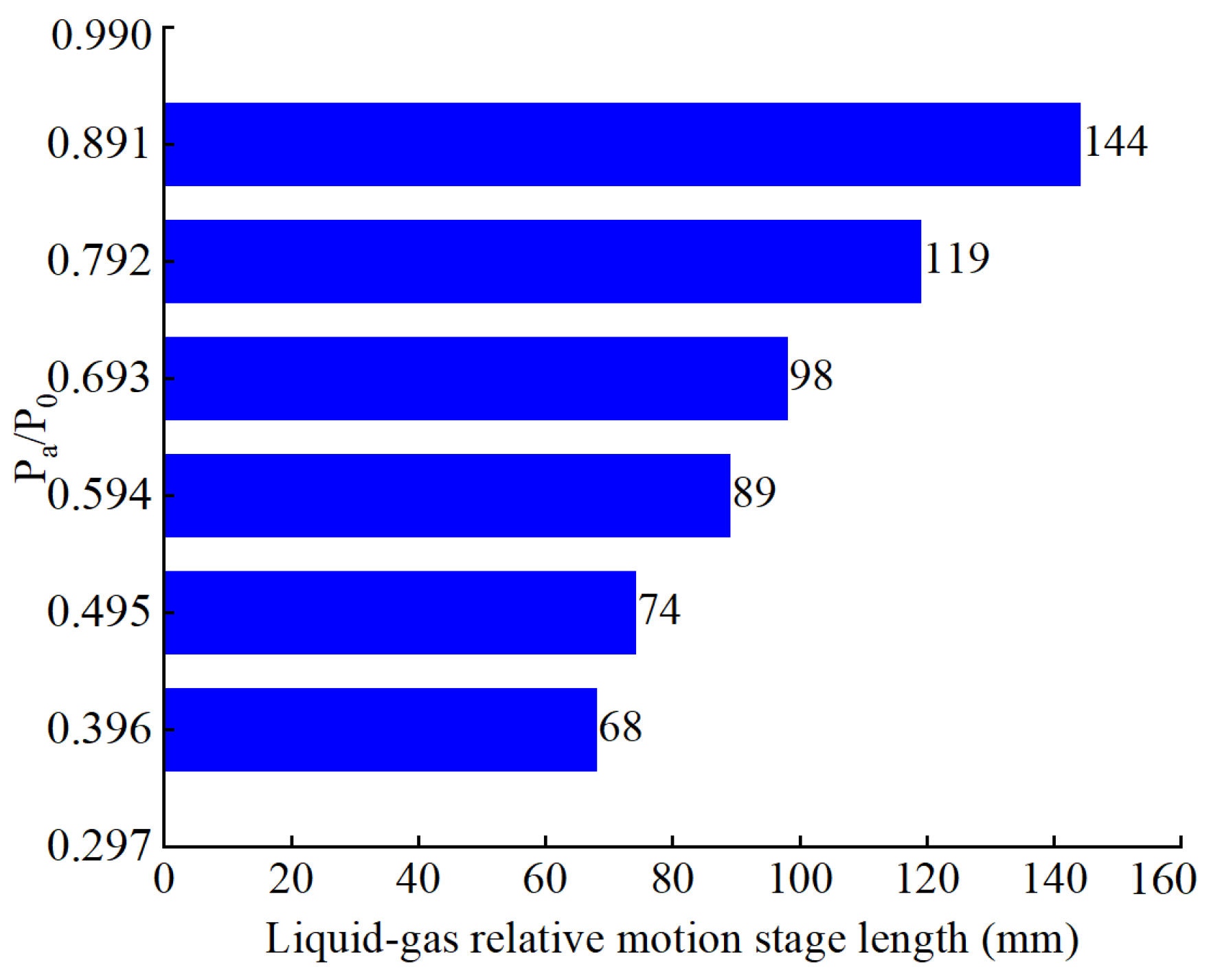

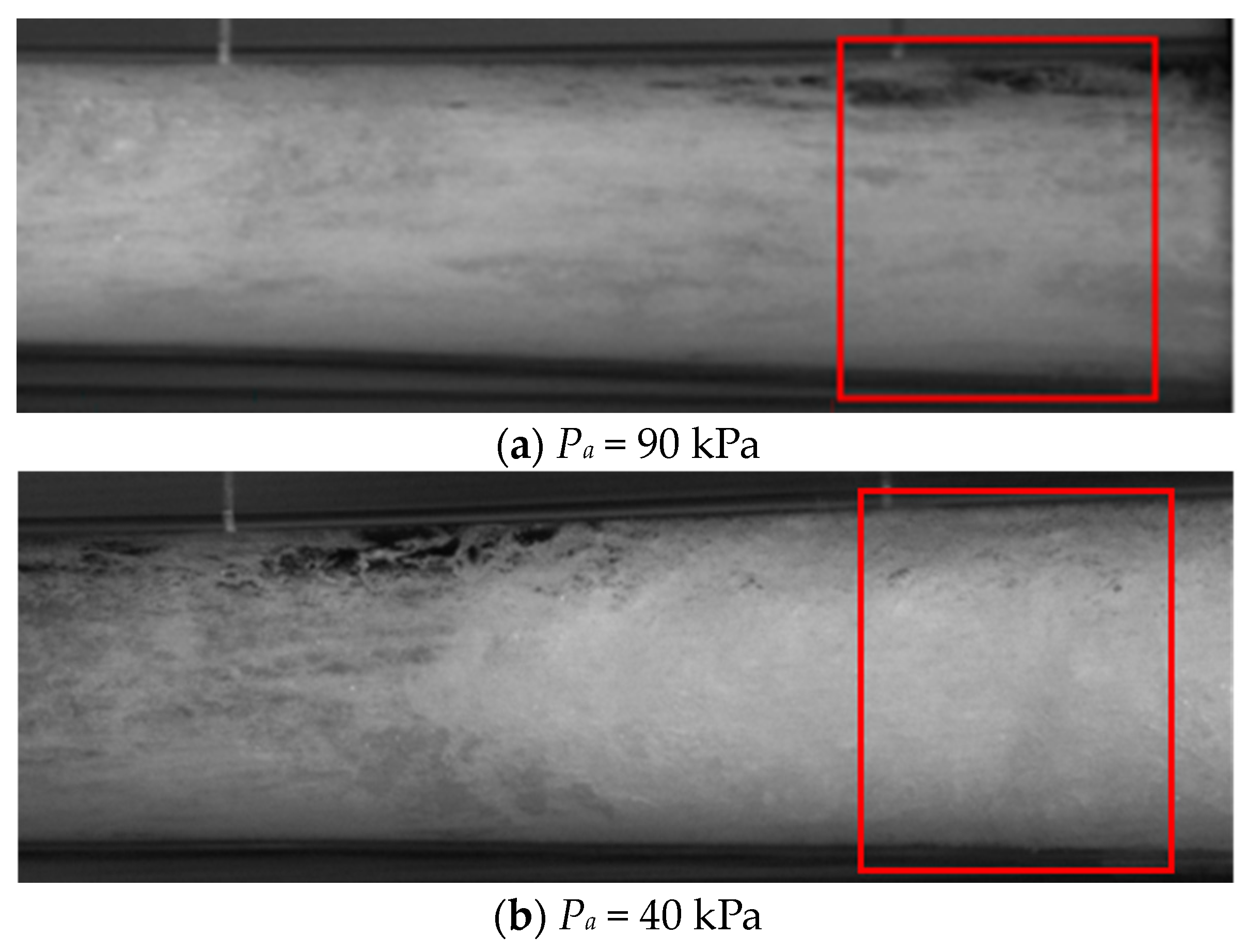

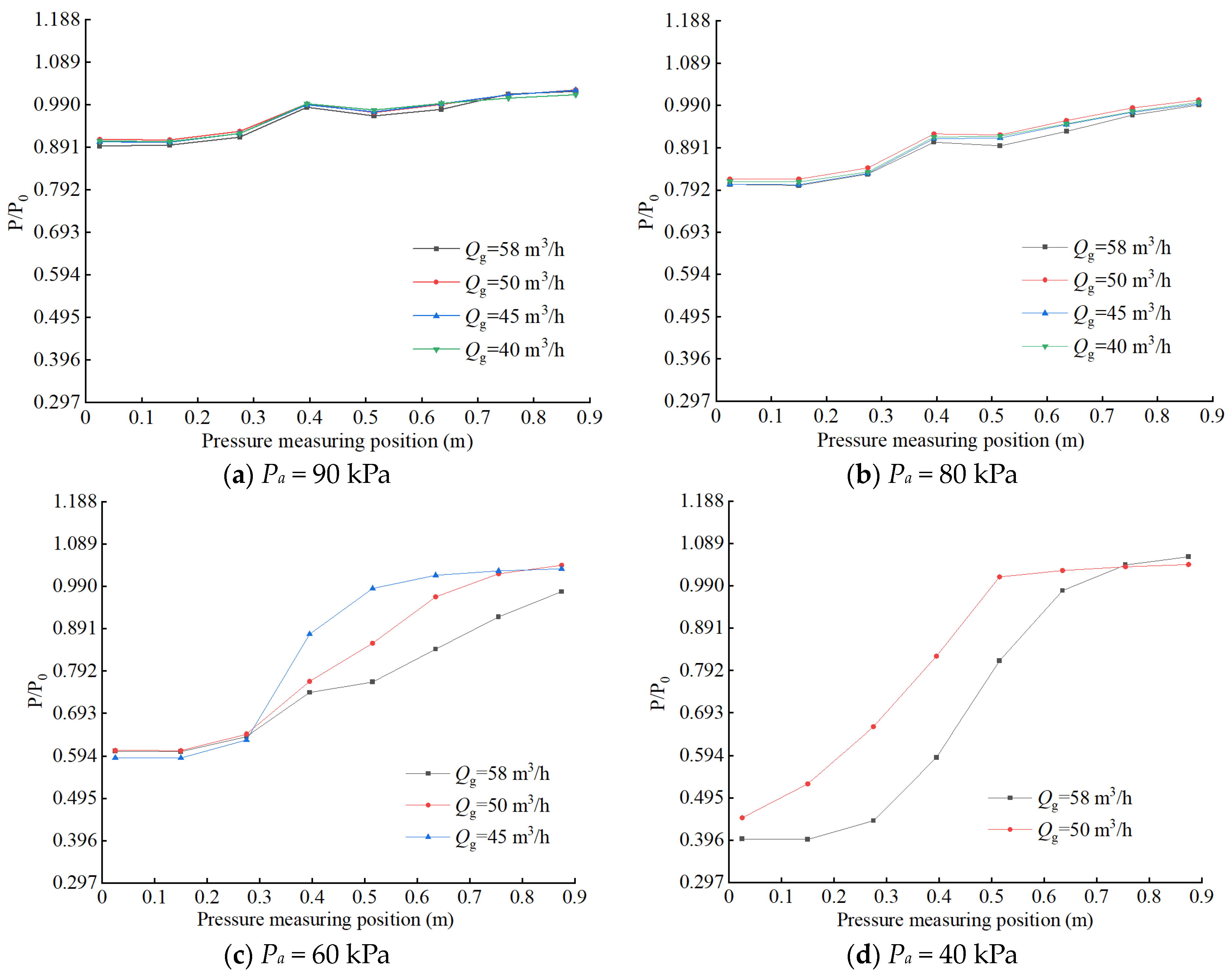

