Simulation Study on Seepage Patterns of Geothermal Reinjection in Carbonate Thermal Reservoir and Geothermal Doublet Well Patterns in Xiong’an New Area

Abstract

:1. Introduction

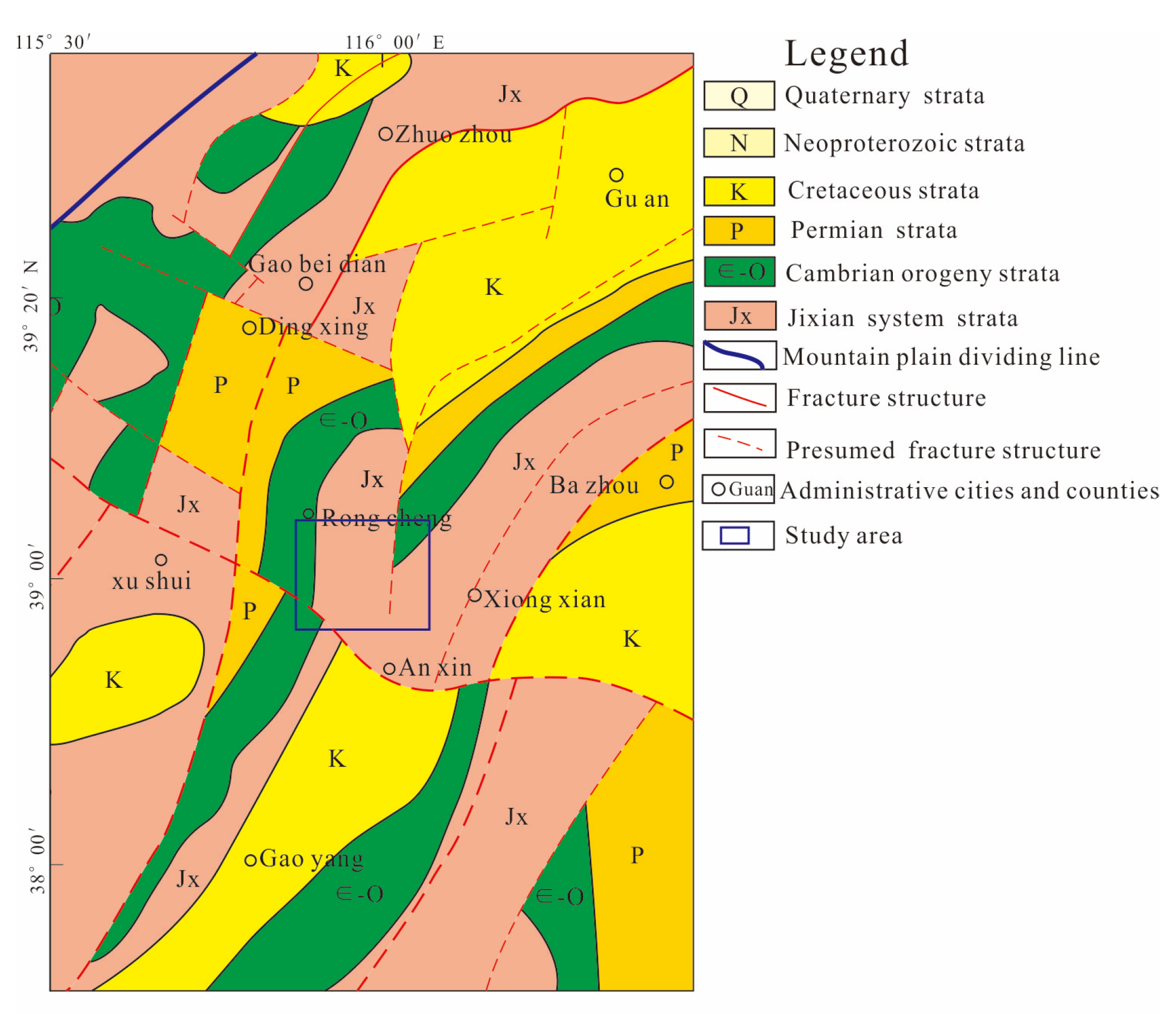

2. Geological Settings

3. Experimental Method

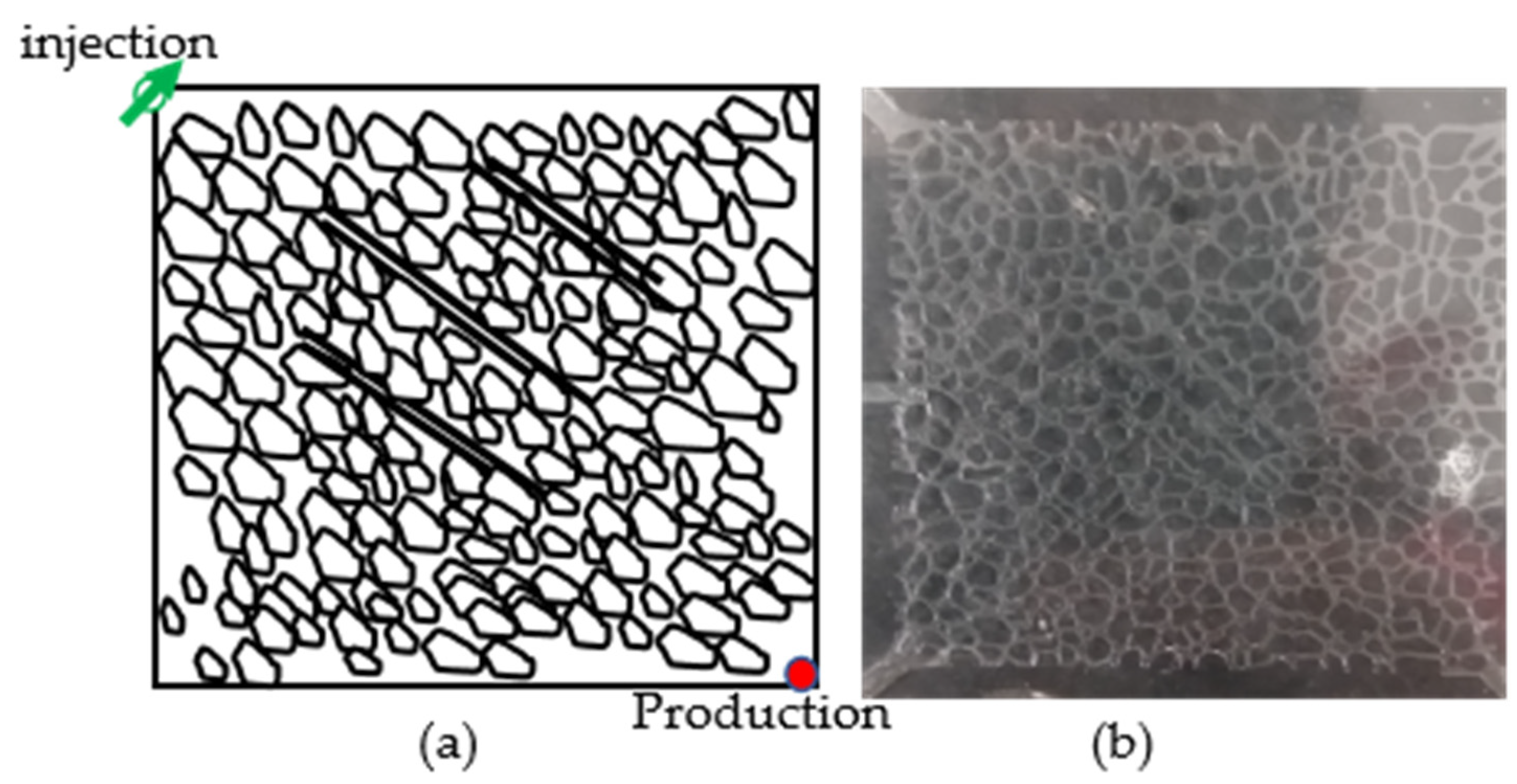

