Effect of Flume Width on the Hydraulic Properties of Overland Flow from Laboratory Observation

Abstract

:1. Introduction

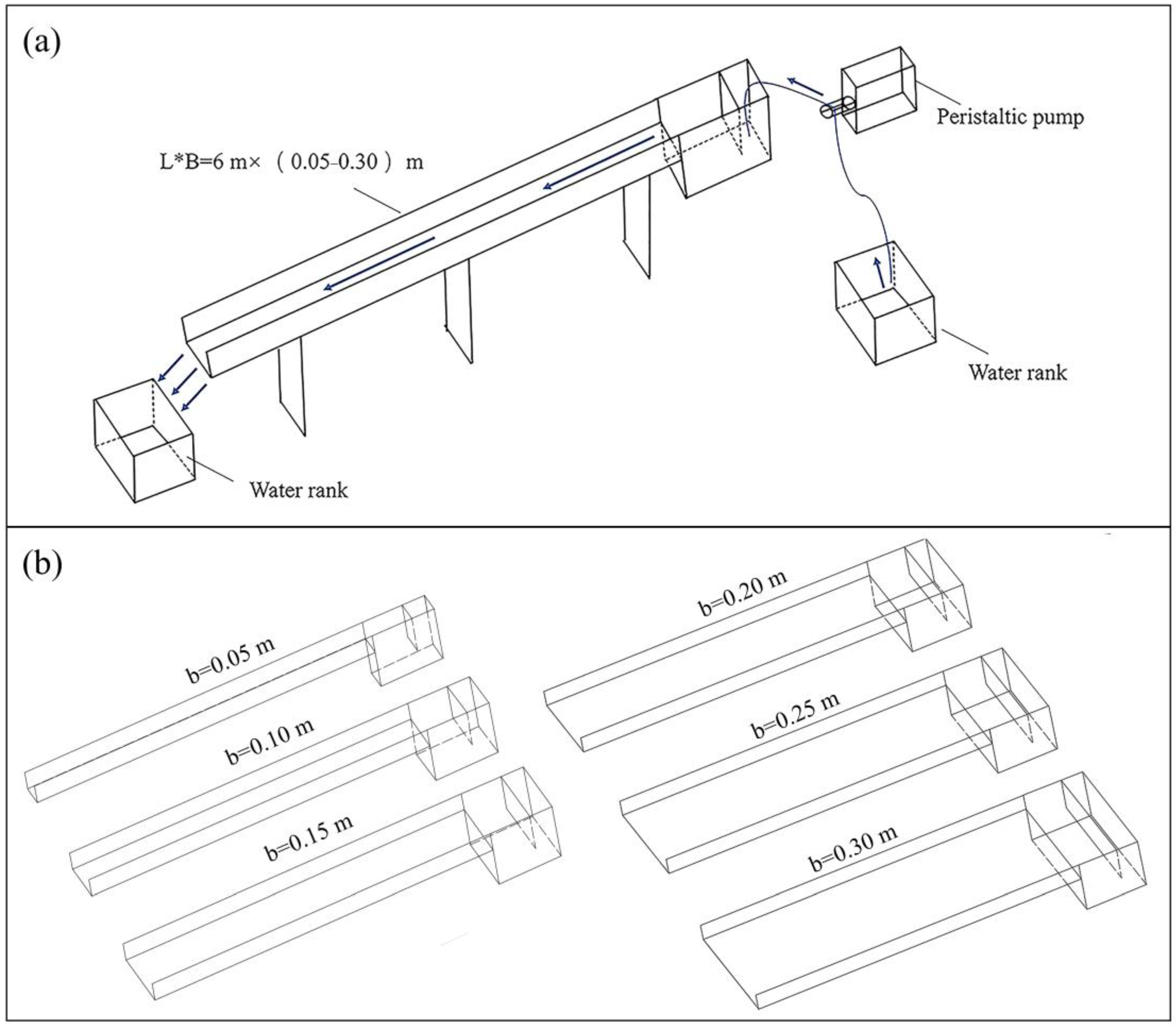

2. Materials and Methods

2.1. Experimental Setup

2.2. Experimental Design

2.3. Calculations of the Hydraulic Parameters

2.3.1. Flow Depth (h)

2.3.2. Relative Average Deviation (RAD)

2.3.3. Reynolds Number (Re)

