Permeable Concrete Barriers to Control Water Pollution: A Review

Abstract

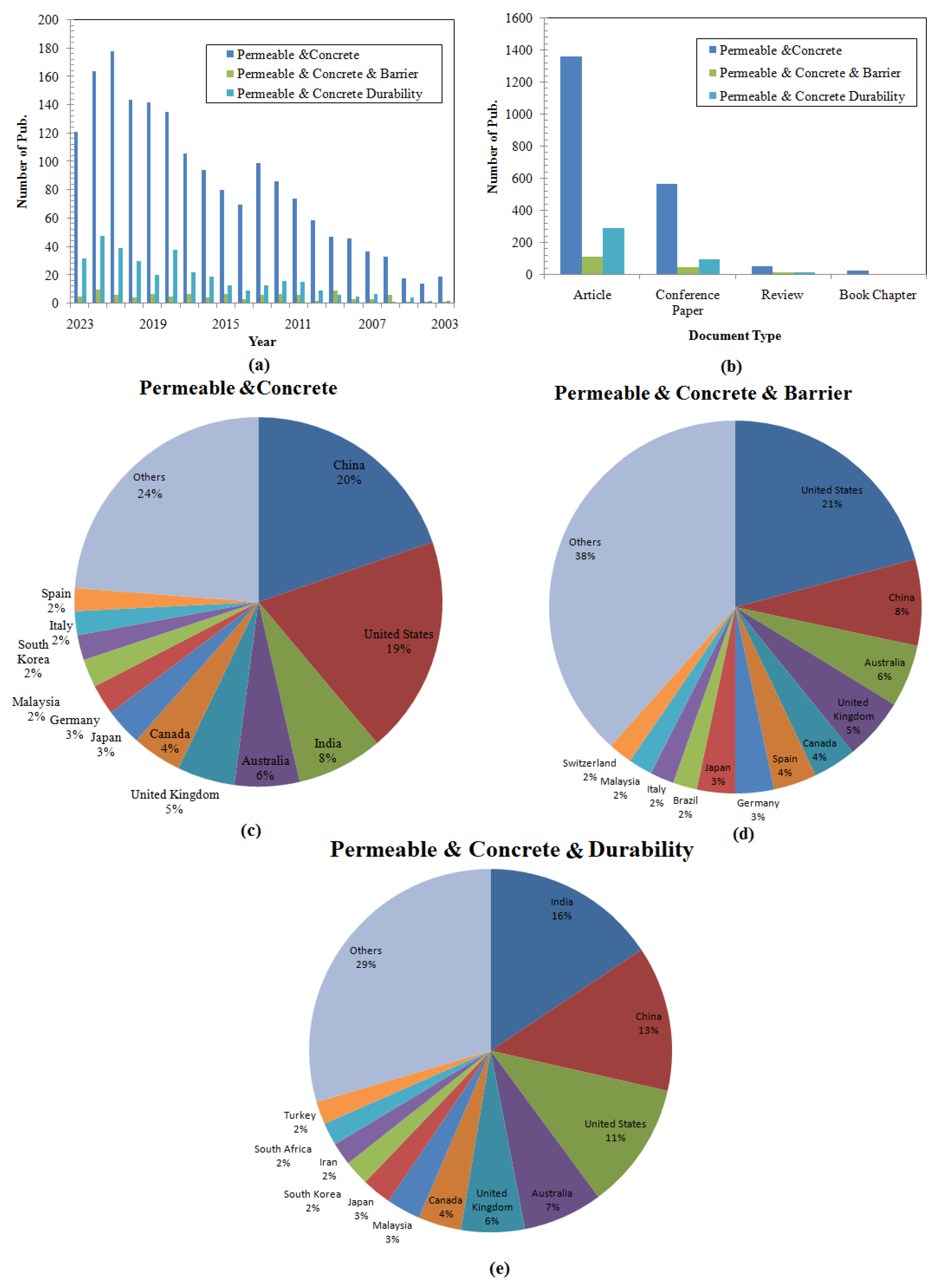

:1. Introduction

- Input materials that are available and produced through standardized production methods. Additionally, they are low cost, which reduces the cost of pollution prevention and control practices;

- Preparation/construction requiring the use of simple devices (e.g., mixers at room temperature) that have a record of long use and experience;

- Characteristic porous structure allowing for its use as a filter and the passage of water without the need to enforce this passage, in addition to having a high specific surface area that enhances the sorption of containments;

- The presence of the amorphous and crystalline hydration phases providing sites for the chemical and physical entrapment of different anions and cations;

- The hydration of the cement creates highly alkaline conditions leading to the precipitation of most of the metallic contaminants;

- Ecofriendly permeable concrete has the potential to reduce the material and energy footprints of these water pollution prevention and control practices, as well as to reduce greenhouse gas emissions.

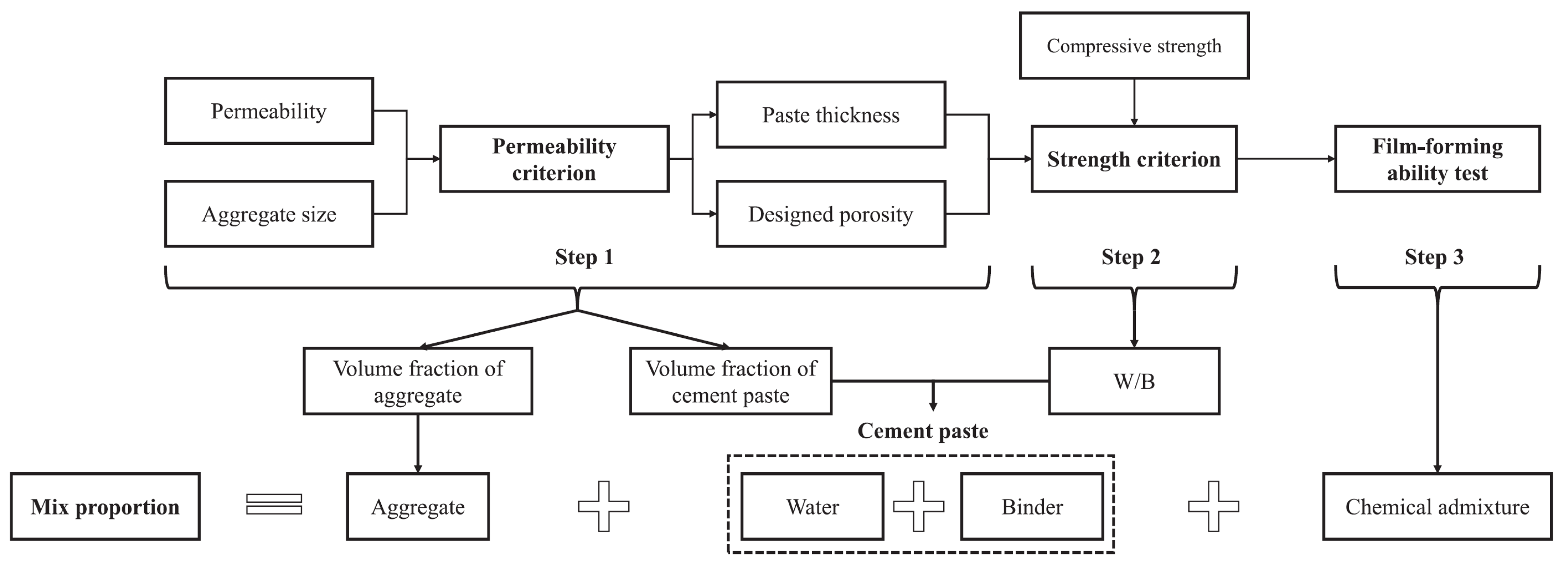

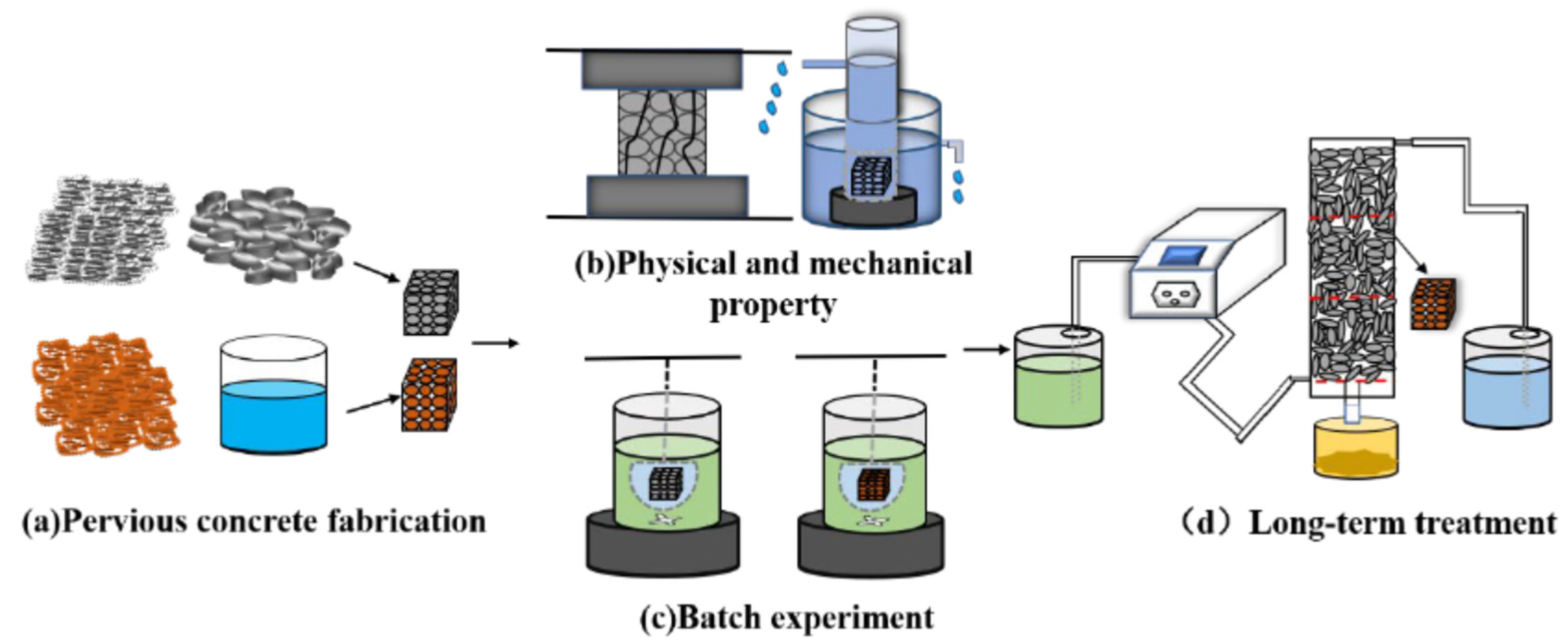

2. Permeable Concrete Mix Design

2.1. Conventional Permeable Concrete Mix Design

- A coarse-aggregate-to-cement ratio in the range of 4:1 to 6:1, in which the volume of aggregate in the hardened materials occupy 50–65% [23]. The grading of the aggregates should be optimized to control the void ratio of the hardened product, whereby single-sized coarse aggregate or narrow-grading coarse aggregate (e.g., between 9.5 and 19 mm) can be used [44,46];

2.2. Innovative Permeable Concrete Mix Design

2.2.1. Permeable Geopolymers Concrete

- Crystalline zeolite is formed in geopolymers at Si/Al < 1;

- Geopolymers of reduced porosity are formed at 1 < Si/Al < 2;

- The porosity of geopolymers are dependent on the solubility of the Si source at 2 < Si/Al.

