Experimental Study on Anti-Scour Property and Erosion Resistance of 3D Mat Materials for Slope Protection in Waterway Engineering

Abstract

1. Introduction

2. Maximum Scouring Experimental Design for 3D Mat Materials for Slope Protection

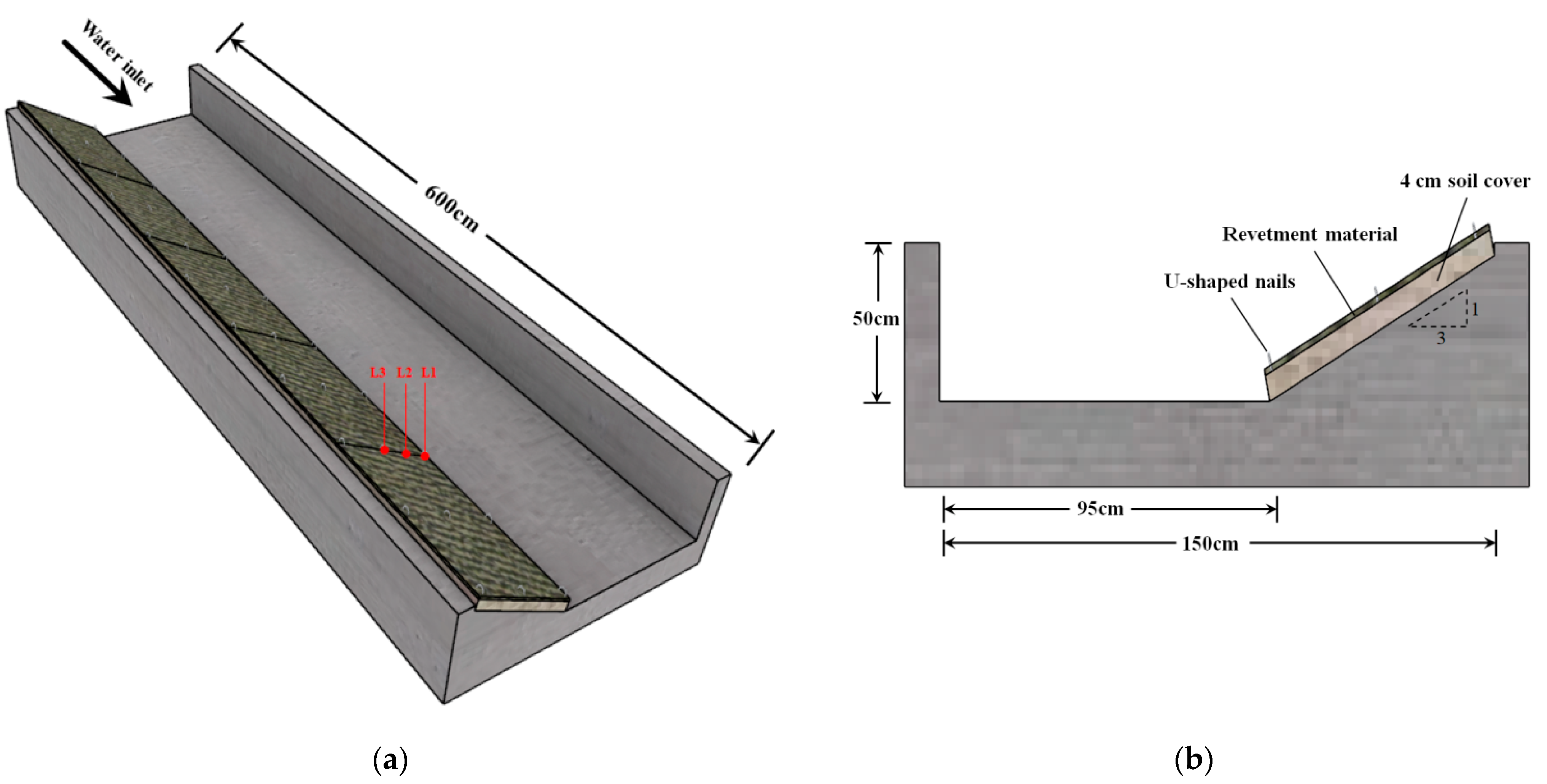

2.1. Design of the Experimental Device