2.3.4. Flow Pattern Index (δ/h)

2.3.5. Specific Energy (Es)

3. Results

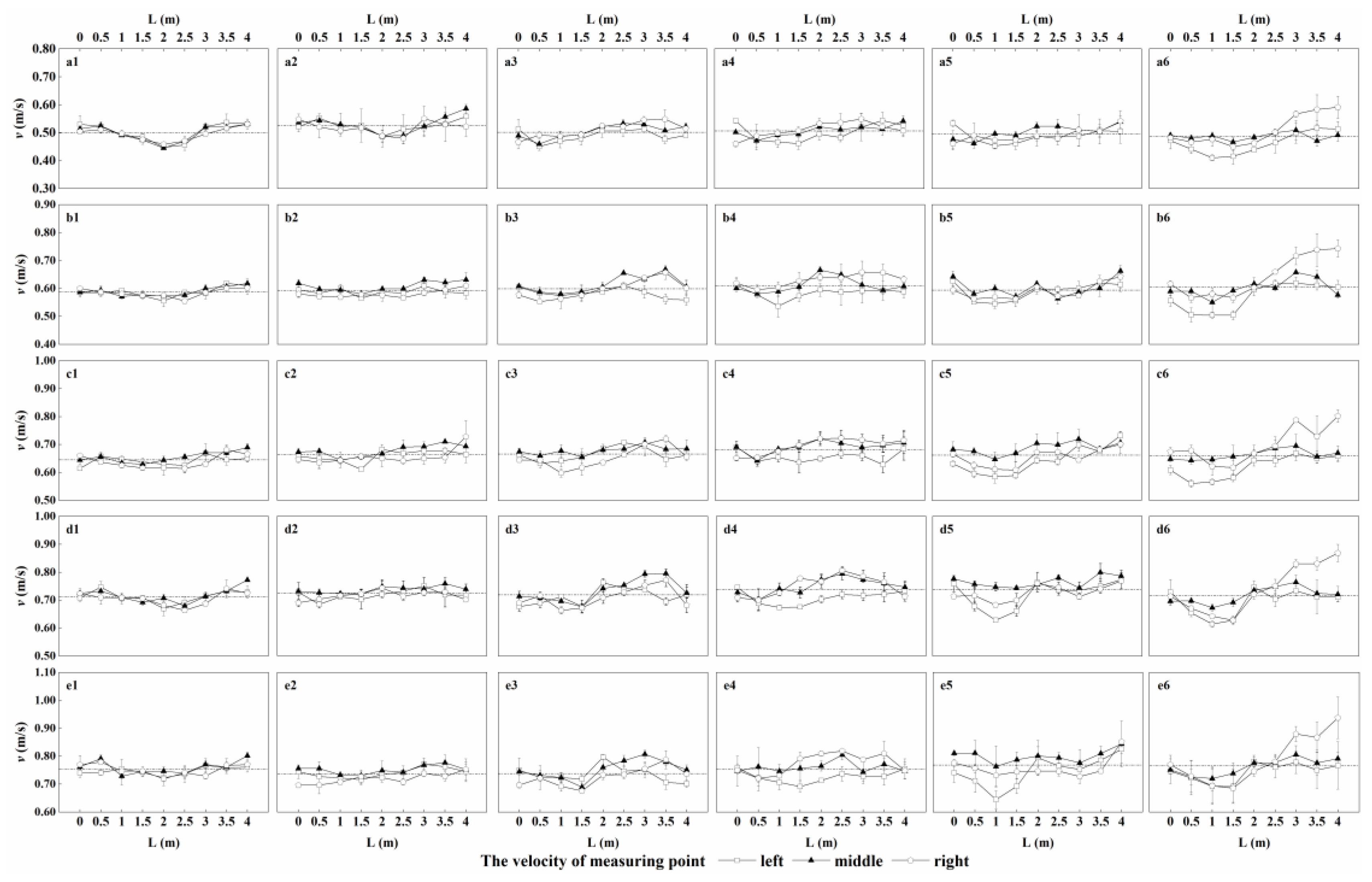

3.1. Flow Velocity Measurement under Different Widths

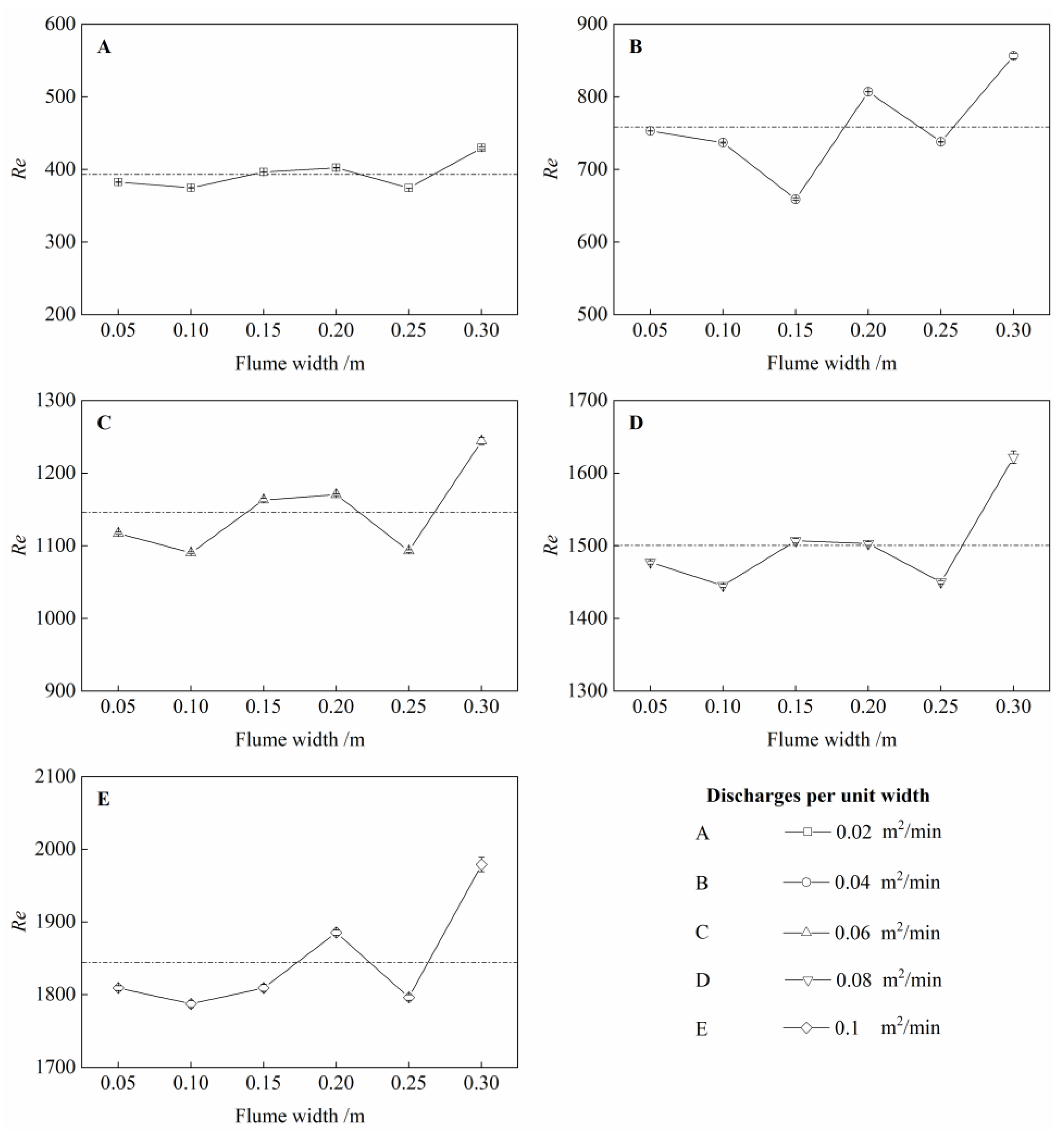

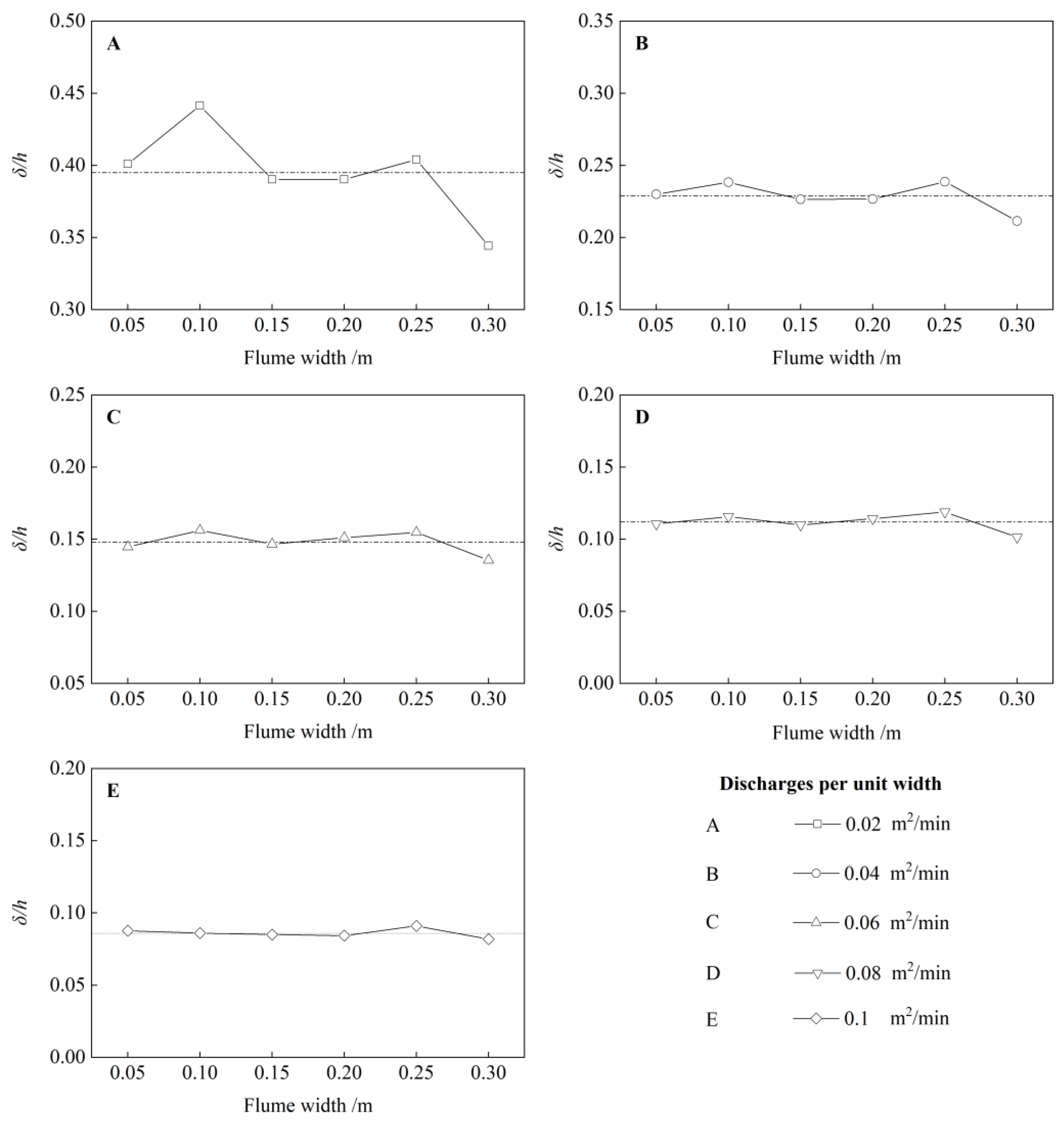

3.2. The Flow Pattern under Different Widths

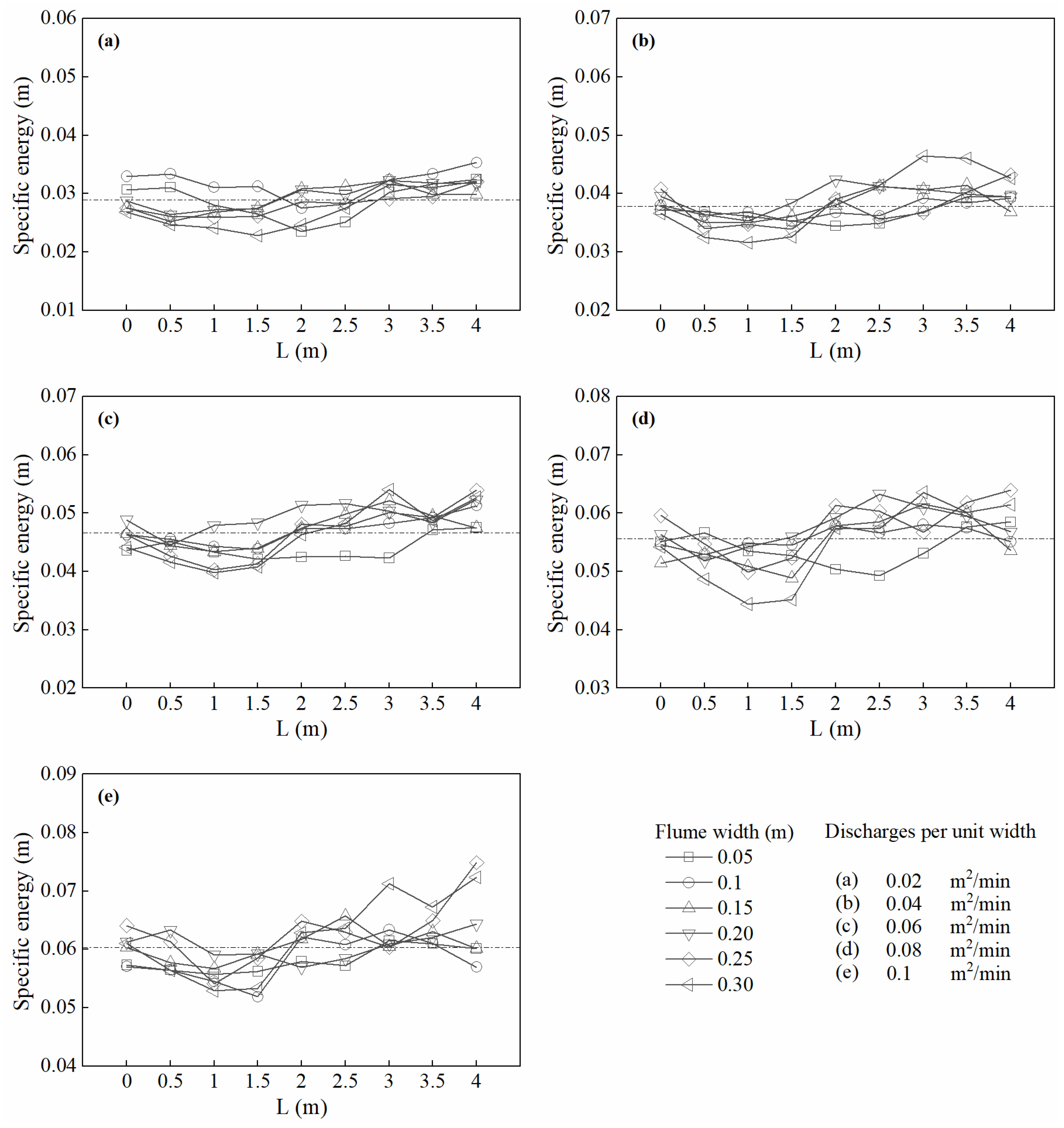

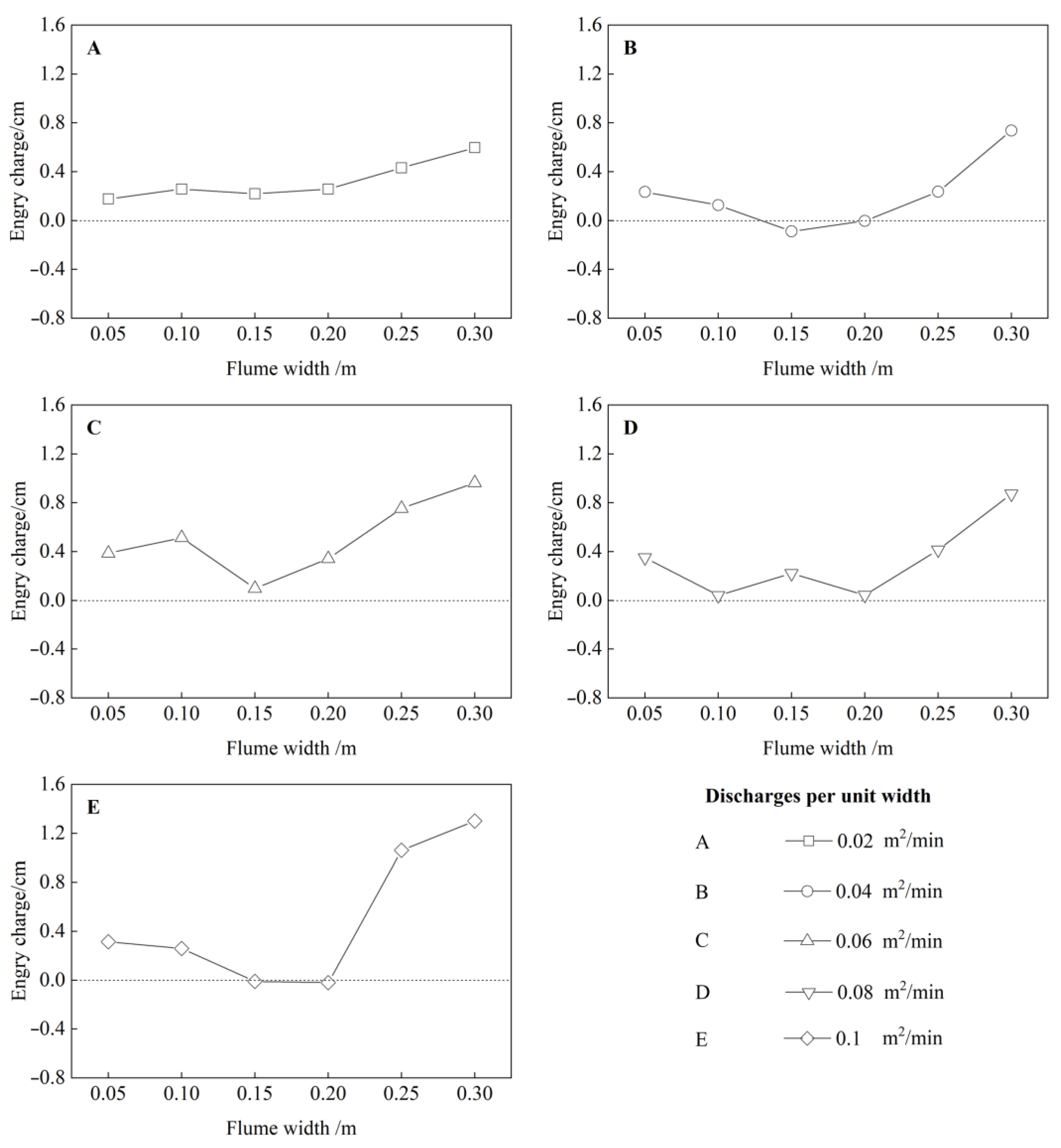

3.3. The Specific Energy under Different Widths

4. Discussion

4.1. Flume Width and Velocity Measurement

4.2. Flume Width and Roll-Wave Development

4.3. The Relationship between Width and ∆Es

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giménez, R.; Govers, G. Flow Detachment by Concentrated Flow on Smooth and Irregular Beds. Soil Sci. Soc. Am. J. 2002, 66, 1475–1483. [Google Scholar] [CrossRef]

- Liu, Y.M.; Zhang, G.H.; Li, L.J.; Han, Y.F. Quantitative effects of hydrodynamic parameters on soil detachment capacity of overland flow. Trans. Chin. Soc. Agric. Eng. 2009, 25, 96–99. [Google Scholar]

- Wang, J.W.; Lv, X.R.; Zhang, K.D.; Li, P.; Meng, H. Unsteady-State Hydraulic Characteristics of Overland Flow. J. Hydrol. Eng. 2019, 24, 04019046. [Google Scholar] [CrossRef]

