Modeling Spring Maize Grain Filling under Film Mulching and Nitrogen Application in a Cold and Arid Environment

Abstract

:1. Introduction

2. Materials and Methods

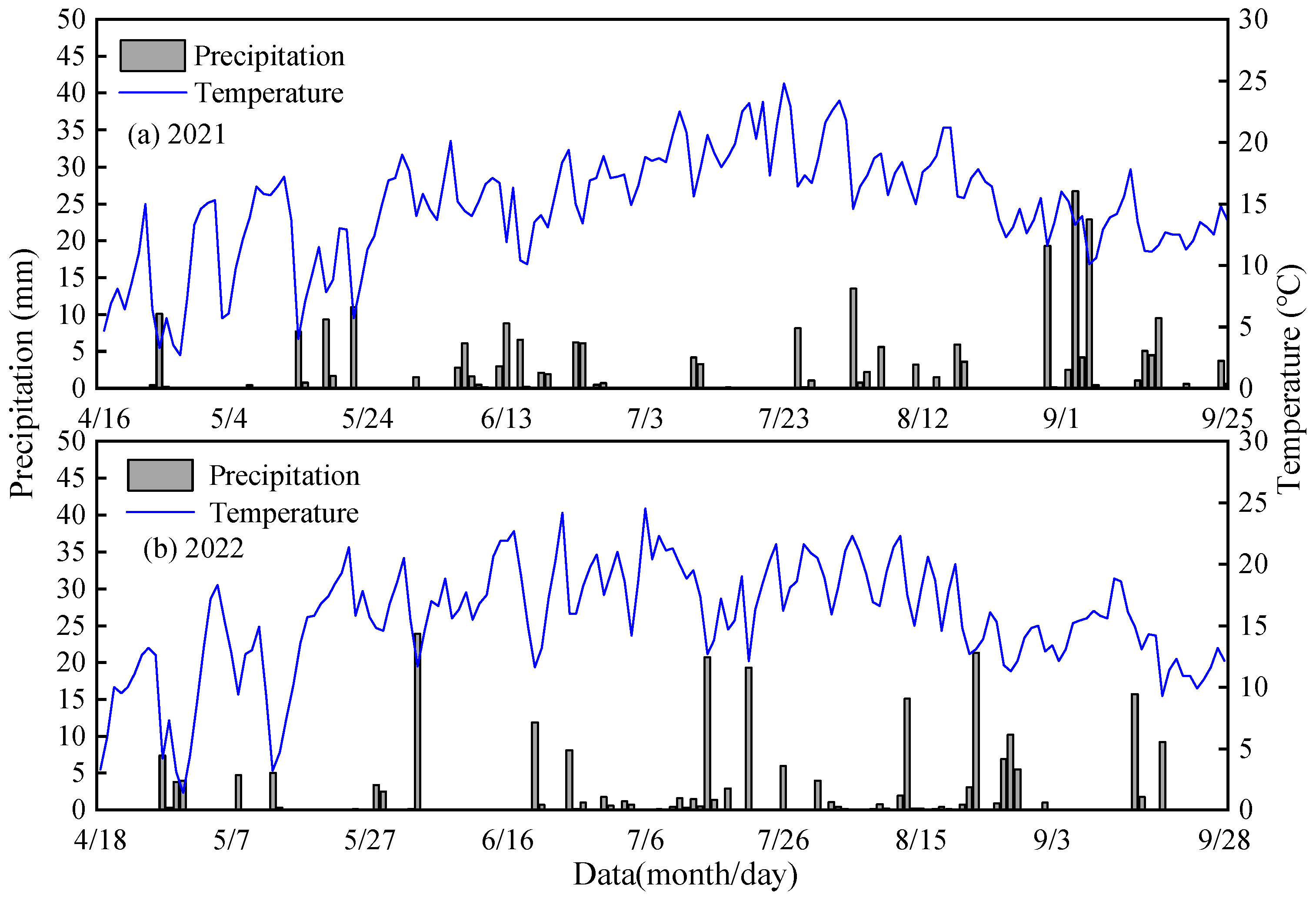

2.1. Site Description

2.2. Experimental Design

2.3. Determination of Maize Grain-Filling Process

2.4. Model Description

2.4.1. Model Fitting

2.4.2. Grain-Filling Rate

- a.

- Initial growth power.

- b.

- Growth increment at maximum grain filling rate (g).

- c.

- Maximal grain filling rate.

- d.

- Time to reach maximum grain filling rate.

- e.

- Mean grain-filling rate.

