3.3. Semi-Empirical Analysis

When the scour hole is in its equilibrium phase, the scoured bed would have attained a particular shape and the shear stress on the bed may be assumed to be equal to the critical Shields stress on the sloping bed [

20]. With the knowledge of bed shear, the bed profile should be determinable with respect to the balance of various forces (drag, lift, weight and frictional forces) exerted on the sediment particles on the sloping bed surface, and finally, the depth of flow may be calculated for a given flow discharge. Prior to the abutment construction, the total discharge, represented as Q, within the compound channel can be formulated as follows:

where the subscript p is related to the initial conditions without the construction of the abutment, f and m are related to the floodplain and main channel, respectively, B

f is the floodplain width, h

fp and U

fp are the flow depth and mean velocity on the floodplain, respectively; B

m is the main channel width; h

mp and U

mp are the flow depth and mean velocity in the main channel, respectively. To enhance the reliability of the model, if possible, it is recommended that these quantities should preferably be obtained from field measurements. However, these are not easily available, as a design flow discharge is typically of the order of 1 in 50 or 100 years. Based on the design discharge, slope and geometry of the compound channel, the depths of flow and velocities on the floodplain and in the main channel can be calculated numerically [

22,

23] or using empirical method [

24].

Once the abutment is constructed, the local bed shear stress at the abutment section increases, particularly at the abutment tip, and this causes localized scour around the abutment [

25]. The local bed shear decreases and the intensity of scouring also reduces with the increase in scour hole size. If the scouring process continues for a sufficiently long time, an equilibrium scoured bed profile would be formed. In this context, the shear stress of the bed at any given point on the scoured bed matches the critical value required for sediment movement on the slope. At the deepest point within the scour hole, this value approximates the critical Shields stress on a flatbed [

20]. In other words, the sediment particles at the deepest location can be assumed to have shear stress under equilibrium scour conditions given by the following equation:

where τ

cd is the critical bed shear stress, θ

c is the critical Shields parameter, ρ

s is the density of sediment, ρ is the density of fluid, g is the acceleration of gravity, and d

∗ is the representative sediment size. For uniform sediment, d

∗ is assumed to be the median size, d

50, and for sediment mixtures, the bed would be armored and d

* is taken as d

95, which is the sediment size of which 95% is finer.