2.2.2. Permeable Magnesium Phosphate Concrete

2.3. Permeable Concrete Mix Design: Future Prospects

3. Characterization and Functional and Durability Performances of Permeable Concrete Materials

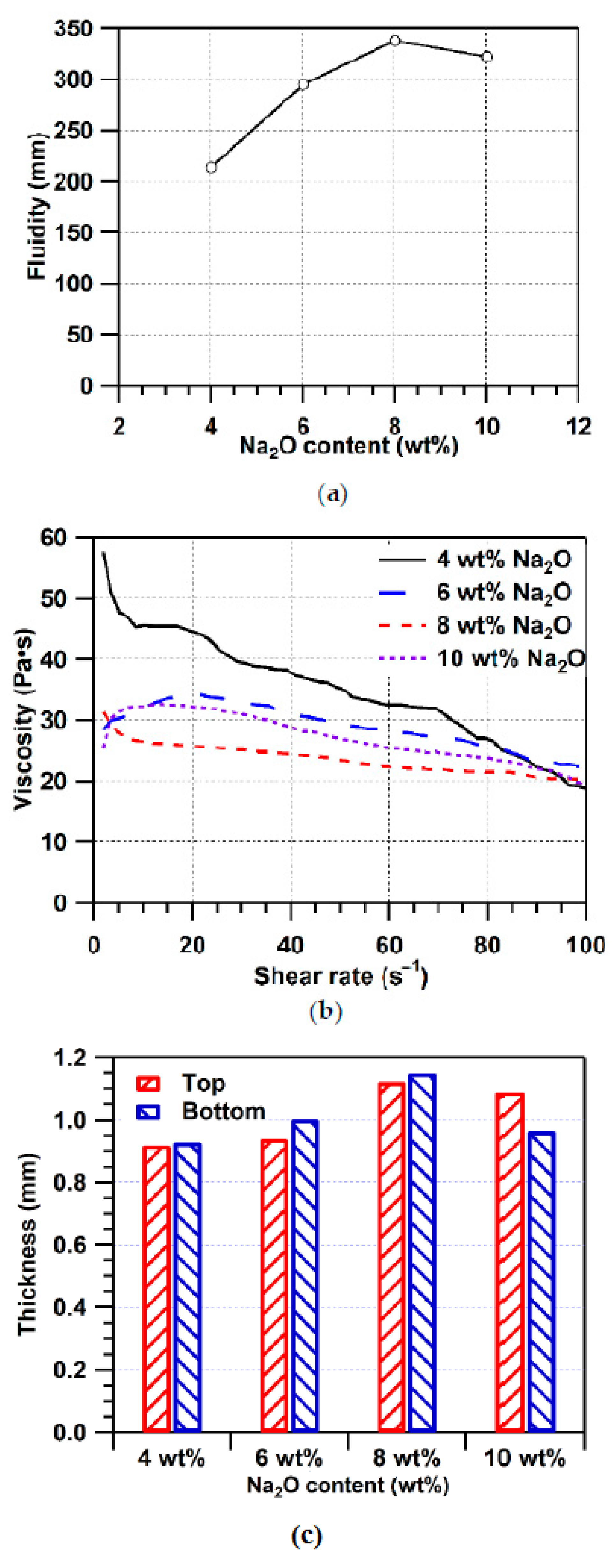

3.1. Rheological Properties of the Paste

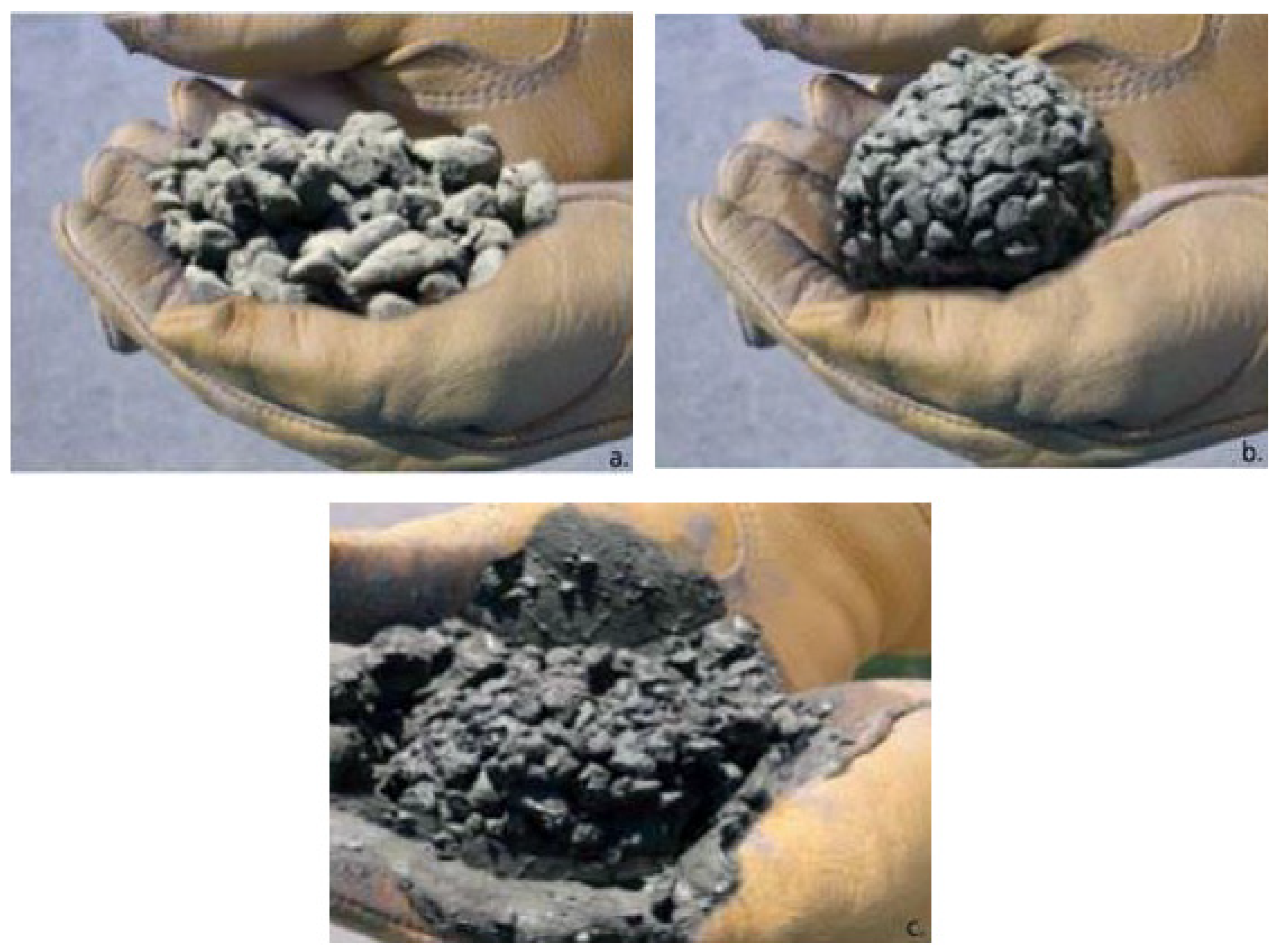

- Hand compacting method: This is a qualitative, easy method for testing the adequacy of the water in the paste and, hence, provides an indication of the paste’s flowability (Figure 5a–c). Scarce water will yield a crumbling of the ball (Figure 5a), and excess water will yield an accumulation of paste on the glove, leaving the aggregates with a minimum coat of cement (Figure 5c). Adequate water will lead to the formation of a ball without excess paste accumulated on the glove (Figure 5c);

3.2. Hydraulic Properties of Hardened Permeable Concrete

- Gravimetric techniques: These are employed to measure the porosity using general standardized ASTM tests: ATSM C457/C457 M-16. It should be noted that a standardized test to measure the porosity of permeable concrete (ASTM C1754) was recently withdrawn;

- Absorption tests: These include the BET and MIP, and standardized ASTM tests are available for fragmented materials: ASTM D5604-96 and ASTM D4404-18, respectively. In addition, auto-clam and Figg tests are used to measure in situ water and air permeability [114];

- Imaging techniques: These are used to construct 3D models for a sample, either using X-ray computed tomography or 2D scanning images and suitable image processing software. These models are used to drive empirical relationships for calculating the pore size and distribution and to model the mechanical and hydrological behavior of the material [97,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138].

3.3. Mechanical Properties

3.4. Durability of Hardened Permeable Concrete

- Physical clogging: an accumulation of suspended particles within the porous structure; this phenomenon does not include a chemical reaction;

- Chemical clogging: which occurs because of the penetration of chemical components into the flow of water through the barrier, leading to scale formation that clogs the porous structure;

- Biological clogging: which occurs because of the reproduction of algae and bacteria within the porous structure of the material.

