Lab-Scale Treatment of Anaerobic Co-Digestion Liquor from Kitchen Waste, Human Feces, and Municipal Sludge Using Partial Nitritation-Anammox Process

Abstract

1. Introduction

2. Materials and Methods

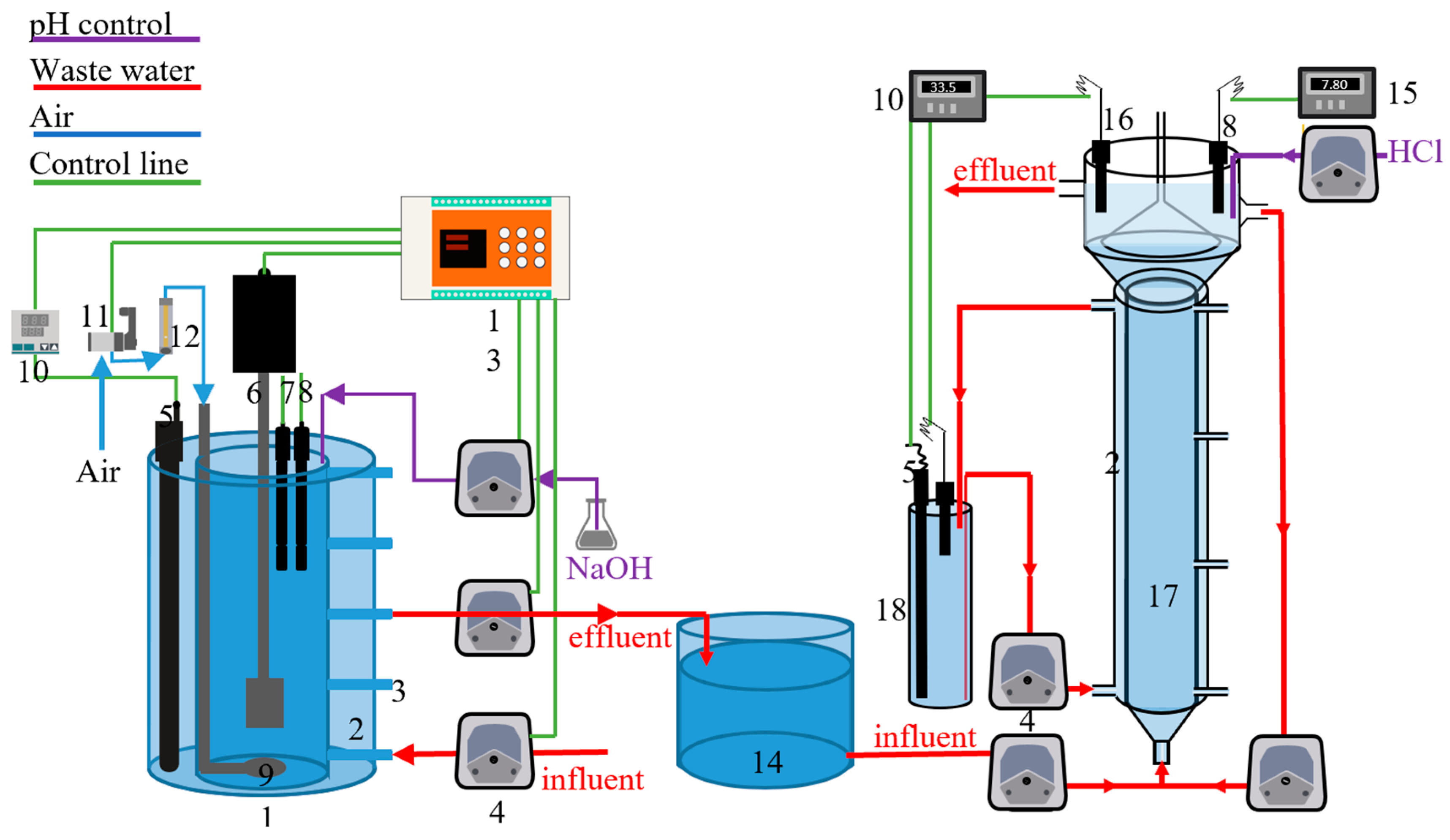

2.1. Experimental Setup

2.2. Inoculated Sludge

2.3. Wastewater

2.4. Reactor Operation and Experimental Design

2.4.1. The Fast Start-Up of Partial Nitritation Process in SBR

2.4.2. The Acclimatization of Partial Nitritation Process to Raw Anaerobic Co-Digestion Liquor

2.4.3. The Acclimatization of Anammox Process to Raw Anaerobic Co-Digestion Liquor

2.5. Chemical and Data Analytical Methods

3. Results

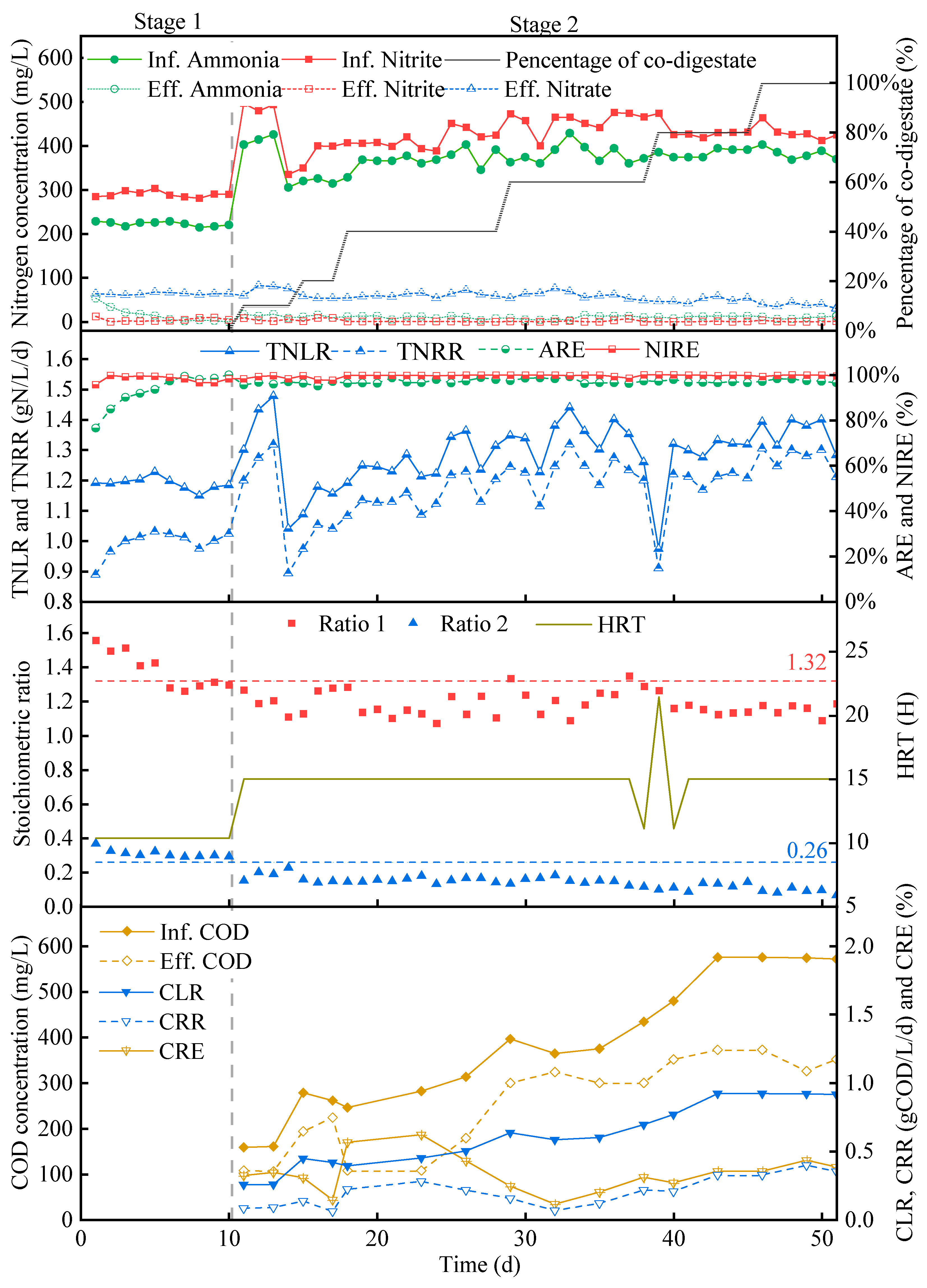

3.1. Start-Up Process of Partial Nitritation in the Sequencing Batch Reactor

3.2. The Acclimatization of Partial Nitritation to Raw Anaerobic Co-Digestion Liquor

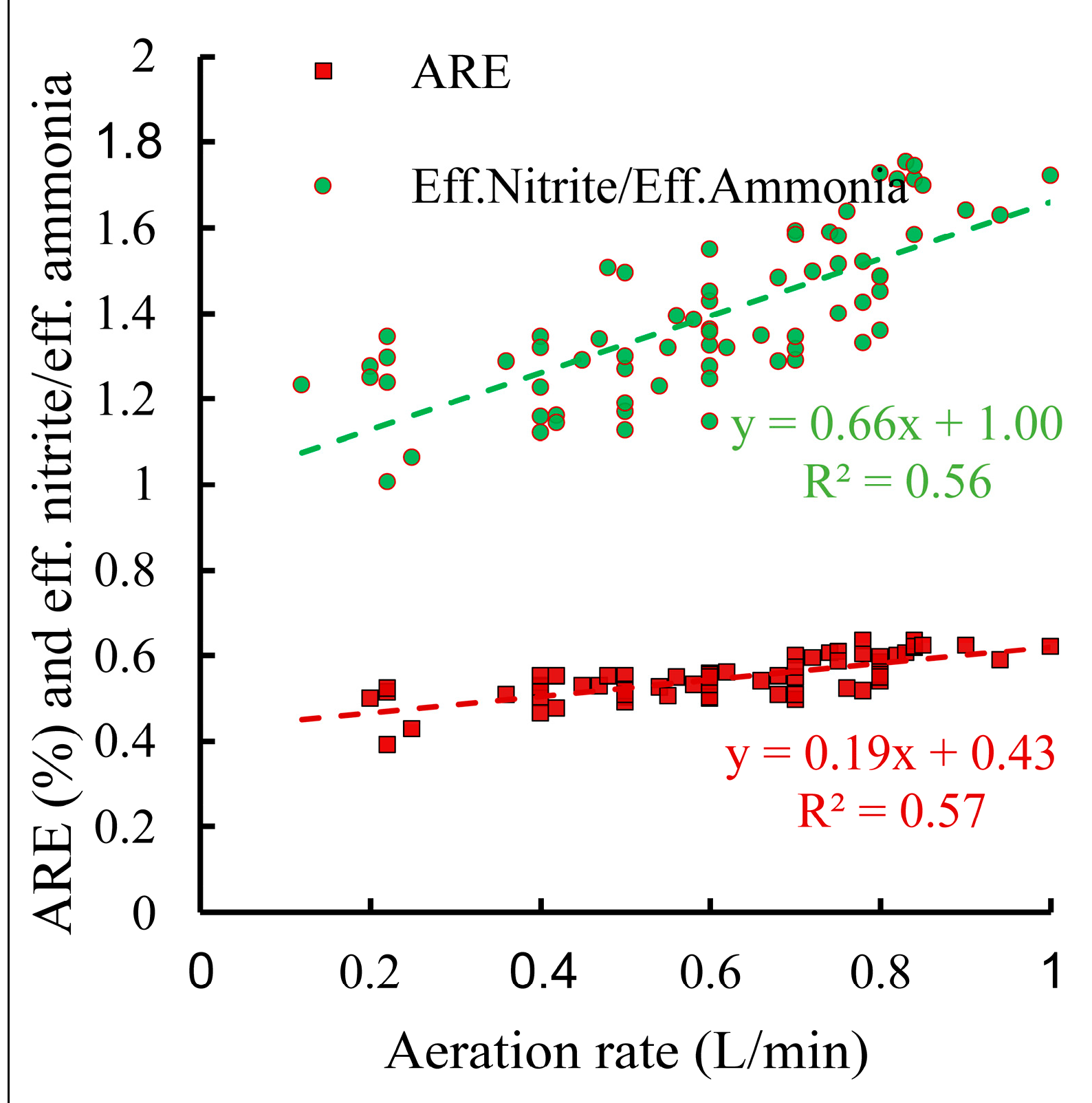

