Influence of Impeller Structure Parameters on the Hydraulic Performance and Casting Molding of Spiral Centrifugal Pumps

Abstract

1. Introduction

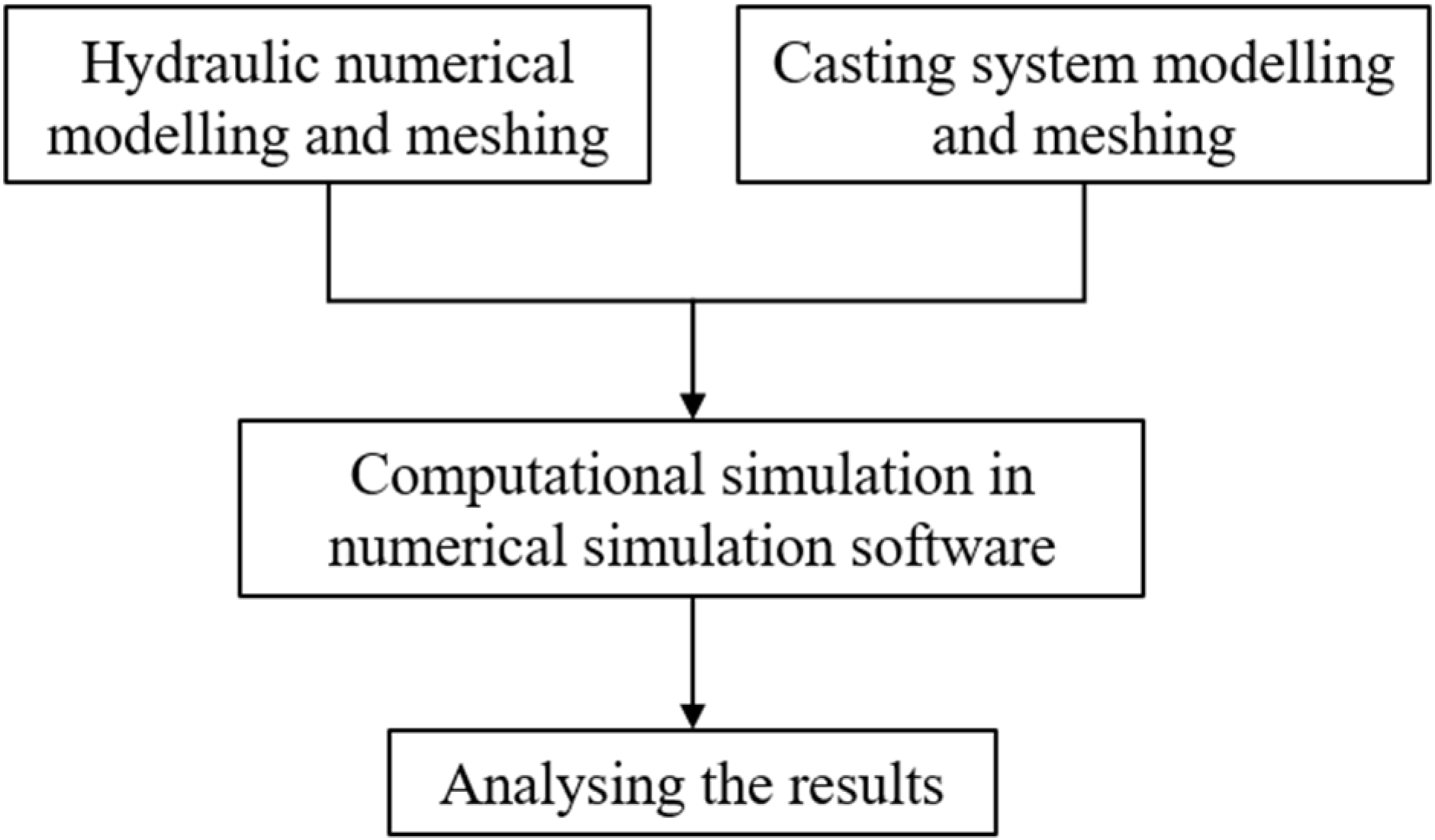

2. Numerical Simulation

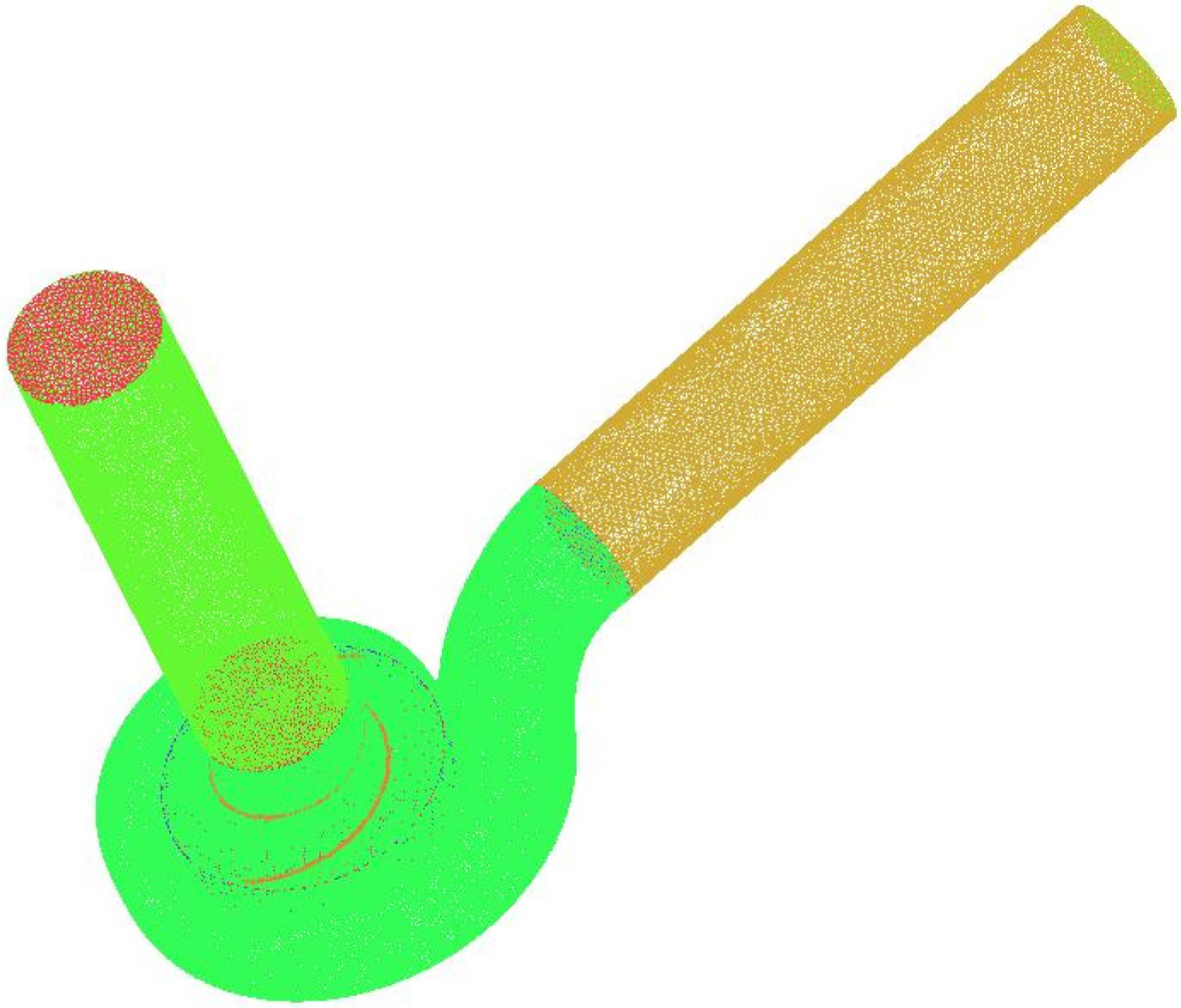

2.1. Computational Modelling and Mesh Segmentation

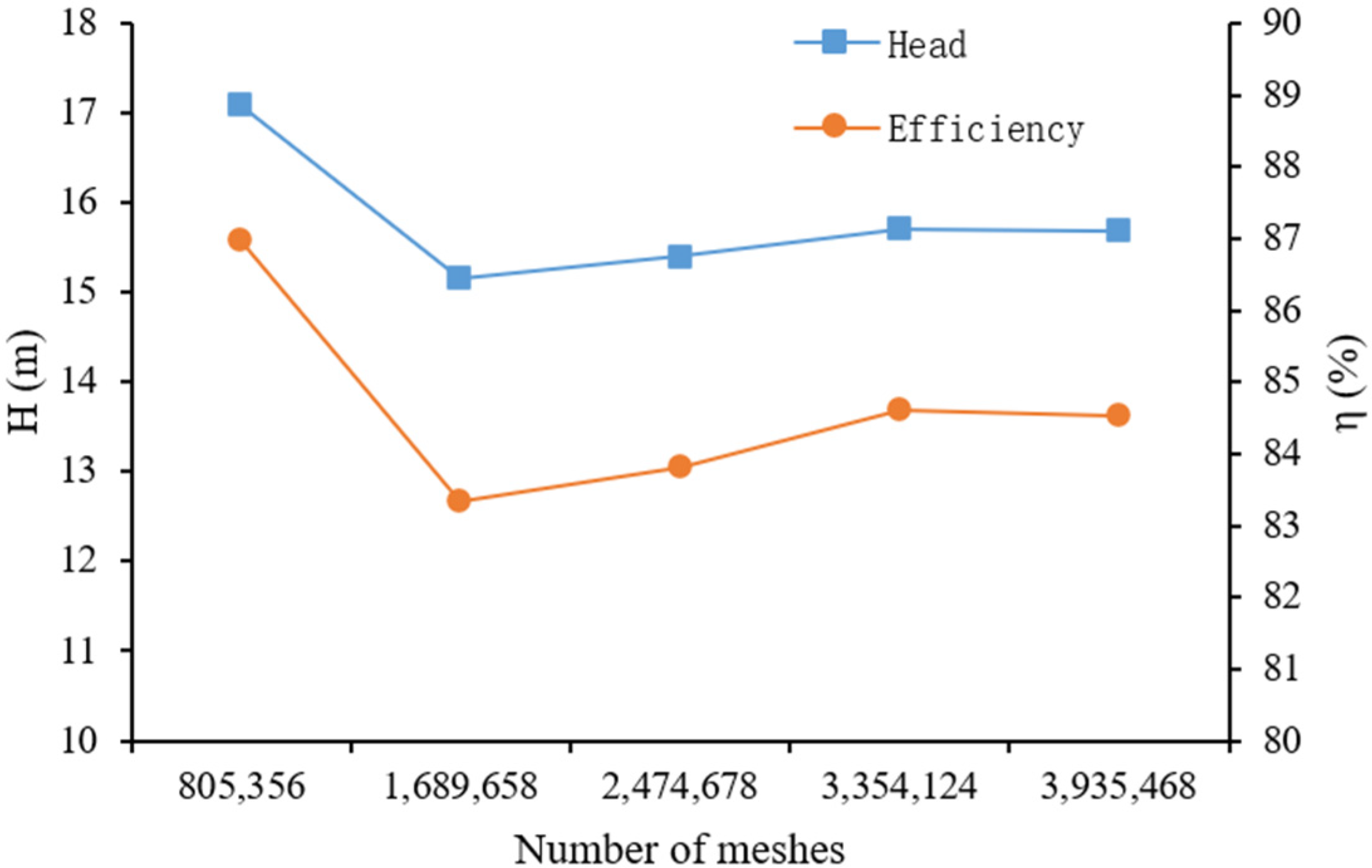

2.2. Mesh-Independent Investigation

2.3. Boundary Conditions

2.4. Casting Simulation

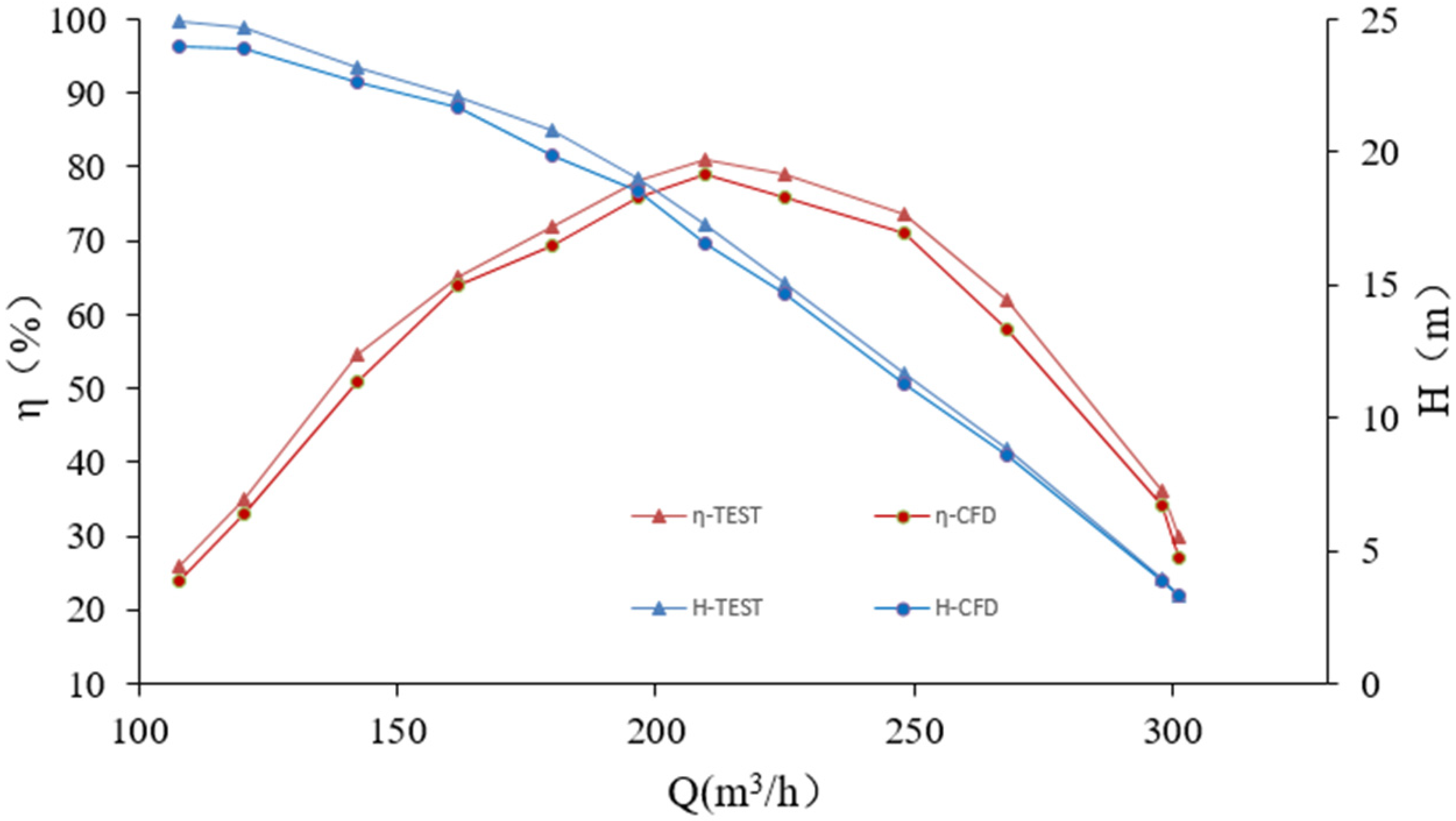

2.5. Experimental Verification

3. Significant Factors Screening

4. Results and Analysis

4.1. Effect of Blade Thickness