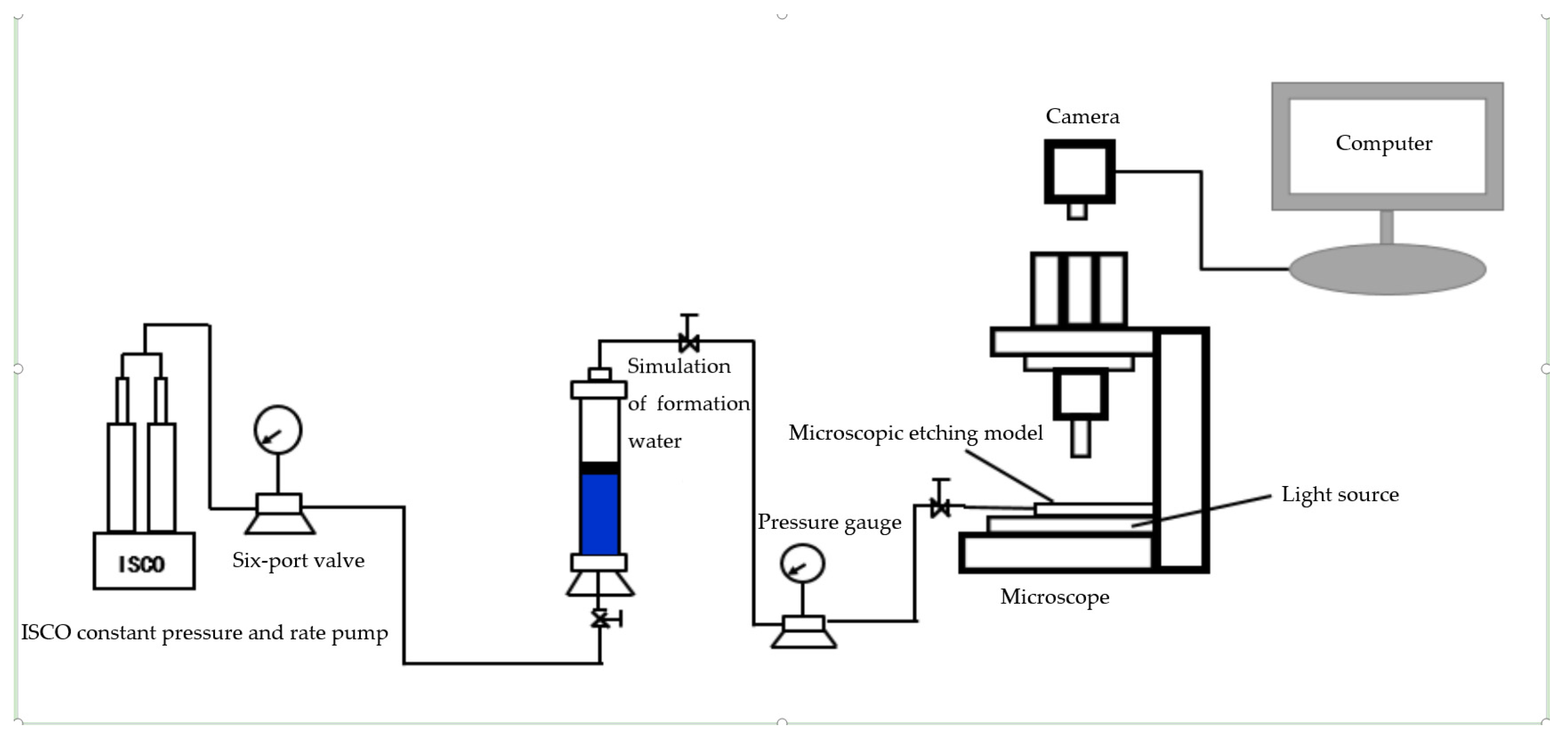

3.1. Visual Seepage Experiment Based on Microscopic Etching Model

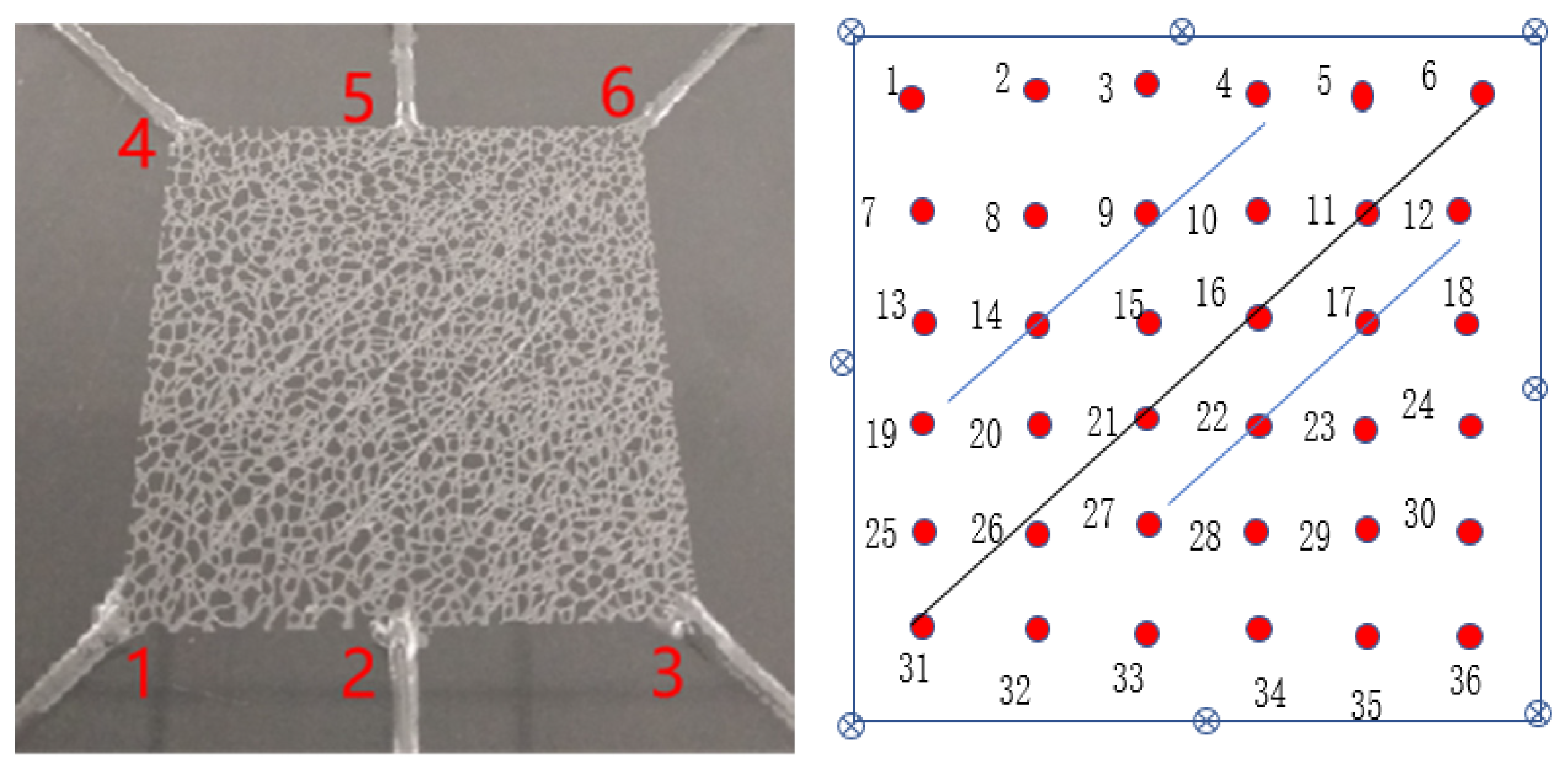

3.2. Seepage Experiment on Physical Cemented Plate Model of Carbonate Fissures

3.3. Numerical Modeling

- A.

- Pressure-field finite element

- B.