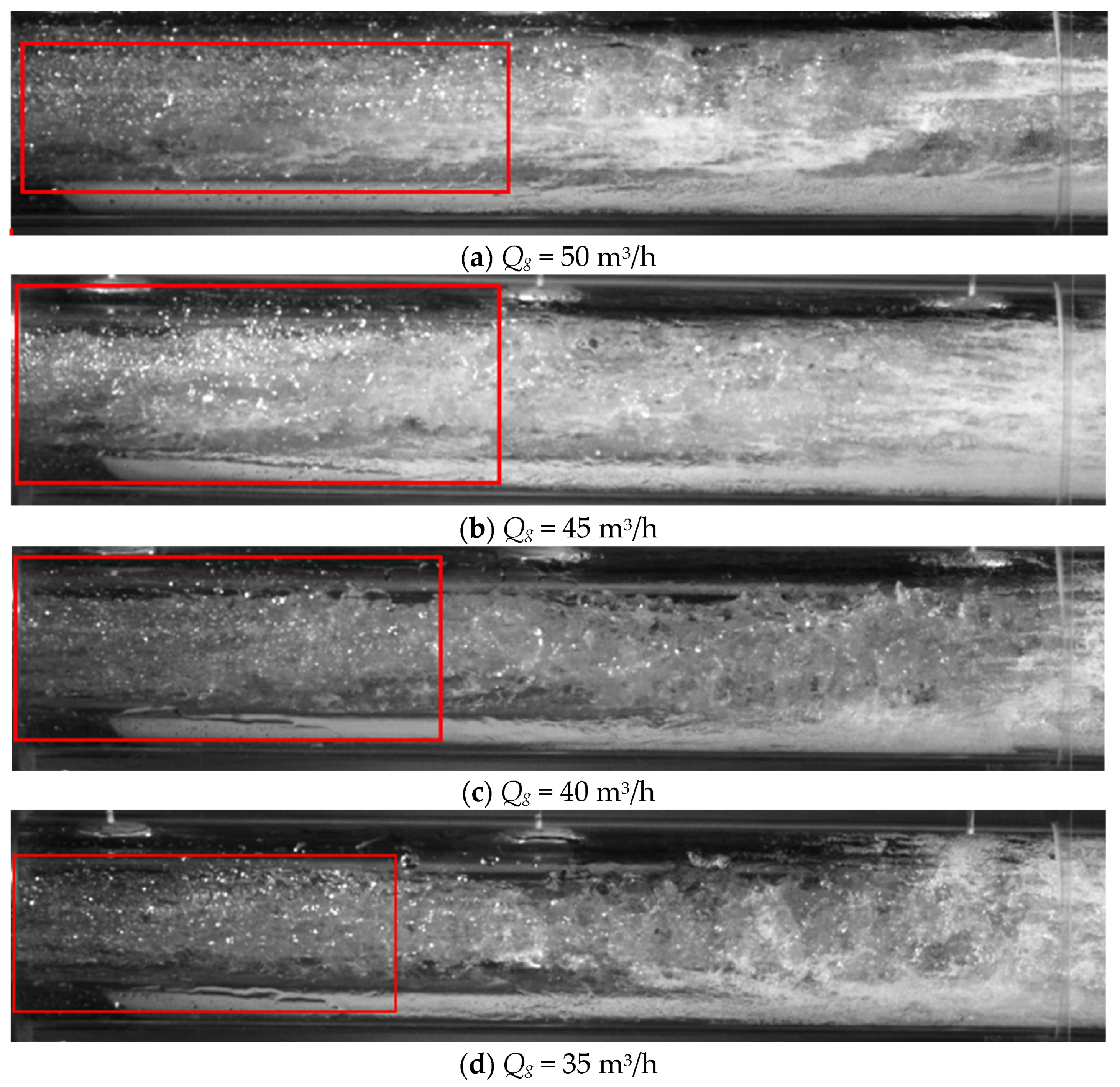

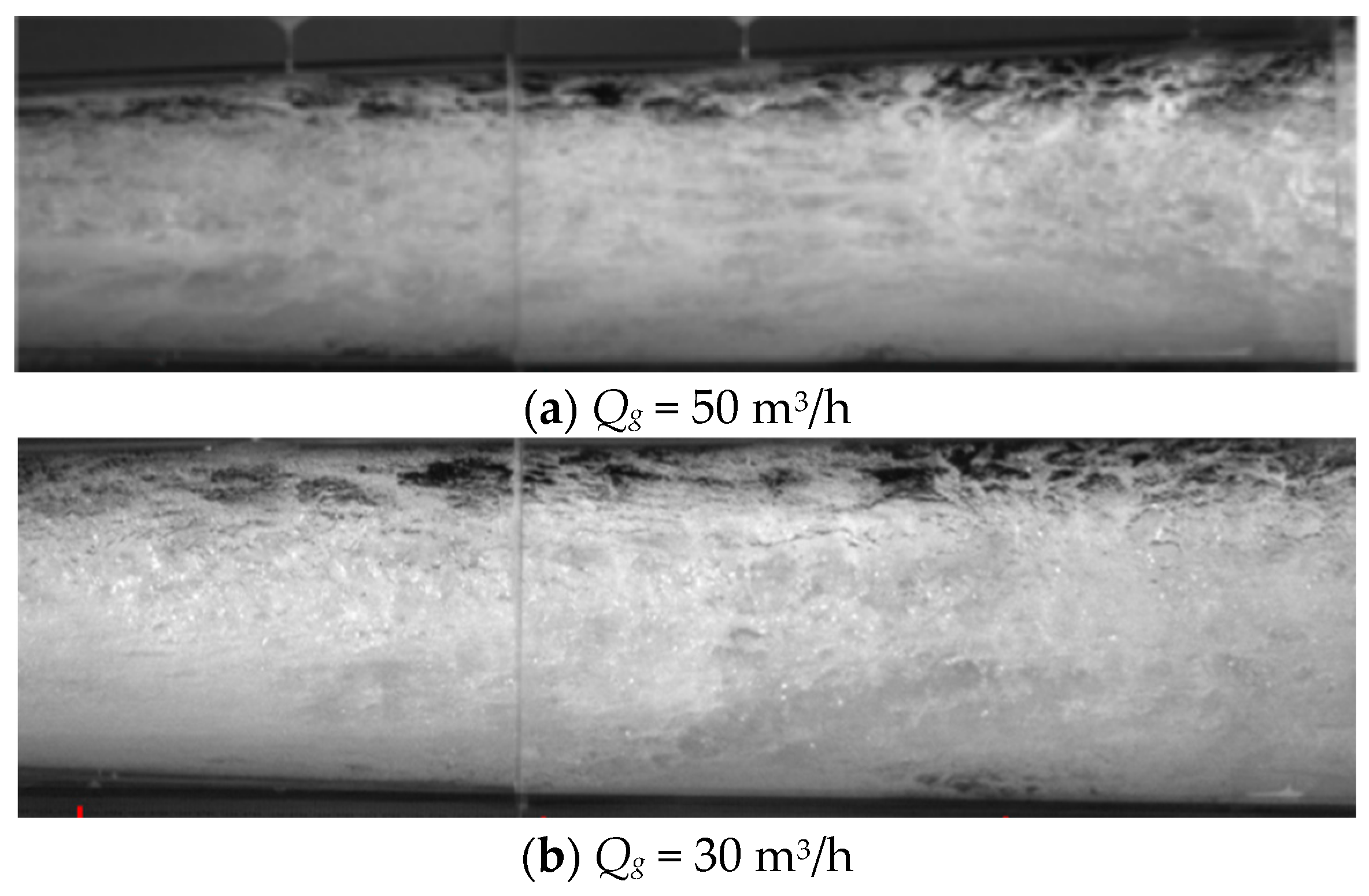

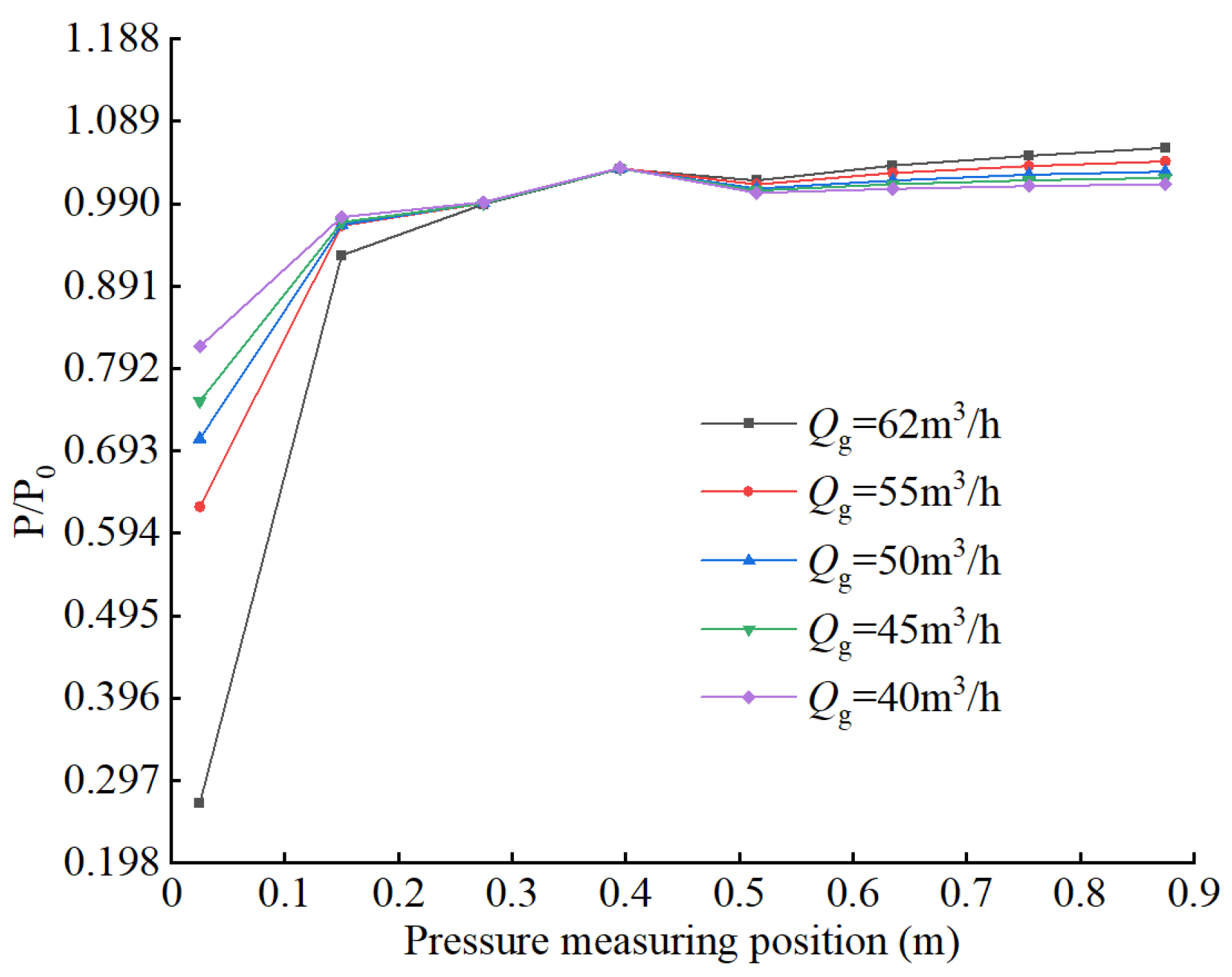