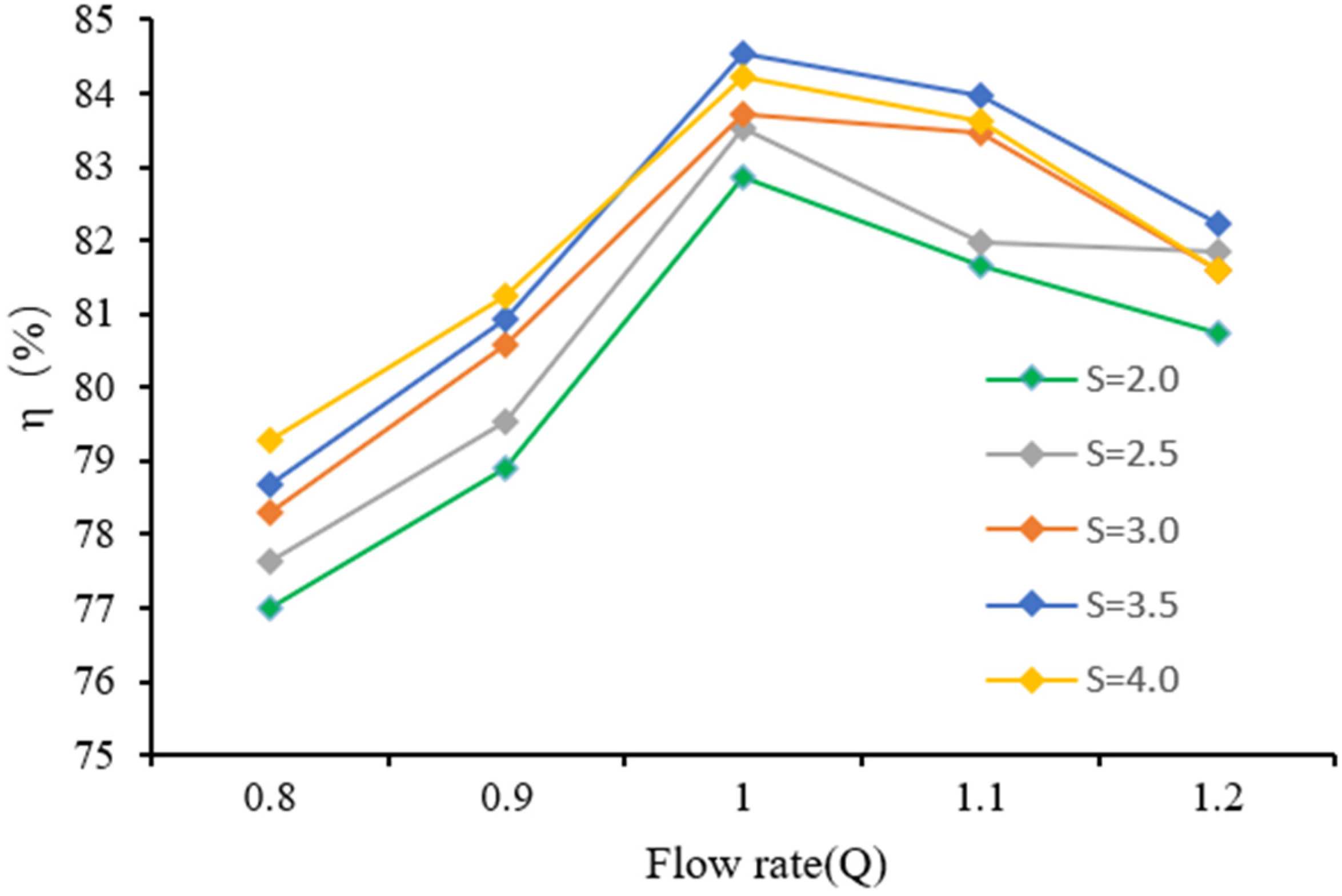

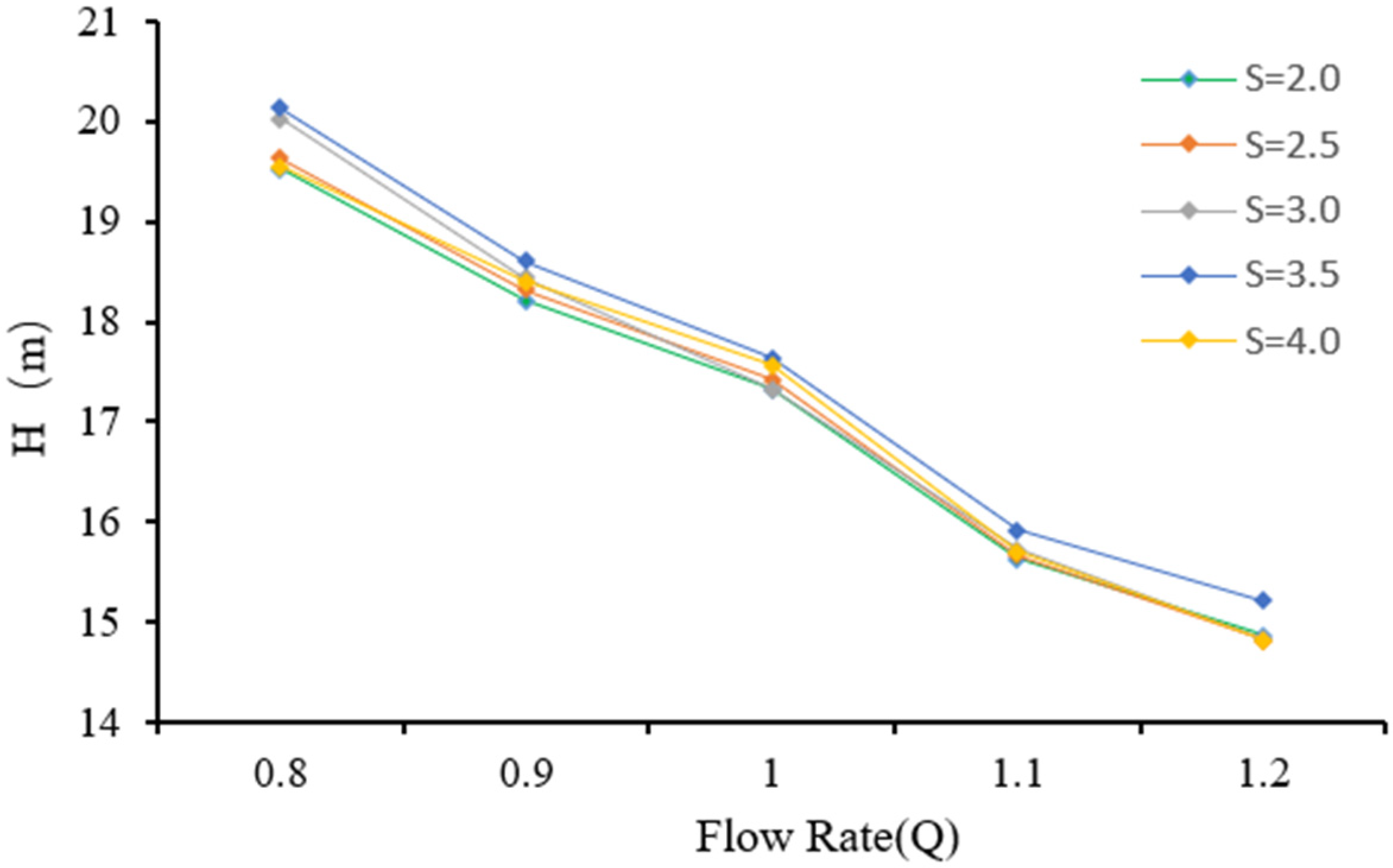

4.1.1. Hydraulic Performance

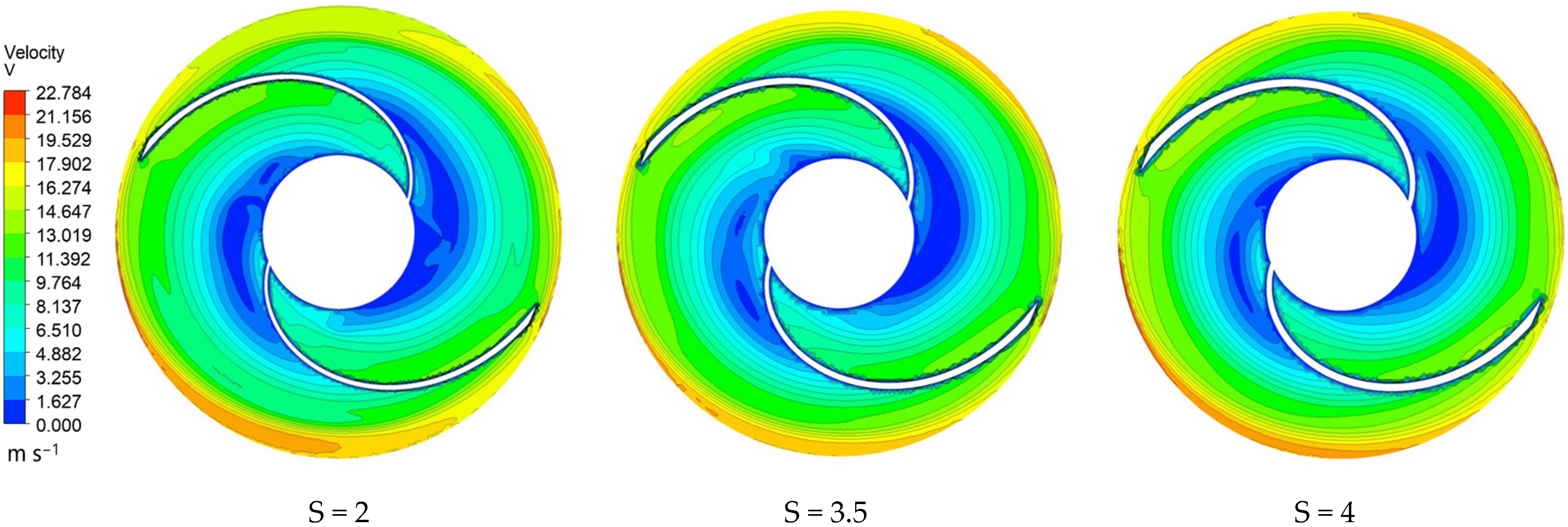

4.1.2. Velocity Field

4.1.3. Pressure Field

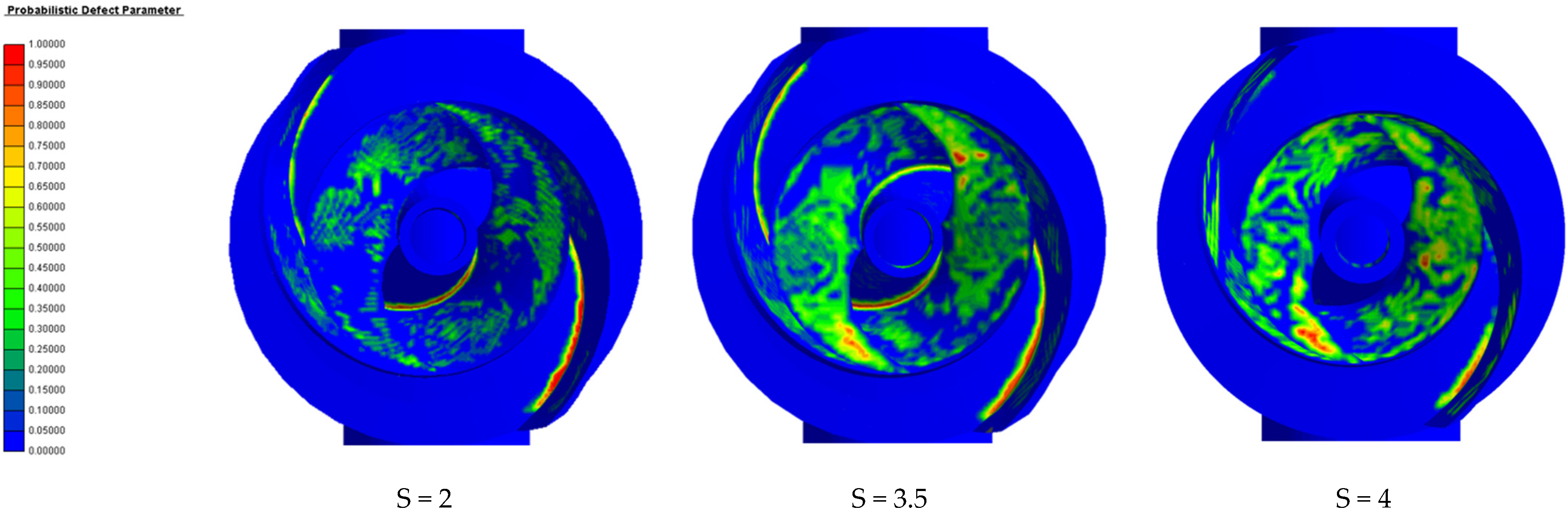

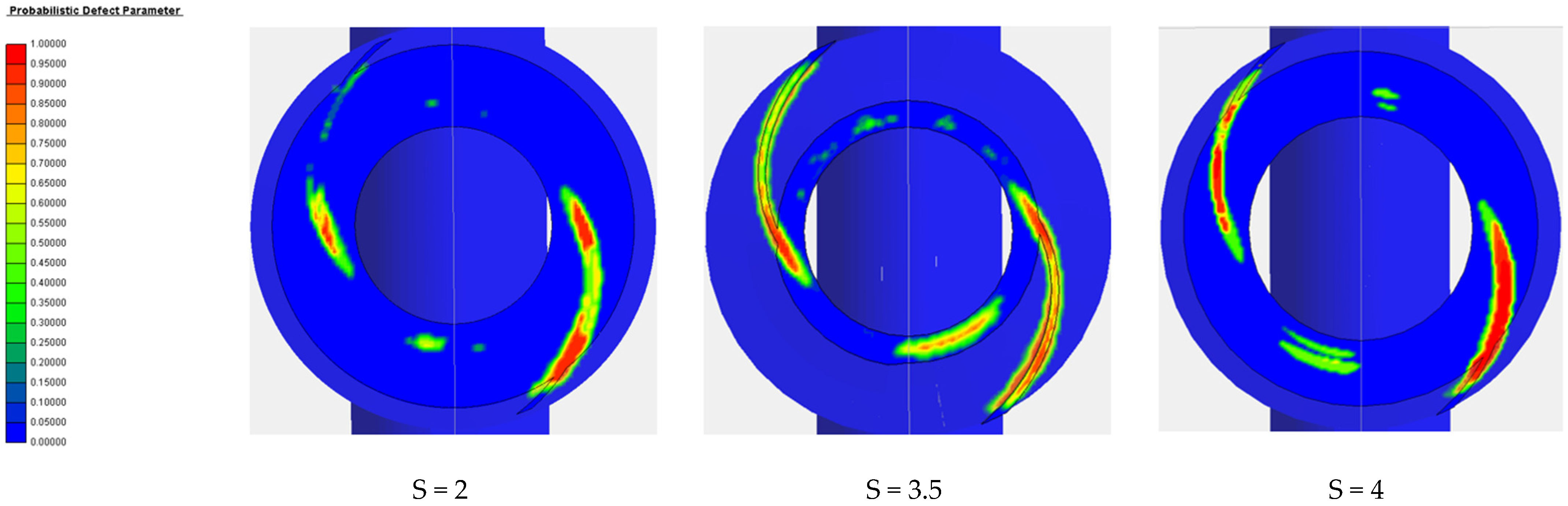

4.1.4. Casting Defects

4.2. Effect of Discharge Width

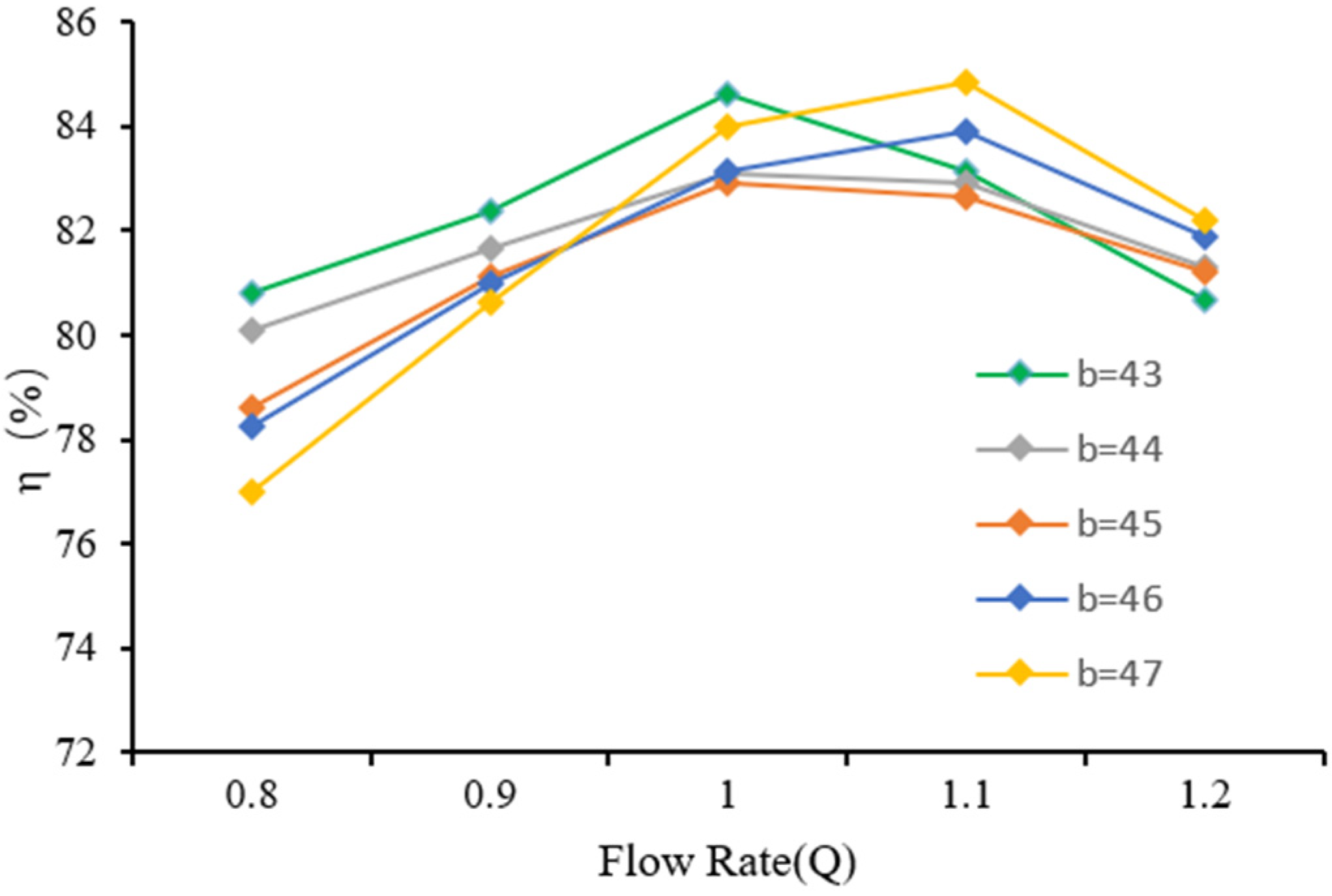

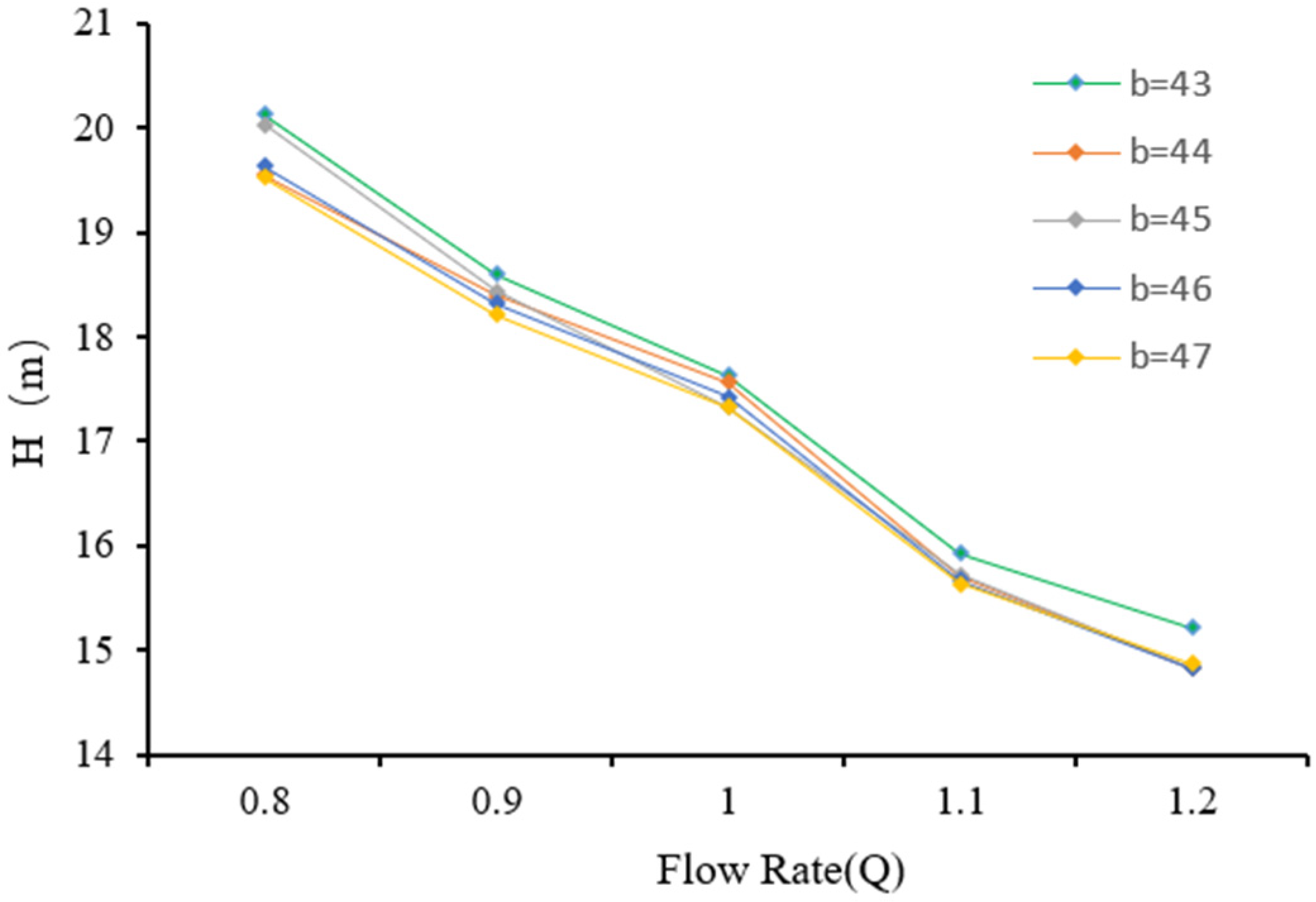

4.2.1. Hydraulic Performance

4.2.2. Pressure Field

4.2.3. Casting Defects

5. Conclusions

