Impact of an Integral Management System with Constructed Wetlands in Pig Slurry Traceability and GHG/NH3 Emissions

Abstract

1. Introduction

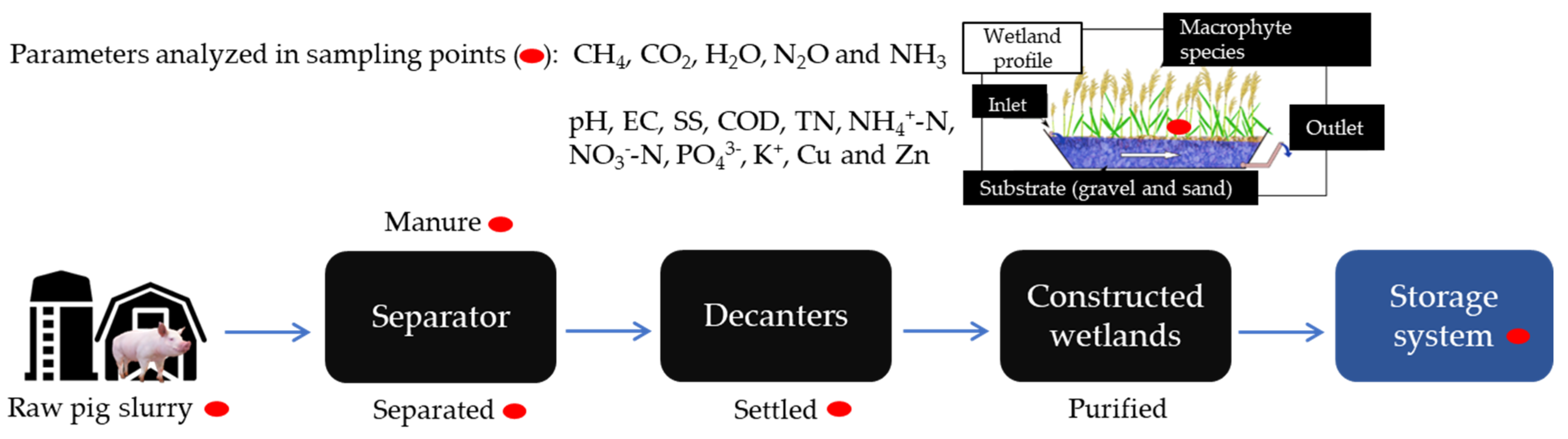

2. Materials and Methods

2.1. Operation

2.2. Pig Slurry Parameters and Methodology

2.3. Experimental Design and Methodology for Measuring Emissions in Pig Slurry Storage Systems

- Raw slurry (RAW, measurements made in the storage tank that receives raw pig slurry).

- Slurry after the phase separator (SEP, measurements made in the first settling pond).

- Settled slurry (DEC, measurements made between the fifth and sixth settling pond).

- Purified slurry (PUR, measurements made in the purified slurry storage pond subjected to drying conditions).

- Manure (MAN, measurements made on a pile of fresh manure resulting from the phase separator).

- Wetland surface without vegetation (WC).

- Wetland surface planted with Phragmites australis (WV).