2.4.3. Grain-Filling Stage

2.4.4. Gray Relational System Correlation Analysis

2.4.5. Path Analysis

2.5. Statistical Analysis

3. Results

3.1. Yield Components

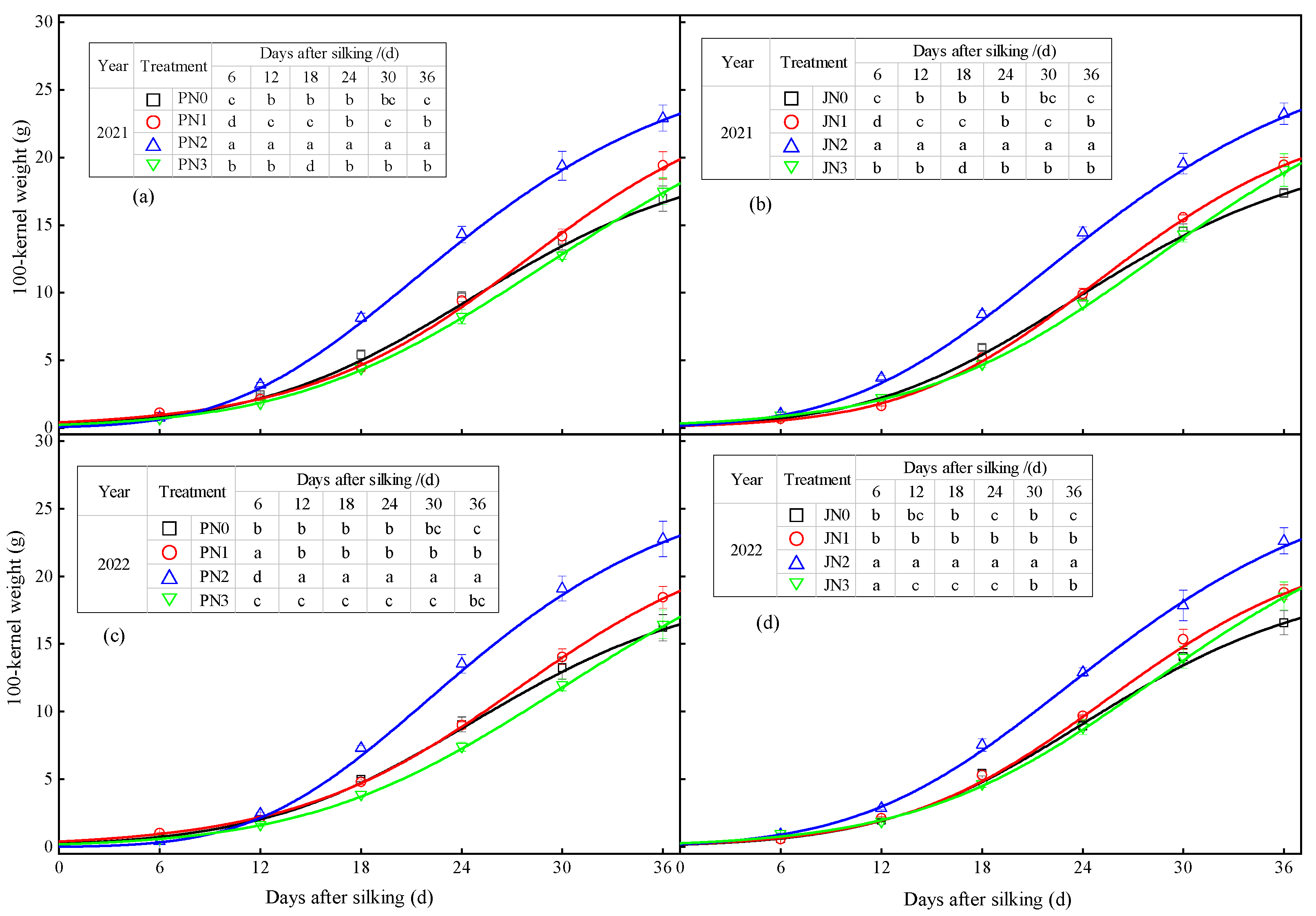

3.2. The 100-Kernel Weight

3.3. Grain-Filling Model

3.4. Characteristic Parameters during Maize Grain Filling

3.5. Parameters at Each Plant Growth Stage

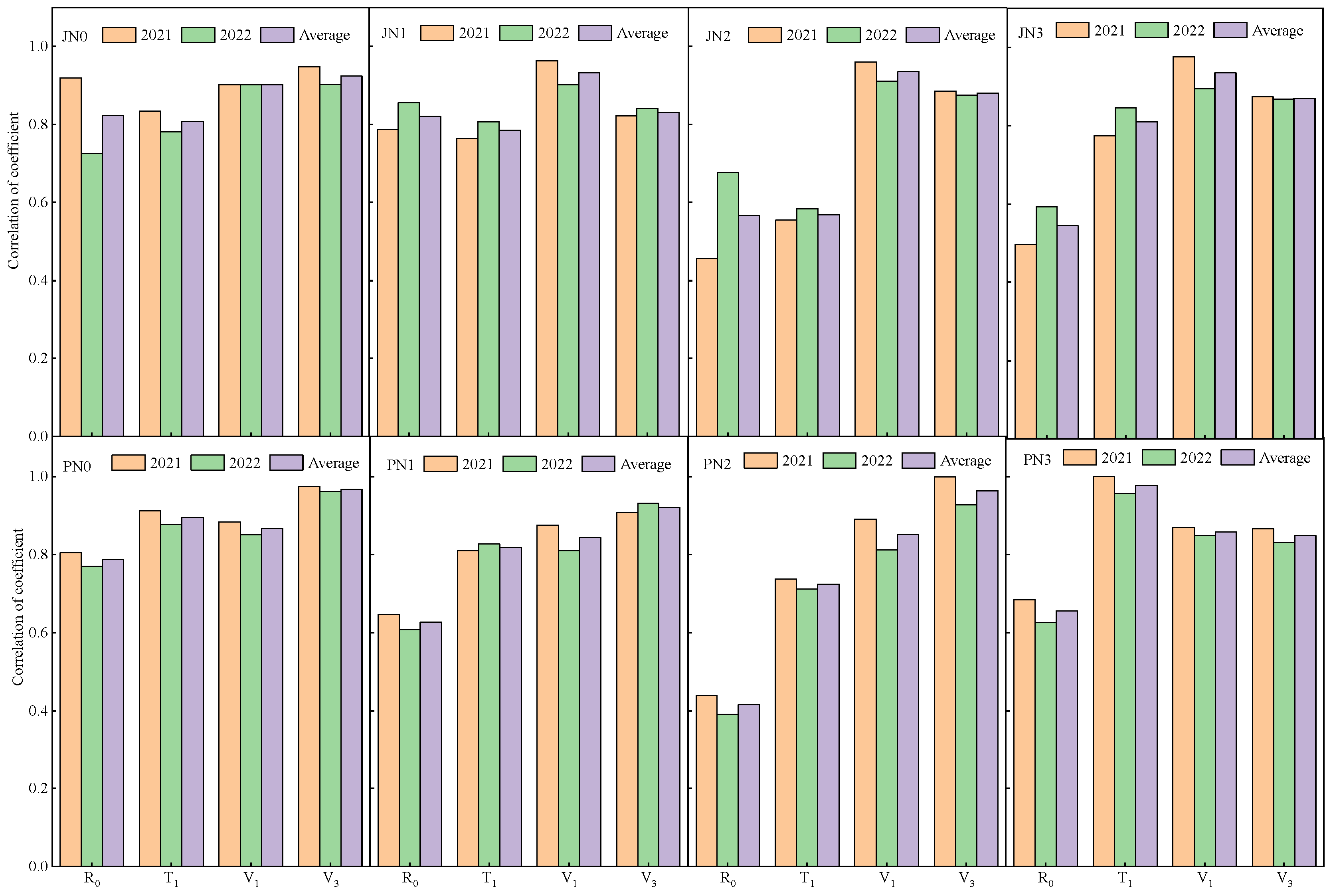

3.6. Correlation Analysis between Grain-Filling Parameters and 100-Kernel Weight

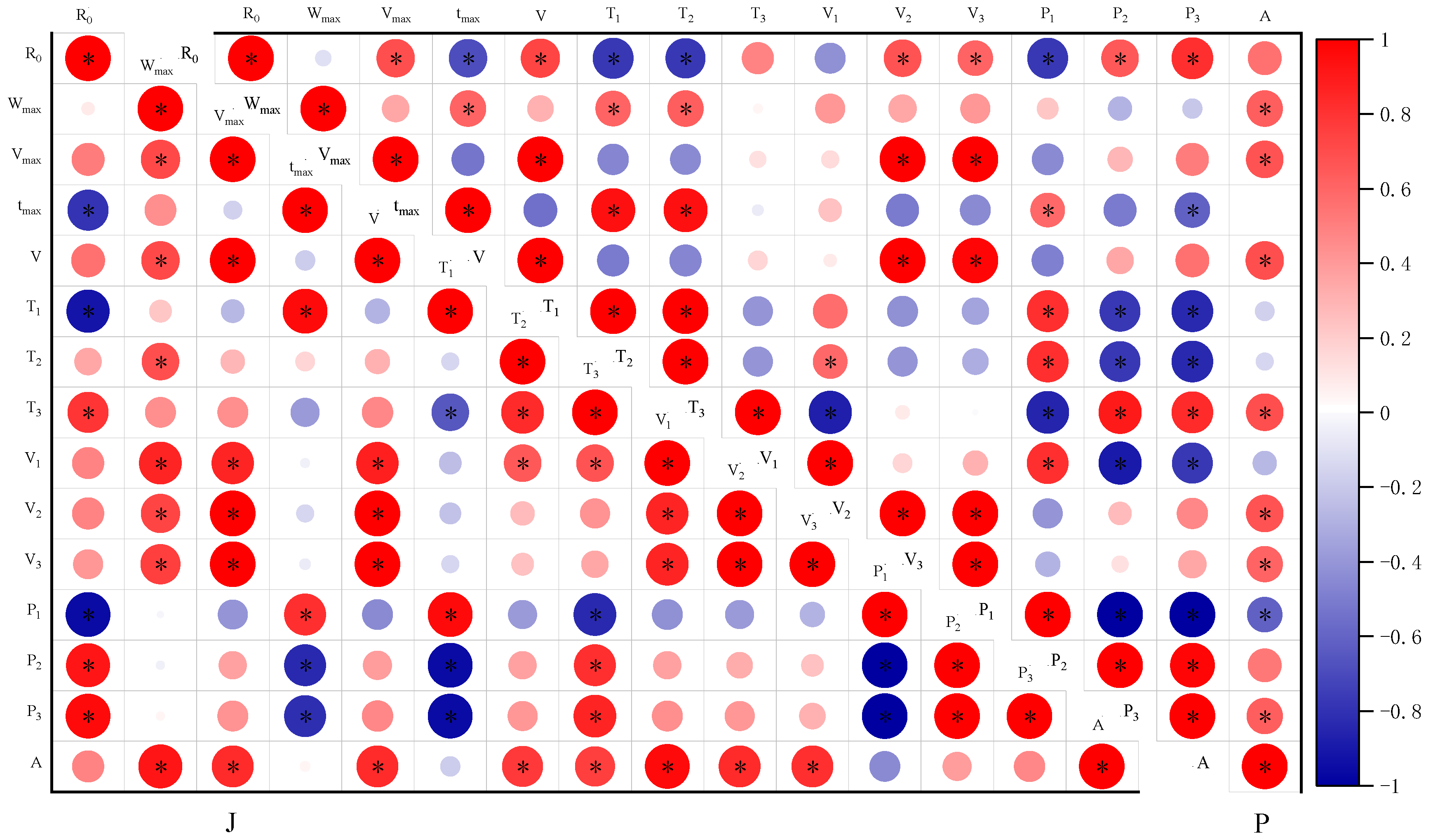

3.7. Correlation and Path Analysis between Grain-Filling Parameters and 100-Kernel Weight

4. Discussion

4.1. Effects of Plastic-Film Mulching and Nitrogen Application on Grain-Filling Characteristic Parameters of Spring Maize

4.2. Effects of Plastic-Film Mulching and Nitrogen Application on Parameters of Filling Stage of Spring Maize

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, W.; Gu, X.; Du, Y.; Chang, T.; Lu, S.; Zheng, X.; Bai, D.; Song, H.; Sun, S.; Cai, H. Effects of mulching on water saving, yield increase and emission reduction for maize in China. Agric. Water Manag. 2022, 274, 107954. [Google Scholar] [CrossRef]

- Li, F.; Zhang, G.; Chen, J.; Song, Y.; Geng, Z.; Li, K.; Siddique, K. Straw mulching for enhanced water use efficiency and economic returns from soybean fields in the Loess Plateau China. Sci. Rep. 2022, 12, 17111. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Yong, L.; Zhang, Z.; Sun, Z.; Wan, Q.; Xu, Y.; Ma, H.; Sang, L.; Liu, Y.; Wang, L.; et al. Effects of plastic mulch on soil water migration in arid oasis farmland: Evidence of stable isotopes. Catena 2021, 207, 105580. [Google Scholar] [CrossRef]

- Rao, S.; Singh, P.; Gonsalves, T. Black plastic mulch affects soil temperature and yield of sweet potato under short season temperate climates. J. Veg. Sci. 2023, 29, 72–83. [Google Scholar] [CrossRef]