- Temperature field finite element

4. Result

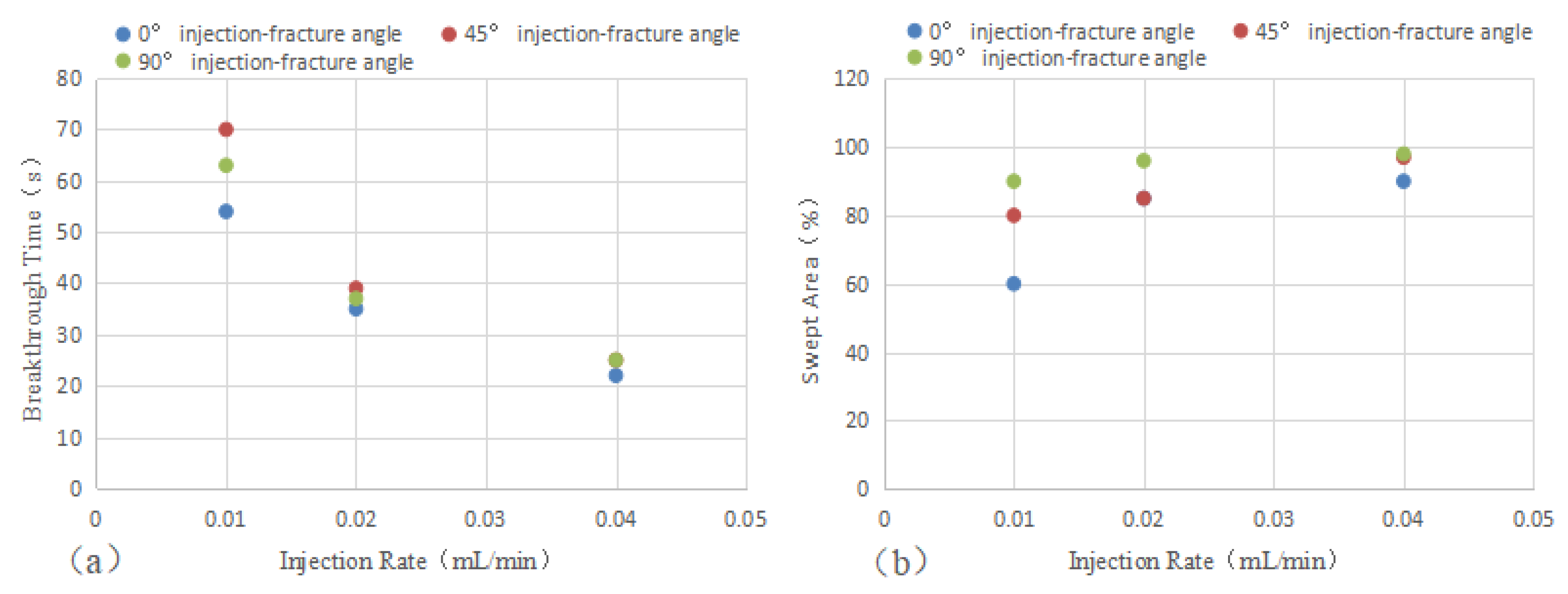

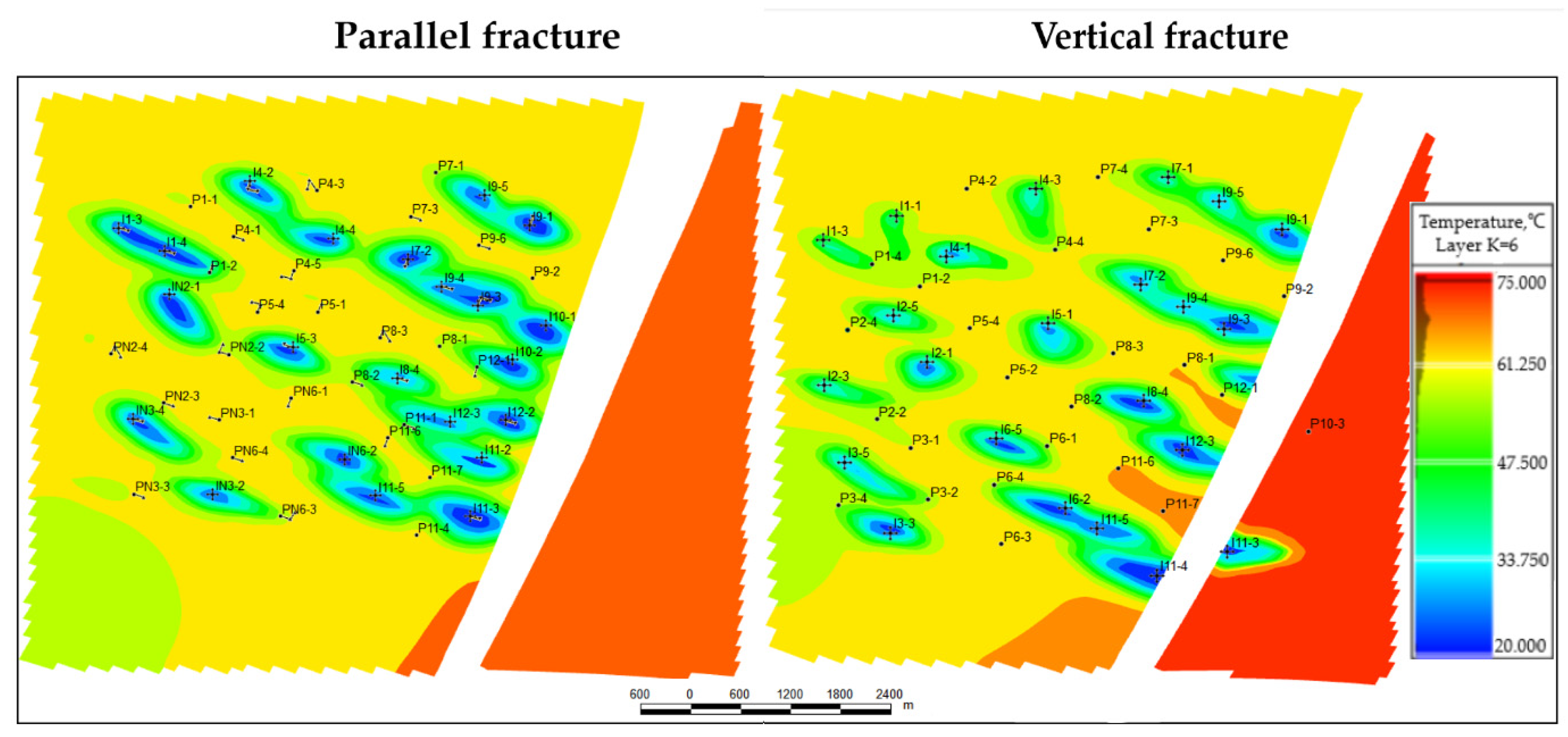

4.1. Macroscopic Spatterns and Distribution Characteristics of Temperature Fields of Injected Water with Different Fracture Azimuths