- Its role in preventing the water accumulation on the aggregate surface, which allowed for the increased formation of dense C-S-H in the interface transitional zone;

- Its ability to mitigate the water absorption and migration into the aggregate that suppresses the ice pressure.

3.5. Pollutants Removal Performance

4. Permeable Reactive Concrete Barriers

- Low energy consumption, which reduces the carbon footprint of the process and the operating costs;

- Requires monitoring its activity with only minimum scheduled maintenance after a specified period of operation, if needed;

- Easily installation and removal procedures;

- Provides efficient and targeted remediation, where these barriers convert specified pollutants to fewer toxic species and/or retains them.

- Reactivity: the capacity of the material should be high enough to allow for the precipitation and/or sorption and/or degradation during its service life;

- Hydraulic conductivity: the barrier should have adequate permeability to allow for the passage of the contaminated ground water without considerable retardation in its velocity;

- Environmental compatibility: the used material should not have the potential to release toxic species into the host environment;

- Long-term physical and chemical stability: the material should have adequate long-term stability to eliminate the need for maintenance of the barrier during its service life.

4.1. Effect of the Aggregates

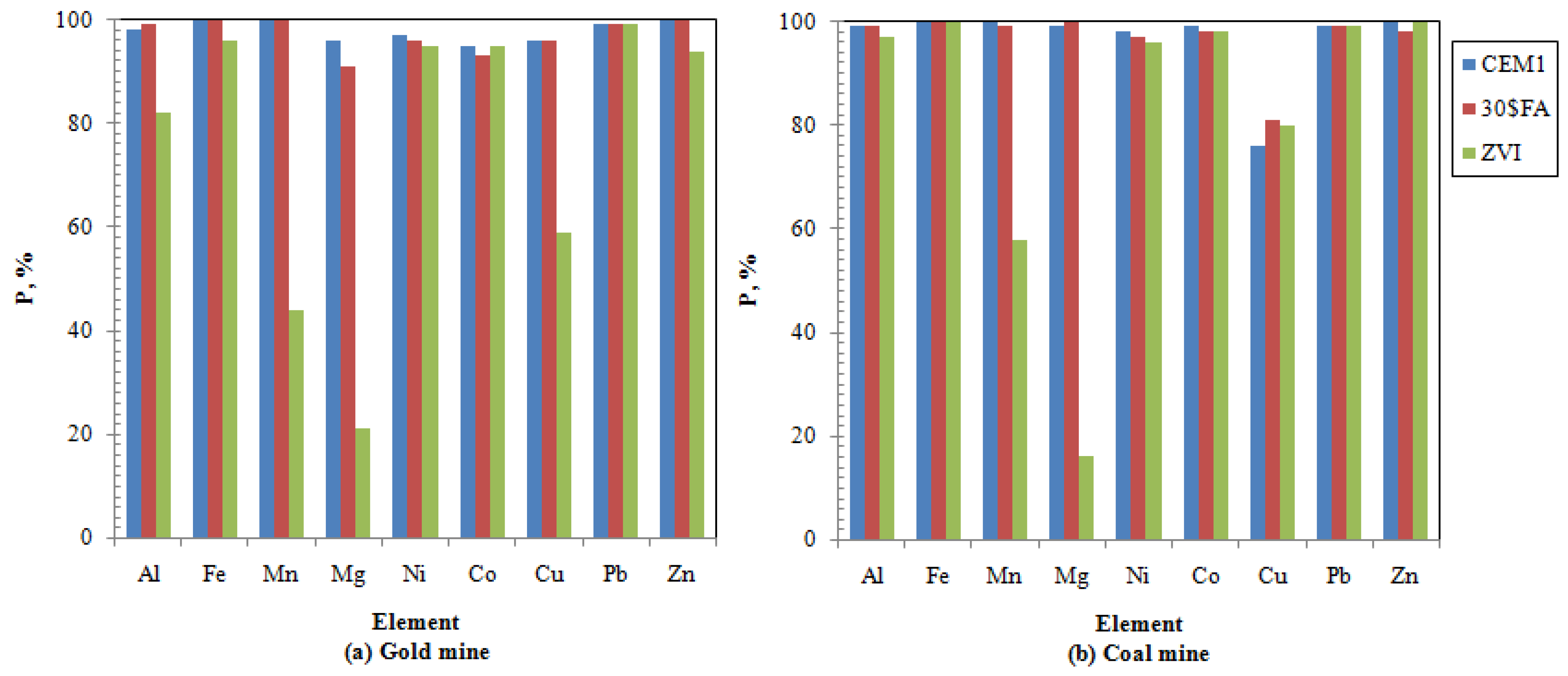

4.2. Use of Supplementary Cementitious Materials

4.3. Performance Comparison with Zero-Valent Iron

4.4. Combined Treatment Method

4.5. Gaps in Investigating Permeable Reactive Concrete Barriers

- The beneficial use of fly ash to improve the mechanical strength of permeable reactive concrete barriers and to provide more active sites for the removal of pollutants is promising [31,174,178,179]. Yet, it was concluded the cement can contribute to an increase in the Cr concentration in the treated plume [178,180]. This point needs to be addressed in depth by investigating the stability of fly ash using a standardized test (e.g., TCLP) to assess the feasibility of this material’s use. In addition, an in-depth analysis of the stability of the hardened material and the deduction of the chromium-leaching mechanism are needed.

- The reported mechanisms of pollutant removal were precipitation due to the alkalinity of the permeable reactive concrete media combined with physical and chemical sorption onto the hardened cement phases, the aggregates, and the SCM [30,173,176,178,179,181]. In particular, the reaction of the sulfate with the portlandite was identified as enhancing the precipitation of the pollutants. The effect of the portlandite reaction with the sulfate on the permeability of the barrier needs to be assessed, as the formation of expansive phases can affect the long-term hydraulic performance of the barrier.

- Concrete is known to have a high alkaline capacity, which has been reported to buffer the treated solution’s pH to an unacceptable value, i.e., 11 [178]. This point can be addressed by using low-pH cement that can buffer the treated solutions to pH values comparable to that of the ZVI. Different types of additives can be used in this respect that should be studied in depth to ensure that the hardened material will meet the hydraulic and pollutant removal performances.

- Innovative permeable concretes have not been tested extensively for their applications in groundwater remediation and acid mine drainage treatment. In particular, magnesium phosphate cement is known for its fast hardening, near neutral pH, low water requirements, and high adhesive strength [5,6]. These materials have been tested for their application in low-development practices but not in permeable reactive barriers.

- The effect of the rheological characteristics of permeable concrete paste and their effects on the hydraulic and pollutant removal performances have been not investigated for permeable reactive concrete barriers. Most of the conducted studies relied on the use of the minimum amount of water (0.21–0.33) in conventional permeable concrete [30,31,156,179,180]. This limited range compared to that used in the low-development impact (0.25–0.45) practices reduces the porosity of the hardened material. This can affect the hydraulic performance of the barriers used in the remediation of the acid mine drainage over the long term, and the formation of expansive phases can lead to a further reduction in the porosity.

- The available experimental data on the performance of permeable concrete reactive materials were conducted within limited time frames of less than a year [21,24,176,178,180,183]. The long-term performances of these materials are required to be studied in depth to ensure the sustainable performance of these barriers throughout their service life and to identify threshold values for their reduced performances affecting their efficiency as a barrier.

- The durability of permeable reactive concrete barriers needs to be addressed to evaluate the effect of harsh operating conditions (i.e., high sulfate and acidic solutions) on the durability of such barriers. Future research needs to address the feasibility of performing scheduled maintenance or substitutions of the barrier material if the barrier does not reach its target remediation prior to reaching unacceptable reduced performances.

- Current research efforts in this field are focused at the lab-scale testing and mainly focus on conducting static experiments, with limited research studying dynamic conditions [30,31,36,181]. There is a need to address the performance of these materials under more realistic conditions that address upscale practical applications of these materials.

- The cost of the remediation technology is an important aspect that affects the decision-making process [21,31,177,180]. The cost estimate for these materials are limited, and these studies have addressed the costs of these materials and trench-type installation costs [24,30,179]. Detailed cost analyses have not been conducted; subsequently, there is a need to address the life cycle costs of the large-scale application of these materials.

- The environmental impacts of the use of permeable reactive concrete barriers need to be addressed. In this respect, the effect of the beneficial use of recycled wastes as SCMs and aggregates in conventional performance concrete should be quantified in terms of the reduction of the environmental footprint. In addition, the impacts of the buffer pH after treatment should be addressed.

5. Conclusions

- The optimization of the mix design of the permeable reactive concrete barrier needs to be guided not only according to the required hydraulic and removal performances but also by the durability of the hardened materials over the designed service life;

- Identifying the environmental impacts of the optimized permeable reactive concrete barrier is crucial to ensure the sustainability of these materials. These impacts should consider the dynamics of the attenuation of the alkaline plume downstream of the barrier of the affected environment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- LiberTexts. Functions of Water. Available online: https://med.libretexts.org/Courses/Metropolitan_State_University_of_Denver/Introduction_to_Nutrition_(Diker)/07%3A_Nutrients_Important_to_Fluid_and_Electrolyte_Balance/7.02%3A_Waters_Importance_to_Vitality (accessed on 26 July 2022).