2.2. Characteristics of Experimental Soil

2.3. Experimental Materials

2.4. Experimental Scheme and Data Collection

3. Results

3.1. Average Flow Velocity, Resistance Coefficient and Turbulent Kinetic Energy Change

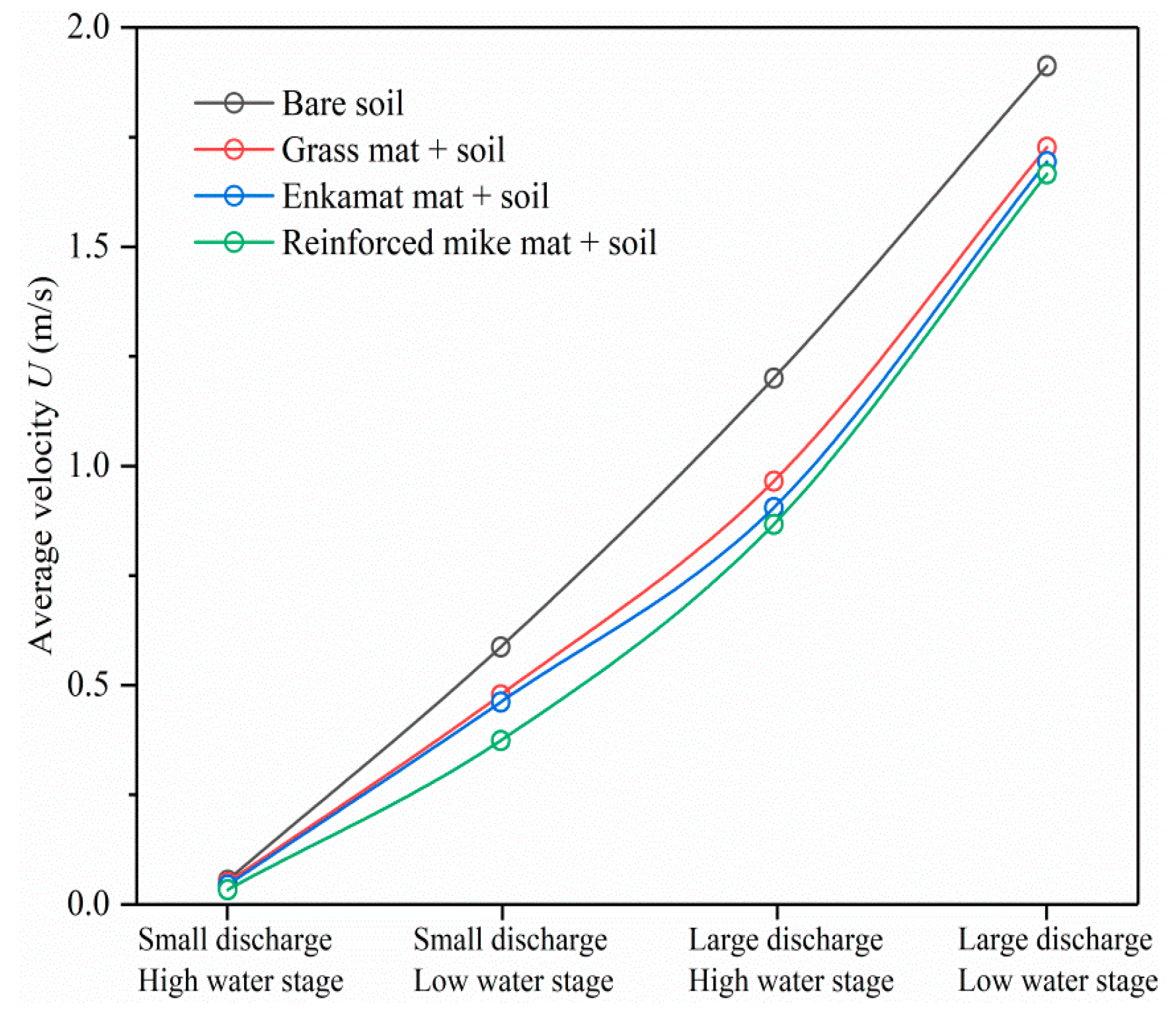

3.1.1. Distribution Law for Average Velocity

3.1.2. Distribution Law for Resistance Coefficient