- Zhang, B.; Hu, H.; Guo, Z.; Gong, S.; Shen, S.; Liao, S.; Wang, X.; Zhou, S.; Zhang, Z. Plastic-film-side seeding, as an alternative to traditional film mulching, improves yield stability and income in maize production in semi-arid regions. J. Integr. Agric. 2023, 22, 1021–1034. [Google Scholar] [CrossRef]

- Blaise, D.; Manikandan, A.; Desouza, N.; Bhargavi, B.; Somasundaram, J. Intercropping and mulching in rain-dependent cotton can improve soil structure and reduce erosion. Environ. Adv. 2021, 4, 100068. [Google Scholar] [CrossRef]

- Quan, H.; Wu, L.; Ding, D.; Yang, Z.; Wang, N.; Chen, G.; Li, C.; Dong, Q.; Feng, H.; Zhang, T.; et al. Interaction between soil water and fertilizer utilization on maize under plastic mulching in an arid irrigation region of China. Agric. Water Manag. 2022, 265, 107494. [Google Scholar] [CrossRef]

- Ramón, A.; Eva, T.; Ignacio, C. Effectiveness of inorganic and organic mulching for soil salinity and sodicity control in a grapevine orchard drip-irrigated with moderately saline waters. Span. J. Agric. Res. 2014, 12, 501–508. [Google Scholar]

- Jiang, X.; Liu, W.; Wang, E.; Zhou, T.; Pei, X. Residual plastic mulch fragments effects on soil physical properties and water flow behavior in the Minqin Oasis, northwestern China. Soil Tillage Res. 2017, 166, 100–107. [Google Scholar] [CrossRef]

- Marion, B.; Jessica, R.; Douglas, G.; Debra, A.; Thomas, L.; Carol, M. Policy considerations for limiting unintended residual plastic in agricultural soils. Environ. Sci. Policy 2017, 69, 81–84. [Google Scholar]

- Zacharias, S.; Claudia, W.; Miriam, S.; Christian, B.; Jan, D.; Josephine, T.; Katherine, M.; Oliver, F.; Gabriele, E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar]

- Jin, X.; An, T.; Gall, A.; Li, S.; Sun, L.; Pei, J.; Gao, X.; He, X.; Fu, S.; Ding, X.; et al. Long-term plastic film mulching and fertilization treatments changed the annual distribution of residual maize straw C in soil aggregates under field conditions: Characterization by 13C tracing. J. Soils Sediments 2018, 18, 169–178. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Jia, W.; Yan, C.; Wang, J. Agricultural plastic mulching as a source of microplastics in the terrestrial environment. Environ. Pollut. 2020, 260, 114096. [Google Scholar] [CrossRef] [PubMed]

- Qi, R.; Jones, D.; Li, Z.; Liu, Q.; Yan, C. Behavior of microplastics and plastic film residues in the soil environment: A critical review. Sci. Total Environ. 2020, 703, 134722. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Ossowicki, A.; Yang, X.; Esperanza, L.; Francisco, D.; Violette, G.; Paolina, G. Effects of plastic mulch film residues on wheat rhizosphere and soil properties. J. Hazard. Mater. 2020, 387, 121711. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Ren, S.; Xu, W.; Liang, C.; Li, J.; Zhang, H.; Li, Y.; Liu, X.; Jones, D.; Chadwick, D.; et al. Effects of plastic residues and microplastics on soil ecosystems: A global meta-analysis. J. Hazard. Mater. 2022, 435, 129065. [Google Scholar] [CrossRef] [PubMed]

- Marta, M.; Sara, G.; Jaime, V.; Juan, A.; Carmen, M. Deterioration pattern of six biodegradable, potentially low-environmental impact mulches in field conditions. J. Environ. Manag. 2017, 200, 490–501. [Google Scholar]

- Zhao, Y.; Zhang, F.; Li, L.; Yang, X.; Zhang, F.; Zhao, W.; He, Q. Substitution Experiment of Biodegradable Paper Mulching Film and White Plastic Mulching Film in Hexi Oasis Irrigation Area. Coatings 2022, 12, 1225. [Google Scholar] [CrossRef]

- Huang, F.; Liu, Z.; Mou, H.; Zhang, P.; Jia, Z. Effects of different long-term farmland mulching practices on the loessial soil fungal community in a semiarid region of China. Appl. Soil Ecol. 2019, 137, 111–119. [Google Scholar] [CrossRef]

- Chen, N.; Li, X.; Shi, H.; Hu, Q.; Zhang, Y.; Leng, X. Effect of biodegradable film mulching on crop yield, soil microbial and enzymatic activities, and optimal levels of irrigation and nitrogen fertilizer for the Zea mays crops in arid region. Sci. Total Environ. 2021, 776, 145970. [Google Scholar] [CrossRef]

- Gao, F.; Li, B.; Ren, B.; Zhao, B.; Liu, P.; Zhang, J. Achieve simultaneous increase in straw resources efficiency and nitrogen efficiency under crop yield stabilization—A case study of NCP in China for up to 8 years. Field Crop. Res. 2022, 278, 108431. [Google Scholar] [CrossRef]

- Chi, Y.; Gao, F.; Muhammad, I.; Huang, J.; Zhou, X. Effect of water conditions and nitrogen application on maize growth, carbon accumulation and metabolism of maize plant in subtropical regions. Arch. Agron. Soil Sci. 2023, 69, 693–707. [Google Scholar] [CrossRef]

- Yang, M.; Ma, S.; Mei, F.; Li, W.; Wang, T.; Guan, X. Adjusting Nitrogen Application in Accordance with Soil Water Availability Enhances Yield and Water Use by Regulating Physiological Traits of Maize under Drip Fertigation. Phyton 2021, 90, 417–435. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Chen, J.; Chen, A.; Wang, L.; Guo, X.; Niu, Y.; Liu, S.; Mi, G.; Gao, Q. Reducing basal nitrogen rate to improve maize seedling growth, water and nitrogen use efficiencies under drought stress by optimizing root morphology and distribution. Agric. Water Manag. 2019, 212, 328–337. [Google Scholar] [CrossRef]