- Zhan, Z.Z.; Jiang, F.S.; Chen, P.S.; Gao, P.Y.; Lin, J.S.; Ge, H.L.; Wang, M.K.; Huang, Y.H. Effect of gravel content on the sediment transport capacity of overland flow. Catena 2020, 188, 104447. [Google Scholar] [CrossRef]

- Zhang, G.H.; Liu, B.Y.; Liu, G.B.; He, X.W.; Nearing, M.A. Detachment of undisturbed soil by shallow flow. Soil Sci. Soc. Am. J. 2003, 67, 713–719. [Google Scholar] [CrossRef]

- Zhang, G.H.; Luo, R.T.; Cao, Y.; Shen, R.C.; Zhang, X.C. Correction factor to dye-measured flow velocity under varying water and sediment discharges. J. Hydrol. 2010, 389, 205–213. [Google Scholar] [CrossRef]

- Zhao, C.H.; Gao, J.E.; Huang, Y.F.; Wang, G.Q.; Zhang, M.J. Effects of Vegetation Stems on Hydraulics of Overland Flow under Varying Water Discharges. J. Irrig. Drain. Eng. 2016, 27, 748–757. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.P.; Abla, M.; Lu, D.; Yan, R.; Ren, Q.F.; Ren, Z.Y.; Yang, Y.H.; Zhao, W.H.; Lin, P.F.; et al. Effects of vegetation and rainfall types on surface runoff and soil erosion on steep slopes on the Loess Plateau, China. Catena 2018, 170, 141–149. [Google Scholar] [CrossRef]

- Cai, W.L.; Huang, H.; Chen, P.N.; Huang, X.L.; Gaurav, S.; Pan, Z.; Lin, P. Effects of biochar from invasive weed on soil erosion under varying compaction and slope conditions: Comprehensive study using flume experiments. Biomass Convers. Biorefin. 2020. [Google Scholar] [CrossRef]

- Cheng, N.S.; Hui, C.L.; Wang, X.K.; Tan, S.K. Laboratory Study of Porosity Effect on Drag Induced by Circular Vegetative Patch. J. Eng. Mech. 2019, 145, 04019046. [Google Scholar] [CrossRef]

- Wang, J. Shallow Flow Hydraulics on a Hillslope and Evolution of Roll Waves under Artificial Rainfall Conditions. Master’s Thesis, Northwest A&F University, Xianyang, China, 2016. [Google Scholar]

- Abrahams, A.D.; Li, G. Effect of saltating sediment on flow resistance and bed roughness in overland flow. Earth Surf. Process. Landf. 1998, 23, 953–960. [Google Scholar] [CrossRef]

- Abrahams, A.D.; Parsons, A.J.; Wainwright, J. Resistance to overland flow on semiarid grassland and shrubland hillslopes, Walnut Gulch, Southern Arizona. J. Hydrol. 1994, 156, 431–446. [Google Scholar] [CrossRef]

- Xia, W.S.; Lei, T.W.; Zhang, Q.W.; Zhao, J. Electrolyte Pulse Migration Model in Shallow Surface Flow on Slopes. J. Hydraul. Eng. 2003, 11, 90–95. [Google Scholar]

- Emmett, W.W. The Hydraulics of Overland Flow on Hillslopes; US Government Printing Office: Washington, DC, USA, 1970; Volume 662.

- Li, X.; Huang, Y.; Lin, J. Effects of different width of scouring flumes on runoff and sediment yield of colluvial deposits of collapsing hill. Trans. Chin. Soc. Agric. Eng. 2016, 32, 136–141. [Google Scholar]

- Wang, W.; Li, X.Y.; Zhang, J.; Liu, Q.; Lei, T.W. Experimental Study of Runoff Velocity Measurement System Based on Conductivity Sensor. Trans. Chin. Soc. Agric. Eng. 2007, 2, 1–5. [Google Scholar]

- Bai, K.Q.; Zhu, Y.; Tian, Y.; Ye, D.P. Construction and Experimental Study of a Shallow Water Flow Velocity Measurement System Based on Photoelectric Sensing Technology. J. Soil Water Conserv. 2021, 35, 34–40. [Google Scholar] [CrossRef]

- Yang, P.P.; Zhang, H.L.; Wang, Y.Q.; Li, R. Particle Image Velocimetry-based Hydrodynamic Characteristics of Surface Flow on Slopes. Trans. Chin. Soc. Agric. Eng. 2020, 36, 115–124. [Google Scholar]

- Wu, S.F.; Wu, P.T.; Yuan, L.F. Experimental Study on Hydraulic Characteristics of Surface Runoff Control and Shallow Water Flow on Slopes. Trans. Chin. Soc. Agric. Eng. 2010, 26, 14–19. [Google Scholar]

- Zhu, Y.; Luo, Q.; Tian, Y. Development of the depth measurement system for shallow flow on slopes using an edge-detection algorithm. Trans. Chin. Soc. Agric. Eng. 2022, 38, 157–165. [Google Scholar]

- Horton, R.E. Erosional development of streams and their drainage basins; hydrophysical approach to quantitative morphology. Geol. Soc. Am. Bull. 1945, 56, 275–370. [Google Scholar] [CrossRef]

- Shang, J.D.; Jiang, X.J. On the Fundamental Dynamic Characteristics of Shallow Water Flow on Erosive Slopes in Initial Ecological Conditions. J. Soil Water Conserv. 1995, 09, 29–35. [Google Scholar]

- Zhang, K.D.; Wang, G.Q.; Sun, X.M.; Yang, F.; Lv, H.X. Experimental Study on Hydraulic Characteristics of Shallow Surface Flow on Slopes. Trans. Chin. Soc. Agric. Eng. 2014, 30, 182–189. [Google Scholar]

- Grayson, R.B.; Moore, I.D. Effect of land-surface configuration on catchment hydrology. In Overland-Flow: Hydraulics and Erosion Mechanics; CRC Press: Boca Raton, FL, USA, 1992; p. 393407. [Google Scholar] [CrossRef]

- Scoging, H.; Parsons, A.J.; Abrahams, A.D. Application of a dynamic overland-flow hydraulic model to a semi-arid hillslope, Walnut Gulch, Arizona. In Overland Flow: Hydraulics and Erosion Mechanics; CRC Press: Boca Raton, FL, USA, 1992; pp. 105–145. [Google Scholar] [CrossRef]