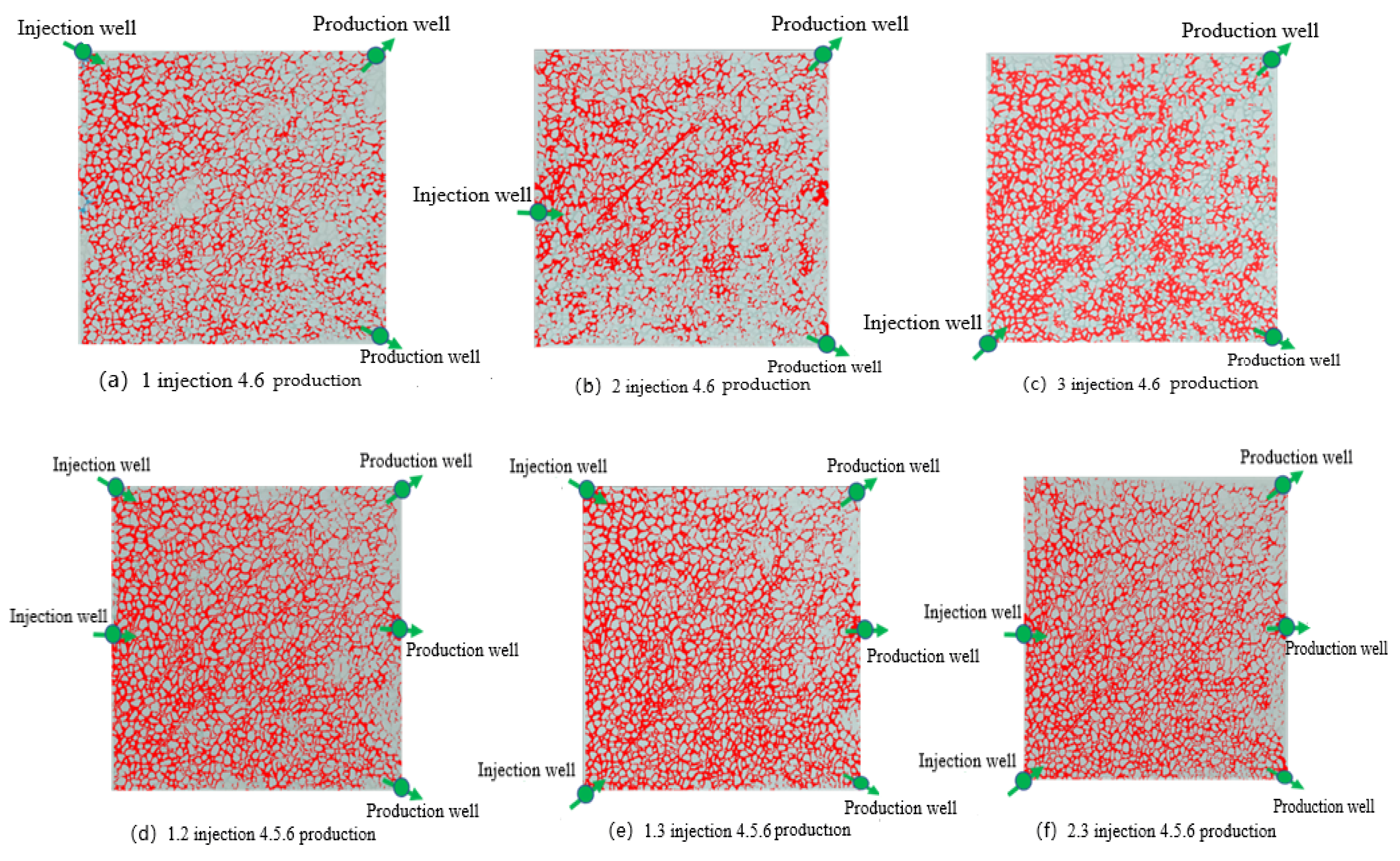

4.2. Study on Seepage Patterns with Different Well Arrangements

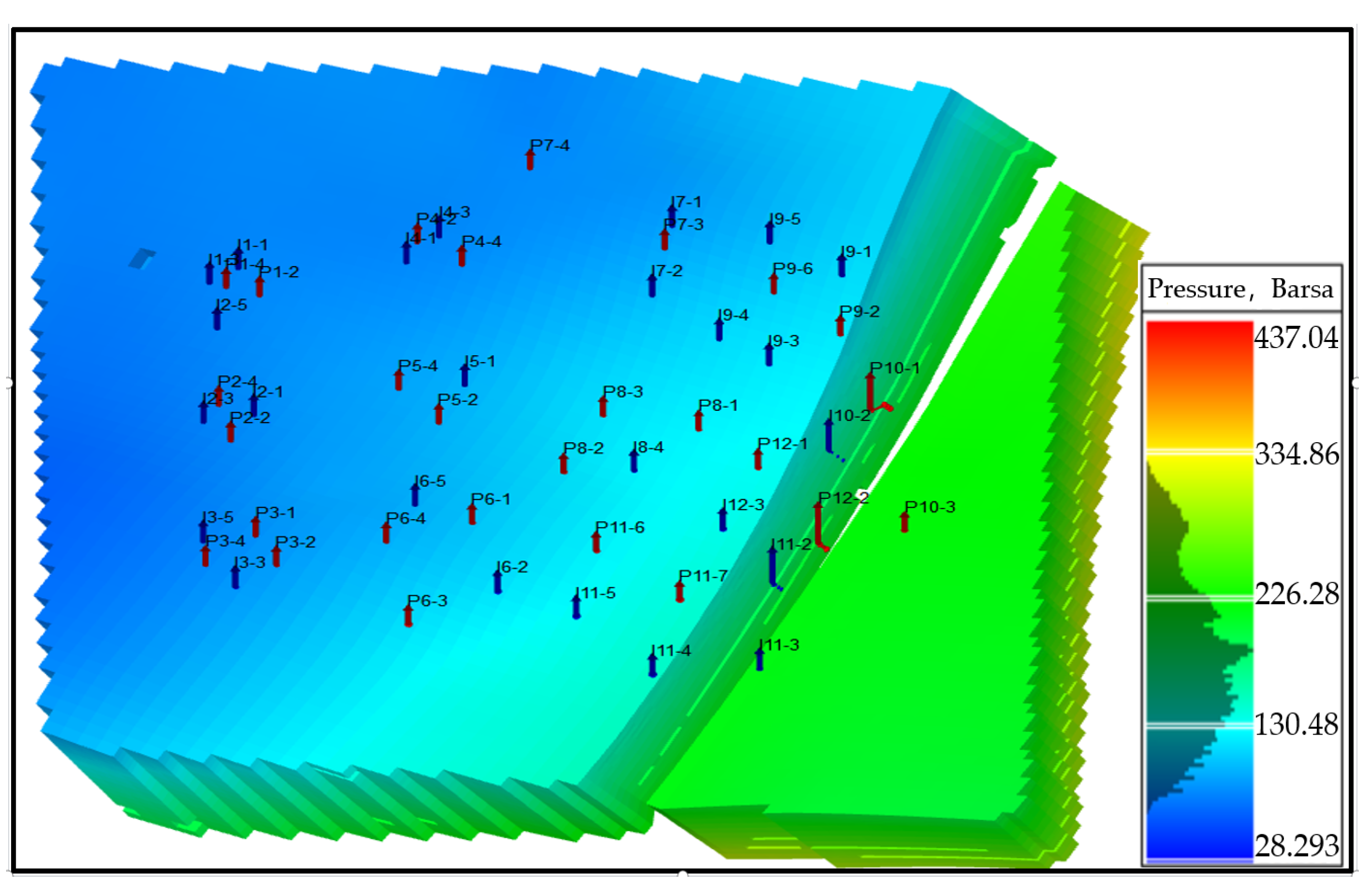

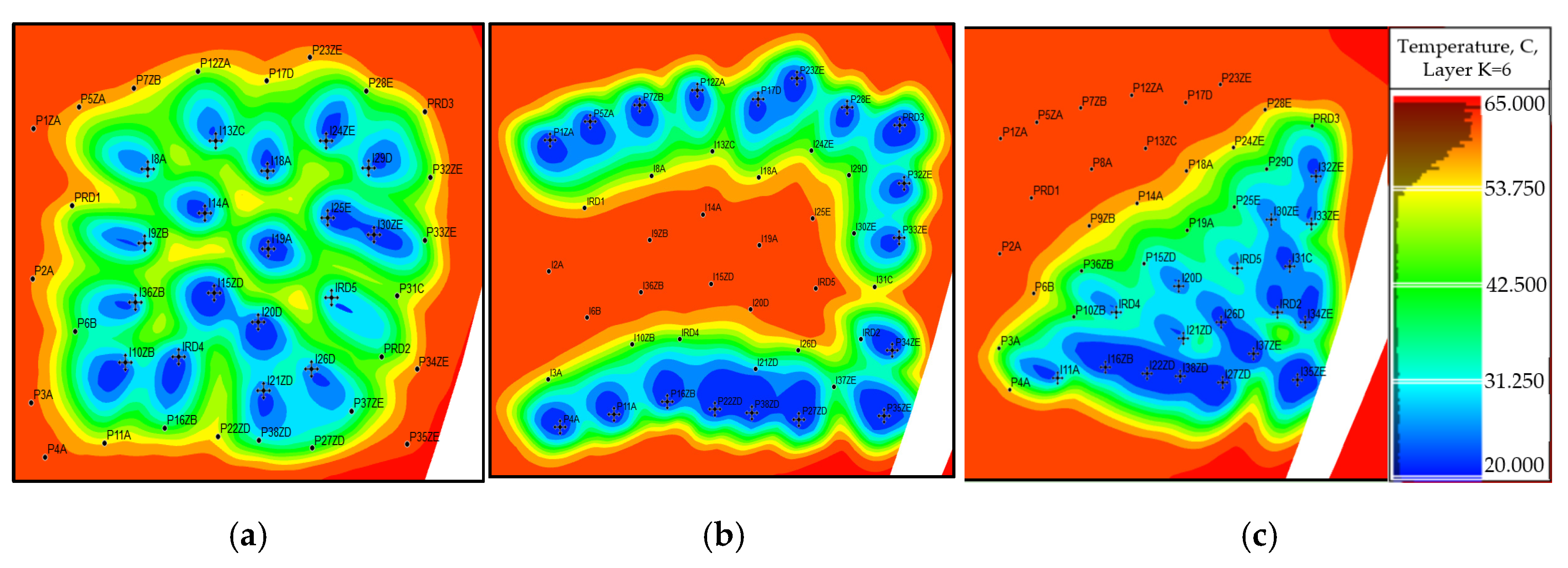

4.3. Modeling of Geothermal Doublet Well Patterns in Xiong’an New Area

4.3.1. Demonstration of Relationship between Well Patterns and Fissures

4.3.2. Demonstration of Spacing of Geothermal Doublet Wells

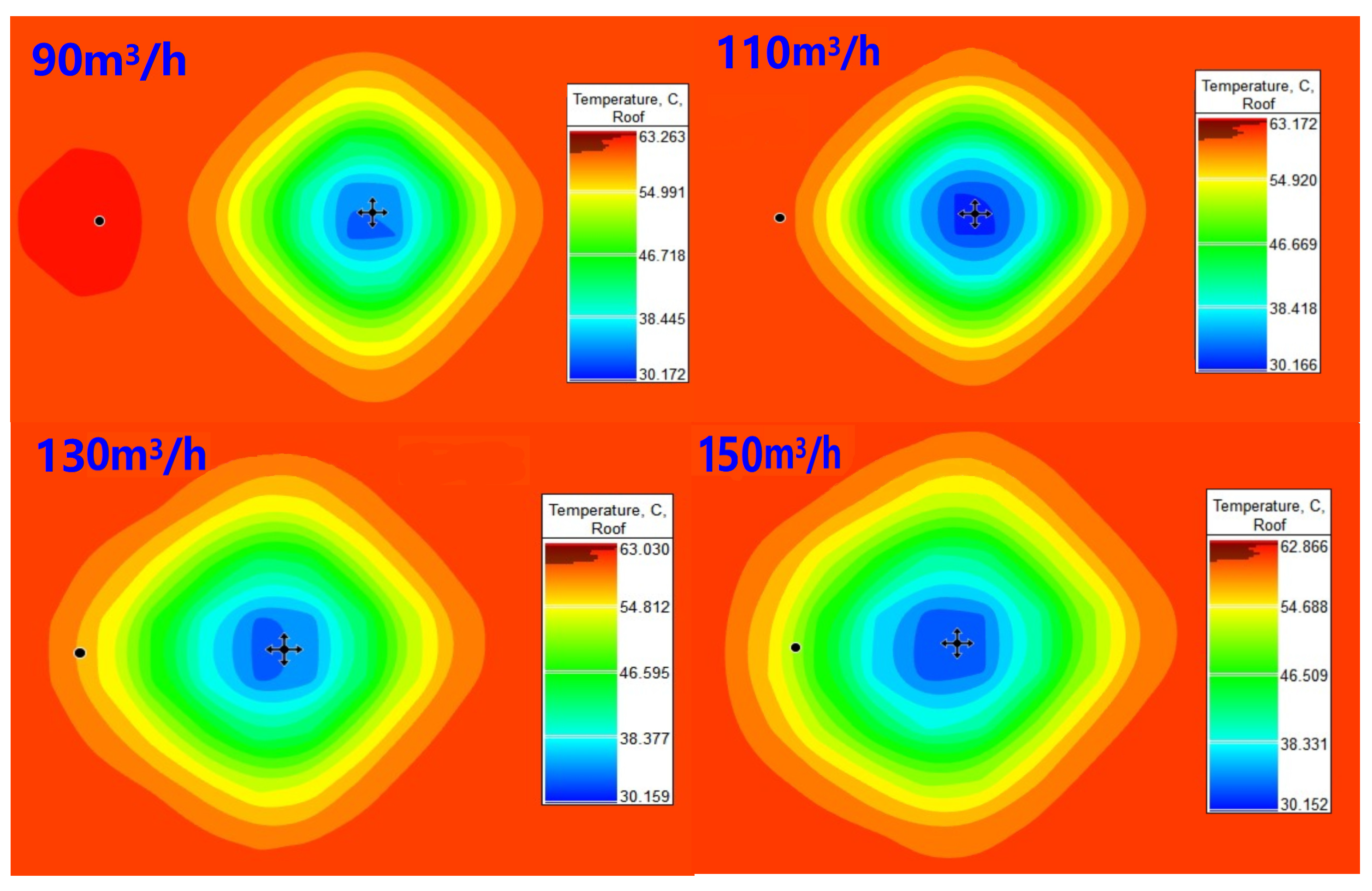

4.3.3. Demonstration of Injection and Production Volumes

4.3.4. Feasibility Demonstration of Well Interchangeability

4.3.5. Demonstration of Centralized Geothermal Doublet Well Patterns

5. Discussion

6. Conclusions

- (1)

- The injection rate and angle of the injected water influenced its seepage pattern in the fracture. The injection rate was negatively correlated to the breakthrough time and positively correlated to the swept area to a great extent. Such correlations were enhanced with a controlled injection angle. The breakthrough time dramatically decreased with the increase in the injection rate, indicating that thermal breakthroughs were more likely to occur with a high reinjection rate. Moreover, as the injection-fracture dip increased, the swept area of the injected water grew larger. The swept area was the largest and most favorable with a 90° dip.