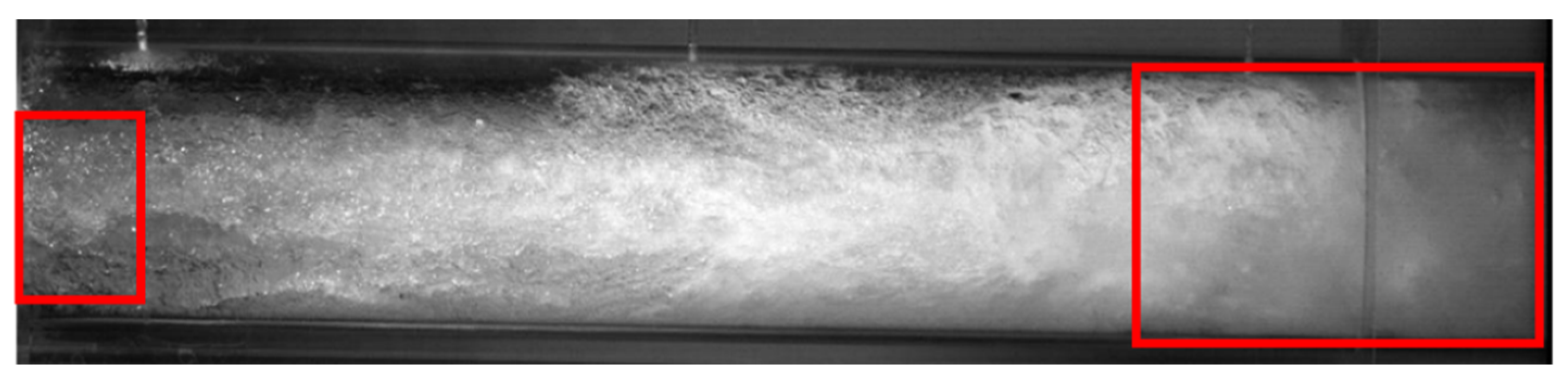

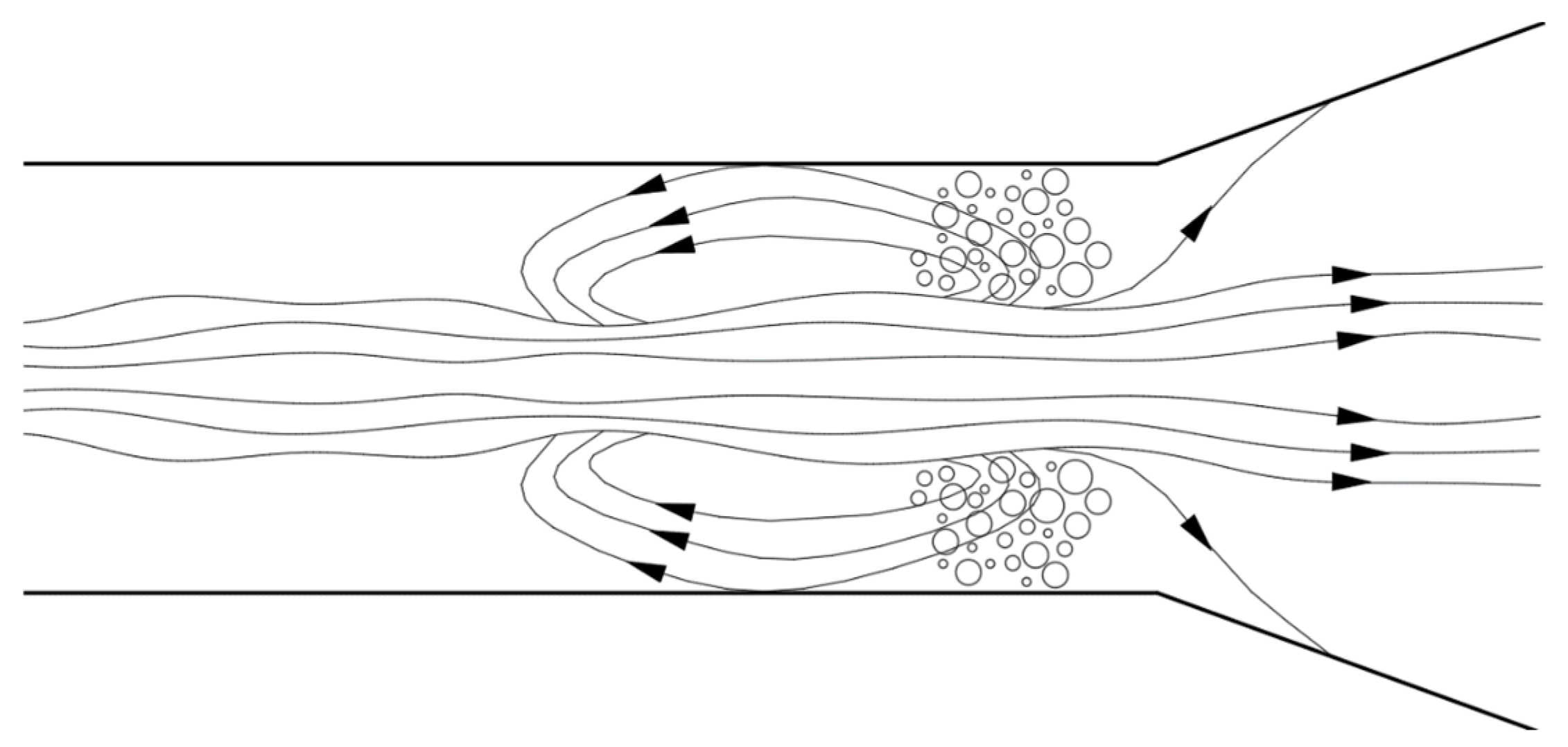