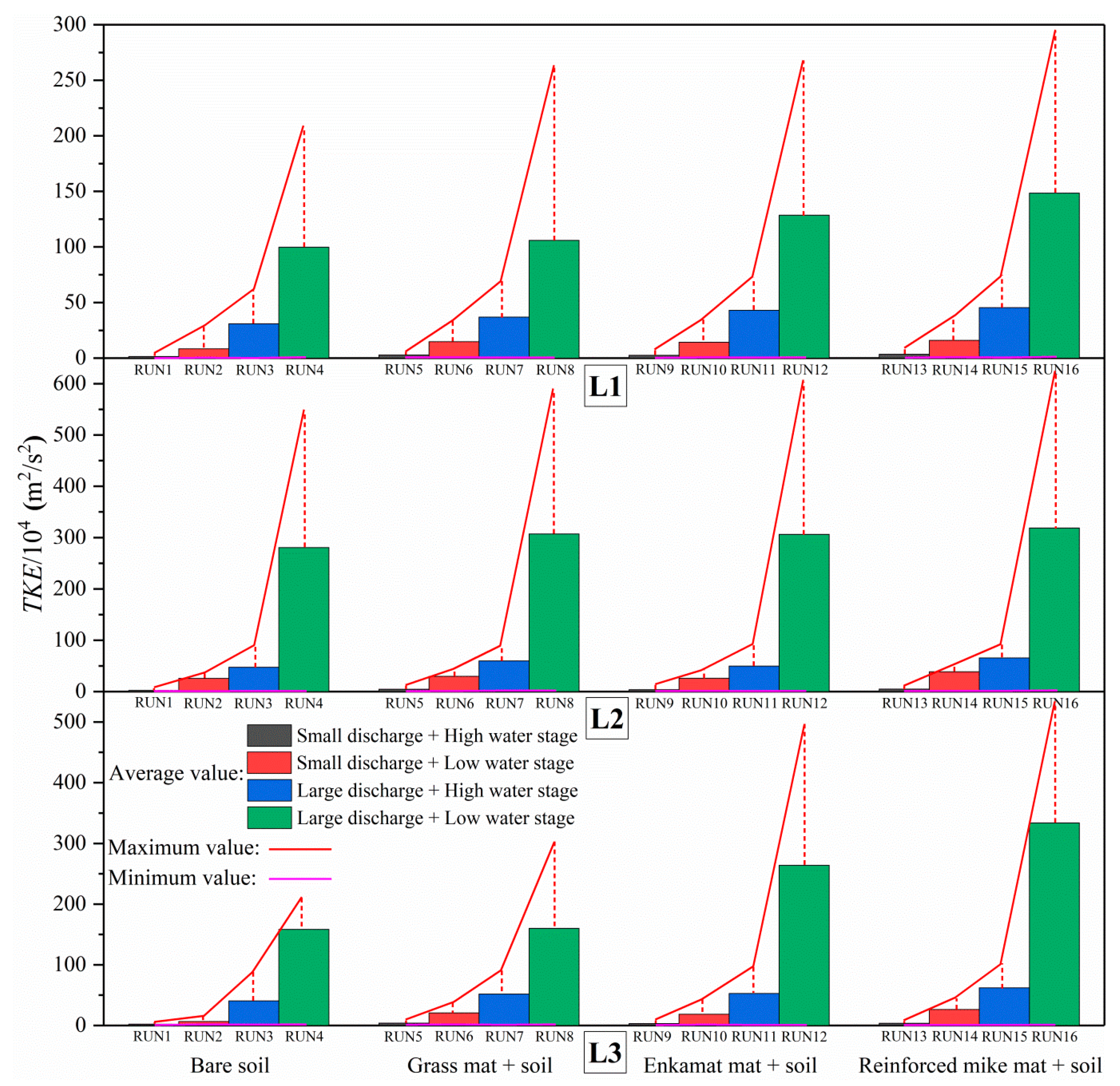

3.1.3. Distribution Law for Turbulent Kinetic Energy (TKE)

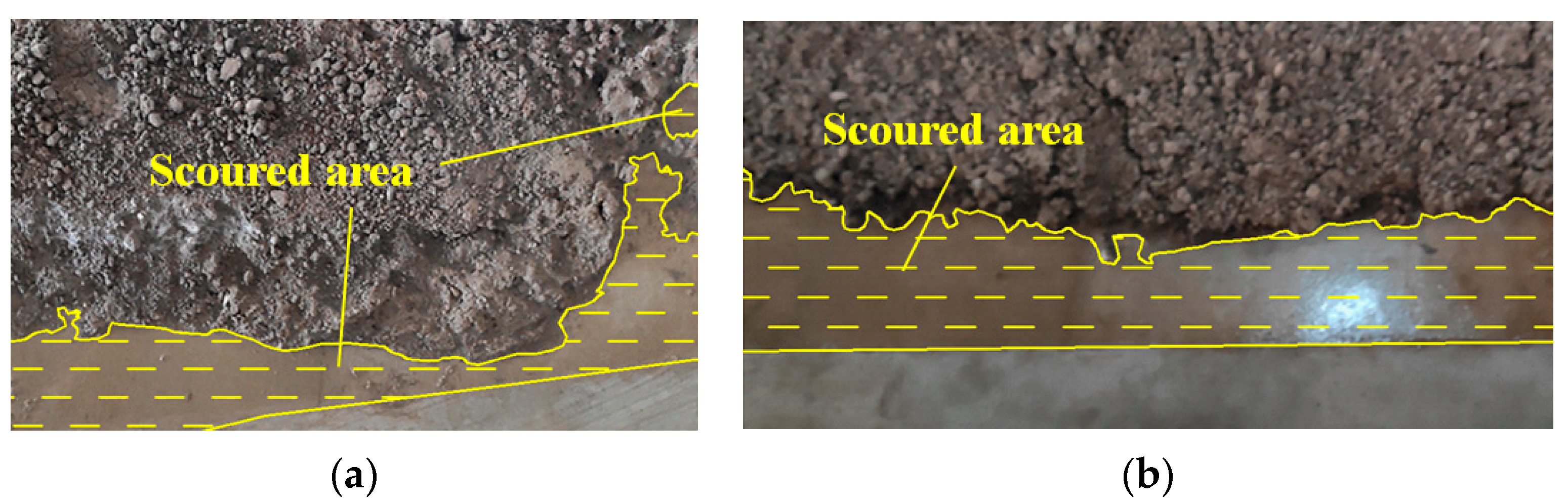

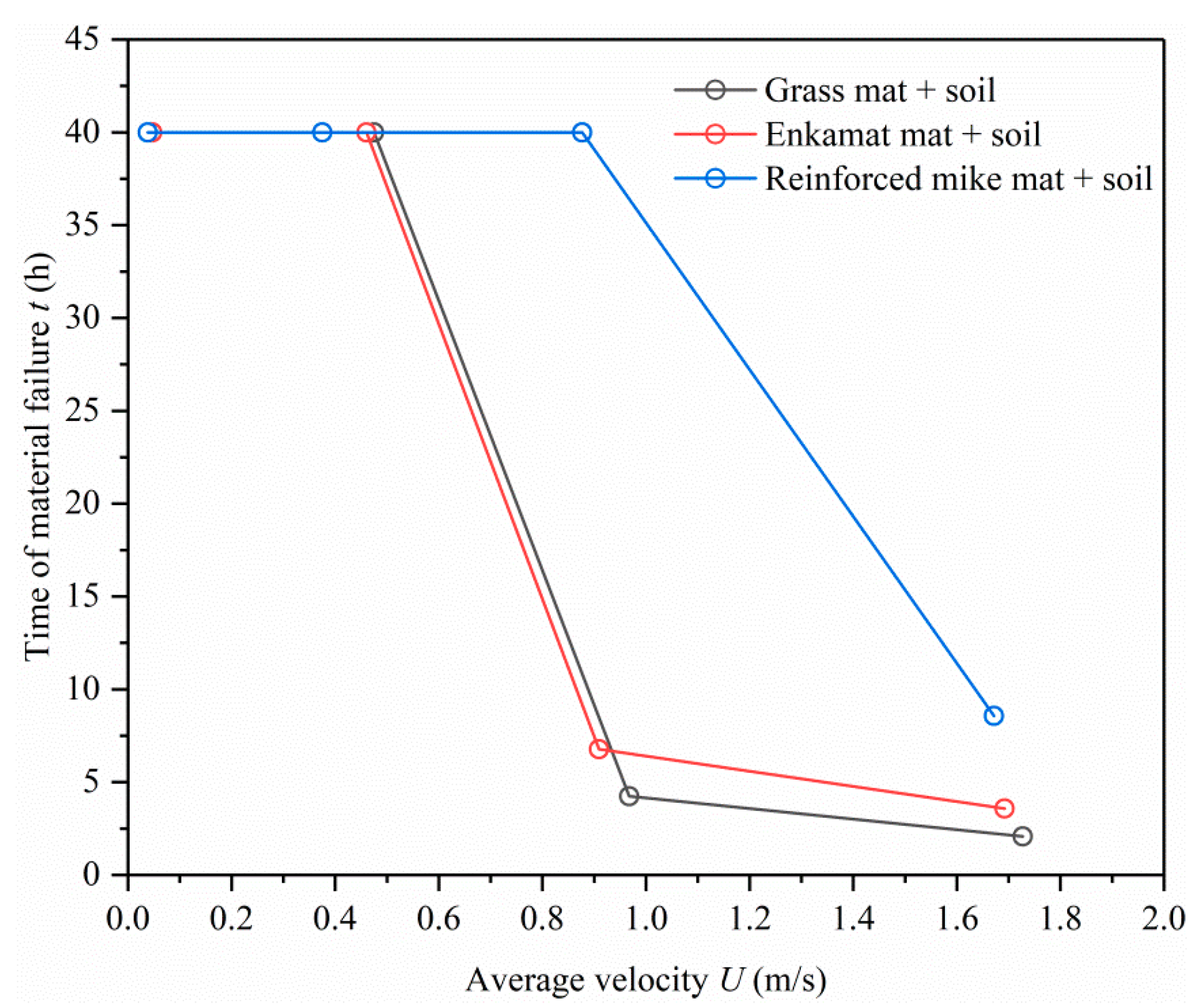

3.2. Erosion Resistance of 3D Mat Materials for Slope Protection

4. Discussion

4.1. Anti-Scour Properties of Mat Materials for Slope Protection