- Abrahams, A.D.; Parsons, A.J.; Hirsch, P.J. Field and laboratory studies of resistance to interrill overland flow on semi-arid hillslopes, southern Arizona. In Overland Flow: Hydraulics and Erosion Mechanics; CRC Press: Boca Raton, FL, USA, 1992; pp. 1–23. [Google Scholar] [CrossRef]

- Hu, S.X.; Abrahams, A.D. Resistance to overland flow due to bed-load transport on plane mobile beds. Earth Surf. Process. Landf. 2004, 29, 1691–1701. [Google Scholar] [CrossRef]

- Noarayanan, L.; Murali, K.; Sundar, V. Manning’s ‘n’ co-efficient for flexible emergent vegetation in tandem configuration. J. Hydro-Environ. Res. 2012, 6, 51–62. [Google Scholar] [CrossRef]

- Ma, L.; Pan, C.Z.; Liu, J.J. Overland flow resistance and its components for slope surfaces covered with gravel and grass. Int. Soil Water Conserv. Res. 2022, 10, 273–283. [Google Scholar] [CrossRef]

- Darboux, F.; Davy, P.; Gascuel-Odoux, C.; Huang, C. Evolution of soil surface roughness and flowpath connectivity in overland flow experiments. Catena 2002, 46, 125–139. [Google Scholar] [CrossRef]

- Hu, S.X.; Abrahams, A.D. The effect of bed mobility on resistance to overland flow. Earth Surf. Process. Landf. 2005, 30, 1461–1470. [Google Scholar] [CrossRef]

- Bond, S.; Kirkby, M.J.; Johnston, J.; Crowle, A.; Holden, J. Seasonal vegetation and management influence overland flow velocity and roughness in upland grasslands. Hydrol. Process. 2020, 34, 3777–3791. [Google Scholar] [CrossRef]

- Fu, S.; Mu, H.; Liu, B.; Yu, X.; Liu, Y. Effect of plant basal cover on velocity of shallow overland flow. J. Hydrol. 2019, 577, 123947. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Zhang, K.D.; Wu, S.F.; Feng, D.Q.; Shang, H.X.; Wang, J.W. Comparative study on different sediment transport capacity based on dimensionless flow intensity index. J. Soils Sediments 2020, 20, 2289–2305. [Google Scholar] [CrossRef]

- Shen, H.W.; Li, R.-M. Rainfall Effect on Sheet Flow over Smooth Surface. J. Hydraul. Div. 1973, 99, 771–792. [Google Scholar] [CrossRef]

- Wang, J.W.; Zhang, K.D.; Gong, J.G.; Yang, F.; Ma, X. Influence of rainfall and slope gradient on resistance law of overland flow. J. Irrig. Drain. 2016, 35, 43–49. [Google Scholar] [CrossRef]

- Yang, P.; Wang, Y.Q.; Zhang, H.L.; Wang, Y.J. Characteristics of overland flow resistance under interaction of rainfall intensity and unit discharge and surface roughness. Trans. Chin. Soc. Agric. Eng. 2018, 34, 145–151. [Google Scholar]

- Jomaa, S.; Barry, D.A.; Brovelli, A.; Sander, G.C.; Parlange, J.Y.; Heng, B.C.P.; Tromp-van Meerveld, H.J. Effect of raindrop splash and transversal width on soil erosion: Laboratory flume experiments and analysis with the Hairsine–Rose model. J. Hydrol. 2010, 395, 117–132. [Google Scholar] [CrossRef]

- Williams, G.P. Flume Width and Water Depth Effects in Sediment-Transport Experiments; US Government Printing Office: Washington, DC, USA, 1970.

- Ciampalini, R.; Torri, D. Detachment of soil particles by shallow flow: Sampling methodology and observations. Catena 1998, 32, 37–53. [Google Scholar] [CrossRef]

- Ma, R.M.; Cai, C.F.; Wang, J.G.; Wang, T.W.; Li, Z.X.; Xiao, T.Q.; Peng, G.Y. Partial least squares regression for linking aggregate pore characteristics to the detachment of undisturbed soil by simulating concentrated flow in Ultisols (subtropical China). J. Hydrol. 2015, 524, 44–52. [Google Scholar] [CrossRef]

- Nearing, M.A.; Bradford, J.M.; Parker, S.C. Soil Detachment by Shallow Flow at Low Slopes. Soil Sci. Soc. Am. J. 1991, 55, 339–344. [Google Scholar] [CrossRef]

- Poesen, J.; De Luna, E.; Franca, A.; Nachtergaele, J.; Govers, G. Concentrated flow erosion rates as affected by rock fragment cover and initial soil moisture content. Catena 1999, 36, 315–329. [Google Scholar] [CrossRef]

- Sun, B.Y.; Xiao, J.B.; Li, Z.B.; Ma, B.; Zhang, L.T.; Huang, Y.L.; Bai, L.F. An analysis of soil detachment capacity under freeze-thaw conditions using the Taguchi method. Catena 2018, 162, 100–107. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Z.; Shen, N.; Chen, H. Modeling soil detachment capacity by rill flow using hydraulic parameters. J. Hydrol. 2016, 535, 473–479. [Google Scholar] [CrossRef]

- Zhang, K.L.; Liu, B.Y.; Cai, Y.M. The standard of unit plot in soil loss prediction of China. Geogr. Res. 2000, 19, 297–302. [Google Scholar]

- Abrahams, A.D.; Parsons, A.J.; Luk, S.-H. Field measurement of the velocity of overland flow using dye tracing. Earth Surf. Process. Landf. 1986, 11, 653–657. [Google Scholar] [CrossRef]

- Wang, J.W.; Zhang, K.D.; Li, P.; Meng, Y.; Zhao, L.Y. Hydrodynamic characteristics and evolution law of roll waves in overland flow. Catena 2021, 198, 105068. [Google Scholar] [CrossRef]

- Jing, X.F. Study on Hydraulic Properties of Shallow Flow on Slope Surface. Master’s Thesis, Northwest A&F University, Xianyang, China, 2007. [Google Scholar]

- Shi, M.X. Influence of Surface Roughness on Hydraulic Characteristics of Overland Flow. Master’s Thesis, Northwest A&F University, Xianyang, China, 2015. [Google Scholar]