- (2)

- Well arrangement methods influenced the seepage pattern of the injected water. Considering the well interference, swept area, and maximum on-site economic benefits, the well pattern of two injectors and three producers was relatively suitable for geothermal reinjection, and the maximum injection-fracture angle of “1 and 2 for injection and 4, 5 and 6 for production” was more suitable with the largest swept area.

- (3)

- The well pattern, well spacing, injection and production volumes, and temperature of the injected water affected the sustainable development and utilization of the geothermal fields. Based on the model demonstration, it is suggested that the resettlement area of Xiong’an New Area arrange its geothermal doublet wells with a spacing of over 500 m, with injection and production volumes lower than 110 m3/h for its geothermal development. Moreover, a vertical fracture well is recommended to reduce geothermal breakthroughs. Injection and production wells should not be interchanged during the development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Wang, G.L.; Liu, F.; Xing, L.X.; Li, M. Characteristics of geothermal resources in sedimentary basins. Geol. China 2019, 46, 255–268. (In Chinese) [Google Scholar]

- Wang, G.L.; Lin, W.J. Main hydro-geothermal systems and their genetic models in China. Acta Geol. Sin. 2020, 94, 1923–1937. (In Chinese) [Google Scholar]

- Zhang, D.Z.; Liu, Z.G.; Lu, H.L. Hebei Geothermal; Geology Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Wang, G.L.; Gao, J.; Zhang, B.J.; Xing, Y.F.; Zhang, W.; Ma, F. Study on the thermal storage characteristics of the Wumishan Formation and huge capacity geothermal well parameters in the Gaoyang low uplift area of Xiong’an New Area. Acta Geol. Sin. 2020, 94, 1970–1980. (In Chinese) [Google Scholar]

- Ma, F.; Wang, G.G.L.; Zhang, W.; Zhu, X.; Zhang, H.X.; Yue, G.F. Structure of geothermal reservoirs and resource potential in the Rongcheng geothermal field in Xiong’an New Area. Acta Geol. Sin. 2020, 94, 1981–1990. (In Chinese) [Google Scholar]

- Kennedy, B.M.; Pruess, K.; Lippmann, M.J.; Ernest, L.M.; Rose, P.E.; Adams, M.; Roberston, T.A.; Moller, N.; Weare, J.; Clutter, T.; et al. A History of Geothermal Energy Research and Development in the United States on 1976–2006; Office of Energy Efficiency and Renewable Energy (EERE): Washington, DC, USA, 2010.