3. Results

3.1. Pig Slurry and Manure

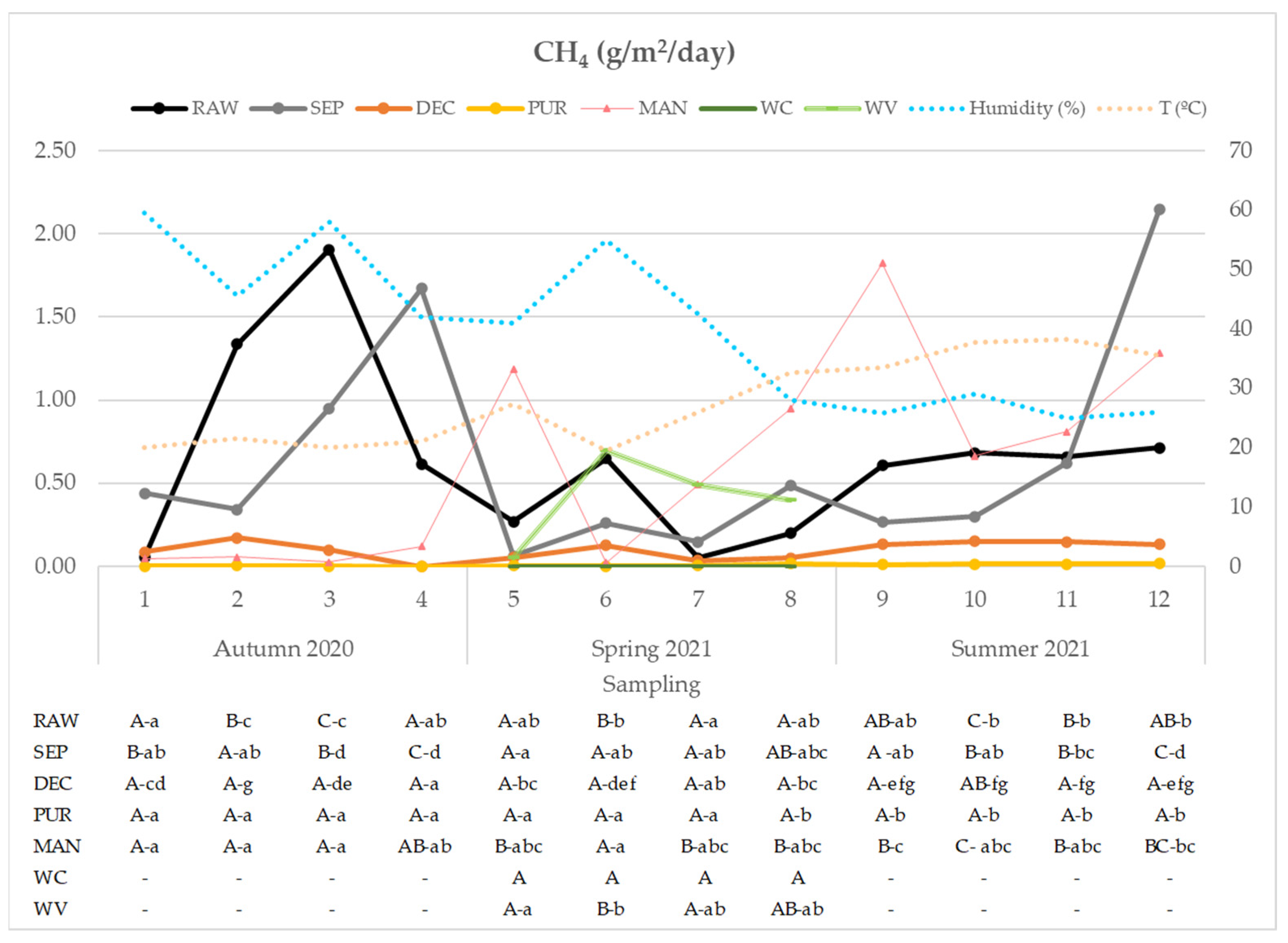

3.2. Gas Emissions during Storage

4. Discussion

4.1. Investigation Facilities and Schedule of the Integral Treatment with Wetlands

4.2. Pig Slurry Traceability

4.3. GHG/NH3 Emissions in Pig Slurry Fractions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huygens, D.; Orveillon, G.; Lugato, E.; Tavazzi, S.; Comero, S.; Jones, A.; Gawlik, B.; Saveyn, H. Technical Proposals for the Safe Use of Processed Manure above the Threshold Established for Nitrate Vulnerable Zones by the Nitrates Directive (91/676/EEC), EUR 30363 EN, 2020th ed.; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Torrens, A.; Folch, M.; Salgot, M. Design and Performance of an Innovative Hybrid Constructed Wetland for Sustainable Pig Slurry Treatment in Small Farms. Front. Environ. Sci. 2021, 8, 577186. [Google Scholar] [CrossRef]

- Scholz, M. Piggery Wastewater Treatment with Integrated Constructed Wetlands. In Wetlands for Water Pollution Control; Elsevier: Amsterdam, The Netherlands, 2016; pp. 419–432. [Google Scholar] [CrossRef]

- Cocolo, G.; Hjorth, M.; Zarebska, A.; Provolo, G. Effect of acidification on solid–liquid separation of pig slurry. Biosyst. Eng. 2016, 143, 20–27. [Google Scholar] [CrossRef]

- Karakashev, D.; Schmidt, J.E.; Angelidaki, I. Innovative process scheme for removal of organic matter, phosphorus and nitrogen from pig manure. Water Res. 2008, 42, 4083–4090. [Google Scholar] [CrossRef]