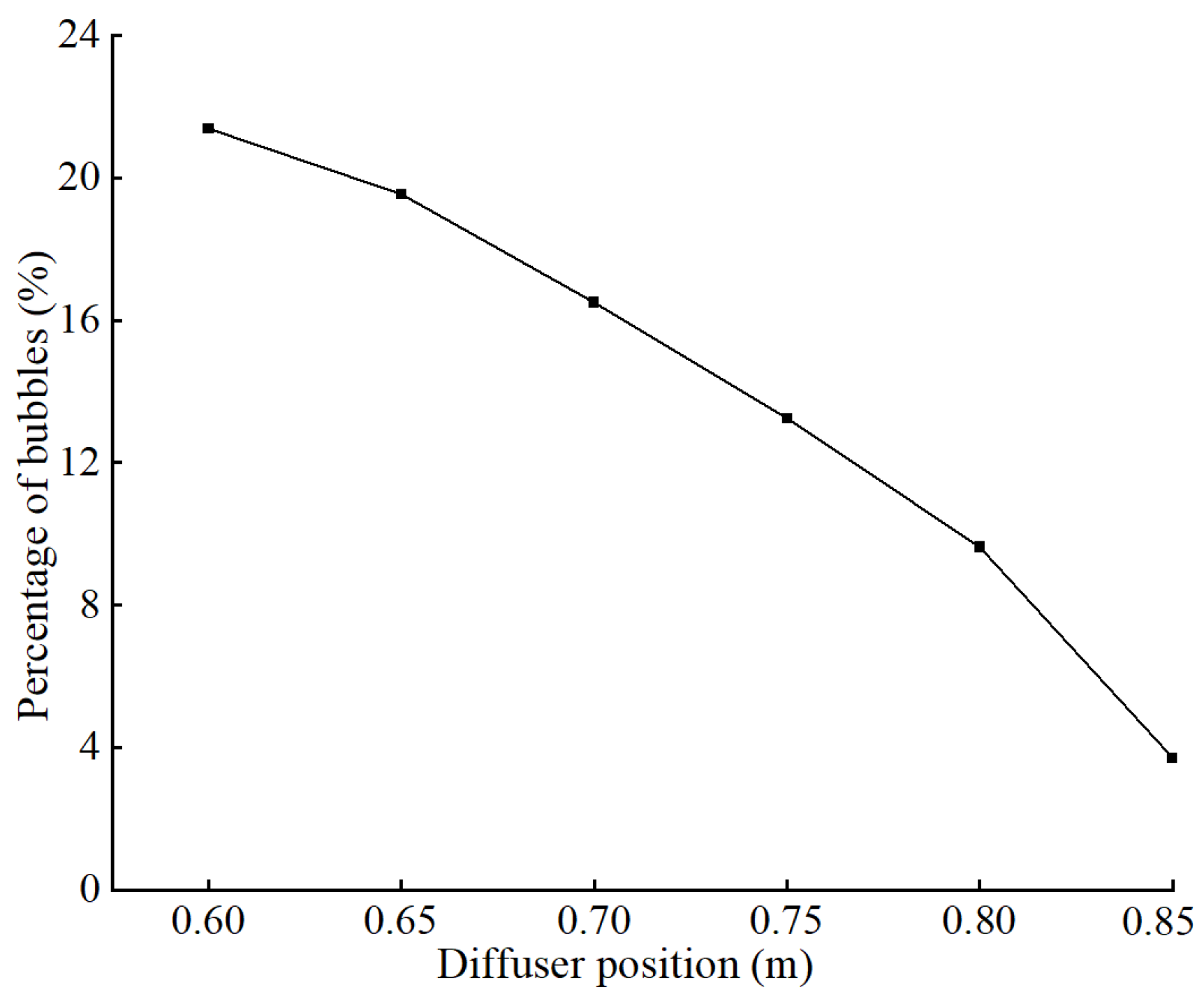

3.2. Internal Mobility Analysis

4. Conclusions

- (1)

- As the inlet pressure rises, the square-nozzle liquid–gas jet vacuum pump pumping volume ratio increases, the maximum volume ratio qmax is 4.93, and the efficiency is higher at low inlet pressures, up to 42.48 per cent, and decreases rapidly at high inlet pressures.

- (2)