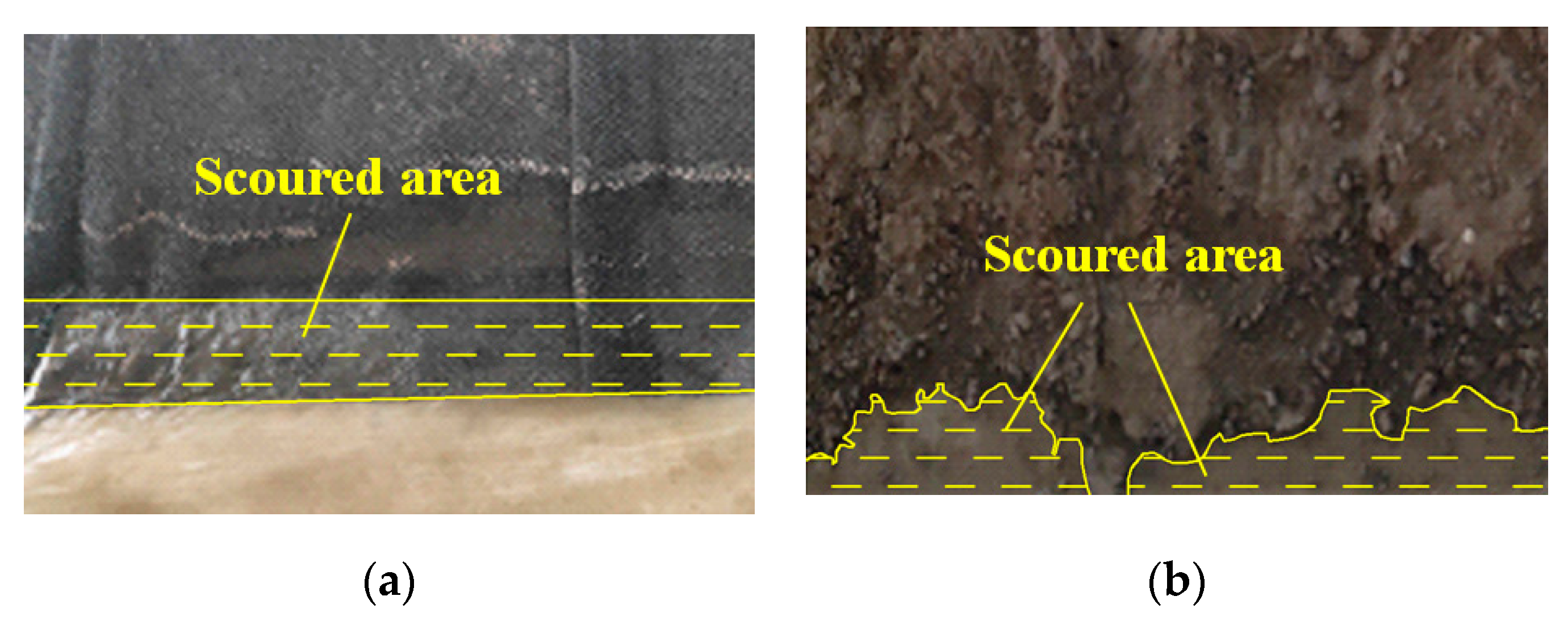

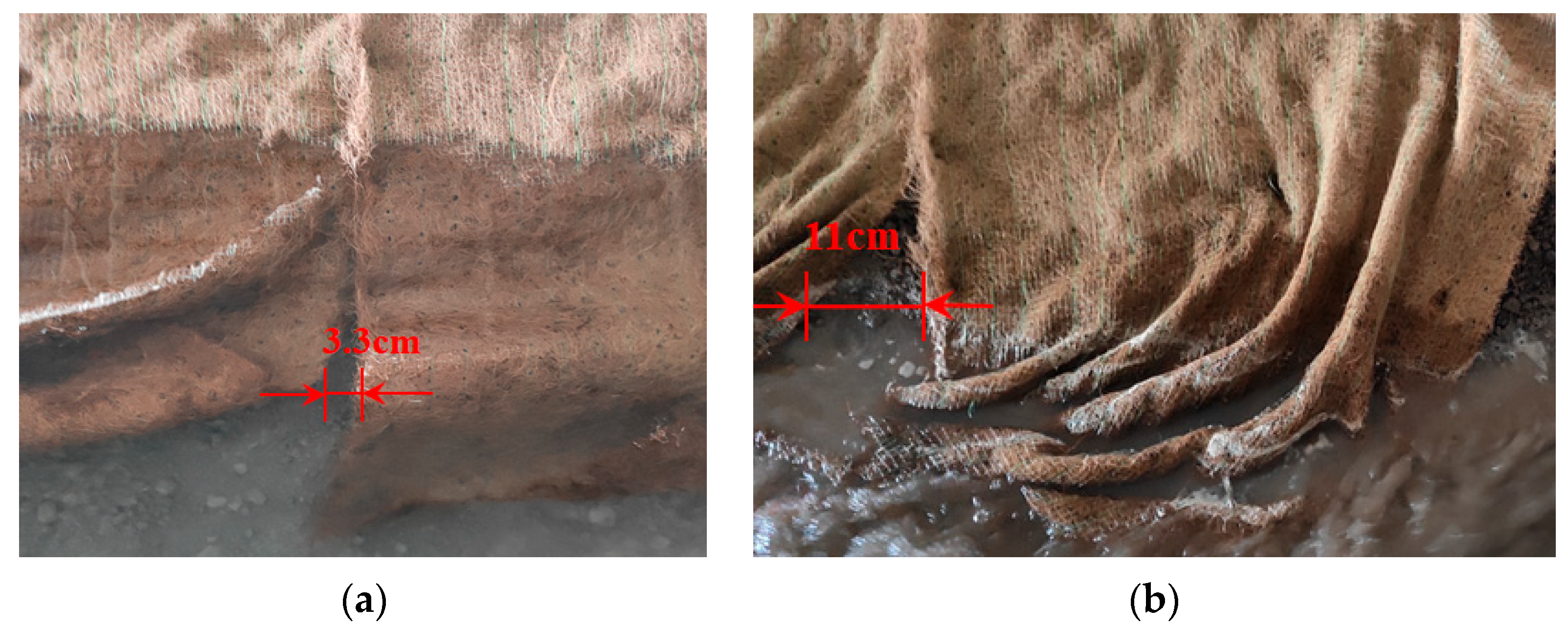

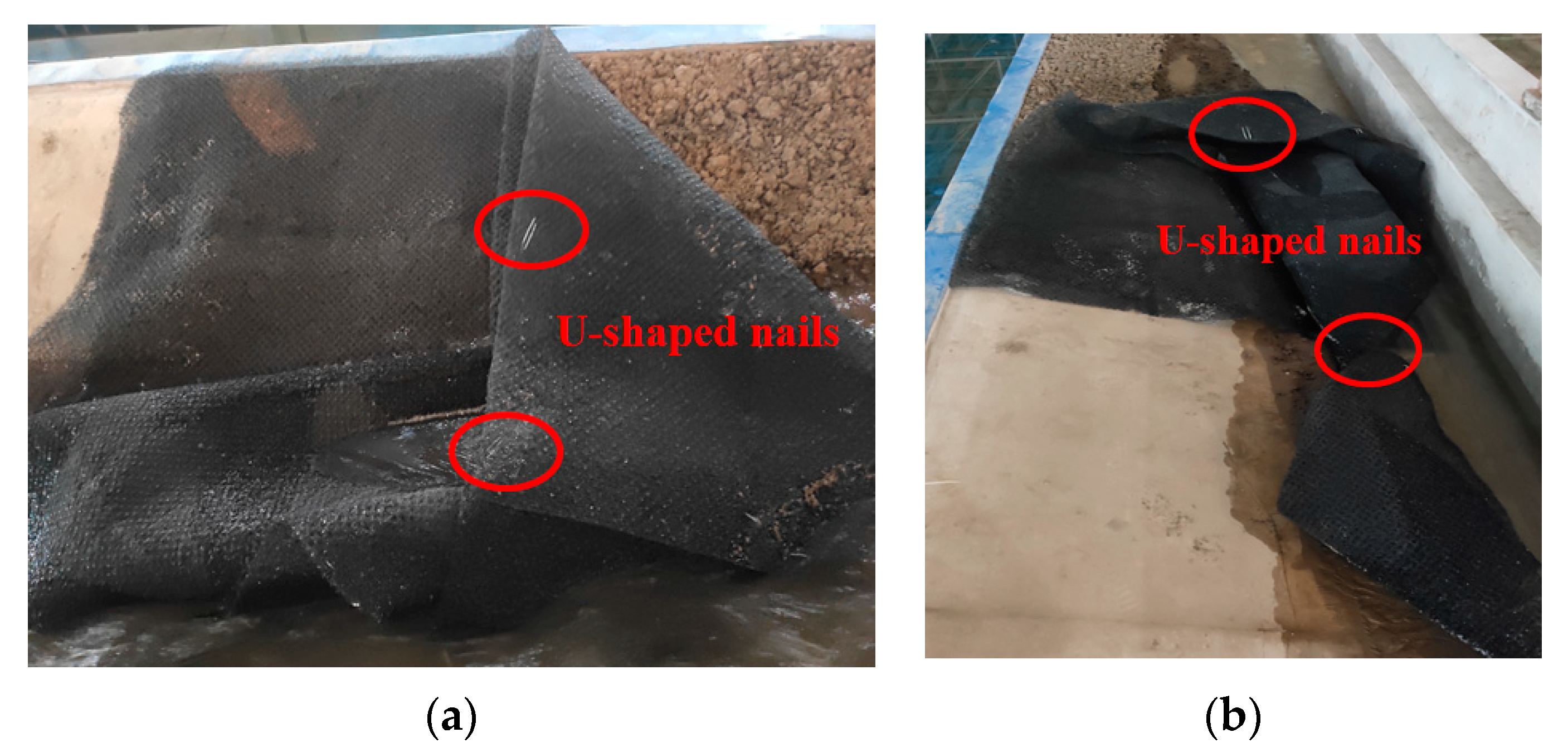

4.2. Failure Characteristics Analysis of 3D Mat Materials for Slope Protection

5. Conclusions

- (1)

- Compared with the bare soil, the 3D mats for slope protection caused more thermal energy to be converted from the kinetic energy of the water, as they increased the comprehensive resistance coefficient of the bed surface, in the order reinforced Mike mats > Enkamat > vegetation grass mats, under the same incoming flow condition. In addition, the average flow velocity in a channel was inversely related to the comprehensive resistance coefficient.