- Jiang, F.S.; He, K.W.; Huang, M.Y.; Zhang, L.T.; Lin, G.G.; Zhan, Z.Z.; Li, H.; Lin, J.S.; Ge, H.L.; Huang, Y.H. Impacts of near soil surface factors on soil detachment process in benggang alluvial fans. J. Hydrol. 2020, 590, 125274. [Google Scholar] [CrossRef]

- Hu, Q.; Chen, J. Analytical Chemistry, 2nd ed.; Huazhong University of Science and Technology Press Co., Ltd.: Wuhan, China, 2020; p. 242. [Google Scholar]

- Reynolds, O. XXIX. An Experimental Investigation of the Circumstances Which Determine Whether the Motion of Water Shall be Direct or Sinuous, and of the Law of Resistance in Parallel Channels; The Royal Society London: London, UK, 1997; pp. 935–982. [Google Scholar]

- Zhang, K.D.; Wang, G.Q.; Sun, X.M.; Wang, J.J. Hydraulic characteristic of overland flow under different vegetation coverage. Adv. Water Sci. 2014, 25, 825–834. [Google Scholar] [CrossRef]

- Zhang, K.D.; Wang, G.Q.; Lv, H.X.; Wang, Z.L. Discussion on flow pattern determination method of shallow flow on the slope surface. J. Exp. Fluid Mech. 2011, 25, 67–73. [Google Scholar]

- Bakhmeteff, B. O Neravnomernom Dwijenii Jidkosti v Otkrytom Rusle; KUBUCH: Saint Petersburg, Russia, 1912. [Google Scholar]

- Liu, J.E.; Wang, Z.L.; Gao, S.J.; Zhang, K.D. Experimental study on hydro-dynamic mechanism of sheet erosion processes on loess hillslope. Trans. Chin. Soc. Agric. Eng. 2012, 28, 144–149. [Google Scholar]

- Zhang, Q.; Zheng, S.Q.; Tian, F.X.; Ma, Y.C. Runoff and sediment yield characteristics of earth road under artificial rainfalland simulated overland flow tests conditions in Loess Plateau. Trans. Chin. Soc. Agric. Eng. 2010, 26, 83–87. [Google Scholar]

- Zhang, L.T.; Gao, Z.L.; Tian, H.W. Hydrodynamic process of soil erosion in steep slope of engineering accumulation. Trans. Chin. Soc. Agric. Eng. 2013, 29, 94–102. [Google Scholar]

- Belanger, J.B. Essai sur la Solution Numerique de Quelques Problemes Relatifs au Mouvement Permanent des Eaux Courantes; Chez Carilian-Goeury, Libraire: Paris, France, 1828. [Google Scholar]

- Zhang, K.D. Research on Hydrodynamic Characteristics of Slope Surface Flow and Sediment Transport Mechanisms; Northwest A&F University: Xianyang, China, 2011. [Google Scholar]

- Mujtaba, B.; de Lima, J.L.M.P. Laboratory testing of a new thermal tracer for infrared-based PTV technique for shallow overland flows. Catena 2018, 169, 69–79. [Google Scholar] [CrossRef]

- Wang, X.K.; Yan, X.F.; Zhou, S.F.; Huang, E.; Liu, X.N. Longitudinal variations of hydraulic characteristics of overland flow with different roughness. J. Hydrodyn. 2014, 26, 66–74. [Google Scholar] [CrossRef]

- Yang, D.M.; Gao, P.L.; Zhao, Y.D.; Zhang, Y.H.; Liu, X.Y.; Zhang, Q.W. Modeling sediment concentration of rill flow. J. Hydrol. 2018, 561, 286–294. [Google Scholar] [CrossRef]

- Yan, J.; Wang, E.P.; Sun, D.P.; Dong, Z.H. Experimental Study on Velocity Distribution Characteristics in Rectangular Cross-Section Open Channel. J. Wuhan Univ. (Eng. Ed.) 2005, 38, 59–64. [Google Scholar]

- Han, J.X.; Huang, F.G.; Xia, P.L.; Wu, Y.L.; Chen, W.W. Parabolic Law for Lateral Distribution of Flow Velocity in Open Channels and Its Applications. People’s Yellow River 2013, 35, 83–85. [Google Scholar]

- Wang, E.P.; Jin, H.; Wang, W.J.; Zhang, Y.Y.; Cao, B. Rectangular Open Channel Velocity Distribution Law and Automated Flow Measurement Methods. People’s Yellow River 2008, 30, 31–32. [Google Scholar]

- Li, X.Z. The Influence of Scour Trenches with Different Widths on the Erosion of Colluvial Deposits in Debris Flow Gullies. Master’s Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2016. [Google Scholar]

- Zhang, G.H. Study on hydraulic properties of shallow flow. Adv. Water Sci. 2002, 13, 159–165. [Google Scholar]

- Meng, H.; Zhang, K.D.; Wang, J.W. Influence factors of hydraulic parameters of roll waves in overland flow. Adv. Water Sci. 2020, 31, 102–111. [Google Scholar] [CrossRef]

- Anderson, J.D.; Wendt, J. Computational Fluid Dynamics; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Chien, N.; Wan, Z. Mechanics of Sediment Transport; American Society of Civil Engineers: New York, NY, USA, 1999; p. 1999. [Google Scholar]

- Bakhmeteff, B.A.; Allan, W. The mechanism of energy loss in fluid friction. Trans. Am. Soc. Civ. Eng. 1946, 111, 1043–1080. [Google Scholar] [CrossRef]

- Ghosh, N.S.; Roy, N. Boundary shear distribution in open channel flow. J. Hydraul. Div. 1970, 96, 967–994. [Google Scholar] [CrossRef]

- Knight, D.W.; Hamed, M.E. Boundary Shear in Symmetrical Compound Channels. J. Hydraul. Eng. 1984, 110, 1412–1430. [Google Scholar] [CrossRef]

- Einstein, H.A. Formulas for the Transportation of Bed Load. Trans. Am. Soc. Civ. Eng. 1942, 107, 561–577. [Google Scholar] [CrossRef]

- Knight, D.W.; Macdonald, J.A. Open Channel Flow with Varying Bed Roughness. J. Hydraul. Div. 1979, 105, 1167–1183. [Google Scholar] [CrossRef]