3.3. The Effect of Air Supply on Partial Nitritation Performance in the Sequencing Batch Reactor

3.4. The Acclimatization of Anammox Process to Raw Anaerobic Co-Digestion Liquor

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kunatsa, T.; Xia, X. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresour. Technol. 2022, 344, 126311. [Google Scholar] [CrossRef]

- Xing, W.; Zhang, Z.; Zhang, X.; Liu, J.; Li, J.; Lin, J.; Yao, H. Mainstream partial Anammox for improving nitrogen removal from municipal wastewater after organic recovery via magnetic separation. Bioresour. Technol. 2022, 361, 127726. [Google Scholar] [CrossRef] [PubMed]

- Kadam, R.; Khanthong, K.; Park, B.; Jun, H.; Park, J. Realizable wastewater treatment process for carbon neutrality and energy sustainability: A review. J. Environ. Manag. 2023, 328, 116927. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Huang, J.; Gao, D. Effects of three storage conditions on the long-term storage and short-term reactivation performances of anammox granular sludge. Int. Biodeterior. Biodegrad. 2021, 164, 105310. [Google Scholar] [CrossRef]

- Vázquez-Padín, J.; Morales, N.; Gutiérrez, R.; Fernández, R.; Rogalla, F.; Barrio, J.; Campos, J.; Mosquera-Corral, A.; Méndez, R. Implications of full-scale implementation of an anammox-based process as post-treatment of a municipal anaerobic sludge digester operated with co-digestion. Water Sci. Technol. 2014, 69, 1151–1158. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Zhang, S.; Yang, S.; Zhang, L.; Peng, Y. Full-scale partial nitritation/anammox (PN/A) process for treating sludge dewatering liquor from anaerobic digestion after thermal hydrolysis. Bioresour. Technol. 2020, 297, 122380. [Google Scholar] [CrossRef]

- Siegrist, H.; Salzgeber, D.; Eugster, J.; Joss, A. Anammox brings WWTP closer to energy autarky due to increased biogas production and reduced aeration energy for N-removal. Water Sci. Technol. 2008, 57, 383–388. [Google Scholar] [CrossRef]

- Kong, Z.; Xue, Y.; Zhang, Y.; Hao, T.; Chen, H.; Sun, J.; Pan, Y.; Li, D.; Li, Y.; Huang, Y. Insights into the carbon neutrality for the treatment process engineering of municipal wastewater by anaerobic membrane bioreactor integrated with partial nitritation-anammox: CO2 reduction and energy recovery. J. Water Process Eng. 2022, 49, 102996. [Google Scholar] [CrossRef]

- Yan, L.; Song, G.-L.; Wu, P.; Zhu, Y.; Zheng, D. A chloride-sensitive corrosion sensor and protector made of an optimized Mg-Al alloy for reinforcing steel. Mater. Des. 2021, 210, 110028. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Chen, X.; Zhong, Z.; Chen, Z.; Chen, J.; Jiang, Y. Salt inhibition on partial nitritation performance of ammonium-rich saline wastewater in the zeolite biological aerated filter. Bioresour. Technol. 2019, 280, 287–294. [Google Scholar] [CrossRef]