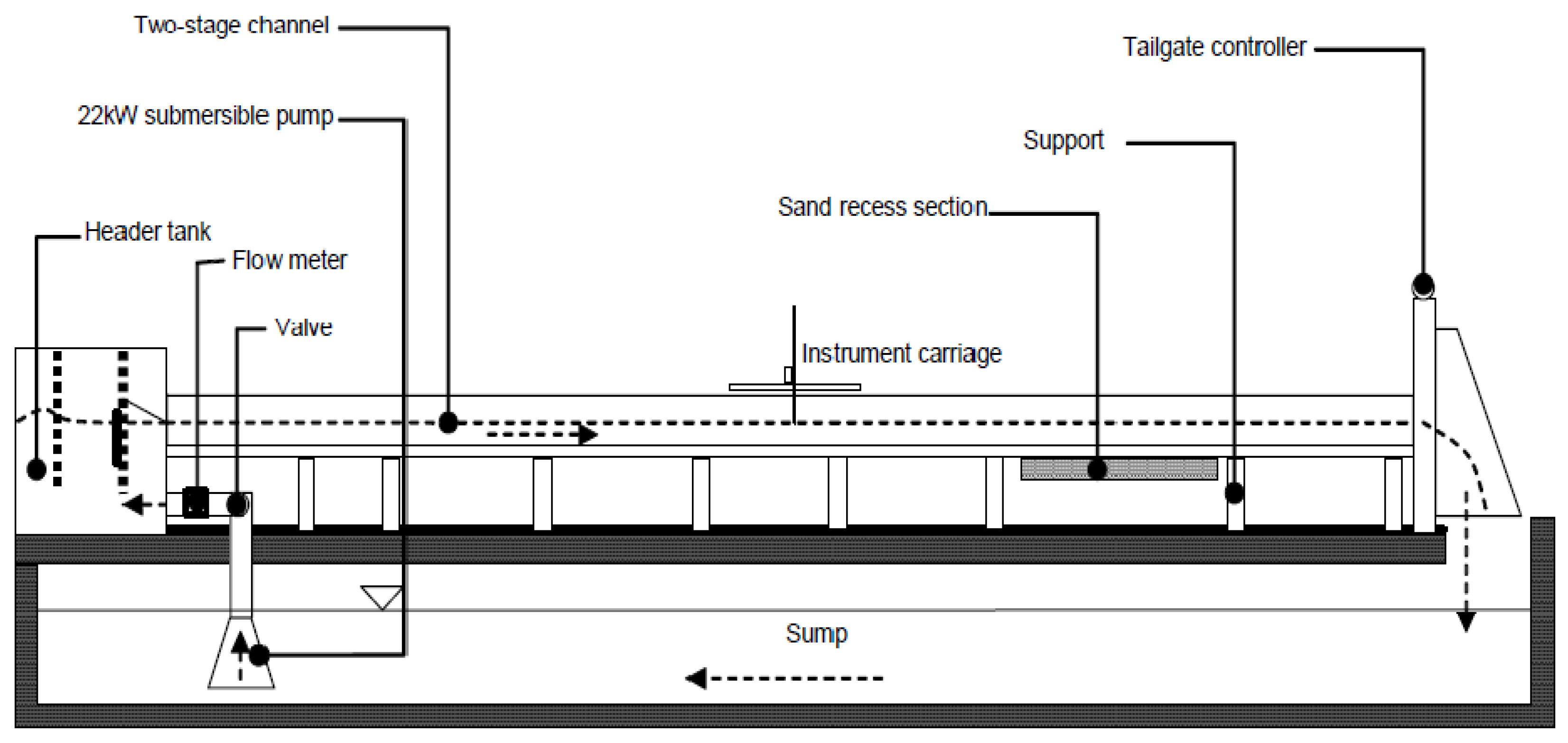

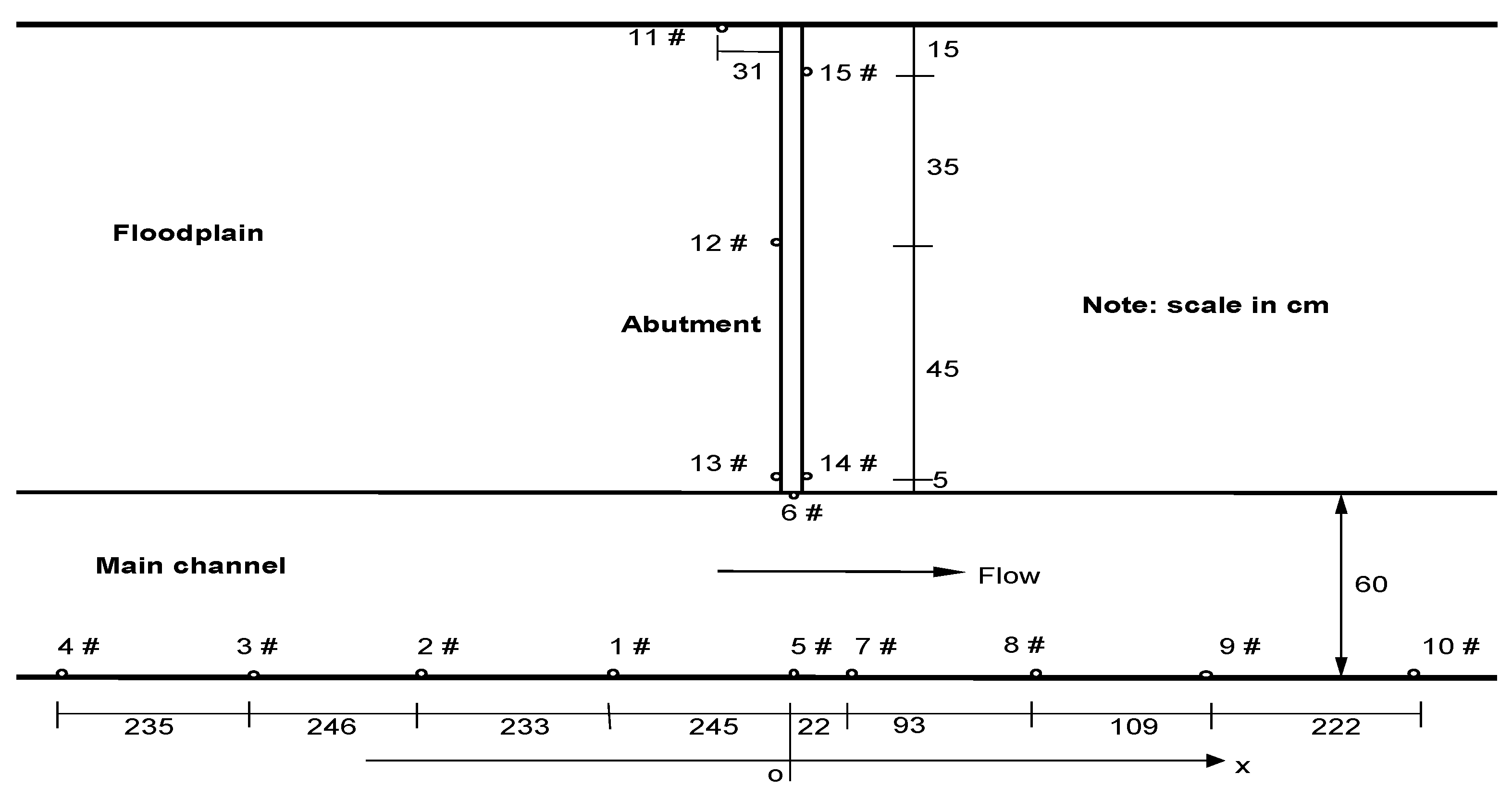

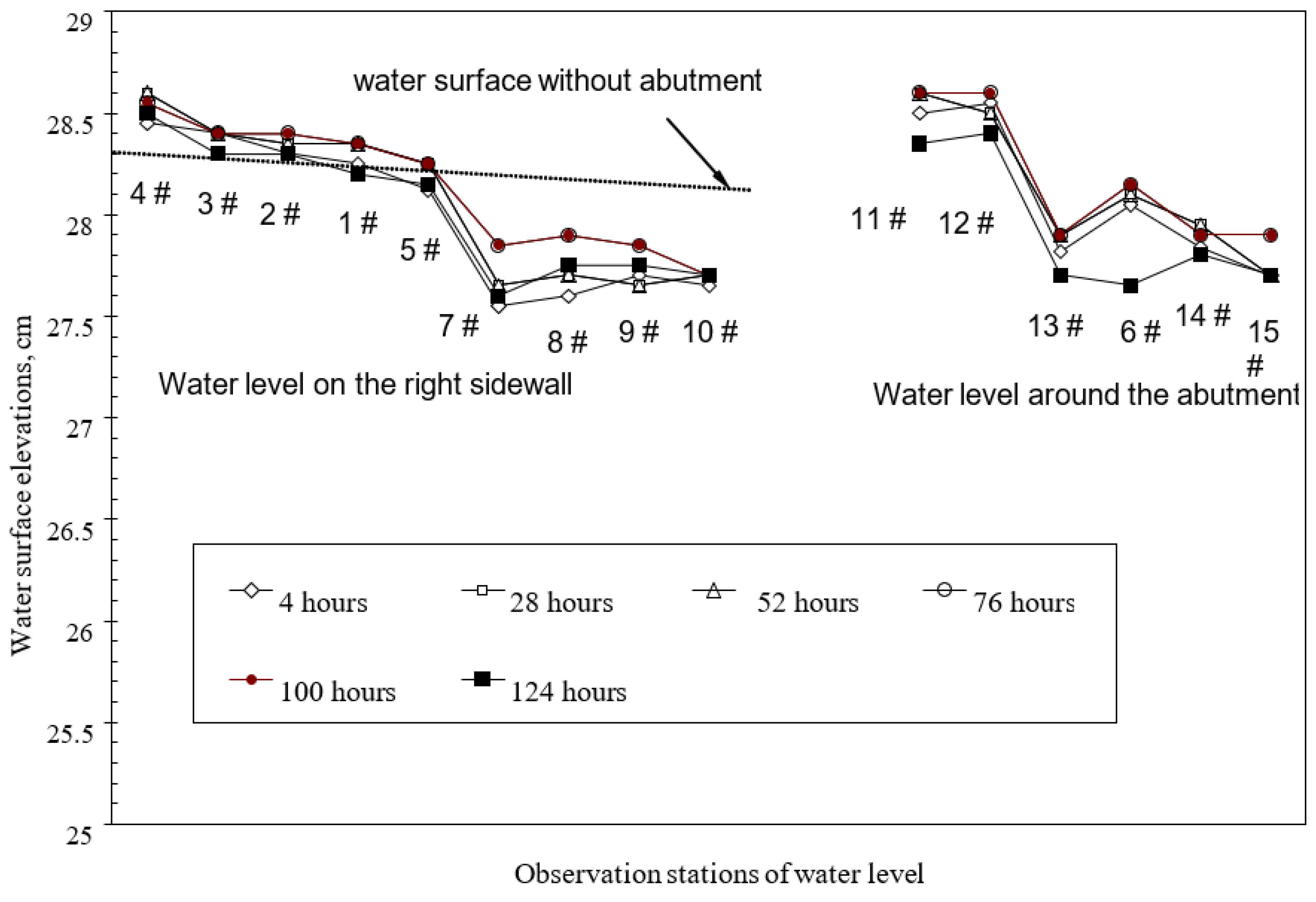

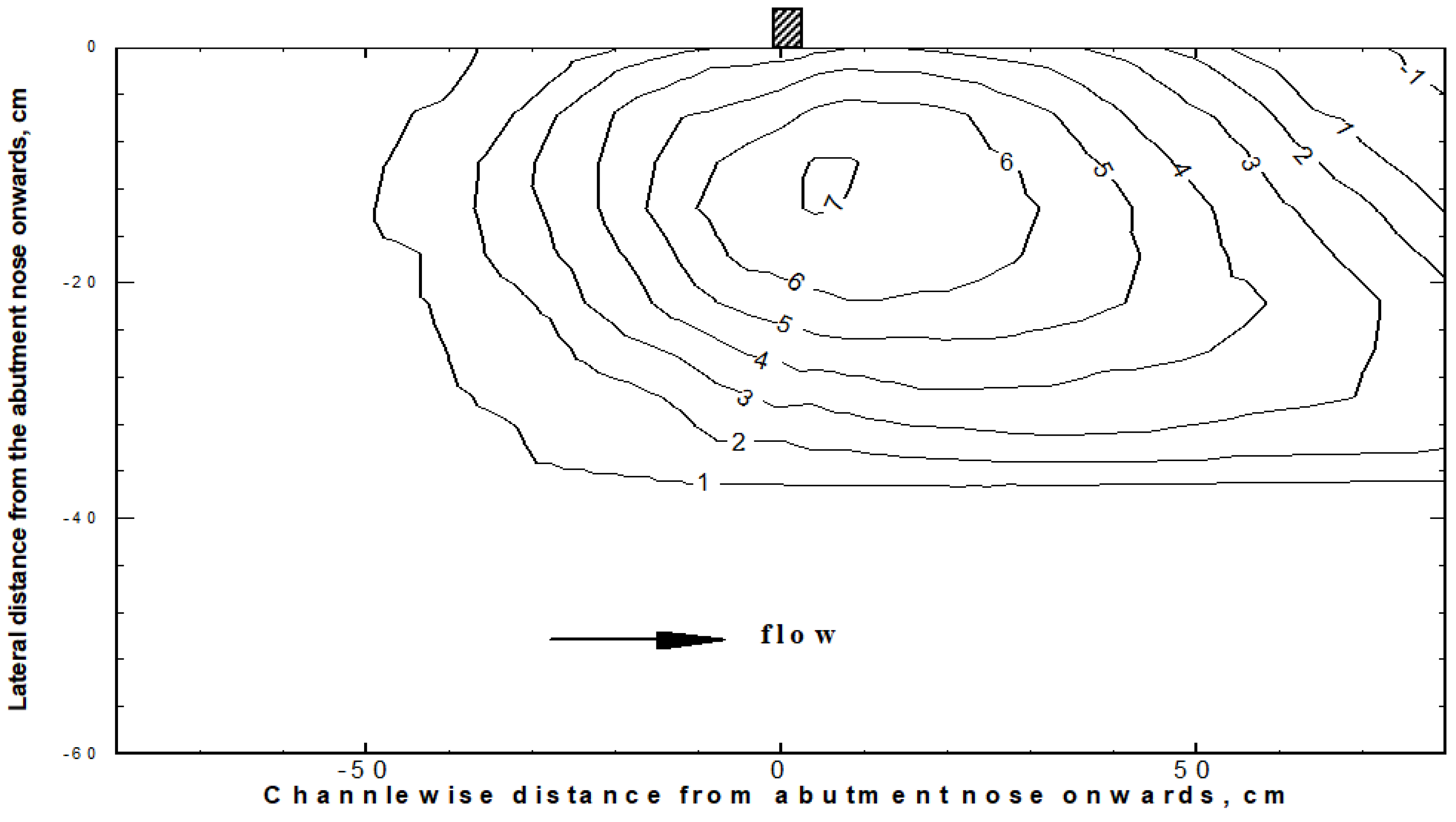

As the scour progresses, it was noticed that the elevation of water surface in the streamwise direction did not change much compared to the flow depth (

Figure 4). This means that the effect of the abutment resulted mainly in an increase in the local velocity. Hence, the depth of flow at any position in the scour hole can be regarded as the sum of the original flow depth (h

mp) and the local scour depth.