- Burton, C.H. Manure management: Treatment strategies for sustainable agriculture, 2nd edition. Livest. Sci. 2006, 102, 256–257. [Google Scholar] [CrossRef]

- Burton, C.H. The potential contribution of separation technologies to the management of livestock manure. Livest. Sci. 2007, 112, 208–216. [Google Scholar] [CrossRef]

- Terrero, M.A.; Muñoz, M.Á.; Faz, Á.; Gómez-López, M.D.; Acosta, J.A. Efficiency of an integrated purification system for pig slurry treatment under mediterranean climate. Agronomy 2020, 10, 208. [Google Scholar] [CrossRef]

- Kadlec, H.R.; Wallace, D.S. Treatment Wetlands, 2nd ed.; Taylor & Francis Group: Boca Ratón, FL, USA, 2009. [Google Scholar]

- Parde, D.; Patwa, A.; Shukla, A.; Vijay, R.; Killedar, D.J.; Kumar, R. A review of constructed wetland on type, treatment and technology of wastewater. Environ. Technol. Innov. 2021, 21, 101261. [Google Scholar] [CrossRef]

- Ottová, V.; Balcarová, J.; Vymazal, J. Microbial characteristics of constructed wetlands. Water Sci. Technol. 1997, 35, 117. [Google Scholar] [CrossRef]

- Harrington, C.; Scholz, M.; Culleton, N.; Lawlor, P.G. The use of integrated constructed wetlands (ICW) for the treatment of separated swine wastewaters. Hydrobiologia 2012, 692, 111–119. [Google Scholar] [CrossRef]

- Scholz, M. Wetlands for Water Pollution Control; Elsevier: Amsterdam, The Netherlands, 2016; pp. 137–155. [Google Scholar] [CrossRef]

- Knight, R.L.; Payne, V.W., Jr.; Borer, R.E.; Clarke, R.A., Jr.; Pries, J.H. Constructed wetlands for livestock wastewater management. Ecol. Eng. 2000, 15, 41–55. [Google Scholar] [CrossRef]

- Hsu, C.-B.; Hsieh, H.-L.; Yang, L.; Wu, S.-H.; Chang, J.-S.; Hsiao, S.-C.; Su, H.-C.; Yeh, C.-H.; Ho, Y.-S.; Lin, H.-J. Biodiversity of constructed wetlands for wastewater treatment. Ecol. Eng. 2011, 37, 1533–1545. [Google Scholar] [CrossRef]

- García-Valero, A.; Martínez-Martínez, S.; Faz, Á.; Terrero, M.A.; Muñoz, M.Á.; Gómez-López, M.D.; Acosta, J.A. Treatment of wastewater from the tannery industry in a constructed wetland planted with Phragmites australis. Agronomy 2020, 10, 176. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed wetlands for treatment of industrial wastewaters: A review. Ecol. Eng. 2014, 73, 724–751. [Google Scholar] [CrossRef]

- Vymazal, J. The use constructed wetlands with horizontal sub-surface flow for various types of wastewater. Ecol. Eng. 2009, 35, 1–17. [Google Scholar] [CrossRef]

- Kadlec, R.H.; Knight, R.L. Treatment Wetland; Lewis Publishers: Boca Ratón, FL, USA, 1997. [Google Scholar]

- Haddis, A.; Van der Bruggen, B.; Smets, I. Constructed wetlands as nature based solutions in removing organic pollutants from wastewater under irregular flow conditions in a tropical climate. Ecohydrol. Hydrobiol. 2020, 20, 38–47. [Google Scholar] [CrossRef]

- Vymazal, J.; Kröpfelová, L. Multistage hybrid constructed wetland for enhanced removal of nitrogen. Ecol. Eng. 2015, 84, 202–208. [Google Scholar] [CrossRef]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Duchaufour, P. Precis de Pedologie; Masson: Paris, France, 1970. [Google Scholar]

- Santonja, G.G.; Georgitzikis, K.; Scalet, B.M.; Montobbio, P.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar] [CrossRef]

- Brix, H. Do macrophytes play a role in constructed treatment wetlands? Water Sci. Technol. 1997, 35, 11–17. [Google Scholar] [CrossRef]

- Tanner, C.C. Plants for constructed wetland treatment systems—A comparison of the growth and nutrient uptake of eight emergent species. Ecol. Eng. 1996, 7, 59–83. [Google Scholar] [CrossRef]