- (2)

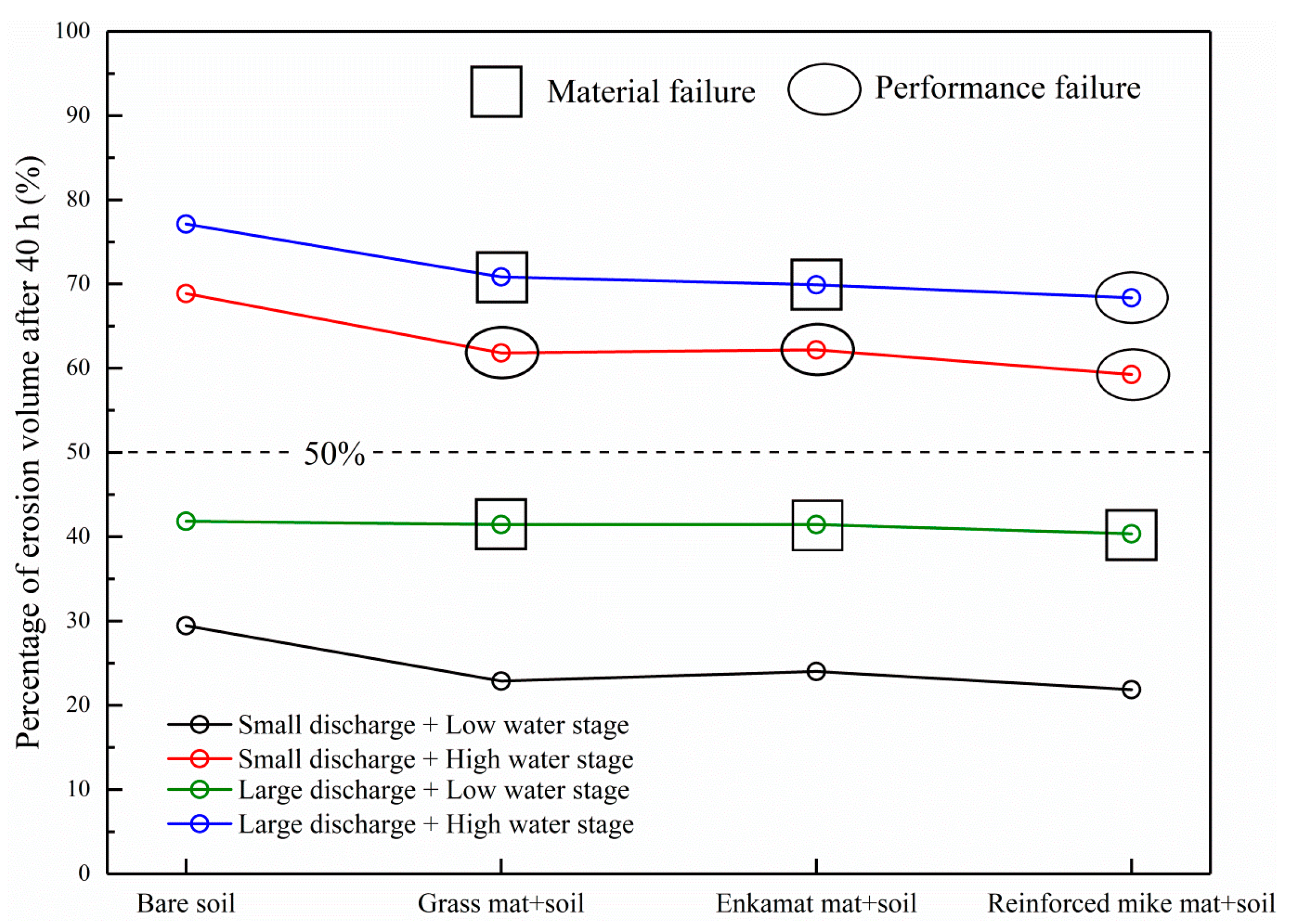

- The failure types of 3D mat materials for slope protection can be divided into material failure and performance failure. The former refers to mechanical damage to the mats, such as material tearing, ejection of fixing steel nails, material floating, etc., while the latter means that the ratio of the volume of the eroded soil on the bank slope to the soil volume before scouring was greater than 50% after the maximum scouring time of 40 h. When the scouring time of the flow reached the maximum duration of 40 h and neither material failure nor performance failure had occurred, this was regarded as “no failure”.

- (3)

- Non-reinforced materials (vegetation grass mats, Enkamat) were dominated by material failure, while reinforced materials (reinforced Mike mats) were dominated by performance failure. Material failure mainly occurred under large flow rate conditions and was more likely to occur when the water stage was lower. Performance failure mainly occurred under high water stage conditions and was more likely to occur when the flow rate was larger. Among the three types of mat materials for slope protection, the order for anti-scour and soil conservation properties was reinforced Mike mats > Enkamat > vegetation grass mats. Moreover, the general law showed that reinforced materials apparently outperform non-reinforced materials in their anti-scour performance and their protection for soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- HaRa, J.; Mamun, M.; An, K.G. Ecological River Health Assessments Using Chemical Parameter Model and the Index of Biological Integrity Model. Water 2019, 11, 1729. [Google Scholar] [CrossRef]

- Bian, Y.Z.; Xue, B.; Zhang, F.J. The changes of Lake Hongze and its driving forces over the past three hundred years. J. Lake Sci. 2021, 33, 1844–1856. [Google Scholar]

- Cao, Y.X.; Xu, L.G.; Fan, H.X.; Mao, Z.Y.; Chen, J.X.; Wang, D.C.; Wu, Y.K. Impact of climate change and human activities on the changes of ecological flow indicators in the Lake Poyang Basin since 1960s. J. Lake Sci. 2021, 34, 232–246. [Google Scholar]