- Cappetti, G.; Parisi, L.; Ridolfi, A.; Stefani, G. Fifteen years of reinjection in the Larderello-Valle Secolo area: Analysis of the production data. In Proceedings of the World Geothermal Congress, Florence, Italy, 18–31 May 1995. [Google Scholar]

- Ungemach, P.; Antics, M. Sustainable geothermal reservoir management practice. In Proceedings of the Geothermal Resources Council Annual Meeting 2009, Reno, NV, USA, 4–7 October 2009. [Google Scholar]

- Diazr, A.R.; Kaya, E.; Zarrouk, S.J. Reinjection in geothermal fields−a worldwide review update. Renew. Sustain. Energy Rev. 2016, 53, 105–162. [Google Scholar]

- Zarrouk, S.; Kaya, E.; O’Sullivan, M.J. A review of worldwide experience of reinjection in geothermal fields. In Proceedings of the 28th NZ Geothermal Workshop, Auckland, New Zealand, 15–17 November 2006. [Google Scholar]

- Matthiasdottir, K.V.; Albertsson, A.; Sigurð-Sson, O. Tracer tests at reykjanes geothermal field, Iceland. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 16–24 April 2015. [Google Scholar]

- Cheng, W.Q.; Liu, J.L.; Chen, H.B. Simulation research on reinjection temperature field of geothermal doublet well. Glob. Geol. 2011, 30, 486–492. (In Chinese) [Google Scholar]

- Feng, S.T.; Wang, C.M.; Yang, Y.B.; Song, W.H.; Liu, S.; Zhao, J.C. Impact assessment of reinjection on sandstone geothermal reservoir:a case study of Northwest Shandong depression. Acta Geol. Sin. 2019, 93, 158–167. (In Chinese) [Google Scholar]

- Ruan, C.X. A Study of Reinjection of Geothermal Resources in the Geothermal Reservoir of the Wumishan Group in Tianjin; China University of Geosciences: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Nam, Y.; Ooka, R. Numerical simulation of ground heat and water transfer for groundwater heat pump system based on real-scale experiment. Energy Build. 2010, 42, 69–75. [Google Scholar] [CrossRef]

- Freedman, V.L.; Waichler, S.R.; Mackley, R.D.; Horner, J.A. Assessing the thermal environmental impacts of angroundwater heat pump in southeastern WashingtonState. Geothermics 2012, 42, 65–77. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Asadulagi, M.-A.M. Development of a Distributed Control System for the Hydrodynamic Processes of Aquifers, Taking into Account Stochastic Disturbing Factors. Water 2023, 15, 770. [Google Scholar] [CrossRef]

- Anastasiya, A.M.; Irina, V.M.; Dmitrii, A.K.; Igor, N.K. The Modeling of Mineral Water Fields Data Structure. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Moscow, Russia, 26–29 January 2021. [Google Scholar]

- Mahmoodpour, S.; Singh, M.; Bär, K.; Sass, I. Thermo-hydro-mechanical modeling of an enhanced geothermal system in a fractured reservoir using carbon dioxide as heat transmission fluid- A sensitivity investigation. Energy 2022, 254, 124266. [Google Scholar] [CrossRef]

- Wei, K.; Nie, F.J.; Guo, Y.; Li, Y.F.; Wang, X.Y. Study on the effect of interwell fracture on geothermal recharge. Renew. Energy Resour. 2020, 38, 24–28. (In Chinese) [Google Scholar]

- Qu, Z.Q.; Zhang, W.; Guo, T.k.; Sun, J.; Gong, F.C.; Tian, Y.; Li, X.L. Numerical simulation of heat mining performance of hotdry rocks with fracture network based on a local thermal non-equilibrium model. J. China Univ. Pet. (Ed. Nat. Sci.) 2019, 43, 90–98. (In Chinese) [Google Scholar]

- Du, L.; Tang, G.; Zhan, H.Y. Seepage and heat transfer characteristics of acid corroded fractures in carbonate rock. Sci. Technol. Eng. 2021, 21, 14333–14344. (In Chinese) [Google Scholar]

- Fan, D.Y.; Sun, H.; Yao, J.; Li, H.F.; Yan, X.; Zhang, K.; Zhang, L. Parametric Analysis of Different Injection and Production Well Pattern in Enhanced Geothermal System. J. Jilin Univ. (Earth Sci. Ed.) 2019, 49, 797–806. (In Chinese) [Google Scholar]

- Wang, G.L.; Lin, W.J.; Liu, F.; Gan, H.N.; Wang, S.Q.; Yue, G.F.; Long, X.T.; Liu, Y.G. Theory and survey practice of deep heat accumulation in geothermal system and exploration practice. Acta Geologica Sinica 2023, 97, 639–660. (In Chinese) [Google Scholar]

- Li, M.; Xing, L.X.; Wang, G.L.; Zhang, W.; Zhao, J.Y. Distribution Characteristics of Fluorine in Deep Geothermal Water and Its Risk Assessment and Suggestions for Utilization in JIZHONG Depression. Geology in China. Available online: https://kns.cnki.net/kcms/detail/11.1167.P.20221012.1750.002.html (accessed on 13 October 2022).