- Jiang, X.; Tian, Y.; Ji, X.; Lu, C.; Zhang, J. Influences of plant species and radial oxygen loss on nitrous oxide fluxes in constructed wetlands. Ecol. Eng. 2020, 142, 105644. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed Wetlands for Wastewater Treatment: Five Decades of Experience. Environ. Sci. Technol. 2011, 45, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Zhang, J.; Ngo, H.H.; Guo, W.; Hu, Z.; Liang, S.; Fan, J.; Liu, H. A review on the sustainability of constructed wetlands for wastewater treatment: Design and operation. Bioresour. Technol. 2015, 175, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Guzmán, F.R.; de Ursinos, J.A.F.R.; Escobar, F.C.; Mateos, P.A.; Barrantes, M.M.D. Proceso ecológico-fotosintético para la depuración de purines en granjas. Tecnol. Agua 2000, 201, 61–66. [Google Scholar]

- Caballero-Lajarín, A. Sistema de Depuración de Aguas Residuales de Origen Ganadero: Humedales artificiales. Ph.D. Thesis, Universidad Politécnica de Cartagena, Cartagena, Spain, 2013. [Google Scholar]

- Caballero-Lajarín, A.; Zornoza, R.; Faz, A.; Lobera, J.B.; Muñoz, M.A.; Domínguez-Oliver, S.G. Combination of Low-Cost Technologies for Pig Slurry Purification under Semiarid Mediterranean Conditions. Water Air Soil Pollut. 2015, 226, 1–15. [Google Scholar] [CrossRef]

- Scholz, M.; Harrington, R.; Carroll, P.; Mustafa, A. The Integrated Constructed Wetlands (ICW) concept. Wetlands 2007, 27, 337–354. [Google Scholar] [CrossRef]

- Mashauri, D.A.; Mulungu, D.M.M.; Abdulhussein, B.S. Constructed wetland at the University of Dar es Salaam. Water Res. 2000, 34, 1135–1144. [Google Scholar] [CrossRef]

- Polprasert, C.; Kittipongvises, S. Constructed Wetlands and Waste Stabilization Ponds. Treatise Water Sci. 2011, 4, 277. [Google Scholar] [CrossRef]

- Christensen, M.L.; Hjorth, M.; Keiding, K. Characterization of pig slurry with reference to flocculation and separation. Water Res. 2009, 43, 773–783. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Mitsch, W.J. A detailed ecosystem model of phosphorus dynamics in created riparian wetlands. Ecol. Model. 2000, 126, 101–130. [Google Scholar] [CrossRef]

- Schulz, C.; Gelbrecht, J.; Rennert, B. Treatment of rainbow trout farm effluents in constructed wetland with emergent plants and subsurface horizontal water flow. Aquaculture 2003, 217, 207–221. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Soli-liquid separation of animal slurry in therory and practice. A review. Agron. Sustain. Dev. 2010, 30, 153. [Google Scholar]

- Stottmeister, U.; Wießner, A.; Kuschk, P.; Kappelmeyer, U.; Kästner, M.; Bederski, O.; Müller, R.A.; Moormann, H. Effects of plants and microorganisms in constructed wetlands for wastewater treatment. Biotechnol. Adv. 2003, 22, 93–117. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.-F.; Ye, G.-Y.; Yi, N.-K.; Lu, L.-J.; Zhang, L.; Yang, L.-Y.; Xiao, L.; Liu, J. Effect of plant physiological characteristics on the removal of conventional and emerging pollutants from aquaculture wastewater by constructed wetlands. Ecol. Eng. 2019, 135, 45–53. [Google Scholar] [CrossRef]

- Real Decreto 306, de 11 de Febrero, por el que se Establecen Normas Básicas de Ordenación de las Granjas Porcinas Intensivas, y se Modifica la Normativa Básica de Ordenación de las Explotaciones de Ganado Porcino Extensivo, Boletín Oficial Del Estado (2020) 13761–13791. Available online: https://www.boe.es/buscar/doc.php?id=BOE-A-2020-2110 (accessed on 21 August 2020).