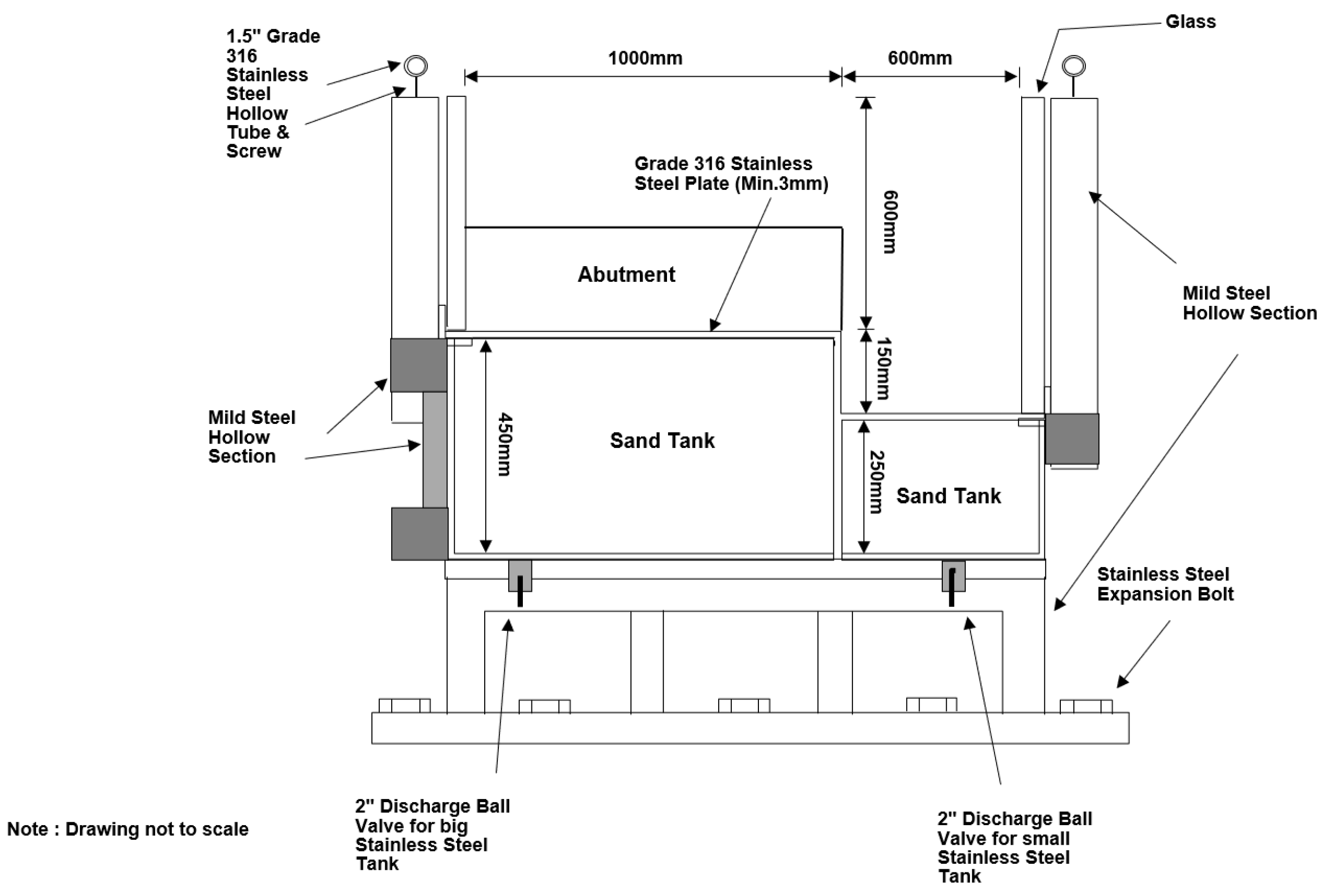

For bankline abutment with a vertical bankfull embankment, the scour hole is formed adjacent to the nose of abutment in the main channel. It is assumed that the lateral scoured profile at the deepest section is at the abutment section, even though the scour contour measurements showed that the maximum scour depth occurs slightly downstream of the abutment section (see

Figure 5). Within this short distance, this assumption would not cause much difference to the flow conditions as the flow dispersed in the floodplain would be comparatively small compared to the total flow in the channel.