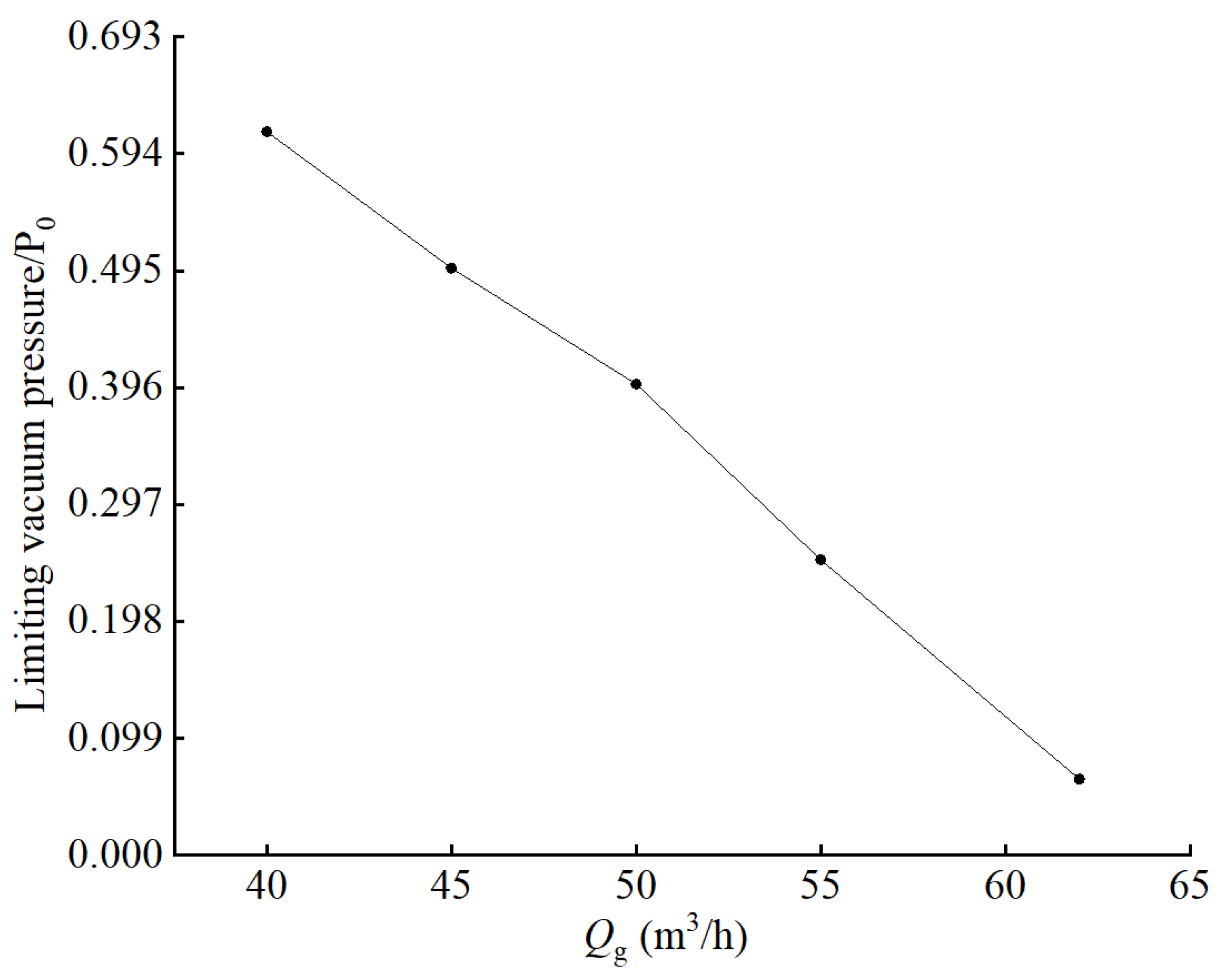

- The pumping volume ratio of the square-nozzle LGJP will increase significantly with the increase in the working water flow rate. The working water flow rate has less influence on the working efficiency, the ultimate vacuum pressure decreases with the increase in the working water flow rate, and the lowest ultimate vacuum pressure is 6.47 kPa.

- (3)

- The length of the phase of liquid–gas relative movement in the throat is shortened with the decrease in working water flow rate and with the decrease in inlet pressure, which further leads to the decrease in pumped gas volume. The higher the degree of mixing of liquid and gas phases in the diffusion tube, the more uniform the distribution of foam flow, and the higher the working efficiency of the liquid–gas jet vacuum pump.

- (4)

- In the extreme vacuum working conditions, the LGJP throat liquid–gas relative movement stage length is extremely short, there is a large number of droplets in the throat after the section of violent reflux, and there is no bubble flow movement stage. There are very few bubbles in the diffusion tube, the bubble diameter along the axis of the movement is gradually reduced, and the number of bubbles is also reduced accordingly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Zhao, G.; Zhao, Y.; Fu, W.; Zheng, Z. Research on hydraulic loss of liquid ring vacuum pump and optimization of shell profile for high efficiency and energy saving. Vacuum 2023, 207, 111633. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Y.; Kang, J.; Zhang, Y.; Meng, F. The effect of discharge areas on the operational performance of a liquid-ring vacuum pump: Numerical simulation and experimental verification. Vacuum 2022, 206, 111425. [Google Scholar] [CrossRef]

- Gao, C. Theory and Test of Pulsed Liquid Jet Pump Technology; China Water Conservancy and Hydropower Press: Beijing, China, 2009. [Google Scholar]

- Huang, F.; Hu, B.; Zuo, W.Q.; Li, S. Experiments on the impact force characteristics of high-pressure water jets with different nozzle shapes. J. Chongqing Univ. 2019, 42, 124–133. [Google Scholar]

- Wu, Z.; Wang, Y.; Zhang, S.; Lv, L.; Wang, W. Numerical simulation of cavitation performance of nozzles of different shapes. Fluid Mach. 2020, 48, 36–41. [Google Scholar]

- Hua, L.; Li, H.; Jiang, Y.; Qin, L. Experimental study on the performance of low and medium pressure spray droplets with square nozzles. J. Irrig. Drain. 2022, 41, 104–109. [Google Scholar]

- Li, Y.; He, X.; Yu, W. Experimental study of the effect of nozzle structure on unsteady jet thrusts. Fluid Mach. 2023, 51, 1–6. [Google Scholar]

- Xu, M.; Long, X.; Yang, X.; Wu, W.; Wang, X.; Wang, X. Effect of nozzle position on the performance of a new annular jet pump. J. Irrig. Drain. Mach. Eng. 2014, 32, 563–566. [Google Scholar]

- Zhang, J.M.; Gan, Z.Y. The effect of a novel nozzle structure on small-scale jets. Laser Technol. 2024, 2, 1–10. [Google Scholar]

- Chen, W.; Fan, W.; Zhang, Q.; Peng, C.; Yuan, C.; Yan, C. Experimental Investigation of Nozzle Effects on Thrust and Inlet Pressure of an Air-breathing Pulse Detonation Engine. Chin. J. Aeronaut. 2012, 3, 381–387. [Google Scholar] [CrossRef]

- Fu, W.; Li, Y.; Liu, Z.; Wu, H.; Wu, T. Numerical study for the influences of primary nozzle on steam ejector performance. Appl. Therm. Eng. 2016, 106, 1148–1156. [Google Scholar] [CrossRef]

- Yun, Q.; Xiang, Q.; Li, H. Experimental study on the performance of several liquid-gas jet pumps with shaped nozzle ejection. Fluid Mach. 2011, 39, 1–16. [Google Scholar]

- Gao, G.; Ling, Y.; Wang, Y. Numerical study of the effect of contraction half angle of throat nozzle section on the flow field characteristics of liquid-gas jet pumps. J. Vac. Sci. Technol. 2020, 40, 174–179. [Google Scholar]

- Isataev, M.S.; Toleuov, G.; Sultan, M. Experimental Investigation of a Free Turbulent Air Jet Outflowing from a Nozzle of Square Shape. J. Eng. Phys. Thermophys. 2020, 93, 172–177. [Google Scholar] [CrossRef]