- In this paper, considering the hydraulic performance and casting molding of the spiral centrifugal pump, the head, efficiency, and residual melt modulus are taken as the response quantities, and using the Plackett–Burman experimental design of resolution III, the blade thickness S and outlet width b2 are the significant influencing factors.

- In the authors’ opinion, in terms of blade thickness, under the small flow condition, the blade thickness can be increased appropriately to improve efficiency, and under the large flow condition, it is necessary to increase the blade thickness cautiously; 3.5 mm is optimal under this model. Increasing the blade thickness will increase the probability of casting defects and reduce the casting molding rate and impeller outlet width; increasing the impeller outlet width will lead to a decrease in head. At a small flow rate increase, the impeller outlet width efficiency will decline, and when the flow rate reaches the design flow rate above, the efficiency will rise. The author believes that increasing the impeller outlet width will lead to design point offset. Increasing the impeller outlet width leads to an increase in residual melt at the connection and a decrease in residual melt on the blade surface, and casting defects are likely to occur at the connection between the blade and the rear cover plate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, C.; Fan, Y. Study on internal structure dynamics of spiral centrifugal pump. Water Pump Technology. 2020, 6, 18–23+40. [Google Scholar]

- Guan, X.F. Overview. In Handbook of Modern Pump Technology; Aerospace Press: Beijing, China, 1995; pp. 6–7. [Google Scholar]

- Liu, X.C.; Han, W.; Li, R.N. Effect of blade wrap angle on cavitation performance of spiral centrifugal fuel pump. Hydraulic Pneum. Seal. 2022, 42, 75–81. [Google Scholar]