- Shen, H.B.; Zhang, X.F.; Qiao, W. Partition curve of hydraulic radius and average sidewall and bed shear stresses in open-channel flows. J. Hydrol. Eng. 2011, 30, 44–48. [Google Scholar]

- Xu, G.; Yang, C.T.; Zhao, L. Minimum Energy Dissipation Rate Theory and Its Applications for Water Resources Engineering. Adv. Water Resour. Eng. 2015, 14, 183–245. [Google Scholar] [CrossRef]

| References | Material | Flume Length (m) | Flume Width (m) |

|---|---|---|---|

| Nearing et al., 1991 [43] | / | 9.00 | 1.00 |

| Ciampalini and Torri, 1998 [41] | Plexiglass | 1.50 | 0.20 |

| Poesen et al., 1999 [44] | Plexiglass | 2.00 | 0.098 |

| Govers, 2002 [1] | Mixed | 4.30 | 0.40 |

| Zhang et al., 2003 [5] | / | 4.00 | 0.35 |

| Ma et al., 2015 [42] | Zincified sheet iron plate | 3.80 | 0.20 |

| Wang et al., 2016 [46] | / | 4.00 | 0.10 |

| Sun et al., 2018 [45] | Plexiglass | 1.00 | 0.04 |

| Zhan et al., 2020 [4] | Zincified sheet iron plate | 4.00 | 0.12 |

| Slope (°) | Flume Width (m) | Discharge per Unit Width (×10−4 m2 s−1) | Water Temperature (°C) | Dynamic Viscosity (×10−4 N·s/m2) |

|---|---|---|---|---|

| 15 | 0.05–0.30 | 0.33, 0.67, 1.00, 1.33, 1.67 | 25.1–32.5 | 7.62–8.8 |

| Discharge per Unit Width (×10−4 m2 s−1) | Flume Width (m) | |||||

|---|---|---|---|---|---|---|

| 0.05 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | |

| 0.33 | 0.449 | 0.427 | 0.446 | 0.442 | 0.453 | 0.463 |

| 0.67 | 0.795 | 0.788 | 0.781 | 0.768 | 0.787 | 0.779 |

| 1.00 | 1.091 | 1.054 | 1.053 | 1.029 | 1.062 | 1.067 |

| 1.33 | 1.312 | 1.291 | 1.302 | 1.271 | 1.269 | 1.311 |

| 1.67 | 1.550 | 1.583 | 1.584 | 1.550 | 1.524 | 1.534 |

| Flume Width (m) | Discharges per Unit Width (m2/min) | Flow Velocity at Measuring Points | ||

|---|---|---|---|---|

| L | M | R | ||

| 0.05 | 0.02 | |||

| 0.04 | ||||

| 0.06 | ||||

| 0.08 | ||||

| 0.1 | ||||

| 0.1 | 0.02 | |||

| 0.04 | ||||

| 0.06 | ||||

| 0.08 | ||||

| 0.1 | a | ab | b | |

| 0.15 | 0.02 | |||

| 0.04 | a | ab | b | |

| 0.06 | ||||

| 0.08 | ||||

| 0.1 | ||||

| 0.2 | 0.02 | |||

| 0.04 | a | a | b | |

| 0.06 | a | a | b | |

| 0.08 | a | a | b | |

| 0.1 | a | a | b | |

| 0.25 | 0.02 | |||

| 0.04 | ||||

| 0.06 | a | b | b | |

| 0.08 | a | b | b | |

| 0.1 | a | b | b | |

| 0.3 | 0.02 | a | ab | b |

| 0.04 | a | b | c | |

| 0.06 | a | b | c | |

| 0.08 | a | ab | c | |

| 0.1 | a | ab | b | |

| Flume Width (m) | Discharge per Unit Width (m2·min−1) | ||||

|---|---|---|---|---|---|

| 0.02 | 0.04 | 0.06 | 0.08 | 0.1 | |

| 0.10 | 374.89 | 736.96 | 1090.56 | 1445.29 | 1787.14 |

| 0.20 | 402.42 | 807.19 | 1170.60 | 1503.17 | 1885.47 |

| 0.30 | 429.53 | 856.39 | 1244.62 | 1621.95 | 1979.24 |

| Standard Deviation | 22.31 | 49.01 | 62.91 | 73.53 | 78.43 |

| Discharge per Unit Width (m2/min) | Flume Width (m) | |||||

|---|---|---|---|---|---|---|

| 0.05 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | |

| 0.02 | 111.4 | 234.2 | 336.3 | 452.5 | 551.9 | 647.9 |

| 0.04 | 62.9 | 126.9 | 192.1 | 260.4 | 317.7 | 385.1 |

| 0.06 | 45.8 | 94.9 | 142.5 | 194.4 | 235.4 | 281.2 |

| 0.08 | 38.1 | 77.5 | 115.2 | 157.4 | 197.0 | 228.8 |

| 0.1 | 32.3 | 63.2 | 94.7 | 129.0 | 164.0 | 195.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Xu, Y.; Yang, M.; Jiang, F.; Zhang, Y.; Huang, Y.; Lin, J. Effect of Flume Width on the Hydraulic Properties of Overland Flow from Laboratory Observation. Water 2023, 15, 3416. https://doi.org/10.3390/w15193416

Tian Y, Xu Y, Yang M, Jiang F, Zhang Y, Huang Y, Lin J. Effect of Flume Width on the Hydraulic Properties of Overland Flow from Laboratory Observation. Water. 2023; 15(19):3416. https://doi.org/10.3390/w15193416

Chicago/Turabian StyleTian, Ye, Yue Xu, Maojin Yang, Fangshi Jiang, Yue Zhang, Yanhe Huang, and Jinshi Lin. 2023. "Effect of Flume Width on the Hydraulic Properties of Overland Flow from Laboratory Observation" Water 15, no. 19: 3416. https://doi.org/10.3390/w15193416

APA StyleTian, Y., Xu, Y., Yang, M., Jiang, F., Zhang, Y., Huang, Y., & Lin, J. (2023). Effect of Flume Width on the Hydraulic Properties of Overland Flow from Laboratory Observation. Water, 15(19), 3416. https://doi.org/10.3390/w15193416