- Elias, M.; Zhang, Z.; Dong, W.; Wang, S.; Liu, M.; Liu, E.; Mei, X. Plastic Film Mulching Improved Maize Yield, Water Use Efficiency, and N Use Efficiency under Dryland Farming System in Northeast China. Plants 2022, 11, 1710. [Google Scholar]

- Wang, X.; Wang, G.; Guo, T.; Xing, Y.; Mo, F.; Wang, H.; Fan, J.; Zhang, F. Effects of plastic mulch and nitrogen fertilizer on the soil microbial community, enzymatic activity and yield performance in a dryland maize cropping system. Eur. J. Soil Sci. 2020, 72, 400–412. [Google Scholar] [CrossRef]

- Fang, H.; Gu, X.; Jiang, T.; Yang, J.; Li, Y.; Huang, P.; Chen, P.; Yang, J. An optimized model for simulating grain-filling of maize and regulating nitrogen application rates under different film mulching and nitrogen fertilizer regimes on the Loess Plateau, China. Soil Tillage Res. 2020, 199, 104546. [Google Scholar] [CrossRef]

- Du, Y.; Sun, J.; Wang, Z.; Zhang, Q.; Cui, B.; Niu, W. Effect of ridge film mulching and nitrogen application rate on seed quality, oil yield and nitrogen-use efficiency of winter oilseed rape in northwest China. Arch. Agron. Soil Sci. 2022, 68, 1385–1397. [Google Scholar] [CrossRef]

- Xie, J.; Shi, X.; Zhang, Y.; Wan, Y.; Hu, Q.; Zhang, Y.; Wang, J.; He, X.; Evgenia, B. Improved nitrogen use efficiency, carbon sequestration and reduced environmental contamination under a gradient of manure application. Soil Tillage Res. 2022, 220, 105386. [Google Scholar] [CrossRef]

- Guo, R.; Qian, R.; Han, F.; Abdul, K.; Sadam, H.; Li, Y.; Zhang, P.; Chen, X.; Ren, X. Managing straw and nitrogen fertilizer based on nitrate threshold for balancing nitrogen requirement of maize and nitrate residue. J. Environ. Manag. 2023, 329, 117084. [Google Scholar] [CrossRef]

- Hamani, A.; Abubakar, S.; Wang, G.; Kama, R.; Kurihara, T.; Liu, K.; Gao, Y.; Duan, A. Optimized application of combined nitrogen and microbial decomposing inoculants increases wheat (Triticum aestivum L.) physiological growth and mitigates global warming potential under different water regimes. Environ. Exp. Bot. 2023, 206, 105170. [Google Scholar] [CrossRef]

- Luo, C.; Wang, R.; Li, C.; Zheng, C.; Dou, X. Photosynthetic characteristics, soil nutrients, and their interspecific competitions in an apple–soybean alley cropping system subjected to different drip fertilizer regimes on the Loess Plateau, China. Agric. Water Manag. 2023, 275, 108001. [Google Scholar] [CrossRef]

- Li, C.; Wang, Q.; Wang, N.; Luo, X.; Li, Y.; Zhang, T.; Feng, H.; Dong, Q. Effects of different plastic film mulching on soil hydrothermal conditions and grain-filling process in an arid irrigation district. Sci. Total Environ. 2021, 795, 148886. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Zhang, Q.; Hu, S.; Wang, R.; Wang, H.; Zhang, K.; Zhao, H.; Ren, S.; Yang, Y.; Zhao, F.; et al. Effects of High Temperature and Drought Stresses on Growth and Yield of Summer Maize during Grain Filling in North China. Agriculture 2022, 12, 1948. [Google Scholar] [CrossRef]

- Hussain, M.; Wang, Z.; Mo, Y.; Huang, G.; Kaousar, R.; Tan, W. Influence of Exogenous 28-Homobrassinolide Optimized Dosage and EDAH Application on Hormone Status, Grain Filling, and Maize Production. Processes 2022, 10, 1118. [Google Scholar] [CrossRef]

- Deng, T.; Wang, J.; Gao, Z.; Shen, S.; Liang, X.; Zhao, X.; Chen, X.; Wu, G.; Wang, X.; Zhou, S. Late Split-Application with Reduced Nitrogen Fertilizer Increases Yield by Mediating Source–Sink Relations during the Grain Filling Stage in Summer Maize. Plants 2023, 12, 625. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Li, Y.; Yang, M.; Li, C.; Song, Y.; Wang, T.; Li, Y.; Shi, Y. Changes in grain-filling characteristics of single-cross maize hybrids released in China from 1964 to 2014. J. Integr. Agric. 2023, 22, 691–700. [Google Scholar] [CrossRef]

- Fu, J.; He, Z.; Jia, B.; Liu, Z.; Li, Z.; Liu, H.; Liu, G. Simulation of maize grain filling process under nitrogen drip irrigation. Soil Fertil. Sci. China 2020, 288, 157–164. [Google Scholar]

- Wang, Y.; Song, Y.; Zhang, Y.; Kong, D.; Zhao, Q.; Lin, J.; Huang, K. Characteristics of starch synthesis and grain filling of common buckwheat. J. Cereal Sci. 2017, 73, 116–121. [Google Scholar] [CrossRef]

- Wen, T.; Jia, Y.; Du, X.; You, J.; Yin, X.; Wen, Z.; Yang, W.; Shi, H.; Gao, H.; Zhu, J.; et al. Response of super and inferior grain filling characteristics in rice to exogenous plant growth regulators based on Richards equation. J. Nanjing Agric. Univ. 2022, 45, 1107–1116. [Google Scholar]

- Du, S.; Qiao, Y.; Li, W.; Chen, H.; Zhao, Z.; Zhang, X.; Cao, C. Effects of sowing date and rate on grain filling characteristics of winter wheat under chilling injury. Chin. J. Eco-Agric. 2014, 22, 551–559. [Google Scholar]

- Yue, K.; Li, L.; Xie, J.; Wang, L.; Liu, Y.; Anwar, S. Tillage and nitrogen supply affects maize yield by regulating photosynthetic capacity, hormonal changes and grain filling in the Loess Plateau. Soil Tillage Res. 2022, 218, 105317. [Google Scholar] [CrossRef]