- Møller, H.B.; Lund, I.; Sommer, S.G. Solid–liquid separation of livestock slurry: Efficiency and cost. Bioresour. Technol. 2000, 74, 223–229. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A.; Fijorek, K. Changes in the properties of pig manure slurry. Acta Biochim. Pol. 1970, 60, 845–850. [Google Scholar] [CrossRef]

- Dinuccio, E.; Berg, W.; Balsari, P. Gaseous emissions from the storage of untreated slurries and the fractions obtained after mechanical separation. Atmos. Environ. 2008, 42, 2448–2459. [Google Scholar] [CrossRef]

- Husted, S. Seasonal Variation in Methane Emission from Stored Slurry and Solid Manures. J. Environ. Qual. 1994, 23, 585–592. [Google Scholar] [CrossRef]

- Veillette, M.; Girard, M.; Viens, P.; Brzezinski, R.; Heitz, M. Function and limits of biofilters for the removal of methane in exhaust gases from the pig industry. Appl. Microbiol. Biotechnol. 2012, 94, 601–611. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Wang, C.; Liu, C.; Sun, H.; Zhang, J.; Zhang, X.; Xin, L. Nutrient removal, methane and nitrous oxide emissions in a hybrid constructed wetland treating anaerobic digestate. Sci. Total Environ. 2020, 733, 138338. [Google Scholar] [CrossRef]

- Wolter, M.; Prayitno, S.; Schuchardt, F. Greenhouse gas emission during storage of pig manure on a pilot scale. Bioresour. Technol. 2004, 95, 235–244. [Google Scholar] [CrossRef]

- Jeppsson, K.-H. SE—Structure and Environment: Carbon Dioxide Emission and Water Evaporation from Deep Litter Systems. J. Agric. Eng. Res. 2000, 77, 429–440. [Google Scholar] [CrossRef]

- Møller, H.B.; Sommer, S.G.; Ahring, B.K. Biological Degradation and Greenhouse Gas Emissions during Pre-Storage of Liquid Animal Manure. J. Environ. Qual. 2004, 33, 27–36. [Google Scholar] [CrossRef]

- Philippe, F.-X.; Nicks, B. Review on greenhouse gas emissions from pig houses: Production of carbon dioxide, methane and nitrous oxide by animals and manure. Agric. Ecosyst. Environ. 2015, 199, 10–25. [Google Scholar] [CrossRef]

- Oenema, O.; Bannink, A.; Sommer, S.G.; Van Groenigen, J.W.; Velthof, G.L. Chapter 12—Gaseous Nitrogen Emissions from Livestock Farming Systems. In Nitrogen in the Environment, 2nd ed.; Hatfield, J.L., Follett, R.F., Eds.; Academic Press: San Diego, CA, USA, 2008; pp. 395–441. [Google Scholar] [CrossRef]

- Wrage, N.; Velthof, G.L.; Van Beusichem, M.L.; Oenema, O. Role of nitrifier denitrification in the production of nitrous oxide. Soil Biol. Biochem. 2001, 33, 1723–1732. [Google Scholar] [CrossRef]

- Inamori, R.; Wang, Y.; Yamamoto, T.; Zhang, J.; Kong, H.; Xu, K.; Inamori, Y. Seasonal effect on N2O formation in nitrification in constructed wetlands. Chemosphere 2008, 73, 1071–1077. [Google Scholar] [CrossRef] [PubMed]

- Søvik, A.K.; Kløve, B. Emission of N2O and CH4 from a constructed wetland in southeastern Norway. Sci. Total Environ. 2007, 380, 28–37. [Google Scholar] [CrossRef] [PubMed]

- Mander, Ü.; Dotro, G.; Ebie, Y.; Towprayoon, S.; Chiemchaisri, C.; Nogueira, S.F.; Jamsranjav, B.; Kasak, K.; Truu, J.; Tournebize, J.; et al. Greenhouse gas emission in constructed wetlands for wastewater treatment: A review. Ecol. Eng. 2014, 66, 19–35. [Google Scholar] [CrossRef]

- Zahn, J.A.; Hatfield, J.L.; Laird, D.A.; Hart, T.T.; Do, Y.S.; DiSpirito, A.A. Functional Classification of Swine Manure Management Systems Based on Effluent and Gas Emission Characteristics. J. Environ. Qual. 2001, 30, 635–647. [Google Scholar] [CrossRef] [PubMed]

- Dewes, T. Effect of pH, temperature, amount of litter and storage density on ammonia emissions from stable manure. J. Agric. Sci. 1996, 127, 501–509. [Google Scholar] [CrossRef]

- Ni, J. Mechanistic Models of Ammonia Release from Liquid Manure: A Review. J. Agric. Eng. Res. 1999, 72, 1–17. [Google Scholar] [CrossRef]