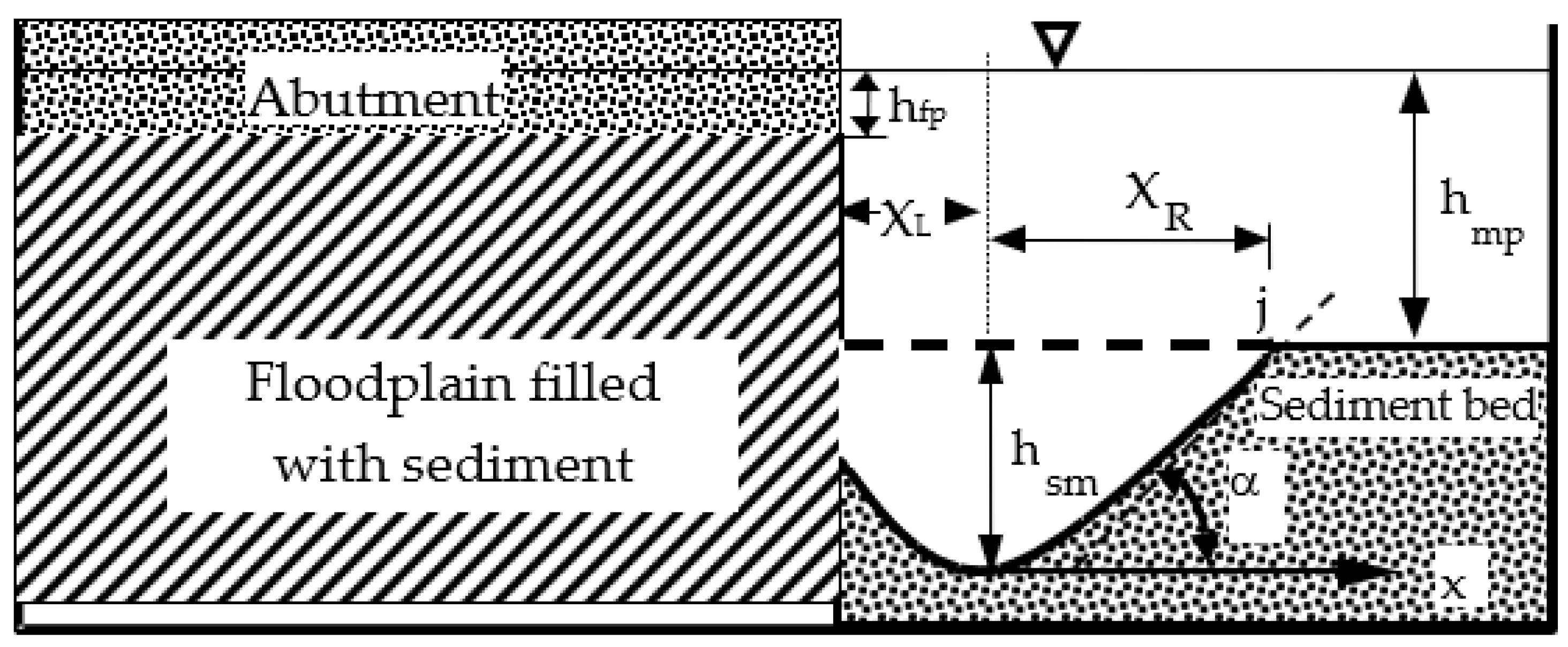

Figure 7 shows that the area of flow above the lateral cross section of the deepest scoured bed profile to the water surface may be segmented into three sub-regions. The first sub-flow region lies within the scour hole with a lateral width of X

L, measured from the abutment nose to the maximum scour depth (h

sm). The second region extends laterally from the maximum scour depth to a point j on the initial bed level, with a width of X

R. The final sub-flow region represents the un-scoured portion, stretching from point j to the sidewall of the main channel. At equilibrium, the shear stress on the bed within the scour hole matches the critical value required to initiate sediment movement on a sloping surface, while on the un-scoured bed, it remains below or equals the critical value for sediment motion on a flatbed [

20].

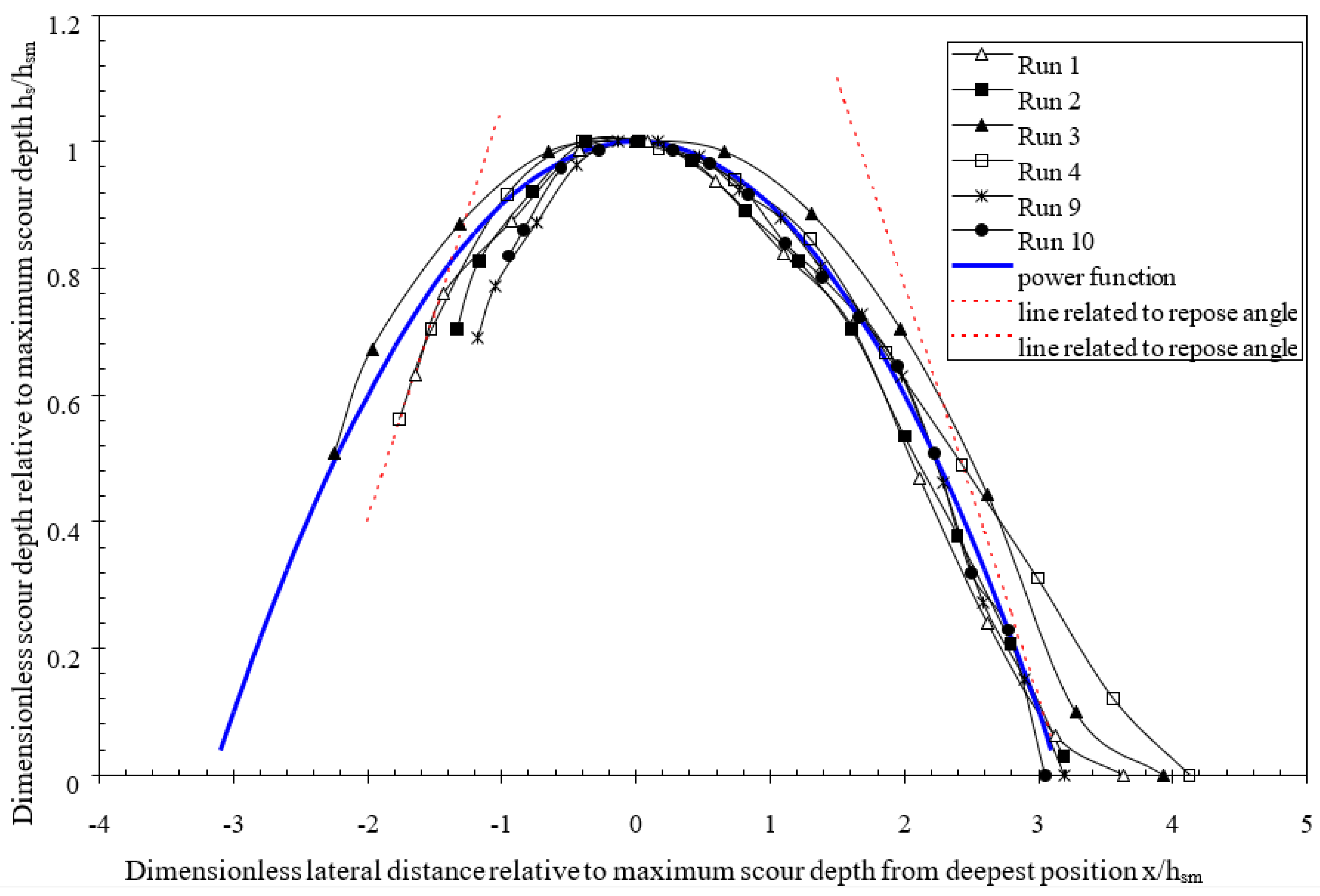

Using a similar approach to the determination of the channel profile of a critical stable channel [

23], the lateral scour hole profile can also be solved numerically with respect to the force balance exerted on the sediment particles on the surface of bed. Considering the deepest scouring location of each run as the origin of the lateral distance, the measured lateral scoured bed profiles are tested for self-similarity by plotting h

s/h

sm against x/h

sm, where h

s is the scour depth at any x-location, and x is measured from the maximum scour point, h

sm.

Figure 8 shows the dimensionless bed profiles for various runs. These lateral bed profiles can be represented by a second-order parabolic function, as shown by the solid line in

Figure 8, which can be expressed as follows:

where the deepest scouring location is the origin of the curve, y is the elevation above the deepest point, and k is the constant associated with the flow conditions and sediment size.

