Prediction of the Mine Water Inflow of Coal-Bearing Rock Series Based on Well Group Pumping

Abstract

1. Introduction

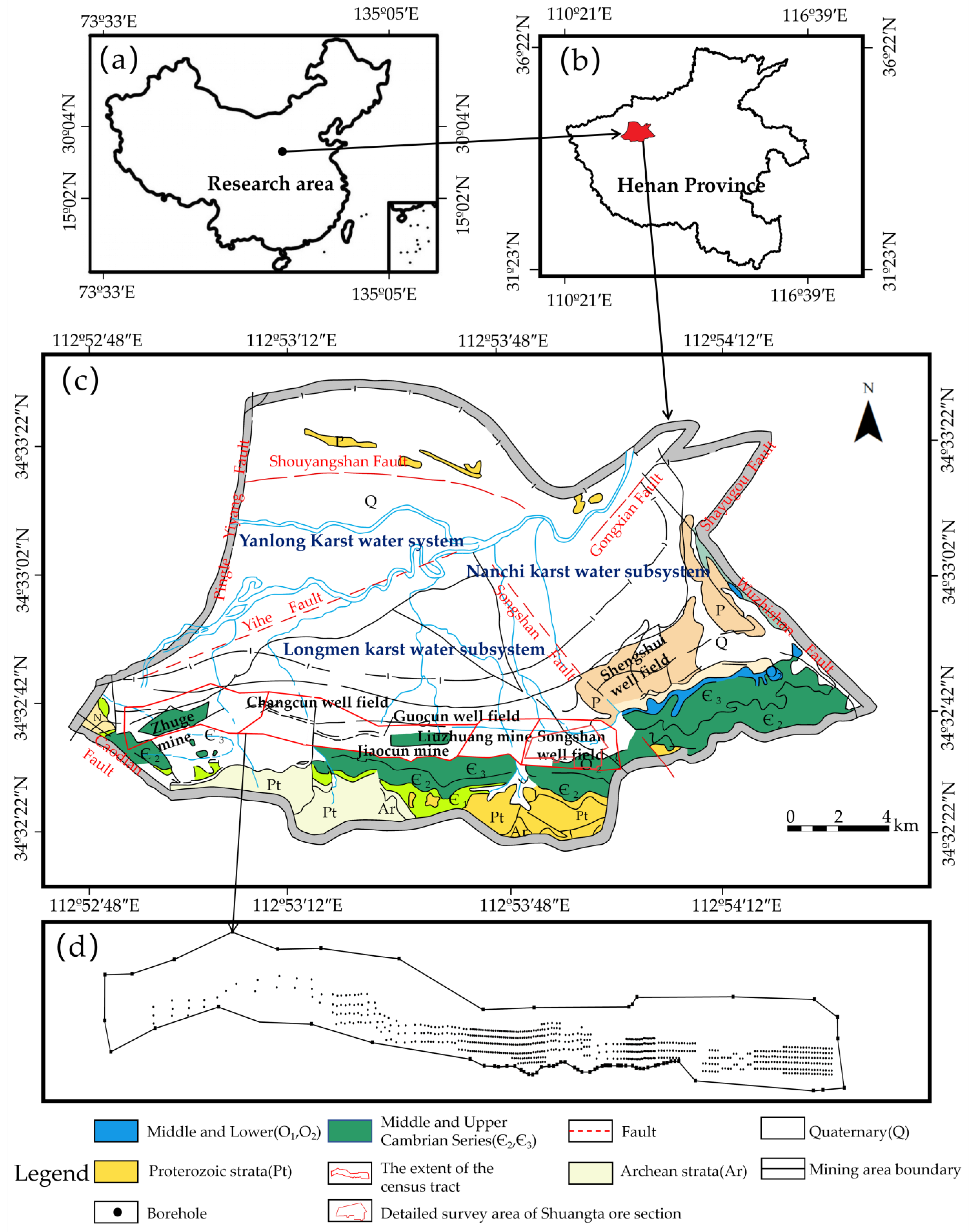

2. Overview of the Research Area

3. Research Methods

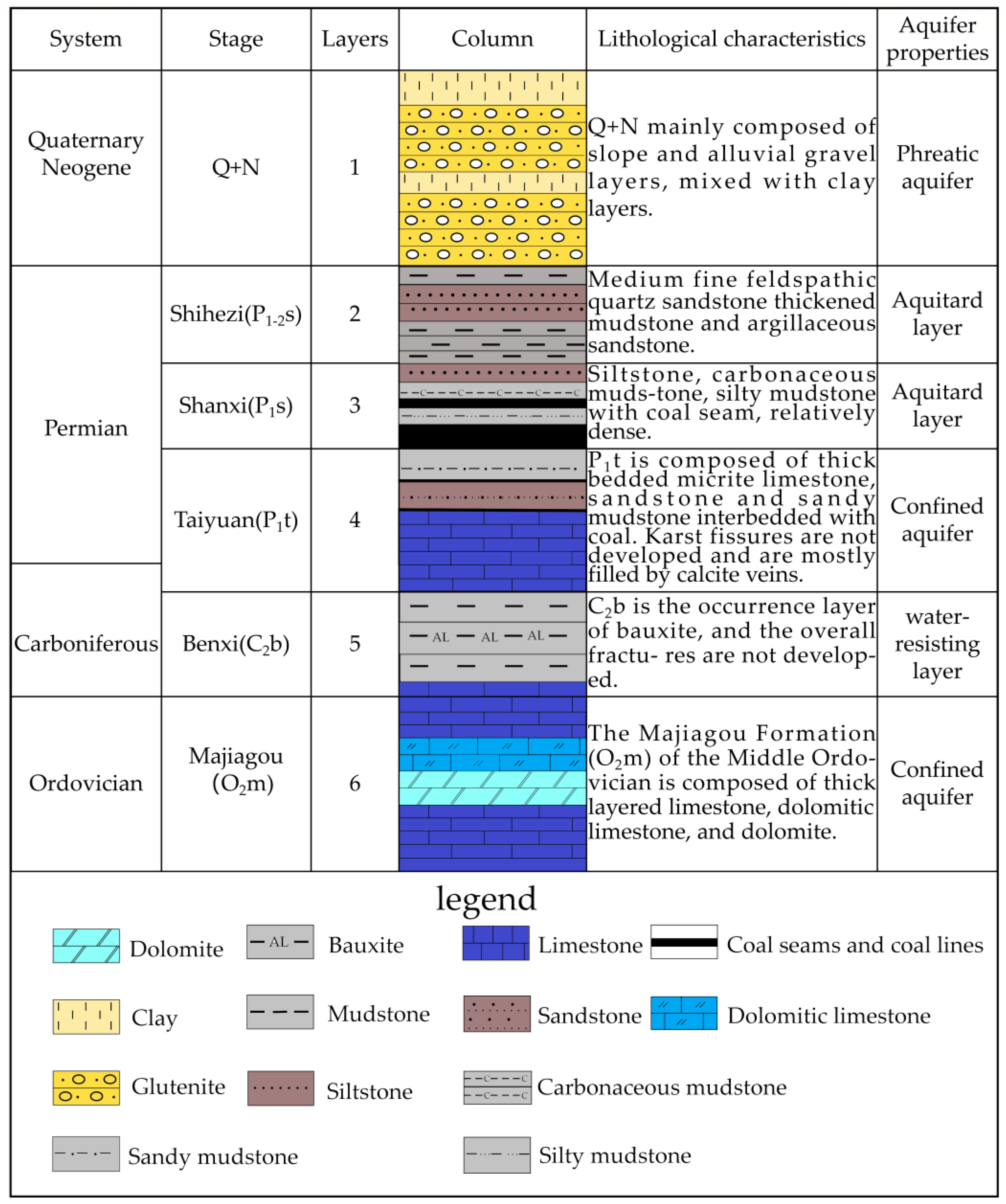

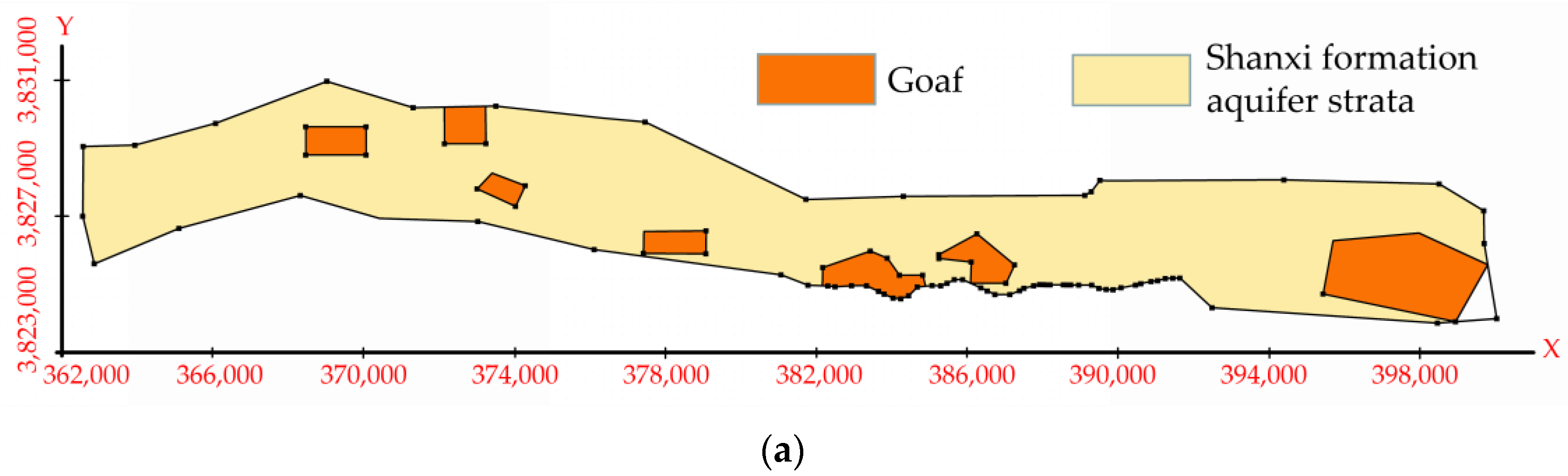

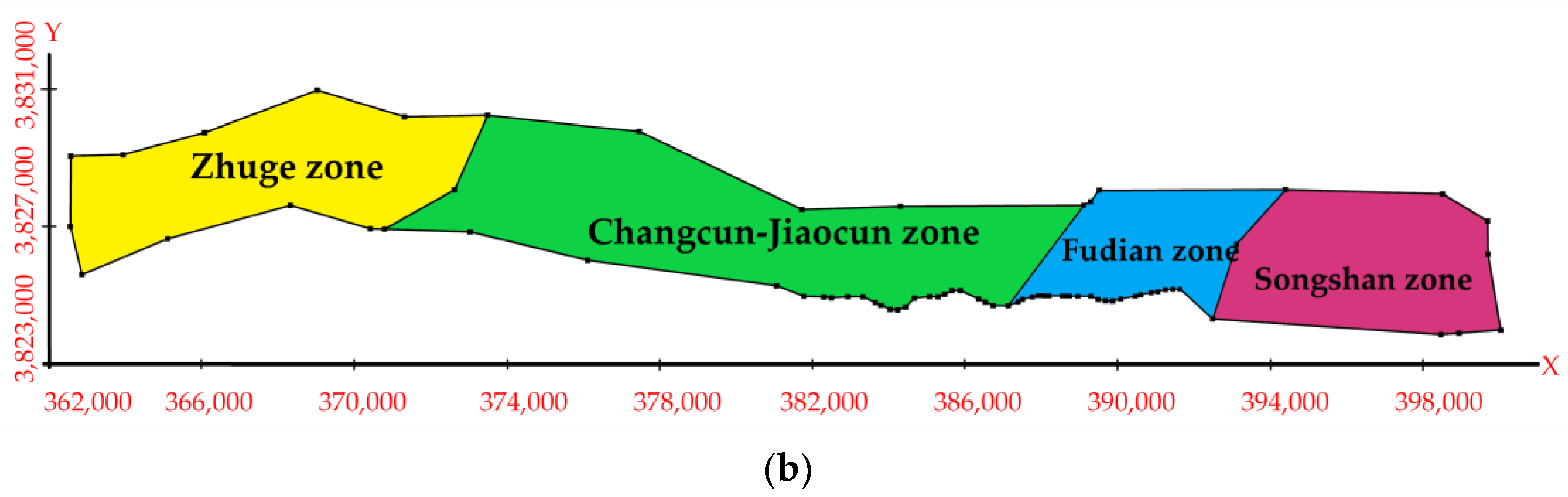

3.1. Establishment of Hydrogeological Conceptual Model

3.2. Establishment of a Mathematical Model of Hydrogeology

3.3. Water Inflow Prediction Methods

3.4. Establishing a Numerical Simulation Model of Yanlong Area

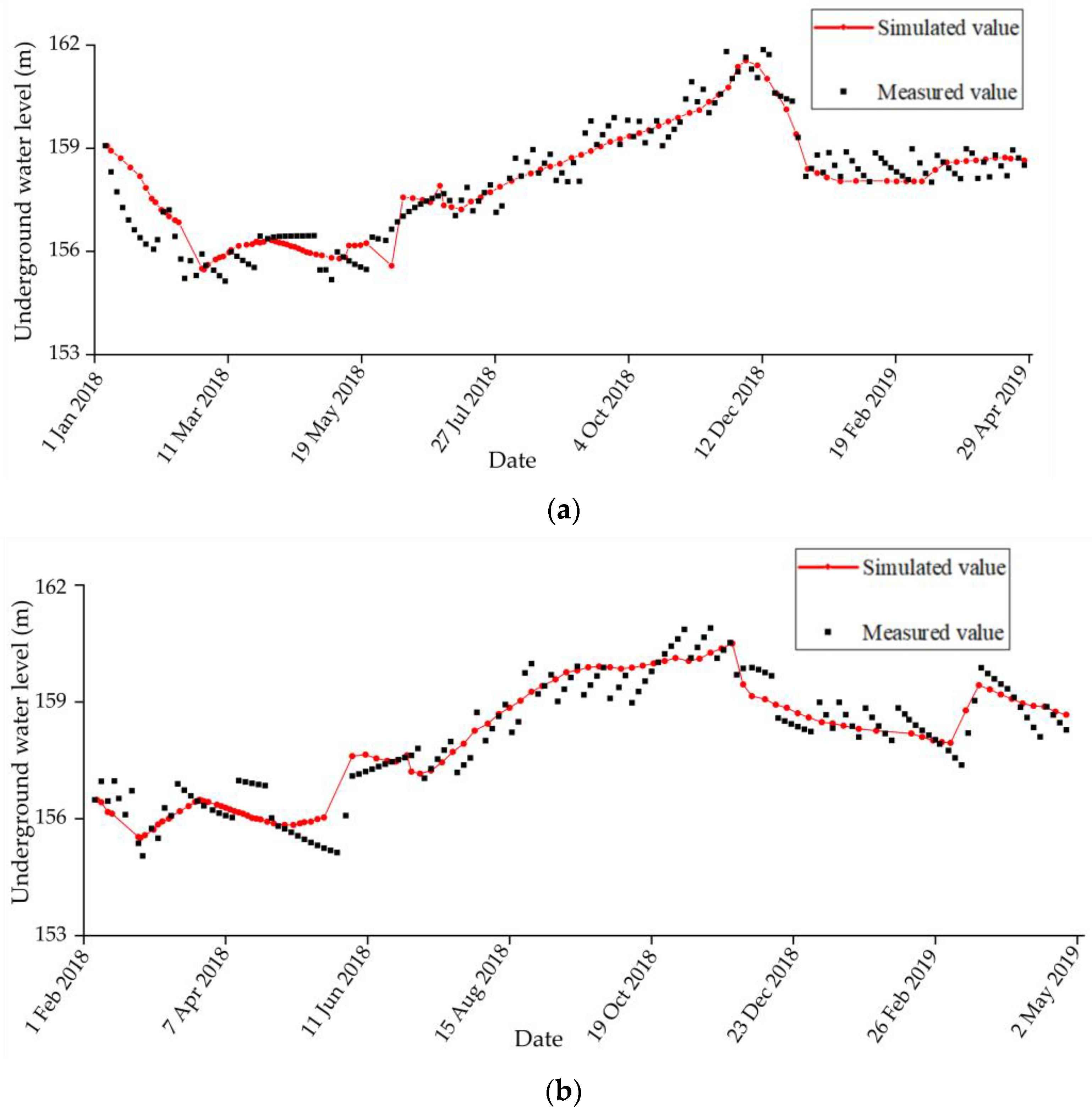

3.4.1. Calibration and Verification of Model Parameters

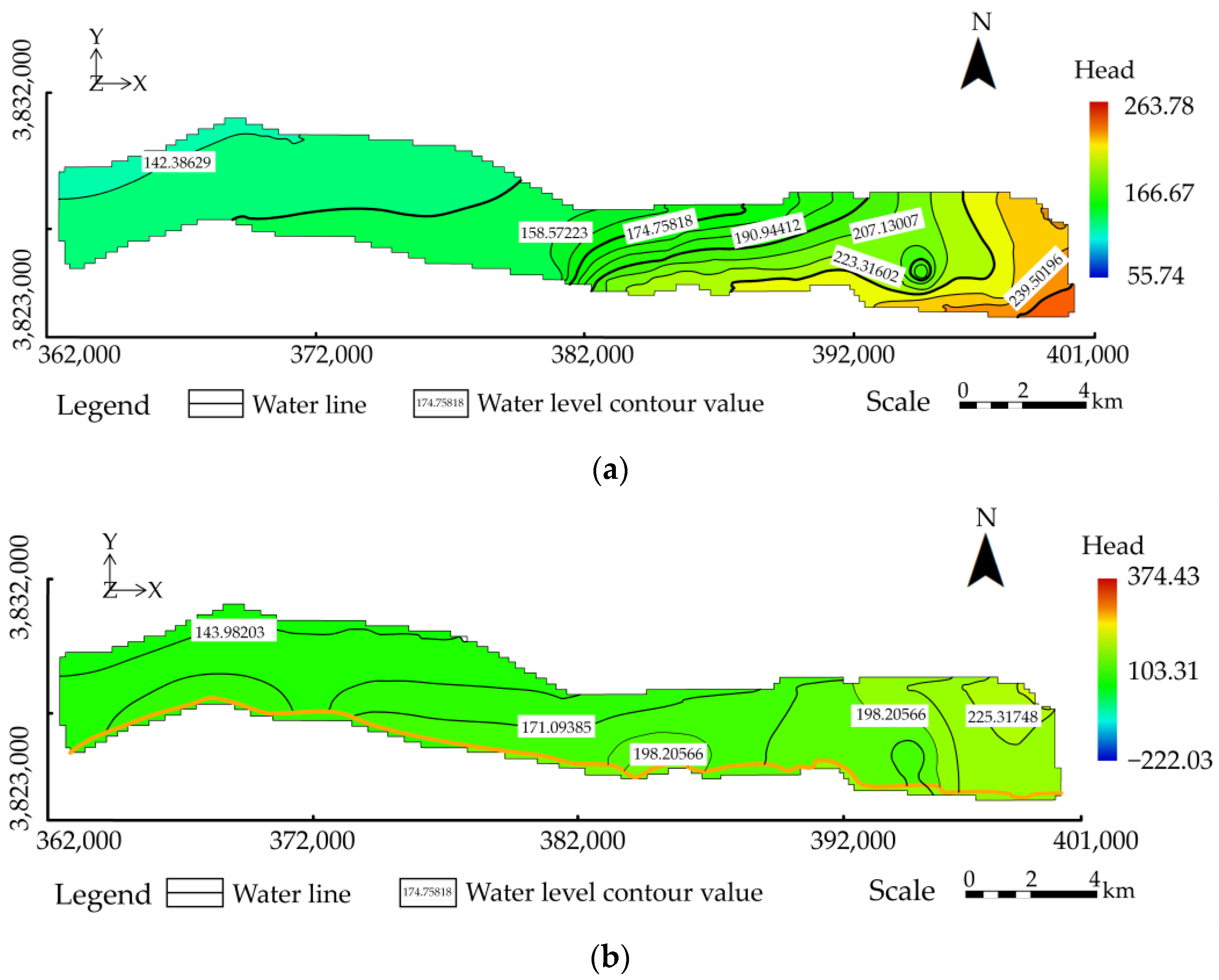

3.4.2. Hydrogeological Parameters and Flow Map

4. Results and Analysis