- Abdel Rahman, R.O.; El-Kamash, A.M.; Hung, Y.-T. Applications of Nano-Zeolite in Wastewater Treatment: An Overview. Water 2022, 14, 137. [Google Scholar] [CrossRef]

- Beaudoin, J.; Odler, I. Hydration, setting and hardening of Portland cement. In Lea’s Chemistry of Cement and Concrete; Elsevier Science: Amsterdam, The Netherlands, 2019; Volume 5, pp. 157–250. [Google Scholar]

- Odler, I. Setting and hardening of Portland cement. In Lea’s Chemistry of Cement and Concrete; Hewlett, P.C., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2006; pp. 241–297. [Google Scholar]

- Rahman, R.O.A.; Ojovan, M.I. Hydration process: Kinetics and thermodynamics. In Sustainability of Life Cycle Management for Nuclear Cementation-Based Technologies; Woodhead Publishing: Sawston, UK, 2021; pp. 125–160. [Google Scholar]

- Rahman, R.O.A.; Rakhimov, R.Z.; Rakhimova, N.R.; Ojovan, M.I. Cementitious Materials for Nuclear Waste Immobilization; Wiley: New York, NY, USA, 2014; ISBN 9781118512005. [Google Scholar] [CrossRef]

- Paine, K.A. Physicochemical and mechanical properties of Portland cement. In Lea’s Chemistry of Cement and Concrete; Elsevier Science: Amsterdam, The Netherlands, 2019; pp. 285–340. [Google Scholar]

- Saleh, H.M.; Rahman, R.O.A. (Eds.) Introductory chapter: Properties and application of cement based materials. In Cement Based Materials; Intech: London, UK, 2018; ISBN 978-1-78984-154-1. [Google Scholar] [CrossRef]

- Wu, Y.; Qiao, W.G.; Li, Y.Z.; Zhang, S.; Sun, D.K.; Tang, C.; Liu, H.N.; Wang, T.J. Development and validation of environmentally friendly similar surrounding rock materials and cement slurry for surrounding rock repair and reinforcement. J. Clean. Prod. 2022, 347, 131288. [Google Scholar] [CrossRef]

- Saleh, H.M.; Eskander, S.B. Innovative cement-based materials for environmental protection and restoration. In New Materials in Civil Engineering; Butterworth-Heinemann: Oxford, UK, 2020; pp. 613–641. [Google Scholar]

- Tian, Y.; Themelis, N.J.; Zhao, D.; Bourtsalas, A.T.; Kawashima, S. Stabilization of Waste-to-Energy (WTE) fly ash for disposal in landfills or use as cement substitute. Waste Manag. 2022, 150, 227–243. [Google Scholar] [CrossRef] [PubMed]

- Abdel Rahman, R.O.; Metwally, S.S.; El-Kamash, A.M. Improving the Performance of Engineering Barriers in Radioactive Waste Disposal Facilities: Role of Nano-Materials. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O., Martínez, L., Kharisov, B., Eds.; Springer Nature: Cham, Switzerland, 2021; pp. 1183–1200. [Google Scholar] [CrossRef]

- Chen, B.; Wu, F.; Qu, G.; Ning, P.; Ren, Y.; Liu, S.; Jin, C.; Li, H.; Zhao, C.; Liu, X.; et al. Waste control by waste: A comparative study on the application of carbide slag and quicklime in preparation of phosphogypsum-based ecological restoration materials. Chem. Eng. Process. Process Intensif. 2022, 178, 109051. [Google Scholar] [CrossRef]

- Lai, H.; Du, J.; Zhou, C.; Liu, Z. Experimental study on ecological performance improvement of sprayed planting concrete based on the addition of polymer composite material. Int. J. Environ. Res. Public Health 2022, 19, 12121. [Google Scholar] [CrossRef]

- Conner, J.R.; Hoeffner, S.L. The history of stabilization/solidification technology. Crit. Rev. Environ. Sci. Technol. 1998, 28, 325–396. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Sandu, A.V.; Vizureanu, P.; Razak, R.A.; Burduhos-Nergis, D.D.; Imjai, T. Solidification/Stabilization Technology for Radioactive Wastes Using Cement: An Appraisal. Materials 2023, 16, 954. [Google Scholar] [CrossRef]

- Tyagi, S.; Annachhatre, A.P. A review on recent trends in solidification and stabilization techniques for heavy metal immobilization. J. Mater. Cycles Waste Manag. 2023, 25, 733–757. [Google Scholar] [CrossRef]

- Tran, H.S.; Viet, N.T.T.; Duong, T.H.; Nguyen, L.H.; Kawamoto, K. Autoclaved aerated concrete grains as alternative absorbent and filter media for phosphorus recovery from municipal wastewater: A case study in Hanoi, Vietnam. Environ. Technol. Innov. 2023, 31, 103175. [Google Scholar] [CrossRef]

- Abou-Elela, S.I.; Abo-El-Enein, S.A.; Hellal, M.S. Utilization of autoclaved aerated concrete solid waste as a bio-carrier in immobilized bioreactor for municipal wastewater treatment. Desalination Water Treat. 2019, 168, 108–116. [Google Scholar] [CrossRef]

- Teymouri, E.; Wong, K.S.; Tan, Y.Y.; Pauzi, N.N.M. Mechanical behaviour of adsorbent pervious concrete using iron slag and zeolite as coarse aggregates. Constr. Build. Mater. 2023, 388, 131720. [Google Scholar] [CrossRef]

- Shabalala, A.; Masindi, V. Insights into mechanisms governing the passive removal of inorganic contaminants from acid mine drainage using permeable reactive barrier. J. Environ. Manag. 2022, 321, 115866. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Sampath, P.V.; Biligiri, K.P. A review of sustainable pervious concrete systems: Emphasis on clogging, material characterization, and environmental aspects. Constr. Build. Mater. 2020, 261, 120491. [Google Scholar] [CrossRef]

- Yun, C.M.; Rahman, M.R.; Kuok, K.K.; Sze, A.C.; Seng, A.L.; Bakri, M.K. Pervious Concrete Properties and Its Applications. In Waste Materials in Advanced Sustainable Concrete: Reuse, Recovery and Recycle; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–23. [Google Scholar]

- Holmes, R.R.; Hart, M.L.; Kevern, J.T. Heavy metal removal capacity of individual components of permeable reactive concrete. J. Contam. Hydrol. 2017, 196, 52–61. [Google Scholar] [CrossRef]

- Park, S.-B.; Tia, M. An experimental study on the water-purification properties of porous concrete. Cem. Concr. Res. 2004, 34, 177–184. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H. Multi-aspect engineering properties and sustainability impacts of geopolymer pervious concrete. Compos. Part B Eng. 2022, 242, 110035. [Google Scholar] [CrossRef]

- Shi, C. Hydraulic cement systems for stabilization/solidification. In Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes; Spence, R.D., Shi, C., Eds.; CRC Press: Boca Raton, FL, USA, 2004; pp. 49–77. [Google Scholar]

- Rahman, R.A.; El Abidin, D.Z.; Abou-Shady, H. Assessment of strontium immobilization in cement–bentonite matrices. Chem. Eng. J. 2013, 228, 772–780. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. Recent trends in the evaluation of cementitious material in radioactive waste disposal. In Natural Resources and Control Processes; Springer: Cham, Switzerland, 2016; pp. 401–448. [Google Scholar]

- Xu, W.; Yang, H.; Mao, Q.; Luo, L.; Deng, Y. Removal of Heavy Metals from Acid Mine Drainage by Red Mud–Based Geopolymer Pervious Concrete: Batch and Long–Term Column Studies. Polymers 2022, 14, 5355. [Google Scholar] [CrossRef]

- Shabalala, A.N.; Ekolu, S.O.; Diop, S.; Solomon, F. Pervious concrete reactive barrier for removal of heavy metals from acid mine drainage—Column study. J. Hazard. Mater. 2017, 323, 641–653. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material–Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Anwar, F.H.; El-Hassan, H.; Hamouda, M.; Hinge, G.; Mo, K.H. Meta-Analysis of the Performance of Pervious Concrete with Cement and Aggregate Replacements. Buildings 2022, 12, 461. [Google Scholar] [CrossRef]

- Zhong, R.; Leng, Z.; Poon, C.-S. Research and application of pervious concrete as a sustainable pavement material: A state-of-the-art and state-of-the-practice review. Constr. Build. Mater. 2018, 183, 544–553. [Google Scholar] [CrossRef]

- Ab Latif, A.; Putrajaya, R.; Ing, D.S. A Review of Porous Concrete Pavement: Compressive Strength and Clogging Investigation. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 29, 128–138. [Google Scholar]

- Muthu, M.; Ramakrishnan, K.C.; Santhanam, M.; Rangarajan, M.; Kumar, M. Heavy metal removal and leaching from pervious concrete filter: Influence of operating water head and reduced graphene oxide addition. J. Environ. Eng. 2019, 145, 04019049. [Google Scholar] [CrossRef]

- Clementino, F.d.S.; Santiago, J.M.; de Sousa, H.F.; da Conceição, I.G.C.; dos Santos, H.C. Use of permeable concrete with additives in wastewater treatment, focusing on biochar: A review. Res. Soc. Dev. 2021, 10, e562101019111. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. Toward Sustainable Cementitious Radioactive Waste Forms: Immobilization of Problematic Operational Wastes. Sustainability 2021, 13, 11992. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous geopolymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Chen, X.; Guo, Y.; Ding, S.; Zhang, H.Y.; Xia, F.Y.; Wang, J.; Zhou, M. Utilization of red mud in geopolymer-based pervious concrete with function of adsorption of heavy metal ions. J. Clean. Prod. 2019, 207, 789–800. [Google Scholar] [CrossRef]

- Yu, H.; Xu, M.; Chen, C.; He, Y.; Cui, X. A review on the porous geopolymer preparation for structural and functional materials applications. Int. J. Appl. Ceram. Technol. 2022, 19, 1793–1813. [Google Scholar] [CrossRef]

- Kočí, V.; Černý, R. Directly foamed geopolymers: A review of recent studies. Cem. Concr. Compos. 2022, 130, 104530. [Google Scholar] [CrossRef]

- Radina, L.; Sprince, A.; Pakrastins, L.; Gailitis, R.; Sakale, G. Foamed geopolymers: A review of recent studies. J. Phys. Conf. Ser. 2023, 2423, 012032. [Google Scholar] [CrossRef]

- ACI. 522R-10. Report on Pervious Concrete (Reapproved 2011); American Concrete Institute: Farmington Hills, MI, USA, 2010; Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=52210&Format=PROTECTED_PDF&Language=English&Units=US_AND_METRIC (accessed on 16 October 2023).