With reference to

Figure 7, it can be assumed that the bed slope at point j should be equal to the submerged repose angle of the sediment particles in still water. If

, where β is the slope of the bed profile at point j, then β would be equal to tan α, where α is the repose angle of the sediment, which can be calculated using the formula proposed by Yu and Knight [

23]. The dotted lines in

Figure 7 show that the angle of repose of the sediment is close to the slope at point j.

Differentiating (3) and substituting

and x = X

R at point j yields the following equation:

From

Figure 7, it can be seen that the ordinate of point j is h

sm and its abscissa is X

R. Hence, using (3), the following equation can be obtained:

From (4) and (5), we can write k and X

R in terms of h

sm and β.

According to the experimental results of the present study, it was found that X

L ≈ X

R/3. Therefore, using (6), the lateral width of the scour hole is as follows:

Since β = tan α and taking α = 33° as a typical value, Equation (7) shows that the scour width is larger than the 2.75 h

sm value suggested by Laursen [

26], bearing in mind that his experiments were carried out under live-bed conditions. The lateral bed profile of the scour hole can be expressed as follows:

With reference to

Figure 7, the flow depth, h, in the main channel at any arbitrary lateral location in the scour hole can be written as follows:

where

.

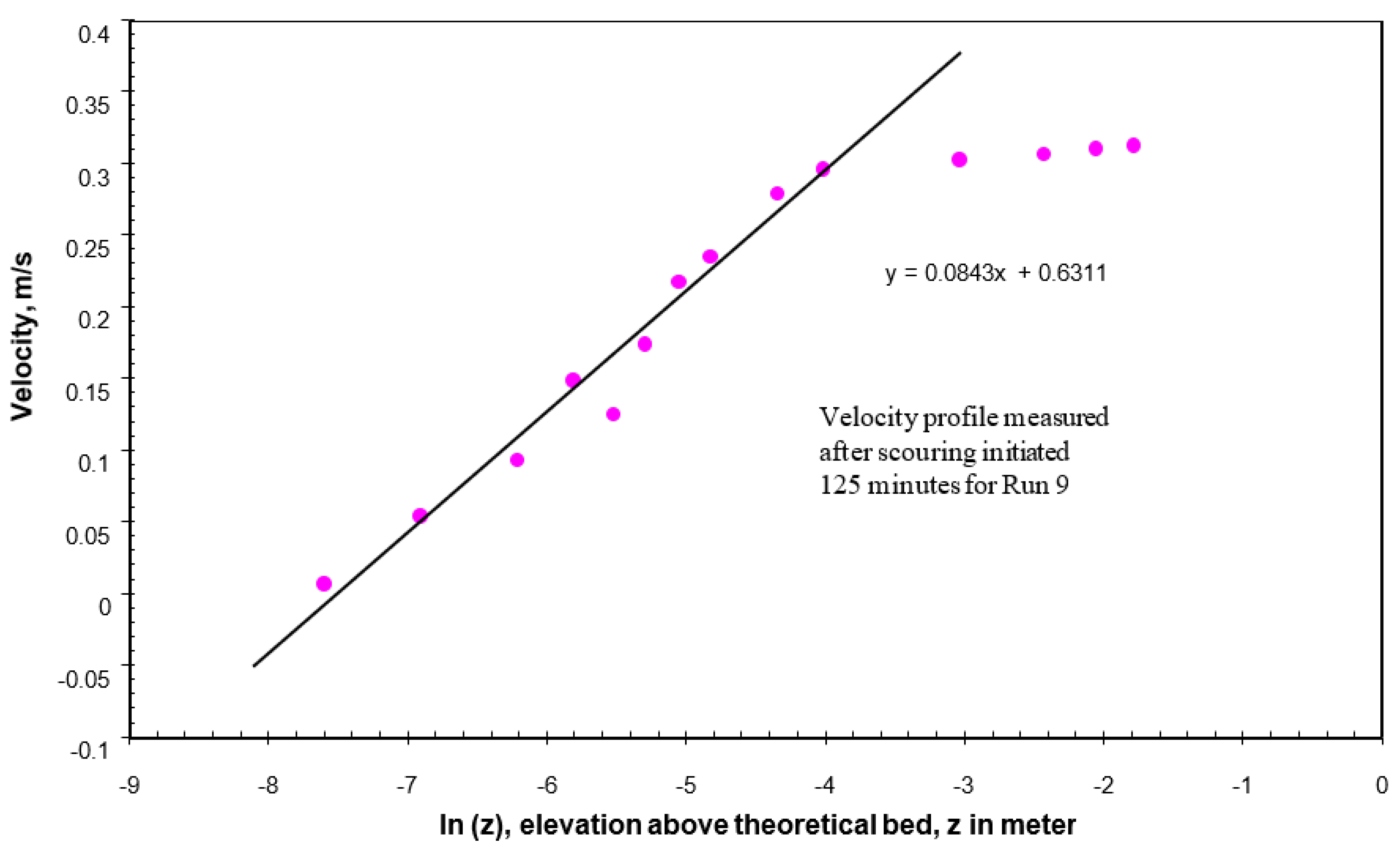

For flow in a wide alluvial channel, we assumed that the velocity distribution for fully turbulent 2D flow may be approximated by the power law [

27].

where U is the depth-averaged velocity, u

∗ is the shear velocity, h is the normal flow depth, k

s is the equivalent sand roughness, (=2d

50); m and n are the coefficient and exponent, respectively. An example of Equation (10) is the one-sixth power law or the Manning–Strickler equation.

From (2) and (10), the depth-averaged velocity at any arbitrary lateral position in the scour hole can be written as follows:

where

.