- Wang, G.H.; Liu, B.B.; Li, X.P.; Liu, J.T.; Ao, H.Y.; Li, Q.M. Seasonal variation of water quality of Xinyunliang River Dianchi Basin and the impact of the riparian ecological restoration. J. Lake Sci. 2012, 24, 334–340. [Google Scholar]

- Chen, B.F.; Huang, W.; Chen, K.N. Research progress on the ecological revetment in riparian. Environ. Eng. 2018, 36, 74–77. [Google Scholar]

- Xia, J.Q.; Liu, X.; Deng, S.S.; Zhou, M.R.; Li, Z.W.; Peng, Y.M. Temporal and spatial distribution of bank retreat in the Jingjiang reach of the Yangtze River after the Three Gorges Project operation and its influence on channel adjustment. J. Lake Sci. 2021, 34, 296–306. [Google Scholar]

- Rini, D.S.; Arisoesilaningsih, E.; Harisuseno, D.; Soemarno, S. Application of Ecohydraulic Bank Protection Model to Improve River Bank Stability and Biotic Community in Surabaya River. J. Degrad. Min. Lands Manag. 2017, 5, 975. [Google Scholar] [CrossRef][Green Version]

- Alam, G.M.; Alam, K.; Mushtaq, S.; Clarke, M.L. Vulnerability to Climatic Change in Riparian Char and River-Bank Households in Bangladesh: Implication for Policy, Livelihoods and Social Development. Ecol. Indic. 2017, 72, 23–32. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Wang, X.J. Issues related to building of water ecological civilization. China Water Resour. 2014, 7, 1–4. [Google Scholar]

- Patsinghasanee, S.; Kimura, I.; Shimizu, Y.; Nabi, M. Experiments and Modelling of Cantilever Failures for Cohesive Riverbanks. J. Hydraul. Res. 2018, 56, 76–95. [Google Scholar] [CrossRef]

- Bejarano, M.D.; Sordo-Ward, Á.; Alonso, C.; Jansson, R.; Nilsson, C. Hydropeaking Affects Germination and Establishment of Riverbank Vegetation. Ecol. Appl. 2020, 30, e02076. [Google Scholar] [CrossRef] [PubMed]

- Udomchai, A.; Hoy, M.; Horpibulsuk, S.; Chinkulkijniwat, A.; Arulrajah, A. Failure of Riverbank Protection Structure and Remedial Approach: A Case Study in Suraburi Province, Thailand. Eng. Fail. Anal. 2018, 91, 243–254. [Google Scholar] [CrossRef]

- Recking, A.; Piton, G.; Montabonnet, L.; Posi, S.; Evette, A. Design of Fascines for Riverbank Protection in Alpine Rivers: Insight from Flume Experiments. Ecol. Eng. 2019, 138, 323–333. [Google Scholar] [CrossRef]

- Jafarnejad, M.; Franca, M.J.; Pfister, M.; Schleiss, A.J. Time-Based Failure Analysis of Compressed Riverbank Riprap. J. Hydraul. Res. 2017, 55, 224–235. [Google Scholar] [CrossRef]

- Thompson, D.M.; Puklin, L.S.; Marshall, A.E. The Long-Term Impact of Channel Stabilization Using Gabion Structures on Zealand River, New Hampshire. Ecol. Eng. 2016, 95, 779–792. [Google Scholar] [CrossRef]

- Beikircher, B.; Florineth, F.; Mayr, S. Restoration of Rocky Slopes Based on Planted Gabions and Use of Drought-Preconditioned Woody Species. Ecol. Eng. 2010, 36, 421–426. [Google Scholar] [CrossRef]

- Zhang, J.L.; Wu, T.T.; Chen, Q.W.; GAO, Y. Application of Reinforced Three-Dimensional Mat in Beach Protection Engineering. Port Waterw. Eng. 2012, 8, 204–206. [Google Scholar]

- Symmank, L.; Natho, S.; Scholz, M.; Schröder, U.; Raupach, K.; Schulz-Zunkel, C. The Impact of Bioengineering Techniques for Riverbank Protection on Ecosystem Services of Riparian Zones. Ecol. Eng. 2020, 158, 106040. [Google Scholar] [CrossRef]

- Nelsen, R.J. Research Quantifies Performance of TRM Reinforced Vegetation. In Erosion of Soils and Scour of Foundations; Briaud, J.-L., Bhatia, S.K., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2005; pp. 1–11. [Google Scholar]

- Xiao, C.Z.; Sun, J.C.; LI, Y.R.; Liu, X.P. Mechanism Analysis of Ecological Slope Protection against Runoff Erosion by Grass Jetting on 3D Geomat. Rock Soil Mech. 2011, 32, 453–458. [Google Scholar]

- Xiao, H.L.; Wang, Z.; Zhang, J.F. Study on the Design Indexes of Three Dimensional Geomat. Rock Soil Mech. 2004, 25, 1800–1804. [Google Scholar]

- Xiao, H.L.; Zhang, J.F. A Study on Erosion-Resistance and Seeding Test of Three Dimensional Geomat. Highway 2005, 4, 163–166. [Google Scholar]

- Zhong, C.X.; Zhang, W. Method and Equipment of Model Test for Scouring Resistance of Riverbank with Grass Cover. J. Hohai Univ. (Nat. Sci.) 2008, 36, 170–174. [Google Scholar]

- Zhang, W.; Zhong, C.X.; Ying, H.H. Experimental Study on Hydraulic Roughness of Revetment with Grass Cover. Adv. Water Sci. 2007, 18, 483–489. [Google Scholar]

- Zhong, C.X.; Zhang, W. Experimental Research on Hydraulic Characteristics of Eco-Bank Protection Covered with Grass. Shuili Shuidian Jishi (Water Resour. Hydropower Eng.) 2010, 41, 22–25. [Google Scholar]