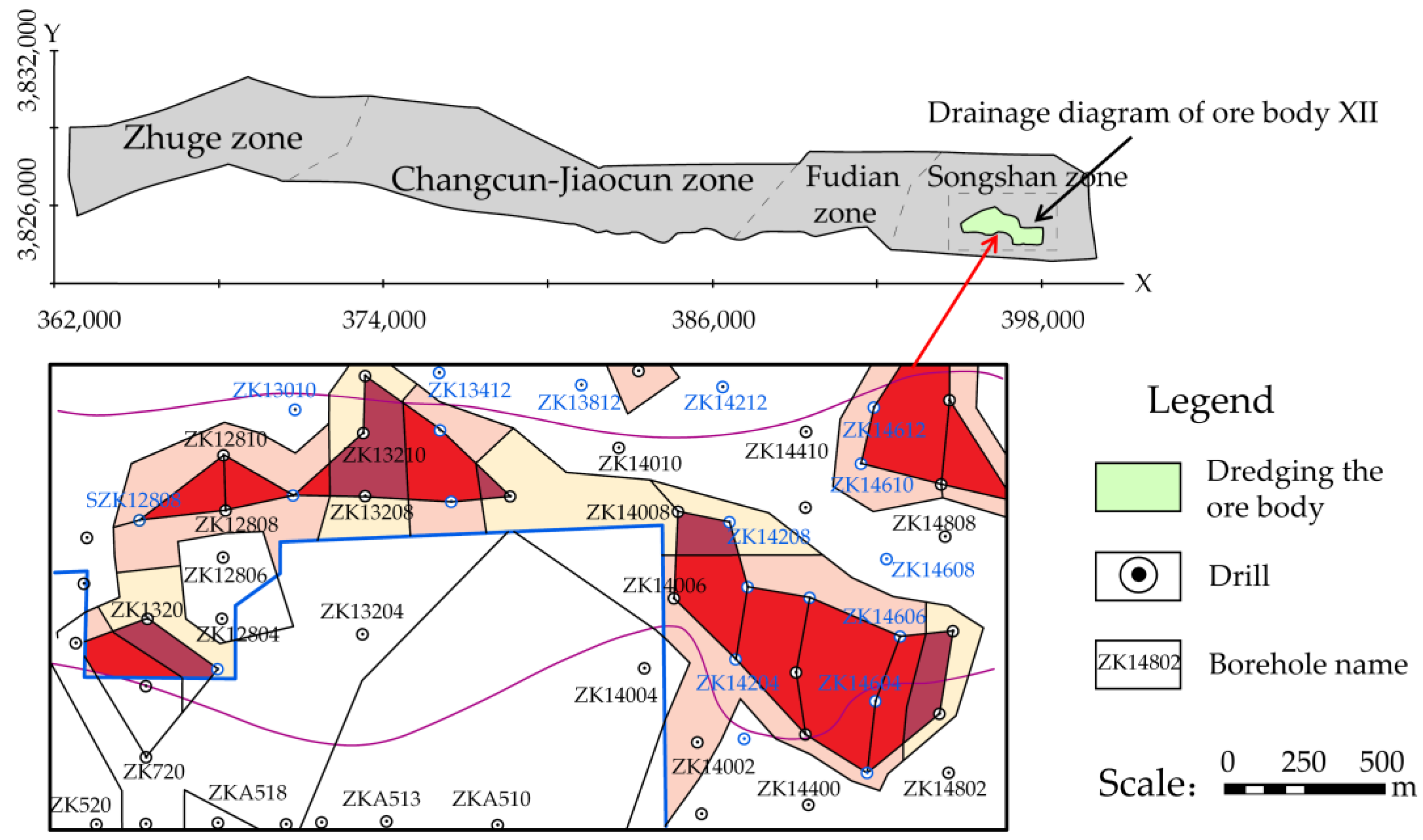

4.1. Predicting Water Inflow of Deposit XII Using the Analytical Method

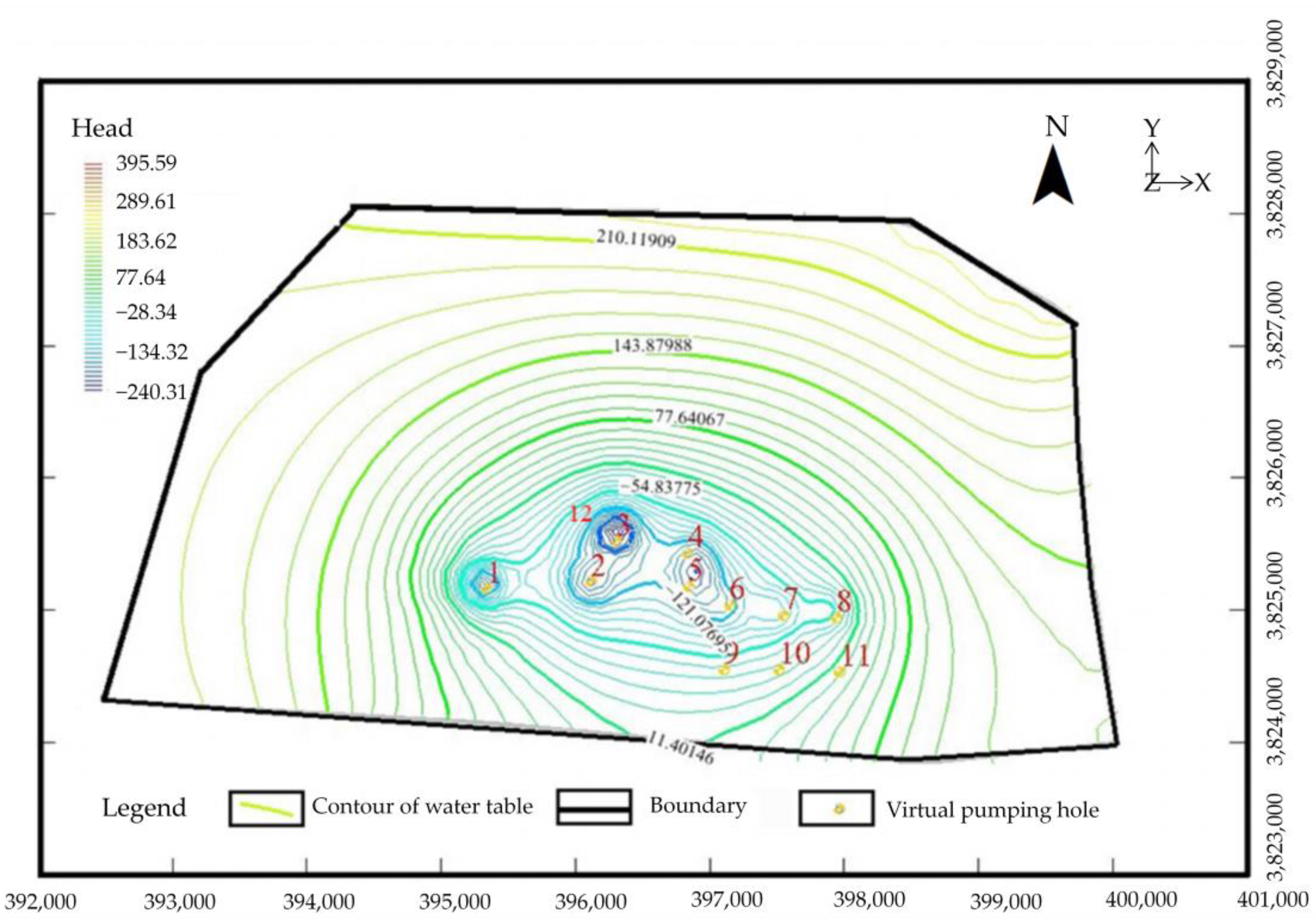

4.2. Numerical Method for Predicting Water Inflow of Ⅻ Orebody

4.2.1. Inflow Water Volume of Bauxite Roof

4.2.2. Inflow Water Volume of Bauxite Floor

4.3. Comparison of the Two Methods

5. Discussion

6. Conclusions

- (1)

- The model is identified and verified by the measured water level, and the average values of , and are 0.86, 0.81 and 2.71, respectively. The correlation or interdependence of the 3D simulation model is built in order to forecast water inflow in the bauxite layer.

- (2)

- The large well method and numerical method predict the water inflow in the Taiyuan Formation of the No. XII orebody in the Songshan