- Busov, K.A.; Mazheiko, N.A. Boiling of a Jet of Superheated Water with Outlet through a Nozzle with a Square Section. High Temp. 2021, 59, 433–437. [Google Scholar] [CrossRef]

- Muvvala, P.; Balaji, C.; Venkateshan, S.P. Experimental investigation on the effect of wire mesh at the nozzle exit on heat transfer from impinging square jets. Exp. Therm. Fluid Sci. 2017, 84, 78–89. [Google Scholar] [CrossRef]

- Witte, J.H. Mixing Shocks and Their Influence on the Design of Liquid-Gas Ejectors. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 1962. [Google Scholar]

- Liao, D.; Lu, H. Study on the basic performance of liquid-liquid-gas jet pump and each correction factor. Hydrodyn. Res. Prog. 1996, 11, 610–617. [Google Scholar]

- Zhang, H.; Zou, D.; Yang, X.; Mou, J.; Zhou, Q.; Xu, M. Liquid-Gas Jet Pump: A Review. Energies 2022, 15, 6978. [Google Scholar] [CrossRef]

- Ge, Q. Establishment of Mathematical Model of Liquid-Gas Jet Pump and Its Numerical Simulation Study. Master’s Thesis, Dalian Jiaotong University, Dalian, China, 2012. [Google Scholar]

- Ge, Y.J.; Ge, Q.; Yang, J. Numerical simulation of throat-to-nozzle distance and determination of its optimal range for liquid-gas jet pump. Fluid Mach. 2012, 40, 21–24. [Google Scholar]

- Xing, R. Liquid-Gas Two-Phase Jet Pump for Non-Condensable Gas Extraction 3D Simulation Study. Master’s Thesis, Shandong University, Jinan, China, 2020. [Google Scholar]

- Zhou, Q.; Zhu, C.; Yang, X.; Chen, J.; Mou, J. Flow Channel Optimization to Improve the Performance of a Liquid-gas Ejector for an Intelligent Toilet Spray Bar. Atmosphere 2024, 15, 58. [Google Scholar]

- Chen, W. Study and Design Optimisation of Suction Characteristics of Liquid-Gas Jet Pump Based on CFD Simulation. Master’s Thesis, Northeastern University, Shenyang, China, 2014. [Google Scholar]

- Bonnington, S.T.; King, A.L. Jet Pumps and Ejectors—A State of the Art Review and Bibliography; Fluid Engineering: London, UK, 1972. [Google Scholar]

- Gebouský, O.; Mařík, K.; Haidl, J.; Zednikova, M. Enhancement of gas entrainment rate in liquid-gas ejector pump. Chem. Eng. Res. Des. 2023, 189, 117–125. [Google Scholar] [CrossRef]

- Cunningham, R.G. Liquid jet pumps for two-phase flows. J. Fluids Eng. 1995, 117, 309–316. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Y.; Chen, H.; Lei, T.; Chen, X.; Wang, X. Experiments on the basic performance of pulsed liquid-gas jet pumps. Nucl. Power Eng. 2010, 31, 133–137. [Google Scholar]

- Xiang, Q.; Wang, C.; Wu, Y.; Li, H. Experimental study on the flow inside the diffusion tube of a liquid-gas jet pump. J. Irrig. Drain. Mach. Eng. 2014, 32, 558–562. [Google Scholar]

- Xu, X.; Mou, J.; Zhang, H.; Zou, D.; Yang, X.; Liu, X.; Qiu, Z.; Dong, B. Experimental Study on Performance of Liquid-Gas Jet Pump with Square Nozzle. Energies 2023, 16, 7951. [Google Scholar] [CrossRef]

- Kumar, R.S.; Mani, A.; Kumaraswamy, S. Analysis of a jet-pump-assisted vacuum desalination system using power plant waste heat. Desalination 2005, 179, 345–354. [Google Scholar] [CrossRef]

- Wang, Y.L. Study on Characteristics of Liquid Gas Jet Pump. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2015. [Google Scholar]

- Xiang, Q.J.; Yun, Q.L.; Li, H. Experiment Study on Hydraulic Performance of Liquid Jet Gas Pump with Wide Range of Area Ratio. Fluid Mach. 2012, 40, 1–5. [Google Scholar]

- Wei, X.; Zhang, R. The axial tip clearance leakage analysis of the winglet and composite blade tip for the liquid-ring vacuum pump. Vacuum 2022, 200, 111027. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Z.; Yang, X.; Xu, X.; Zhu, C.; Zou, D.; Zhou, Q.; Fang, K.; Zhang, X.; Mou, J. Experimental Study on the Performance and Internal Flow Characteristics of Liquid–Gas Jet Pump with Square Nozzle. Water 2024, 16, 2358. https://doi.org/10.3390/w16172358

Cao Z, Yang X, Xu X, Zhu C, Zou D, Zhou Q, Fang K, Zhang X, Mou J. Experimental Study on the Performance and Internal Flow Characteristics of Liquid–Gas Jet Pump with Square Nozzle. Water. 2024; 16(17):2358. https://doi.org/10.3390/w16172358

Chicago/Turabian StyleCao, Zhengqing, Xuelong Yang, Xiao Xu, Chenbing Zhu, Daohang Zou, Qiwei Zhou, Kaiyue Fang, Xinchen Zhang, and Jiegang Mou. 2024. "Experimental Study on the Performance and Internal Flow Characteristics of Liquid–Gas Jet Pump with Square Nozzle" Water 16, no. 17: 2358. https://doi.org/10.3390/w16172358

APA StyleCao, Z., Yang, X., Xu, X., Zhu, C., Zou, D., Zhou, Q., Fang, K., Zhang, X., & Mou, J. (2024). Experimental Study on the Performance and Internal Flow Characteristics of Liquid–Gas Jet Pump with Square Nozzle. Water, 16(17), 2358. https://doi.org/10.3390/w16172358