- Zhou, F.; Li, Y.H.; Li, Q.F. Analysis of flow-solid coupling forces in spiral centrifugal pumps under different working conditions. Hydraul. Pneum. Seal. 2023, 43, 19–22. [Google Scholar]

- Thi, H.; Viet, A.T. Optimization of the Meridional Plane Shape Design Parameters in a Screw Centrifugal Pump Impeller. KSFM J. Fluid Mach. 2021, 24, 15–25. [Google Scholar]

- Thi, H.; Ujjwal, S.; Young, D. Hydraulic and Suction Performances of the Screw Centrifugal Pump for Live Fish Transfer According to Impeller Blade Inlet Shapes. Korean Soc. Fluid Mech. 2022, 25, 16–25. [Google Scholar]

- Thi, H.; Ujjwal, S.; Young, D. Effect of impeller inlet and passage meridional shapes on screw centrifugal pump performance. In Proceedings of the Spring Meeting of the Korean Society of Mechanical Engineers, Seoul, Republic of Korea, 3–7 November 2020. [Google Scholar]

- Wu, C.G.; Fan, Y.Z. Research on gas-liquid two-phase flow in spiral centrifugal pump. Water Supply Drain. 2020, 56, 973–978+985. [Google Scholar]

- Ren, W.L.; Zhao, Z.F.; Hao, Z.R. Influence of medium viscosity on internal flow characteristics of spiral centrifugal pumps. Mar. Eng. 2021, 43, 241–246. [Google Scholar]