- Ren, H.; Jiang, Y.; Zhao, M.; Qi, H.; Li, C. Nitrogen Supply Regulates Vascular Bundle Structure and Matter Transport Characteristics of Spring Maize Under High Plant Density. Front. Plant Sci. 2021, 11, 602739. [Google Scholar] [CrossRef] [PubMed]

- Yu, N.; Zhang, J.; Liu, P.; Zhao, B.; Ren, B. Integrated agronomic practices management improved grain formation and regulated endogenous hormone balance in summer maize (Zea mays L.). J. Integr. Agric. 2020, 19, 1768–1776. [Google Scholar] [CrossRef]

- Wei, S.; Wang, X.; Li, G.; Qin, Y.; Jiang, D.; Dong, S. Plant Density and Nitrogen Supply Affect the Grain-Filling Parameters of Maize Kernels Located in Different Ear Positions. Front. Plant Sci. 2019, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Commuri, P.; Jones, R. Ultrastructural characterization of maize (Zea mays L.) kernels exposed to high temperature during endosperm cell division. Plant Cell Environ. 2010, 22, 375–385. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zou, Q.; Ding, W. Effects of Combined Application of Slow-release Fertilizer on the Filling Characteristics of Summer Maize. Water Sav. Irrig. 2022, 324, 84–90+101. [Google Scholar]

- Li, A.; Zhang, J.; Cui, X.; Zhao, L.; Liu, J.; Hu, T. Nitrogen fertilizer synergist in urea under irrigation for high yield of summer maize at the filling stag. Trans. CSAE 2023, 39, 99–110. [Google Scholar]

- Pico, L.; Vyn, T. Dry Matter Gains in Maize Kernels Are Dependent on Their Nitrogen Accumulation Rates and Duration during Grain Filling. Plants 2021, 10, 1222. [Google Scholar] [CrossRef]

- Gasura, E.; Setimela, P.; Edema, R.; Gibson, P.; Okori, P.; Tarekegne, A. Exploiting Grain-Filling Rate and Effective Grain-Filling Duration to Improve Grain Yield of Early-Maturing Maize. Crop Sci. 2013, 53, 2295–2303. [Google Scholar] [CrossRef]

- Li, Q.; Du, L.; Feng, D.; Ren, Y.; Li, Z.; Kong, F.; Yuan, J. Grain-filling characteristics and yield differences of maize cultivars with contrasting nitrogen efficiencies. Crop J. 2020, 8, 990–1001. [Google Scholar] [CrossRef]

| Year | Treatment | Ear Length (cm) | Ear Diameter (mm) | Kernels | Ear Weight (g) |

|---|---|---|---|---|---|

| 2021 | JN0 | 16.8 ± 0.66 c | 45.86 ± 1.82 b | 476 ± 10.69 d | 184.66 ± 5.18 c |

| JN1 | 18.4 ± 0.71 bc | 47.61 ± 1.81 ab | 504 ± 13.12 cd | 211.66 ± 10.23 bc | |

| JN2 | 20.2 ± 0.63 ab | 51.36 ± 2.07 ab | 574 ± 9.87 ab | 240.00 ± 9.68 ab | |

| JN3 | 19.3 ± 0.51 ab | 50.73 ± 1.08 ab | 532 ± 17.47 bc | 234.55 ± 11.89 ab | |

| PN0 | 17.2 ± 0.33 c | 46.95 ± 2.06 b | 480 ± 13.01 d | 198.57 ± 5.27 c | |

| PN1 | 18.6 ± 0.55 bc | 48.81 ± 1.51 ab | 518 ± 17.24 cd | 226.57 ± 8.18 ab | |

| PN2 | 20.5 ± 0.26 a | 52.91 ± 1.30 a | 588 ± 15.01 a | 248.57 ± 7.09 a | |

| PN3 | 19.3 ± 0.74 ab | 50.37 ± 1.75 ab | 544 ± 9.87 bc | 245.30 ± 10.17 a | |

| F test | F | 0.317 ns | 0.519 ns | 1.310 ns | 3.768 ns |

| N | 12.297 ** | 4.383 * | 20.542 ** | 15.072 ** | |

| F × N | 0.045 ns | 0.122 ns | 0.061 ns | 0.055 ns | |

| 2022 | JN0 | 15.8 ± 0.45 d | 40.18 ± 1.00 d | 420 ± 11.14 f | 167.64 ± 7.60 e |

| JN1 | 17.2 ± 0.46 bcd | 43.56 ± 1.24 cd | 456 ± 16.17 ef | 193.16 ± 5.37 cd | |

| JN2 | 19.7 ± 0.65 a | 49.18 ± 1.46 ab | 546 ± 15.28 ab | 225.52 ± 8.74 ab | |

| JN3 | 18.4 ± 0.57 ab | 48.36 ± 1.20 ab | 504 ± 10.82 cd | 216.95 ± 8.16 abc | |