- Singh, A.; Jagadeesh, G.S.; Sampath, P.V.; Biligir, K.P. Rational Approach for Characterizing In Situ Infiltration Parameters of Two-Layered Pervious Concrete Pavement Systems. J. Mater. Civ. Eng. 2019, 31, 04019258. [Google Scholar] [CrossRef]

- NRMCA. Previous in Practice Methods Materials Admixtures Guide to Specifying Pervious Concrete; National Ready Mixed Concrete Association: Silver Spring, MD, USA. Available online: https://www.perviouspavement.org/downloads/PiP1.pdf (accessed on 16 October 2023).

- Xie, H.-Z.; Li, L.G.; Ng, P.-L.; Liu, F. Effects of Solid Waste Reutilization on Performance of Pervious Concrete: A Review. Sustainability 2023, 15, 6105. [Google Scholar] [CrossRef]

- Wijeyawardana, P.; Nanayakkara, N.; Gunasekara, C.; Karunarathna, A.; Law, D.; Pramanik, B.K. Improvement of heavy metal removal from urban runoff using modified pervious concrete. Sci. Total Environ. 2022, 815, 152936. [Google Scholar] [CrossRef] [PubMed]

- Elizondo-Martinez, E.J.; Andres-Valeri, V.C.; Jato-Espino, D.; Rodriguez-Hernandez, J. Review of porous concrete as multifunctional and sustainable pavement. J. Build. Eng. 2020, 27, 100967. [Google Scholar] [CrossRef]

- Teymouri, E.; Pauzi, N.N.M.; Wong, K.S. Developing Lignite Pervious Concrete for Application in Pedestrian Walkways and Urban Runoff Treatment. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 2949–2967. [Google Scholar] [CrossRef]

- Ozel, B.F.; Sakallı, Ş.; Şahin, Y. The effects of aggregate and fiber characteristics on the properties of pervious concrete. Constr. Build. Mater. 2022, 356, 129294. [Google Scholar] [CrossRef]

- Soto-Pérez, L.; Hwang, S. Mix design and pollution control potential of pervious concrete with non-compliant waste fly ash. J. Environ. Manag. 2016, 176, 112–118. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Kim, H.-H.; Kim, C.-S.; Jeon, J.-H.; Park, C.-G. Effects on the physical and mechanical properties of porous concrete for plant growth of blast furnace slag, natural jute fiber, and styrene butadiene latex using a dry mixing manufacturing process. Materials 2016, 9, 84. [Google Scholar] [CrossRef]

- Aoki, Y.; Sri Ravindrarajah, R.; Khabbaz, H. Properties of pervious concrete containing fly ash. Road Mater. Pavement Des. 2012, 13, 1–11. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Opiso, E.M.; Supremo, R.P.; Perodes, J.R. Effects of coal fly ash and fine sawdust on the performance of pervious concrete. Heliyon 2019, 5, e02783. [Google Scholar] [CrossRef] [PubMed]

- Carmichael, M.J.; Arulraj, G.P.; Meyyappan, P.L. Effect of partial replacement of cement with nano fly ash on permeable concrete: A strength study. Mater. Today Proc. 2021, 43, 2109–2116. [Google Scholar] [CrossRef]

- López-Carrasquillo, V.; Hwang, S. Comparative assessment of pervious concrete mixtures containing fly ash and nanomaterials for compressive strength, physical durability, permeability, water quality performance and production cost. Constr. Build. Mater. 2017, 139, 148–158. [Google Scholar] [CrossRef]

- Arifi, E.; Cahya, E.N. Effect of fly ash on the strength of porous concrete using recycled coarse aggregate to replace low-quality natural coarse aggregate. AIP Conf. Proc. 2017, 1887, 020055. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar]

- Ortega-Villar, R.; Lizarraga-Mendiola, L.; Coronel-Olivares, C.; Lopez-Leon, L.D.; Bigurra-Alzati, C.A.; Vazquez-Rodriguez, G.A. Effect of photocatalytic Fe2O3 nanoparticles on urban runoff pollutant removal by permeable concrete. J. Environ. Manag. 2019, 242, 487–495. [Google Scholar] [CrossRef]

- Liang, X.; Cui, S.; Li, H.; Abdelhady, A.; Wang, H.; Zhou, H. Removal effect on stormwater runoff pollution of porous concrete treated with nanometer titanium dioxide. Transp. Res. D Transp. Environ. 2019, 73, 34–45. [Google Scholar] [CrossRef]

- Jian, S.; Wei, B.; Zhi, X.; Tan, H.; Li, B.; Li, X.; Lv, Y. Abrasion resistance improvement of recycled aggregate pervious concrete with granulated blast furnace slag and copper slag. J. Adv. Concr. Technol. 2021, 19, 1088–1099. [Google Scholar] [CrossRef]

- Dahiru, D.; Ibrahim, M.; Gado, A.A. Evaluation of the effect of volcanic ash on the properties of concrete. ATBU J. Environ. Technol. 2019, 12, 79–100. [Google Scholar]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P. Pervious concrete pavement incorporating GGBS to alleviatepavement runoff and improve urban sustainability. Road Mater. Pavement Des. 2016, 19, 167–181. [Google Scholar] [CrossRef]

- Kim, I.T.; Park, C.; Kim, S.; Cho, Y.-H. Evaluation of field applicability of pervious concrete materials for airport pavement cement treated drainage base course. Mater. Res. Innov. 2015, 19, 378–388. [Google Scholar] [CrossRef]

- Divsholi, B.S.; Lim, T.Y.D.; Teng, S. Durability properties and microstructure of ground granulated blast furnace slag cement concrete. Int. J. Concr. Struct. Mater. 2014, 8, 157–164. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesŏglu, M.; Kareem, Q.; İpek, S. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete. Mater. Struct. 2014, 49, 521–536. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Yan, C.; Liu, Y. Influence of crushing index on properties of recycled aggregates pervious concrete. Constr. Build. Mater. 2017, 135, 112–118. [Google Scholar] [CrossRef]

- Zou, D.; Wang, Z.; Shen, M.; Liu, T.; Zhou, A. Improvement in freeze-thaw durability of recycled aggregate permeable concrete with silane modification. Constr. Build. Mater. 2020, 268, 121097. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2020, 22, 2181–2196. [Google Scholar] [CrossRef]

- Liu, W.J. Performance of new permeable concrete materials based on mechanical strength. Nat. Environ. Pollut. Technol. 2019, 18, 1683–1689. [Google Scholar]

- Debnath, B.; Sarkar, P.P. Quantification of random pore features of porous concrete mixes prepared with brick aggregate: An application of stereology and mathematical morphology. Constr. Build. Mater. 2021, 294, 123594. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P.P. Characterization of pervious concrete using over burnt brick as coarse aggregate. Constr. Build. Mater. 2020, 242, 11815. [Google Scholar] [CrossRef]

- Li, L.G.; Ng, P.L.; Zeng, K.L.; Xie, H.Z.; Cheng, C.M.; Kwan, A.K.H. Experimental study and modelling of fresh behaviours of basalt fibre-reinforced mortar based on average water film thickness and fibre factor. Materials 2023, 16, 2137. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, B.; Wu, M. Mechanical strengths and durability properties of pervious concretes with blended steel slag and natural aggregate. J. Clean. Prod. 2020, 271, 122590. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- Mondal, S.; Biligiri, K.P. Crumb Rubber and Silica Fume Inclusions in Pervious Concrete Pavement Systems: Evaluation of Hydrological, Functional, and Structural Properties. J. Test. Eval. 2018, 46, 20170032. [Google Scholar] [CrossRef]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Adamu, M.; Ayeni, K.O.; Haruna, S.I.; Ibrahim Mansour, Y.E.-H.; Haruna, S. Durability performance of pervious concrete containing rice husk ash and calcium carbide: A response surface methodology approach. Case Stud. Constr. Mater. 2021, 14, e00547. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar] [CrossRef]

- Hari, R.; Mini, K. Mechanical and durability properties of basalt-steel wool hybrid fibre reinforced pervious concrete–A Box Behnken approach. J. Build. Eng. 2023, 70, 106307. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Liew, M.S.; Alaloul, W.S.; Khed, V.C.; Hoong, C.Y.; Adamu, M. Properties of nano-silica modified pervious concrete. Case Stud. Constr. Mater. 2018, 8, 409–422. [Google Scholar] [CrossRef]

- Tarangini, D.; Sravana, P.; Rao, P.S. Effect of nano silica on frost resistance of pervious concrete. Mater. Today Proc. 2022, 51, 2185–2189. [Google Scholar] [CrossRef]

- Nazeer, M.; Kapoor, K.; Singh, S. Strength, durability and microstructural investigations on pervious concrete made with fly ash and silica fume as supplementary cementitious materials. J. Build. Eng. 2023, 69, 106275. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Pang, S.D.; Geng, J.; Yang, H. Application of Sterculia foetida petiole wastes in lightweight pervious concrete. J. Clean. Prod. 2020, 246, 118972. [Google Scholar] [CrossRef]

- Khankhaje, E.; Razman, M.; Mirza, J.; Warid, M.; Rafieizonooz, M. Properties of sustainable lightweight pervious concrete containing oil palm kernel shell as coarse aggregate. Constr. Build. Mater. 2016, 126, 1054e1065. [Google Scholar] [CrossRef]

- Krishnan, C.; Santhanam, M.; Kumar, M.; Rangarajan, M. Iron oxide-modified pervious concrete filter for lead removal from wastewater. Environ. Technol. Innov. 2022, 28, 102681. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Muthukumar, S.; Saravanan, A.J.; Raman, A.; Sundaram, M.S.; Angamuthu, S.S. Investigation on the mechanical properties of eco-friendly pervious concrete. Mater. Today Proc. 2021, 46, 4909–4914. [Google Scholar] [CrossRef]

- Giustozzi, F. Polymer-modified pervious concrete for durable and sustainable transportation infrastructures. Constr. Build. Mater. 2016, 111, 502–512. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious concrete mixture optimization, physical, and mechanical properties and pavement design: A review. J. Clean. Prod. 2020, 288, 125095. [Google Scholar] [CrossRef]