- Hu, Y.Z.; Pan, Y.; Chen, Y.P. Experimental studies on scouring resistance of reinforced turf on land-side slope. Hydro-Sci. Eng. 2016, 1, 51–57. [Google Scholar]

- Álvarez-Mozos, J.; Abad, E.; Giménez, R.; Campo, M.A.; Goñi, M.; Arive, M.; Casalí, J.; Díez, J.; Diego, I. Evaluation of Erosion Control Geotextiles on Steep Slopes. Part 1: Effects on Runoff and Soil Loss. Catena 2014, 118, 168–178. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, W.; Lu, Y.J.; Song, Y.T.; Yan, D.L. Theoretical and Experimental Study on Resistance Characteristics of Shrub Vegetation Distribution Area. Adv. Water Sci. 2020, 31, 556–564. [Google Scholar]

- Huai, W.X.; Zhong, Y.; Yang, Z.H. Study on mechanism of energy spending and transition in open channel flow with suspended canopy. J. Hydraul. Eng. 2018, 49, 397–403. [Google Scholar]

- Wang, G.Y.; Du, G.S.; Wang, Y. The Experimental Research on Hydrodynamic Characteristics of the Overland Flow on the Slope with Three Dimensional Geomat. Chin. J. Hydrodyn. 2015, 30, 406–411. [Google Scholar]

- Wang, G.; Sun, G.; Li, J.; Li, J. The Experimental Study of Hydrodynamic Characteristics of the Overland Flow on a Slope with Three-Dimensional Geomat. J. Hydrodyn. 2018, 30, 153–159. [Google Scholar] [CrossRef]

- Enkamat Permanent Erosion Prevention Mat. Available online: www.geosyntetika.cz/files/download/enkamat_gb_2008.pdf (accessed on 10 March 2022).

| Moisture Content (%) | Density (g/cm3) | Plastic Limit (%) | Liquid Limit (%) | Dry Density (g/cm3) | Soil Property |

|---|---|---|---|---|---|

| 26.8 | 1.92 | 19.94 | 31.63 | 1.57 | Silt loam |

| Material Type | Reinforced | Polymeric Materials | Reinforced Materials | Thickness (mm) | Unit Weight (g/m2) |

|---|---|---|---|---|---|

| Vegetation grass mats | No | Straw, wheat straw, etc. | - | 10 | 370 |

| Enkamat | No | Amide | - | 10 | 400 |

| Reinforced Mike mats | Yes | Polypropylene | Hexagonal double-twisted Galfan-coated steel wire mesh | 10 | 600 |

| Experimental Group | Protection Materials | Flow Rate | Water Stage | Average Flow Velocity (m/s) | Average Water Depth (m) | Hydraulic Radius (m) | Slope Energy (‰) | Raw Material | Materials Laid |

|---|---|---|---|---|---|---|---|---|---|

| RUN 1 | Bare soil | Small | High | 0.052 | 0.458 | 0.447 | 0.021 |  |  |

| RUN 2 | Small | Low | 0.589 | 0.337 | 0.332 | 0.265 | |||

| RUN 3 | Large | High | 1.205 | 0.459 | 0.448 | 0.365 | |||

| RUN 4 | Large | Low | 1.907 | 0.337 | 0.331 | 0.205 | |||

| RUN 5 | Vegetation grass mats | Small | High | 0.045 | 0.458 | 0.447 | 0.005 |  |  |

| RUN 6 | Small | Low | 0.472 | 0.337 | 0.331 | 0.101 | |||

| RUN 7 | Large | High | 0.964 | 0.458 | 0.447 | 0.005 | |||

| RUN 8 | Large | Low | 1.724 | 0.337 | 0.331 | 0.091 | |||

| RUN 9 | Enkamat | Small | High | 0.045 | 0.458 | 0.447 | 0.004 |  |  |

| RUN 10 | Small | Low | 0.372 | 0.337 | 0.331 | 0.021 | |||

| RUN 11 | Large | High | 0.907 | 0.458 | 0.447 | 0.068 | |||

| RUN 12 | Large | Low | 1.687 | 0.337 | 0.332 | 0.237 | |||

| RUN 13 | Reinforced Mike mats | Small | High | 0.038 | 0.458 | 0.447 | 0.012 |  |  |

| RUN 14 | Small | Low | 0.459 | 0.337 | 0.331 | 0.031 | |||

| RUN 15 | Large | High | 0.874 | 0.458 | 0.447 | 0.110 | |||

| RUN 16 | Large | Low | 1.680 | 0.338 | 0.332 | 0.359 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Xu, H.; Wang, X.; Zhang, M.; Liu, W.; Zhu, Y.; Liu, Z. Experimental Study on Anti-Scour Property and Erosion Resistance of 3D Mat Materials for Slope Protection in Waterway Engineering. Water 2022, 14, 1392. https://doi.org/10.3390/w14091392

Yang Y, Xu H, Wang X, Zhang M, Liu W, Zhu Y, Liu Z. Experimental Study on Anti-Scour Property and Erosion Resistance of 3D Mat Materials for Slope Protection in Waterway Engineering. Water. 2022; 14(9):1392. https://doi.org/10.3390/w14091392

Chicago/Turabian StyleYang, Yanhua, Haiyong Xu, Xin Wang, Mingjin Zhang, Wanli Liu, Yude Zhu, and Zhe Liu. 2022. "Experimental Study on Anti-Scour Property and Erosion Resistance of 3D Mat Materials for Slope Protection in Waterway Engineering" Water 14, no. 9: 1392. https://doi.org/10.3390/w14091392

APA StyleYang, Y., Xu, H., Wang, X., Zhang, M., Liu, W., Zhu, Y., & Liu, Z. (2022). Experimental Study on Anti-Scour Property and Erosion Resistance of 3D Mat Materials for Slope Protection in Waterway Engineering. Water, 14(9), 1392. https://doi.org/10.3390/w14091392