| PN0 | 16.6 ± 0.60 cd | 42.07 ± 1.05 cd | 434 ± 14.19 f | 180.97 ± 8.88 de | |

| PN1 | 17.8 ± 0.54 bc | 45.59 ± 1.28 bc | 476 ± 8.08 de | 207.34 ± 5.11 bc | |

| PN2 | 19.7 ± 0.31 a | 50.77 ± 1.10 a | 560 ± 16.77 a | 239.68 ± 7.26 a | |

| PN3 | 18.7 ± 0.62 ab | 49.72 ± 1.73 a | 518 ± 11.72 bc | 231.02 ± 11.22 ab | |

| F test | F | 1.166 ns | 3.632 ns | 2.705 ns | 6.054 * |

| N | 14.436 ** | 20.777 ** | 33.602 ** | 21.360 ** | |

| F × N | 0.198 ns | 0.028 ns | 0.025 ns | 0.001 ns |

| Year | Treatment | A | B | K | N | R2 |

|---|---|---|---|---|---|---|

| 2021 | JN0 | 21.07 d | 8.2209 bc | 0.1233 bc | 0.4688 c | 0.9966 |

| JN1 | 23.84 c | 16.2059 b | 0.1361 b | 0.5538 bc | 0.9982 | |

| JN2 | 28.76 a | 2.0937 c | 0.1036 e | 0.2184 d | 0.9975 | |

| JN3 | 26.85 b | 19.8775 b | 0.1190 cd | 0.6862 b | 0.9948 | |

| PN0 | 20.45 d | 15.9095 b | 0.1307 bc | 0.6526 b | 0.9948 | |

| PN1 | 24.61 c | 84.5079 a | 0.1560 a | 1.0821 a | 0.9949 | |

| PN2 | 27.92 ab | 1.2074 c | 0.1055 de | 0.1302 d | 0.9956 | |

| PN3 | 27.37 b | 7.1372 bc | 0.0967 e | 0.4370 c | 0.9955 | |

| 2022 | JN0 | 20.05 d | 13.8132 bcde | 0.1327 ab | 0.5720 bc | 0.9933 |

| JN1 | 22.95 c | 24.4889 b | 0.1413 a | 0.6905 b | 0.9969 | |

| JN2 | 28.03 a | 4.2791 de | 0.1096 cd | 0.3409 d | 0.9942 | |

| JN3 | 25.89 b | 19.2472 bc | 0.1203 bc | 0.6660 b | 0.9942 | |

| PN0 | 19.71 d | 16.8316 bcd | 0.1323 ab | 0.6566 b | 0.9931 | |

| PN1 | 23.45 c | 58.3346 a | 0.1483 a | 1.0071 a | 0.9970 | |

| PN2 | 27.52 a | 1.7116 e | 0.1132 cd | 0.1429 e | 0.9949 | |

| PN3 | 26.37 b | 9.3674 cde | 0.0996 d | 0.4801 cd | 0.9948 |

| Treatment | 2021 | 2022 | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | K | N | A | B | K | N | |

| F | p < 0.05 | p < 0.01 | p > 0.05 | p < 0.05 | p < 0.05 | p > 0.05 | p > 0.05 | p > 0.05 |

| N | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 |

| F × N | p > 0.05 | p < 0.01 | p < 0.01 | p < 0.01 | p > 0.05 | p < 0.01 | p > 0.05 | p < 0.01 |

| Year | Treatment | R0 | Wmax (g) | Vmax (g·d−1) | Tmax (d) | V (g·d−1) |

|---|---|---|---|---|---|---|

| 2021 | JN0 | 0.2660 bc | 9.2716 g | 0.7781 f | 22.9945 e | 0.5255 g |

| JN1 | 0.2464 bc | 10.7564 e | 0.9419 c | 24.7335 c | 0.6350 c | |

| JN2 | 0.5198 b | 11.6248 c | 0.9879 b | 21.2223 f | 0.6702 b | |

| JN3 | 0.1744 bc | 12.5256 a | 0.8832 d | 27.9679 b | 0.5936 e | |

| PN0 | 0.2059 bc | 9.4461 f | 0.7464 g | 23.7066 d | 0.5019 h | |

| PN1 | 0.1443 c | 12.4916 a | 0.9357 c | 27.8546 b | 0.6224 d | |

| PN2 | 0.9585 a | 10.8987 d | 1.0168 a | 20.6870 g | 0.6905 a | |

| PN3 | 0.2218 bc | 11.9348 b | 0.8030 e | 28.8146 a | 0.5427 f | |

| F test | F | 1.159 ns | 24.604 ** | 36.485 ** | 735.078 ** | 61.790 ** |

| N | 12.441 ** | 1720.615 ** | 819.132 ** | 7305.257 ** | 1165.034 ** | |

| F × N | 2.687 ns | 357.5 ** | 38.649 ** | 397.004 ** | 48.186 ** | |

| 2022 | JN0 | 0.2368 b | 9.0770 e | 0.7657 f | 23.5439 f | 0.5159 f |

| JN1 | 0.2069 b | 10.7174 d | 0.8952 c | 24.8379 d | 0.6016 c | |

| JN2 | 0.3257 b | 11.8500 b | 0.9684 b | 22.9227 g | 0.6557 b | |

| JN3 | 0.1814 b | 12.0211 a | 0.8676 d | 27.7440 b | 0.5833 d | |

| PN0 | 0.2035 b | 9.1268 e | 0.7283 g | 24.0921 e | 0.4898 g | |

| PN1 | 0.1475 b | 11.7357 bc | 0.8671 d | 27.2463 c | 0.5779 d | |

| PN2 | 0.9323 a | 10.7968 d | 1.0695 a | 21.3741 h | 0.7262 a | |

| PN3 | 0.2089 b | 11.6448 c | 0.7830 e | 29.5873 a | 0.5287 e | |

| F test | F | 4.323 ns | 6.078 * | 10.590 ** | 267.399 ** | 16.105 ** |

| N | 11.062 ** | 1088.563 ** | 928.594 ** | 3229.572 ** | 1402.091 ** | |

| F × N | 5.904 ** | 140.065 ** | 111.705 ** | 312.109 ** | 165.747 ** |

| Year | Treatment | Gradual Increase Period | Rapid Increase Period | Slow Increase Period | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T1 (d) | V1 (g·d−1) | P1 | T2 (d) | V2 (g·d−1) | P2 | T3 (d) | V3 (g·d−1) | P3 | ||

| 2021 | JN0 | 13.6736 e | 0.2220 d | 0.1457 c | 18.6417 cd | 0.6777 f | 0.6055 b | 28.0583 b | 0.1851 de | 0.2487 b |

| JN1 | 16.0782 c | 0.2313 cd | 0.1576 bc | 17.3106 d | 0.8215 c | 0.6024 bc | 25.1564 b | 0.2253 b | 0.2400 bc | |

| JN2 | 11.0230 f | 0.2796 a | 0.1087 d | 20.3986 b | 0.8560 b | 0.6129 a | 34.3933 a | 0.2309 ab | 0.2784 a | |

| JN3 | 17.6831 b | 0.2626 b | 0.1751 b | 20.5696 b | 0.7717 d | 0.5970 c | 28.4869 b | 0.2130 c | 0.2280 c | |