For a straight compound channel with uniform geometry, the slopes for the floodplain and main channel are typically similar and the mean velocities at the approach section are given by the following formulas:

where R

fp and R

mp are the hydraulic radii, n

fp and n

mp are Manning’s roughness of the floodplain and main channel, respectively. Eliminating S

0 in (12) and (13) yields the following formula:

Substituting (14) into (1), the mean velocity of the un-scoured section from point j (see

Figure 7) to the sidewall of the main channel can be written as follows:

During the experiments, it was observed that the flow directions are not perpendicular to the cross section at the deepest scour location. The flow is being diverted as it approaches the abutment tip towards the main channel and the separation of flow occurs at the lee side of abutment. Lim and Nugroho [

25] observed similar deflection behavior for setback abutment sited on the floodplain. The yaw angle of the flow diversion in the streamwise direction at any arbitrary point of this cross section depends on its geometrical position as well as the ambient flow conditions. The closer it is to the abutment nose, the larger the yaw angle [

9], and this trend has been confirmed from the path of the large-scale vortices by Yu et al. [

20]. Consequently, the yaw of the flow causes a reduction in the conveyance of flow and a correction is needed to calculate the flow discharge through the scour hole section. We assume that the correction factor, denoted as f, is generally proportional to the ratio of the unobstructed main channel flow discharge to the total approach flow discharge, i.e.,

. Considering the correction to the yaw and the non-uniform of flow distribution in the scour hole section, the flow discharge passing through this scour hole section, Q

ss, may be written as follows:

where

, and k

3 is a coefficient. Since

, the term

can be approximated by the following expression:

Substituting (17) into (16) yields the following equation:

which can be further simplified as follows:

The flow discharge over the un-scoured section, Q

us, can be written as follows:

Hence, the total flow discharge can be calculated using the following equation:

where the first term of the right side is the discharge, Q

ss, related to the scour hole (19) and the second term is the discharge, Q

us, associated with the un-scoured bed (20). The equilibrium scour depth can be obtained by solving (4), (19), (20) and (21) using Excel spread sheets or other programs such as FORTRAN, C or Visual Basic.

It should be noted that the solution need not state whether the original bed in the main channel is at the threshold condition of sediment motion. When the approach flow conditions are higher than the threshold condition of sediment motion, the channel bed would be mobile and the flow depth exceeds the critical depth for sediment incipient motion. Otherwise, the flow depth is smaller than the critical depth of sediment incipient motion. In a broad sense, the scour depth is defined as the bed elevation prior to the abutment construction minus the elevation of the deepest scour point. However, in most studies, the experiments were carried out by imposing approximately the threshold velocity on the floodplain, which is supposed to give the most extreme scour depths if the runs are of sufficiently long duration [

3,

28]. In this sense, the definition of the maximum scour depth was confined to compare with such a critical condition.

3.4. Sample Calculation

A sample calculation is shown for the case of Run 1. The measured flow discharge, Q, was 0.0425 m

3/s. With a sediment size of 0.93 mm and ρ

s = 2640 kg/m

3, the corresponding angle of repose was measured, which was 33° and β = 0.65. The measured flow depths were h

mp = 0.209 m and h

fp = 0.059 m. The calculated hydraulic radii are R

mp = 0.131 m and R

fp = 0.054 m. The measured flow velocities in the main channel and floodplain were U

mp = 0.249 m/s and U

fp = 0.195 m/s. The critical Shields parameter θ

c = 0.031 according to the Shields diagram [

29]. We adopted mk

3 = 3.9, n = 1/3, and the equivalent sand roughness k

s = 2d

50 = 1.86 mm. Hence, the coefficient k

1 = 0.175 using

. The measured water surface slope without the abutment was 0.00065. Based on the velocity measurements in the floodplain and main channel for different flow discharges, the mean roughness was evaluated from (12) and (13) for the floodplain and main channel to be n

fp = 0.0186 m

−1/3s and n

mp = 0.0264 m

−1/3s, respectively. The mean approach velocity computed using (15) was 0.249 m/s (herein U

mp was over-assigned), and the correction factor

= 0.731.

Using the solver in the Excel spread sheet, the maximum scour depth can be calculated by trial and error using (19), (20) and (21). For Run 1, we will first assume a value of hsm = 0.08 m. Using (18) and (19), Qss = 0.0285 m3/s and Qus = 0.0140 m3/s, respectively. Using (21), the total calculated flow discharge for this first trial scour depth was Q = 0.0425 m3/s, which was exactly the same as the experimental total discharge. Hence, the calculated maximum scour depth was 0.08 m, which agrees well with the measured scour depth of 0.079 m. The iteration needs to be repeated if Q from (21) is different from the measured value.

3.5. Comparison with Experimental Results

For the present set of experimental data listed in

Table 1, the approach mean velocities on the main channel and floodplain were measured using the ADV. It was found by trial and error that mk

3 in (19) equals 3.9 to obtain a good prediction for the equilibrium maximum scour depth. The Shields parameter θ

c = 0.031 for the 0.93 mm sediment, and this is assumed to be applicable to the bed at the deepest location on the scour hole, which is basically flat. The repose angle of the sediments was measured, which was 33° and β = 0.65.