- Osada, T.; Shiraishi, M.; Hasegawa, T.; Kawahara, H. Methane, nitrous oxide and ammonia generation in full-scale swine wastewater purification facilities. Front. Environ. Sci. Eng. 2017, 11, 10. [Google Scholar] [CrossRef]

| Stage | Work Units | Processed Volume | Characteristic * |

|---|---|---|---|

| Phase separator (Segalés, Kompact 1-100) | 1 | 10–12 m3/h | Mesh: 500 µm |

| Decanters (bricklaying and plumbing work) | 6 units in series | 160 m3/week | 3.20 × 36.25 × 0.42 m |

| Constructed wetlands (bricklaying and plumbing work) | 25 independent units | 50–100 m3/week | Cell size: 25 × 1.7 × 1.2 m |

| Filling substrates (from below): 30 cm fine gravel (ø = 2–20 mm) 50 cm coarse gravel (ø = 20–40 mm) 10 cm fine gravel 30 cm washed sand | |||

| HRT: 3-5-20 days Phragmites australis (5 plants/m2) |

| Season | Autumn | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample type ** | RAW | SEP | DEC | PUR | Red (%) *** | ||||||||||||

| Parameter * | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | |||||

| pH | 7.37 | ± | 0.02 | a | 7.55 | ± | 0.01 | b | 7.92 | ± | 0.03 | c | 7.90 | ± | 0.06 | c | - |

| EC (ds m−1) | 15.34 | ± | 0.13 | c | 15.62 | ± | 0.22 | c | 12.77 | ± | 0.20 | b | 12.05 | ± | 0.26 | a | 21 |

| SS (mg L−1) | 483.3 | ± | 28.9 | c | 366.7 | ± | 28.9 | b | 4.2 | ± | 3.4 | a | 0.0 | ± | 0.0 | a | 100 |

| COD (g L−1) | 25.67 | ± | 3.79 | c | 17.67 | ± | 3.21 | b | 5.47 | ± | 0.40 | a | 5.15 | ± | 1.24 | a | 80 |

| TN (g L−1) | 2.13 | ± | 0.51 | b | 1.97 | ± | 0.41 | b | 1.29 | ± | 0.05 | ab | 1.05 | ± | 0.06 | a | 50 |

| NH4+-N (g L−1) | 1.52 | ± | 0.04 | b | 1.65 | ± | 0.36 | b | 1.00 | ± | 0.02 | a | 0.70 | ± | 0.05 | a | 54 |

| NO3−-N (mg L−1) | 5.87 | ± | 0.19 | b | 6.55 | ± | 0.11 | b | 5.74 | ± | 0.56 | b | 4.26 | ± | 0.34 | a | 27 |

| PO43− (mg L−1) | 323.7 | ± | 302.3 | ab | 553.2 | ± | 3.1 | b | 78.2 | ± | 11.4 | a | 0.0 | ± | 0.0 | a | 100 |

| K+ (mg L−1) | 1348.8 | ± | 51.2 | d | 1279.7 | ± | 3.6 | c | 1021.7 | ± | 1.8 | b | 917.2 | ± | 11.1 | a | 32 |

| Cu (mg L−1) | 0.05 | ± | 0.01 | b | 0.05 | ± | 0.01 | b | 0.04 | ± | 0.00 | b | 0.00 | ± | 0.00 | a | - |

| Zn (mg L−1) | 0.07 | ± | 0.12 | a | 0.08 | ± | 0.14 | a | 0.03 | ± | 0.05 | a | 0.00 | ± | 0.00 | a | - |

| 1 Agronomic dosage (L ha−1 yr−1) | 79,982 | 86,364 | 131,734 | 161,250 | |||||||||||||

| 1 N (kg ha−1) | 170.0 | 170.0 | 170.0 | 170.0 | |||||||||||||

| 1 P2O5 (kg ha−1) | 19.35 | 35.71 | 7.70 | 0.00 | |||||||||||||

| 1 K2O (kg ha−1) | 129.9 | 133.1 | 162.1 | 178.2 | |||||||||||||

| Season | Spring | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample type ** | RAW | SEP | DEC | PUR | Red (%) *** | ||||||||||||

| Parameter * | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | |||||

| pH | 7.39 | ± | 0.31 | a | 7.30 | ± | 0.31 | a | 7.50 | ± | 0.32 | a | 7.86 | ± | 0.33 | a | −6 |