mining area to be 72,786.66 m3/d and 71,500 m3/d, respectively. The numerical method predicts the average inflow and maximum inflow of the Majiagou Formation in the No. XII orebody to be 59,000 m3/d and 82,600 m3/d, respectively. Thus, it is established that the bauxite in the Songshan mining area will be exploited; the displacement of the roof and floor is greater than 72,786.66 m3/d and 82,600 m3/d.

- (3)

- When mining bauxite ore, it is recommended to construct curtain walls in the southern mining area to reduce the infiltration of precipitation into the bauxite ore roof and floor. Alternatively, the grouting and inclined borehole pumping methods can be used, which are beneficial for draining the bauxite ore roof and dewatering the floor below the critical safe water level.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huo, A.; Wang, X.; Zhao, Z.; Yang, L.; Zhong, F.; Zheng, C.; Gao, N. Risk Assessment of Heavy Metal Pollution in Farmland Soils at the Northern Foot of the Qinling Mountains, China. Int. J. Environ. Res. Public. Health 2022, 19, 14962. [Google Scholar] [CrossRef] [PubMed]

- Huo, A.; Zhao, Z.; Luo, P.; Zheng, C.; Peng, J.; Abuarab, M.E.L.S. Assessment of Spatial Heterogeneity of Soil Moisture in the Critical Zone of Gully Consolidation and Highland Protection. Water 2022, 14, 3674. [Google Scholar] [CrossRef]

- Huo, A.; Yang, L.; Luo, P.; Cheng, Y.; Peng, J.; Nover, D. Influence of landfill and land use scenario on runoff, evapotranspiration, and sediment yield over the Chinese Loess Plateau. Ecol. Indic. 2021, 121, 107208. [Google Scholar] [CrossRef]

- Li, T.; Song, H.; Huang, G.; Bi, Y.; Li, X. Assessment of groundwater changing trends through the generalized large well method with confined–unconfined flow model in open-pit mine area. Environ. Earth Sci. 2014, 72, 4599–4606. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Tan, T.; Zhang, L.; Zhu, S.; Xu, F. Evolution and modeling of mine water inflow and hazard characteristics in southern coalfields of China: A case of Meitanba mine. Int. J. Min. Sci. Technol. 2022, 32, 513–524. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, J.; Zhang, Y.; Wu, X.; Li, X. Principal component analysis and BP neural network of mine water inflow prediction research. Coal Technol. 2018, 37, 201–203. (In Chinese) [Google Scholar]