- Lang, L.; Duan, H.; Chen, B. Properties of pervious concrete made from steel slag and magnesium phosphate cement. Constr. Build. Mater. 2019, 209, 95–104. [Google Scholar] [CrossRef]

- Gowda, S.B.; Goudar, S.K.; Thanu, H.; Monisha, B. Performance evaluation of alkali activated slag based recycled aggregate pervious concrete. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Lai, Z.; Hu, Y.; Fu, X.; Lu, Z.; Lv, S. Preparation of porous materials by magnesium phosphate cement with high permeability. Adv. Mater. Sci. Eng. 2018, 2018, 5910560. [Google Scholar]

- Zhao, S.; Zhang, D.; Li, Y.; Gao, H.; Meng, X. Physical and Mechanical Properties of Novel Porous Ecological Concrete Based on Magnesium Phosphate Cement. Materials 2022, 15, 7521. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.; Jang, J.; Khalid, H.R.; Lee, H. Water purification characteristics of pervious concrete fabricated with CSA cement and bottom ash aggregates. Constr. Build. Mater. 2017, 136, 1–8. [Google Scholar] [CrossRef]

- Phillip, E.; Choo, T.F.; Khairuddin, N.W.A.; Abdel Rahman, R.O. On the Sustainable Utilization of Geopolymers for Safe Management of Radioactive Waste: A Review. Sustainability 2023, 15, 1117. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S. A comprehensive review on fly ash-based geopolymer. J. Compos. Sci. 2022, 6, 219. [Google Scholar] [CrossRef]

- Garg, M.; Valeo, C.; Gupta, R.; Prasher, S.; Sharma, N.R.; Constabel, P. Integrating natural and engineered remediation strategies for water quality management within a low-impact development (LID) approach. Environ. Sci. Pollut. Res. 2018, 25, 29304–29313. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Ji, Y. Mechanical properties and permeability of red mud-blast furnace slag-based geopolymer concrete. SN Appl. Sci. 2021, 3, 23. [Google Scholar] [CrossRef]

- Liang, X.; Ji, Y. Experimental study on durability of red mud-blast furnace slag geopolymer mortar. Constr. Build. Mater. 2020, 267, 120942. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- Walling, S.A.; Provis, J.L. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. Life cycle of nuclear cementitious structures, systems, and components. In Sustainability of Life Cycle Management for Nuclear Cementation-Based Technologies; Rahman, R.O.A., Ojovan, M.I., Eds.; Elsevier-Woodhead Publishing: Sawston, UK, 2021; pp. 89–121. [Google Scholar] [CrossRef]

- Zheng, X.; Pan, J.; Easa, S.; Fu, T.; Liu, H.; Liu, W.; Qiu, R. Utilization of copper slag waste in alkali-activated metakaolin pervious concrete. J. Build. Eng. 2023, 76, 107246. [Google Scholar] [CrossRef]

- Lo, F.-C.; Lee, M.-G.; Lo, S.-L. Effect of coal ash and rice husk ash partial replacement in ordinary Portland cement on pervious concrete. Constr. Build. Mater. 2021, 286, 122947. [Google Scholar] [CrossRef]

- Cai, J.; Liu, Z.; Xu, G.; Tian, Q.; Shen, W.; Li, B.; Chen, T. Mix design methods for pervious concrete based on the mesostructure: Progress, existing problems and recommendation for future improvement. Case Stud. Constr. Mater. 2022, 17, e01253. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. Techniques to test cementitious systems through their life cycles, In Sustainability of Life Cycle Management for Nuclear Cementation-Based Technologies; Rahman, R.O.A., Ojovan, M.I., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 407–430. [Google Scholar] [CrossRef]

- Li, K. Durability Design of Concrete Structures: Phenomena, Modeling, and Practice, 1st ed.; John Wiley & Sons Singapore Pte. Ltd.: Singapore, 2016. [Google Scholar]

- Malhotra, V.M.; Carino, N.J. Handbook on Non-Destructive Testing of Concrete; CRC Press, LLC: Boca Raton, FL, USA, 2004. [Google Scholar]

- Martins Filho, S.T.; Bosquesi, E.M.; Fabro, J.R.; Pieralisi, R. Characterization of pervious concrete focusing on non-destructive testing. Rev. IBRACON Estrut. Mater. 2020, 13, 483–500. [Google Scholar] [CrossRef]

- Park, S.; Ju, S.; Kim, H.-K.; Seo, Y.-S.; Pyo, S. Effect of the rheological properties of fresh binder on the compressive strength of pervious concrete. journal of materials research and technology. J. Mater. Res. Technol. 2022, 17, 636–648. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H. Influence of cement flow and aggregate type on the mechanical and acoustic characteristics of porous concrete. Appl. Acoust. 2010, 71, 607–615. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Fresh state characteristics of foam concrete. J. Mater. Civ. Eng. 2008, 20, 111–117. [Google Scholar] [CrossRef]

- Harshith, S.D.; Ahmad, E. Experimental Investigation of Porous Concrete for Concrete Pavement. Int. J. Eng. Res. 2020, 9, 657–660. [Google Scholar] [CrossRef]

- Juradin, S.; Mihanović, F.; Ostojić-Škomrlj, N.; Rogošić, E. Pervious Concrete Reinforced with Waste Cloth Strips. Sustainability 2022, 14, 2723. [Google Scholar] [CrossRef]

- da Costa, F.B.; Haselbach, L.M.; da Silva Filho, L.C. Pervious concrete for desired porosity: Influence of w/c ratio and a rheology-modifying admixture. Constr. Build. Mater. 2021, 268, 121084. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, T.; Yang, Y.; Lin, Z.; Wei, J.; Yu, Q. Maximum paste coating thickness without voids clogging of pervious concrete and its relationship to the rheological properties of cement paste. Constr. Build. Mater. 2018, 168, 732–746. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, D.; Liu, T.; Zhou, A.; Shen, M. A novel method to predict the mesostructure and performance of pervious concrete. Constr. Build. Mater. 2020, 263, 120117. [Google Scholar] [CrossRef]

- Jimma, B.E.; Rangaraju, P.R. Film-forming ability of flowable cement pastes and its application in mixture proportioning of pervious concrete. Constr. Build. Mater. 2014, 71, 273–282. [Google Scholar] [CrossRef]

- Risson, K.D.B.D.S.; Sandoval, G.F.B.; Pinto, F.S.C.; Camargo, M.; De Moura, A.C.; Toralles, B.M. Molding procedure for pervious concrete specimens by density control. Case Stud. Constr. Mater. 2021, 15, e00619. [Google Scholar]

- Banevičienė, V.; Malaiškienė, J.; Boris, R.; Zach, J. The Effect of Active Additives and Coarse Aggregate Granulometric Composition on the Properties and Durability of Pervious Concrete. Materials 2022, 15, 1035. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K.; Ean, L.-W. Mix Design and Engineering Properties of Fiber-Reinforced Pervious Concrete Using Lightweight Aggregates. Appl. Sci. 2022, 12, 524. [Google Scholar] [CrossRef]

- Muda, M.M.; Legese, A.M.; Urgessa, G.; Boja, T. Strength, Porosity and Permeability Properties of Porous Concrete Made from Recycled Concrete Aggregates. Constr. Mater. 2023, 3, 81–92. [Google Scholar] [CrossRef]

- Geng, H.; Xu, Q.; Duraman, S.B.; Li, Q. Effect of Rheology of Fresh Paste on the Pore Structure and Properties of Pervious Concrete Based on the High Fluidity Alkali-Activated Slag. Crystals 2021, 11, 593. [Google Scholar] [CrossRef]

- Laskar, A.I.; Bhattacharjee, R. Effect of Plasticizer and Superplasticizer on Rheology of Fly-Ash-Based Geopolymer Concrete. ACI Mater. J. 2013, 110, 513–518. [Google Scholar]

- Amini, K.; Asce, S.M.; Wang, X.; Delatte, N.; Asce, F. Statistical modeling of hydraulic and mechanical properties of pervious concrete using nondestructive tests. J. Mater. Civ. Eng. 2018, 30, 04018077. [Google Scholar] [CrossRef]

- Bordelon, A.C.; Roesler, J.R. Spatial distribution of synthetic fibers in concrete with X-ray computed tomography. Cem. Concr. Compos. 2014, 53, 35–43. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, G.; Ming, R.; Cui, X.; Li, L.; Xu, H. Numerical study on seepage flow in pervious concrete based on 3D CT imaging. Constr. Build. Mater. 2018, 161, 468–478. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Hu, M.; Wang, J. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images. Constr. Build. Mater. 2019, 200, 687–702. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Dong, Q.; Yuan, J.; Hong, Q. Mechanical performance study of pervious concrete using steel slag aggregate through laboratory tests and numerical simulation. J. Clean. Prod. 2020, 262, 121208. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Linking pore system characteristics to the compressive behavior of pervious concrete. Cem. Concr. Compos. 2016, 70, 130–138. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, H.; Deng, Z.; He, J. Water permeability of pervious concrete is dependent on the applied pressure and testing methods. Ann. Mater. Sci. Eng. 2015, 2015, 404136. [Google Scholar] [CrossRef]

- Lederle, R.; Shepard, T.; Meza, V.D.L.V. Comparison of methods for measuring infiltration rate of pervious concrete. Constr. Build. Mater. 2020, 244, 118339. [Google Scholar] [CrossRef]

- Sandoval, G.F.; Galobardes, I.; Teixeira, R.S.; Toralles, B.M. Comparison between the falling head and the constant head permeability tests to assess the permeability coefficient of sustainable Pervious Concretes. Case Stud. Constr. Mater. 2017, 7, 317–328. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens. ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading). ASTM: West Conshohocken, PA, USA, 2016. [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. Sustainability of cementitious structures, systems, and components (SSC’s): Long-term environmental stressors, In Sustainability of Life Cycle Management for Nuclear Cementation-Based Technologies; Rahman, R.O.A., Ojovan, M.I., Eds.; Elsevier-Woodhead Publishing: Sawston, UK, 2021; pp. 181–232. [Google Scholar] [CrossRef]

- ASTM C452-21; Standard Test Method for Potential Expansion of Portland-Cement Mortars Exposed to Sulfate. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C1778; Standard Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction in Concrete. ASTM: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTMC666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C88; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM: West Conshohocken, PA, USA, 2018. [CrossRef]