- Papanikolaou, G.; Pantopoulos, K. Iron metabolism and toxicity. Toxicol. Appl. Pharmacol. 2005, 202, 199–211. [Google Scholar] [CrossRef] [PubMed]

- Kuenen, J.G. Anammox bacteria: From discovery to application. Nat. Rev. Microbiol. 2008, 6, 320–326. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gao, D. The transformation from anammox granules to deammonification granules in micro-aerobic system by facilitating indigenous ammonia oxidizing bacteria. Bioresour. Technol. 2018, 250, 439–448. [Google Scholar] [CrossRef] [PubMed]

- Clesceri, L.S.; Greenberg, A.E.; Eaton, A.D. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 1998. [Google Scholar]

- HJ/T 399-2007; Water Quality-Determination of the Chemical Oxygen Demand-Fast Digestion Spectrophotometric Method. Environmental Protection Standard of the People’s Republic of China: Beijing, China, 2007.

- Wang, J.; Li, L.; Liu, Y.; Li, W. A review of partial nitrification in biological nitrogen removal processes: From development to application. Biodegradation 2021, 32, 229–249. [Google Scholar] [CrossRef]

- Suarez, C.; Rosenqvist, T.; Dimitrova, I.; Sedlacek, C.J.; Modin, O.; Paul, C.J.; Hermansson, M.; Persson, F. Biofilm colonization and succession in a full-scale partial nitritation-anammox moving bed biofilm reactor. Microbiome 2024, 12, 51. [Google Scholar] [CrossRef] [PubMed]

- Hassan, G.K.; El-Gohary, F.A. Evaluation of Partial Nitritation/Anammox Process for Reduction of Pollutants from Sanitary Landfill Leachate. Water Air Soil Pollut. 2021, 232, 134. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, G.; Li, Y.-Y. A review on upgrading of the anammox-based nitrogen removal processes: Performance, stability, and control strategies. Bioresour. Technol. 2022, 364, 127992. [Google Scholar] [CrossRef] [PubMed]

- Schraa, O.; Rosenthal, A.; Wade, M.; Rieger, L.; Miletić, I.; Alex, J. Assessment of aeration control strategies for biofilm-based partial nitritation/anammox systems. Water Sci. Technol. 2020, 81, 1757–1765. [Google Scholar] [CrossRef]

- Wang, S.; Yu, H.; Su, Q.; Zuo, J. Exploring the role of heterotrophs in partial nitritation-anammox process treating thermal hydrolysis process-anaerobic digestion reject water. Bioresour. Technol. 2021, 341, 125762. [Google Scholar] [CrossRef]

- Driessen, W.; Hendrickx, T. Two Decades of Experience with the Granular Sludge-Based ANAMMOX® Process Treating Municipal and Industrial Effluents. Processes 2021, 9, 1207. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef]

- Magrí, A.; Béline, F.; Dabert, P. Feasibility and interest of the anammox process as treatment alternative for anaerobic digester supernatants in manure processing—An overview. J. Environ. Manag. 2013, 131, 170–184. [Google Scholar] [CrossRef]

- Scaglione, D.; Lotti, T.; Ficara, E.; Malpei, F. Inhibition on anammox bacteria upon exposure to digestates from biogas plants treating the organic fraction of municipal solid waste and the role of conductivity. Waste Manag. 2017, 61, 213–219. [Google Scholar] [CrossRef]

- Kwon, K.; Kim, H.; Kim, W.; Lee, J. Efficient nitrogen removal of reject water generated from anaerobic digester treating sewage sludge and livestock manure by combining anammox and autotrophic Sulfur denitrification processes. Water 2019, 11, 204. [Google Scholar] [CrossRef]