- Miladinović, B.; Vakanjac, V.R.; Bukumirović, D.; Dragišić, V.; Vakanjac, B. Simulation Of Mine Water Inflow: Case Study Of The Štavalj Coal Mine (Southwestern Serbia). Arch. Min. Sci. 2015, 60, 955–969. [Google Scholar] [CrossRef][Green Version]

- Ren, T. Analysis of hydrogeological characteristics and prediction of mine inflow in Xinqiao coal mine. West-China Explor. Eng. 2019, 31, 156–158. (In Chinese) [Google Scholar]

- Li, B.; Zhang, H.; Luo, Y.; Liu, L.; Li, T. Mine inflow prediction model based on unbiased Grey-Markov theory and its application. Earth Sci. Inform. 2022, 15, 855–862. [Google Scholar] [CrossRef]

- Ma, D.; Bai, H. Groundwater inflow prediction model of karst collapse pillar: A case study for mining-induced groundwater inrush risk. Nat. Hazards 2014, 76, 1319–1334. [Google Scholar] [CrossRef]

- Hadiyan, P.P.; Moeini, R.; Ehsanzadeh, E. Application of static and dynamic artificial neural networks for forecasting inflow discharges, case study: Sefidroud Dam reservoir. Sustain. Comput. Inform. Syst. 2020, 27, 100401. [Google Scholar] [CrossRef]

- Ren, B. Analysis on hydrological features and prediction on mine water inrush value in Hongling mine. Coal Eng. 2012, 4, 46–49. (In Chinese) [Google Scholar]

- Rupp, D.E.; Schmidt, J.; Woods, R.A.; Bidwell, V.J. Analytical assessment and parameter estimation of a low-dimensional groundwater model. J. Hydrol. 2009, 377, 143–154. [Google Scholar] [CrossRef]

- Wang, D.; Sui, W. Hydrogeological Effects of Fault Geometry for Analysing Groundwater Inflow in a Coal Mine. Mine Water Environ. 2021, 41, 93–102. [Google Scholar] [CrossRef]

- Wang, J.; Chen, S.; Wu, Y.-Q.; Hu, A. Simulation and prediction of water quality nitrogen based on ANN in Jinghe River, Shaanxi Province. Yellow River 2014, 36, 67–70+110. (In Chinese) [Google Scholar]

- Golian, M.; Teshnizi, E.S.; Nakhaei, M. Prediction of water inflow to mechanized tunnels during tunnel-boring-machine advance using numerical simulation. Hydrogeol. J. 2018, 26, 2827–2851. [Google Scholar] [CrossRef]

- Dong, D.; Sun, W.; Xi, S. Optimization of Mine Drainage Capacity Using FEFLOW for the No. 14 Coal Seam of China’s Linnancang Coal Mine. Mine Water Environ. 2012, 31, 353–360. [Google Scholar] [CrossRef]

- Surinaidu, L.; Gurunadha Rao, V.V.S.; Srinivasa Rao, N.; Srinu, S. Hydrogeological and groundwater modeling studies to estimate the groundwater inflows into the coal Mines at different mine development stages using MODFLOW, Andhra Pradesh, India. Water Resour. Ind. 2014, 7-8, 49–65. [Google Scholar] [CrossRef]

- Körner, P.; Pluntke, T.; Sachse, A.; Böttcher, N.; Naumov, D.; Kolditz, O.; Bernhofer, C. Inverse determination of groundwater inflow using water balance simulations. Environ. Earth Sci. 2014, 72, 4757–4769. [Google Scholar] [CrossRef]

- Ma, Q.; Luo, Z. Three-dimensional numerical simulation for predicting mine water inflow. J. Xi’an Univ. Sci. Technol. 2015, 35, 236–241. (In Chinese) [Google Scholar]

- Zhang, K.; Cao, B.; Lin, G.; Zhao, M. Using Multiple Methods to Predict Mine Water Inflow in the Pingdingshan No. 10 Coal Mine, China. Mine Water Environ. 2015, 36, 154–160. [Google Scholar] [CrossRef]

- Wu, C.; Wu, X.; Zhu, G.; Qian, C. Predicting mine water inflow and groundwater levels for coal mining operations in the Pangpangta coalfield, China. Environ. Earth Sci. 2019, 78, 130. [Google Scholar] [CrossRef]

- Yin, H.; Wei, J.; Lefticariu, L.; Guo, J.; Xie, D.; Li, Z.; Zhao, P. Numerical Simulation of Water Flow from the Coal Seam Floor in a Deep Longwall Mine in China. Mine Water Environ. 2016, 35, 243–252. [Google Scholar] [CrossRef]

- Gao, R.; Yan, H.; Ju, F.; Mei, X.; Wang, X. Influential factors and control of water inrush in a coal seam as the main aquifer. Int. J. Min. Sci. Technol. 2018, 28, 187–193. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H.; Tu, W.; Mou, C.; Wan, X. Numerical-Analytical Method for Predicting Water Inflow into the Tunnel through Conductive Fault Fracture Zone. Pol. J. Environ. Stud. 2023, 32, 2885–2892. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wu, Z.; Huang, T.; Peng, D. A Dynamic Modeling Approach to Predict Water Inflow during Karst Tunnel Excavation. Water 2022, 14, 2380. [Google Scholar] [CrossRef]

- Farhadian, H.; Nikvar Hassani, A.; Katibeh, H. Groundwater inflow assessment to Karaj Water Conveyance tunnel, northern Iran. KSCE J. Civ. Eng. 2016, 21, 2429–2438. [Google Scholar] [CrossRef]

- Gabov, V.V.; Zadkov, D.A.; Babyr, N.V.; Fangwei, X. Nonimpact rock pressure regulation with energy recovery into the hydraulic system of the longwall powered support. Eurasian Min. 2021, 2021, 55–59. [Google Scholar] [CrossRef]

- Zadkov, D.A.; Gabov, V.V.; Babyr, N.V.; Stebnev, A.V.; Teremetskaya, V.A. Adaptable and energy-efficient powered roof support unit. Min. Informational Anal. Bull. 2022, 6, 46–61. [Google Scholar] [CrossRef]