- Teymouri, E.; Wong, K.S.; Rouhbakhsh, M.; Pahlevani, M.; Forouzan, M. Evaluating the Clogging Phenomenon in Pervious Concrete from January 2015 to December 2022. Civ. Sustain. Urban Eng. 2023, 3, 70–80. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Harvey, J.T.; Liang, X.; Xie, N.; Jia, M. Purification effect on runoff pollution of porous concrete with nano-TiO2 photocatalytic coating. Transp. Res. Part D Transp. Environ. 2021, 101, 103101. [Google Scholar] [CrossRef]

- Pilon, B.S.; Tyner, J.S.; Yoder, D.C.; Buchanan, J.R. The effect of pervious concrete on water quality parameters: A case study. Water 2019, 11, 263. [Google Scholar] [CrossRef]

- Muthu, M.; Santhanam, M.; Kumar, M. Pb removal in pervious concrete filter: Effects of accelerated carbonation and hydraulic retention time. Constr. Build. Mater. 2018, 174, 224–232. [Google Scholar] [CrossRef]

- Yousefi, A.; Matavos-Aramyan, S. Mix Design Optimization of Silica Fume-Based Pervious Concrete for Removal of Heavy Metals from Wastewaters. Silicon 2018, 10, 1737–1744. [Google Scholar] [CrossRef]

- Azad, A.; Saeedian, A.; Mousavi, S.-F.; Karami, H.; Farzin, S.; Singh, V.P. Effect of zeolite and pumice powders on the environmental and physical characteristics of green concrete filters. Constr. Build. Mater. 2019, 240, 117931. [Google Scholar] [CrossRef]

- Alighardashi, A.; Mehrani, M.J.; Ramezanianpour, A.M. Pervious concrete reactive barrier containing nano-silica for nitrate removal from contaminated water. Environ. Sci. Pollut. Res. Int. 2018, 25, 29481–29492. [Google Scholar] [CrossRef]

- Medawela, S.; Indraratna, B.; Athuraliya, S.; Lugg, G.; Nghiem, L.D. Monitoring the performance of permeable reactive barriers constructed in acid sulfate soils. Eng. Geol. 2021, 296, 106465. [Google Scholar] [CrossRef]

- Rad, P.R.; Fazlali, A. Optimization of permeable reactive barrier dimensions and location in groundwater remediation contaminated by landfill pollution. J. Water Process Eng. 2020, 35, 101196. [Google Scholar] [CrossRef]

- Rahman, R.A.; Moamen, O.A.; Hanafy, M.; Monem, N.A. Preliminary investigation of zinc transport through zeolite-X barrier: Linear isotherm assumption. Chem. Eng. J. 2012, 185–186, 61–70. [Google Scholar] [CrossRef]

- Day, S.R.; O’Hannesin, S.F.; Marsden, L. Geotechnical techniques for the construction of reactive barriers. J. Hazard. Mater. 1999, 67, 285–297. [Google Scholar] [CrossRef] [PubMed]

- Thakur, A.K.; Vithanage, M.; Das, D.B.; Kumar, M. A review on design, material selection, mechanism, and modelling of permeable reactive barrier for community-scale groundwater treatment. Environ. Technol. Innov. 2020, 19, 100917. [Google Scholar] [CrossRef]

- Faisal, A.A.H.; Sulaymon, A.H.; Khaliefa, Q.M. A review of permeable reactive barrier as passive sustainable technology for groundwater remediation. Int. J. Environ. Sci. Technol. 2017, 15, 1123–1138. [Google Scholar] [CrossRef]

- Singh, R.; Chakma, S.; Birke, V. Performance of field-scale permeable reactive barriers: An overview on potentials and possible implications for in-situ groundwater remediation applications. Sci. Total. Environ. 2023, 858, 158838. [Google Scholar] [CrossRef]

- Song, J.; Huang, G.; Han, D.; Hou, Q.; Gan, L.; Zhang, M. A review of reactive media within permeable reactive barriers for the removal of heavy metal(loid)s in groundwater: Current status and future prospects. J. Clean. Prod. 2021, 319, 128644. [Google Scholar] [CrossRef]

- Sakr, M.; El Agamawi, H.; Klammler, H.; Mohamed, M.M. Permeable reactive barriers as an effective technique for groundwater remediation: A review. Groundw. Susain. Dev. 2023, 21, 100914. [Google Scholar] [CrossRef]

- O’Hannesin, S.F.; Gillham, R.W. Long-term performance of an in situ “iron wall” for remediation of VOCs. Groundwater 1998, 36, 164–170. [Google Scholar] [CrossRef]

- Smith, J.; Boshoff, G.; Bone, B. Good practice guidance on permeable reactive barriers for remediating polluted groundwater, and a review of their use in the UK. Land Contam. Reclam. 2003, 11, 411–418. [Google Scholar] [CrossRef]

- Flury, B.; Eggenberger, U.; Mäder, U. First results of operating and monitoring an innovative design of a permeable reactive barrier for the remediation of chromate contaminated groundwater. Appl. Geochem. 2009, 24, 687–696. [Google Scholar] [CrossRef]

- Wanner, C.; Zink, S.; Eggenberger, U.; Mäder, U. Assessing the Cr(VI) reduction efficiency of a permeable reactive barrier using Cr isotope measurements and 2D reactive transport modeling. J. Contam. Hydrol. 2012, 131, 54–63. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pleasant, S.; Jain, P.; Powell, J.; Townsend, T. Calcium carbonate-based permeable reactive barriers for iron and manganese groundwater remediation at landfills. Waste Manag. 2016, 53, 128–135. [Google Scholar] [CrossRef]

- Budania, R.; Dangayach, S. A comprehensive review on permeable reactive barrier for the remediation of groundwater contamination. J. Environ. Manag. 2023, 332, 117343. [Google Scholar] [CrossRef] [PubMed]

- Mehrani, M.J.; Mehrani, A.A.; Alighardashi, A.; Ramezanianpour, A.M. An experimental study on the nitrate removal ability of aggregates used in pervious concrete. Desalination Water Treat 2017, 86, 124–130. [Google Scholar] [CrossRef]

- Ekolu, S.O.; Bitandi, L.K. Prediction of Longevities of ZVI and Pervious Concrete Reactive Barriers Using the Transport Simulation Model. J. Environ. Eng. 2018, 144, 04018074. [Google Scholar] [CrossRef]

- Thisani, S.K.; Von Kallon, D.V.; Byrne, P. Co-Remediation of Acid Mine Drainage and Industrial Effluent Using Passive Permeable Reactive Barrier Pre-Treatment and Active Co-Bioremediation. Minerals 2022, 12, 565. [Google Scholar] [CrossRef]

- Shabalala, A. Efficacies of Pervious Concrete and Zero-Valent Iron as Reactive Media for Treating Acid Mine Drainage; Mine Water Solutions; Pope, J., Wolkersdorfer, C., Weber, A., Sartz, L., Wolkersdorfer, K., Eds.; IMWA: Wendelstein, Germany, 2020; pp. 83–87. [Google Scholar]

- Shabalala, A.N. Utilisation of Pervious Concrete for Removal of Heavy Metals in Contaminated Waters: Opportunities and Challenges. In Proceedings of the 6th World Congress on Civil, Structural, and Environmental Engineering (CSEE’21), Virtual Conference, 21–23 June 2021. Paper No. ICEPTP 302. [Google Scholar] [CrossRef]

- Shabalala, A.; Ekolu, S. Quality of water recovered by treating acid mine drainage using pervious concrete adsorbent. Water SA 2019, 45, 638–647. [Google Scholar] [CrossRef]

- Thisani, S.K.; Von Kallon, D.V.; Byrne, P. Effects of Contact Time and Flow Configuration on the Acid Mine Drainage Remediation Capabilities of Pervious Concrete. Sustainability 2021, 13, 10847. [Google Scholar] [CrossRef]

- Ekolu, S.O.; Solomon, F.; de Beer, F.; Bitandi, L.; Kilula, R.N.; Maseko, K.T.; Mahlangu, F.G. Measurement of pore volume, connectivity and clogging of pervious concrete reactive barrier used to treat acid mine drainage. Environ. Sci. Pollut. Res. 2022, 29, 55743–55756. [Google Scholar] [CrossRef] [PubMed]

- Solomon, F.H.; Ekolu, S.O.; Musonda, I. Gravity-Fed Column Configuration for Acid Mine Drainage Experiment. Int. J. Eng. Technol. 2019, 11, 348–354. [Google Scholar] [CrossRef]

- Ekolu, S.O.; Azene, F.Z.; Diop, S. A concrete reactive barrier for acid mine drainage treatment. In Proceedings of the Institution of Civil Engineers-Water Management; Thomas Telford Ltd.: London, UK, 2014; Volume 167, pp. 373–380. [Google Scholar]