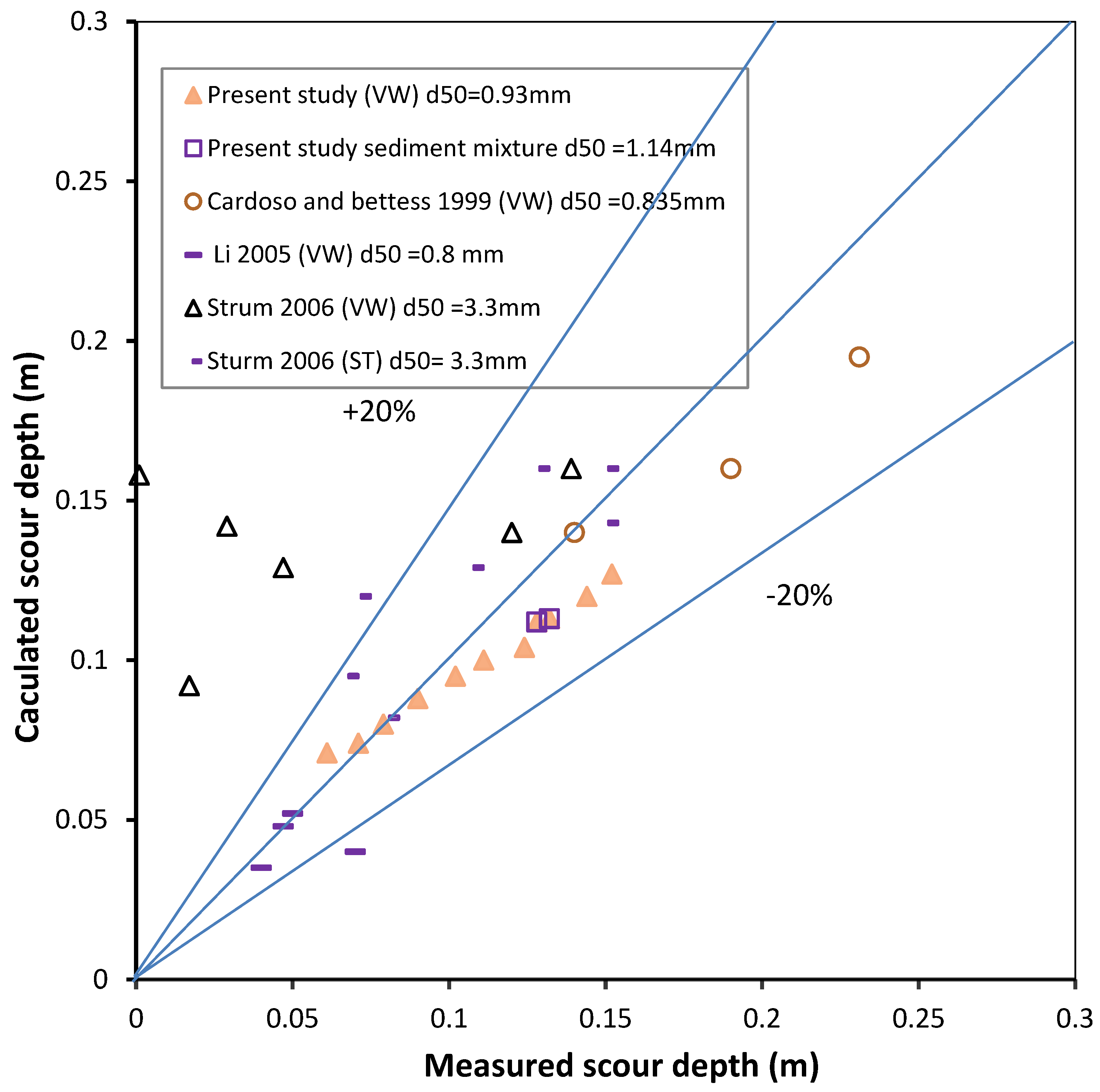

Figure 9 depicts the experimental values against the calculated values for maximum scour depths. The calculated errors ranged from −19% to 14%. The agreement and consistency for the dataset of the 0.93 mm sediment were good. The general trend is that the equations over-predict for the shallow scour holes and under-predict for the deep scour holes for our test range. The reasons for the consistent results are as follows: (1) the same bed material (uniform sediment 0.93 mm) was used; (2) the maximum scour depths were determined from the bed-contours of the scour hole, rather than one-point measurement; (3) the water levels at the approach zone were read using the manometer; and (4) the total flow discharges were recorded using the flow meter. The inconsistency of the dataset might be due to the velocity measurements in the main channel to determine the roughness n

mp.

In addition to the present experiments, three data points from Cardoso and Bettess [

12] were used to check the model. They conducted three tests of Type III (b) in a 22 m long, 2.44 m wide flume. The bed width of the main channel was 1.56 m, and the floodplain width was 0.8 m. The latter was 0.08 m higher than the main channel bed. The submerged floodplain bank had a slope of 1:1. The sediment size used was 0.835 mm with a sediment gradation of 1.26. The corresponding repose angle was assumed to be 33° as the sediment size was close to that of the present experiments. The equilibrium maximum scour depths given in

Table 2 of their paper were measured from the reference level of the floodplain bed. Hence, in order to be consistent with the present definition of the equilibrium scour depths, the data given in their

Table 2 were reduced by the floodplain height of 0.08 m.

Figure 9 shows the calculated values agree well with their experimental results, with errors ranging from −18% to 9 %, and this is better than the trend of the present experiment dataset. It is noted that the experimental set-ups were slightly different, as we used vertical and fixed main channel walls, whereas Cardoso and Bettess [

12] used an inclined and erodible wall. An inclined wall (1:1) may shift the flow much more away from the abutment nose. This is the reason why the predictions for Cardoso and Bettess [

12] are slightly higher than the predictions for the present experiments.

Furthermore, we used four data points of a vertical wall from Li [

21] to check the model. He conducted five tests of Type III (b) in a 30 m long, 1.2 m wide flume. The bed width of the main channel was 0.8 m. The floodplain (width 0.32 m) was 0.08 m higher than the main channel bed. The submerged floodplain bank had a slope of 1:1. The sediment size used was 0.8 mm with a sediment gradation of 1.37. The corresponding repose angle was assumed to be 34°. The maximum scour depths of this study were given in

Table 3.

Figure 9 depicts that the agreement between measured and calculated scour depths for the previous study is acceptable. This is probably because the dimensions of flume and sediment size are similar to that of the present study.

Finally, we used six data points of a vertical wall and seven data points of a spill-through (two horizontal; one vertical) from Sturm [

17] to check the model. He conducted 13 tests of Type III (b) in a 24.4 m long, 4.2 m wide flume. The bed width of the main channel was 0.55 m. The floodplain (width 3.66 m) was 0.154 m higher than the main channel bed. The submerged floodplain bank had a slope of 2.6 H:1 V. The sediment size used was 3.3 mm with a sediment gradation of 1.3. The corresponding repose angle was assumed to be 33°. The maximum scour depths given in

Table 4 of his paper were measured from the reference level of the floodplain bed. Hence, in order to be consistent with the present definition of the equilibrium scour depths, the data given in their

Table 3 have been reduced by the floodplain height of 0.154 m.

Figure 9 shows that (1) the errors in Sturm’s data range from 13% to 80% for a vertical wall, and from −6% to 28% for spill-through, (2) the calculated values are higher than the measured values of scour depth as the experiments last only for 24 to 65 h, and this period is not enough for scour depth to reach equilibrium. It is observed that, for the same discharge and water depth, the measured scour depths for both the spill-through and vertical wall are close to each other and, in some cases, the measured scour depth for spill-through is higher than that for a vertical wall. In addition, there was a relatively long slope connecting the bed of the main channel and the bed of the flood plain. From the above, we can conclude that (1) the shape factor of abutment has less effect on scour depth in the main channel, and (2) the shape factor of spill-through is the same as that of the vertical wall and is equal to one.