- Egorkina, N.; Petrov, A. The method of constructing the cavitation characteristics of a screw centrifugal pump using the methods of hydrodynamic modeling. Mater. Sci. Eng. 2019, 492, 12–15. [Google Scholar] [CrossRef]

- Emilio, E.; Paladino; Rafael, F.L.; De, C.; Josiane, W.; Thales, C.; Lavoratti, E. Theoretical and experimental analysis of multiphase twin-screw pumps operating in serial arrangement. J. Pet. Sci. Eng. 2022, 216, 110–130. [Google Scholar]

- Yasushi, T.; Kazuhiro, T. Influence of meridian shape on screw-type centrifugal pump performance. In Proceedings of the ASME 2002 Fluids Engineering Division Summer Meeting, Montreal, QC, Canada, 14 July 2002. [Google Scholar]

- Bai, Y.; Zhang, H.; Huang, L.; Gao, X. Numerical simulation and optimization of impeller die casting based on ProCAST. Therm. Process. Technol. 2021, 50, 71–75. [Google Scholar]

- Samraj, A.; Ponnusamy, R.; Ganesan, V. Numerical and experimental approach to eliminate defects in al alloy pump- crank case processed through gravity die casting route. Mater. Today Proc. 2020, 37, 1772–1777. [Google Scholar]

- Yao, L.J.; Zhao, H.H.; Zhong, K.S. Research on closed impeller rapid casting technology based on ProCAST and 3D printing technology. Mech. Electr. Eng. 2015, 32, 1166–1169+1191. [Google Scholar]

- Zhang, F.; Zhang, J.; Xi, L.; He, Z.; Wang, Y. Numerical simulation study of aluminium alloy impeller investment casting. Foundry Technol. 2016, 37, 805–808. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, X.; Wu, S. Numerical Simulation of Bubble Migration in Liquid Titanium Alloy Melt During Vertical Centrifugal Casting Process. J. Harbin Inst. Technol. 2019, 6, 91–96. [Google Scholar]

- Zhang, X.; Hu, B.B.; Feng, Y.M. Multi-objective optimization design of spiral centrifugal pump based on RBF neural network and DECIMO algorithm. J. Drain. Lrrigation Mach. Eng. 2022, 40, 667–673. [Google Scholar]

- Wu, C.S.; Zhang, W.Q.; Wu, P. Effects of blade pressure side modification on unsteady pressure pulsation and flow structures in a centrifugal pump. J. Fluids Eng. 2021, 143, 111208. [Google Scholar] [CrossRef]

- Zhang, L.W.; Wu, C.S. Influence of blade thickness distribution on flow structure and performance of centrifugal pump. Fluid Mach. 2023, 51, 19–25+65. [Google Scholar]

- Mousavi, N.; Kothapalli, G.; Habibi, D.; Lachowicz, S.W.; Moghaddam, V. A real-time energy management strategy for pumped hydro storage systems in farmhouses. J. Energy Storage 2020, 32, 101928. [Google Scholar] [CrossRef]

- Gulich, J.F. Effect of Reynolds number and surface roughness on the efficiency of centrifugal pump. J. Fluid Eng. 2003, 125, 670–679. [Google Scholar] [CrossRef]

- Ulanicki, B.; Kahler, J.; Coulbeck, B. Modeling the Efficiency and Power Characteristics of a Pump Group. J. Water Resour. Plan Manag. 2008, 134, 88–93. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, L.; Tang, H.; Wang, Z.; Zhao, F.; Ji, X.; Zhang, H. Primary instability, sensitivity and active control of flow past two tandem circular cylinders. Ocean. Eng. 2024, 294, 116863. [Google Scholar] [CrossRef]

- Léopold, G.; Nadot, Y.; Billaudeau, T.; Mendez, J. Influence of artificial and casting defects on fatigue strength of moulded components in Ti-6Al-4V alloy. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1026–1041. [Google Scholar] [CrossRef]

| Item | Factors | Low Level (−) | High Level (+) |

|---|---|---|---|

| A | DJ (mm) | 170 | 180 |

| B | D2 (mm) | 295 | 305 |

| C | b2 (mm) | 43 | 47 |

| D | β2 (°) | 20 | 24 |

| E | S (mm) | 2 (shroud) 4 (hub) | 4 (shroud) 6 (hub) |

| F | R2 (mm) | 42 | 44 |

| G | R1 (mm) | 87 | 89 |

| Factors | P (H) | P (η) | P (R) |

|---|---|---|---|

| DJ (mm) | 0.113 | 0.539 | 0.098 |

| D2 (mm) | 0.036 | 0.045 | 0.025 |

| b2 (mm) | 0.027 | 0.016 | 0.047 |

| β2 (°) | 0.067 | 0.035 | 0.248 |

| S (mm) | 0.022 | 0.031 | 0.039 |

| R2 (mm) | 0.489 | 0.264 | 0.532 |

| R1 (mm) | 0.230 | 0.623 | 0.364 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Luo, Y.; Li, Z.; Shen, Z.; Ye, D. Influence of Impeller Structure Parameters on the Hydraulic Performance and Casting Molding of Spiral Centrifugal Pumps. Water 2024, 16, 1598. https://doi.org/10.3390/w16111598

Wang C, Luo Y, Li Z, Shen Z, Ye D. Influence of Impeller Structure Parameters on the Hydraulic Performance and Casting Molding of Spiral Centrifugal Pumps. Water. 2024; 16(11):1598. https://doi.org/10.3390/w16111598

Chicago/Turabian StyleWang, Chao, Yin Luo, Zihan Li, Zhenhua Shen, and Daoxing Ye. 2024. "Influence of Impeller Structure Parameters on the Hydraulic Performance and Casting Molding of Spiral Centrifugal Pumps" Water 16, no. 11: 1598. https://doi.org/10.3390/w16111598

APA StyleWang, C., Luo, Y., Li, Z., Shen, Z., & Ye, D. (2024). Influence of Impeller Structure Parameters on the Hydraulic Performance and Casting Molding of Spiral Centrifugal Pumps. Water, 16(11), 1598. https://doi.org/10.3390/w16111598