- Zhao, J.; Nie, G.; Wen, Y. Monthly precipitation prediction in Luoyang city based on EEMD-LSTM-ARIMA model. Water Sci. Technol. 2023, 87, 318–335. [Google Scholar] [CrossRef]

- Huo, A.; Wang, X.; Liang, Y.; Jiang, C.; Zheng, X. Integrated numerical model for irrigated area water resources management. J. Water Clim. Chang. 2020, 11, 980–991. [Google Scholar] [CrossRef]

- Chang, H. Hydrogeological characteristics analysis and mine inflow prediction of Shangzhai coal mine in Guanling County. Resour. Inf. Eng. 2017, 32, 61–62+64. (In Chinese) [Google Scholar]

- Li, P.; Guo, H.; Wu, K.; Jin, M.; Li, X. Numerical Simulation and Forecast of Mine Discharge in Wanghe Coal Mine. Earth Sci. -J. China Univ. Geosci. 2011, 36, 755–760. (In Chinese) [Google Scholar]

- Zhang, Z.; Li, L. Groundwater Resources in China (Comprehensive Volume); China Cartographic Publishing House: Beijing, China, 2004; pp. 21–30. (In Chinese) [Google Scholar]

- Li, B.; Wu, H.; Liu, P.; Fan, J.; Li, T. Construction and application of mine water inflow prediction model based on multi-factor weighted regression: Wulunshan Coal Mine case. Earth Sci. Inform. 2023, 16, 1879–1890. [Google Scholar] [CrossRef]

- Huo, A.; Peng, J.; Cheng, Y.; Luo, P.; Zhao, Z.; Zheng, C. Hydrological Analysis of Loess Plateau Highland Control Schemes in Dongzhi Plateau. Front. Earth Sci. 2020, 8, 528632. [Google Scholar] [CrossRef]

- Cao, D. Numerical simulation of underground water drainage and dewatering quantity from Ordovician limestone of low group seam in Dongtan mine. Coal Sci. Technol. 2011, 39, 98–102. (In Chinese) [Google Scholar]

- Mehl, S.; Hill, M.C. Development and evaluation of a local grid refinement method for block-centered finite-difference groundwater models using shared nodes. Adv. Water Resour. 2002, 25, 497–511. [Google Scholar] [CrossRef]

- Luo, Q.; Zhao, B.; Mao, X.; Han, Y.; Luo, X.; Hu, Y. Prediction and analysis of mine water inflow based on numerical simulation method. J. Northwest Univ. Nat. Sci. Ed. 2022, 52, 1100–1110. (In Chinese) [Google Scholar]

- Xu, Z.; Hu, B.X.; Davis, H.; Kish, S. Numerical study of groundwater flow cycling controlled by seawater/freshwater interaction in a coastal karst aquifer through conduit network using CFPv2. J. Contam. Hydrol. 2015, 182, 131–145. [Google Scholar] [CrossRef][Green Version]

- Malekzadeh, M.; Kardar, S.; Shabanlou, S. Simulation of groundwater level using MODFLOW, extreme learning machine and Wavelet-Extreme Learning Machine models. Groundw. Sustain. Dev. 2019, 9, 100279. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, W. Prediction of inflow from overlying aquifers into coalmines: A case study in Jinggezhuang Coalmine, Kailuan, China. Environ. Geol. 2007, 55, 775–780. [Google Scholar] [CrossRef]

- Yihdego, Y.; Paffard, A. Predicting Open Pit Mine Inflow and Recovery Depth in the Durvuljin soum, Zavkhan Province, Mongolia. Mine Water Environ. 2016, 36, 114–123. [Google Scholar] [CrossRef]

- Veyskarami, M.; Hassani, A.H.; Ghazanfari, M.H. Modeling of non-Darcy flow through anisotropic porous media: Role of pore space profiles. Chem. Eng. Sci. 2016, 151, 93–104. [Google Scholar] [CrossRef]

- Domingue, C.; Lemieux, J.-M.; Grenon, M.; Molson, J.; Therrien, R.; Lajoie, P.-L.; Blessent, D. Numerical Evaluation of Grouting Scenarios for Reducing Water Inflows from Major Faults in Underground Excavations. Mine Water Environ. 2019, 38, 497–506. [Google Scholar] [CrossRef]

- Chen, W.; Li, W.; Wang, Q.; Qiao, W. Evaluation of Groundwater Inflow into an Iron Mine Surrounded by an Imperfect Grout Curtain. Mine Water Environ. 2021, 40, 520–538. [Google Scholar] [CrossRef]

- Fan, L.; Ma, X. A review on investigation of water-preserved coal mining in western China. Int. J. Coal Sci. Technol. 2018, 5, 411–416. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, Y.; Lu, T.; Wang, B.; Zeng, G.; Zhang, X. Computing of Permeability Tensor and Seepage Flow Model of Intact Malan Loess by X-ray Computed Tomography. Water 2023, 15, 2851. [Google Scholar] [CrossRef]

| Drill Hole | Water Inflow (L/S.M) | Permeability Coefficient (m/d) | Formation | Water Inflow (L/S.M) | Permeability Coefficient (m/d) | Formation |