- Holmes, R.R.; Hart, M.L.; Kevern, J.T. Removal and breakthrough of lead, cadmium, and zinc in permeable reactive concrete. Environ. Eng. Sci. 2018, 35, 408–419. [Google Scholar] [CrossRef]

| SCMs | Aggregates | Fibers | ||||

|---|---|---|---|---|---|---|

| Material | Refs. | Material | Refs. | Material | Refs. | |

| Natural materials | Metakaolin (MK) | [53,61] | Basalt | [51,56,63,79] | Basalt fibers | [78,86] |

| Nano-clay | [81,90] | Lignite | [50] | Jute fibers | [54] | |

| Limestone | [20,51,52,59,66,71,80] | |||||

| Granite | [31,84,88,92] | |||||

| Pumice | [51,90] | |||||

| Zeolite | [20] | |||||

| Industrial wastes | Fly ash | [11,25,31,52,53,55,56,57,58,59,60,89,94] | Recycled concrete aggregate | [60,64,66,70,71,72,73,81,90] | Plastic fibers | [81,90] |

| Blast furnace slag | [25,54,64,66,67,68,69] | Recycled brick aggregate | [74,75,76,77] | Fine saw dust | [57] | |

| Volcanic ash | [65] | Iron slag | [20] | |||

| Copper slag | [64] | Steel slag | [79] | |||

| Silica fume | [25,56,61,80,81,82,89] | Crumb rubber | [82] | |||

| Calcium carbide | [84] | |||||

| Sugarcane bagasse ash | [95] | |||||

| Agro-waste | Biochar | [37,83] | Petioles from Sterculia foetida plant | [91] | N-A * | |

| Rice husk | [84,85] | Oil palm kernel shell | [92] | |||

| Chemicals | Nano silica | [59,87,88] | N-A * | Steel and steel wool fibers | [51,75,81,85,86,90] | |

| Polypropylene | [51,67,75] | |||||

| Polyphenylene sulfide | [85] | |||||

| Glass | [85] | |||||

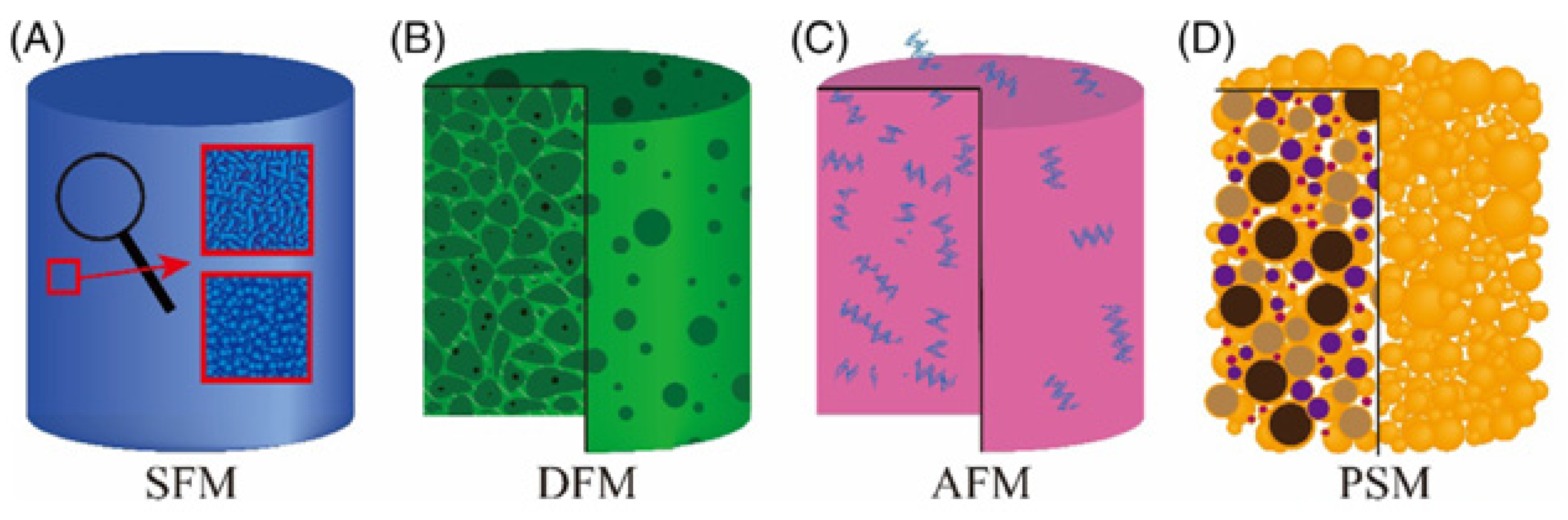

| Method | Preparation | Pore Characteristics | Applications |

|---|---|---|---|

| SFM | The porous structure is self-formed without the addition of any material | Porous structure cannot be observed directly Pores are small | Sorption Membrane filtration |

| DFM | Foaming agents, surfactants, or both are used | Large pore diameter that can directly be observed Noted circular pores on the surface and irregular internal bubbles pores | Building insulation Building lightweight |

| AFM | Porous filler or materials are added | Reflects the filler’s pore structure rather than that between the filler and geopolymer | Various applications including Adsorption Ultralight weight Building insulation |

| PSM | Bonding of the aggregates | The pore structure is formed in geopolymers or between the aggregates and geopolymers The pore diameter is related to the aggregate size Pores are observed directly | Porous pavement Permeable concrete |

| Contaminant | Permeable Concrete Mix Design | Removal Conditions | P, % | Refs. | ||||

|---|---|---|---|---|---|---|---|---|

| Aggregates | A/C | w/c | Additives | Co, ppm | t, h | |||

| Pb | Gravel | 5.5 | 0.4 | - | 2-207.2 | 72 | 84–91 | [24] |

| Limestone | 5.5 | 0.4 | - | 2-207.2 | 87–88 | |||

| GB * | 5.5 | 0.4 | - | 2-207.2 | 88.5–92 | |||

| Gravel | 5.5 | 0.4 | FA, 33.5% | 2-207.2 | 31.5–92 | |||

| Limestone | 5.5 | 0.4 | FA, 33.5% | 2-207.2 | 87–88 | |||

| GB * | 5.5 | 0.4 | FA, 33.5% | 2-207.2 | 68.5–95.5 | |||

| Na | 5 | 0.37 | - | 50 | 0.5 | 38 | [40] | |

| Cd | Gravel | 5.5 | 0.4 | - | 0.11-112.4 | 72 | 95–97 | [24] |

| Limestone | 5.5 | 0.4 | - | 0.11-112.4 | 56–80 | |||

| GB * | 5.5 | 0.4 | - | 0.11-112.4 | 16–99 | |||

| Gravel | 5.5 | 0.4 | FA, 33.5% | 0.11-112.4 | 48–97 | |||

| Limestone | 5.5 | 0.4 | FA, 33.5% | 0.11-112.4 | 54–64 | |||

| GB * | 5.5 | 0.4 | FA, 33.5% | 0.11-112.4 | 39.5–78 | |||

| Cu | Pumice | 3 | 0.35 | Pumice, 10% SF **, 5% | Na | Na | 97 | [155] |

| Ni | Pumice | 3 | 0.35 | Pumice, 10% SF, 5% ** | Na | Na | 71 | [155] |

| Zn | Gravel | 5.5 | 0.4 | - | 0.65-65.38 | 72 | 96 | [24] |

| Limestone | 5.5 | 0.4 | - | 0.65-65.38 | 72–80 | |||

| GB * | 5.5 | 0.4 | - | 0.65-65.38 | 67–100 | |||

| Gravel | 5.5 | 0.4 | FA, 33.5% | 0.65-65.38 | 56–96.5 | |||

| Limestone | 5.5 | 0.4 | FA, 33.5% | 0.65-65.38 | 76 | |||

| GB * | 5.5 | 0.4 | FA, 33.5% | 0.65-65.38 | 32–88 | |||

| Location | Nature of the Contamination | PRB Specification | Performance | Refs. | |||

|---|---|---|---|---|---|---|---|

| Target Contaminant | Site Characteristics | Plume Characteristic | Dimension | Barrier Materials and Specification | |||

| Ontario, Canada | Perchloroethene (PCE) and trichloroethene (TCE) | Medium–fine sand underlain by a clayey silt deposit at 9 m below ground level | 1 m wide and1 m thick, Co = 270ppm (TCE) Co = 50 ppm (PCE) | L = 5.5m, W = 1.6 m, D = 2.2 m | CPRB mixture of ZVI and commercial coarse sand (22:78) | After 299 days, the TCE and PCE were reduced by 90% and 85% with an uncertainty of less than ± 5%. | [167] |

| Northern Ireland, UK | TCE | Sand and gravel over Sherwood sandstone | Co = 390 ppm | Full scale D = 8 m | F&GPRB with ZVI as the active material | Calcite precipitation observed in the upstream improved the ZVI reactivity. No biological fouling. | [164,168] |

| Willisau, Switzerland | Chromate | Clayey and silty sand underlined by sand and gravel | Co < 10 ppm | Full scale | Double array of vertical piles containing iron shavings and gravel | Did not achieve its removal target due to its location in nearly oxygen and calcium carbonate saturated aquifer in a regime of high groundwater velocities. | [169,170] |

| Florida, USA | Iron and manganese | Clayey sand | Co = 30 ppm (Fe) Co = 1.62 ppm (Mn) | L = 6 m, W = 0.9 m, D = 4.6 m | Limestone and crushed concrete | In the first year, Fe removal efficiency 91–95% Reduced performance after three years showed due to clogging. | [171] |

| Material | Mix Design | Performance | Refs. | ||

|---|---|---|---|---|---|

| W/C | A/C | Supplemented Material | |||

| Red mud | 0.21–0.23 | 3.25 | Red mud 25, 50% superplasticizer | Reduced the compressive strength, effective at pH = 4 hydraulic retention time of 20 h | [30] |

| FA | 0.27 | 4.02 | Fly ash 30% superplasticizer | Enhanced the real acid mine drainage treatment | [31] |

| FA+ nano silica | 0.26 | 5 | Fly ash 20%, Nano silica 6% | Enhanced the nitrate removal and compressive strength | [157] |

| SF+ zeolite+ iron oxide | 0.25 | 4 | SF 5.05% zeolite 5.45% iron oxide 0.5% | Enhanced the heavy metal removal | [155] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdel Rahman, R.O.; El-Kamash, A.M.; Hung, Y.-T. Permeable Concrete Barriers to Control Water Pollution: A Review. Water 2023, 15, 3867. https://doi.org/10.3390/w15213867

Abdel Rahman RO, El-Kamash AM, Hung Y-T. Permeable Concrete Barriers to Control Water Pollution: A Review. Water. 2023; 15(21):3867. https://doi.org/10.3390/w15213867

Chicago/Turabian StyleAbdel Rahman, Rehab O., Ahmed M. El-Kamash, and Yung-Tse Hung. 2023. "Permeable Concrete Barriers to Control Water Pollution: A Review" Water 15, no. 21: 3867. https://doi.org/10.3390/w15213867

APA StyleAbdel Rahman, R. O., El-Kamash, A. M., & Hung, Y.-T. (2023). Permeable Concrete Barriers to Control Water Pollution: A Review. Water, 15(21), 3867. https://doi.org/10.3390/w15213867