- Dai, M.G.; Ma, P.P.; Lei, H.F.; Hu, J.G.; Guo, X.F.; Zhang, J.Y.; Bao, Z.G. Distribution characteristics and favorable targets of karst geothermal reservoir of Wumishan Formation in Xiong’an New Area. Chin. J. Geol. (Sci. Geol. Sin.) 2020, 55, 487–505. (In Chinese) [Google Scholar]

- Tang, B.N.; Zhu, C.Q.; Qiu, N.S.; Cui, Y.; Guo, S.S.; Chen, C. Characteristics of the karst thermal reservoir in the Wumishan Formation in the Xiong’an New Area. Acta Geol. Sin. 2020, 94, 2002–2012. (In Chinese) [Google Scholar]

- Wang, S.Q.; Zhang, B.J.; Li, Y.Y.; Xing, Y.F.; Yuan, W.Z.; Li, J.; Gao, J.; Zhao, T. Heat accumulation mechanism of deep ancient buried hill in the northeast of Gaoyang geothermal field, Xiong’an New Area. Bull. Geol. Sci. Technol. 2021, 40, 12–21. (In Chinese) [Google Scholar]

- Zhang, H.; Wang, G.; Zhang, W.; Ma, F.; Zhu, X.; Yue, G.; Yu, M. Characteristics of the Rongcheng Bulge geothermal field and the evolution of geothermal fluids, Xiong’an New Area, China. Water 2022, 14, 2468. (In Chinese) [Google Scholar] [CrossRef]

- Cao, Q.; Fang, C.H.; Li, Y.; Wang, H.X.; Fang, Q.; Shi, X.Y. Development status of geothermal reinjection at home and abroad and its enlightenment. Oil Drill. Prod. Technol. 2021, 43, 203–211. (In Chinese) [Google Scholar]

- Kamila, Z.; Kaya, E.; Zarrouk, S.J. Reinjection in geothermal fields: An updated worldwide review 2020. Geothermics 2021, 89, 101970. [Google Scholar] [CrossRef]

- Zhu, J.L.; Zhu, X.M.; Lei, H.Y. Analysis of impact of pressure compensation between geothermal wells on reinjection effeciency. Acta Energ. Sol. Sin. 2012, 33, 56–62. (In Chinese) [Google Scholar]

- Wang, S.F.; Liu, J.R.; Lin, P.; Li, H.K.; Yin, M.; Pang, J.M.; Sun, C.X.; Gao, X.R. A study of reinjection experiment and tracer test in a karst geothermal reservoir. Hydrogeol. Eng. Geol. 2013, 40, 129–133. (In Chinese) [Google Scholar]

- Kong, Y.L.; Pang, Z.H.; Shao, H.B.; Kolditz, O. Optimization of well-doublet placement in geothermal reservoirs using numerical simulation and economic analysis. Environ. Earth Sci. 2017, 76, 118. [Google Scholar] [CrossRef]

- Dou, H.P.; Chen, X.H.; Zhou, Q.C.; Zhuang, W.J.; Lian, Z.H. Simulation study on thermal recovery and thermal recoverable under balanced exploitation condition:A case study of Guantao sandstone geothermal reservoir in Renqiu area. Geotech. Investig. Surv. 2021, 49, 39–45. (In Chinese) [Google Scholar]

| Well Pattern | Injection–Production Ratio | Injection Rate (mL/min) | Well Placement |

|---|---|---|---|

| 1 Injector and 2 Producers | 2:1 | 0.02 | Injector:1 and Producers:4.6 |

| Injector:2 and Producers:4.6 | |||

| Injector:3 and Producers:4.6 | |||

| 2 Injector and 3 Producers | 1:5:1 | 0.015 | Injectors:1.2 and Producers:4.5.6 |

| Injectors: 1.3 and Producers:4.5.6 | |||

| Injectors:2.3 and Producers:4.5.6 |

| Injection Angle (°) | Injection Rate (mL/min) | Breakthrough Time (s) | Breakthrough Velocity (m/d) | Injection Time (s) | Swept Area (%) |

|---|---|---|---|---|---|

| 0 | 0.01 | 54 | 1.508 | 74 | 60 |

| 0 | 0.02 | 35 | 2.327 | 49 | 85 |

| 0 | 0.04 | 22 | 3.703 | 62 | 90 |

| 45 | 0.01 | 70 | 0.823 | 95 | 80 |

| 45 | 0.02 | 39 | 1.477 | 65 | 85 |

| 45 | 0.04 | 25 | 2.304 | 51 | 97 |

| 90 | 0.01 | 63 | 1.293 | 130 | 90 |

| 90 | 0.02 | 37 | 2.202 | 40 | 96 |

| 90 | 0.04 | 25 | 3.258 | 56 | 98 |

| Correlation | |||||

|---|---|---|---|---|---|

| Dependent Variable | Control Variable | Breakthrough Time (s) | Breakthrough Velocity (m/d) | Injection Time (s) | Swept Area (%) |

| Injection Rate | N/A | −0.903 | 0.867 | −0.57 | 0.64 |

| Injection Angle (°) | −0.909 | 0.874 | −0.584 | 0.802 | |

| Injection Angle | N/A | 0.116 | −0.121 | 0.212 | 0.602 |

| Injection Rate | 0.27 | −0.243 | 0.258 | 0.783 | |

| Well Pattern | Injection-Production Ratio | Injection Rate (mL/min) | Injection Angle (°) | Well Location | Swept Area (%) |

|---|---|---|---|---|---|

| One injectors and two producers | 2:1 | 0.02 | 90 | Injector:1 and Producers:4.6 | 75.68 |

| 45 | Injector:2 and Producers:4.6 | 59.62 | |||

| 0 | Injector:3 and Producers:4.6 | 65.7 | |||

| Two injectors and three producers | 1:5:1 | 0.015 | 1:90; 2:45 | Injectors:1.2 and Producers:4.5.6 | 92.21 |

| 1:90; 3:0 | Injectors: 1.3 and Producers:4.5.6 | 92 | |||

| 2:45; 3:0 | Injectors:2.3 and Producers:4.5.6 | 86.45 |

| Well No. | Test Water Temperature (°C) | Recharge Temperature (°C) | Production Temperature (°C) | Temperature Difference (°C) |

|---|---|---|---|---|

| Boao1# | 56 | 35 | 49 | −7 |

| Jintai1# | 51 | 35 | 48 | −3 |

| Zhongjin1# | 51 | 35 | 49 | −2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Y.; Li, M.; Du, L.; Li, S. Simulation Study on Seepage Patterns of Geothermal Reinjection in Carbonate Thermal Reservoir and Geothermal Doublet Well Patterns in Xiong’an New Area. Water 2023, 15, 2683. https://doi.org/10.3390/w15152683

Qiao Y, Li M, Du L, Li S. Simulation Study on Seepage Patterns of Geothermal Reinjection in Carbonate Thermal Reservoir and Geothermal Doublet Well Patterns in Xiong’an New Area. Water. 2023; 15(15):2683. https://doi.org/10.3390/w15152683

Chicago/Turabian StyleQiao, Yong, Man Li, Li Du, and Shaohua Li. 2023. "Simulation Study on Seepage Patterns of Geothermal Reinjection in Carbonate Thermal Reservoir and Geothermal Doublet Well Patterns in Xiong’an New Area" Water 15, no. 15: 2683. https://doi.org/10.3390/w15152683

APA StyleQiao, Y., Li, M., Du, L., & Li, S. (2023). Simulation Study on Seepage Patterns of Geothermal Reinjection in Carbonate Thermal Reservoir and Geothermal Doublet Well Patterns in Xiong’an New Area. Water, 15(15), 2683. https://doi.org/10.3390/w15152683