|---|---|---|---|---|---|---|

| ZK13408 | 0.307 | 0.4893 | P1t | 0.1643 | 1.4033 | O2m |

| ZK14606 | 0.047 | 0.2124 | 0.0331 | 0.1763 | ||

| ZK12608 | 0.171 | 0.2838 | 0.0282 | 0.1227 | ||

| ZK15812 | 0.101 | 0.1435 | 0.0606 | 0.2493 | ||

| ZK15802 | 0.547 | 0.8125 | 0.0161 | 0.0588 | ||

| ZK9606 | 0.0393 | 0.0648 | 0.00668 | 0.0174 | ||

| ZK2304 | 0.635 | 0.9538 | 0.0295 | 0.1283 | ||

| ZK4108 | 0.0392 | 0.0489 | 0.0411 | 0.1682 |

| Parameter | Average Water Level Change in Observation Well (m) | M | ||||||

|---|---|---|---|---|---|---|---|---|

| −20% | −10% | −5% | 0% | 5% | 10% | 20% | ||

| 1.3586 | 0.7014 | 0.2471 | 0 | −0.1128 | −0.2386 | −0.6714 | 5.7 | |

| −0.4114 | −0.2986 | −0.1471 | 0 | 0.1718 | 0.3357 | 0.6796 | 2.4 | |

| Rainfall | −0.0443 | −0.0186 | −0.0014 | 0 | 0.0157 | 0.0329 | 0.0757 | 0.2 |

| −0.0691 | −0.0457 | −0.0157 | 0 | 0.0114 | 0.0071 | 0.0114 | 0.1 | |

| Borehole | Evaluation Index | ||

|---|---|---|---|

| SJ02 | 0.89 | 0.88 | 1.72 |

| ZK2304 | 0.90 | 0.88 | −0.62 |

| ZK9606 | 0.91 | 0.73 | −1.70 |

| ZK13408 | 0.85 | 0.83 | 3.39 |

| ZK4108 | 0.78 | 0.72 | −4.92 |

| ZK7100 | 0.82 | 0.80 | 3.92 |

| Number | Formation | Parameter Partition | Horizontal Permeability Coefficient (m/d) | Vertical Permeability Coefficient (m/d) | Storage Coefficient (1/m) | Gravity- Specific Yield (1/m) |

|---|---|---|---|---|---|---|

| 1 | Q + N | 12 | 1.2 | — | 0.2 | |

| 2 | P1-2s | 0.0012 | 0.00012 | 0.000011 | — | |

| 3 | P1s | 1–7 | 1.2 | 0.12 | 0.00001 | — |

| 8 | 0.4 | 0.04 | 0.000012 | — | ||

| 4 | P1t | 1 | 0.19 | 0.019 | 0.000015 | — |

| 2 | 0.53 | 0.053 | 0.000015 | — | ||

| 3 | 0.28 | 0.028 | 0.000015 | — | ||

| 4 | 0.4 | 0.04 | 0.000015 | — | ||

| 5 | C2b | 0.00015 | 0.000015 | 0.000011 | — | |

| 6 | O2m | 2.6 | 0.26 | 0.000030 | — |

| XII Ore Body Parameters | K (m/d) | H (m) | M (m) | F (km2) | R (m) | r0 (m) | R0 (m) | Q (m3/d) |

|---|---|---|---|---|---|---|---|---|

| Taiyuan Formation | 0.40 | 498.72 | 99.70 | 2.28 | 3154.00 | 853.00 | 4007.00 | 72,786.66 |

| Virtual Pumping Well | X Coordinate | Y Coordinate | Floor Elevation of Taiyuan Formation (m) | Water Inflow (m3/d) | Formation |

|---|---|---|---|---|---|

| T11 | 397,966 | 3,824,532 | 97 | −1900 | P1t |

| T9 | 397,105 | 3,824,550 | 66 | −1800 | |

| T6 | 397,153 | 3,825,038 | −68 | −5000 | |

| T8 | 397,942 | 3,824,942 | −11 | −5000 | |

| T7 | 397,551 | 3,824,960 | −42 | −5000 | |

| T10 | 397,515 | 3,824,550 | 66 | −1300 | |

| T3 | 396,304 | 3,825,523 | −207 | −1100 | |

| T1 | 395,337 | 3,825,162 | −158 | −8500 | |

| T2 | 396,115 | 3,825,217 | −144 | −9000 | |

| T5 | 396,846 | 3,825,177 | −110 | −6000 | |

| T4 | 396,838 | 3,825,429 | −160 | −7000 | |

| T12 | 395,661 | 3,825,424 | −189 | −10,000 | |

| The total water inflow | −71,500 m3/d | P1t | |||

| Virtual Pumping Well | X Coordinate | Y Coordinate | Benxi Formation Floor Elevation (m) | Minimum Inflow (m3/d) | Critical Safe Water Level (m) | Normal Inflow (m3/d) | Maximum Inflow (m3/d) |

|---|---|---|---|---|---|---|---|

| T11 | 397,966 | 3,824,532 | 84 | −500 | 60 | −300 | −420 |

| T9 | 397,105 | 3,824,550 | 60 | −500 | 36 | −300 | −420 |

| T6 | 397,153 | 3,825,038 | −75 | −4000 | −99 | −3000 | −4200 |

| T8 | 397,942 | 3,824,942 | −22 | −4500 | −46 | −4800 | −6720 |

| T7 | 397,551 | 3,824,960 | −60 | −4000 | −84 | −3500 | −4900 |

| T10 | 397,515 | 3,824,550 | 37 | −500 | 13 | −200 | −280 |

| T3 | 396,304 | 3,825,523 | −216 | −12,000 | −240 | −12,500 | −17,500 |

| T1 | 395,337 | 3,825,162 | −165 | −8000 | −189 | −9850 | −13,790 |

| T2 | 396,115 | 3,825,217 | −151 | −6000 | −175 | −6650 | −9310 |

| T5 | 396,846 | 3,825,177 | −117 | −5000 | −141 | −4800 | −6720 |

| T4 | 396,838 | 3,825,429 | −167 | −5000 | −191 | −5500 | −7700 |

| T12 | 395,661 | 3,825,424 | −196 | −7600 | −220 | −7600 | −10,640 |

| The total water inflow | −57,600 m3/d | −59,000 m3/d | −82,600 m3/d | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, H.; Wang, J.; Lu, Y.; Rao, Z.; He, K.; Hao, S.; Huo, A.; Adnan, A. Prediction of the Mine Water Inflow of Coal-Bearing Rock Series Based on Well Group Pumping. Water 2023, 15, 3680. https://doi.org/10.3390/w15203680

Zhai H, Wang J, Lu Y, Rao Z, He K, Hao S, Huo A, Adnan A. Prediction of the Mine Water Inflow of Coal-Bearing Rock Series Based on Well Group Pumping. Water. 2023; 15(20):3680. https://doi.org/10.3390/w15203680

Chicago/Turabian StyleZhai, Hongtao, Jucui Wang, Yangchun Lu, Zhenxing Rao, Kai He, Shunyi Hao, Aidi Huo, and Ahmed Adnan. 2023. "Prediction of the Mine Water Inflow of Coal-Bearing Rock Series Based on Well Group Pumping" Water 15, no. 20: 3680. https://doi.org/10.3390/w15203680

APA StyleZhai, H., Wang, J., Lu, Y., Rao, Z., He, K., Hao, S., Huo, A., & Adnan, A. (2023). Prediction of the Mine Water Inflow of Coal-Bearing Rock Series Based on Well Group Pumping. Water, 15(20), 3680. https://doi.org/10.3390/w15203680