| EC (ds m−1) | 8.18 | ± | 0.35 | a | 8.34 | ± | 0.35 | a | 8.27 | ± | 0.35 | a | 7.58 | ± | 0.35 | a | 7 |

| SS (mg L−1) | 172.7 | ± | 7.3 | b | 276.3 | ± | 11.7 | c | 168.7 | ± | 7.1 | b | 1.0 | ± | 0.5 | a | 99 |

| COD (g L−1) | 10.56 | ± | 0.45 | c | 19.73 | ± | 0.83 | d | 7.70 | ± | 0.32 | b | 4.64 | ± | 0.20 | a | 56 |

| TN (g L−1) | 1.37 | ± | 0.06 | c | 2.23 | ± | 0.09 | d | 1.08 | ± | 0.05 | b | 0.59 | ± | 0.02 | a | 57 |

| NH4+ -N (g L−1) | 0.90 | ± | 0.04 | b | 1.21 | ± | 0.05 | c | 0.86 | ± | 0.04 | b | 0.41 | ± | 0.02 | a | 54 |

| NO3− -N (mg L−1) | 0.00 | ± | 0.00 | a | 0.00 | ± | 0.00 | a | 0.00 | ± | 0.00 | a | 0.19 | ± | 0.01 | b | - |

| PO43− (mg L−1) | 399.5 | ± | 16.9 | c | 624.5 | ± | 26.4 | d | 132.1 | ± | 5.6 | b | 31.9 | ± | 1.3 | a | 92 |

| K+ (mg L−1) | 831.2 | ± | 35.1 | a | 831.8 | ± | 35.1 | a | 868.1 | ± | 36.6 | a | 830.9 | ± | 35.1 | a | 0 |

| Cu (mg L−1) | 0.04 | ± | 0.00 | a | 0.04 | ± | 0.00 | a | 0.05 | ± | 0.00 | b | 0.04 | ± | 0.00 | ab | - |

| Zn (mg L−1) | 0.16 | ± | 0.01 | a | 0.14 | ± | 0.01 | a | 0.19 | ± | 0.01 | b | 0.15 | ± | 0.01 | a | - |

| 1 Agronomic dosage (L ha−1 yr−1) | 124,369 | 76,328 | 157,330 | 287,452 | |||||||||||||

| 1 N (kg ha−1) | 170.0 | 170.0 | 170.0 | 170.0 | |||||||||||||

| 1 P2O5 (kg ha−1) | 37.14 | 35.63 | 15.54 | 6.86 | |||||||||||||

| 1 K2O (kg ha−1) | 124.5 | 76.5 | 164.5 | 287.7 | |||||||||||||

| Season | Summer | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample type ** | RAW | SEP | DEC | PUR | Red (%) *** | ||||||||||||

| Parameter * | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | Mean | ± | SD | |||||

| pH | 7.29 | ± | 0.31 | a | 7.30 | ± | 0.31 | a | 7.83 | ± | 0.04 | a | 7.86 | ± | 0.33 | a | - |

| EC (ds m−1) | 9.85 | ± | 0.42 | b | 9.22 | ± | 0.39 | b | 9.36 | ± | 0.06 | b | 7.92 | ± | 0.73 | a | 20 |

| SS (mg L−1) | 197.3 | ± | 8.3 | b | 444.0 | ± | 18.7 | c | 1.4 | ± | 2.3 | a | 1.0 | ± | 0.5 | a | 99 |

| COD (g L−1) | 10.75 | ± | 0.45 | b | 29.60 | ± | 1.25 | c | 5.93 | ± | 1.01 | a | 4.64 | ± | 0.20 | a | 57 |

| TN (g L−1) | 1.71 | ± | 0.07 | b | 2.26 | ± | 0.10 | c | 1.47 | ± | 0.18 | ab | 1.33 | ± | 0.06 | a | 22 |

| NH4+ -N (g L−1) | 1.10 | ± | 0.05 | ab | 1.26 | ± | 0.05 | b | 0.91 | ± | 0.16 | a | 1.00 | ± | 0.04 | a | 9 |

| NO3− -N (mg L−1) | 2.05 | ± | 0.09 | b | 2.09 | ± | 0.09 | b | 2.11 | ± | 0.13 | b | 0.19 | ± | 0.01 | a | 91 |

| PO43− (mg L−1) | 271.2 | ± | 11.4 | b | 620.8 | ± | 26.2 | c | 81.2 | ± | 35.3 | a | 31.9 | ± | 1.3 | a | 88 |