| PN0 | 14.4023 d | 0.2383 c | 0.1704 b | 18.6085 cd | 0.6518 g | 0.5982 c | 26.2052 b | 0.1797 e | 0.2314 c | |

| PN1 | 19.2577 a | 0.2816 a | 0.2227 a | 17.1938 d | 0.8211 c | 0.5794 d | 20.8855 c | 0.2309 ab | 0.1979 d | |

| PN2 | 11.0191 f | 0.2374 c | 0.0949 d | 19.3358 bc | 0.8791 a | 0.6147 a | 34.0464 a | 0.2361 a | 0.2905 a | |

| PN3 | 17.0560 b | 0.2244 cd | 0.1413 c | 23.5173 a | 0.6990 e | 0.6067 b | 35.8250 a | 0.1906 d | 0.2520 b | |

| F test | F | 25.037 ** | 1.186 ns | 4.655 * | 1.640 ns | 26.823 ** | 12.372 ** | 0.055 ns | 10.168 ** | 2.603 ns |

| N | 366.649 ** | 17.224 ** | 56.688 ** | 36.078 ** | 604.133 ** | 49.668 ** | 29.577 ** | 315.356 ** | 57.550 ** | |

| F × N | 25.952 ** | 49.804 ** | 20.018 ** | 6.600 ** | 31.149 ** | 27.797 ** | 7.305 ** | 24.005 ** | 16.841 ** | |

| 2022 | JN0 | 14.5999 d | 0.2166 c | 0.1598 bc | 17.8880 c | 0.6679 e | 0.6015 cd | 25.8950 cd | 0.1834 e | 0.2386 cd |

| JN1 | 16.1637 c | 0.2462 b | 0.1755 b | 17.3485 c | 0.7822 c | 0.5967 d | 24.0136 d | 0.2160 c | 0.2277 d | |

| JN2 | 12.8649 e | 0.2743 a | 0.1273 d | 20.1155 b | 0.8414 b | 0.6098 ab | 31.9647 ab | 0.2284 b | 0.2629 b | |

| JN3 | 17.6321 b | 0.2504 b | 0.1725 b | 20.2239 b | 0.7578 d | 0.5978 d | 28.1966 bc | 0.2090 d | 0.2297 d | |

| PN0 | 14.9112 d | 0.2235 c | 0.1711 b | 18.3616 c | 0.6361 f | 0.5982 d | 25.7241 cd | 0.1754 f | 0.2307 d | |

| PN1 | 18.3472 a | 0.2709 a | 0.2142 a | 17.7982 c | 0.7603 d | 0.5829 e | 22.1208 d | 0.2131 cd | 0.2029 e | |

| PN2 | 12.3209 e | 0.2136 c | 0.0969 e | 18.1065 c | 0.9249 a | 0.6145 a | 31.6848 ab | 0.2486 a | 0.2887 a | |

| PN3 | 18.0025 ab | 0.2134 c | 0.1474 cd | 23.1696 a | 0.6821 e | 0.6051 bc | 34.7078 a | 0.1864 e | 0.2475 c | |

| F test | F | 13.727 ** | 32.962 ** | 0.077 ns | 1.781 ns | 9.582 ** | 0.826 ns | 1.364 ns | 5.917 * | 0.588 ns |

| N | 236.601 ** | 32.617 ** | 47.528 ** | 28.910 ** | 687.790 ** | 39.971 ** | 23.316 ** | 337.909 ** | 49.305 ** | |

| F × N | 13.421 ** | 46.210 ** | 10.688 ** | 8.852 ** | 82.415 ** | 10.829 ** | 4.371 * | 42.318 ** | 10.521 ** | |

| Treatment | Parameter | Correlation Coefficient | Direct Path Coefficient | Indirect Path Coefficient | |||

|---|---|---|---|---|---|---|---|

| R0→A | T1→A | V1→A | V3→A | ||||

| J | R0 | 0.487 | 0.040 | −0.0252 | 0.0312 | 0.2426 | |

| T1 | −0.195 | 0.028 | −0.0360 | −0.0165 | −0.0852 | ||

| V1 | 0.950 | 0.065 | 0.0134 | −0.0071 | 0.5006 | ||

| V3 | 0.805 | 0.596 | 0.0265 | −0.0093 | 0.0546 | ||

| P | R0 | 0.548 | 0.025 | −0.3081 | −0.0654 | 0.4232 | |

| T1 | −0.172 | 0.397 | −0.0194 | 0.0865 | −0.2404 | ||

| V1 | −0.278 | 0.152 | −0.1707 | 0.2259 | 0.2130 | ||

| V3 | 0.614 | 0.703 | 0.0915 | −0.0520 | 0.0461 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Zhang, H.; Yu, S.; Zhou, C.; Chen, X.; Teng, A.; Lei, L.; Li, F. Modeling Spring Maize Grain Filling under Film Mulching and Nitrogen Application in a Cold and Arid Environment. Water 2024, 16, 88. https://doi.org/10.3390/w16010088

Chen T, Zhang H, Yu S, Zhou C, Chen X, Teng A, Lei L, Li F. Modeling Spring Maize Grain Filling under Film Mulching and Nitrogen Application in a Cold and Arid Environment. Water. 2024; 16(1):88. https://doi.org/10.3390/w16010088

Chicago/Turabian StyleChen, Tao, Hengjia Zhang, Shouchao Yu, Chenli Zhou, Xietian Chen, Anguo Teng, Lian Lei, and Fuqiang Li. 2024. "Modeling Spring Maize Grain Filling under Film Mulching and Nitrogen Application in a Cold and Arid Environment" Water 16, no. 1: 88. https://doi.org/10.3390/w16010088

APA StyleChen, T., Zhang, H., Yu, S., Zhou, C., Chen, X., Teng, A., Lei, L., & Li, F. (2024). Modeling Spring Maize Grain Filling under Film Mulching and Nitrogen Application in a Cold and Arid Environment. Water, 16(1), 88. https://doi.org/10.3390/w16010088