- Soliman, M.; Eldyasti, A. Ammonia-Oxidizing Bacteria (AOB): Opportunities and applications—A review. Rev. Environ. Sci. Biotechnol. 2018, 17, 285–321. [Google Scholar] [CrossRef]

- She, Z.; Zhao, L.; Zhang, X.; Jin, C.; Guo, L.; Yang, S.; Zhao, Y.; Gao, M. Partial nitrification and denitrification in a sequencing batch reactor treating high-salinity wastewater. Chem. Eng. J. 2016, 288, 207–215. [Google Scholar] [CrossRef]

- Lu, H.; Li, Y.; Shan, X.; Abbas, G.; Zeng, Z.; Kang, D.; Wang, Y.; Zheng, P.; Zhang, M. A holistic analysis of ANAMMOX process in response to salinity: From adaptation to collapse. Sep. Purif. Technol. 2019, 215, 342–350. [Google Scholar] [CrossRef]

- Dinh, N.T.; Nguyen, T.H.; Mungray, A.K.; Duong, L.D.; Phuong, N.-T.; Nguyen, D.D.; Chung, W.J.; Chang, S.W.; Tuan, P.D. Biological treatment of saline domestic wastewater by using a down-flow hanging sponge reactor. Chemosphere 2021, 283, 131101. [Google Scholar]

- Wang, H.; Peng, L.; Mao, N.; Geng, J.; Ren, H.; Xu, K. Effects of Fe3+ on microbial communities shifts, functional genes expression and nitrogen transformation during the start-up of Anammox process. Bioresour. Technol. 2021, 320, 124326. [Google Scholar] [CrossRef]

- Jiang, Z.; Xu, X.; He, Y.; Zeng, M.; Zhang, M.; Liu, W.; Wu, N. Advancing the Comprehension of Iron Ions with Different Valences in Anammox-Based Processes: Insight into the Response and Mechanism Based on Prediction and Classification Machine Learning Models. ACS ES&T Water 2023, 3, 3716–3727. [Google Scholar]

- Huang, X.; Yao, K.; Yu, J.; Dong, W.; Zhao, Z. Nitrogen removal performance and microbial characteristics during simultaneous chemical phosphorus removal process using Fe3+. Bioresour. Technol. 2022, 363, 127972. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, M.; You, S.; Ma, D.; Zhao, J.; Chen, Z. Effect of Fe3+ on the sludge properties and microbial community structure in a lab-scale A2O process. Sci. Total Environ. 2021, 780, 146505. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Huang, J.; Li, D.; Liu, C.; Tian, D. Lab-Scale Treatment of Anaerobic Co-Digestion Liquor from Kitchen Waste, Human Feces, and Municipal Sludge Using Partial Nitritation-Anammox Process. Water 2024, 16, 2321. https://doi.org/10.3390/w16162321

Wang X, Huang J, Li D, Liu C, Tian D. Lab-Scale Treatment of Anaerobic Co-Digestion Liquor from Kitchen Waste, Human Feces, and Municipal Sludge Using Partial Nitritation-Anammox Process. Water. 2024; 16(16):2321. https://doi.org/10.3390/w16162321

Chicago/Turabian StyleWang, Xiaolong, Jialu Huang, Dongqian Li, Chao Liu, and Dayong Tian. 2024. "Lab-Scale Treatment of Anaerobic Co-Digestion Liquor from Kitchen Waste, Human Feces, and Municipal Sludge Using Partial Nitritation-Anammox Process" Water 16, no. 16: 2321. https://doi.org/10.3390/w16162321

APA StyleWang, X., Huang, J., Li, D., Liu, C., & Tian, D. (2024). Lab-Scale Treatment of Anaerobic Co-Digestion Liquor from Kitchen Waste, Human Feces, and Municipal Sludge Using Partial Nitritation-Anammox Process. Water, 16(16), 2321. https://doi.org/10.3390/w16162321