| K+ (mg L−1) | 910.0 | ± | 38.4 | a | 954.5 | ± | 40.3 | ab | 1077.8 | ± | 69.5 | b | 830.9 | ± | 35.1 | a | 9 |

| Cu (mg L−1) | 0.16 | ± | 0.05 | ab | 0.08 | ± | 0.08 | ab | 0.05 | ± | 0.05 | a | 0.20 | ± | 0.01 | b | - |

| Zn (mg L−1) | 0.51 | ± | 0.10 | a | 0.29 | ± | 0.22 | a | 0.25 | ± | 0.21 | a | 0.54 | ± | 0.02 | a | - |

| 1 Agronomic dosage (L ha−1 yr−1) | 99,532 | 75,065 | 115,811 | 127,609 | |||||||||||||

| 1 N (kg ha−1) | 170.0 | 170.0 | 170.0 | 170.0 | |||||||||||||

| 1 P2O5 (kg ha−1) | 20.17 | 34.83 | 7.03 | 3.05 | |||||||||||||

| 1 K2O (kg ha−1) | 109.1 | 86.3 | 150.4 | 127.7 | |||||||||||||

| Sample Type | Manure | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Season | Autumn | Spring | Summer | |||||||||

| * Parameter | Mean | DS | Mean | DS | Mean | DS | ||||||

| DM (%) | 25.80 | ± | 0.01 | a | 30.71 | ± | 0.10 | b | 43.66 | ± | 1.54 | c |

| pH | 7.57 | ± | 0.02 | a | 7.45 | ± | 0.05 | a | 8.62 | ± | 0.30 | b |

| EC (dS m−1) | 1.18 | ± | 0.01 | a | 1.31 | ± | 0.16 | a | 2.00 | ± | 0.07 | b |

| TN (g kg−1) | 3.95 | ± | 0.01 | b | 3.56 | ± | 0.01 | a | 3.72 | ± | 0.13 | a |

| N-NH4+ (g kg−1) | 1.37 | ± | 0.00 | b | 1.05 | ± | 0.02 | a | 2.54 | ± | 0.09 | c |

| NO3− -N (mg kg−1) | 4.72 | ± | 0.13 | c | 0.00 | ± | 0.00 | a | 0.28 | ± | 0.04 | b |

| TOC (%) | 10.56 | ± | 0.02 | a | 10.56 | ± | 0.26 | a | 15.81 | ± | 0.15 | b |

| PO43− (mg kg−1) | 451.4 | ± | 2.8 | b | 939.4 | ± | 0.0 | c | 84.5 | ± | 3.0 | a |

| K+ (mg kg−1) | 741.2 | ± | 4.5 | c | 701.0 | ± | 0.0 | b | 0.1 | ± | 0.0 | a |

| Cu (mg kg−1) | 1.20 | ± | 0.02 | b | 0.15 | ± | 0.01 | a | 1.86 | ± | 0.07 | c |

| Zn (mg kg−1) | 1.47 | ± | 0.05 | b | 0.42 | ± | 0.02 | a | 0.51 | ± | 0.02 | a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Garrido, M.; Terrero Turbí, M.A.; El bied, O.; Cano, Á.F. Impact of an Integral Management System with Constructed Wetlands in Pig Slurry Traceability and GHG/NH3 Emissions. Water 2024, 16, 2351. https://doi.org/10.3390/w16162351

Gómez-Garrido M, Terrero Turbí MA, El bied O, Cano ÁF. Impact of an Integral Management System with Constructed Wetlands in Pig Slurry Traceability and GHG/NH3 Emissions. Water. 2024; 16(16):2351. https://doi.org/10.3390/w16162351

Chicago/Turabian StyleGómez-Garrido, Melisa, Martire Angélica Terrero Turbí, Oumaima El bied, and Ángel Faz Cano. 2024. "Impact of an Integral Management System with Constructed Wetlands in Pig Slurry Traceability and GHG/NH3 Emissions" Water 16, no. 16: 2351. https://doi.org/10.3390/w16162351

APA StyleGómez-Garrido, M., Terrero Turbí, M. A., El bied, O., & Cano, Á. F. (2024). Impact of an Integral Management System with Constructed Wetlands in Pig Slurry Traceability and GHG/NH3 Emissions. Water, 16(16), 2351. https://doi.org/10.3390/w16162351